Joinery, Cabinetmaking & Kitchen Manufacturing Industries

m a g a z i n e September 2025

Joinery, Cabinetmaking & Kitchen Manufacturing Industries

m a g a z i n e September 2025

interzum & Ligna command attention

d u s t f r e e dust free buyers advice

working stations

new inserts & new surface materials

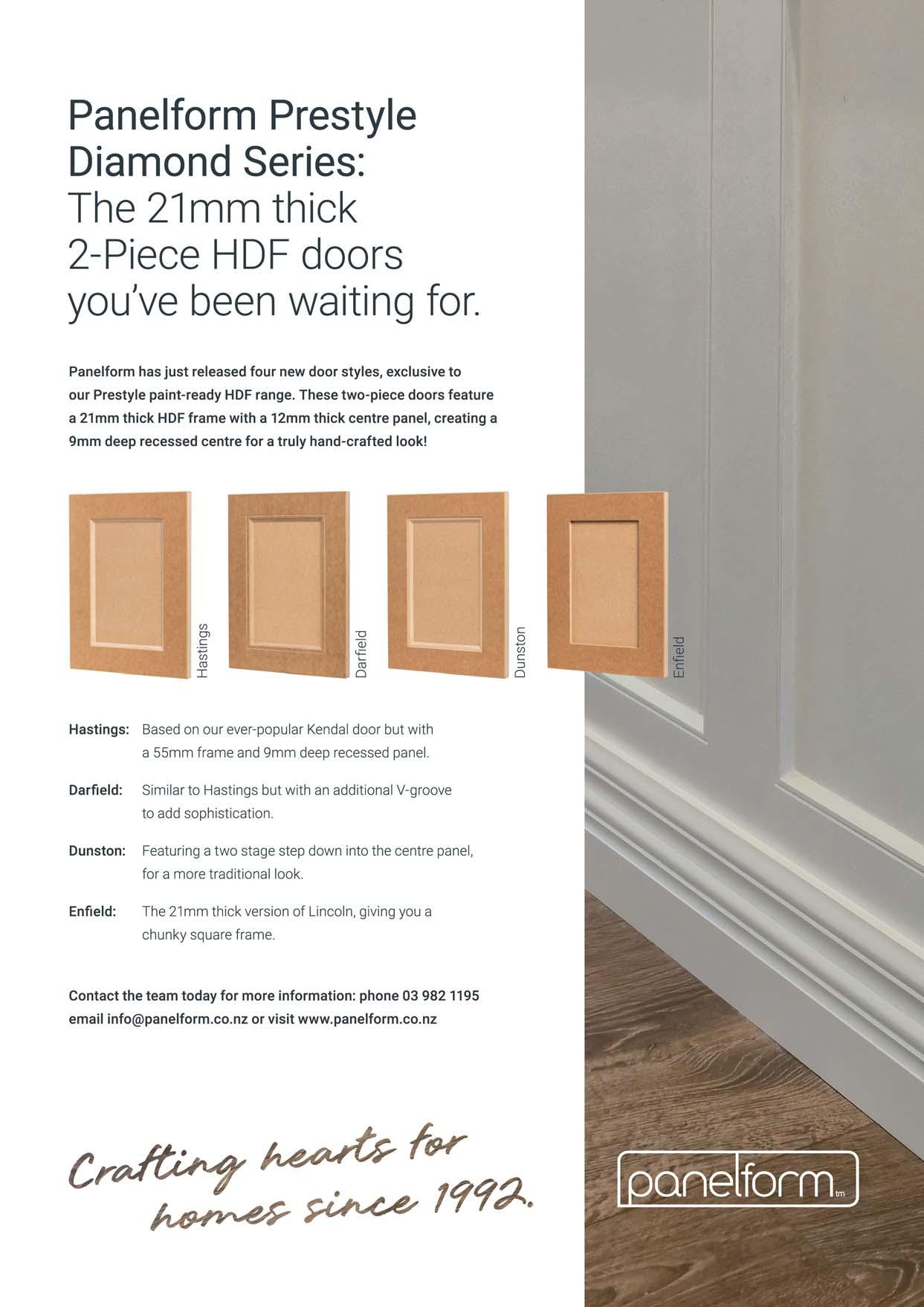

The Häfele Alto Slim drawer system offers effortless integration across kitchens, wardrobes and bathrooms. Designed for modern cabinetry with clean lines and a slim, refined profile, the new and improved Alto Slim delivers both style and versatility to suit any space.

Now updated with a new 167mm drawer height, the Alto Slim range offers even more flexibility. Choose from four heights, two modern finishes in Matt White and Matt Black, plus front tilt adjustment and internal front panels to achieve a consistent, minimal interior.

COVER

Master Joiners 4

New president Nathan Moore introduces himself and notes a key goal of his term is to increase connection among joiners around the country.

Laminex Update 10

Rachel Silcock reflects on the importance of mindset in sustaining growth and talks of ‘radical candor’, the combination of caring and challenging to achieve this.

NKBA news 78

Rachael Kwok writes of the importance of international exposure for our design community and of how we often excel on the world design stage.

Steering a Course 84

Ian Featherstone discusses how lean manufacturing can eliminate waste, reduce errors and create a more efficient customer based business.

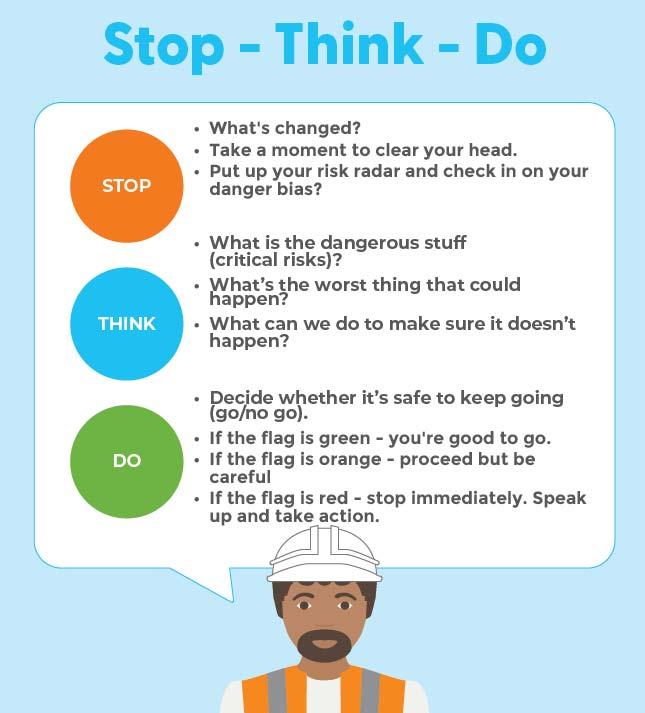

Safety Series 94

Laminex explain that when we become too familiar with a task we tend to become blind to its risks, to overcome this we need to StopThink-Do.

News & Info 4 - 16

State of the Industry 86

NZJMF membership 88

Classifieds 96

Advertiser index 96

For four days in May, interzum became the international stage for innovative materials, intelligent components and smart technologies that will shape the homes of tomorrow.

A lot of time, money and expertise is spent on selecting and installing what are perhaps the hardest working and most viewed surfaces in the home. We have a look at new product offerings from several local suppliers.

An impressive project in pictures from Clayfield Kitchen Designs in Moreton Bay, Queensland featuring Resene’s AquaLAQ™ clear sealer to produce a stunning natural finish through-out this modern home.

At Ligna 2025 the spotlight was on digitalisation, automation, artificial intelligence, smart production and using wood and wood-based materials in a sustainable and climate friendly manner. We talk to local suppliers that were there.

As tolerance levels for dust and other contaminants in the factory and wider community have decreased many manufacturers have had to reassess the state of their dust extraction. We talk to suppliers about what you should look for if you are in the market to buy.

20.8.2025

working together to keep Master Joiners strong, united, and future-focused

It’s a real honour to be writing my first column as National President of Master Joiners. As this issue lands, we’ll be doing the final prep for our National Conference — one of the most important events in our calendar. It’s always a key moment for our industry, bringing together ideas, energy, and direction for the year ahead. I’m looking forward to the conversations and momentum that will come out of it.

Stepping into this role is both exciting and humbling. I’ve been involved with Master Joiners for over 15 years, including two terms as Canterbury President, totalling six years. Over that time, I’ve seen the organisation evolve, face challenges, and continue to grow stronger — thanks to the commitment of our members and the leadership of those who’ve come before me.

I want to acknowledge the outstanding work of our immediate past president – Nathan Busch, whose professionalism and steady leadership have left a strong legacy.

Continuing that level of integrity and focus is something I take seriously. I also know that I won’t be doing this alone — I’ll be relying heavily on the support of the Master Joiners Council and Executive. Their experience, insight, and dedication are vital, and I’m grateful to be working alongside such a capable team.

There’s no denying that the last 18 to 24 months have been tough for many of us in the Joinery industry — not because of overwhelming demand, but quite the opposite.

A slowdown in workload, coupled with increasing pricing pressure, has made it a challenging time for businesses across the country. Many have had to make hard decisions, adapt quickly, and find new ways to stay competitive and resilient. And while there are still challenges ahead, I believe the worst is behind us.

As we approach spring, there seems to be greener pastures ahead — in more ways than one. There’s a sense of renewal in the air, and signs of recovery are beginning to show. It’s a good time to reset, refocus, and look forward with optimism.

One of my key goals during my tenure is to strengthen the sense of connection among joiners across the country. We’re a diverse group, spread across regions and specialties, but we share a common craft and a commitment to excellence. I believe there’s real value in bringing us together more often — not just at national events, but through regional collaboration, shared resources, and open communication. When we connect, we grow stronger as an industry.

As the saying goes, “If you want to go fast, go alone. If you want to go far, go together.”

That’s the spirit I want to bring into this role — one of unity, shared purpose, and collective progress. Whether it’s through mentoring, networking, or simply

picking up the phone to support a fellow joiner, we all have a role to play in lifting each other up.

I also want to keep professionalism front and centre. Our work is built on skill, pride, and attention to detail, and we need to keep raising the bar. That means supporting our members with training, resources, and recognition — and continuing to advocate for the value of quality joinery in New Zealand homes and businesses.

This is a time of opportunity for our industry. Whether it’s adapting to new technologies, responding to market shifts, or attracting the next generation of skilled tradespeople, we have plenty to focus on. I’m keen to hear from members across the country — your ideas, your challenges, and your successes. This is your organisation, and your voice matters.

Thank you for the trust you’ve placed in me. I’m looking forward to the journey ahead and to working together to keep Master Joiners strong, united, and futurefocused.

Nathan Moore National President, Master Joiners

With this September issue we have completed thirty years of publishing this magazine. It is as much a testament to the tenacity of myself and my editor Michael as it is to the valuable ongoing support of the Master Joiners, to our many advertisers over the years and most importantly though, to the degree of support we have received from our readership over the years. The last time I commented on our longevity was some five years ago at our 25th anniversary. Since then the major event has been Covid 19 which has affected in one way or another, all of us.

The enduring thing for me though has been the sense of moving on, to keep introducing new trends and new products which is what we have done through the magazine. It has also seen the maturing of the change in the guard at Master Joiners that started back in 2018. The organisation has grown in membership and become more structured with new leadership and notions of their role in the world with this wider membership. We are pleased as always to be associated with and represent the Master Joiners. We have continued our support particularly for the Apprentice Awards and look forward to the 2025 Master Joiners Conference this year in Rotorua. As the Conference is held in mid September, we will be covering it in our December issue.

Interestingly, on the trade show level, since the demise of the AWISA Exhibitions in Australia, we now see more and more local events cropping up to fill the gap between the big biannual shows in Europe. Of more recent times there have been more challenges with economic uncertainty both locally and internationally. For the magazine we have travelled through these uncertain times, reporting on those things important to our audience of tradespeople, suppliers and specifiers in a consistent and as unbiased way as we can. I think that is a big part of why we are still here.

For this our 120th issue, we have some interesting features both local and from overseas. We take a look at the two major trade shows from Germany, Interzum and Ligna, held in late May with commentaries from several companies that had stands there. We also look at the latest in sinks and benchtops, always a favourite over the years. Of note in this issue is our feature on the ins and outs of dust extraction in the factory. Although often advertised in the magazine it is a subject we tend to overlook so have a good look at this one. Lots of new product and new advertisers in this one as well. Without further ado I’ll let you get on with looking at the rest of the magazine.

Bob Nordgren

Official Publication of the New Zealand Joinery Manufacturers Federation magazine

The magazine for the joinery, cabinetmaking & kitchen manufacturing industries

Editor Michael Goddard michael@joiners.net.nz

Publisher Bob Nordgren bob@joiners.net.nz

M42 Aldersgate Rd, Box 27-513, Mt. Roskill, Auckland, 1440. Ph: +64-9-624 4680

Subscriptions & Mailings bob@joiners.net.nz

JOINERS Magazine Online www.joiners.co.nz

ISSN 1173-6836

JOINERS Magazine is the official publication of the New Zealand Joinery Manufacturers Federation. It is distributed to members of the joinery, cabinetmaking and kitchen manufacturing industries and is published quarterly in March, June, September and December. Advertising statements or editorial opinion are not necessarily those of the publisher, its staff, the New Zealand Joinery Manufacturers Federation Inc., or their executives, unless expressly stated. All articles printed in JOINERS Magazine are subject to copyright and cannot be reproduced without the express consent of the Publisher or the authors therein. Advertisements and articles are accepted without liability as to the accuracy or otherwise of the factual matters represented.

The woodworking machinery sales and servicing company who hold the SCM agency in New Zealand currently situated at 606 Rosebank Rd in Avondale are are making a move up the road and round the corner to 13 Patiki Road, Avondale, Auckland 1026.

“We are moving to a stand alone building rather than the current mix of office and wharehouse across two buildings,” says owner John Fleet. “It brings everything under one roof making it easier for us and our clients.”

The company will be at the new premises from the 15th of October.

ph 09 820 9486 www.machinesrus.co.nz

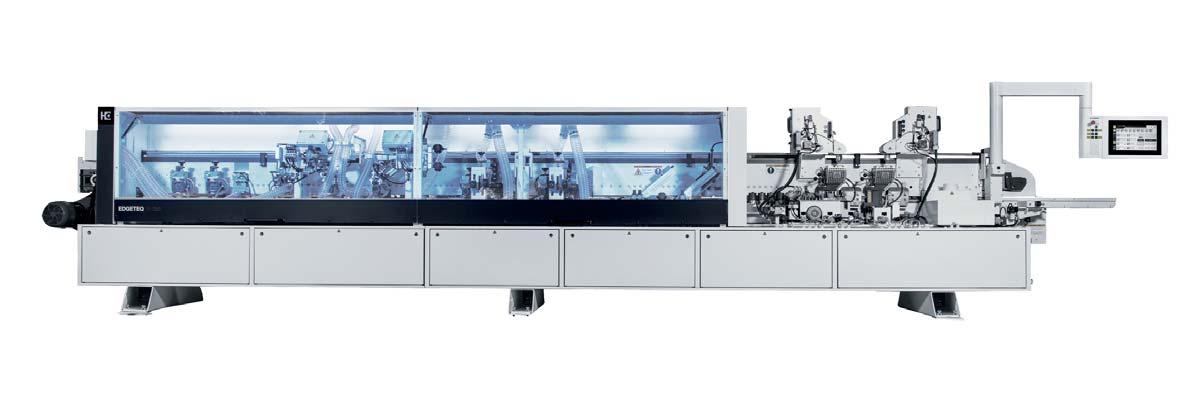

Hutchco has commissioned New Zealand’s first laser postcoating system at its Highbrook, Auckland site, after a two-year project to strengthen edging supply continuity.

The system allows on-demand coating of ABS/PVC edge banding for laser and related application methods, with trials confirming it runs on existing processing settings. For more on this go to page 26.

finish matters most

Forty years of flawless finishing touches

For the last 40 years Kantek has been adding the finishing touches to joinery, cabinetry and furniture projects across New Zealand. We pride ourselves on sourcing premium products from Europe to compliment your project and we combine this with decades of meticulous experience to get results that stand the test of time.

for

Formany New Zealand athletes, the path from competitive sport into long-term employment can be uncertain. Skills honed through sports, including selfmotivation, teamwork, and performance under pressure are incredibly valuable, but are often overlooked in traditional career pathways.

The BCITO Sports programme is bridging this gap. Designed to help current and former athletes establish fulfilling careers in the trades, it offers tailored support, training and clear pathways into building and construction.

Programme lead Jeremy Benton explains, “At 15–17, 81% of young Kiwis are active in sport, but this falls after they graduate. By offering career opportunities that enable them to keep up the activities they love, we’re promoting a stronger workforce and a healthier New Zealand.”

For sports clubs, the programme also supports them to remain attractive to members by emphasising the apprenticeships, micro credentials and career progression on offer. Being part of the programme helps match athletes with employers who understand the requirements of their extra-curricular activities.

Liam Robinson, a BCITO qualified builder, and club cricket and rugby player in his native Canterbury, says having a boss like Mike Kingston, owner of Kingston Builders, has made all the difference to enabling him to follow his passions.

It’s awesome having a boss who’s so accommodating and genuinely understands what it’s really like. We all love sport, so we’re happy to work a bit harder to make it work,” he says.

“BCITO has been awesome in helping me get qualified in my apprenticeship. They’ve been really accommodating, both with my sport commitments and on the work site. If you love it, why not do both?”

Benton says team sport provides players with a lot of transferrable skills that make them invaluable to employers in the trades.

“It’s about coming together for a common goal. You could be 20 years younger or older than your teammates, but you’re all there to improve, to lift each other and to get better as a team.”

However, it’s not only team sports players who shine in the trades. The mental and physical discipline of shot-put star, Olympian and builder Tom Walsh has also seen him become one of the programme’s ambassadors, acknowledging the need for athletes to have a strong career plan post professional sport.

BCITO Sports isn’t just another programme, it’s a strategy for what comes next. It recognises the drive and potential in athletes and supports them with the skills and opportunities to build a solid career in the trades, all while staying active in the sports they enjoy.

With 16 in-demand building and construction trades to choose from, each with its own pathway, you can start as an apprentice and work your way towards running your own business.

For more information on the BCITO Sports programme, visit https://bcito.org.nz/bcito-sports/

In my last column, I reflected on the importance of performance and transformation, the dual engines that keep a business relevant and resilient. Since then, we’ve brought our Laminex NZ sales, marketing, and leadership teams together to double down on what this looks like in practice, and how mindset plays a pivotal role.

At our national conference, we explored the concept of mindset, particularly the idea of negativity bias - the brain’s default to focus on risk. Left unchecked, it stifles creativity, limits collaboration, and ultimately blocks growth. But when we reframe challenges and ask better questions, we shift from judgement to curiosity, from silos to shared purpose.

That shift is key to growth and we’re fortunate to work with customer partners already embracing this way of thinking. As part of our own transformation, one principle we’re embedding at Laminex is “radical candor”. Popularised by leadership coach Kim Scott, radical candor is the combination of caring personally and challenging directly. In an industry as tight-knit as ours, it's easy to fall into the trap of politeness or over-reassurance, but real transformation requires real conversations. At Laminex, we are working hard to embed this at every level of our business because true transformation requires open conversations, even when they’re tough. It’s how trust and progress are built.

Transformation also requires looking forward, not just in the rearview mirror at performance, but out the front window. The last time we undertook major homeowner and market research was in 2018, and it’s fair to say the world has changed a bit since then! So, we’re embarking on market research. While still in the early stages, the signals are clear: consumers are shopping in more considered ways.

Finally, transformation also means building a stronger talent pipeline. We’re investing in talent, with our Hamilton and Taupō plants at the heart of our business. We know the future of Laminex depends on passionate, skilled people who want to grow a career in manufacturing. That’s why we’re launching a new manufacturing cadetship programme designed to bring bright talent into our business and equip them with the skills to grow and lead.

If you know a school leaver, second-chancer or future leader who’d thrive in a hands-on, high-performing, values-led environment, we’d love to talk.

Together, it’s not just about supplying the best surfaces. It’s about building a better industry - one that performs, transforms, and grows with purpose.

Rachel Silcock General Manager Laminex New Zealand

We’ve taken your feedback on board and made key updates to the Blum Shop to enhance your online experience, making it faster, clearer, and more efficient. The new order history feature provides a comprehensive overview of past orders, including dates, items, quantities, totals, delivery status, documents, and even tracking links, making reordering effortless. You can now compare up to three products at a time with key differences clearly highlighted, so you always choose the best fit for your project. And for products that require assembly, you’ll now find technical and assembly instructions all on the product page.

A new order history feature marks a key improvement to Blum Shop.

See how the new Blum Shop can streamline your ordering process and support you on every job.

Jon from Spindles NZ has recently retired to travel the world and has handed his business to Farnese NZ. Farnese now have the capability to look after anyone with an HSD spindle who needs it serviced or repaired. They also carry a large range of HSD spindles in stock for anyone needing one in a hurry.

Rob from Farnese NZ says, "Jon was a long-time friend of ours and when he came to me to see if we would like to take over his spindle business we jumped at it. Jon had previously taught us how to repair and service HSD spindles before Covid, so it was a no brainer to take it on.

This makes Farnese self-sufficient, having it all in house means we can look after our customers even better. Farnese have the Manpower to do quick turn arounds, so if a spindle needs attention, we can jump on it right away and give amazing service"

If you need your HSD spindle repaired, or you're in need for a new one, Get in touch with Farnese today! www.farnese.co.nz

Back in April NZ Panels Group advised that it was making structural changes to the business that would make it easier for customers to do business with them. Part of that change was to align the sales and customer service teams together under the NZ Panels Group brand. That change has now been completed and means the Impey's and Shearers merchant brands are set to phase out.

As the business has reallocated sales teams so customers generally deal with just one NZPG account manager (and a Dezignatek one in some cases), they have taken the opportunity to strengthen their sales capability.

The following new faces have joined NZ Panels Group in business development roles under the leadership of North Island Sales Manager Alan Rowe and South Island Sales Manager Ian Harris.

John McBeath, BDM South Island

John will be well known to many in the South Island from his previous role in joinery sales management with Carters. He is hugely experienced and will bring that to bear with his customers in Christchurch and north

Miguel Kader, BDM Auckland

Miguel is also hugely experienced in the joinery space having spent many years with Carters Albany in joinery sales. He is a great addition to the NZPG team and will be working with customers across the Auckland region.

Paul Hammerich, BDM Auckland

A familiar face to many, NZ Panels Group has welcomed back Paul 'Hammer' Hammerich who was sales manager for Kopine particleboard flooring for many years. Now that the Kopine plant has been upgraded, Hammer will be helping promote their particleboard flooring products along with our other products through the merchant channel.

As part of the changes, promotions have resulted for two existing members of the NZ Panels Group team:

Stacey Hollis, NI Sales Manager Merchant channel

Stacey Hollis is a longstanding member of the NZ Panels Group sales team and has been promoted into the newly created role as Sales Manager for the merchant channel.

Sean Opie

Upper North Island Sales Manager

Sean extends his sales manager role beyond Auckland to now take on the Upper North Island He continues to report into North Island Sales and Distribution Manager, Alan Rowe.

the heart of every quality renovation or build is a simple principle: strong relationships, strong outcomes. We believe that sourcing timber joinery and cabinetry locally keeps our projects reliable, efficient, and responsive. When builders, joiners, and suppliers work together within New Zealand, we reduce delays, simplify logistics, and create a smoother path from design to delivery.

Choosing locally made products is more than convenience—it’s a commitment to community, sustainability, and craftsmanship. Locally-sourced timber products supports jobs, preserves skills, and ensures materials meet our exacting standards. Additionally working within trusted networks like the Master Joiners supplier

network strengthens connections, provides assurance, and delivers results that our clients can count on.

Sustainability is built in. Locally sourced joinery and cabinetry reduces transport emissions, and encourages smarter, more efficient use of resources. For builders, joiners, and homeowners alike, this philosophy means projects that are better for the environment, better for the people building them, and better for the communities they serve. In every project, we build not just structures—but trust, resilience, and pride in locally made craftsmanship.

Meet the suppliers participating in the Master Joiners Crafting The Future Conference 2025

In an increasingly competitive market, efficiency, precision, and reduced post-installation callbacks are top priorities. The 2025 refresh of the Hideaway Compact range delivers improvements that squarely target the needs of kitchen manufacturers and installers.

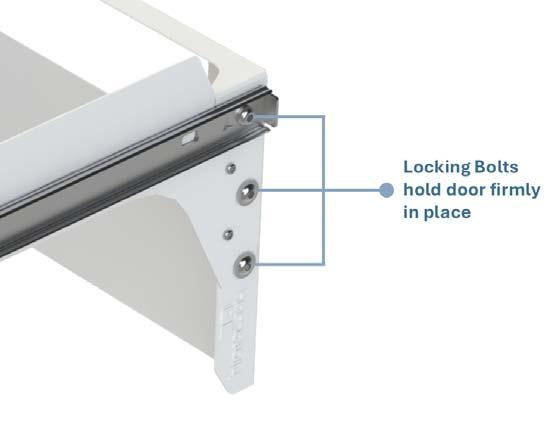

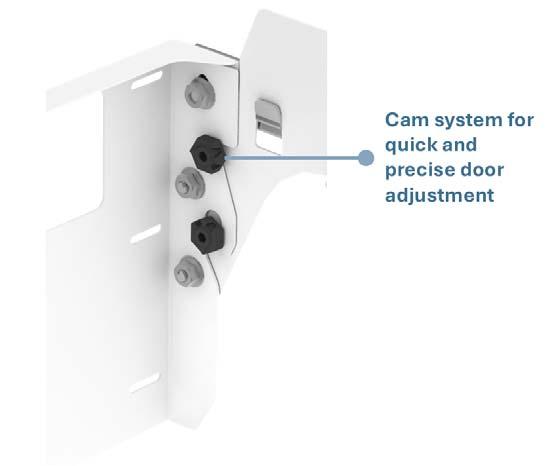

One of the biggest challenges in waste bin installation is aligning the door panel flawlessly. Misalignment leads to unsightly gaps and, worse, return trips to fix doors that have drifted over time. Hideaway Compact tackles this by utilising the proven door adjustment system from the premium Concelo® range. Precise alignment of door fronts is now quick and intuitive using cams for vertical (+/- 2.5mm) and tilt (+/- 0.75°) adjustment and enlarged slots for horizontal adjustment.

Once door alignment is complete, the door position is securely fixed with three M6 bolts each side, dramatically reducing the likelihood of movement after installation—an upgrade that practically eliminates post-installation site visits.

The new Compact body design now uses Euroscrew fixing on both the top and sides, positioned at System 32 spacing. This not only enhances the pullout resistance—key to longterm durability—but also ensures consistent and repeatable positioning across models. The side mount fixings on the new Compact body have also been repositioned to make them easily accessible for faster installation.

Each product includes instructions with a QR code linking to installation animations— perfect for installation teams on site who need visual guidance fast. This small but significant touch reduces training time and ensures even new installers can execute with confidence.

The Hideaway Compact range now accommodates a wider array of cabinetry styles. Improvements to the door bracket design now allow framed doors down to a minimum rail width of 50mm, while a generous open area on the door bracket leaves plenty of space for handle placement, empowering designers and manufacturers with freedom and flexibility in design.

The 2025 Hideaway Compact refresh is a prime example of design that’s attuned with the needs of kitchen manufacturers. It's faster to install, easier to adjust, and engineered to stay put. In a market where every minute on-site costs money, Hideaway Bins has made sure its bins won’t be the reason installers go back for round two.

To learn more, visit hideawaybins.co.nz or contact Hideaway’s National Distribution Partner – Hafele, or Regional Distributors – Carters, Impey’s and Industry HQ.

6-Way CAM system for quick and precise door adjustment

Locking bolts hold door Uses System 32 drilling patterns and features high strength Euro screws.

Every aspect of the product design has been revised to make installation faster and easier. A superior product for no additional cost! Contact your preferred distributor for a product demonstration. Available from

When you meet Eduardo it’s instantly clear you’re talking to someone who lives and breathes joinery. His energy is contagious and his stories stretch back to childhood in Brazil – long before he imagined running a thriving Auckland workshop.

Eduardo moved to New Zealand in 2008, lured by his brother’s promise: “You can make good money in the building industry here.” While not a qualified builder, he brought something equally valuable - a joinery pedigree spanning four generations. Both parents came from joinery families, so sawdust was practically in his DNA.

Some of Eduardo’s earliest memories are from his grandfather’s workshop. “I used to spend hours there after school and on weekends,” he recalls. “We weren’t allowed to touch the machines but when no one was around, one of my brothers would spin the bandsaw flywheel with his feet to get the blade moving - and I’d have a go at cutting something. We’d never turn the power ongetting caught would’ve been the end of us!”

It was a mischievous start, but it stuck - all four brothers became joiners. Eduardo’s proud he can still show all ten fingers intact, not something all his relatives can claim.

After eight years in NZ building, Eduardo returned to his first love and founded Evolution Building Solutions Ltd in Mt Wellington. The business has grown steadily and now has a team of 12, including 5 qualified joiners. Space is tight, but the workshop is clean, organised and built around producing quality work.

Evolution specialise in high-end architectural joinery. “A good joiner can make anything out of

“I didn’t even want to buy a sander but now I wouldn’t be without it.” - Eduardo Fernandes.

wood. I learned the old-school ways, but I love bringing in new technology too.

Innovation is reflected in his lineup of modern classical machinery: a Felder K540S panel saw, D963 thicknesser, Format-4 planer and more recently, a Felder FW 950 classic wide belt sander.

The FW 950 classic has a 950mm working width with a combination sanding unit for calibration and fine sanding. “I’ve fallen in love with this machine,” Eduardo admits. “I didn’t even want to buy a sander but now I wouldn’t be without it. We use it for veneer sanding, solid timber jobs, prepping MDF before paintingeven calibrating veneer thickness. The belt adjusts to 0.1mm, and the oscillation feature gives a great finish and makes the belts last much longer than I thought they would.”

Despite his affection for the Felder sander, Eduardo’s favourite machine is his K540S panel saw. “The sliding table glides so smoothly I can move it with my fingertip, and the accuracy is precise. For the kind of work we do, accuracy is everything. I know every cut will be perfectly sized and square.”

With four generations of joinery expertise and modern machinery, Evolution Building Solutions is proving that tradition and innovation can work hand in hand - creating a business built to thrive for years to come.

WithFor four days in May interzum became the international stage for innovative materials, intelligent components and smart technologies that will shape the homes and workplaces of tomorrow. We asked local suppliers who attended the show for their comment and perceptions.

around 60,000 trade visitors from 157 countries and over 1,600 exhibitors from 57 countries, interzum 2025 confirmed its position as the world’s leading platform for furniture production and interior design.

For four days, Cologne became the international stage for innovative materials, intelligent components and smart technologies that will shape the homes and workplaces of tomorrow. A spirit of positivity and optimism, and a willingness to effect change were the hallmarks of this year’s trade fair.

The guiding theme of “Rethinking Resources: Circular and Bio-based Solutions” lay at the heart of interzum 2025 and wove its way through the exhibition halls. From foams made from recycled waste to recovered fibres from MDF and HDF boards to resource-efficient zinc recycling systems, sustainability was the dominant theme at many exhibitors’ stands. The trade fair offered a comprehensive overview of the market, packed with

innovation and impressively indepth specialist content. Cologne was also the venue for many product launches, highlighting the pace of development in the industry.

Trends and knowledge sharing

In addition to informing the exhibitors’ product presentations, interzum 2025’s central theme was also reflected in the diverse event programme. The three interzum Trend Forums looked at key issues affecting the future of the industry – from biocircular materials and resource-efficient furniture design to the Digital Product Passport as the key to a circular economy.

The interzum Trend Stage once again served as the trade fair’s knowledge hub. Renowned experts gave presentations, in which they shared detailed insights into international industry trends, provided in-depth market analyses and discussed the current regulatory environment. The interzum Product Stage augmented the programme with actionable tips relating to new products, best practices and forward-looking strategies from the exhibitors. What all of these presentations made clear was that the industry isn’t simply watching the transition from the sidelines, but actively driving progress.

interzum award 2025

As in previous years, a particular highlight of the trade fair was the interzum award. In 2025, it had a strong link to the central theme with the introduction of a special “Rethinking Resources” category. From a total of 146 entries submitted by 80 companies from 23 countries, the jury of experts selected 66 exceptionally forwardlooking innovations – including

twelve entries that were awarded the highest distinction: “Best of the Best”. The award-winning products were displayed in an exhibition on Boulevard North and attracted a great deal of interest from trade fair visitors.

In his concluding remarks, Matthias Pollmann, Koelnmesse’s Vice President Trade Fair Management, said: “interzum 2025 has demonstrated the strength of this industry’s will to innovate – and the strength of its desire for sustainable change. We’re already looking ahead to the next event, when we intend to keep on supporting this process of transformation and stimulating new ideas. Our aim is to continue to offer the industry a platform where global trends are not only discussed, but actively shaped.”

The next edition of interzum will take place in Cologne from 11 to 14 May 2027.

At Interzum 2025, Blum transported visitors on a themed journey inspired by Jules Verne, inviting them to travel “around the world in 80 minutes” through an immersive stand experience.

Building on the 2023 theme “For Everyone,” this year’s focus on “Everywhere” reflected Blum’s mission to offer innovative furniture solutions for diverse living spaces—kitchens, bedrooms, bathrooms, and more—across the globe. The stand showcased smart, stylish designs like hidden pantries, new drawer systems, and space-saving storage, highlighting Blum’s commitment to quality, creativity, and sustainability.

A standout for joiners was the debut of PLICOBOX, a modular box system developed in collaboration with EGGER. Engineered for rapid installation, a solution designed for bedrooms and living spaces, PLICOBOX’s patented folding design allows users to secure the base and back panel without tools in under a minute: “Fold. Push. Done.”

The debut of PLICOBOX and the further evolution of their pocket door system REVEGO captured a lot of interest on the Blum stand.

The system is available in silk white, pyrite beige, and carbon black, and supports up to 25 kg.

Also turning heads at Interzum was the latest evolution of Blum’s pocket door innovation: the halfheight REVEGO. Designed for spaces that cannot accommodate full-height solutions, this compact door system delivers the same seamless, handle-less design and slide-away operation as the original for upper cabinetry, benchtops, and specialty storage

areas. Its integrated track and softclose features ensure a flawless user experience.

Like the full-height model, halfheight REVEGO lets fronts glide smoothly into slim, preassembled pockets—ideal for hiding appliances, coffee stations, or workspaces.

Designed to suit a wide range of applications, the system covers front heights from 1130mm to 2980mm, offering flexibility

across different cabinet sizes. Blum’s TIP-ON push-to-open technology allows effortless, handle-free access and a consistent look throughout the room. Installation is simple, with pre-assembled pockets saving time on-site. Whether fitting a small kitchen, multi-use area, or entertainment unit, half-height REVEGO gives joiners a flexible, space-saving solution without sacrificing style or function.

Following Interzum, the New Zealand team hosted 22 of our local customers at Blum’s Austrian headquarters for a three-day visit. Led by our Austrian team, the trip offered hands-on factory tours, a closer look at Blum’s manufacturing, and memorable social activities. It was a rewarding experience that strengthened relationships and gave guests a deeper understanding of the Blum brand.

www.blum.com

At Harn, we’ve always believed that hardware should be more than just a mechanical component. It should be an integral part of the design story. Since 1994, we’ve been engineering drawer and runner systems in Malaysia, driven by a commitment to precision, performance, and sustainability.

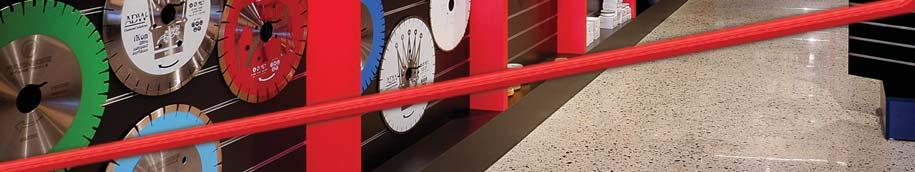

This year at Interzum Cologne, the world’s leading trade fair for furniture production and interior design, we introduced our latest innovation: Alunan T7, the world’s first 7.2mm double-wall drawer profile. It’s a design that is already making waves internationally — not just for its sleek appearance, but also for the way it redefines space efficiency and material use in modern joinery.

We were honoured that Alunan T7 received the Interzum High Product Quality Award 2025, a recognition that celebrates products setting new benchmarks in innovation, quality, and functionality. For us, the award is not just about the product itself— it’s about the people, partnerships, and feedback that have shaped it along the way.

On paper, 7.2mm might not seem like a lot. But in the world of cabinetry, every millimetre counts. Alunan T7’s ultra-slim profile offers more internal drawer space without increasing the overall footprint. That extra space can mean greater storage capacity in kitchens, more flexibility in wardrobe layouts, or simply more room for your client’s everyday essentials.

Made from 99% recyclable steel, the slim form doesn’t compromise on strength. Paired with our proven RITMA T runner system, it delivers the smooth, silent movement that Harn hardware is known for, backed by load ratings of 35kg and 60kg.

Since its launch in May 2025, Alunan T7 has travelled from Europe to Oceania, making its way from Interzum in Cologne to the Kitchen+Bath Show in Melbourne, and now into the conversations of joiners and cabinetmakers worldwide.

For the New Zealand market where quality, durability, and refined design are essential, T7 offers a compelling proposition. It’s a premium product designed

for long-term use but remains competitively positioned for midto-upper market projects. T7 brings a modern, understated elegance that works across applications.

Alunan T7 is part of a broader hardware ecosystem built on the RITMA T Platform, which also supports our Alunan T and RITMA Cube profiles. This shared runner technology allows manufacturers to mix and match designs while maintaining consistency in performance and installation— unlocking even greater flexibility in project planning.

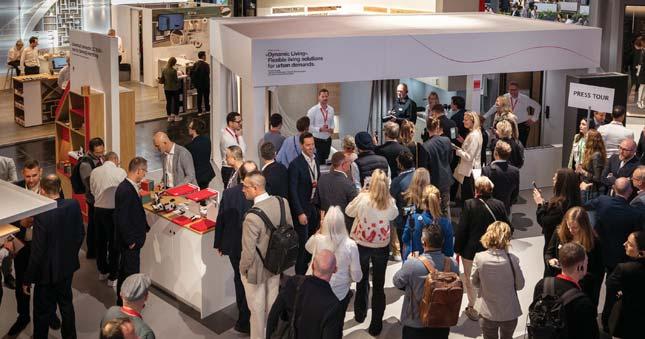

Held from 20–23 May in Cologne, Germany, Interzum 2025 once again proved to be the world’s leading trade fair for furniture production and interior design. Häfele made a commanding presence with a 1,600 m² booth that embodied its guiding principle: Maximising the Value of Space. Together.

The event was a vibrant showcase of Häfele’s latest innovations, including the launch of the Häfele Lighting sub-brand, which offers fully integrated lighting solutions for both furniture and interior spaces. Also unveiled was the Free Slim flap fitting, a sleek, ultra-compact system designed to optimise upper cabinet storage, and the Slido F-Flush57, a new sliding hardware solution that enhances space efficiency with minimal installation depth

Three members of the Häfele New Zealand team attended, engaging with global colleagues, customers and suppliers. “Interzum is more than a trade fair, it’s a global stage for innovation and connection,” said Simon from the NZ team. “The energy at the booth was phenomenal, and the feedback on our new products was overwhelmingly positive.”

The stand also showcased Häfele’s co-creation approach, with collaborative projects demonstrating how the brand works hand-in-hand with partners to deliver tailored solutions. The Dynamic Living concept - adaptable living environments enabled by smart design and technology, offered a glimpse into the future of flexible spaces.

As Häfele continues to push boundaries in design and functionality, Interzum 2025 served as a powerful reminder of the brand’s global reach and its unwavering focus on innovation, collaboration, and customer-driven solutions.

Interzum 2025 in Cologne was more than a showcase of products for Hettich. It was a celebration of innovation, teamwork, and global partnerships. Under the theme “Transforming Spaces – with innovative motion”, Hettich brought to life how furniture can be more functional, flexible and inspiring.

Thousands of visitors from across the world experienced 1,100m² of live demonstrations, new product debuts, and futureoriented concepts. From the special “Spinnovate your space” show performed every 20 minutes to live demonstrations and new products, the event was a highenergy hub for creativity and industry exchange.

The atmosphere was one of energy and teamwork. “It was particularly impressive to experience the enthusiasm of our customers from different countries and to feel the Hettich spirit at first hand,” said Lena Brugesser from the team at Hettich’s home in Kirchlingern. The team worked around the clock, knocking off from the stand to host two evening events with more than 1,000 guests and making sure visitors felt at home.

Hettich’s presence at Interzum reaffirmed its role as a driving force in the furniture fittings industry, blending product innovation with a personal approach. As one customer from Spain put it, “The Hettich brand stands far above the product itself.”

Key Moments from Interzum

● 1,100m² showcase – A busy stand filled with live demos, future concepts and product launches.

● “Spinnovate your space”

– Performed every 20 minutes, drawing steady crowds and reflecting how our interiors might look in future and the role cabinetry hardware could play.

● Global reach – Thousands of visitors to the Hettich stand alone, from countries in every continent.

● Big events – Over 1,000 guests joined evening functions in Cologne.

● Team spirit – A collaborative effort from Hettich and FGV teams worldwide to deliver a seamless experience.

● Innovation highlights – Sneak peeks at the next generation of FurnSpin releases with full glass sides and cable management, the new AvoSys hinge, and the brand new Interior Fittings range.

For New Zealand’s cabinetmakers, the event signals exciting developments ahead. With pioneering solutions like the FurnSpin and Interior Fittings now readily available in the country, and design assets like AvoSys hinge due in 2026, our local market remains at the forefront

of adopting the world’s most innovative storage and motion technologies.

Also making a splash with its refreshed presence at the show was Italian heritage brand FGV, recently part of the Hettich network. FGV brought its own distinct Italian design flair to Interzum, showing how the two brands complement each other while offering customers greater choice.

Interzum 2025 may have ended, but as with every biennial this event rolls around, the momentum is just beginning.

https://www.hettich.com/en-de/ inspiration/fairs-showrooms/ interzum

● Part of the Hettich Network – FGV showcased its own product innovations while highlighting the unique Italian style that sets it apart.

● Strong brand presence – A clearly defined identity at the stand, while working closely with Hettich to create a unified experience for visitors.

● Live demonstrations – Visitors explored FGV’s precision-engineered hinges, slides and fittings, seeing how they complement Hettich solutions.

● Celebrating together – A lively stand party and joint events in Cologne underlined the close partnership between the two brands.

● Coming soon to NZ – Selected FGV products will soon be available in New Zealand, bringing more choice and flexibility to local cabinet makers.

Hettich’s Interior Fittings range is the result of German engineering precision and Italian design. Crafted for kitchens, living spaces, and wardrobes, these systems maximise storage potential while maintaining a clean, sophisticated aesthetic.

From pull-out shelves to tall-unit systems and innovative corner solutions, each product is designed to optimise access, improve ergonomics, and seamlessly integrate into diverse interior styles. Its order made easy.

Supported by and integrated with Hettich’s broader ecosystem of products, the Interior Fittings form part of a complete, harmonised approach to furniture functionality.

With an emphasis on quality, adaptability, and long-term performance, Hettich enables designers, manufacturers, and homeowners to create interiors that are as practical as they are beautiful.

For Sales enquiries

Our friendly Customer Service team 0800 438 842 | sales-nz@hettich.com Or reach out to your Territory Manager for more information

THE RANGE

PANTRY STORAGE

1. Olona pull-out pantry, full extension with integrated Silent System soft-closing and optional upgrade for soft-opening

BASE UNITS

2. Lario 2 tier pull-out

[Not pictured]

• Naro single internal drawer

CORNER CABINETS

3. Orta corner unit pull-out with individually extending rear shelves

4. Salso corner unit swivel pull-out with individually extending shelves

[Not pictured]

• Goro corner unit pull-out

• Senio corner unit swivel pull-out with individual fronts

www.designwithhettich.co.nz

Premium hardware for exceptional cabinetry. Because the details matter. designwithhettich.co.nz shop.hettich.com/nz_EN/

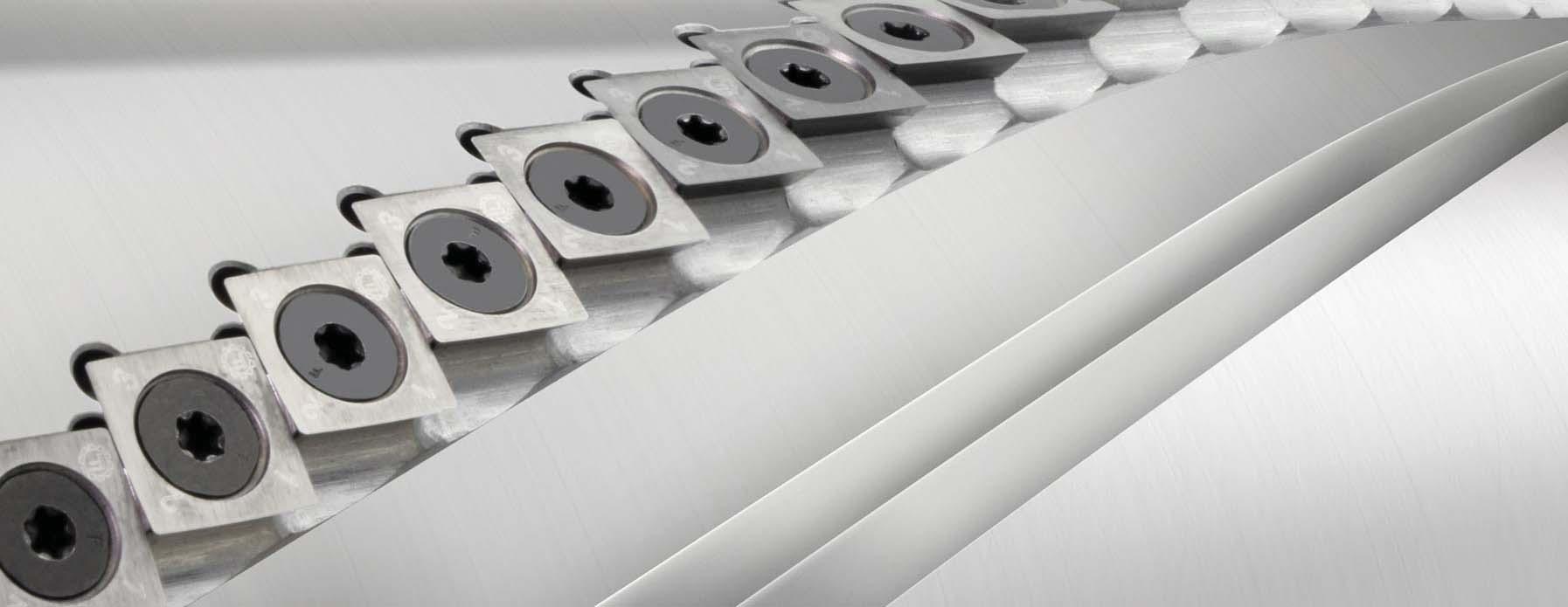

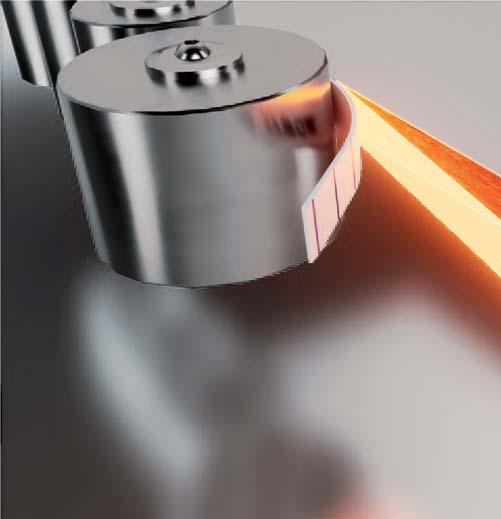

The Laser Coater applies a 0.2mm colour-matched polymer layer to standard ABS and PVC edging, producing tape ready for laser, Hyfuse, hot-air, NiR edgebanding.

Laser edging has long been the benchmark finish. But in New Zealand’s import-dependent market, supply has been the sticking point. Covering hundreds of décor matches in multiple widths, thicknesses and laser formats from offshore alone was never sustainable. For many joiners, that slowed the shift away from hotmelt, despite laser’s clear advantages.

Building on 35 years sourcing premium European materials, Hutchco has delivered a practical fix - bringing New Zealand’s first Laser Post-Coating System online. It’s a fundamental change in the supply model, making the chain more responsive to actual demand.

Simon Hornby, Marketing at Jacks, has seen the progression first-hand: “Co-extruded is the benchmark for finish; post-coated is close – and both are far easier, faster and cleaner than glue.”

Henk van Oeveren of HPTech, who trialled post-coated tape on Hyfuse, backs this up from a processing perspective. He noted “it appears to deliver a bond and finish very close to coextruded.” In his view, the key is quick calibration of heat, speed, and pressure to get machines dialled in – and with that support, customers will find the transition straightforward. More availability, he says, will “speed the transition from glue to laser,”

Mark Leith, Managing Director, Hutchco expands further.

“While laser technology is still in transition, on-demand post-coating has become the sustainable path for adoption. With bond strength and finish now comparable to co-extruded, the investment was an easy call. After six years in the laser market, German produced co-extruded Greenguard PP Prolaser remains a bulk part of Hutchco’s supply.

“The challenge has been balancing high-volume stock on shelves with efficient, flexible distribution that avoids unnecessary production and importation waste.”

His visit to Interzum in Cologne in May 2025 reaffirmed that approach, strengthening his resolve to overcome the remaining hurdles of compatibility, décor range, and offshore lead times.“For us, it’s about confidence for joiners and a smoother supply chain – a win on both sides,” he said.

The Laser Coater applies a 0.2mm colour-matched polymer layer to standard ABS and PVC edging,

producing tape ready for laser, Hyfuse, hot-air, NiR edgebanding.

Alongside it, the ProJumbo slitting, introduced in 2021, takes 275 mm master rolls and cuts them down to any width required. By embedding onsite gluing, slitting and now laser coating in Auckland, Hutchco has locked in a more responsive supply system with tighter quality control, faster turnaround, and less waste.

For the market, that translates to reduced lead times, greater décor choice. For joiners, it means confidence that edging will be both available and compatible cementing Hutchco’s position as an industry leader closing the gap between design intent and joinery execution.

Leading the transformation of NZ edgeband supply with the first local laser edge post-coating system.

• 110+ laser-ready décors

• Converting PVC & ABS to laser edging

• Colour-matched polymer coating

• NZ trials on Laser, Hyfuse, Hot-Air & NIR edgebanders

• Lower VOC emissions in production

www.hutchco.co.nz/availability

Contact our team for bulk edgeband rates for german made co-extruded PP Prolaser. 09 5736110 | cs@hutchco.co.nz

A lot of time, money and expertise is spent on selecting and installing what are perhaps the hardest working and most viewed surfaces in kitchens and commercial spaces. We look at new product offerings in both sinkware and benchtop materials from several local suppliers.

Hot on the heels of a major range update for Prime Melamine, NZ Panels Group has followed up with the launch of a new Porcelain benchtop range and a range refresh for Wilsonart HPL.

The porcelain category is a new one for NZ Panels Group which has been a long-standing player in the benchtop market with its Prime Stone, Prime HPL, Wilsonart HPL and Durasein products.

The new Prime Porcelain range is a partnership with global porcelain supplier Estrella. The initial range of 10 designs has been chosen for wide appeal and for their versatility to work with other cabinetry surfaces. Veined options, terrazzo, travertine and softly muted designs cover all the bases.

The ultra-compact sintered stone is manufactured from a blend of clays, feldspar, and natural mineral oxides fused together under extremely high temperature and pressure. Porcelain aka sintered stone is known for its exceptional durability, particular its heat, stain and scratch-resistant properties. A non-porous, hygienic surface with UV resistance, its suitable for both indoor and outdoor kitchen use and has a 25 year warranty.

All slabs are supplied in an economical 3200 x 1600mm size at 12mm thick, but Absolute Black is also available as a 20mm option.

Wilsonart range gets a refresh This popular range of highpressure laminate has been updated with 9 new designs added to the range, all with matched edgetape.

With the relaunch comes a major investment in better and larger samples, with folders now having an A6 size. New display boards being introduced to the market will have most colours sampled in A6 with a handful of small chips remaining for solid or small patterned designs.

The range now totals 54 colours and the 3660 x 1530 sheet size makes it an economical option to work with. With NZ Panels Group able to press all Wilsonart sheets on substrates up to 3600mm x 1220mm, it provides added potential for use as wall panels in commercial areas, along with cabinetry and doors. The edgetape offer has now been extended and nearly all colours have matching tape either 53 or 54mm wide.

Five of the new designs, such as Aluma Marble, are provided in a new Fieldstone finish, an organic texture that closely resembles stone with a honed surface that is less reflective and strengthened with AEON™ Enhanced Scratch & Scuff-Resistant Performance Technology. Layered on top of the Fieldstone finish are fine, irregular veins and features in a higher sheen, which create natural contrast and dimensional detail.

Over the coming weeks, sales teams from NZ Panels Group will be out on the road visiting joiners and fabricators to update them with the new product ranges.

NZ Panels Group is pleased to bring this exciting new porcelain surface range to the New Zealand market. In partnership with global supplier Estrella, Prime Porcelain offers exceptional durability and is suitable for both indoor and outdoor use

With a range chosen for versatility and appeal, attractive pricing and an economical slab size of 3200 x 1600 x 12mm, Prime Porcelain is sure to appeal.

View the full range at the Prime Panels website and ask your joinery account manager for more information.

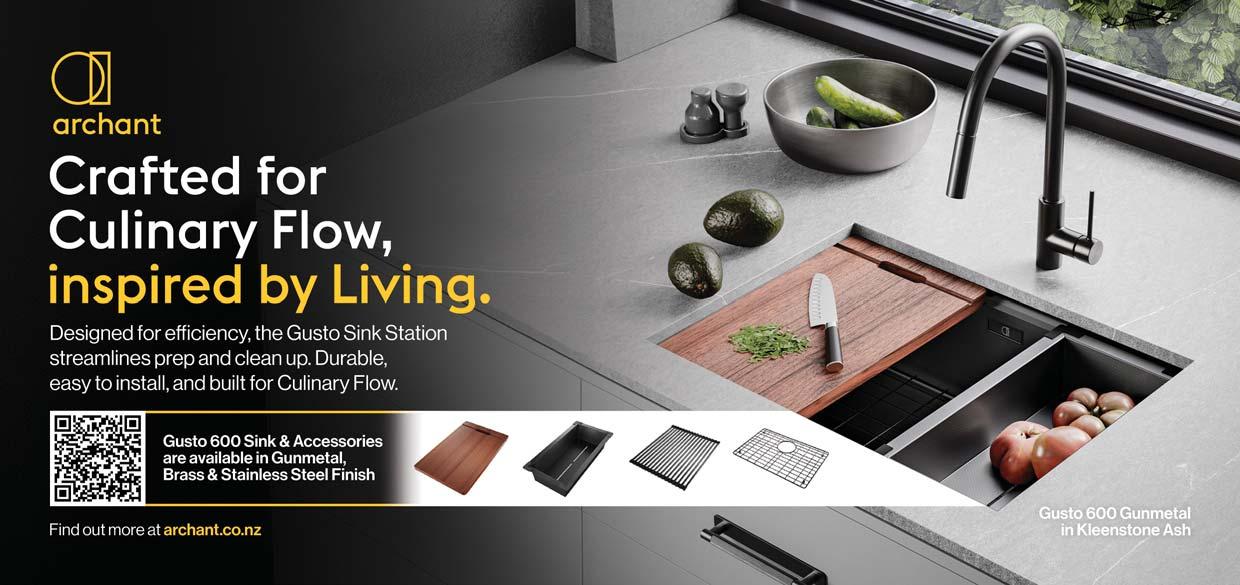

For years, the sink has been a purely functional fixture. The Gusto 600 Sink Station challenges that idea, transforming the sink into a centrepiece for cooking, entertaining, and creating. It’s a workstation, a prep zone, and a design statement all in one.

At just 600mm wide, the Gusto 600 integrates seamlessly into standard cabinetry while delivering the performance of a much larger setup. Its thoughtfully designed accessories, from the solid cutting board to the stainless colander, fit perfectly over the basin, allowing chopping, rinsing, and draining to happen in one central space. The result is a smoother workflow, more usable bench space, and a kitchen that works as beautifully as it looks.

The Gusto 600’s premium Whisper Finish elevates the everyday with a soft, matte texture that not only resists scratches but also reduces glare, making it a design statement in any space. Available in Stainless Steel, Brushed Gunmetal, and Brushed Brass, it offers a timeless palette that blends effortlessly with modern and classic interiors alike.

With the Gusto 600 Sink Station, the sink is no longer just where the washing up happens — it’s where the kitchen experience begins. It’s a place to prepare, to serve, and to share. Creating the ultimate culinary flow, inspired by living.

Known for its high quality and incredible durability, Wilsonart has introduced nine stunning new HPL designs to the range, all with matched edgetape.

While best known and loved as a benchtop surface, the entire range can be pressed on MDF up to 3600x1220 for use as wall panels, cabinetry and doors.

Distributed exclusively by NZ Panels Group, this range offers an economical 3660 x 1530 sheet size. View all new colours and order samples on the Wilsonart website or contact your joinery account manager.

Santorini Sinkware leads in sophisticated homeware design, offering products that blend timeless aesthetics with exceptional craftsmanship. Each piece is meticulously handcrafted, ensuring unparalleled value, style, and appeal, making a bold statement in any home.

Delta Range

Handcrafted 1.2mm (XL Overflows): Made from 1.2 mm 304 grade 18/10 stainless steel, this range features straight lines, bold styling, and a satin finish, ideal for budget-conscious, design-oriented homeowners.

Titan Range

Handcrafted 1.5mm: Crafted from heavy gauge 1.5 mm 304 grade 18/10 stainless steel, with 15 mm tight radius corners, the Titan Range offers durability, flexibility, and a clean, bold look.

Lavello Centro Range

Handcrafted 1.2mm, these sinks come with a roller mat, small sink insert, drainer tray, and chopping board, the Centro packages combine functionality and elegance.

Athena Range

Anthracite Nano Sinks 1.2mm: With Nano-infused stainless steel technology, the Athena Range offers a durable, attractive anthracite finish.

San Michel Range 1.0mm (XL Overflows): Similar to the Atlas Range, the San Michel Range features modern XL overflows, ideal for apartments and townhouses.

Atlas Range

Pressed 0.9mm: Economical with classic curves, the Atlas Range includes accessories, sounddeadening pads, and designer wastes, made from 0.9 mm 304 grade 18/10 stainless steel.

Tapware

Our tapware range features ceramic disc technology, “Wels” rated and “Watermark” approved, enhancing both functionality and aesthetics.

At Rocket Hardware, we produce high-quality, stylish products that elevate your home's look and feel, ensuring they stand the test of time.

For trade inquiries, please email: info@rockethardware. co.nz

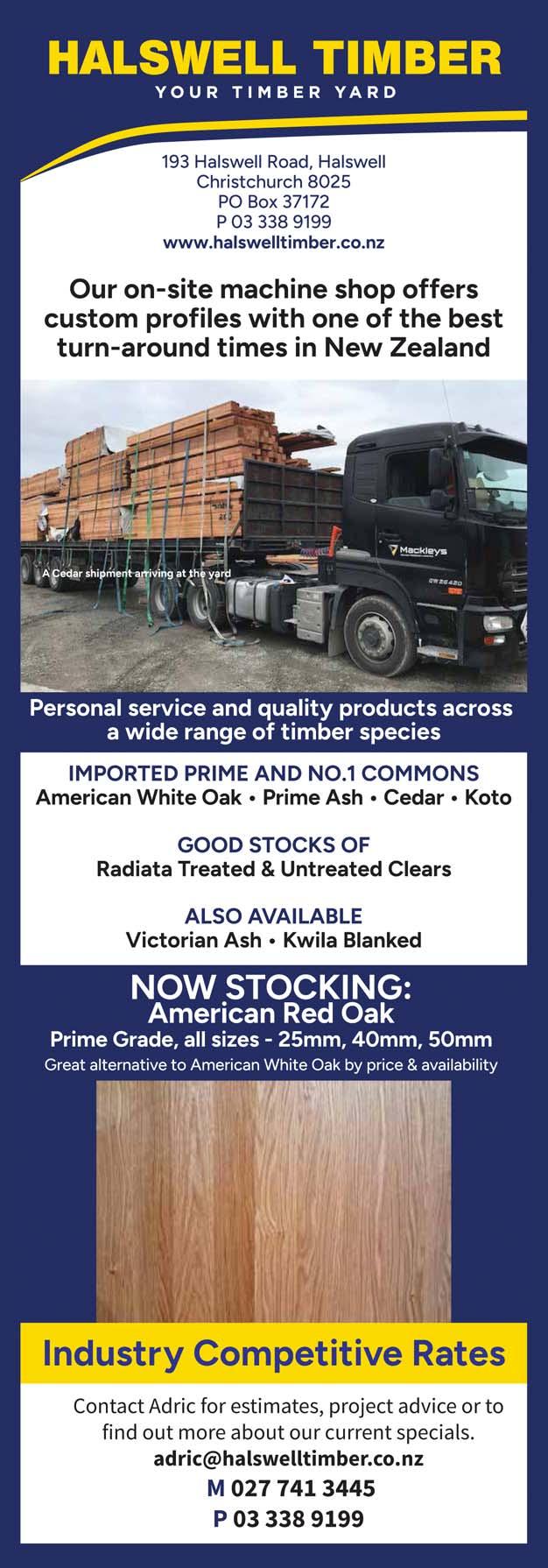

Barry Illsley established Barry Illsley Building & Joinery 15 years ago in 2010, starting out with residential builds, renovations, alterations and project management across the Manawatu region.

“The business has grown steadily since then to a point where both necessity and opportunity came into play,” says Barry. “The work we do most now involves kitchens, sculleries, laundries and interior pre hung doors necessitating the need for more productive technology while at the same time providing us with an opportunity to grow the joinery side of the business.”

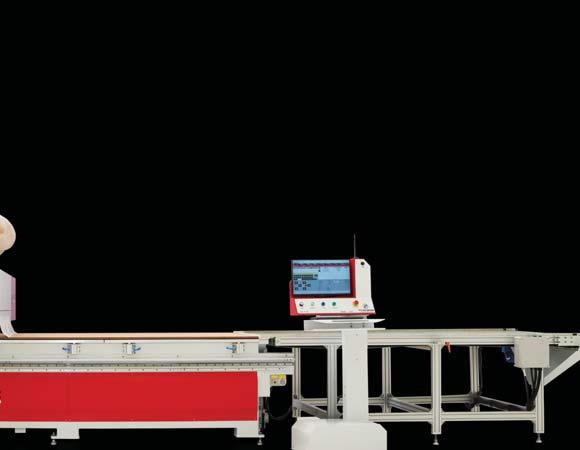

To this end about nine months ago after a good search he bought a CNC Fusion ATC 28/13 Auto Labelling Line and a Fravol Master 200 edgebander from machinery suppliers Farnese NZ and had them installed in his factory in Palmerston North. “The factory is split in two, one part dealing with the building

business where we have four builders and the other part dealing with the growing joinery business with another three staff.” Barry explains.

Why these two machines? “They both ticked a lot of boxes but essentially they both have a small footprint, were well priced and do the job. They move us forward in terms of increased productivity and precision” says Barry. The ATC 28/13 using Cabinet Vision software can process 2.8m by 1200mm size sheets with a

solid gantry style system and an automatic tool changer. The auto load and auto labelling function provides for part labelling using a Honeywell laser printer enabling easy storage of components. The whole machine takes up just 10.8m by 3.5m.

The second machine is the Fravol M200 edgebander which also is compact (3m by 2m). “The move to gluepot technology was a real plus. The glue pot takes up to 1kg at a time with a machine warm up time of only 6 to 8 minutes. The

machine can run up to 9 metres per minute and apply to most surfaces.” Barry explains.

What has this meant for the business? “We do a lot of kitchen cabinetry these days and these two machines combined can save us up to two days in production time. That really counts for us.”

Another important aspect has been service and training. “The team from Farnese have been marvellous. A quick efficient install and some training as required and off we went” comments Barry. “Their support and response times have also been really up to scratch. All in all, a good project well completed for both Farnese and us.”

For further information contact Barry at Barry Illsley Building & Joinery, Palmerston North, ph 027 427 8457, email barry@bib.kiwi, or visit www.illsleybuilding.co.nz

Discover precision and performance with the Farnese Apex CNC machine, featuring a 9kW router, versatile drilling, and automatic material handling for seamless efficiency. Elevate your production line today!

Experience unparalleled precision and versatility with the Titan 5-Axis CNC machine. Its advanced multi-axis capabilities streamline complex machining tasks, boosting productivity and efficiency for top-tier manufacturing.

Farnese Showroom now open!

10/38 Eaglehurst Rd, Ellerslie

While you’re reviewing benchtop and sink insert options in this month’s issue of JOINERS Magazine, why not consider how to also make the most of the space under the sink for your clients?

A Hodge Podge of Cleaning Supplies? Sort the Chaos with FIT’s Giamo Cleaning Supply Storage Options

Giamo, from FIT, is an affordable range of quality kitchen storage solutions that enhance the functionality and efficiency of kitchen cabinets. Within the range are two units specifically designed to keep cleaning supplies neat and tidy, and readily accessible.

The soft close Giamo Pull Out Detergent Unit is cleverly designed to be installed on either left or right side and has side spacers so that it clears door hinges. It has a generous 15kg load capacity and an easy to wipe solid base.

For an even more convenient spec, there’s the Giamo Pull Out Detergent Storage with Removable Baskets. In addition to all of the other unit’s features, with this one you can slide out the basket and take it directly to the cleaning task, making household chores just that little bit easier.

Base Mounted Soft Close Kitchen Bins That Work Under Sinks

You’re likely aware of FIT’s large range of Kiwi-designed Tanova pull out kitchen waste bins which includes options in both classic white and modern dark grey for cabinets from 300mm wide to 800mm wide at various price points.

Did you know the Tanova range also includes two base mounted bins that are perfect for installation in under sink cupboards? These provide a convenient, two-bucket, soft close unit for kitchens that

don’t have the space for a full drawer-fronted kitchen waste bin within its own cabinet. One of the units, with two 12l buckets, requires a space just 238mm wide and 350mm high. The other, with two 15l buckets, needs 315mm wide and 292mm high.

For Extremely Limited Space?

Working in an even tighter space? That’s not a problem for FIT’s Tanova range which includes separately orderable side mounting brackets that allow you to mount any of the Tanova Simplex handle-type units under a sink to one side of the cabinet.

If your only option is to mount a simple waste bucket on the back of a cabinet door, the Tanova Cabinet Door Bin Hanger Bracket makes this task easy.

For more info about FIT’s Giamo and Tanova ranges, check their website – www.fit-nz.co.nz - or contact your Fit rep, phone 09 431 0025 or email info@fit-nz.co.nz to discuss your requirements.

Fit is the proud New Zealand distributor of Vauth-Sagel’s premium German designed and made kitchen storage solutions. Make one-door and two-door corner kitchen cabinets usable and accessible with these corner options, manufactured in Germany to precise standards, and designed for a lifetime

For more than 60 years (since 1962), Vauth-Sagel has been developing and manufacturing high quality, innovative products for the global furniture

For Palmerston North based business Lee Builders the recent purchase of two machines from Farnese NZ was part of an update and expansion of their wooden joinery making into a nest based manufacturing operation in a process to handle the increasing demand they have been experiencing. Bob Nordgren from JOINERS Magazine spoke with owner Jared Kenyon about how this all came about.

Lee Builders was established back in 2011 to provide a range of services from construction, school support, maintenance programmes and end to end services, “A one stop shop if you like’ comments Jared. They operate from a 1200m2 in Tennent Drive, which they moved into in 2019.

“We have around eighty to ninety staff at any one time, providing a wide range of skills from construction, joinery, flooring, plumbing and electricians. We deal with local government such as the Palmerston North Council, the Ministry of Education and NZ Defence Force, we provide specialised service packages to local schools and work closely with a number of aged care facilities. We also provide commercial preventative and corrective maintenance programmes for various businesses. A growing and important part of all this has been our joinery section.” he explains.

The company works with HK Kitchens in Tauranga and Hagley Kitchens in Christchurch as well as several rest homes run by Oceania, Metlifecare, Bupa and Rymans to provide bespoke solutions be it new or renovative.

“To streamline what we do and meet the increased demand we looked at our joinery production and ways to improve it. We knew the team at Proform (now Farnese) and consulted with them. We eventually bought a second hand CNC Router (Fusion ATC 38/13R) and a new Fravol Master M200 edgebander some four months ago.” Jared explains “ These two machines now form the basis of our joinery production facility within the factory. We have a team of four in the joinery section who are now able to increase production to meet demand. It also cuts out the reliance for any middle men we may have used in the past.”

The Fusion ATC CNC Router has been particularly useful, a sturdy gantry style CNC machine with a 3.6m by 1.2m flatbed, it is good to process solid wood, MDF and particle board panels and even plastic, aluminium and composite materials. “It is ideal for nesting” comments Jared “and is proving to be a reliable, cost effective solution for us. Of note has been the twelve tool automatic tool changer that has saved a lot of time in the production process. We would estimate up to eight hours saved on each kitchen we produce with this machine and the new edgebander.”

Alongside this was the install of the Fravol edgebanding machine. “This has been a real winner for us too: a small footprint but without losing any edge quality” explains Jared. The Fravol is a versatile, easy to use machine with a colour touch screen. This machine is good for both industrial

and bespoke use with a heat up time of just six to eight minutes and a glue capacity of 1kg.

And what about the install and servicing? “Quick and efficient in both cases, always responsive when needed” comments Jared. “The machines are easy to use and with the training given by Farnese we were up and running very quickly.”

And what of the future? “The business as a whole is a lot more than just the joinery section but these machines will make it easier and quicker to complete a lot of the work we do and to the high standard we offer our clientele. We will be looking to build on the progress we have already made.”

For further information contact Jared Kenyon at Lee Builders at jared@leebuilders.co.nz or visit www.leebuiders.co.nz

Farnese New Showroom: 10/38 Eaglehurst Road, Ellerslie

When: 15th- 16th October, 9am-5pm

Lunch will be served, and throughout the day, a variety of refreshments will be available, including snacks, beer, wine, tea, and coffee.

Sage Doors recently announced the launch of Timbalook® Ohakune and Papamoa – a product featuring the multi-awardwinning Master Oak product from Unilin in Belgium.

Joining Sage Doors’ already established and well-loved Timbalook® range, Timbalook® Papamoa and Ohakune are an answer to what cabinetmakers and designers have been asking for –more colours in the Timbalook® range! When we first saw the Ohakune and Papamoa colours in Belgium before their official release, we immediately knew that we needed to add them to our range.

Timbalook ® Ohakune and Papamoa are a veneer alternative, featuring the look and feel of a natural timber veneer, but with a more durable surface and greater colour stability than that of a veneer.

Every cabinetmaker will have experienced the stress of replacing an oak veneer door. Trying to get the veneer colour to match can add a lot of stress to an install. Timbalook® gives you a natural veneer look, without the colour matching stress of natural veneer – replacements are quick, simple and easy.

The Timbalook® range is highly scratch resistant and durable, making it ideal for busy family homes & commercial spaces, where you need a beautiful timber look with extra durability. The product is made using the same technology as the Quick Step laminate flooring – a product that is known for its durability.

The Timbalook® product features an extra-large sheet size of 2800 x 2070mm to allow for large panels, wall panelling, and horizontal grain options. The range is also available with our Shapes, Handles & Angles, including Profile Handles, Angled Edges, thick panels & shaped parts. With curves so popular in design, an HPL laminate is also available to make manufacturing curves easier.

The Timbalook® range is available with a quick four-day lead time all year around and can also be supplied pre-drilled for added convenience. Our online ordering software enables you to import Cabinet Vision, Microvellum, and Mozaik files, to auto-populate your order with all the drilling and routing as per your design. Alternatively, drilling can also easily be added online using our adjustable templates. Many are choosing to order doors pre-drilled to save time during assembly.

The Timbalook® range is priced at an accessible price-point, typically lower than an acrylic product. With nine colours available, at a fraction of the cost, time and headache of a natural veneer, but with the same natural look and feel, the Timbalook® will help you finish your kitchens faster, with a lower cost & less stress.

Get in touch with Sage Doors for samples!

When a tornado tore through Albany on Auckland’s North Shore in 2011 it caused chaos for many, but it also helped launch a family business that’s still thriving today. For Mark and Sue Botha, that unexpected weather event triggered a surge in insurance-related remedial work through Reinst8 IT Ltd, the company they’d just launched from home. Within nine months, demand had outgrown the small set-up and they moved into a commercial space in Pakuranga, Auckland. “It really lit the fuse,” recalls Mark.

Mark brought a strong background in building and cabinetmaking to the table, while Sue played an equally vital role in managing the growing business behind the scenes. “We’re very hands-on,” says Sue. “We’ve built this from the ground up, and we’re always looking at how we can do things better.”

Today, Reinst8 IT is a family-run operation in every sense with son Matt now also fully involved in the day-to-day.

In 2015, the Botha family launched The Cabinet Guys — a division of Reinst8 IT that offered more than just repair work. “We found that some clients didn’t just want their kitchens put back to how they were,” says Mark. “They were ready for a full facelift.” This evolution marked the beginning of a broader service, one that stepped outside of insurance-based work and into high-quality residential and light commercial renovations.

“We’re basically project managers,” Mark explains. “We’ll restore everything from the foundations to the roof but cabinetry was always a sticking point.”

While coordinating trades like plumbers, electricians and builders was straightforward, getting cabinetry made on time proved far more difficult.

“Flooring and cabinetry were always the bottlenecks,” he says. “That’s when I realised if we wanted control and consistency, we needed our own cabinet shop.”

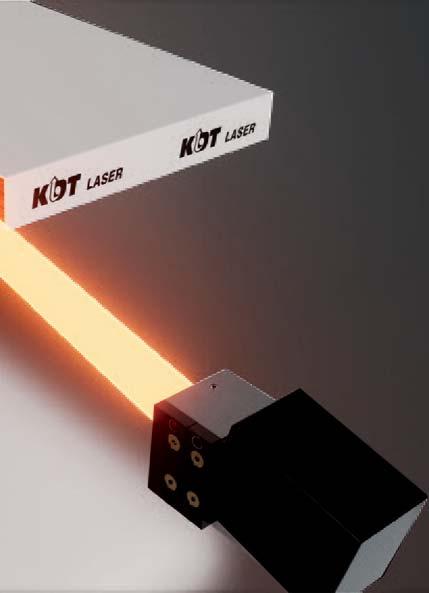

“Our new KDT laser edgebander has completely eliminated all of the manual blading and glue cleaning we had to do with the hot-melt machine,”

In 2015, Mark equipped his first cabinetmaking space with a Felder K500S panel saw and a P200 preglued edgebander, both supplied by Jacks. As the business grew, so did the demands on the workshop. Four years later, a Homag hot-melt edgebander was added. But Mark still wasn’t completely satisfied.

“I was always frustrated with the glue line. It’s the first thing you see and if we wanted to grow and win more clients, the quality had to be better.”

After attending JacksTech 2024 — initially with plans to look at nesting CNCs — Mark’s attention shifted. “We saw the finish coming off the KDT laser edgebander and thought, ‘What’s more important? Speed, or delivering a product that really stands out?’”

That decision led to their latest investment: a next-generation KDT laser-only edgebander, also from Jacks. With no glue pot at all, the KDT uses laser technology to create a seamless, invisible bond between tape and board — eliminating the glue line entirely. Servo-controlled trimming units

with auto setup mean program changes are fast, simple and accurate.

“Our new KDT laser edgebander has completely eliminated all of the manual blading and glue cleaning we had to do with the hot-melt machine,” says Mark. “We’ve kept that one for remedial jobs where we need to match existing cabinetry, but for new work the laser finish sets us apart. It’s a game changer.”

The move reflects the same mindset that’s driven the business since day one: anticipate problems, find better ways to solve them and always stay a step ahead. Whether it’s a tornado in Albany or the latest in edgebanding technology, the Bothas — Mark, Sue and Matt — continue to turn challenges into opportunities.

Waterborne low VOC coating system for cabinetry, joinery, shop fittings, kitchens and doors

The residential project showcased in this feature is found in South Queensland and was made and installed by award winning Clayfield Kitchen Designs based in Narangba, a suburb of Moreton Bay 30 odd kilometres north of Brisbane. Owned and run by Paul Carius, the company specialises in high end cabinetry made to exact customer, designer or architectural requirements.

The cabinetry created is found throughout the residence. “This was a substantial project where we had to produce cabinetry for the kitchen as well as lounge areas and bedrooms” Paul comments. “We cut, edge and make all our own cabinetry in our factory while we supply a range of feature doors and panels from our Black Mountain Doors company (see box) which in this case is made with American Oak veneer for the cabinetry doors.”

Paul also uses a range of two pack spray coated finishes as well as their ‘Hand Painted’ finished kitchens. “We use and recommend the Resene Aqual water based range of finishes because they offer low VOC, have virtually no odour, are very easy to use, have a quick and easy clean up process and produce a very high standard of finish that you need for substantial high quality jobs such as this one.”

For this particular job he used the Resene AquaLAQ™ Clear Sealer and the AquaLAQ™ Soft Touch Clear sealer. The finish and the use of American Oak veneer produced a stunning theme for the cabinetry throughout the residence. AquaLAQ™ is a single pack waterborne acrylic using the latest technology. It is fast drying and has been specifically formulated to minimise grain raising on MDF board.

Paul has some forty five years in the building industry and has made countless kitchens, bathrooms, elevators, food courts, night clubs, shopping mall kiosks, computer workstations and reception counters. Paul says “While we deal with large budget projects such as this one we also deal with jobs on lesser budgets (through their sister company Express Kitchens) as well. Our years of experience benefit both large and small projects accordingly.” Their cabinetry has been recognised with Awards including best Commercial Interiors in 2024, Best Kitchen at Building Design Queensland in 2022 and in 2012.

For further information contact Paul Carius at Clayfield Kitchen Designs Pty Ltd, Shed 8, 10 Cerium St, Narangba, Queensland, 4504, Australia, email paul@clayfieldkitchens.com. au or go to their website at www. clayfieldkitchens.com.au

Exciting range of veneers from Black Mountain Doors

Paul established Black Mountain Doors when he saw a gap in the market for hand crafted, made to measure doors. The company focuses on the natural beauty of various timbers through a range of exquisite veneers that include American Oak, Queensland Walnut, Wenge, Blackbutt, Tallowood and Spotted Gum to name few.

These doors are meticulously hand made to spec and finished with the best coatings available. Certainly a key benefit of dealing with Paul who has worked with both solid timber and veneers since the 1980s.

50+ Years of Edgeband Excellence

Since introducing the first thermoplastic edgeband in 1970, REHAU has led the global furniture industry with German-engineered quality and aesthetic excellence. Our RAUKANTEX® range, trusted by fabricators for over five decades, is renowned for surfaceto-edge perfection, processing ease, and innovative breakthroughs. In 2008, REHAU introduced a breakthrough — RAUKANTEX LaserEdge — redefining how seamless edgebanding should look and perform.

What is LaserEdge?

LaserEdge replaces traditional hotmelt glue with a co-extruded polymer functional layer, enabling a direct, adhesive-free bond between edgeband and board. This creates a permanent zero-joint, a flawless connection both visually and structurally.

Whether processed via laser, hot-air, NIR, or hydrogen technologies, RAUKANTEX LaserEdge delivers a superior finish, with no visible glue lines and zero compromise on quality.

No adhesive

No joints

No problem

In kitchens, bathrooms, and commercial interiors, RAUKANTEX LaserEdge helps fabricators meet the growing demand for clean lines, modern finishes, and long-term quality.

Engineered for the Trade

With over 17 years of experience in laser edgeband manufacturing, REHAU continues to support cabinet makers and interior designers with:

A wide in-stock program across styles and colors

Custom solutions for unique projects

Seamless integration with existing machinery

Designed for Perfection, Built to Last RAUKANTEX LaserEdge delivers end users:

Optical excellence: invisible joints and perfect color match

Functional durability: heat, moisture, and chemical resistance

Environmentally conscious: no adhesives, more healthy

As part of our 2025 roadshow, REHAU proudly launches the LaserEdge Certification Program, helping you take the craftsmanship to the next level.

How it works:

1. Submit 3 furniture samples

2. Undergo testing in finishing, joint quality, and peel-off strength

3. Earn certification if you meet the benchmark

Certified partners will receive:

1. Official listing on the REHAU website

2. Enhanced customer trust and visibility

3. Increased marketing exposure at REHAU channels

Want to be recognized as a leader in seamless design? Contact us now and start your journey towards excellence!

(https://www.rehau.com/nz-en/interiors/ certified-partners)

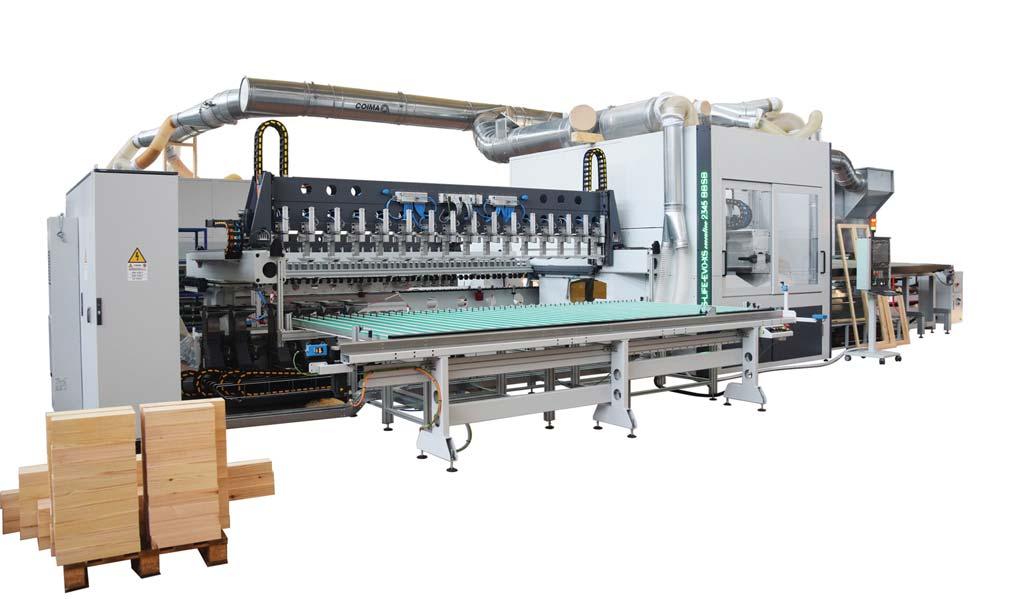

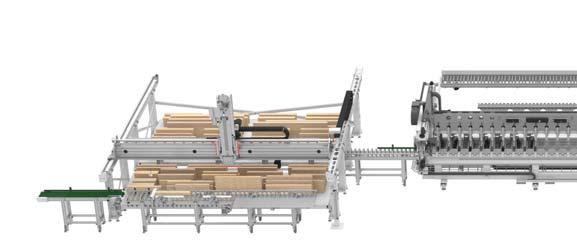

InAt Ligna 2025 the spotlight was on digitalization, automation, artificial intelligence, smart production and using wood and wood-based materials in a sustainable and climate friendly manner. We invited local woodworking machinery suppliers who represent some of the biggest brand names in the global industry for their input.

its 50th anniversary year, LIGNA 2025 once again proved to be the leading platform for the international woodworking community, featuring 1,433 exhibitors from 49 countries. From May 26 to 30, it brought together the global woodworking and wood processing industry in Hanover.

“LIGNA has impressively reaffirmed its unique position as the world’s leading trade fair for the industry. Around 78,000 visitors from 156 countries came to Hanover – that is a strong result,” said Dr. Jochen Köckler, CEO at Deutsche Messe AG. “Despite all the benefits of digitalization, nothing can replace the experience of seeing machines in live operation at a trade fair. The combination of innovation, technological progress, and passion is the best foundation for renewed investment.”

Whether in forestry, sawmilling, production, manufacturing, or craft industries, exhibitors presented solutions spanning the entire value chain, showing how current challenges can be addressed and

turned into opportunities. The spotlight was on digitalization, automation, artificial intelligence, smart production, sustainable and climate-friendly construction using wood and wood-based materials, and the responsible, future-oriented use of wood as a resource.

With its three focus topics –connectivity, sustainable production, and engineered wood – LIGNA addressed precisely the areas that not only concern the industry but also offer genuine hope for a world urgently seeking sustainable development. Exhibitors clearly embraced their responsibility, as

evidenced across all ten exhibition halls, two pavilions, and the outdoor area, covering a total of 114,078 square meters. A wide array of smart solutions – from reforestation to finished products – confirm the status of wood as a renewable raw material and the construction material of the moment.

900 Trade Fair Premieres