As interiors shift toward thoughtful, tactile design, hardware is stepping into the spotlight. Handles are no longer just functional; they’re an extension of your style.

From bold statements to subtle accents, each piece in our new range is designed to add character and elevate your space. Our new brochure showcases this striking collection—get ready to see (and feel) the difference.

Master Joiners 4

Nathan Moore speaks of the challenges currently facing the industry and the need to remain focused, professional and connected.

Laminex Update 12

Rachel Silcock reflects on the critical nature of people in the success of our industry and the need to ensure pathways for new talent to enter.

NKBA news 76

Rachael Kwok presents the NKBA predictions for 2026 along with comments from members on materials, colours, trends and costs.

Steering a Course 80

Ian Featherstone lists a number of common themes that have challenged over the past year and provides some suggestions that might help in 2026.

Safety Series 91

Laminex offer sage advice as we move into the holiday season and provides a health check list to encourage personal and employee safety.

News & Info 4 - 20

State of the Industry 82

NZJMF membership 84

Classifieds 92

Advertiser index 92

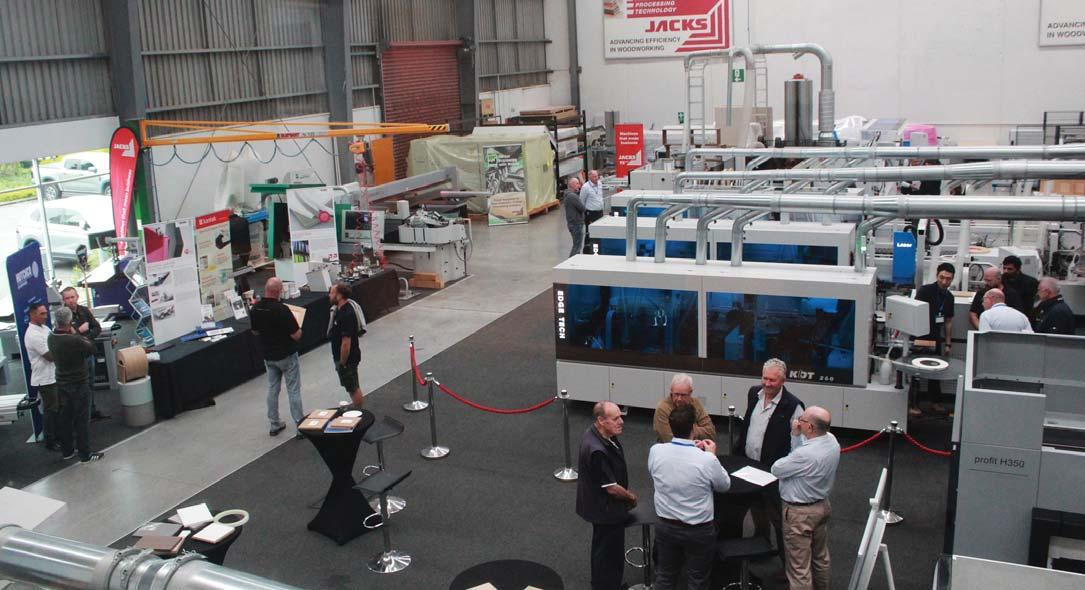

Auckland machinery suppliers Biesse, Farnese and Jacks all invited clients to showroom machinery displays on the same two days in midSeptember. We report on what all described as very successful events.

Regional awards, Category awards, Apprentice awards and the overall Supreme and Premier awards have been decided for another year. We have pics of all the winning entries and commentary on some.

Australian decorative surfaces supplier polytec have crossed the ditch promising local manufacturers more choice in decorative panels and benchtops. We look at the product and the people.

In a repeat of previous years we present our Christmas handles special, of the popular, the trending and the practical to assist in completing your cabinetry and furniture projects.

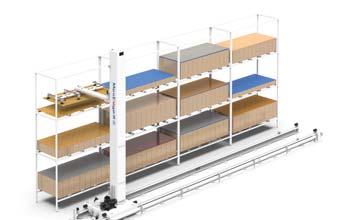

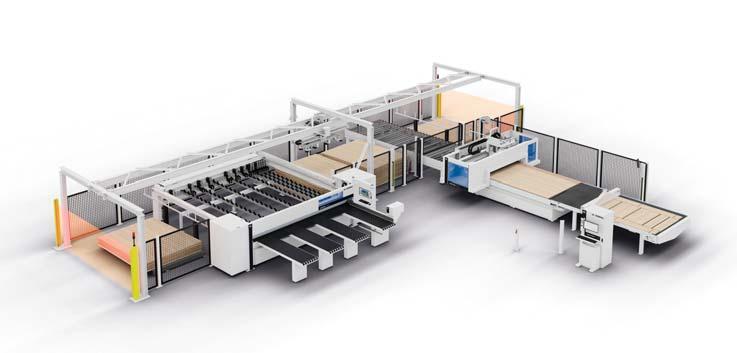

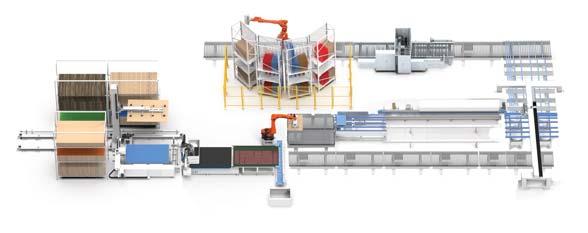

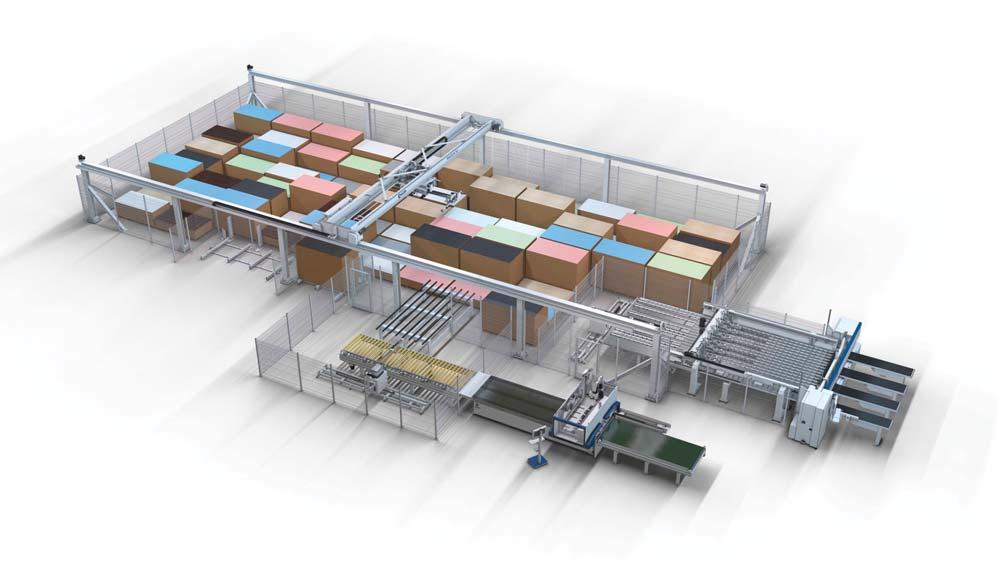

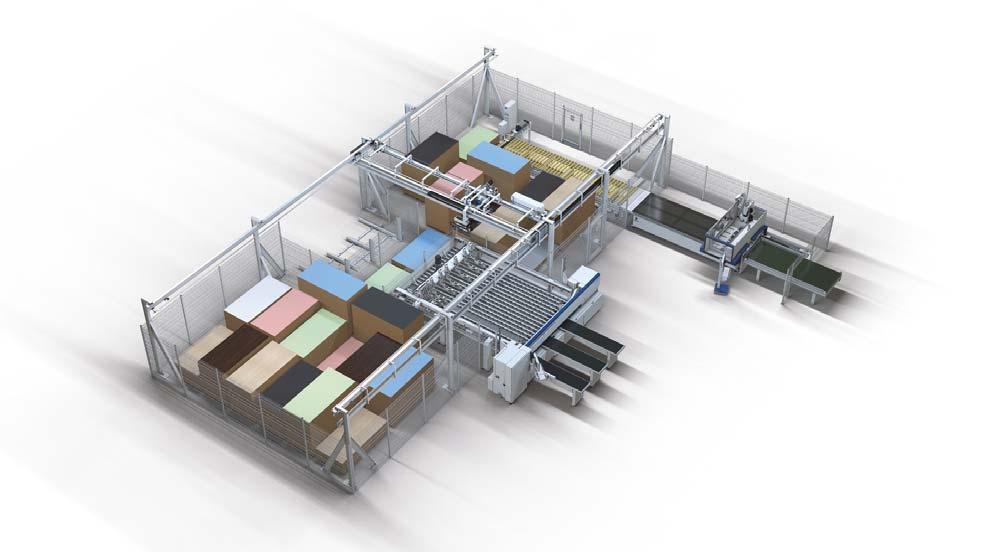

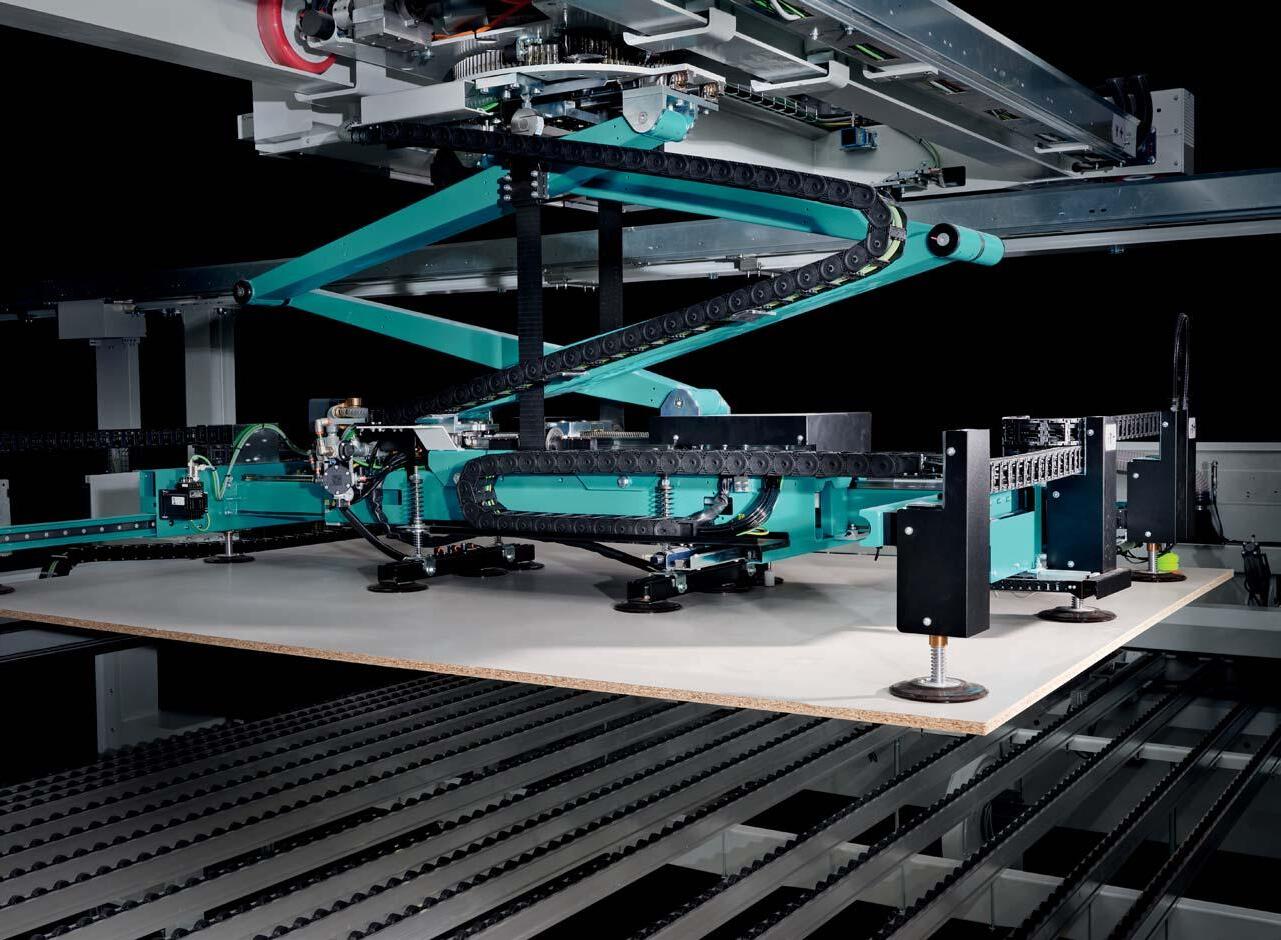

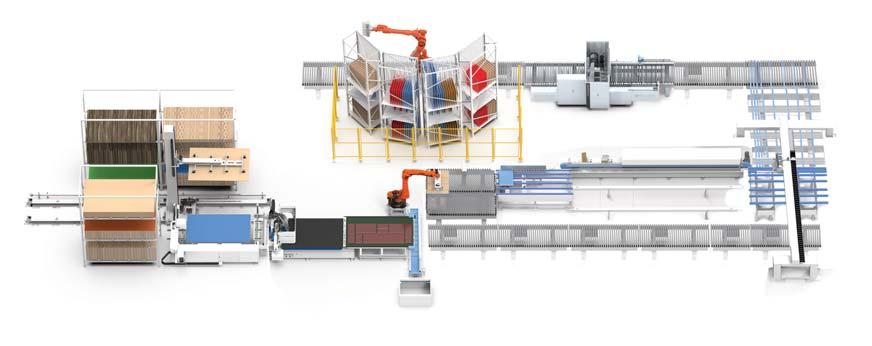

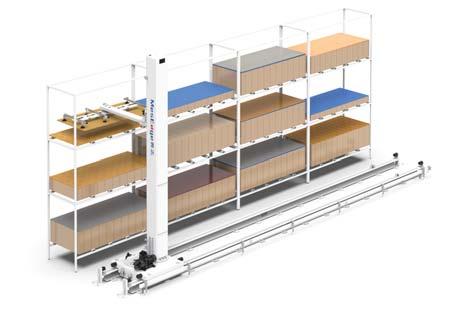

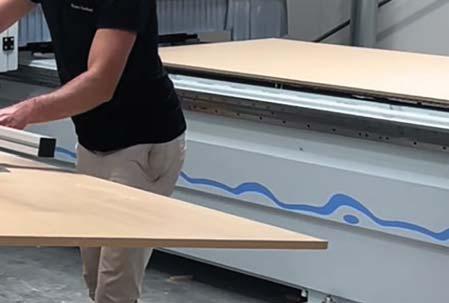

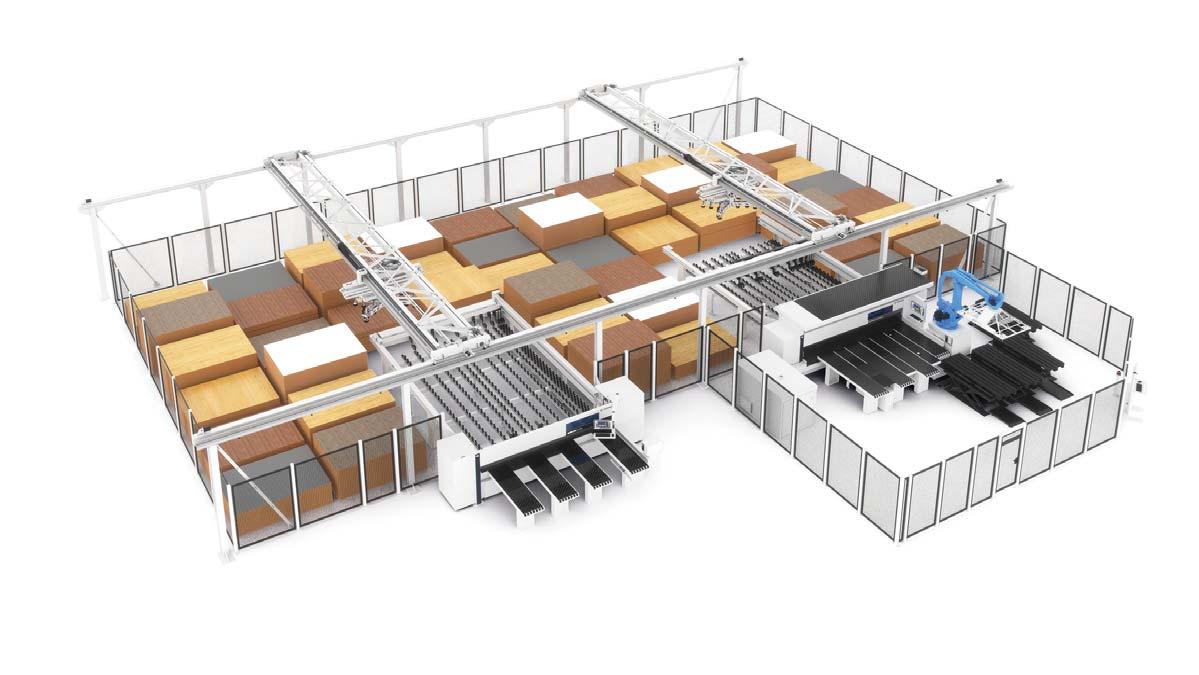

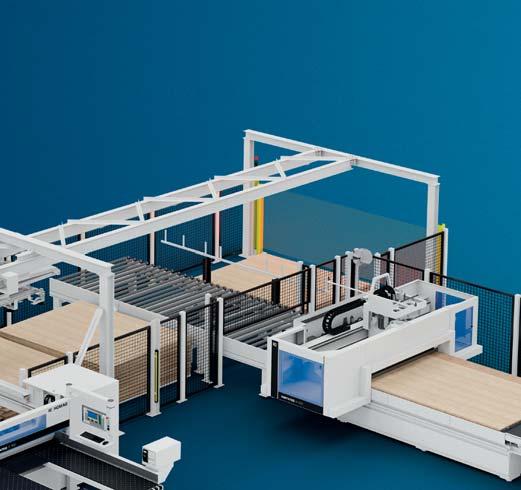

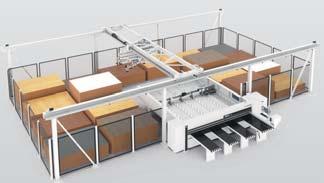

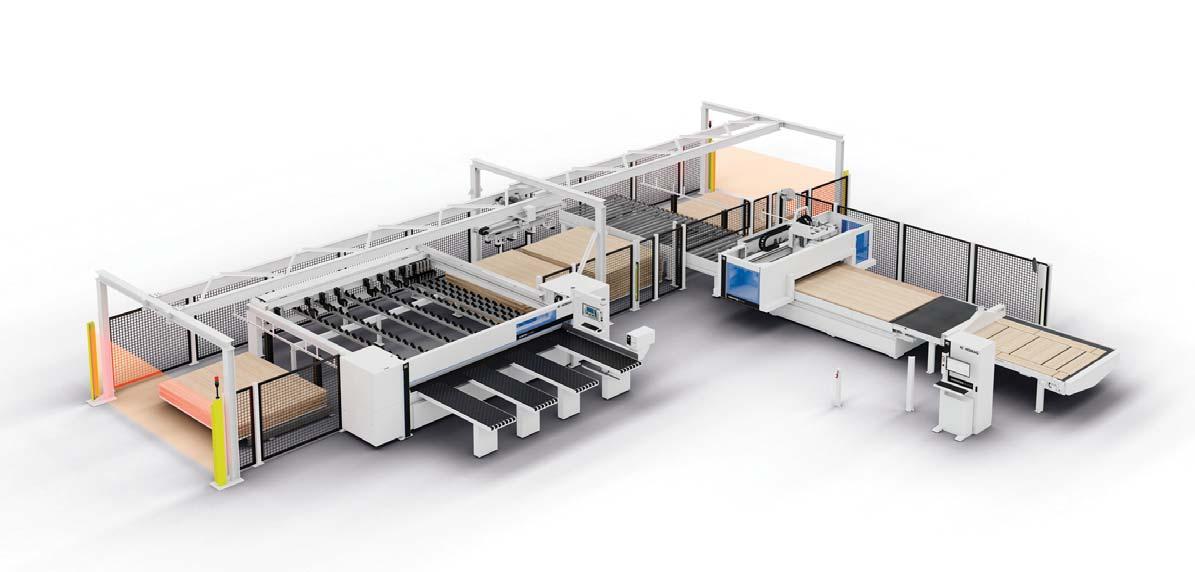

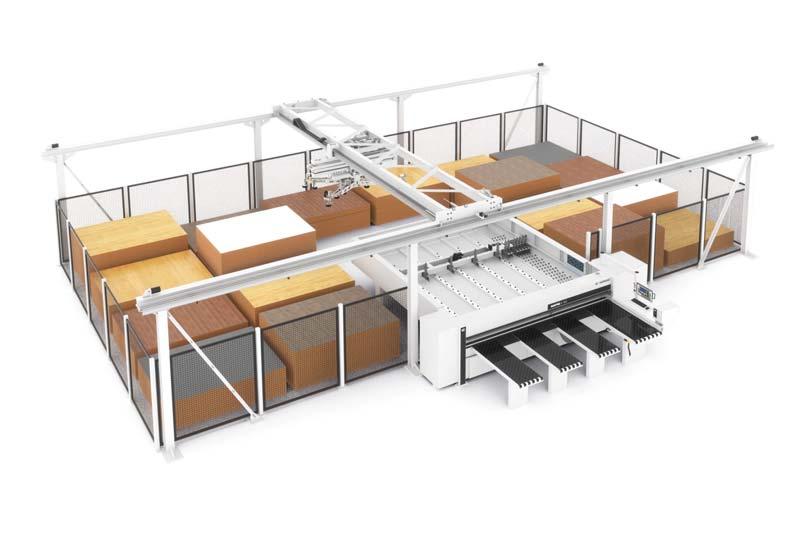

Bulky to store and heavy to handle, panel can be a logistical and physical choke point. From automated storage systems to jib cranes and vacuum lifters we look at options to handle panel efficiently and safely.

from the president 20.11.2025

As we approach the end of 2025, it’s a time for reflection, and for realism. The past six – twelve months have been some of the most challenging our industry has faced in recent memory.

Unfortunately, we’ve seen several joinery businesses forced to close their doors during this period, a sobering reminder of the pressures many are under. These closures underscore the need for resilience, collaboration, and a renewed focus on quality as we navigate what lies ahead.

Across the country, the picture is mixed. The North Island continues to feel the brunt of the slowdown, with workloads and confidence at concerning levels. In contrast, the South Island shows some signs of optimism, though no region is immune to the challenges. The next six months will be tough for most, with the Christmas shutdown looming and tax obligations early in the new year adding further strain to already tight margins.

One of the most pressing issues we face is the growing presence of below par imported and non compliant products in the market. These substandard materials compromise the integrity of our work and erode trust in the industry. Coupled with workmanship concerns that have surfaced in some areas, these factors threaten the reputation we’ve worked so hard to build. Cutting corners might seem tempting in difficult times, but it’s never the answer. Our commitment to excellence is what sets us apart, and it’s what will carry us through.

As Master Joiners, we must continue to advocate for compliance and quality standards. This means educating clients about the value

of professional joinery, challenging poor practices, and supporting each other to uphold the standards that define our craft. We also need to keep professionalism front and centre, because when times are tough, reputation matters more than ever.

Despite the headwinds, there are reasons to remain positive. The South Island’s resilience is encouraging, and across the country, there is a strong sense of community among joiners. Now more than ever, connection matters. Whether through regional meetings, peer support, or simply picking up the phone, let’s keep the lines of communication open. When we share ideas and resources, we strengthen not just individual businesses, but the industry as a whole.

Looking ahead to 2026, recovery will take time, but opportunities will come. By focusing on quality, compliance, and professionalism, we can position ourselves strongly for the upturn.

I encourage every member to stay engaged, reach out, share your challenges, and lean on the network we’ve built together. This is what Master Joiners is all about: unity, shared purpose, and collective progress.

All the best for the run into Xmas, we will see you on the other side.

Nathan Moore National President, Master Joiners

Another summer, another Christmas on it’s way. It has been an interesting winter especially with the three, two day open houses held by Biesse, Farnese and Jacks in Auckland in mid October. Signs of green shoot? Maybe. Certainly there was genuine interest at all three events. People were looking carefully and no doubt comparing. It will be interesting to see what both the suppliers and potential customers do over the next six months or so.

For the Master Joiners the big event was of course the Annual Conference and the announcement of the Master Joiners Award winners for 2025. The Rotorua Events centre was a good choice of venue for the event. What caught my eye were two other venues used : the Scion centre for the Gathering and Te Puia, an iconic cultural venue for the Awards evening on the Saturday night. Impressive sites, both of them. Hats off to Allison Delaney and her team at Master Joiners.

Congrats to all the winners and in particular, the big winners Wackrows Joinery for the Supreme Award and Carlielle Kitchens for the Premier Award. We cover the Supreme Award in this issue (and all the other winners) and then the Premier Award in detail in our March 2026 issue. As always a great thank you to all the sponsors without which this doesn’t happen Hey I’ve got to say a big shout out for all the Apprentice Award winners. This industry goes nowhere without them. That is why the magazine has supported the Apprentice Awards every year for thirty years on the trot now.

The feature on handling and storing panel is important. It’s a subject which sits in the background but is really important for the smooth running of the industries we follow especially the cabinetmaking sector. Makes for interesting reading to see what is available out there. It comes at a time when a new supplier comes to market in polytec. This is in my view an exciting development for the New Zealand marketplace. Competition makes for more choice. We round off with what has become our annual pictorial nod to the handles market, an important aspect of the kitchen and furniture making process.

The Conference and Awards were once again a real success. This comes from both the involvement of sponsors and all the Master Joiner members who entered the various Awards. A big thank you to all of you. The combination is what makes it work. Finally, Michael and I would like to wish everyone a Merry Xmas and a Happy New Year and look forward to doing all again next year!

Bob Nordgren

Official Publication of the New Zealand Joinery Manufacturers Federation magazine

Publisher Bob Nordgren bob@joiners.net.nz The magazine for the joinery, cabinetmaking & kitchen manufacturing industries

Editor Michael Goddard michael@joiners.net.nz

M42 Aldersgate Rd, Box 27-513, Mt. Roskill, Auckland, 1440. Ph: +64-9-624 4680

Subscriptions & Mailings bob@joiners.net.nz

JOINERS Magazine Online www.joiners.co.nz

ISSN 1173-6836

JOINERS Magazine is the official publication of the New Zealand Joinery Manufacturers Federation. It is distributed to members of the joinery, cabinetmaking and kitchen manufacturing industries and is published quarterly in March, June, September and December. Advertising statements or editorial opinion are not necessarily those of the publisher, its staff, the New Zealand Joinery Manufacturers Federation Inc., or their executives, unless expressly stated. All articles printed in JOINERS Magazine are subject to copyright and cannot be reproduced without the express consent of the Publisher or the authors therein. Advertisements and articles are accepted without liability as to the accuracy or otherwise of the factual matters represented.

From furniture to homes: The future is built with wood.

Together, HOMAG, WEINMANN, SYSTEM TM and KALLESOE provide comprehensive production solutions for manufacturers of optimized timber, engineered wood, timber construction, interior fittings, furniture and more. With over 500 years of combined experience in machinery engineering, automation systems, and software technology, our focus is on building strong partnerships that enhance your productivity, precision, and profitability. This is how we are building living spaces. Together, with you.

With New Zealand’s construction and interiors sectors entering a recovery phase in 2026, Hettich is ready to support the industry with expanded product solutions, reliable supply, and deep market insight.

Managing Director Rob Deed notes that while a return to positive growth in the construction sector appears increasingly likely in 2026, the reverberations of 2025’s contraction on the industryparticularly in downstream trades like interiors - require suppliers to strike a careful balance. “Consistency, responsiveness, and long-term thinking will be key to supporting our customers through this transitional period,” he says.

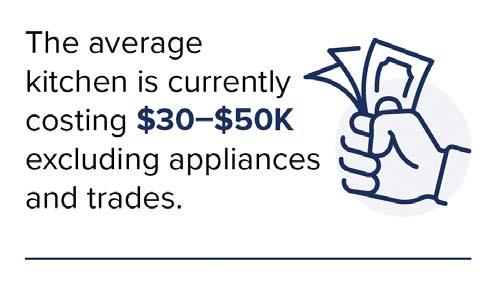

After a challenging 2025, the New Zealand construction industry is forecast to grow at an average annual rate of 4% from 2026 to 2029, driven by major infrastructure investments and a recovering residential market. Residential building activity is expected to rise 7.9%, while nonresidential construction will grow by 6.0%, supported by government investment in transport, health, and education.

Government infrastructure investment - addressing a $210 billion deficit - is expected to drive

sustained construction activity, while easing inflation, improving consumer confidence, and a projected GDP growth of 1.5% in 2026 signal a broader economic recovery. Meanwhile, ANZ is forecasting a 5% rise in house prices and QV data showing early signs of stabilisation, indicating the housing market is expected to rebound in 2026.

The interiors market is also set for expansion, with the New Zealand interior design sector projected to grow at a compound annual growth rate of 5% through 2030. Renovation and remodeling are leading the charge, as homeowners and developers seek smarter, more sustainable, and more personalised spaces.

What to look for in a supplier partner in 2026

As the market becomes more competitive and customer expectations rise, choosing the right supplier is critical. Trade professionals should seek partners who offer:

● Reliability: Consistent product quality, dependable delivery, and responsive support.

● Innovation: A forwardthinking approach to design, sustainability, and smart functionality.

● Collaboration: Training, comarketing, and technical support that empower your business.

● Global Expertise, Local Insight: The ability to translate international trends into locally relevant solutions.

What to expect from Hettich in the next 12 months

● Digital Enablement: Enhancing our online tools, configurators, and technical resources to streamline specification and installation.

● Product Innovation: Launching new products that reflect global design trends for premium interior projects - think new generations of integrated lighting for drawers, spinlines, and hinges.

● Steady and Competitive Pricing and Partnership: In 2026, Hettich remains committed to delivering the consistency our customers value. Expect transparent communication on where growth opportunities exist and proactive collaboration to help you capture that growth.

● A New Brand for Smart Value Builds: With the first product releases from recently acquired FGV, Hettich is set to make this brand more accessible for New Zealand customers.

For Sales enquiries

Our friendly customers service team 0800 438 842 | sales-nz@hettich. com Or reach out to your Territory Manager for more information Visit www.designwithhettich.co.nz

&

1. National Construction Pipeline Report 2024 Forecasts a return to growth in New Zealand’s construction sector from 2026, with total activity projected to rise to $63.7 billion by 2029.

2. NZIER Consensus Forecasts – September 2025 Predicts GDP growth of 1.5% in 2026 and a recovery in household spending, supporting demand in residential and interiors markets.

3. Building Industry Update Q4 2025 Indicates cautious optimism for 2026, with commercial and infrastructure builds gaining traction and material costs easing.

4. Cotality Home Value Index – September 2025 Shows early signs of recovery in the property market, with increased sales and listings, and expectations for growth into 2026.

5. ANZ Property Focus –October 2025 Forecasts 5% house price growth in 2026, driven by easing interest rates and a cyclical economic recovery.

6. QV House Price Index – September 2025 Provides regional insights into property value trends, showing stabilisation and modest growth in key areas.

7. New Zealand Interior Design Market Size & Outlook - 2024/2025 Projects growth trends in New Zealand’s Interior Design Market using 2024 as the base data year.

8. EBOSS Pulse Report – October 2025 Highlights signs of stabilisation in the construction sector, with building consents steady and infrastructure projects gaining momentum.

9. Oxford EconomicsOctober 2025 New Zealand Construction Outlook, Q3 2025: Construction dips in 2025 before rebounding strongly in 2026.

AvanTech YOU Illumination

The smallest pieces of hardware can deliver the biggest moments of delight. The 2026 generation of AvanTech YOU Illumination can now be paired with wooden drawers.

Premium hardware for exceptional cabinetry. www.designwithhettich.co.nz

Auckland woodworking machinery supplier Machines R Us are pleased to introduce the Woodfast range of woodworking machinery to the New Zealand market. Designed to meet the needs of woodworking professional the range is robust, reliable and packed with features while remaining at very competitive prices.

The Woodfast range whose origins date back to 1941 in South Australia includes a wide array of saws, thicknessers, planers, sanders and lathes which have consistently met and set the standard in the global woodworking industry.

The machinery is currently manufactured in China and is the only Chinese imported woodworking machinery range which arrives onshore with full CE Certificate ratings valid across Europe and in Australia and New Zealand. This means all safety criteria such as wiring systems and health and safety considerations are compliant with New Zealand regulations which is rather unique in the New Zealand market with product from China.

Machines R Us Managing Director John Fleet says the Woodfast range enables them to offer quality machinery to all price points across the woodworking sector.

“We are delighted to bring this range of time proven machinery to New Zealand, its quality of build and performance along with competitive pricing fits well with the other premium brands we are agents for in New Zealand and enables us to offer our clients real value taking into account their budget and manufacturing requirements.”

The range has created a lot of interest locally with Machines R Us reporting strong interest from local woodworkers and kitchen manufacturers.

For more info phone 09 820 9486, go to www.machinesrus.co.nz, or visit Machines R Us in their new showroom at 13 Patiki Rd in Avondale, Auckland

1941 - Woodfast Machinery began on June 11, 1941, when two young toolmakers John Hagan and Bonar Powell established a small tool manufacturing company in Woodville. South Australia under the name 'P&H Tools SA’.

1944 - The first woodworking machine a small belt and disc sander, was manufactured in 1944 and marketed under the trade name Woodfast. This was followed by a 100mm (4") buzzer (Jointer) and later by a very successful 14" cast iron frame Bandsaw.

1946 - In 1946, a 6" Jointer was added to the range and it was decided to discontinue the manufacture of engineer's hand tools and to concentrate on woodworking machinery. Also in 1946, John Hagan became the sole proprietor of the company which is still owned by his family.

1950 - It was not until 1950, however, that the name of the company was changed to Woodfast Machinery Co. a reflection of the progress that had been made in serving the great demand for woodworking machinery after World War II. October, 1950, bought the Port Road property.

1963 - In 1963, extensions gave the factory a total area of 270,000 square feet and by June, 1965, the number of employees had grown to 61. By then, the firm was producing 21 different machines. These not only enjoyed good sales throughout Australia but, in addition, 12% of the total production was being exported.

1980 - By 1980, the factory floor space had grown to 360,000 square feet and plans were being made to design and erect a new showrooms and administration complex on the Port Rd. frontage which was completed by 1984.

1984 - In 1984, Mr. Hagan retired from the role of Managing Director having led the development of the company for more than 40 years. He was replaced by Mr Bronte Edwards.

2004 - In 2004 Woodfast Machinery Co. was sold to QCR China manufacturing company the following in total: The design and manufacturing rights for two woodturning lathes, Models C-1000 and M910. Also the singular word only Woodfast in horizontal font.

2014 - Woodfast was registered as a trademark by Qingdao Jinling Electric Company (QCR) of Qingdao China.

2018 - Tony Mirabile, CEO and founding director of Beyond Tools (established in 1986, formerly known as For Wood Tools and Machinery Sales) and of wholesale company Jaccra Industries, becomes the CEO of Woodfast Australia Pty Ltd. In this role, he is responsible for distributing Woodfast products throughout Australia and the Asia-Pacific region.

2022 - QCR (China) partnered with Jaccra Industries (Australia) to further develop and enhance the Woodfast product line. Jaccra Industries now manages the distribution of Woodfast products in Australia. Asia Pacific and expanding into the European market and globally - expanding market reach and integrating advanced technologies.

2025 - Woodfast remains a leading name in woodworking machinery, known for its commitment to quality and customer satisfaction, backed by the support and resources of Jaccra Industries.

We design and manufacture dust extraction systems right here in

Dust Collectors

Extraction Fans

Modular Ducting Systems

Flexible Duct

Rotary Valves

Down-draught Sanding Tables

Extraction Arms

Spray Booth & Drying Rooms

Shredders & Briquette Machines

Blum is kicking off summer with a bit of fun — we’re giving away 100 frisbees to the industry! Be one of the first 100 to scan the QR code and fill in your company delivery details, and a frisbee will be on its way to you. No strings attached — we won’t save or use your details for anything other than getting your frisbee to your door.

www.blum.com

A recent sale by NZ SCM agent Machines R Us of a Nova SI 400 3200mm sliding table saw to the new IKEA store in Auckland was one of their easier ones. “IKEA have a global policy of buying SCM,” says Machine R Us director John Fleet. “So when they needed a sliding saw for their Auckland store they came to see us. With 500 odd stores across more than 60 countries the policy is a testament to the reliability of the SCM brand and the regard it is held in globally.”

Auckland IKEA shop carpenter Tui Niwa who is a joiner by trade says he can see why IKEA choose SCM. He uses the saw for a wide variety of tasks involved in the ongoing fit out and renewal of displays within the store and likes its simplicity of setup, ease of use and exceptional accuracy.

SLaminex New Zealand™

ince my last column, I was lucky to have attended my second Master Joiners Conference in Rotorua. Often, we get caught in the day-to-day, so it was important to carve out the time to connect and celebrate with customers, including having some robust conversations on the future of the industry and the influences – one of which is people.

People are a critical component to business success and many customers I spoke to had spoken to the pipeline of talent into the industry, or lack thereof, and the significant impact when the highly experienced leaves their business. This poses the question, as a supply partner, what does our role look like in supporting talent and the industry?

We’re proud to have gone live in November with He Rito, a twoweek work experience pilot programme at our Auckland DC. ‘He Rito’ means heart of the flax and the intent is to provide a future for Maori and Pacific students. The pilot included talking to students at Mt Roskill High School about the opportunities, led by our Auckland DC Manager, Sue Evans, and Inwards Goods Supervisor, Vaughan Pauli; who also interviewed the top candidates. We selected three students to attend the two-week programme at our DC (working half days) to understand what goes on in a warehouse and what opportunities could exist after they finish school. We are hoping this pilot to be a success so it can become permanent, as we need more visibility of the opportunities and possibilities amongst the upcoming generation in an industry that helps build NZ.

Last month we celebrated an incredible milestone, 40 years of service from one of our most respected and long standing team members at Laminex Particle Board Plant Taupō, Roy Goddard. He has held many roles from Foreman to Training Manager, but currently leads the production line, what he loves most for more than 20+ years. We’re fortunate to have many people like Roy who are passionate about what they do and lead our business. We’re thankful for Roy’s leadership and contribution to Laminex

I’d like to highlight Michelle Moffitt, our National Sales Manager. From day one, Michelle has immersed herself in the industry, building strong customer connections through meetings, attending the Master Joiners Conference, and engaging at other key events Her customer-first approach has already made a real impact, with more fresh ideas to come in 2026.

As the festive season approaches, our team will be taking a welldeserved break over the holidays. You can find our operating hours at laminex.co.nz/holiday-hours.

This year has brought its challenges and opportunities, often challenging our mindset. From me personally and on behalf of our entire team, thank you for your continued support. I wish you and your family a safe and revitalising break over Christmas and the New Year, with a positive 2026.

Rachel Silcock General Manager Laminex

New Zealand

I am thrilled to join the team at Laminex NZ and build on the great work and momentum for 2025 and beyond. Having worked across several industries both here in NZ and abroad, across different roles spanning sales and marketing, I am excited to bring the skills gathered and inject some fresh ideas and energy into our business.

What are some of your goals for the next 12 months in the role?

Customer centricity is a key driver for our success, so it’s important we maintain open dialogue and gather customer feedback on how we can continually improve to support them. As a team we are committed to working in partnership with our customers to deliver our

Biesse, a global leader in manufacturing integrated lines and machines for processing wood, glass, stone, metal and advanced materials, is proud to announce the appointment of Peter Worrell as Customer Care Director for Australia and New Zealand.

Peter joins Biesse with more than two decades of experience across operations, engineering and customer service. Beginning his career as an aerospace engineer, he has a strong history of leading technical teams, implementing maintenance strategies and driving customer initiatives.

In his new role, Peter will focus on strengthening Biesse’s customer care operations, developing the company’s preventative maintenance programs, enhancing service and parts delivery efficiency, and ensuring that every Biesse customer receives premium support for the life of their machine ownership.

Michael Bullock, Biesse Australia and New Zealand CEO says “Customer Care is at the heart of Biesse’s commitment to its customers. Peter’s experience and leadership will play an important part in elevating our service experience and delivering even greater value to our customers.”

core products and make it easy to do business with us. A key objective for myself and the team over the next 12 months will be ensuring we are supporting our customers whilst delivering operational excellence.

I am enjoying meeting many of our customers and look forward to meeting more over the next few months. We appreciate that service will set us apart and we are grateful for our valued customers choosing our quality products. I look forward to updating the industry on what we are up to at Laminex as we innovate and evolve.

Commenting on his appointment, Peter said: “Biesse is a globally respected brand known for its quality, innovation and customer experience. I’m excited to join a team that shares my passion for excellence and customer satisfaction, and I look forward to building on Biesse’s current service foundation.”

Peter’s appointment reinforces Biesse’s strategic commitment to delivering premium support and partnerships with Biesse customers and across its multi-material industries.

Biesse.com

Farnese NZ Ltd’s recent two-day open house event, held at their Auckland showroom in Ellerslie, was hailed as a resounding success by General Manager Rob Hutchings. The event showcased a variety of machinery from Farnese’s renowned range, including several of their top-performing models as well as Edge Banders from their Fravol range.

“The goal of this event was to provide our customers with the opportunity to get handson experience with the machinery we offer,” Rob explains. “It was clear from the turnout that many attendees were serious about making purchases, which made for some very productive conversations.”

The feedback from visitors was overwhelmingly positive, with several new sales resulting from the event. Rob shared that Farnese NZ is keen to continue expanding this open house concept in the future, possibly collaborating with other machinery suppliers to create an even bigger event for the joinery sector.

Farnese NZ, which was formerly known as Proform CNC Ltd, has made significant strides in growing its presence in the local market. In addition to their comprehensive range of woodworking machinery, the company has also seen strong demand for their accessories catering to the stone cutting industry. “We’ve made great inroads into the stone cutting market here in New Zealand, and this side of our business is really taking off,” says Rob.

The event was also supported by other industry partners, including Robertson & Sinclair Ltd and software specialists Joinery IT, adding further value for attendees. Attendees were treated to great weather and good food, making the event not only informative but enjoyable as well.

With more developments and exciting initiatives on the horizon for Farnese NZ we will be eagerly awaiting what their next event will bring.

The modern, compact design of the Italian FRAVOL M200-23 EDGEBANDER saves space without compromising on performance or edge quality. A mix of solutions, applications and

A classic among machines for processing wood and wood products.F.I.MA.L. circular saws are the perfect woodworking solution for people who must perform frequent cuts with different angles. g es in just 3 metres.

The Winner series from Masterwood has been designed to meet the needs of most companies, offering the best technical solutions on the market. Winner machiningcentres offer flexibility of usage, reliability and high productivity.

Founded in 1963 in Tuscany (Italy), designs and manufactures woodworking machines created to respond to the needs of artisans and small-scale kitchen and furniture manufacturers.

Biesse organised tours to Next Level Joinery, DBJ Furniture, Kitchen Mania and Linea Stone to demonstrate cutting edge Biesse technology processing different materials in a variety of manufacturing operations.

An open house in mid-October for machinery supplier Biesse at their showroom in the Auckland suburb of Wiri reflected the company’s recent branding reset with its emphasis on the latest technologies for processing across a number of materials including wood, glass, stone, plastic and composites.

A steady flow over the two days saw clients and potential clients from around the country view working demonstrations of a range of Biesse machines cutting multiple materials on-site and being given the option to visit four prominent companies around Auckland. Next Level Joinery, DBJ Furniture, Kitchen Mania and Linea Stone were each selected to display cutting edge Biesse technology processing different materials in a variety of manufacturing operations.*

Sales Director for Biesse Australia & New Zealand, Lee Barlow said the branding reset reflected the multi material nature of the company and they wanted to ensure the branding made that clear. “Wood is still our core but glass, stone, composites and metal have become very important. We found that both locally and internationally we had many customers using multi-materials across their projects and having a strong presence in all materials enables us to provide for their machinery requirements across their production activity.”

Recent acquisitions by Biesse have strengthened this presence.

“With our Intermac range we have long been known for our ability to cut and process stone and glass,” says Lee,” but the purchase of Italian companies GMM and Bavelloni over the last few years have significantly added to our glass and stone portfolio, with GMM being the world leader in Bridge Saws for cutting stone and Bavelloni being renowned experts in glass cutting and processing. Both companies meshed well with our own range filling any gaps in our portfolio and providing a complete service to our clients.”

Service has also been an important part of the reset. “Biesse has always been very conscious of the importance of after sales service,” says newly appointed Customer Care Director Peter Worrell. “But we are looking to be even more active and efficient in this area ensuring our staff have the right skills through training, upskilling and improved product knowledge. We will also be talking to our clients on the value of preventative maintenance, helping them to pro actively anticipate the timing of such things as seal and bearing replacements for instance, which effectively reduces and takes control of machinery downtime.”

Visitors also had the opportunity to talk with trade partners across the associated sectors of panel product, software, tooling and dust extraction, and of course once again to experience Biesse’s renowned Italian hospitality with a lunch menu of woodfired pizza, pasta and seafood dishes.

The two day function was rounded off on the Thursday night with a function at Blum’s showroom on Rosedale Rd, a wind down for both hosts and clients over a drink and light refreshments.

This year’s Biesse Material Days, held in partnership with Blum, once again highlighted the value of collaboration within the joinery and cabinetry sector. The event successfully fostered meaningful conversations, knowledge sharing, and industry engagement. Some guests also attended Blum’s after-event, reinforcing the strong interest in continued partnership across the sector.

As with last year, Blum and Biesse worked closely to deliver a hands-on, practical experience focused on innovation and workflow efficiency. The event also welcomed participation from key software partners, including Cabinet Vision and Microvellum, offering visitors a well-rounded view of integrated manufacturing solutions.

Blum’s after-event offered guests an informal, engaging setting to connect. The overall atmosphere was positive, and the newly renovated showroom proved an ideal environment for open discussion, networking, and product exploration. Blum showcased the latest unreleased REVEGO version 3, now on display in Blum's refreshed space, drawing significant interest and positive feedback from attendees. The new Concelo entro pullout waste bin system also featured, offering a functional and refined option for modern kitchen layouts. REVEGO, in particular, proved to be a standout—its seamless pocket system capability resonating strongly with designers and manufacturers looking to maximise spatial flexibility.

The space performed well in action and generated several promising new leads—an encouraging sign as the market looks ahead to 2026.

Continuing a tradition that reflects the industry’s commitment to community, funds raised from guided event tours were donated to the Child Cancer Foundation. Both Blum and Biesse matched the donation total, further amplifying the contribution.

Overall, the event reaffirmed the value of collaboration and shared industry momentum. As manufacturers continue to navigate changing market demands, partnerships like that between Blum and Biesse play a key role in connecting solutions, suppliers, and ideas that help move the industry forward.

If you’ve got a collaborative event idea, touch base with our team at info.nz@blum.com or reach out to your Blum Representative.

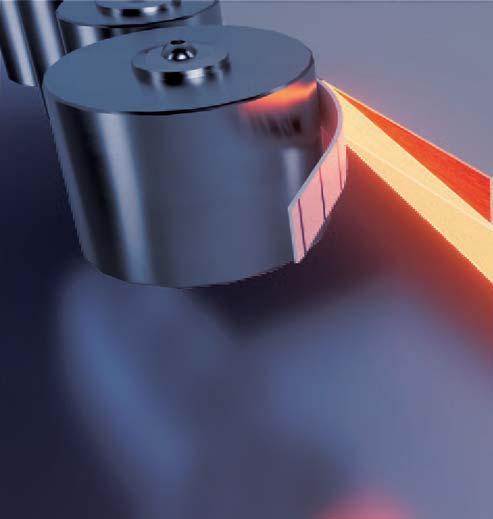

The Jacks 2025 Expo was all about showcasing the latest innovations in edgebanding — from cutting-edge machinery to advanced materials and services.

One of the standout highlights was KDT laser technology. With zero glue-line now an industry standard, true laser processing remains the ultimate solution for laser tape. Visitors were impressed by its ease of operation, superior bond strength, low energy consumption and instant readiness. Jacks offer three KDT laser edgebanders, giving customers flexibility to match their production needs.

Another crowd favourite was the KDT KE-395J 45° edgebander. With handleless pull drawers trending, this machine drew significant attention. It dramatically reduces what is typically a time-consuming process, delivering a consistent, high-quality finish that manual methods simply can’t achieve.

Materials

On the materials front, Rehau’s Pigmento range stole the spotlight. This innovative laser tape virtually eliminates the framing effect caused by edge trimming, creating a seamless one-piece look. Pigmento’s coloured flecks run through the tape thickness, so trimming reveals matching tonesfurther disguising the join between face and edge.

Industry service leaders Hutchco and Kantek were on hand to discuss new developments. Of particular interest was their laser melt coating service, which removes the need for a glue pot in edgebanders. If a tape in their range isn’t available in laser format, they can apply a lasercompatible polymer coating, colour-matched to the tape,

achieving a near-zero joint finish. This service even makes veneer tape laser-compatible, a gamechanger for many joiners.

Customer Engagement

Jacks Sales Manager, Dylan Staples, summed up the event:

“We were thrilled with the turnout, with customers flying in from all over the country. The feedback was extremely positive. Our goal wasn’t just to showcase the latest edgebanders, but to present the complete edgebanding process — machines, materials, operator training, service and maintenance. Customers want to see the whole cake, not just a slice.

We’re pleased not only with the response to this strategy but also with the confidence many showed in investing in KDT edgebanders, especially KDT laser models. It’s a great blueprint for future shows.”

• Application friendly

• Solvent based timber stain

• For interior use

• Designed tp prevent pooling or blotching

• Can be used with multiple clear coats

• Available in a wide range of the latest fashionable colours

Designed as a high quality furniture stain for kitchens, shop fittings, cabinets, desks, panelling, partitions and most interior wood.

Whangarei Paint Centre Whangarei (09) 430 2414

Wairau Paint Centre

Auckland (09) 443 3430

PPG Industries NZ Ltd

Auckland (09) 573 1620

Grayson Auto Colour Centre

Auckland (09) 278 0685

Autolink Distributors Ltd

Hamilton (07) 846 1443

Linkup Paints (BOP) Ltd

Tauranga (07) 571 8921

Complete Paints Ltd Napier (06) 843 1122

Total Paint Supplies Ltd

New Plymouth (06) 769 9415

Total Body Shop Ltd

Wellington (04) 586 6681

Paintco

Nelson (03) 546 6660

PPG Industries NZ Ltd

Christchurch (03) 384 0255

Rainbow Paints Ltd

Dunedin (03) 474 0659

Southern Paints

Invercargill (03) 218 4664

Otago Southland Master Joiners

Otago-Southland Branch welcome Ryan as a Master Joiner Intern. At the start of Term 1, Otago – Southland Branch connected with Cromwell College to explore an opportunity for a promising Year 11 student who had shown real enthusiasm for the joinery industry. A few months later, Kate RuleMunro reconnected with the school and provided a flier for their newsletter, careers page, and daily notices. The school then carefully selected the student it felt most deserving of the award.

We wanted the recognition to be meaningful, so we arranged for a ‘keep’ trophy and a Makita drill kit valued at around $600— “something practical and lasting” Kate shares. Both were delivered ahead of the school’s awards evening, where they were presented to Ryan during the scholarship section. Ryan was delighted, and we’re excited to see where his interest in joinery takes him and look forward to supporting his journey ahead.

Get involved in the Master Joiner Internship Programme, you can make a real difference by helping connect your local Master Joiners branch with nearby schools through our internship programme. It’s a great way to support young people exploring a future in joinery while strengthening ties with the schools in your community. Members can sign up through their branch—every connection counts!

SCM won a SMAU award for its intelligent spindle which can anticipate faults before they occur..

Thanks to sensors, software, and artificial intelligence technologies, SCM Group has transformed the electrospindle of a machining center into a predictive monitoring and maintenance system capable of reducing costs and downtime while optimizing the entire lifecycle of the machine.

Predicting a fault before it occurs, increasing production efficiency, and turning maintenance into a proactive service: this is the vision behind “Smart Spindle”, the innovation developed by SCM Group and recognized at the 19th edition of SMAU, held in Milan on November 5–6.

SCM Group has reimagined one of the key elements of its CNC machines—the electrospindle—turning it into an intelligent node within a broader ecosystem of smart services.

Developed in collaboration with Hiteco, a Group company, the electrospindle is equipped with a smart control unit that collects and interprets data from sensors monitoring critical parameters such as temperature, vibration, and tool change cycles. The system can anticipate faults and trigger predictive interventions before a problem occurs.

ning their platform with updates based on user feedback.

With the much-anticipated release of our latest REVEGO version coming next year, now is the perfect time to get familiar with the Blum Shop and how it can support your workflow. Whether you’re planning ahead for upcoming projects or simply keeping an eye on new solutions entering the market, having confidence in the ordering process makes integrating new products faster and easier from day one.

To help with that, we’ve continued refining the Blum Shop experience based on your feedback. Recent updates have made the platform easier to navigate and use. You’ll now find assembly and technical instructions directly on product pages, a streamlined order history view that makes reordering effortless, and a comparison tool that allows you to evaluate up to three products side-by-side. These improvements are designed to support smoother planning, clearer decision-making, and more efficient ordering — without disrupting your workflow.

And we’re not finished. The Blum Shop will continue to evolve, and your insights play a key role in shaping what comes next. If you have suggestions, ideas, or features you’d like to see, we’re always open to hearing them. Please reach out to your Blum Representative or to our team—we genuinely value your input.

Now’s a great time to explore the Blum Shop, get comfortable, and be ready for what’s just around the corner. Visit shop.blum.nz to get started!

The Conference was held this year in Rotorua in mid September at the Energy Events Centre. The theme was ‘Crafting The Future’. The site for the Conference was spacious and ideal, while the weather remained good throughout the three days. I had the privilege of meeting and briefly addressing the Executive Committee on the Thursday. Although I had not met many of the Committee before I was impressed by their attentiveness and commitment. A good conference looked likely!

The two evening events on the Thursday and Friday were really memorable for where they were held. The Conference organisers did themselves proud. The Gathering was held at Scion which is New Zealand’s leading Crown Research Institute focused on forest science, bioproducts and innovation in timber and bio based materials (see picture). This was notable as Scion took us on a fascinating guided tour of their facilities, something they don’t often do I was told. It was followed by a short Q&A session with their Henri Bailleres who the following day was a guest speaker at the Conference venue. A delightful location for meeting friends old and new garnished with amazing food to nibble on. Many thanks to Innergy for sponsoring this evening.

The following night was Quiz Night at the Skyline sponsored by newcomer Polytec. An absorbing ride up in a gondola led to a spectacular view of Rotorua. The smorgasboard meal was fantastic as was the Quiz night itself.

In between these events were the business sessions on the Friday and Saturday. Notable was the Keynote Presentation on the Friday morning run by Bruce Poling from The Joinery Coach. Maximising what you have to get ahead leads to opportunities for growth. A well received session. We have a contribution from Bruce in this issue as well. The other guest speaker was employment lawyer Tess von Dadelszen who spoke about issues affecting both employers and employees across all areas of workplace law. A really interesting session. We hope to hear more from her in the New Year.

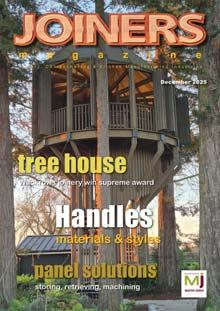

The highlight of the Conference came on the Saturday night with the Master Joiners Awards evening held at Te Puia, an iconic cultural venue in Rotorua. The architecture of the site is truly impressive. The Supreme Award sponsored this year by Allegion went to Wackrows Joinery with their amazing Treehouse entry. We have a feature on this winning entry in this issue and some commentary

from Liam Wackrow about the project. We will cover the other major award, the Premier Award sonsoered by Blum and won by Carlielle Kitchens in our March 2026 issue. Congratulations go to all the winners in this year’s Awards. Of particular note of course are the Apprentice Awards which this magazine has now supported every year for the past thirty years. Our thanks particularly to BCITO for their support.

Last but not least are the organisers of this event. Hearty thanks to Allison Delaney and her team from Master Joiners. Thanks especially to their Marketing Manager Aleximie Holleaux who did a grand job with the Awards ceremony. Was good to catch up with so many people this time round. Look forward to doing it all again next year!

Bob Nordgren

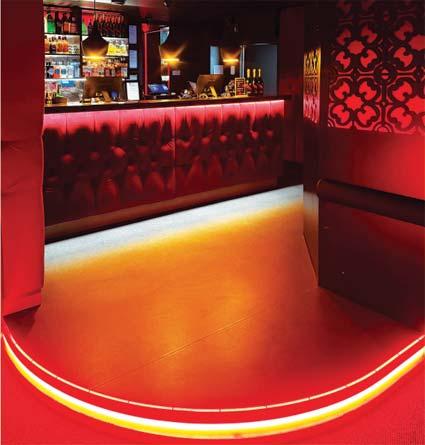

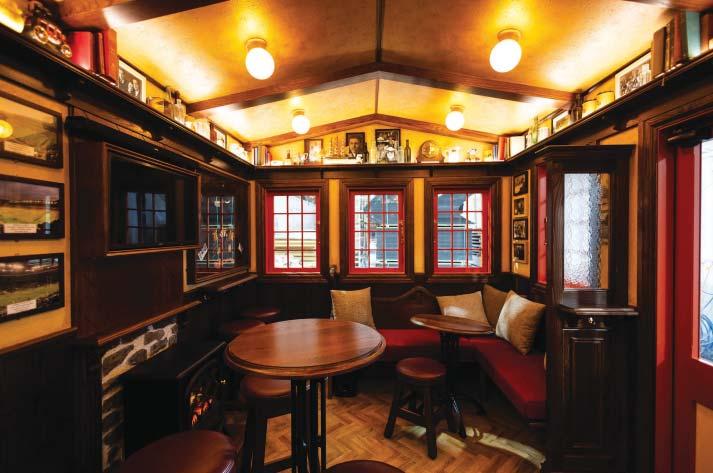

This year’s Supreme Award winner at the 2025 Master Joiners Awards held in Rotorua in mid September was won by an amazing Tree house by Cambridge based Wackrows Joinery. Bob Nordgren from JOINERS Magazine caught up with the Wackrows team to find out more about their stunning winning entry.

Situated within a small stand of Redwoods, the tree house stands 14.5 metre high on a central cylindrical trunk, with a 9 ton bar platform some 7 metres off the ground linked together by a spiral staircase. The bar platform itself is encased by 16 Cedar shutter bi-folds staggered from 2.2 metres to 4 metres around the facets with faceted jambs linking them together.

Twelve months in the making, this was a once in a lifetime opportunity with a focused client and a supportive head contractor. Due to the structure design,

this construction posed many challenges making this more out of the square or norm.

“Transporting the custom bar cabinetry and bi-folds up the spiral staircase followed by a complex install process at height was a key challenge” comments Liam, one of the owners of Wackrows. Each component had to be carefully handled and precisely fitted due to its bespoke design at height. Every piece of timber you see in the project was supplied and handled in some form by the Wackrows Joinery team.

Each part of the project demands commentary. Let’s start with the staircase. Custom profile band sawn Cedar was used to fit around the internal and external radiuses while radiused Kwila stair treads were shaped off the CNC after being laser templated. H3.2 Pine droppers, struts and joints were hand mortised to conceal any structural steel connections. Above this was the suspended band sawn Cedar door to lock the platform mid staircase (to

keep rodents and birds out!) and a hidden Cedar clad toilet door at the platform height of 7 metres.

At the platform level is the bar room of about 14 square metres of floor space. The bar itself features a faceted radiused bar top matching the floor pattern. The bar cabinetry had to home two bar fridges, an ice maker, plumbing utilities and glass storage in what was a tight radius which meant every unit was custom angled to fit many varying rectangles.

“This was indeed a challenging project which took some twelve months to complete from beginning to end” says Liam. “It certainly tested all our joinery skills to meet the client brief, and we are immensely proud of what we have created in the end.” A worthy winner indeed.

For more information contact the team at Wackrows Joinery, 13 Gillies St, Cambridge, ph 07 827 5981, email info@wackrows.co.nz or visit www.wackrowsjoinery.co.nz

Based in Cambridge the joinery business was established back in 1973 by Gus Wackrow. It is now run by Liam his son along with Carl Riley and Bryce Norris.

They have over the years been a specialist in timber window joinery, wooden door joinery, kitchens including installation and other cabinetry. Their work can be found all around New Zealand. The firm has grown to now have some eighteen staff. They have been past winners of various Master Joiners Awards including Best Kitchen, but this is their first Supreme Award.

Note: As well as winning the Supreme Award, the Treehouse also won the Best Creative Use Of Timber and Best Timber Project Awards

“The Treehouse is a remarkable showcase of exceptional timber craftsmanship, innovative design, and meticulous execution”

“an outstanding example of timber joinery that strikes an effective balance between functionality, aesthetics and environmental sensitivity”

“seamless integration of structural steel with handcrafted timber elements demonstrates a high level of skill and attention to detail, making it a true standout in the industry”

“This project distinguishes itself by integrating robust timber joinery within a unique and adventurous architectural concept. Overall, it stands as a strong representation of industry best practice, delivering a visually striking and enduring timber structure that responds thoughtfully to its environment”

Judge’s comments

The selection of products are crucial to a brilliant design and function. It will stand the test of time with choice of enduring quality products.

High end joinery at its best. Matching timber elements and lighting details echo the kitchen, reinforcing continuity across the home while allowing this space to shine on its own terms.

Cool !!! love the vibe of this bar, an entertainers dream. I would be proud to serve a drink in this bar.

Beautifully made and presented, a stunning piece of cabinetry

Nice to see in house photos, even smaller details like the beautifully spaced wine glass holder are good to see

Waterborne low VOC coating system for cabinetry, joinery, shop fittings, kitchens and doors

WORK SMARTER

TRAIN AN APPRENTICE

ALREADY HAVE THE EXPERIENCE?

GROW YOUR BUSINESS THROUGH TRAINING

Have your team work smarter, learn up-to-date skills.

Help them learn the skills and become qualified.

Get skills recognised with a formal qualification.

Training an apprentice is an investment in your business and the industry.

Jack Hitchcox of Dunedin’s Bespoke Cabinets was awarded the prestigious Ernie Jelinek Cup for Most Promising Apprentice at the Master Joiners Excellence Awards.

The Ernie Jelinek Cup, presented by cup sponsor BCITO, is awarded annually to a timber joinery apprentice who has demonstrated exceptional skill, commitment and potential. Jack received the award in front of industry peers at the Excellence Awards Dinner at Te Puia, Rotorua in September.

"Ernie Jelinek was greatly involved with the Joinery Industry Training Organisation (JITO) and today we continue to recognise his contribution to the joinery industry with the awarding of the Ernie Jelinek Cup. We want to congratulate Jack on receiving this great honour for 2025," said Nathan Moore, National President, Master Joiners.

“Jack joined Bespoke Cabinets as a young after-school and holiday worker, and it was immediately clear that his talents were better suited to working with tools than pushing a broom. Jack is also incredibly dependable. He often beats me to work in the morning and I’ve never once seen him

pack up early. Last month, I was away from work for two weeks, and Jack ran the company in my absence – every job was delivered on time, and everything was handled professionally. He’s a once in a generation apprentice,” said employer Spencer Bremner.

Jack said he’d been lucky to work on some unique projects and to learn from people who’d trusted him with responsibility early on. “Running jobs and taking on complex builds has pushed me to grow quickly, and I’m grateful for the support of my employer, my BCITO training advisor, and everyone who has backed me along the way. This recognition motivates me to keep raising the bar and contributing to the future of our trade.”

Greg Durkin, Director at BCITO, said the award is a testament to the strength of talent coming through the trades. “Apprentices like Jack represent the future of the joinery profession. Their determination, willingness to learn and creativity ensure that traditional craftsmanship continues to thrive. BCITO is proud to support and celebrate the next generation of joiners through our ongoing sponsorship of the Ernie Jelinek Cup.”

For the first time, New Zealand’s joinery, design, and construction community can experience polytec — one of Australia’s most trusted decorative surface brands, renowned for its combination of functionality, architectural appeal, and manufacturing excellence.

For over 35 years, polytec, a Borg Group company, has been synonymous with design-led, durable and functional surface solutions, offering a system of melamine decorative boards, high-pressure laminates (HPL) and matching edging that allow seamless coordination across joinery and wall-lining applications. With an extensive offer that includes 60 matching melamine and benchtop HPL designs, the collection offers endless creative possibilities, from contemporary kitchen joinery to commercial fit-outs — all backed by a reputation for design consistency, quality and value.

Award-winning Auckland architect Michael Cooper was among the first to specify polytec in New Zealand.

“I saw the range at the Melbourne Design Show earlier this year and just loved it — it’s not often you walk by and think, this will change everything. There’s nothing else in the market that compares with the polytec Woodmatt finish. I’ve chosen Society Oak for a kitchen, Botany Oak for wardrobes and bedheads, and we’re also considering Manor Oak and Ecru Oak. Our joiner loves working with it — it’s incredibly high quality and easy to handle.”

Local cabinetmakers are equally positive. Warren Smith from Kitchencraft Interiors says: “It gives us another string to our bow, a product with solid foundations and great quality. Their range is exciting and their sample presentation is excellent. But having local stock on hand with strong and very enthusiastic sales support from Ian Atkinson and the team made all the difference.”

Warren made the point that their business would still be supporting NZ-made product but appreciated the ability to have more options for their customers with the addition of polytec

A particular emphasis on bespoke automation and robotics has allowed Borg to achieve incredibly efficient production, at scale, of an extensive product range which under the polytec brand includes decorative panels, custom doors and benchtop laminates.

A 37-year history of innovation and growth, founded by the Borg Group

From its origins in a small joinery business founded by Michael and John Borg in 1988, polytec has grown into one of Australia’s largest decorative surface brands. Its extraordinary growth has been achieved by an absolute commitment to investing in the most technologically advanced and computer integrated manufacturing systems.

A particular emphasis on bespoke automation and robotics has allowed Borg to achieve incredibly efficient production, at scale, of an extensive product range which under the polytec brand includes decorative panels, custom doors and benchtop laminates.

The commitment to innovation is already in evidence with the NZ start-up where the company’s first

Combilift Slipsheet is being used to swiftly unload containers in a record seven minutes.

The Borg Group’s broader operations include growing and harvesting renewable plantation pine, manufacturing MDF and particleboard, and producing decorative panels and doors across advanced, technology-led facilities. A significant proportion of board material is reclaimed, repurposed and reintroduced into production, ensuring timber waste is minimised and resources are continuously reused.

This commitment to sustainability extends to energy generation where the Oberon manufacturing site in NSW hosts Australia’s largest rooftop solar array, spanning eight hectares with over 27,000 solar panels, alongside an on-site wastewater treatment and recycling plant.

All polytec board products are manufactured from E0 or E1 substrates, with particleboard incorporating recycled wood content, and all timber sourced from PEFC, Responsible Wood and GreenTag-certified plantations.

Chief Executive Officer Jim Snelson says establishing a New Zealand distribution operation has been a long-considered decision.

“We’re confident there’s strong demand for polytec products in New Zealand, and our production efficiencies allow us to supply board and laminate to the East Tamaki warehouse at competitive prices,” he said.

“We’re also fortunate to have a local team with outstanding experience and industry connections, enabling us to get up and running quickly.”

Supporting NZ joiners

In New Zealand, Ian Atkinson and Jack Allan are leading the sales charge for polytec – Ian is an industry veteran well known to many while Jack is a Kiwi, relocated from polytec in Melbourne. Anne Knight is in a part-time specification role supporting architects and designers.

The warehouse team is led by Branch Manager Roger Miller, supported by Marshall Hutchinson (Hutch) and Terry Tangata.

(Continued over page)

What’s on offer from polytec for NZ Joiners

From its well-stocked East Tamaki warehouse, polytec can supply melamine decorative panels, benchtop laminates, and edgetape to customers across the Upper North Island and beyond, with prompt and reliable delivery:

• 80 colours in the melamine range in finishes that cover all the bases from a lowreflective anti-fingerprint

matt (Venette) through to gloss, matt and woodgrain textures (Woodmatt and Ravine).

• Longer 3100 mm melamine panels for select colours

• A benchtop HPL range of 95 colours that includes 60 melamine matches

• Matched 22x1mm ABS edgetape for all colours in either 20m or 100m rolls. A wider 29mm tape is available on select colours.

The versatility of the range in terms of panels size and the ability to co-ordinate vertical and horizontal surfaces provides immense versatility for both residential and commercial projects.

With higher stud heights now the norm in new residential builds, the longer 3100 panels are fast becoming industry standard and are ideal for overheight joinery and wall panels.

The versatility of the range in terms of panels size and the ability to coordinate vertical and horizontal surfaces provides immense versatility for both residential and commercial projects.

Sample boards and sample boxes are available for joiners and the full range can be viewed online at the polytec New Zealand website at www.polytec.co.nz. Contact details for the sales and specification team can also be found on the contacts page.

In a repeat of previous years in our December issue we once again bring the Christmas handles pictorial, of the popular, the trending and the practical to assist in completing your cabinetry and furniture projects.

The latest in Decorative Hardware.

The 2025 Déco Collection by Häfele redefines the art of touch. From bold statements to refined classics, each piece captures the evolving language of design.

Browse Our Range

Space-saving solution for modern living spaces.Key technical specifications:

Häfele is set to launch Slido F-Park72A in 2026, a new pivot sliding system designed to maximise space and deliver a clean, modern aesthetic. This innovative solution allows doors to pivot and slide smoothly into a concealed pocket, creating uninterrupted access and a minimalist look for kitchens, living areas, and multi-functional spaces.

The system is engineered for ease of installation and long-term durability, making it ideal for designers and installers who want to offer their clients value, but not compromise on performance and simplicity. Slido F-Park72A supports handle-free fronts and integrates seamlessly with contemporary cabinetry designs.

Easy installation & adjustments

Pre-mounted system for quick and easy installation. Use of standard hinges make adjustments very intuitive.

Optimum price/performance ratio

High-quality technology at a reasonable price –Ideal for cost-optimised projects.

Easy to use

Intuitive operation without complicated mechanisms.

Compact form & seamless movement

The doors move smoothly and quietly, ensuring maximum convenience.

– Door height: Up to 2800 mm

– Door weight: Up to 30 kg

– Door thickness: 19–25 mm

– Opening width: Flexible single or double-door configurations

– Mechanism: Pivot sliding with concealed pocket integration

– Installation: Pre-assembled components for simplified setup

– Finish options: Compatible with a range of modern finishes

With its official rollout planned for early 2026, Slido F-Park72A promises to deliver flexibility, elegance, and performance, empowering designers to create spaces that are both functional and inspiring.

www.fit-nz.co.nz

Earlier this year, we announced the launch of Opticoat® – our thermoformed door products, made using the latest in automated coating technology from Europe. Today, we are excited to further expand these opportunities with our newest addition, the Opticoat Handles.

Opticoat Handles are available in 3 different style options:

Profile Handle:

Featuring a sleek and subtle ‘shark nose’ detail along the full edge, available on both 18mm and 22mm thick door styles.The Profile Handle requires the use of a backing rail in the cabinet, which does reduce the capacity of the drawer, which is why we also have the …

J Handle:

The J Handle is a handy all-in-one option for maximising drawer capacity. As no backing rail required in the carcass, it provides the seamless handle-less look, with full use of the drawer space. This handle is only available on 22mm thick doors.

Inset Handle:

The Inset Handle is similar to the J Handle, but the length and position is fully adjustable. This makes it perfect for tall doors (you can set the handle length and position), vanities (you can have a left & right door, with the handle meeting in the middle) and doors where you want a custom width handle. This handle is only available on 22mm thick doors.

These 3 different handle options can either be used on their own, or used together throughout the project. For example, on a kitchen with J Handles, the top drawer front could have a Profile Handle on the bottom edge, with the J Handle below creating the backing rail element required. And then the Inset Handles could be customised as required for the tall cabinets.

The Opticoat® handle options can be used on a flat door or frame profiles, but are not suitable for linear profiles. Opticoat is available up to 3100 long in all of our profiles, with options for full return panels with no join lines in the back of the panel. If you’d like samples of the product, or would like to learn more, get in touch with our team!

Some materials don’t just complete a design—they define it. Solid brass lives in that rare space where craftsmanship, performance and beauty meet. In 2025, its appeal is stronger than ever: warm to the eye, reassuring in the hand and timeless across styles. When the brief calls for authenticity and longevity, solid brass answers with quiet confidence.

Why solid brass feels different The first impression is tactile. Lift a solid brass pull and there’s a calm, even weight; edges are crisp, threads engage smoothly, and the hardware seats with precision. That integrity isn’t surface-deep— it’s built in. Over time, doors and drawers see thousands of touchpoints. Solid brass responds with stability and composure, so the daily ritual of opening a drawer feels considered, not accidental.

Designed for

New Zealand homes

Local conditions ask more of finishes. From coastal air to seasonal humidity, kitchens here work hard. Solid brass offers two credible pathways. Advanced coated finishes—such as modern PVD—deliver consistent colour

Solid brass pairs effortlessly with timber veneers and painted shaker, brings warmth to minimal laminates, and grounds expressive stones and porcelains.

and excellent durability when a low-maintenance brief is essential. Unlacquered “living” brass, by contrast, embraces change; it develops a natural patina that softens and deepens with handling, telling the story of a kitchen being lived in. Both choices are honest; each creates a distinct design narrative.

Three design directions— beautifully resolved by Archant

Berkley: tactile precision with knurled detail.

Berkley pairs solid brass construction with a refined diamond-knurl texture, catching light across its criss-crossed ridges while brushed ends keep the silhouette modern. Available across practical lengths with

complementary knobs, it brings confident grip and visual rhythm to wider drawers and tall fronts.

Fade XL: elegant proportion for expansive cabinetry.

A long, linear profile that reads as architecture rather than ornament, Fade XL extends the much-loved Fade ® language into 160, 320 and 640 mm spans. Precisionengineered from solid brass and offered in Antique Brass and Brushed Anthracite, it delivers a minimalist, luxurious touch that aligns form and function on larger doors and drawers.

Lexden: Art Deco poise, reimagined for today.

Geometric lines, luxurious finishes and a poised hand feel define Lexden—a solid-brass handle that bridges classic and contemporary

schemes with ease. Available in Antique Brass and Brushed Anthracite and in multiple sizes, its sleek proportions add a note of tailored sophistication to any interior.

Framing the palette — and the experience Great hardware doesn’t compete with the scheme—it completes it. Solid brass pairs effortlessly with timber veneers and painted shaker, brings warmth to minimal laminates, and grounds expressive stones and porcelains. Brushed and satin treatments feel refined and contemporary; deeper, antiqued tones introduce quiet depth. The result is a finish that photographs beautifully on day one and looks intentional years later.

Blum has recently reinvented its Auckland showroom — a space designed not just to display hardware, but also to inspire, educate, and support how joiners work with clients and plan their projects.

The updated showroom now features a variety of kitchen styles, plus home office, living area, and bathroom setups to demonstrate how our solutions work throughout the home. Rather than relying on catalogues or online images, you can open drawers, run your hands over surfaces, and get a true sense of movement and functionality. It’s a space built for practical conversation, hands-on learning, and confident decision-making.

A standout feature of the renovation is the installation of REVEGO V3, the newest pocket door solution set to be released next year. Seeing REVEGO V3 in action offers joiners the chance to understand the system’s spatial advantages, installation considerations, and the sleek, seamless movement it delivers. Getting familiar with it now means you’ll be prepared to specify, quote, and integrate it into projects the moment it launches.

The showroom is also a useful tool for supporting your client consultations. Bringing clients in often speeds up decisionmaking significantly — they can compare finishes, systems, and configurations side-byside, reducing indecision and minimising redesigns later in the process. It also elevates your service approach, positioning you as a detail-driven partner who guides clients through thoughtful, informed choices.

Blum is currently undertaking a significant upgrade to its Automatic Warehouse in Auckland, marking an important step in strengthening supply performance and ensuring future growth across the joinery and cabinetry industry. The upgrade, which is now well underway, will more than double current capacity once completed — increasing efficiency, improving responsiveness, and helping minimise delivery delays during peak seasonal periods.

To maintain service throughout the upgrade, the warehouse team has been operating two shifts, six days a week. The investment now

With our barista-quality coffee and varied meeting spaces, the new showroom space offers a cosy, welcoming environment to talk design with your clients.

Blum’s showroom team is available to talk through technical questions, design challenges, and planning considerations. Whether it’s a hinge angle puzzle, waste bin placement, or storage layout, a short conversation can often save hours on site.

Whether you’re exploring new solutions, helping a client finalise selections, or simply looking for ideas to refine your own design approach, the newly renovated Blum showroom is built to help you do your best work. Pop in and see the team at 621 Rosebank Road, Avondale, Auckland for a freshly brewed coffee and check out the refreshed new space, or book in a time with your Blum Representative to have them show you around.

being made in system expansion and automation will support a faster, more agile supply chain for years to come. Once complete,

the upgrade will allow Blum to react quickly to urgent orders and support industry demand more effectively during busy periods.

As the industry continues to pick up momentum — with strong order growth recorded through September and October — Blum appreciates the patience and support shown by customers throughout this improvement phase.

The company looks forward to sharing the benefits of the new system and celebrating its new showroom and warehouse facilities in 2026. www.blum.com

Timber has a unique way of grounding a space and creating a sense of connection and warmth. Veneer provides the medium for us to celebrate that natural beauty in a resource-conscious way. At New Zealand Panels Group (NZPG) across the Prime and Bestwood veneer ranges, our focus has always been the same: select the right logs, match them with care, and help designers and joiners get the best out of the material.

We sat down with Johnny Dobbyn* who has spent more than 30 years working closely with veneer and timber, sourcing it, grading it, studying how it behaves, and helping people use it well.We talked about what inspires him, how sustainability is shaping the journey ahead, and why education, collaboration and communication matter so much in this category.

Q1. Johnny, you’ve worked with veneer and timber for many years now. What keeps you so passionate about it?

Johnny: I’ve worked with veneer for a long time and what still gets me is how every piece tells a story. No two are ever the same. The grain, the movement, the way it is prepared and finished, the way the colour shifts as the light hits it, it feels alive. Veneer brings real warmth and character into an interior space, and it does that without needing to use large volumes of timber. That balance of beauty and respect for the resource is something I’ve always valued.

Q2. The Prime and Bestwood veneer ranges are often spoken about together and have long been recognised names in New Zealand interiors. How do the two sit alongside each other today?

Johnny: They really come from the same place. The same sourcing philosophy, the same care from the team in selection and the same

One of the most meaningful things about veneer is how efficiently it uses the timber resource.

focus on helping people achieve a great finish. Two great New Zealand brands, under one roof. The variety across the combined offering means designers and joiners can find exactly the right tone and grain character for their project.

What we know matters most to joiners and designers is reliability. Knowing it will be consistent, confident it will be well-matched, obviously within the limits of the natural product, which can vary from species to species, different cuts and layups - especially nowadays with more stains and finishes than ever before.

Q3. Sustainability is a big focus. How can veneer support designers in creating more sustainable projects?

Johnny: One of the most meaningful things about veneer is how efficiently it uses the timber resource. Because you’re slicing the timber flitch into thin sheets, you make use of far more of the tree. Both our veneer ranges are Eco Choice Aotearoa accredited, so there’s independent assurance behind the environmental performance.

And then there’s our Track My Tree programme is very cool –available on selected New Zealand native veneers, the material can be traced back to the exact forest it came from. It reconnects people to the place, the landscape, the story. It reminds us that this is a real natural material with real roots - pun intended!

(continued over page)

NZ Panels Group is the country’s leading manufacturer and distributor of interior products with a range that covers pressed decor panels, benchtop surfaces, sinks and taps, commercial washroom products and particleboard flooring.

Discover more at nzpanels.co.nz

Q4. You’ve also been running veneer training across the country. What drove that?

Johnny: Because veneer is a natural product, it is very nuanced and understanding it makes a huge difference. Things like sequencing, book matching, slip matching, mismatching, finish choices all affect the final look. Over the years, I’ve had so many great conversations with joiners and designers about how to get the best from veneer. While there has been a lot of development and change in production, finishing and staining, craftsmanship still plays an important role when working with veneer, after all, it is still wood.

To make sure that joiners and furniture makers get the result they are after, we have some helpful technical resources and checklists which are available through our sales and customer service teams with information and questions that help us deliver

the perfect products for your projects, factoring in the cut, placement, style and application is important as we are working with natural products that do vary from tree to tree and are not identical like melamine or HPL products.

We developed a CPD-accredited veneer training presentation with the NZIA that we’ve been delivering around the country. It’s practical and hands-on with real examples, real answers, real projects. The feedback has been great. People leave feeling more confident and more inspired to use veneer. Also with a new or renewed realization of the craftmanship and skill that joiners / furniture makers invest in our product to create something truly unique.

Q5. What excites you about where veneer is heading next?

Johnny: There’s a real shift back toward materials that feel natural and that are in harmony with

the environment. People want warmth, texture, and authenticity and veneer offers all of that.

The mismatch layup (available in our Prime Toitu or Art range) is a wonderful development over the last 10 years. It creates a more “solid wood look” over the traditional bookmatch / slip match repeated pattern look. This embraces the whole look of the timber species that has been chosen and is very forgiving for overall matching of the individual boards when large quantities are involved and or certain stains or finishes are used. Not only does this use more of the natural resource than other styles but it also saves on wastage where the variation is part of the product, perfect for when you are using veneer together with solid timbers.

If a more uniform look is what you are after, our Evoake veneer has a matching grain and colour, providing a more standard, repeatable pattern available

in both crown and quarter cut options, something for everyone.

We’re seeing more use of curves, layered textures, and grain as a design feature rather than just a background. It’s a really exciting time. I think veneer is only going to become more central to how interior spaces feel; calmer, more grounded, more human.

Thanks to Johnny for sharing his passion, knowledge and craft and for reminding us that when we understand a material deeply, we can do something truly special with it.

If you feel that you would benefit from receiving training on our veneer products, register your interest today by emailing us at marketing@nzpanels.co.nz

* Johnny Dobbyn is the Veener Category Manager for New Zealand Panels Group

Millwood Ltd, established by husband and wife team Andrew and Kirsten Miller, has gone from strength to strength since they started as timber importers and wholesalers back in late 2017. Bob Nordgren from JOINERS Magazine caught up with them recently to find out more about them and their business.

The number of wholesale timber suppliers in New Zealand is relatively small but very competitive. Andrew and Kirsten are from South Africa having come to New Zealand back in the mid 2000’s. “Timber has been in our veins so to speak from the start” explains Andrew. “I was in the timber business back in South Africa and Kirsten worked in the furniture manufacturing sector when we first met so when we decided to move to New Zealand it was pretty much on the cards we would end up back in the timber business.”

After stints with some other well known timber companies that came to fruition when they set up Millwood Ltd in 2017. “With some kind help, we started out using a shed and as it grew we moved to our current location some three years ago” recalls Andrew.

From the start they had a more traditional, hands on approach with direct customer involvement. “The buck stops with us so to speak” comments Andrew “and our customers know who they are dealing with at all times.”

Andrew who is very hands on in the warehouse and on the fork hoist, supervises most orders going out of the door, with the help of Jared and Wikus. “Customer happiness experts” is what the trio proudly call themselves.

They have both had a number of years being coached by Andrew to understand and work towards

the best yield for customers’ orders. Kirsten, also capable in the warehouse, focuses on the accounting and stock control side of things.

They operate from two buildings in East Tamaki with about 1000 square metres of storage space. They have a solid range of imported and local timbers. “Popular species at the moment include American White, Ash and Oak while we have European Oak and Beech from Italy and African Iroko and Sapele dried and supplied from Italy as well” Andrew comments, as well as