JIA WEI TEH

MATERIAL EXPLORATION REPORT

INTRODUCTION.......................................................................... PRODUCTION TIMELINE OF CORK..................................... CORK HOUSE................................................................................ SOURCED MATERIALS OF CORK........................................... PRODUCTION TIMELINE OF LEATHER (MODERN)....... PRODUCTION TIMELINE OF LEATHER (TRADITIONAL).......................................................................... POST TANNERY............................................................................ SOURCED MATERIALS OF LEATHER.................................... MATERIAL EXPERIMENTS PART I......................................... MATERIAL EXPERIMENTS PART II....................................... CONCLUSION............................................................................... PROTOTYPE.................................................................................. REPORT CONCLUSION.............................................................. BIBLIOGRAPHY............................................................................ 3-4 5-8 9-10 11-12 13-14 15-16 17-18 19-20 21-60 61-74 75-76 77- 86 87-88 89-90 CONTENTS PAGE

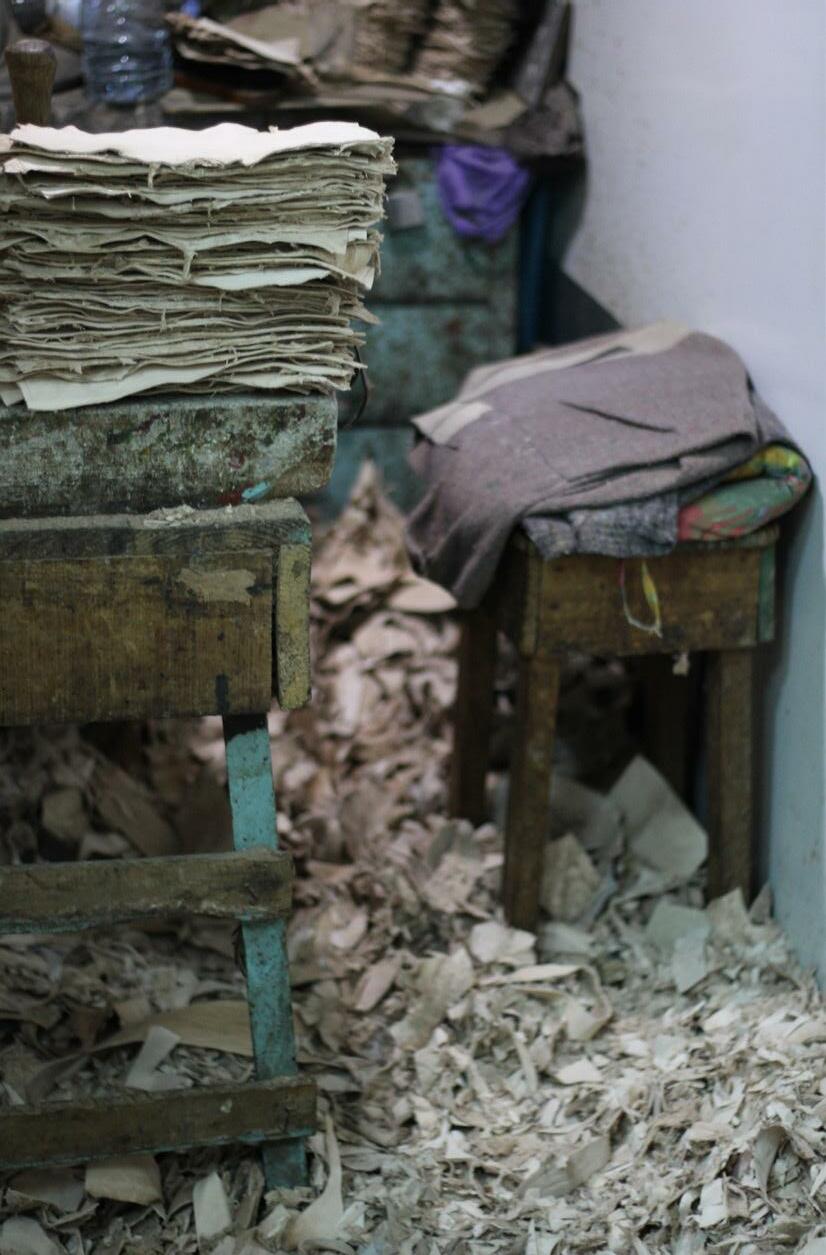

Leather Tannery in Fes, Morocco.

Leather Tannery in Fes, Morocco.

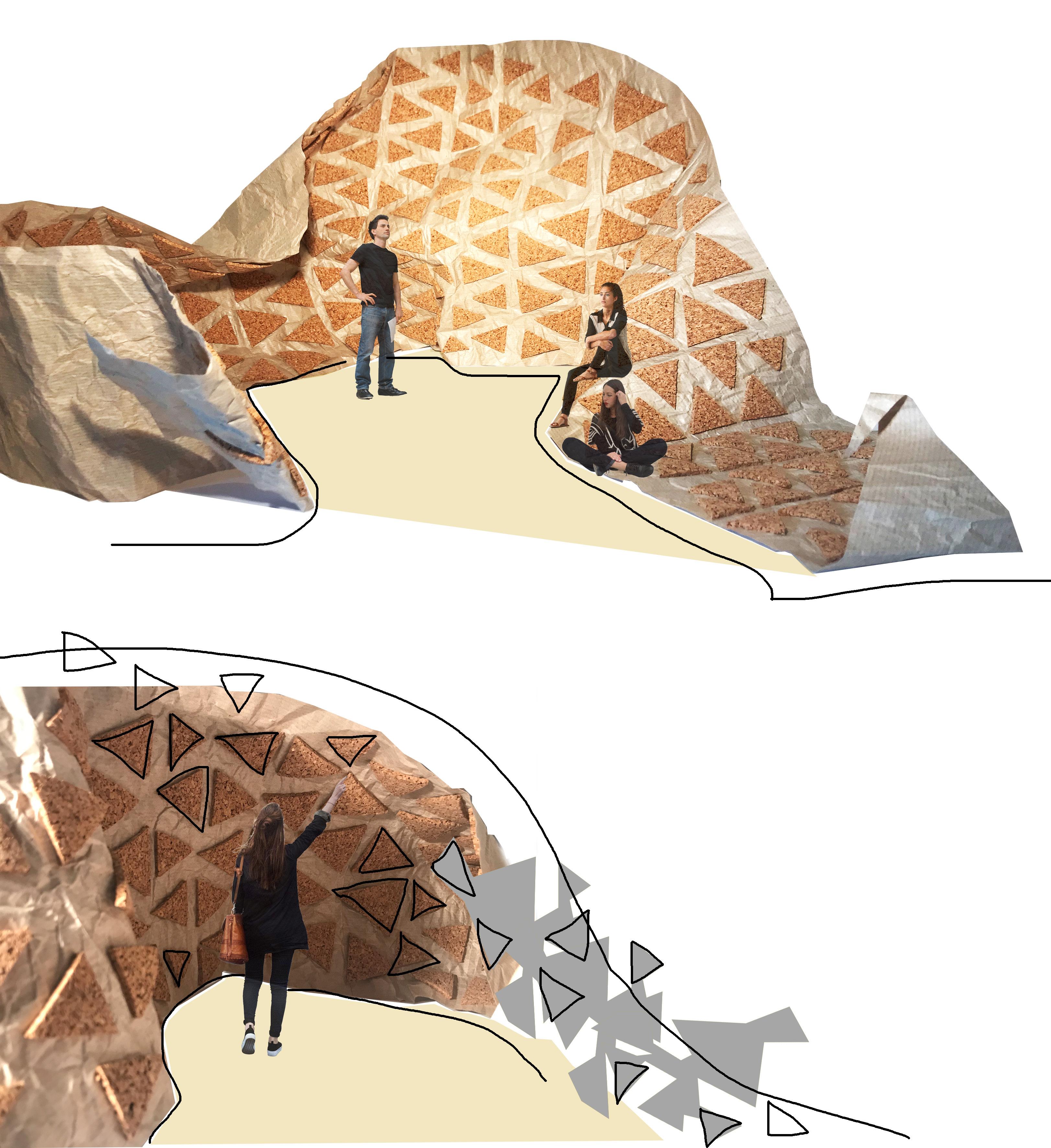

Within this report you will find the research into the production of the materials cork and leather with experiments taken on such fabrics to provide a conclusion to making a set of modular system columns to be used as spacial dividers or features.

Throughout the pages, you will find a common theme of deconstruction leading to reconstruction. This had become a way of me truly understanding the materiality better and assist in developing a new form of product. Throughout such matters, the thought of understanding a persons relationship with the materials and the presence of both natural and artificial light against the cork and leather; were always on my mind. The prototype created was to enhance a spacial and personal experience. The aim I gave myself throughout the testing was to find a way of making such raw materials stay in their organic state but provide a more delicate aesthetic and meaningful presence.

It was also intended to use leather as a non-structural material whilst having cork as a structured fabric. The result of this came to the contrasting relationship of the ethical and non-ethical products, whereby the cork column became a structure to the leather. However the cork was assisted structurally by a transparent tube which was chosen to allow a presence of light and to enhance delicacy. Then the weight of the cork being pulled by gravity gives the end piece a structured and sturdy finish.

MATERIAL EXPLORATION OF CORK AND LEATHER INTRODUCTION

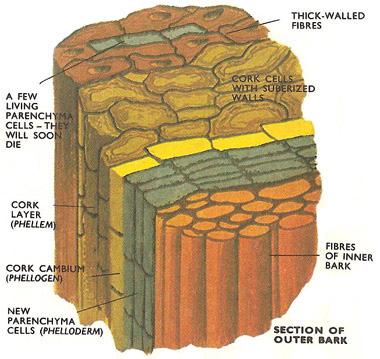

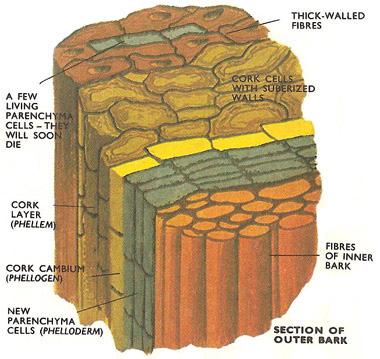

A

closer look at the

structure

of

a cork tree.

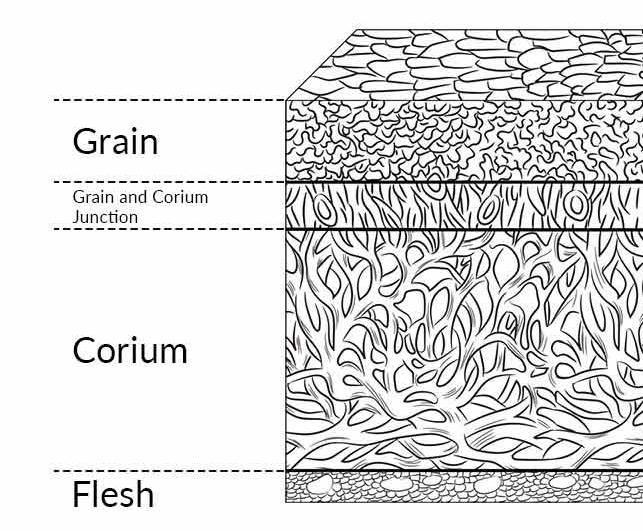

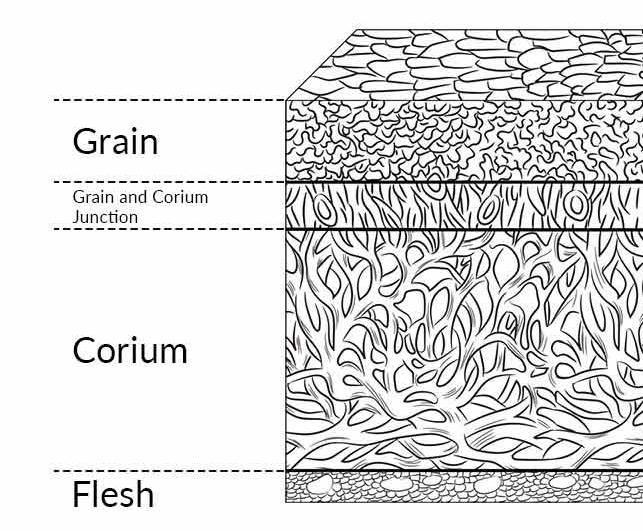

A closer look at the structure of hide.3

The reason why I chose these two products is because of their similarities but controversial differences. They both act as a skin to natural bodies such as the cork being the bark to the tree and then leather being the hide of an animal. They are both rather brutal finishes, but have great strength and range of uses.

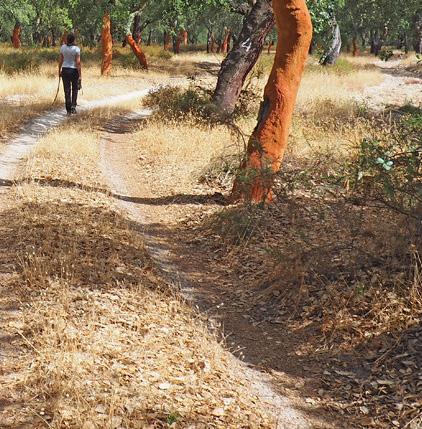

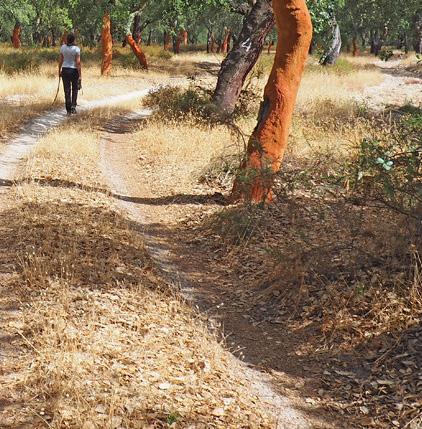

Cork is regarded as environmentally friendly with cork production being sustainable due to the cork tree not being cut down when the material is harvested. Rather only the bark is removed which allows the tree to continue to grow. However it is a delicate bark to harvest because there comes a skill in doing so, so not to damage the tree trunk and therefore its growth. The material is easily recyclable and the forests support a particular rare habitat for Iberian Peninsula and other endangered species. The most common use of cork is for wine bottles which is the most environmentally friendly alternative to other wine stoppers. Plastic stoppers to be specific produce 10 times more CO2 whilst aluminium screws release 26 times more CO2 than a cork stopper.

Cork has been used for a long time and was very popular in the 19th century and is an upcoming material these past few years. However it is interesting to know that leather is the first material used by humans in history due to its great strength and durability and uses. However it is sad to know that after all this time of having it around, there is such a pore recycling process. Never-mind its harmful chemicals used in the production process.

Studying these two materials is a reminder that we are the ones in control of sustainability now, and that actions must be taken sooner than before to prevent environmental matters reaching a point of devastation. We can start with our personal choices in materials.

A closer look at the structure of leather. 4

FROM TREE TO END MATERIAL

THERE ARE ABOUT 2,200,00 HECTARES OF CORK FORESTS WORLD-WIDE. MOST OF WHICH ORIGINATE IN PORTUGAL AND SPAIN.

THE TREES MUST GROW FOR AT LEAST 25 YEARS BEFORE THE BARK CAN BE REMOVED TO CREATE THE CORK.

ONLY EXTRACTED FROM EARLY MAY TO LATE AUGUST.

BARK IS REMOVED FROM THE CORK TREE, TRADITIONALLY USING A VERY SHARP AXE. THE BARK CAN BE EXTRACTED IN 9-YEAR INTERVALS ALTHOUGH IT CAN TAKE UP TO 13 YEARS FOR THE CORK TO REACH AN ACCEPTABLE SIZE.

‘GENTLE CORK’

BARK THAT IS OF HIGH QUALITY IDEALLY USED TO MAKE WINE AND CHAMPAIGNE STOPPERS.

PRODUCTION TIMELINE OF CORK

5

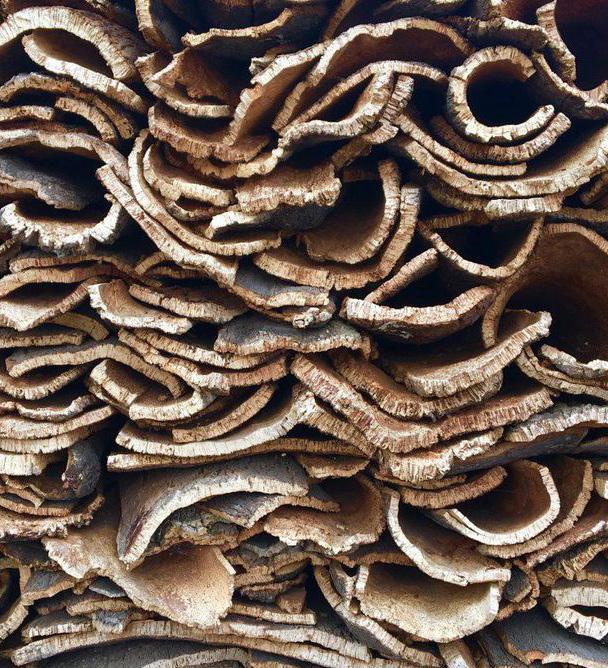

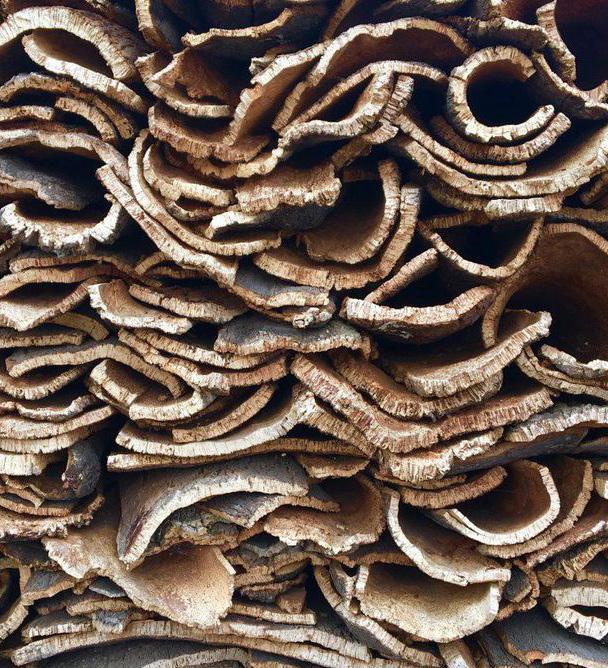

ONCE THE CORK IS REMOVED IT IS THEN CARRIED BY HAND AND STACKED IN PILES IN THE FOREST OR YARD OF A FACTORY.

THEY ARE PLACED IN LARGE COPPER VATS WITH BOILING WATER. THIS WILL SOFTEN, CLEAN AND MAKE THE PLANKS MORE FLEXIBLE.

THE PLANKS ARE REMOVED FROM THE VAT WHEREBY THE POOR QUALITY OUTER LAYER IS SCRAPPED OFF.

THEY ARE SUBMURGED FOR 30-75 MINUTES.

THEY ARE LEFT TO CURE IN THE SUN, RAIN AND FRESH AIR FOR SOME WEEKS. IN THIS TIME THEY WILL FLATTEN OUT AND LOSE ATLEAST 20% OF THEIR ORIGINAL MOISTURE.

‘VIRGIN CORK’

BARK FROM THE FIRST HARVEST IS OF POOR QUALITY AND IS THEREFORE USED TO MAKE INDUSTRIAL PRODUCTS, BUILDING INSULATION AND FLOORING.

THE PLANKS ARE STACKED IN A CONTROLLED DARK SELLER ALLOWED TO DRY AND CURE UNDER HUMIDITY FOR A FEW MORE WEEKS.

6

THE BOILED PLANKS ARE FLATTER AND THEREFORE EASIER TO WORK WITH IN THE NEXT STAGES.

MACHINE ASSISTED HAND PUNCHING IN AMORIM’S FACTORY, PORTUGAL.

NEXT THEY ARE GRADED AND CUT INTO WORKABLE PIECES.

SOME WILL BE USED FOR PUNCHING CORKS OUT OF, WITH SOME OF THE REAMINING TO BE GROUND UP INTO GRANUELS THAT CAN BE GLUED TOGETHER TO MAKE AGGLOMERATE CORK.

THIS IS A SKILLED PROCESS AS ANY WRONG DECISION CAN RESULT IN CORK BEIGN WASTED.

7

PURE AGGLOMERATED CORK

FORMED BY PACKING CORK PARTICLES INTO A MOLD THEN COVERING IT AND SECURING IT TIGHTLY

COMPOUND AGGLOMERATED CORK

MADE BY COATING THE GRANULES IN A THIN ADHESIVE AND THEN PRESSED INTO A MOULD AND SLOWLY HEATED (TEMPERATURE VARYING ON ADHESIVE USED)

CORKS ARE THEN PLACED INTO BINS ACCORDING TO THEIR GRADE, READY FOR SHIPMENT.

WASTE CORK AND VIRGIN CORK IS PASSED THROUGH A MACHINE BREAKING IT INTO SMALL PIECES.

AGGLOMERATED CORK IS FORMED THROUGH DIFFERENT WAYS OF BINDING THESE CORK PARTICLES TOGETHER.

CORKS ARE THEN PLACED INTO BINS ACCORDING TO THEIR GRADE, READY FOR SHIPMENT.

WASTE CORK AND VIRGIN CORK IS PASSED THROUGH A MACHINE BREAKING IT INTO SMALL PIECES.

AGGLOMERATED CORK IS FORMED THROUGH DIFFERENT WAYS OF BINDING THESE CORK PARTICLES TOGETHER.

8

Cork house is designed by architect Matthew Barnett Howland with Dido Milne and Oliver Wilton. It won many awards including the RIBA National Award 2019. It was designed with respect for the natural surroundings and in the essence of early nineteenth century archi tecture whilst having great sustainability and the use of biogenic construction. The cork blocks cut out from solid masses of agglomerated cork, are fitted together without any form of adhesive, rather with the power of gravity and some interlocking designs. It is said to have a tranquil feeling inside with the effect of the light catching the materials creating a sense of warmth and security.

“As sustainability becomes integral to all construction, this development pushes us further to look beyond the requirements and aspire to really integrate ourselves with nature.”

Cork Fabrication Research B-Made at The Bartlett UCL Cork CNC Machining Wup Doodle

CORK HOUSE THE CAPABILITIES OF THE MATERIAL

9

The skylights and framing work as a weight down on the cork to hold it to gether structurally.

This requires no need for complicated layers in the wall for insulation, weather protection etc. Rather cork does it all.

The production process of the cork used in the Cork House.

The production process of the cork used in the Cork House.

10

THE CORK I HAVE

DETAILS OF MATERIALS

WINE CORKS

Pack of 25 new tapered corks for wine bottles. Brought off Amazon. Package size is 176 x 90 x 48mm; 59g. Cork size on average is 40 x 20 x 20mm; 1.5g.

Cost - £4.69 (19p/cork)

DETAILS OF MATERIALS

CORK SHEETS

Pack of 3 high quality cork sheets. Brought off Amazon. Package size is 300 x 200 x 75mm; 2340g. Individual Cork sheet is 1000 x 300 x 4mm; 780g.

Cost - £15.00 (£5.00/sheet)

THE MATERIAL

SOURCED

11

WINE CORKS

CREATED BY PUNCHING HOLES THROUGH THE CORK BARK

PURE AGGLOMERATED CORK

FORMED BY PACKING CORK PARTICLES INTO A MOLD THEN COVERING IT AND SECURING IT TIGHTLY

CORK SHEETS ARE CUT AWAY FROM BLOCKS

In the experiments I have done with these materials, I have found more interest in the sheets than the wine corks. One reason being that I prefer this with the leather. I believe they are more interesting together.

12

IN A MODERN FACTORY SETTING

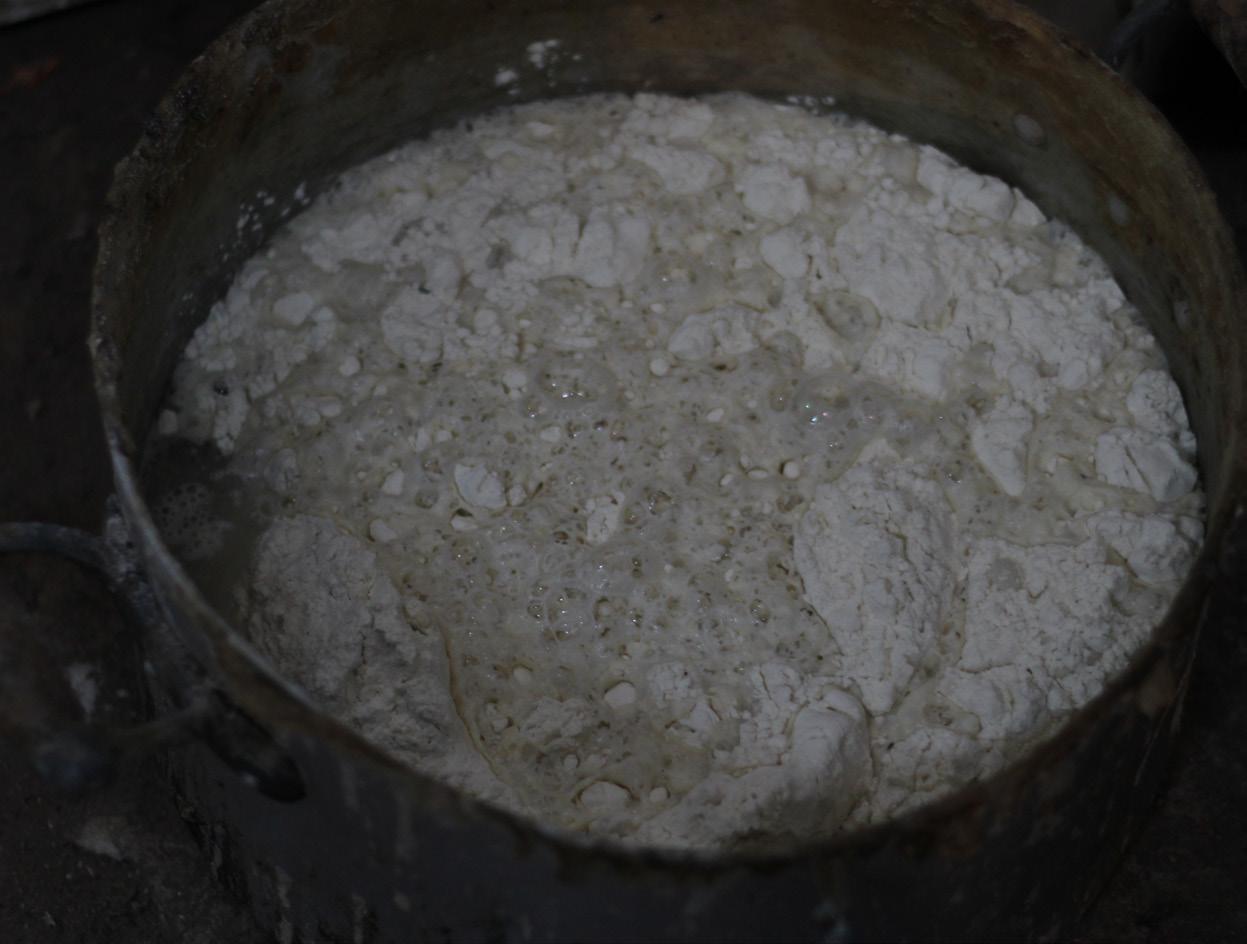

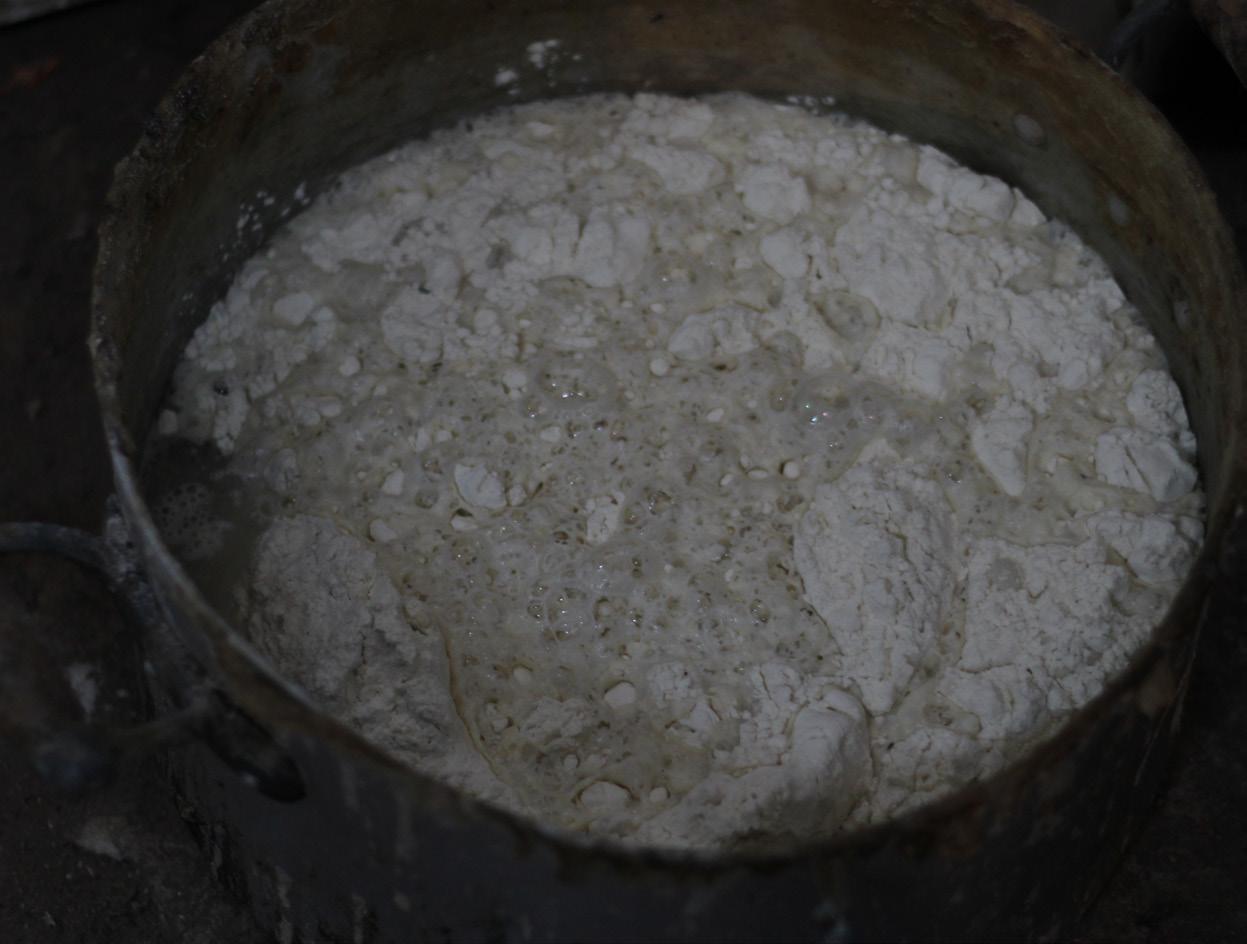

SOAKING

THE SALTED PRESERVED HIDE MUST BE REHYDRATED BY SOAKING IN WATER

UNHAIRING AND LIMING

THE SKINS ARE TREATED WITH SODIUM SULPHIDE AND HYDRATED LIME TO DESTROY THE HAIR OR WOOL.

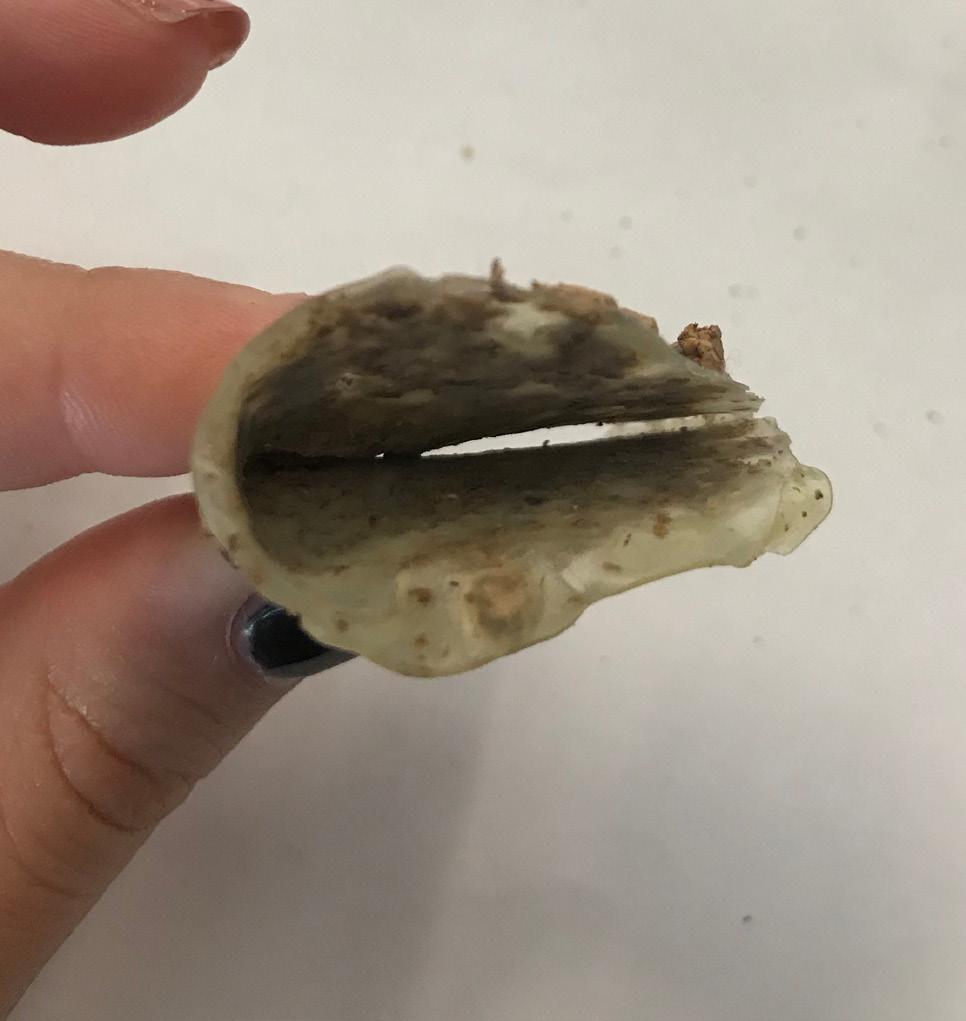

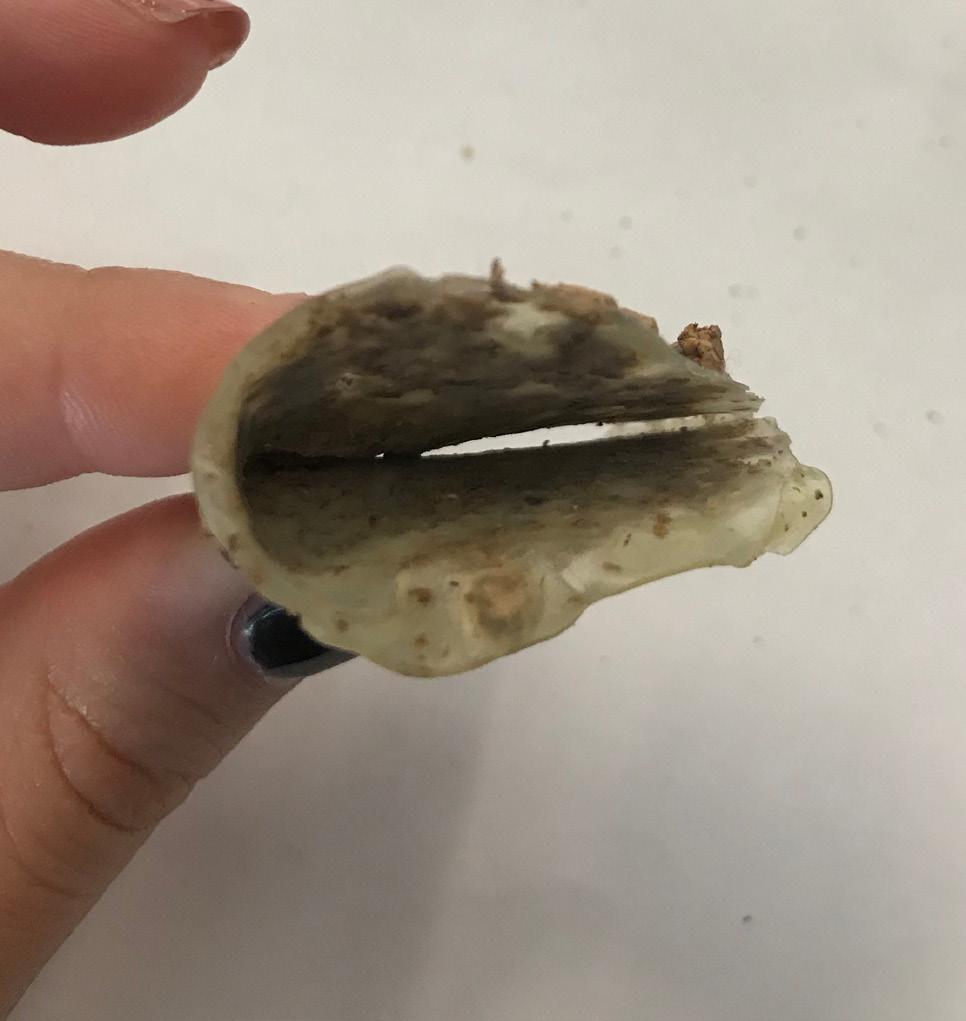

HERE THE STRUCTURE SWELLS AND A TRANSLUCENT AND JELLY LIKE MATERIAL FORMS. IT IS CALLED ‘WET BLUE’.

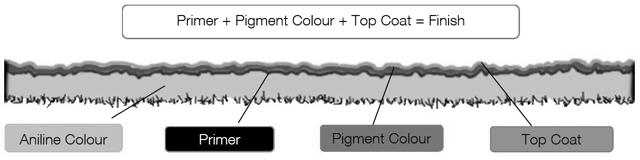

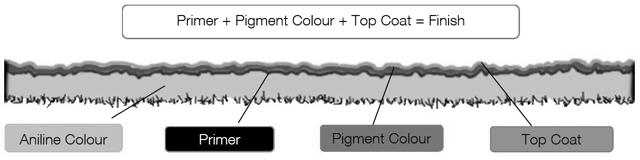

FINISHING

THIS WILL BE DOWN TO THE DESIRED AESTHETIC FOR UPHOLSTERY, FASHION ETC. THIS MAY INCLUDE: RESINS, PIGMENTS, FILLERS, DULLERS, SMOOTHING, IMPLENTING PATTERNS. ALL TO THE CUSTOMERS REQUIREMENTS.

DRYING

THE DYE MUST BE ‘FIXED’ TO THE MATERIAL. LEATHER IS HUNG ON FRAMES AND DRIED IN HEATED TUNNELS FOR FOUR TO SIX HOURS.

PRODUCTION TIMELINE OF LEATHER

13

DELIMING AND BATING

WEEK ACIDS ARE USED TO LOWER THE PH AND REDUCE SWELLING. IT IS TREATED WITH BATING ENZIMES TO CLEAN THE GRAIN AND MAKE IT SMOOTH AND SILKY.

PICKLING

TREATED WITH SULPHURIC ACID TO OBTAIN THE DESIRED PH FOR THE BEST PENETRATION OF THE TANNING AGENT.

TANNING

THE MOST COMMON TANNING CHEMICALS ARE CHROMIUM TANNING SALTS, VEGETABLE TANNINS AND GLUTARALDEHYDE.

FATLIQUORING

SMALL QUANTITIES OF OIL ARE ADDED TO CHROMIUM TANNED LEATHER BECAUSE THEY WILL DRY OUT HARD AND CRUSTY IF NOT.

DYEING

CHRONIUM TANNED LEATHER IS BLUE IN COLOUR AND MUST BE TANNED TO OBTAIN THE DESIRED COLOUR. THE DYE COLOUR ACTS AS A BASE COLOUR FOR FINISHING.

MECHANICAL OPERATIONS

HERE THE WATER MUST BE SQUEEZED OUT OF THE LEATHER.

14

IN A TRADITIONAL SETTING

THE SKINS ARE BOUGHT TO THE TANNERY FROM THE SLAUGHTER HOUSE ON DONKEYS

THE SKINS ARE PUT IN WHITE VATS WITH WATER, LIMESTONE AND PI GEON DROPPINGS FOR 3 DAYS

THE LIMESTONE REMOVES HAIR AND THE ACID IN PIGEON DROPPINGS SOFTENS THE SKINS

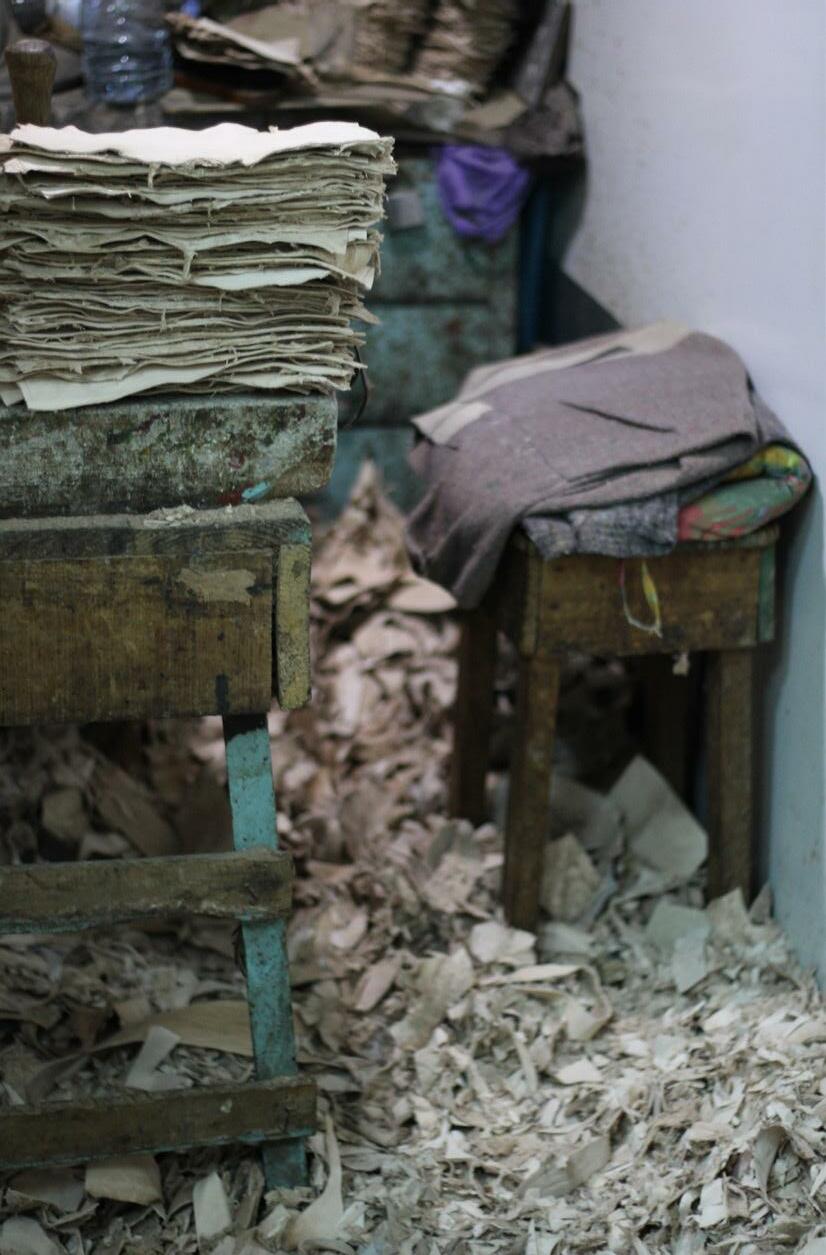

These are my own photographs taken in Fes, Morocco whereby there are some of the biggest traditional leather tannery.

PRODUCTION TIMELINE OF LEATHER

15

THE SKINS ARE WASHED IN WATER AND THEN MOVED TO THE COLOUR VATS

THE DYES USED ARE NATURAL AND MAY CONSIST OF RED POPPIES, OR ANGE HENNA, YELLOW SAFFRON, BLUE INDIGO ETC.

THE DYES ARE MIXED WITH ALUM STONE WHICH HELP SET THE COL OURS

SKINS ARE THEN TAKEN TO THE ROOF FOR DRYING BEFORE BEING TAKEN TO STORAGE

IN THE BUILDING THEY ALSO HAVE THE EQUIPMENT AND MATERIALS TO MAKE PRODUCTS

THEY ARE NEXT TAKEN TO STORAGE WHERE THEY WILL BE CUT

16

POST TANNERY MAKING A LIVING

Preparing the softer material. Leather pieces are backed onto thick, soft fabric

The images above are my photographs taken in Morocco of the adhesive being made for the use of sticking leather together. The ingredients were: 5 litres of water, 1 kg of flour and 13 grams of ash.17

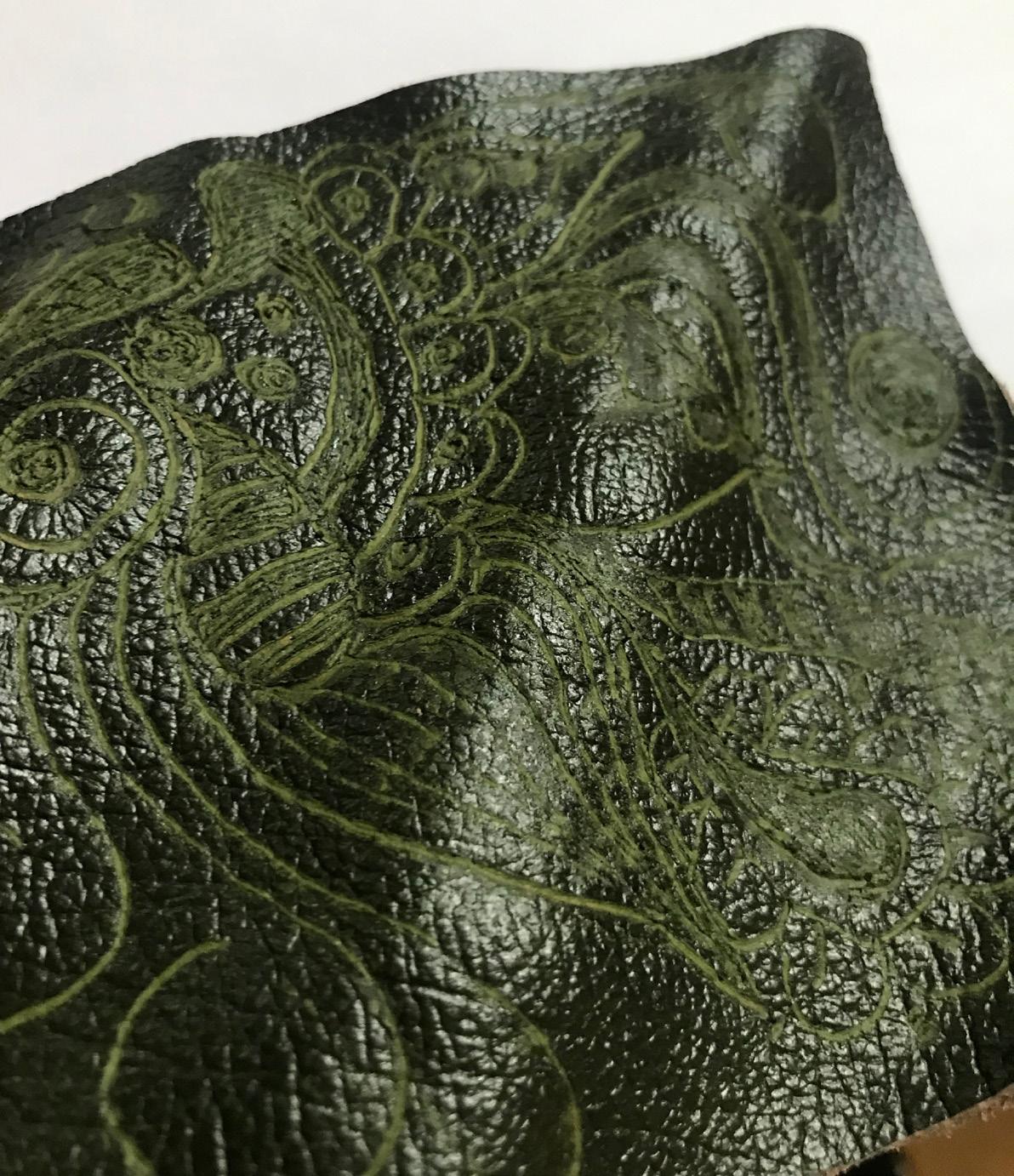

These are cut into neater squares. The leather is embossed with patterns and decorated with various sewing techniques; ready for creating finished products.

Embossing the leather is done by heating the iron pattern stamp and then pressing it firmly into the leather.

These images I took capture a small process in Morocco whereby the leather is made into a softer fabric by backing it onto a thick piece of soft material and then embossing it with patterns to then make finished products such as cushions, bags and more. The men that worked in this small space had very minor jobs such as cutting or sewing but similar to many other locals, it has to be done in order to make a living, even if it is very low pay. (Minimum wage in Morocco is £238.62/month)

In the experiments of leather, I will attempt some of the methods as shown above: joining fabrics together, cutting, sewing and embossing etc. Another technique I saw in Morocco was applying gold leaf to leather with a hot decorative wheel.

18

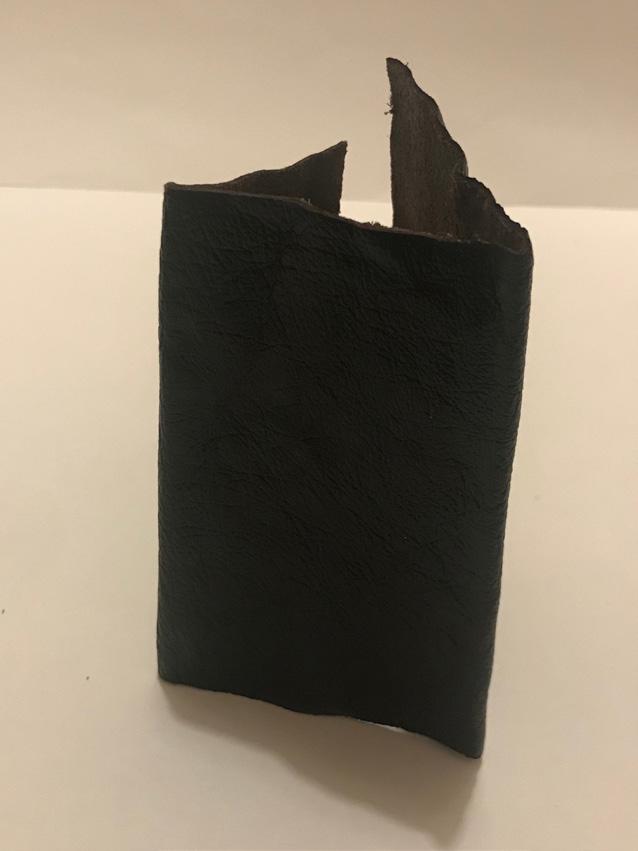

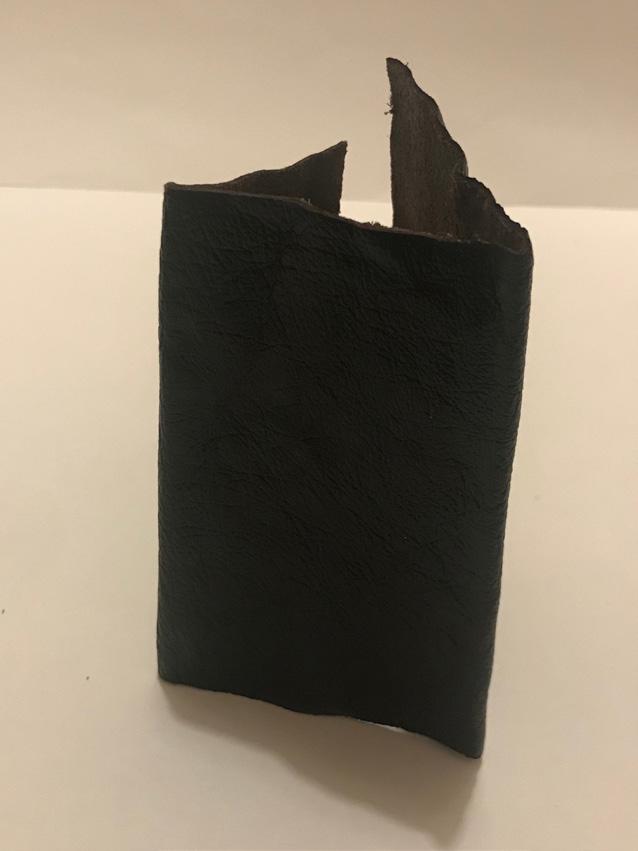

DETAILS OF MATERIALS

LEATHER SCRAPS

Bag of mixed quality, sizes and colour leather scraps. 100% genuine leather. Furniture upholstery scraps. Brought from Sofas4u. 1kg bag.

Cost - FREE (postage £2)

THE MATERIAL

THE

LEATHER I HAVE SOURCED

Black - Black/Red - Blue - Brown

The black leather from the bag.

19

In the experiments I have mostly used black cow leather as the bag contained about 90% of this. Therefore this is what I had access to. I could have gone and brought leather of different colours and from different animals but I would like to be as sustain able as possible; by using scraps from furniture shops I am recycling a non-sustainable material. The size of the scraps restricted me from created larger scale experiements but this reflects from my point above.

COW GOAT

CAMEL

Common leather found in Morocco.

Hard Thick Thin

Soft

COW GOAT

CAMEL

Common leather found in Morocco.

Hard Thick Thin

Soft

20

TESTING THE BOUNDARIES OF BOTH MATERIALS INDIVIDUALLY

Before experimenting with Cork and Leather together, I will first look at the materials individually. I believe that by doing this, I will have a better understanding on their properties including strengths and weaknesses, advantages and disadvantages, durablity and more. This will have better implications on the experiments done with them together in the next chapter.

The aim for these experiments is to learn about the physicality over the aesthetic. While these investigations take place, I hope to stumble upon unexpected qualities and weaknesses which will assist in the design stage where by the materials are combined together.

MATERIAL EXPERIMENTS PART I

CORK AND LEATHER BAGS FOR SALE (PORTUGAL) LEATHER BAGS FOR SALE (MOROCCO) 21

1. CORK 2. LEATHER STRENGTH CORK IN THE FOLD DECONSTRUCTION RECONSTRUCTION DECORATING DECONSTRUCTION RECONSTRUCTION FORM THROUGH DECONSTRUCTION 22

It can be seen below that cork is very weak in tension. I stacked three 4mm cork sheets on-top of each-other (12mm) and pulled at either side. The result was that it immediately sheared.

STRENGTH

TESTING TENSION AND FOLDING

a b CORK 23

Later on I experiment how the folding and tension of cork can be assisted by other materials to strengthen it.

f

Shown in the above images, once I had reached the point of (d) the cork began to tear when I folded it further. This is due to the nature of the agglomerated cork sheet being that it is 4mm thick and the particles are not firmly stuck together and therefore hold a lot of gaps between each-other which are vulnerable to breakage. However cork can be used in folding successfully, this can be done when the cork is much thin ner and made into a leather whereby it is stuck to a fabric backing. This has been used well in many fashion elements.

c d

e

24

Cork Leather is a sustainable material and now com petes with animal leather. Therefore this is a major contradiction in my two materials.

A MORE SUSTAINABLE LEATHER

A MORE SUSTAINABLE LEATHER

CORK IN THE FOLD 25

South African designer, Suzaan Heys, completed a collection of clothing, accessories and footwear made of cork. This was to show the timeless qualities of the material.

The 2013 collection was called ‘Doors of Perception’ to announce that cork is not a rigid material.

The material she used was cork leather which is created by slicing very thin sheets from cork blocks and backing with a supportive fabric.

Such form of cork shows that it is not a rigid material and its possibilities are high.

26

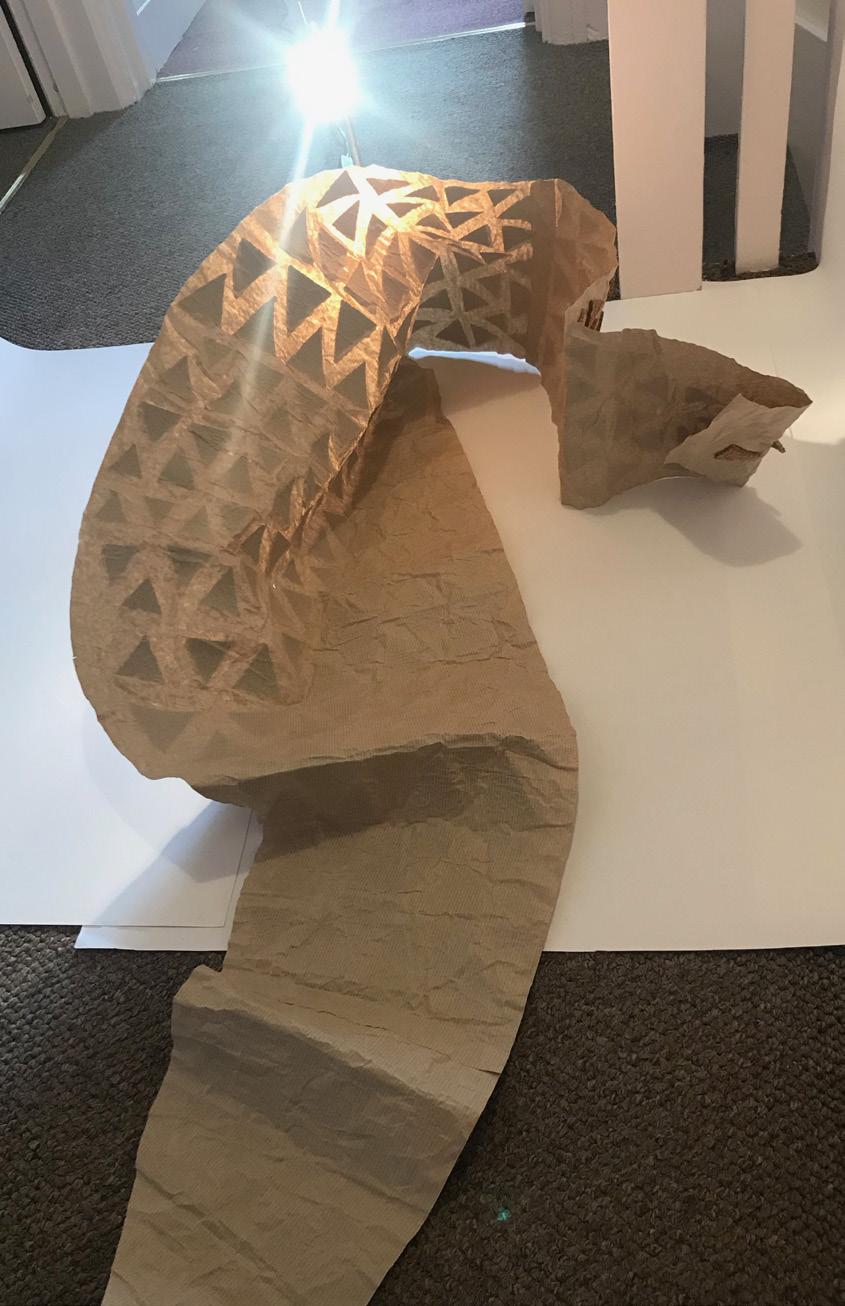

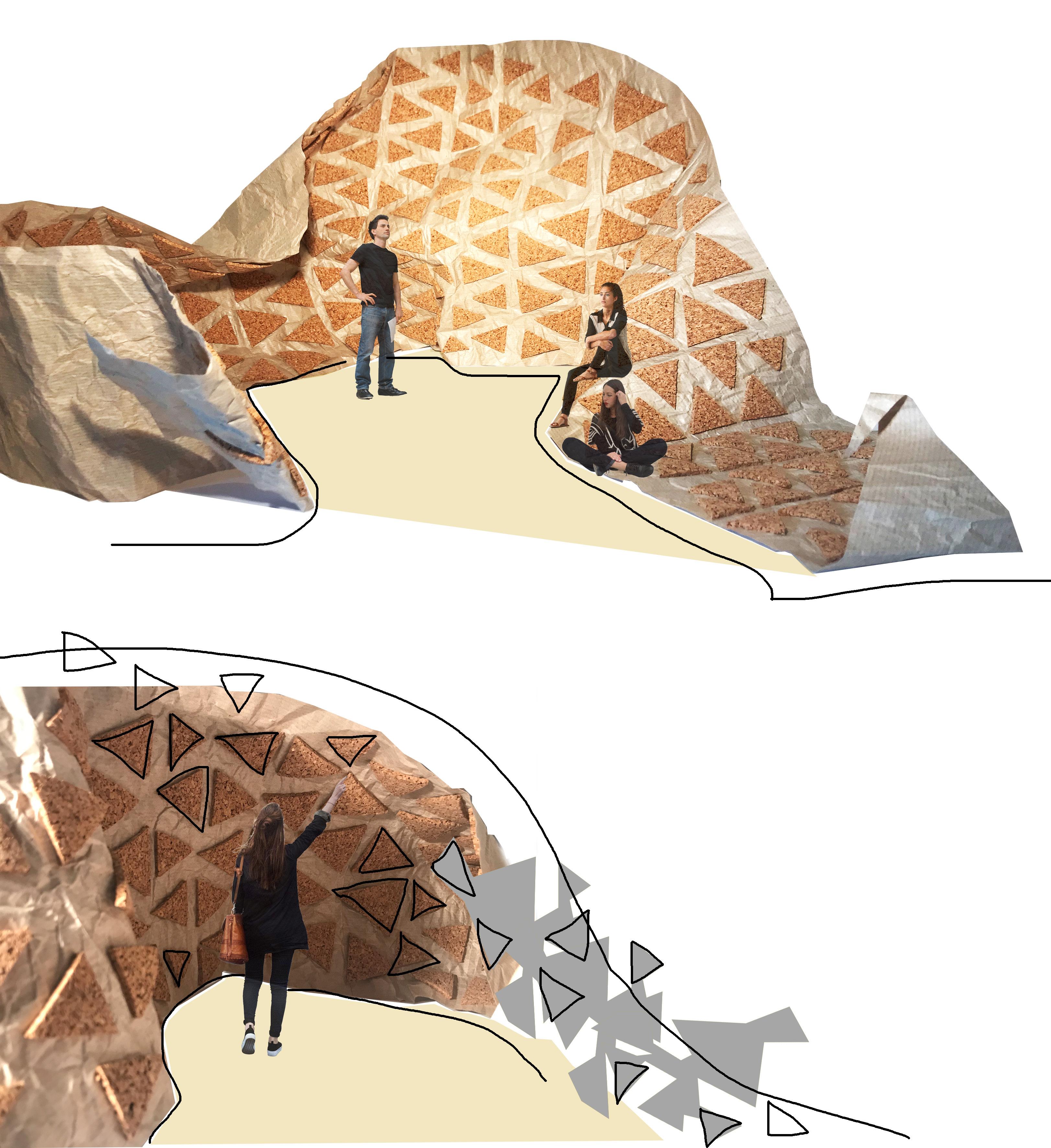

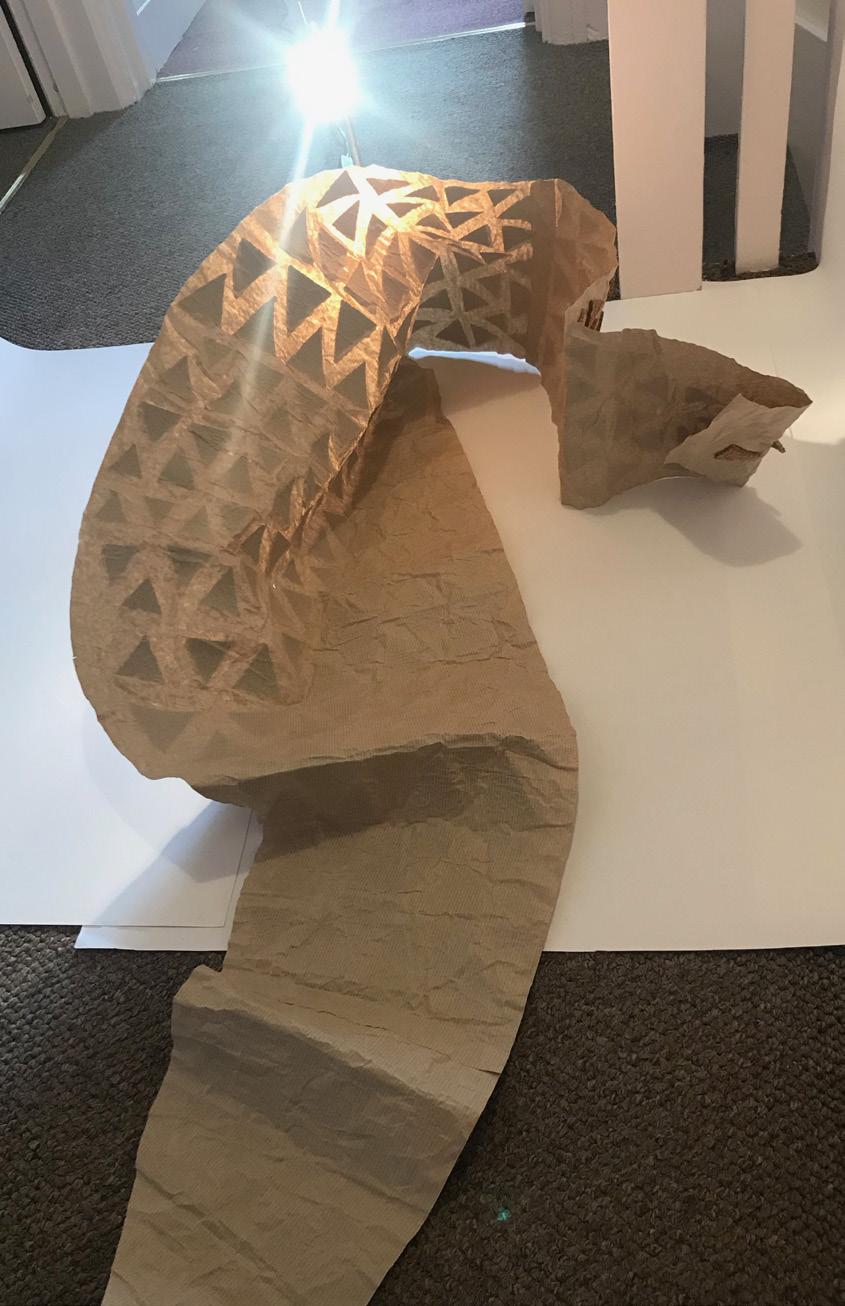

Due to cork being better at folding if it is in a thinner form, I wanted to create a fabric which played with the thicker material I have (4mm).

This was done by using small triangles cut from the 4mm sheets which were then stuck to brown paper using wood glue.

The result it has on a space is rather effective as it still has a rigid form providing great structure but has opportunity to fold and create more intimate spaces. Additionally, where the light comes through on the opposite side is very warm ing.

RIGID CORK IN THE FOLD

RIGID CORK IN THE FOLD

27

28

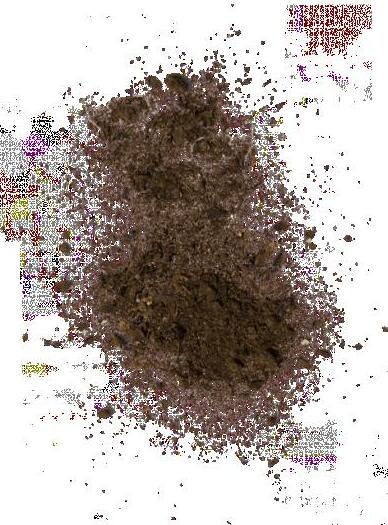

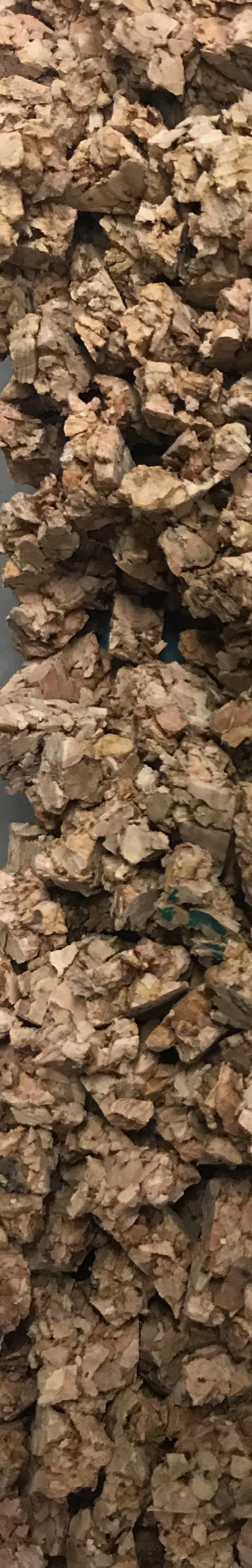

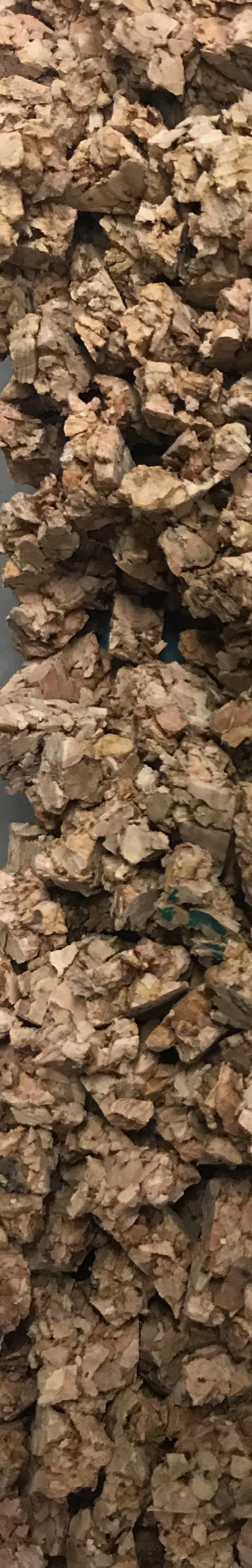

After seeing how easy the agglomerated cork sheets broke apart, I decided to try and see how far I could take this.

MANUALLY BROKEN WITH HANDS broken up with hands to separate the particles where they have naturally glued themselves together.

MANUALLY BROKEN FOR LONGER breaking up the pieces into finer particles.

MACHINE BROKEN IN BLENDER

I put the cork into a blender and found it gave a more uneven result with some fine pieces and some bits that were almost

DECONSTRUCTION

BREAKING DOWN AGGLOMERATED CORK SHEETS

29

The cork shown above was broken down in a blender. It took about 2mins to blend it to this point from the large pieces of the sheets. Therefore it is very possible to break it down further without effort. However I liked the size and texture of these pieces so therefore have used it the most in further experiments.

30

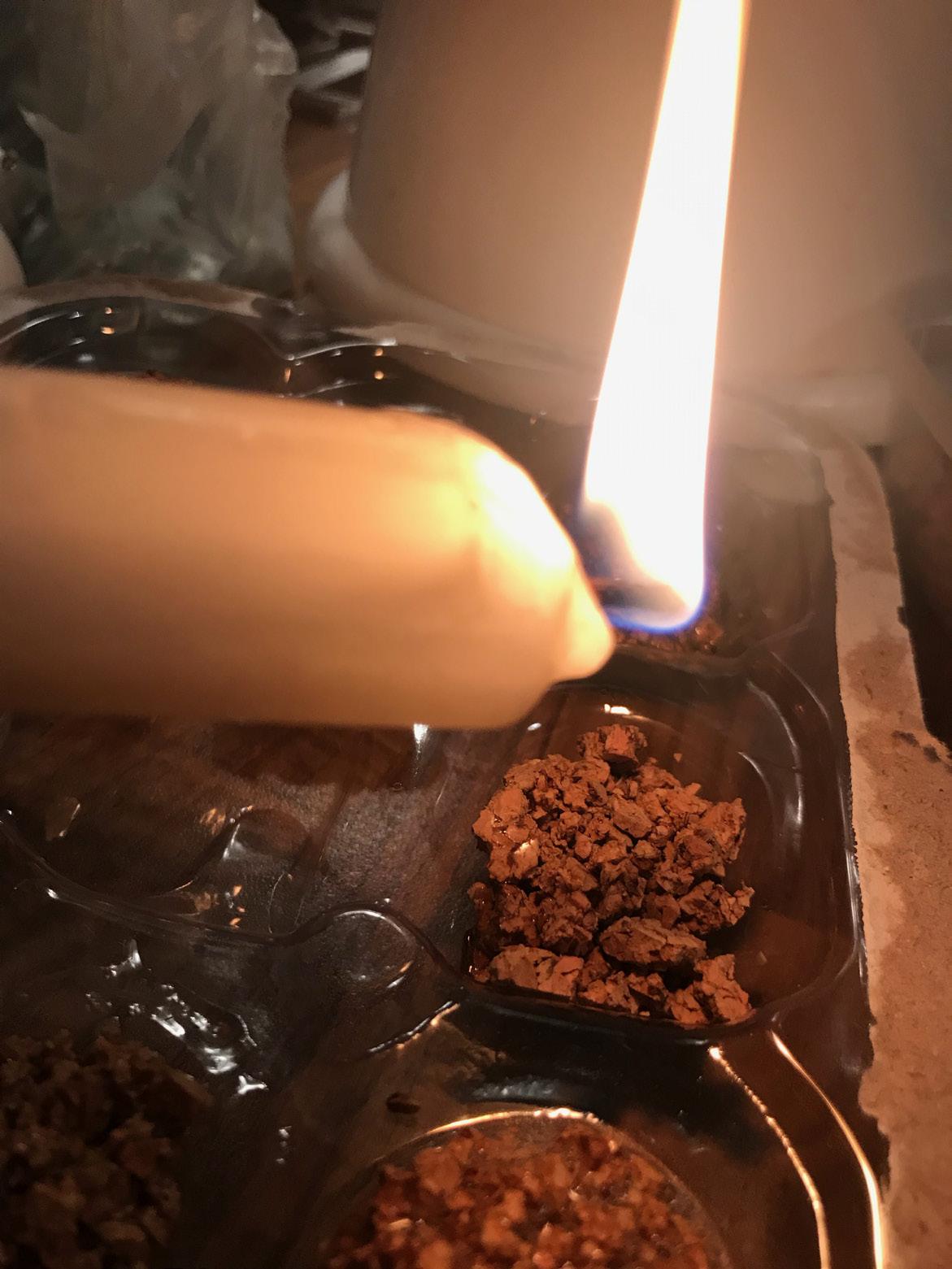

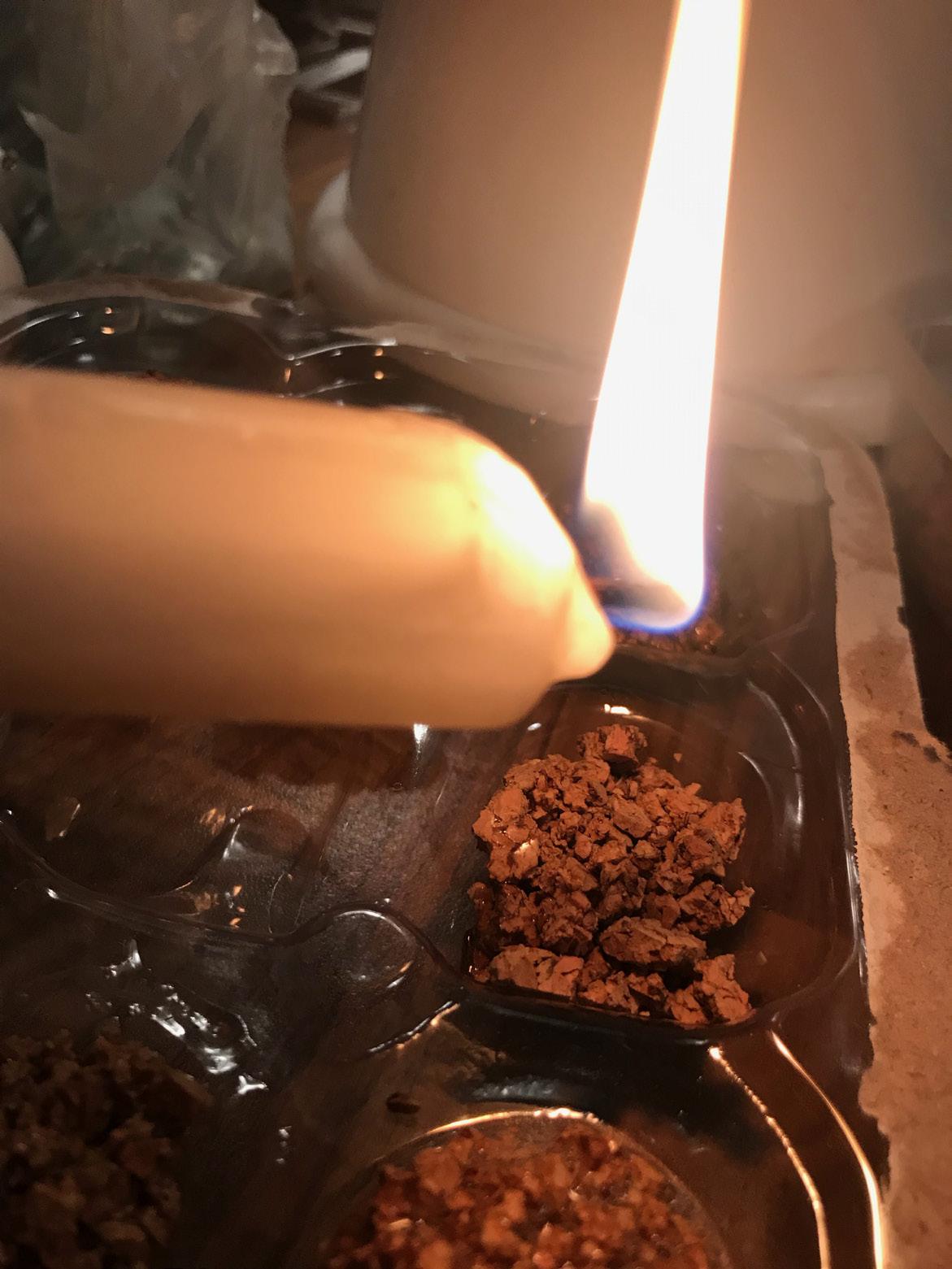

These experiments were done to see how I could re-stick the cork particles de-constructed in the blender. However I also wanted to test if I could create a 3D shape from a mould with the cork. This is why I chose this plastic sheet due to the deep holes it had, almost like an ice-cube tray. The result reminded me of rocks and the wax I found to be most successful.

RECONSTRUCTION

RE-FORMING PIECES OF CORK

31

COLOURED PVA GLUE WITH FOOD COLOUR ING 1:1 ratio of glue to cork 2:1 ratio of glue to cork 3:1 ratio of glue to cork WAX PVA GLUE 1:1 ratio of glue to cork 1:2 ratio of glue to cork 3:1 ratio of glue to cork Mixed cork and wax Cork and wax in layers Wax poured over cork A B C G D E F H I 32

F

Wax poured over cork

Most of the cork fell off as it was not attached to the wax. This is due to the wax not reaching the bottom of the tray.

E D

E D

Cork and wax in layers

I poured wax into the tray and then layered cork on-top, this was repeated twice and then topped with wax. This was the most successful to me as the mould was success ful. The cork showing through the wax is good as it is still visible but supported.

Cork and wax mixed

This cube was made by combining the wax and cork in a mix and then setting in the tray. This was hard as the wax dries quickly. But it was a successful mould.

RE-FORMING THE BARK

F

33

1:1 ratio of glue to cork

This was the second most success ful of these three. The cork has stuck with the glue however it did not keep as good as a mould.

1:2 ration of glue to cork

This was the most successful with the cork being stuck together by half the amount of glue. This allowed it to be light enough to create a delicate mould but enough to keep it stuck together. It held it’s shape best.

3:1 ratio of glue to cork

This was the least successful. It was too wet and the glue became too heavy for the cork to keep a good form.

A

1:1 ratio of glue to cork

This was the most successful. The die coloured the mould and some of the cork an the shape held the best.

2:1 ration of glue to cork

Due to the food-colouring changing the consistency of the glue, it made it more watery and the bottom of the mold would not dry (4 days and it still wasn’t) Therefore the top fell apart from the bottom.

3:1 ratio of glue to cork

The same situation with B applied to C. However the dye was more successful with more glue as this is what the dye was added to.

H

B

G

I

C

34

THE CONSTRUCTION OF A FLEXIBLE BARK a. b. c. 35

Before latex dried

The images show how I reconstructed the different sized cork particles with rubber latex. The result was that the light passed through a. than the others with c. having the least light passing through. However c. was better in the fold which was successful in strenghtening the cork sheet compared to when it was it was in its previous state. The latex and cork became very easy to cut tidy pieces from too.

36

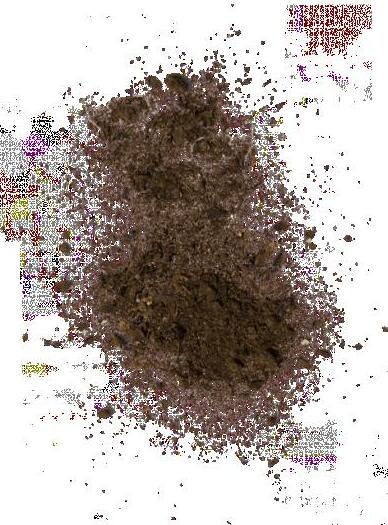

Once I had the cork broken down to a desired amount, it reminded me of soil and back on the tree bark in which it is from. In which case I began thinking about the natural environment. This could be of great relevance to the sustainability theme.

I then wanted to preserve the particles with an adhesive, however the latex gave an unpleasant and dull finish, I was looking for a more delicate look.

A MORE DELICATE APPROACH WITH ADHESIVE 37

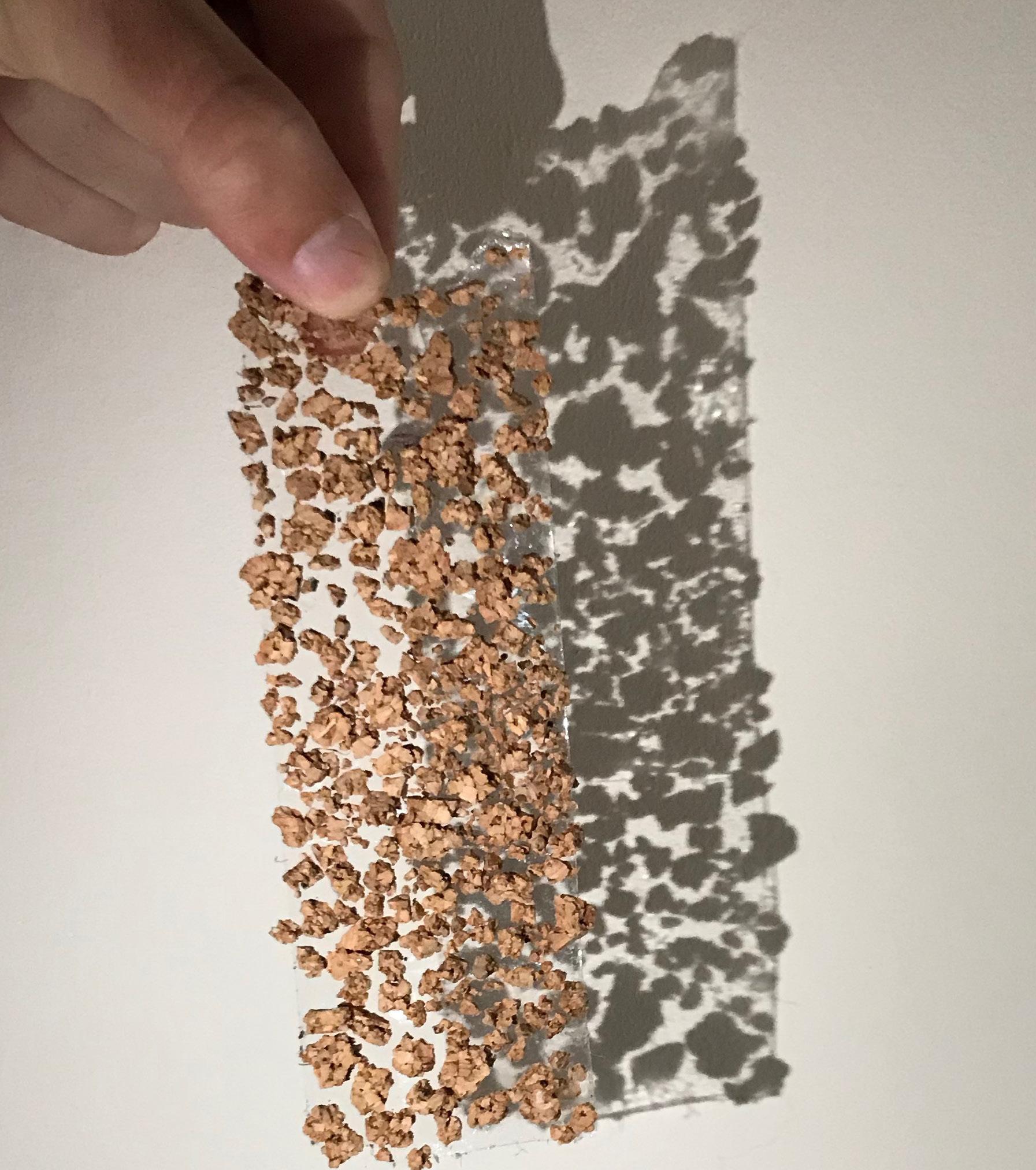

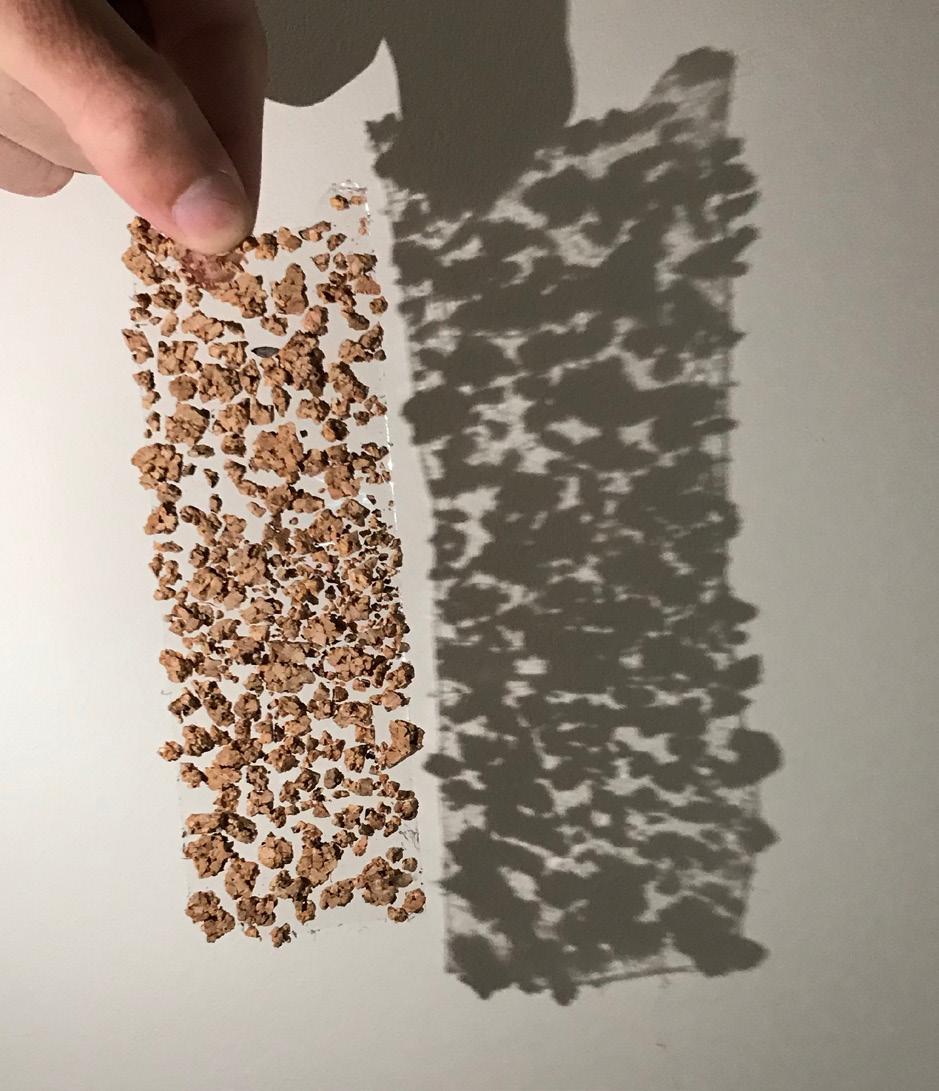

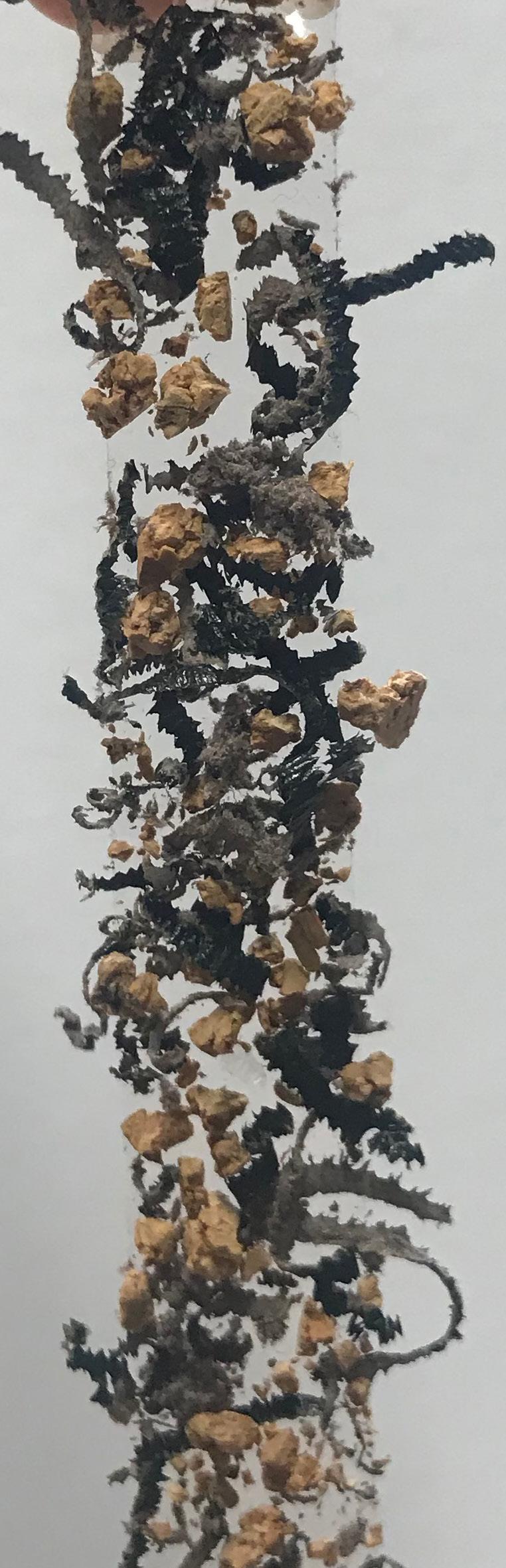

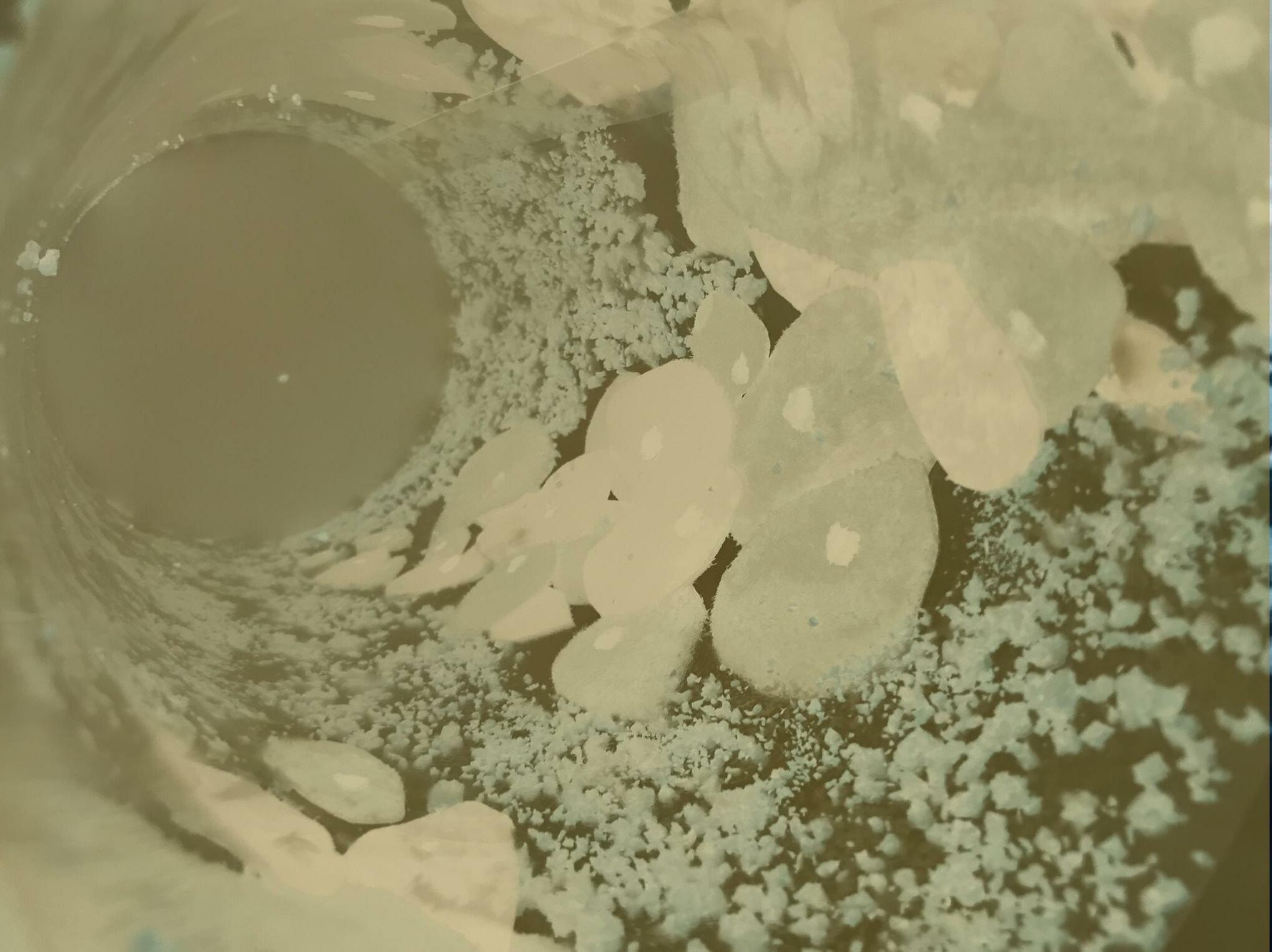

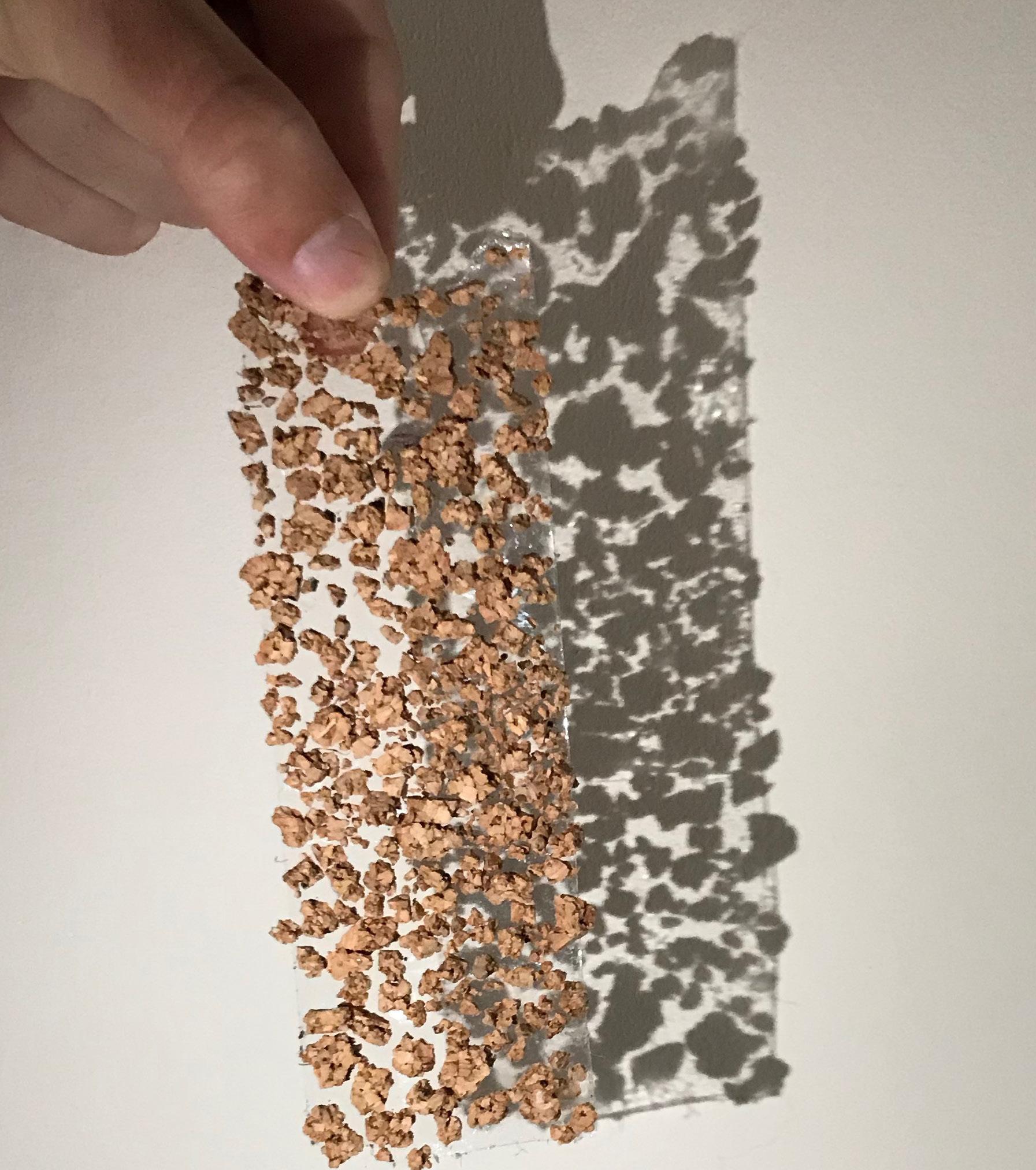

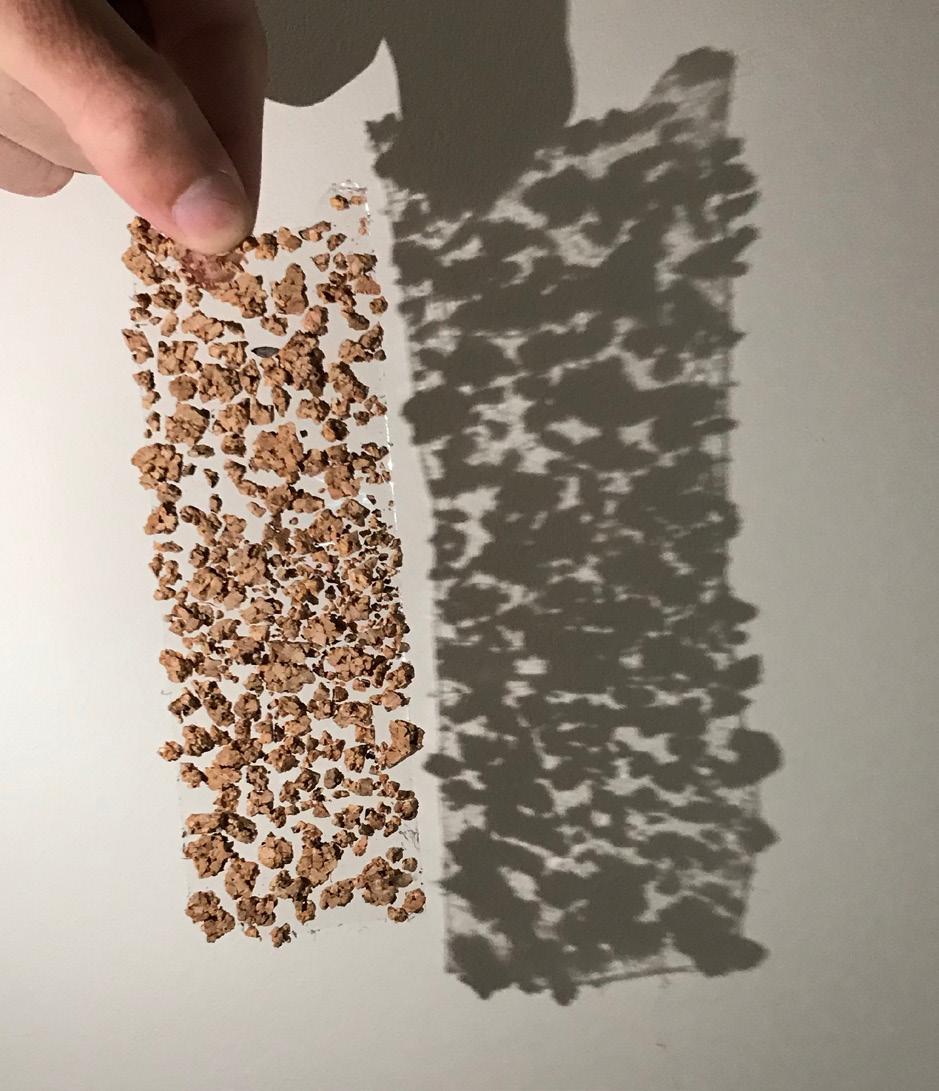

I decided to pick up the particles with sellotape, this was successful in providing a more delicate finish. Therefore I would like to experiment with this on a larger scale.

38

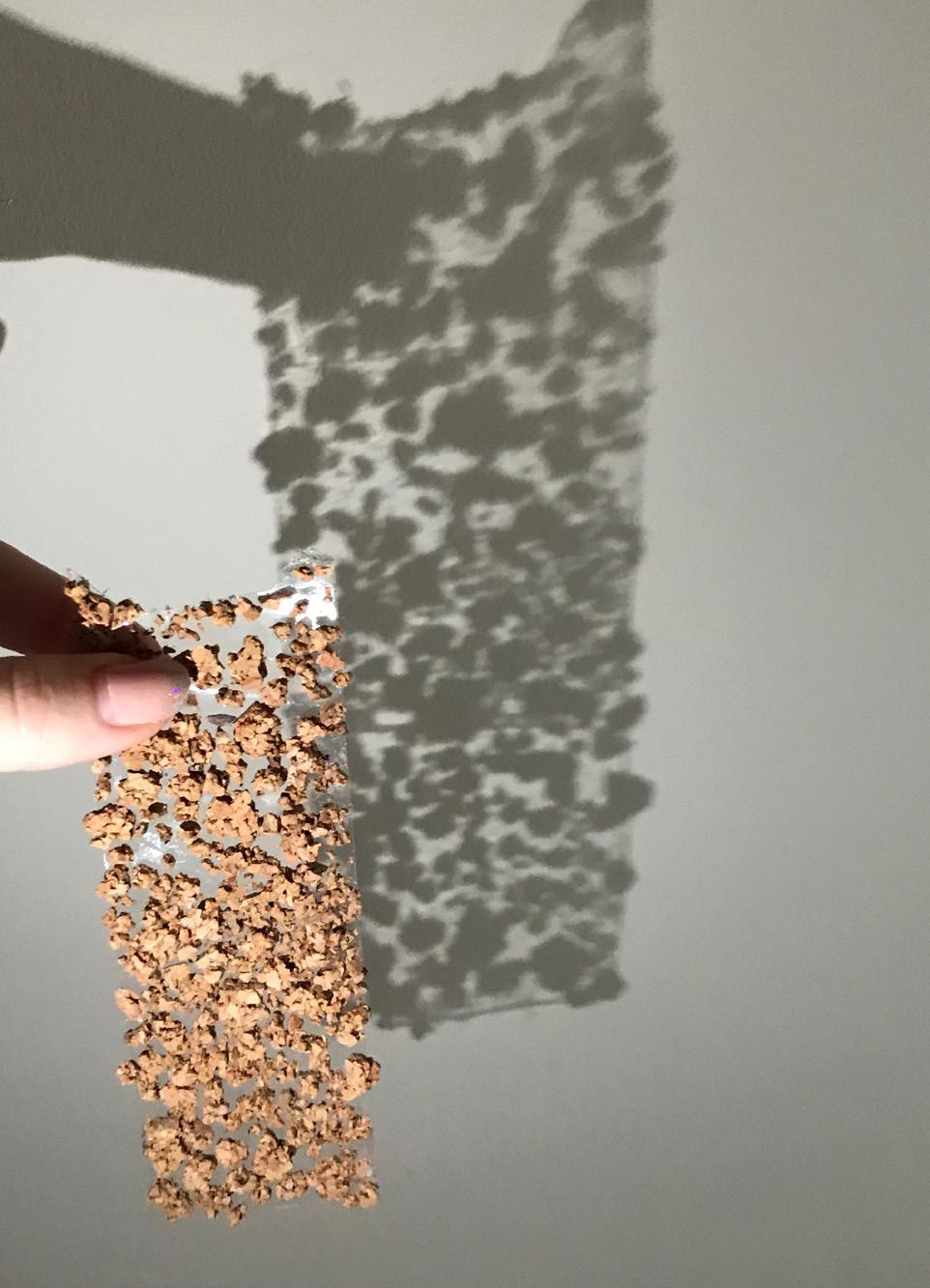

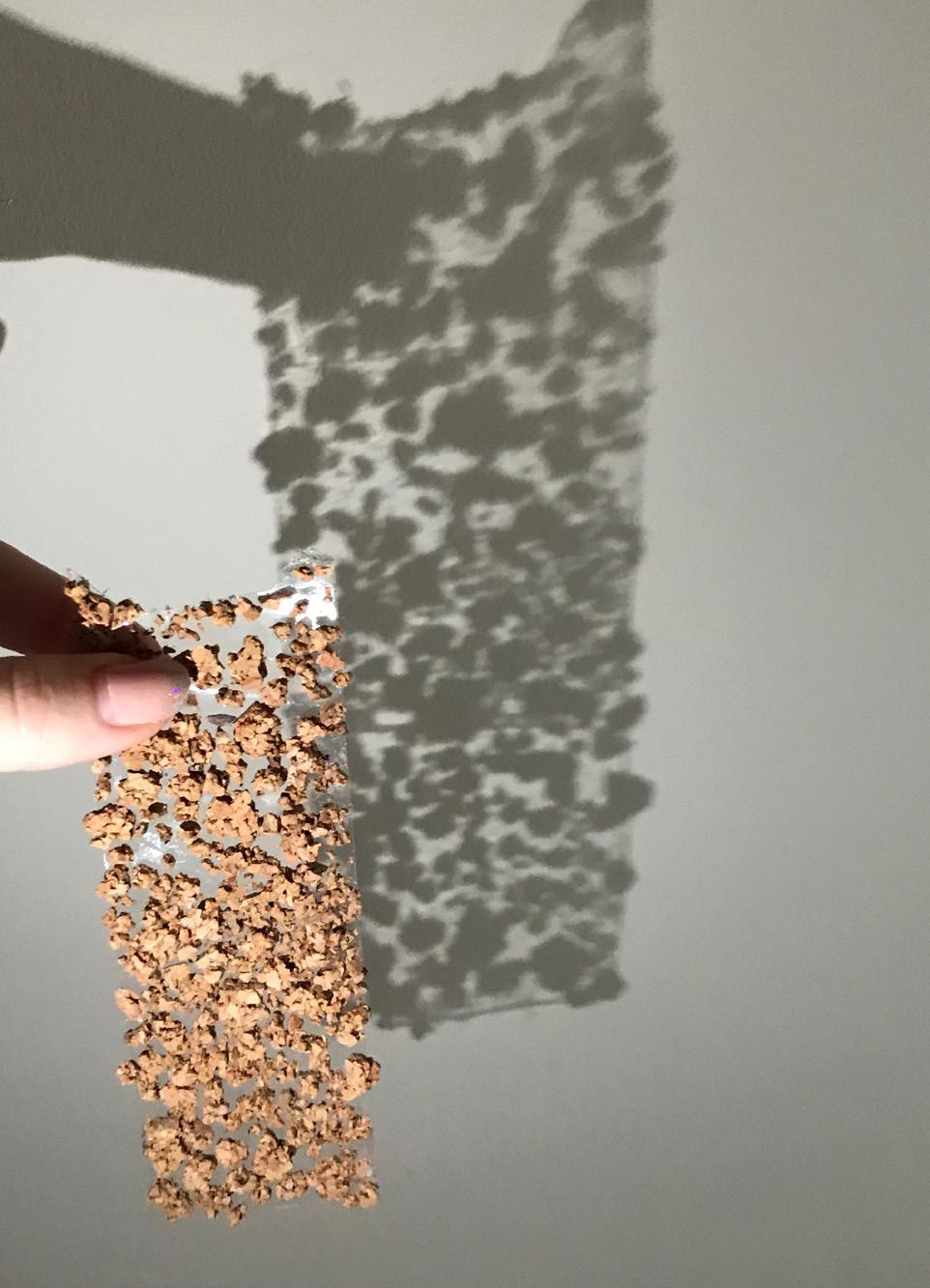

THE EFFECT WITH LIGHT

THE MATTER IS IN YOUR HANDS

39

The images show how lighting displayed onto the cork strip can cast a natural and beautiful shadow. The shadows give a similar effect of shadows casted amongst trees. The light passing through may appear as how they light passes between leaves and natural objects.

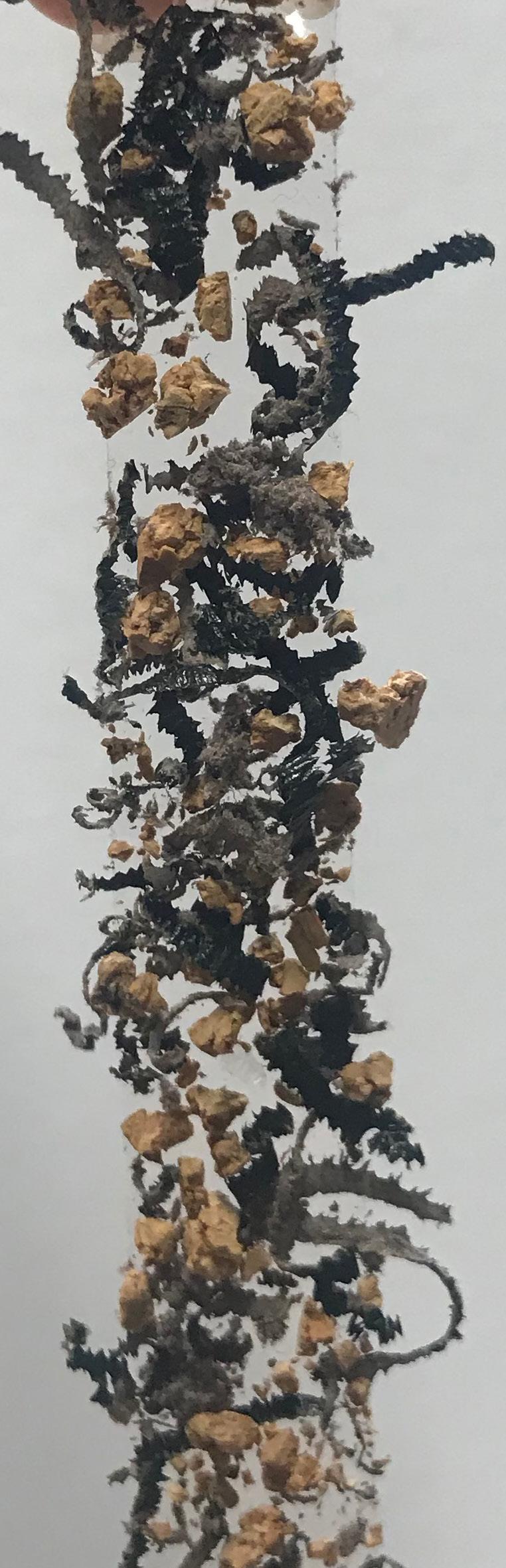

The cork granules are stuck to this strip due to it being sellotape.

The cork granules placed onto this plastic explain how the matter of the rubbish comes from our hands and how we respond to how we dispose of such matter. It provokes the thought of how such plastic cannot be recycled and so we should switch to alternatives before it is too late. So that plastic can stop filling our oceans and forests whereby it is having effect on the natural world surrounding it.

40

A candle placed in the heart of the tube to represent the life of the tree and all that runs off it.

I decided to create this clear cylinder with the cork particles attached to it by spray adhesive, to represent where the cork has come from. That being the bark of a tree which has been removed and gone through several processes, including crushing up pieces and then packing to form blocks. I believe this makes a viewer rethink where the product has come from which can often go without thought.

This has begun my thoughts in creating something which encourages the viewer to think of where they get products from and whether it is ethical. Cork is a popular product at the moment due to its ethical qualities. However my other material leather is rather the opposite. Some shops are now beginning to offer alternatives such as faux leather and in Dr Martens, a pair of vegan leather boots.

Therefore there are acts being taken on how we can be more ethical, preserve our natural environment and more. The spacial element I could create may encourage this thought process.

A TRANSPARENT TREE TRUNK

41

To the right it shows the pieces from Metamorphosis, an artwork done by Keiko Sato. It captures memories of scenes in nature.

“When I create a work, I first follow the nature, structure, quality and the meaning of materials and objects that I am dealing with” she says further, “In the end, I use this emotional meaning and the organic structure of objects to give form to my work.”

Keiko

Keiko

Sato - Metamorphosis

Casting shadows of the environment around the tree. The spread of its roots and show ing how its much more than just the tree that is affected with man created disasters, but the whole environment around it.

42

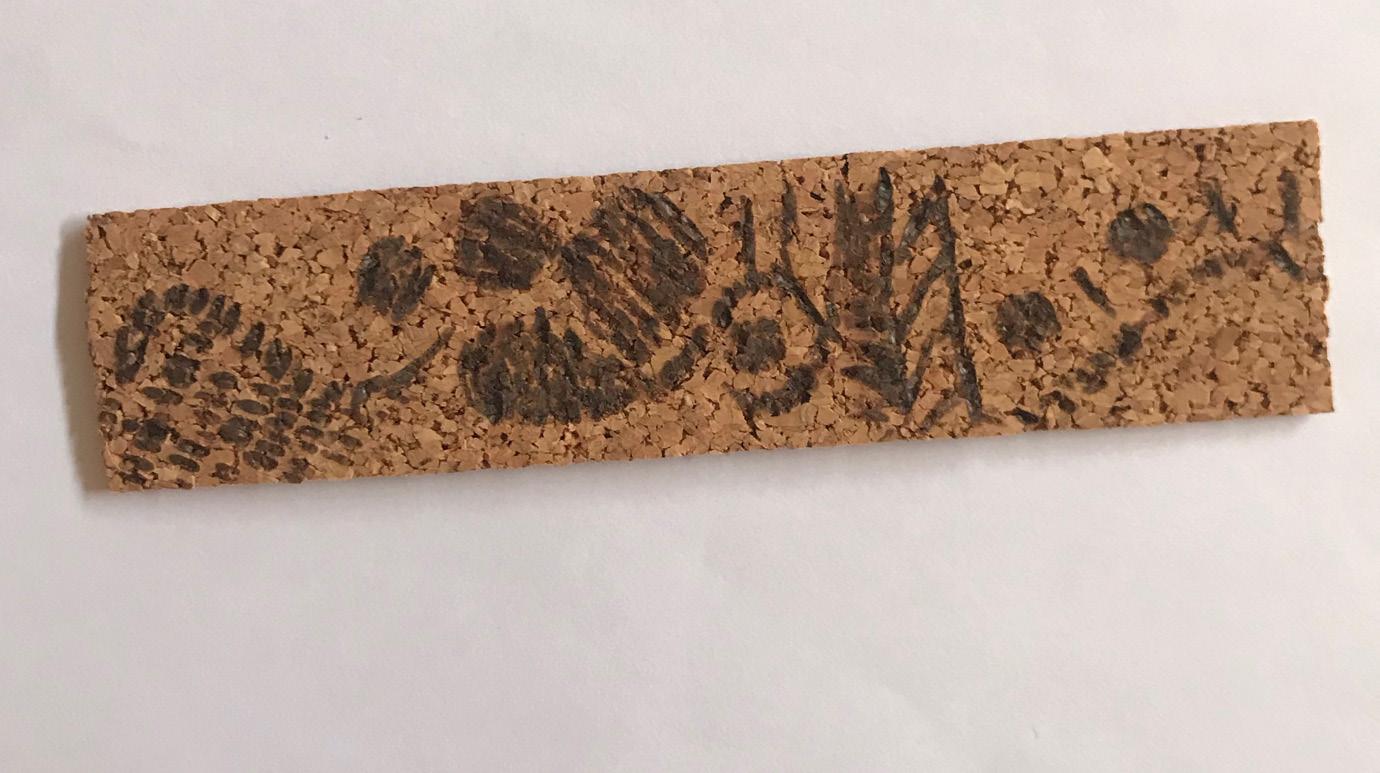

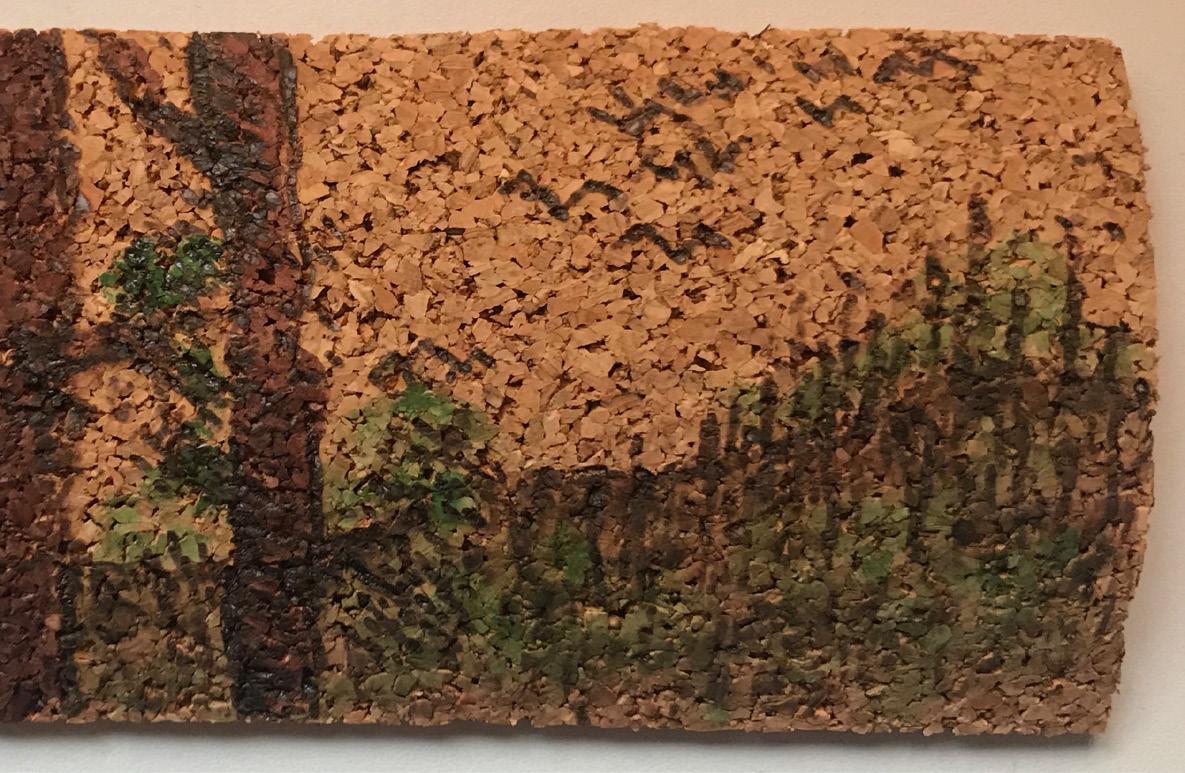

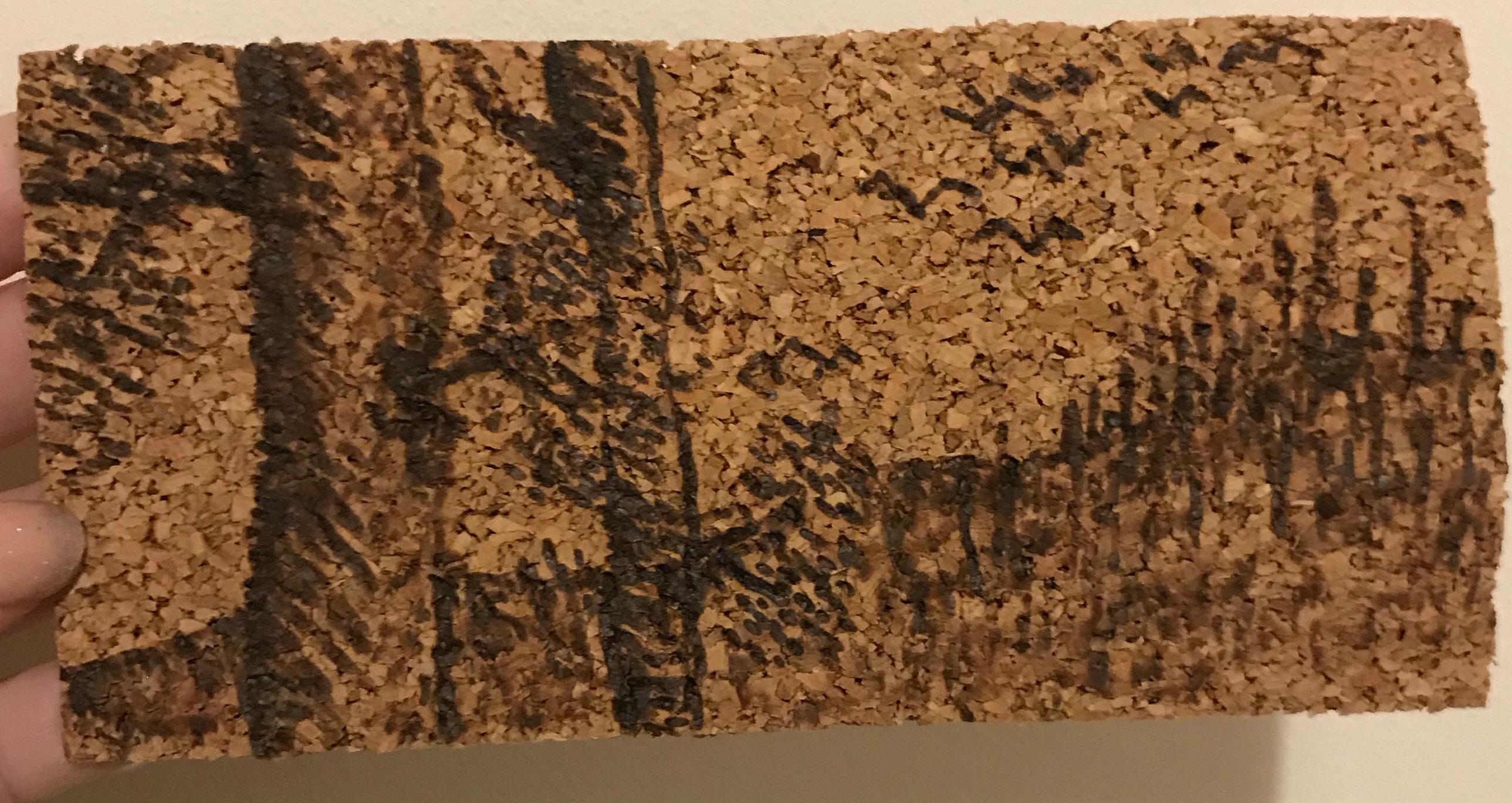

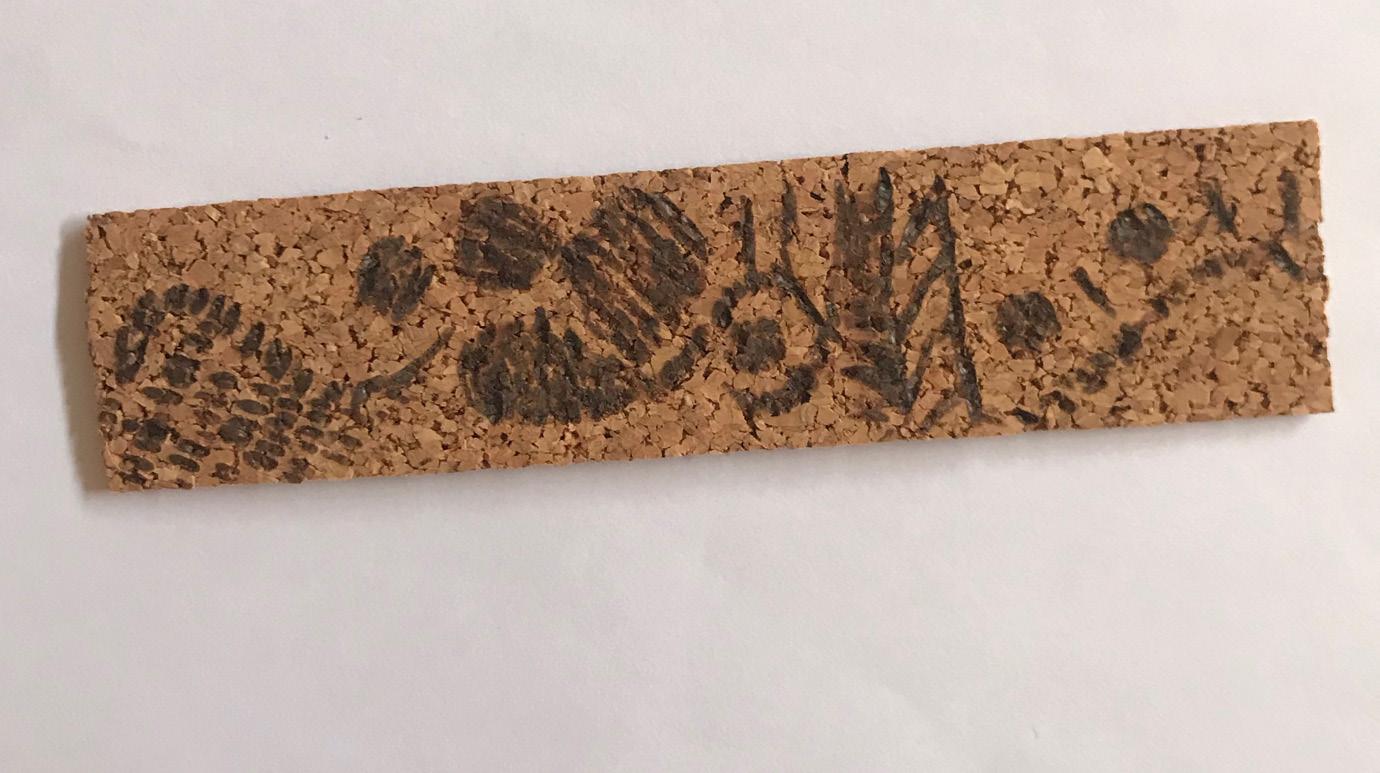

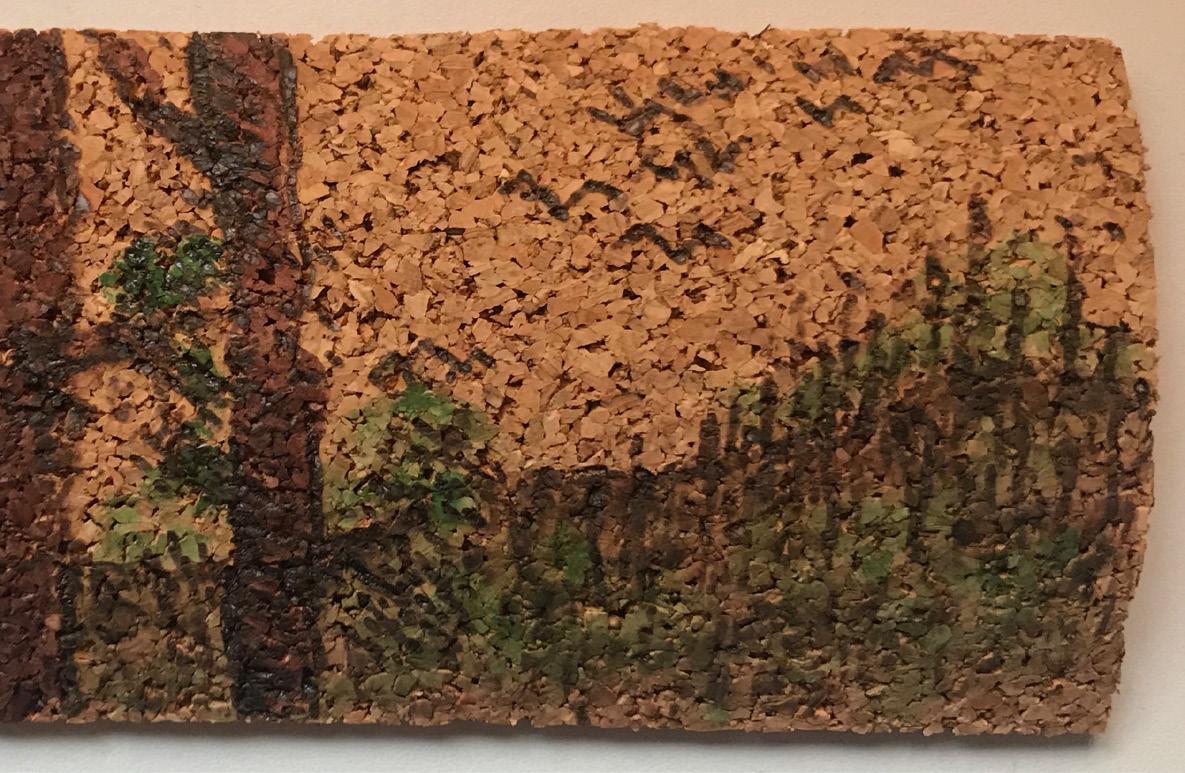

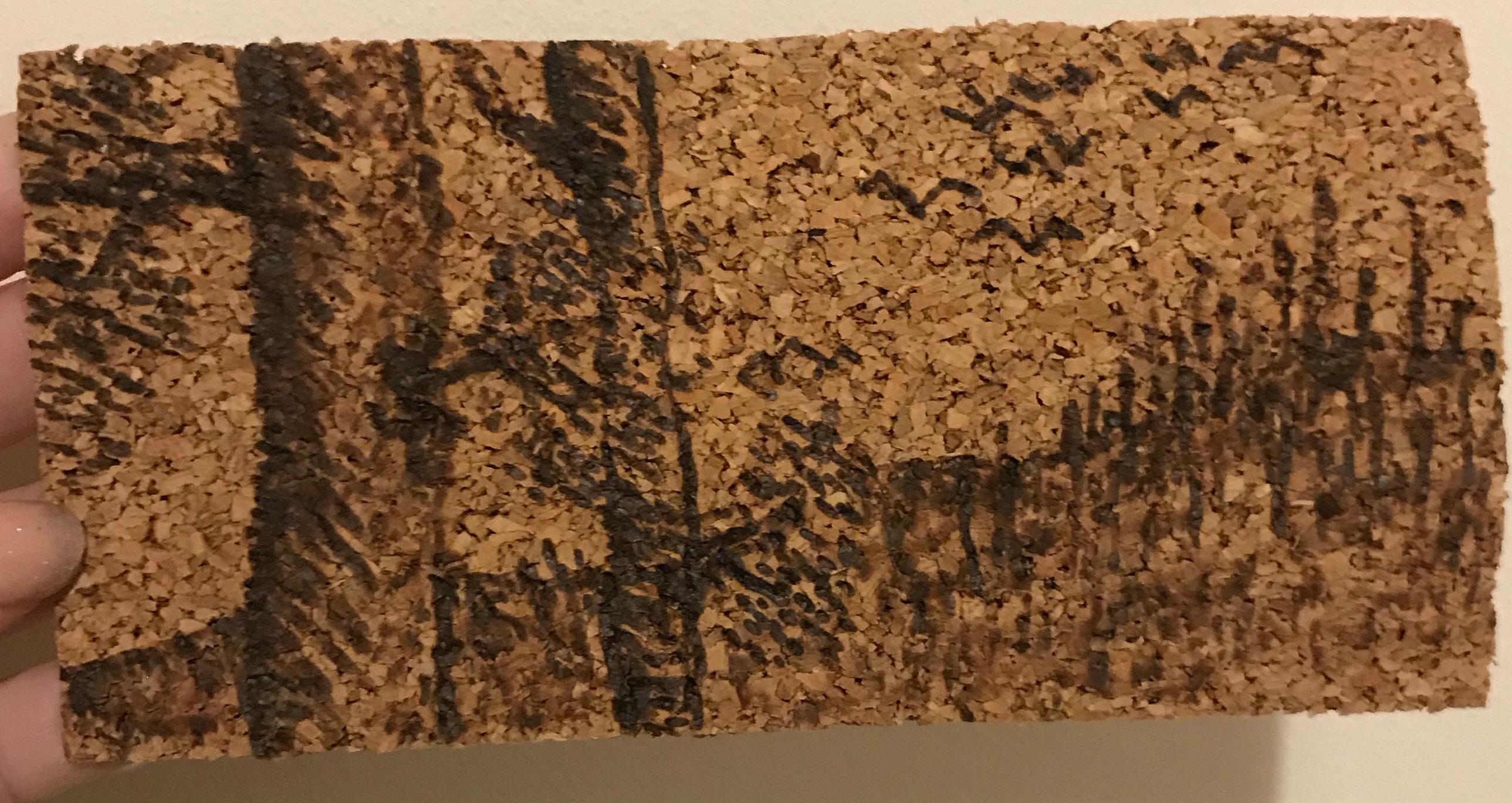

I wanted to see how I could decorate the material I bought. Burning it became of interest to me as cork is known for many advantages in building, some of these include good insulation, sound proofing and fire resistance. Therefore I was intrigued if a soldering iron would be successful in burning patterns into both the agglomerated cork sheets and wine corks; or whether due to its good fire resistance it would fail.

Soldering the wine cork was more successful than the cork sheet. This is because the lines appeared more like dots on the sheet due to the nature of the agglomerated cork, it was not a smooth canvas to burn neat patterns onto. However even though the wine cork was better in this sense, it was also difficult considering its size and curvature.

DECORATING THE MATERIAL PYROGRAPHY

43

Pyrography (the term means writing with fire)

Pyrography or wood-burning art is almost a lost art where the beauty of it comes from the warm organic beauty and the connection to nature. It was at its best in the 19th Century but dates back to the 17th Century. It is achieved by using various temperatures with different heads of the tool, and the way the iron is applied. After the design is done, the artists would usually dye the canvas (usually wood). Traditionally it can be done using any heated metal implement.

Below is my own attempt. It shows an image of two trees in the foreground with the view of a hilly forest in the background and birds flying in a flock.

After creating the pyrography image on the cork, I thought it would be interesting to add ink to it to give more depth with colour. The ink was very successful on the cork as it instantly dyes it and absorbs into the granules leaving it with a vivid colour. However it was difficult to blend the colour out.

Brunhilde Asleep by Margaret Fernie Eaton 1902.

Brunhilde Asleep by Margaret Fernie Eaton 1902.

44

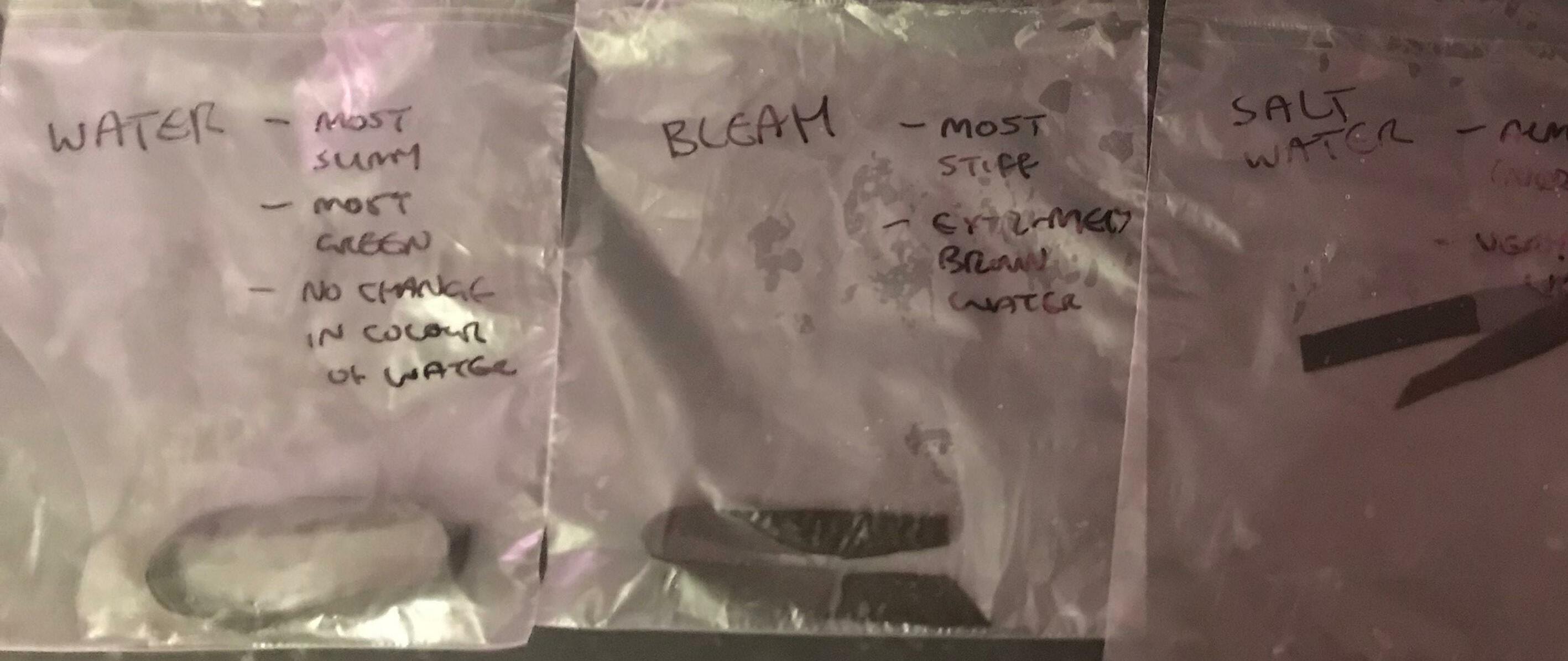

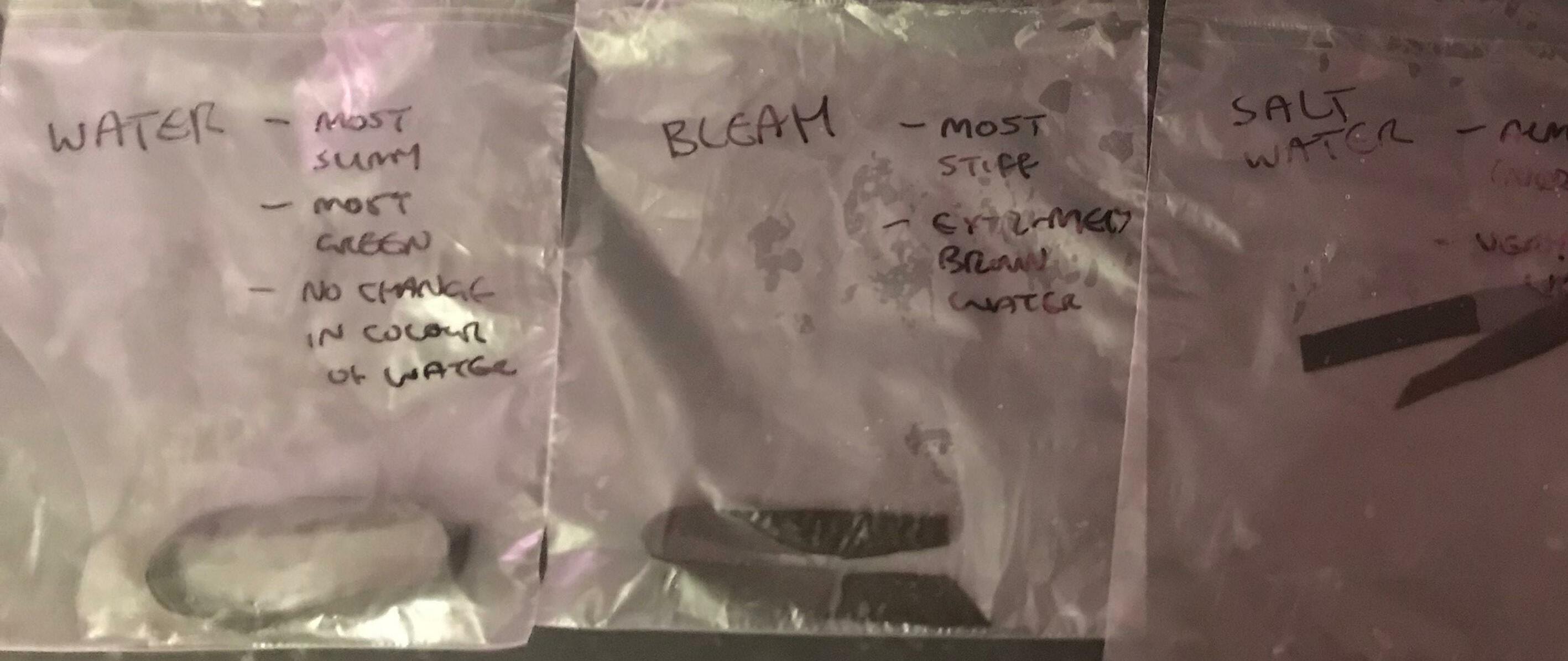

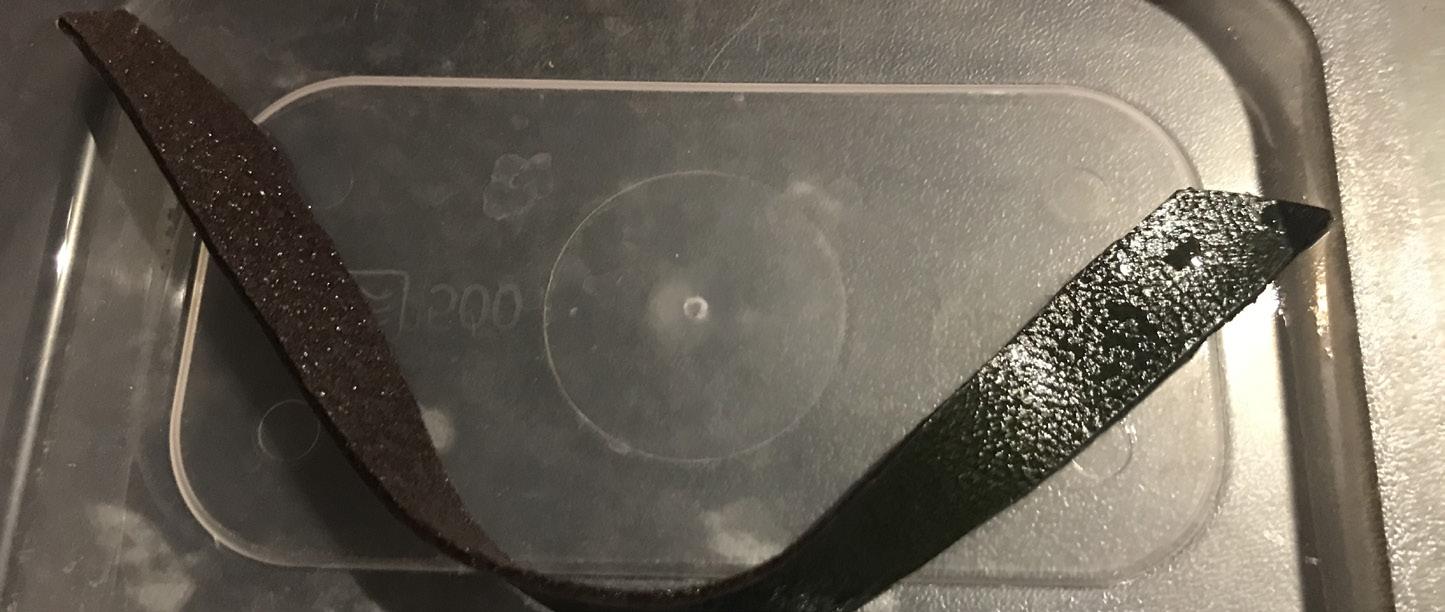

WEAKENING LEATHER WITH SOLUTIONS

I decided to test the leather’s strength by putting strips of the same size from the same piece into various solutions, I wanted to see if this would alter the material and cause any weakness due to leather being such a strong material. They were left for 2 weeks due to their being no change after 1 week.

DECONSTRUCTION LEATHER

45

WATER BLEACH

THE RESULTS AFTER 2 WEEKS OF BEING SOAKED

Colour of water did not change, the leather became more slimy than the others and the colour of the leather changed the most but still barely with more tint of green.

Colour of water went extremely brown but the colour of the leather did not change at all. The leather became slightly more stiff.

SALT WATER

The leather remained ‘normal’ but the salt water became very brown.

VINEGAR

The vinegar became more purple but the leather colour did not change. However it was the 2nd most stiff out of all experiments.

From experimenting with four different solutions and for having the leather strips soaking for 2 weeks, I thought that the leather would have been weakened. The result with this is that it didn’t. This shows that leather is a very strong material in terms of resistance.

46

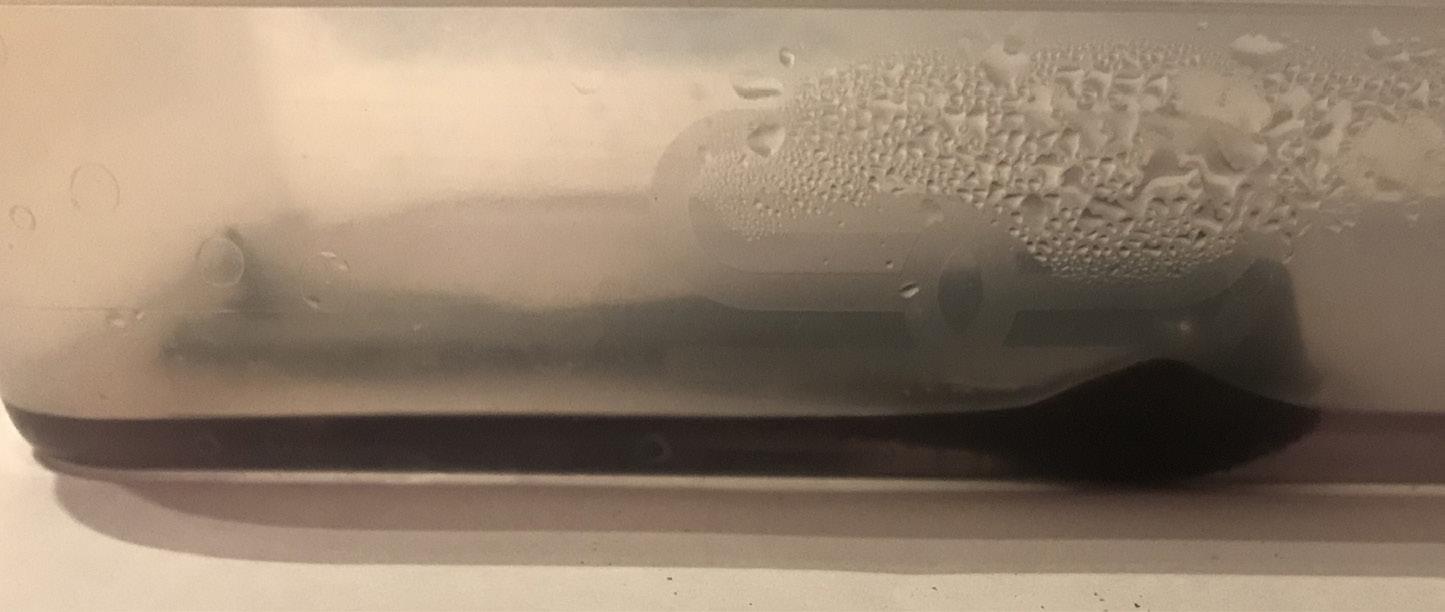

CHANGING THE STATE OF THE LEATHER

The back of the leather became more furry after scraping away at it.

The front of the leather became much softer after scraping away at it. It also seemed to make the piece feel a lot thinner.

47

It will be worth experimenting with these scrapings with different adhesives.

Leather is known well for the strength it holds in its material, I would like to test its strength by deteriorating the fabric through different methods. Then afterwards, seeing if it is possible to reconstruct it into something interesting. Similar to the cork, it can be seen as rather brutal finish and therefore I would like to experiment with creating something more delicate or more aesthetically pleasing.

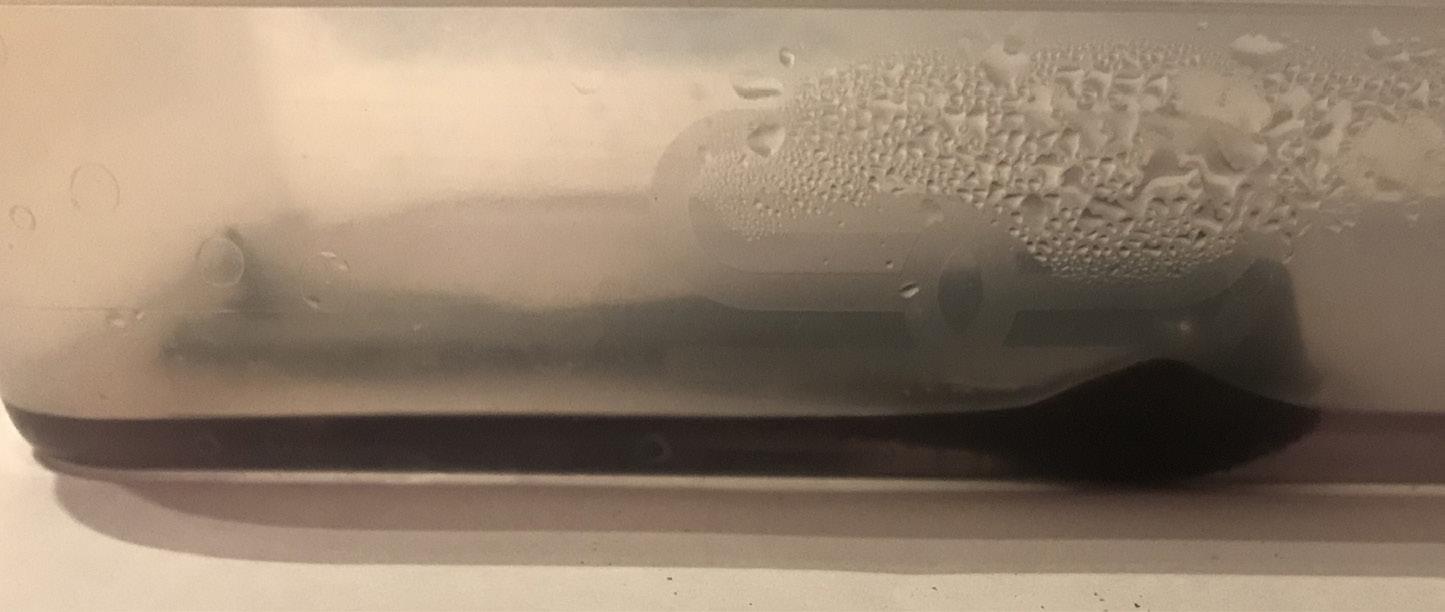

I also attempted to harden the leather. I let the hot water be absorbed fully into the leather and then set it over a bottle to dry. The result was that it was not as stiff as I would liked it to be, but the dents from the bottle were significantly shown once it had dried.

The ‘fur’ scraped off from the back of the leather

The ‘fur’ scraped off from the back and front of the leather

The ‘fur’ scraped off from the front of the leather

The ‘fur’ scraped off from the back of the leather

The ‘fur’ scraped off from the back and front of the leather

The ‘fur’ scraped off from the front of the leather

48

REJOINING THE HIDE

As I experimented with the cork with the different adhesives on the granules, this was repeated here except with hand cut small leather strips. The first image (left) was taken half way through drying and the second, after flipping over to dry the under side. At this point, only the wax had completely dried with the wood glue still partially wet and the pva glue still very wet.

RECONSTRUCTION

A B

F I

C

D E

G

J

H K

49

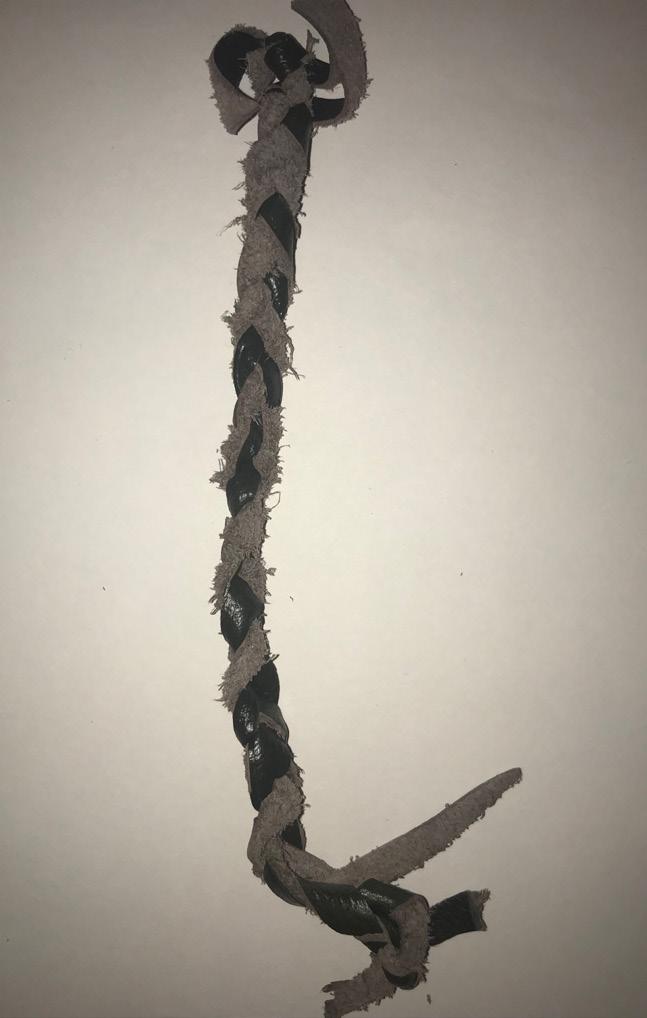

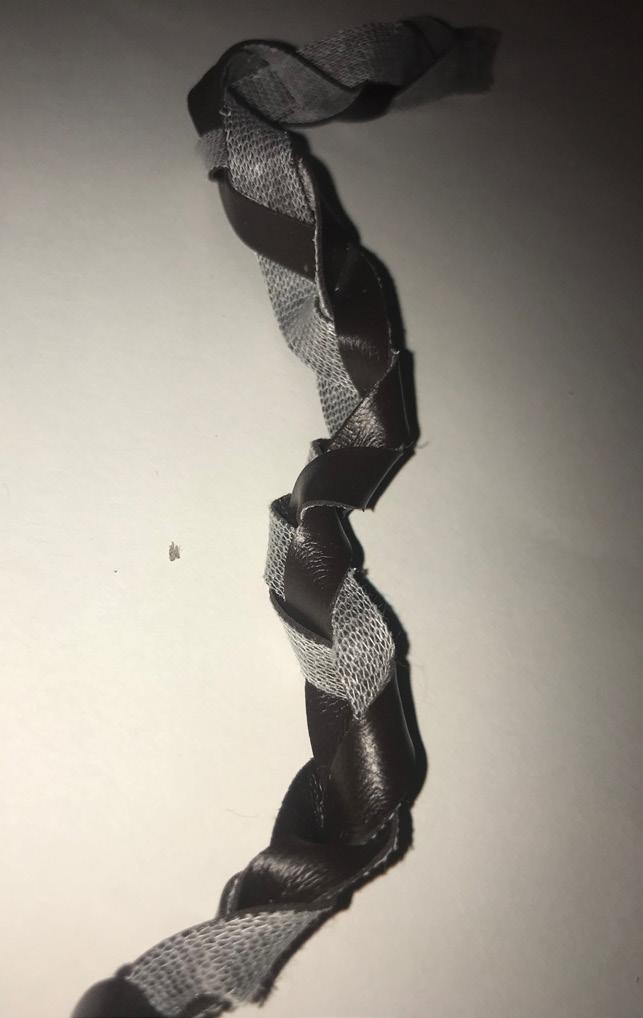

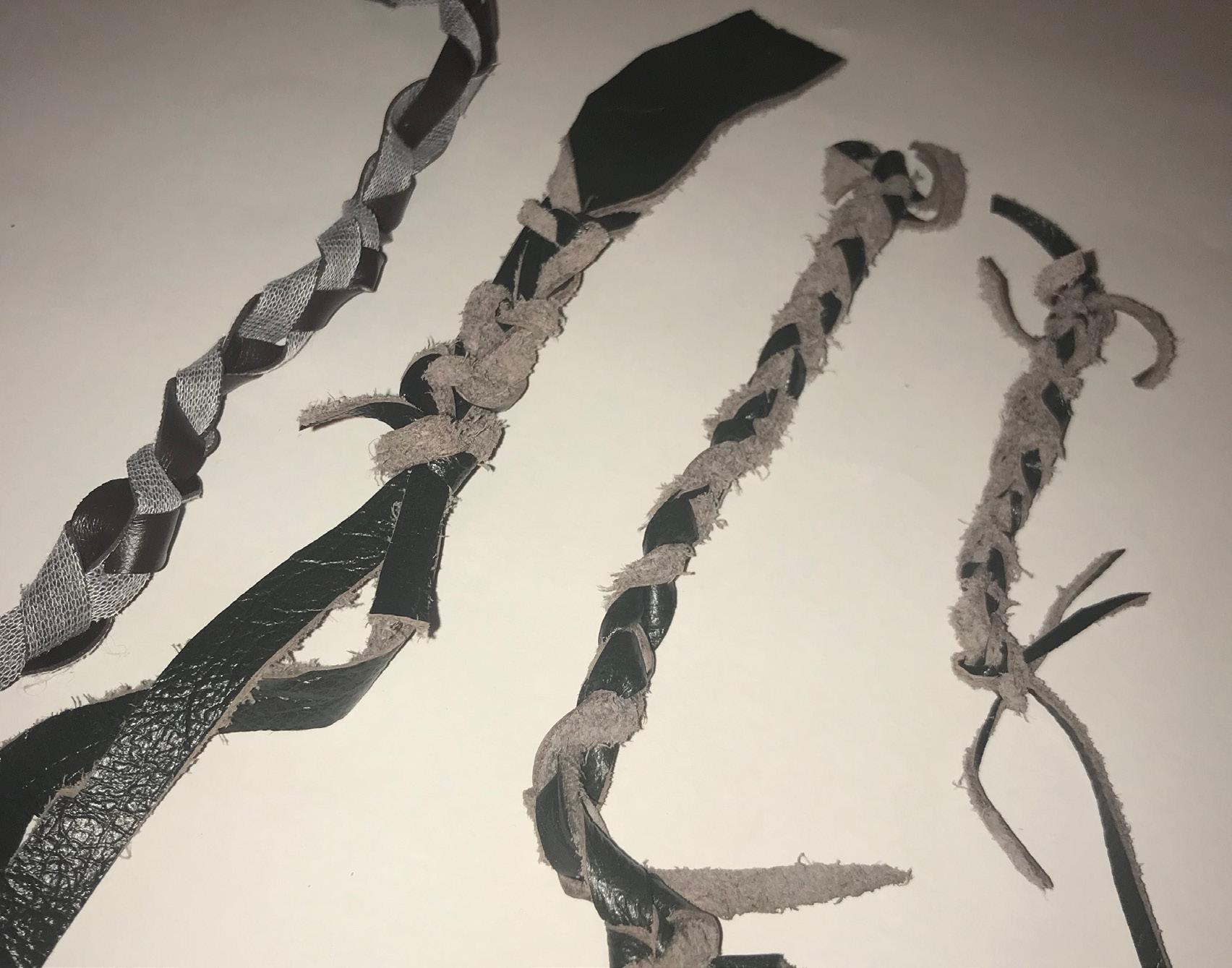

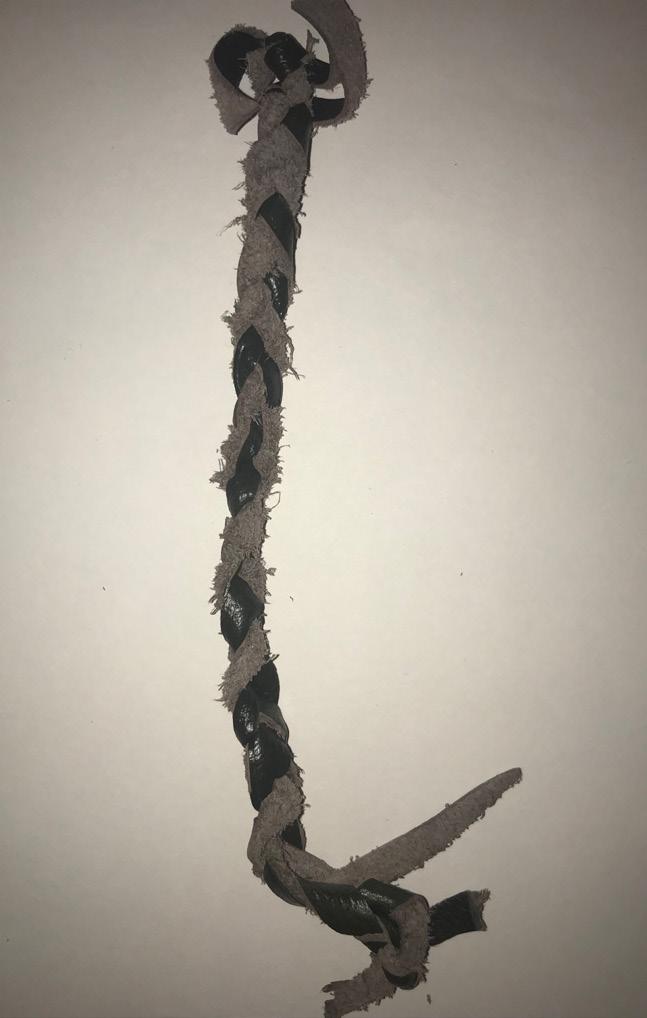

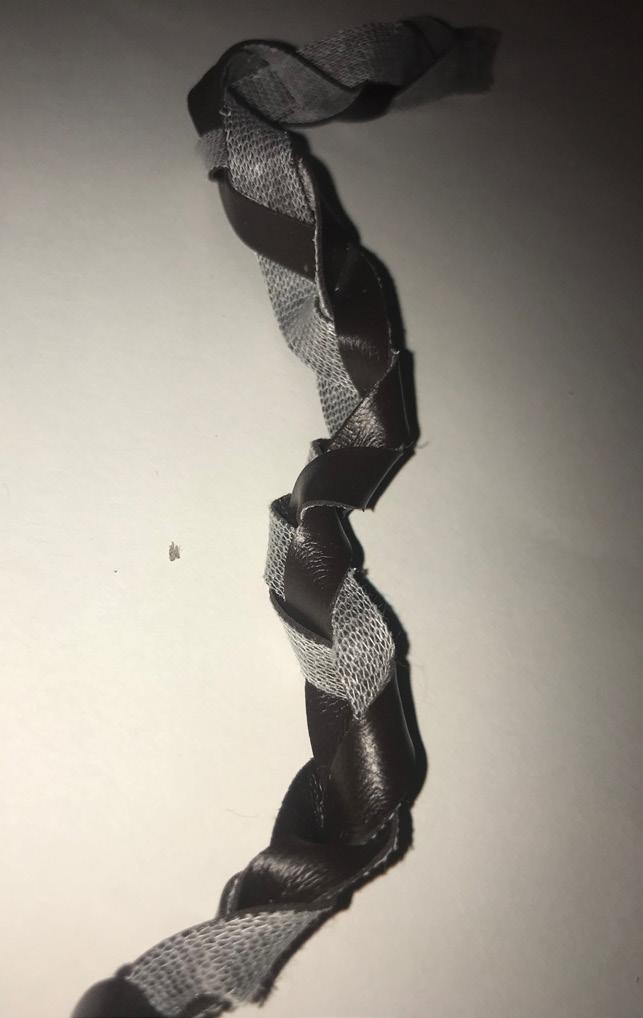

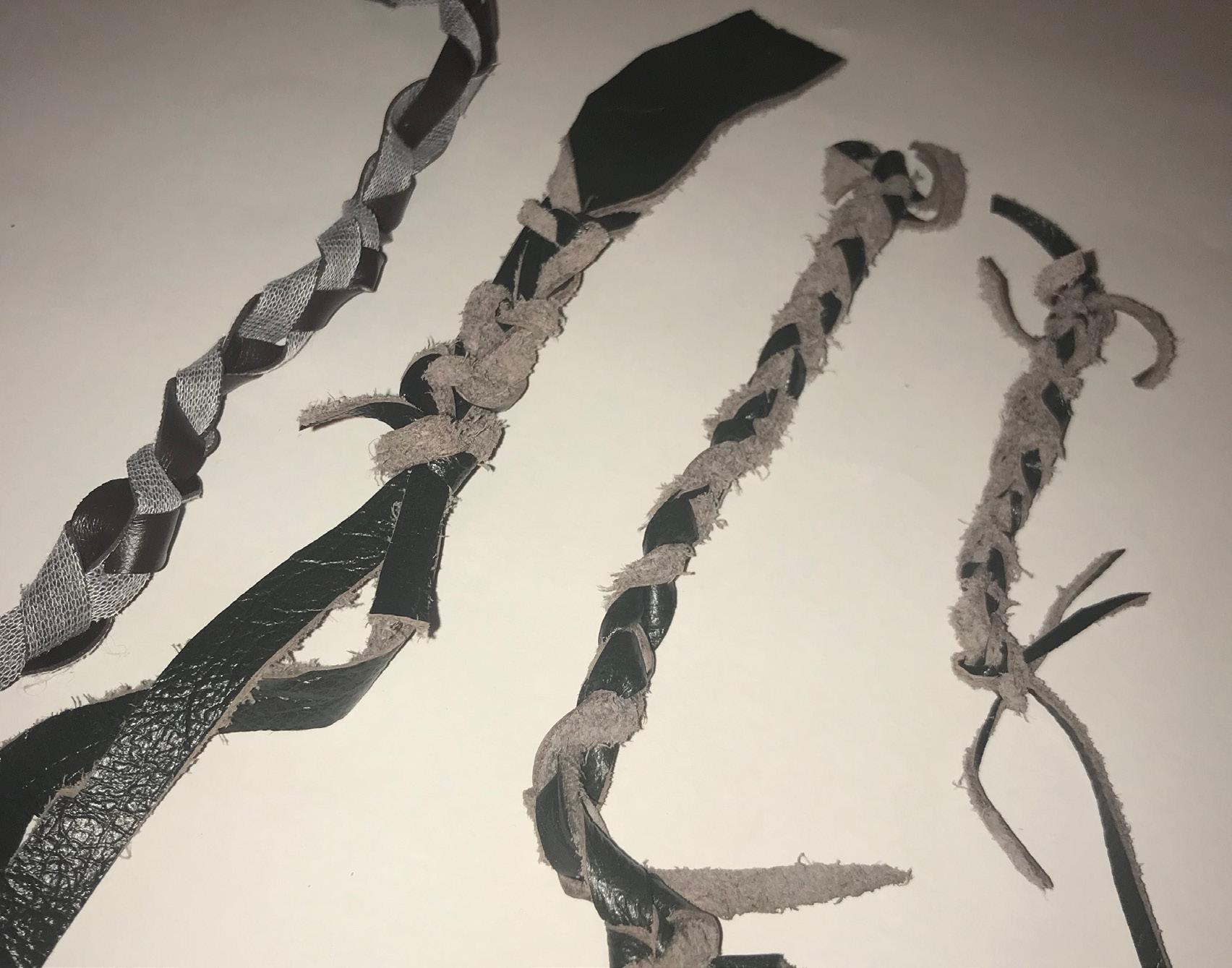

I attempted braiding with leather but because the fabric is rather tough, I found it difficult. A. is faux leather which shows a near traditional 3 piece braid. Whereas the others are real leather which give an untidy finish. B. is done using 4 strips working the outside two over and inwards. C. is a traditional 3 piece plate done with real leather. D. is a 4 piece brade with thinner cut strips to test if the aesthetic was better than thick strips. When pulling at the braides, they are very strong in tension and the leather does not change in shape or strength after doing so.

A B C D

50

A. Mixed with wood glue.

This binded really well and kept a descent form.

B. Wood glue and leather in layers. This was the most unsuccessful with the wood glue. The bottom layer failed to dry and fell apart from the leather. Resulting in a thin piece missing half of the rest.

C. Wood glue over leather. This was the most successful with the wood glue. It binded and dried well whilst keeping its form.

G. Blue ink wood glue mixed with leather.

I added blue ink to the wood glue then mixed it with the leather. This was a success. The blue colour remained as well as the form of the mold and the adhesive was strong.

H. Blue ink PVA glue mixed with leather.

This was very unsuccessful. The Pva dried very thin and the colour was not vivid. The adhesive is not very strong either.

I. Green ink wood glue mixed with leather. This was the most successful of all experiments. The colour remained bold, the adhesive was good and the form of the mold remained.

THE ADHESIVES

51

D. Mixed with PVA glue. This was the most successful with the PVA. However it does not seem as strong as wood glue.

E. PVA glue and leather in layers

This experiment kept falling apart and took the longest to dry.

F. PVA glue over leather. This became very thin once the glue dried. It doesn’t keep a good form and doesn’t feel like a strong adhesive.

The worst adhesive is the PVA as not only does it take the longest to dry but when dry it is very thin, colour can be lost if once added and it does not seem to bind the leather together well. The wood glue was the best at binding the leather. It remains in the form of the mold but most successfully brings the leather together and seems quite strong. The wax is great in terms of moulding but it becomes very fragile to breaking once dry.

J. Wax mixed with leather.

This was the best with keeping its form from the mold and binding the leather.

K. Leather pushed into wax. This was to experiment how thin the wax could be to successfully bind the leather. It worked but was very delicate once dried.

52

Spanish designer Jorge Penadés has moulded together shredded leather and natural bone glue to create pieces of furniture. The finish is very vivid in colour and more of a piece of art than furniture. They are made by recycling leftover leather from the car, fashion, upholstery, shoe industries which is bonded with the natural bone glue. “The bones are a by-product of meat, and are boiled in a bain-marie for a certain amount of time and at a certain temperature,” he explained. “As the water evaporates, you’re left with this kind of stone which is then smashed and reveals the glue.”

FORMING A STRUCTURE

53

He starts by shredding leather with an office paper shredder then adds these to the glue which are placed tightly into moulds and set to dry. When dry, the top layer is shaved off to reveal the marble effect. It is then polished with shellac, a natural resin from an insect.

He believes this process could be used for many things including flooring, shoes and tiles.

54

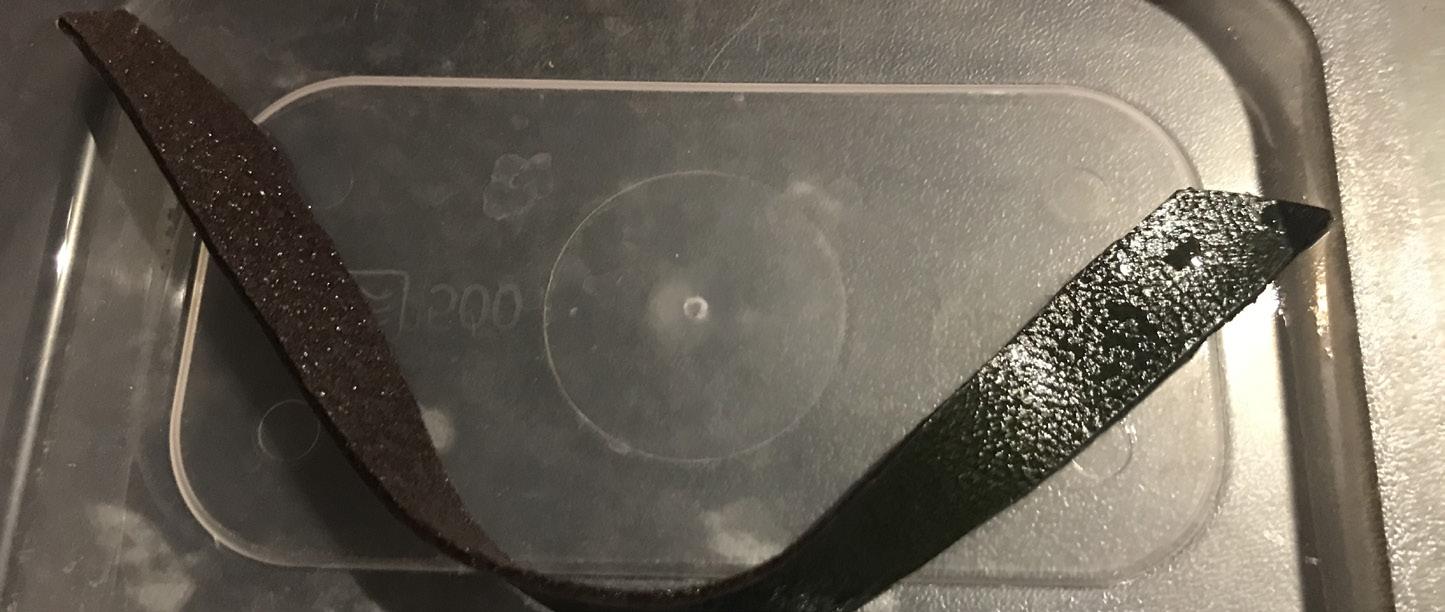

DECORATING

PYROGRAPHY

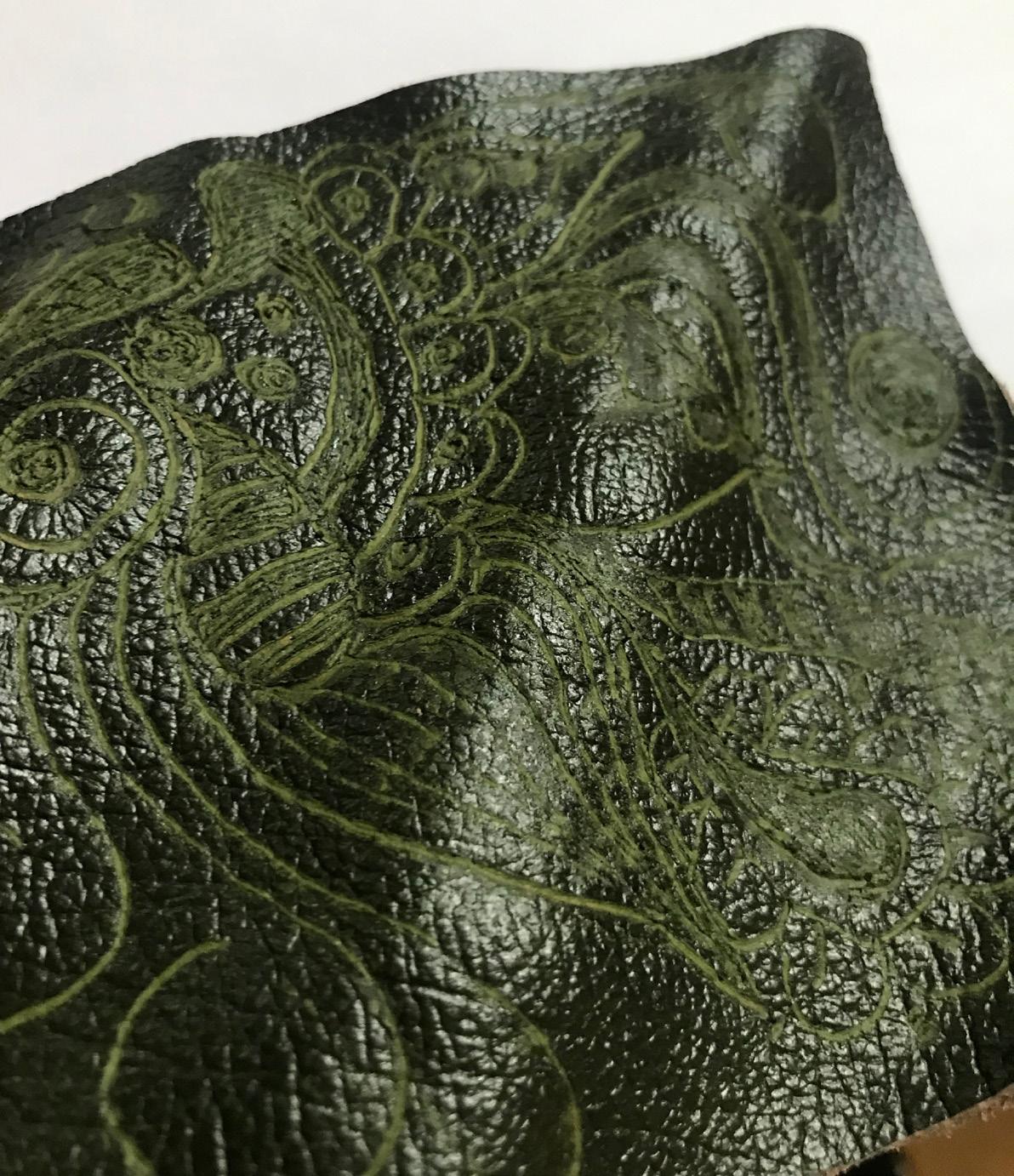

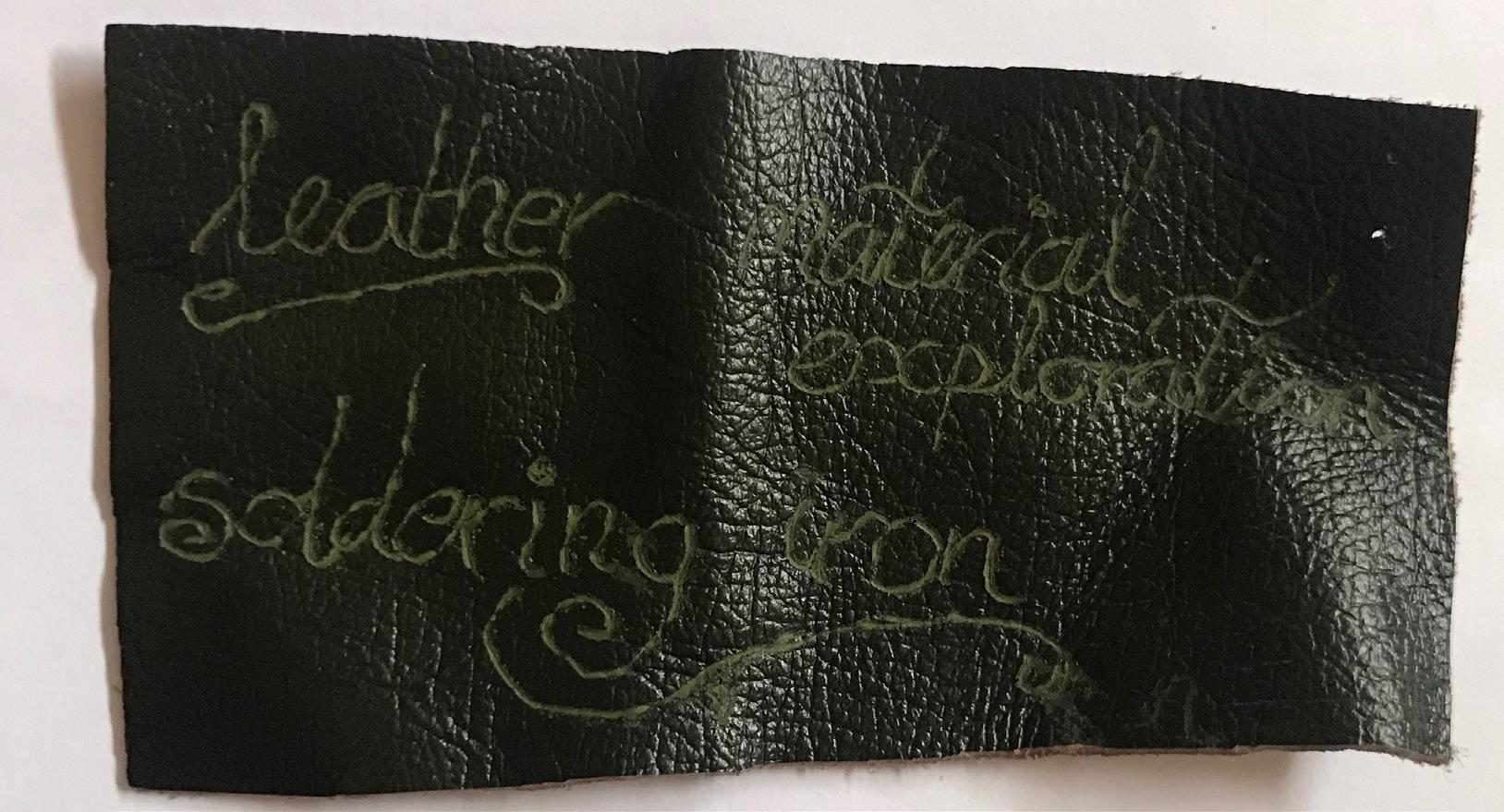

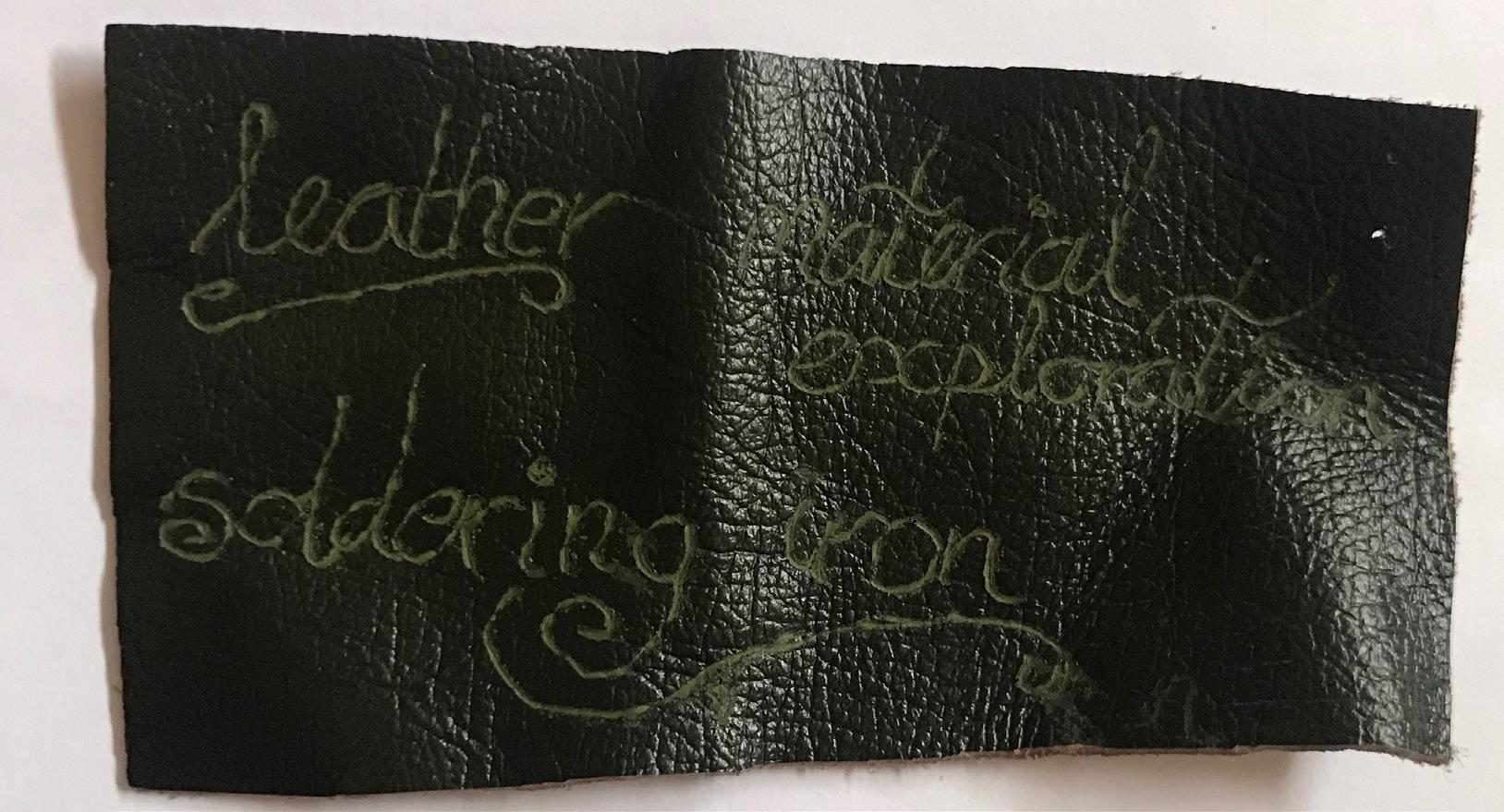

To decorate the leather I decided to attempt doing pyrography using a soldering iron.

55

Both writing and soldering patterns were successful. However I was surprised to see how the leather revealed a green underneath the black.

It was interesting to see the finish of leather strips cut away from the decorated piece. This adds finer detail and depth to the strips.

56

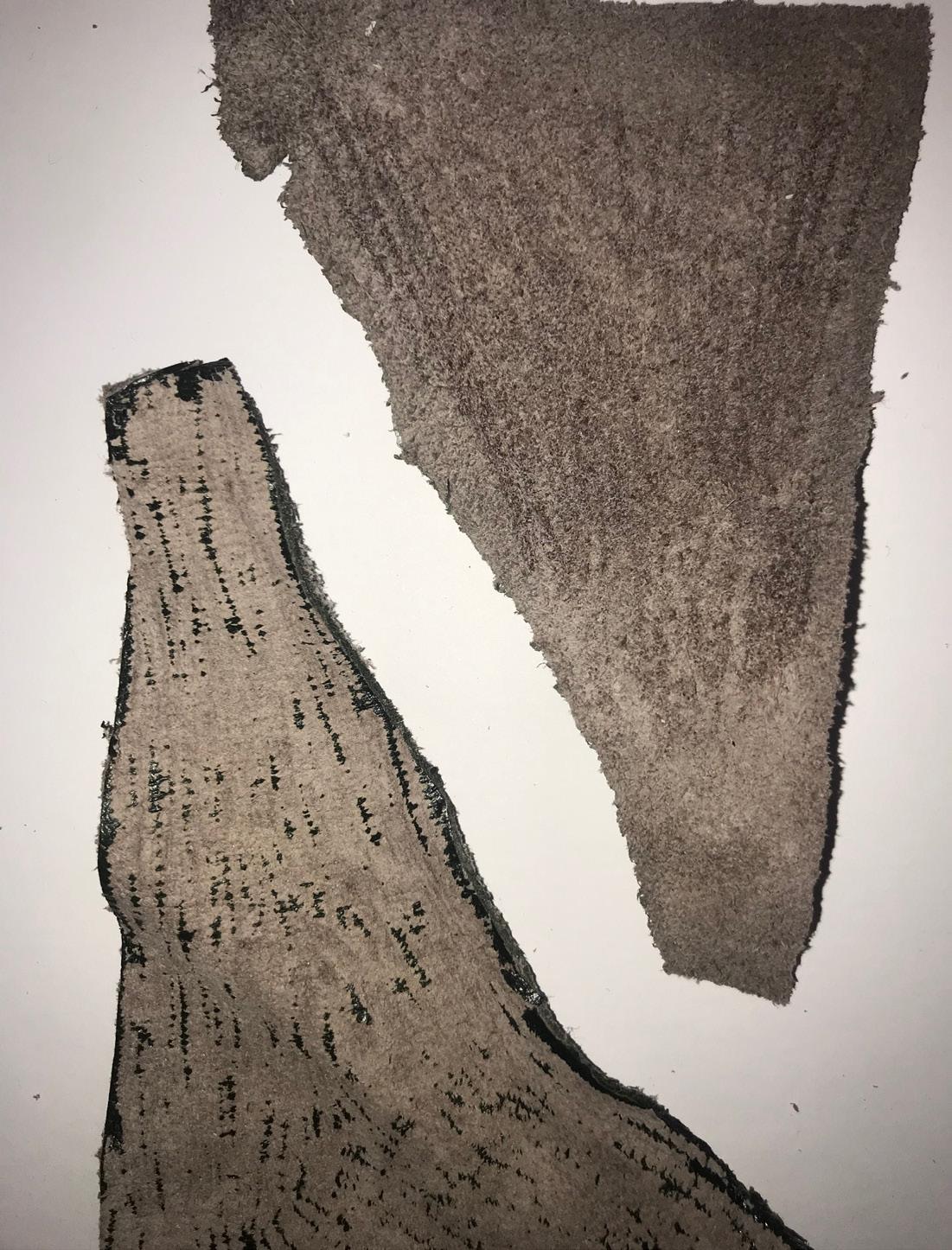

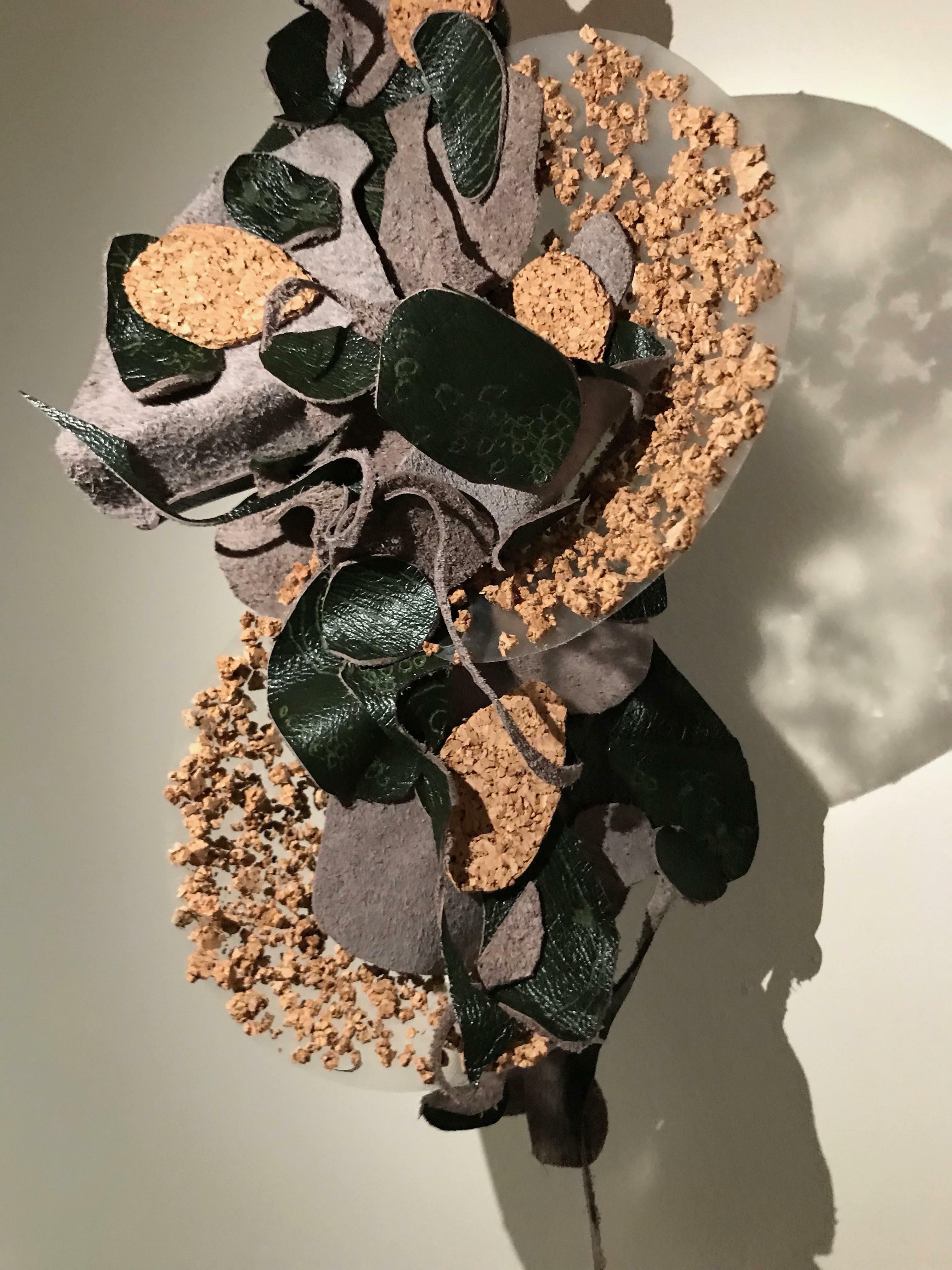

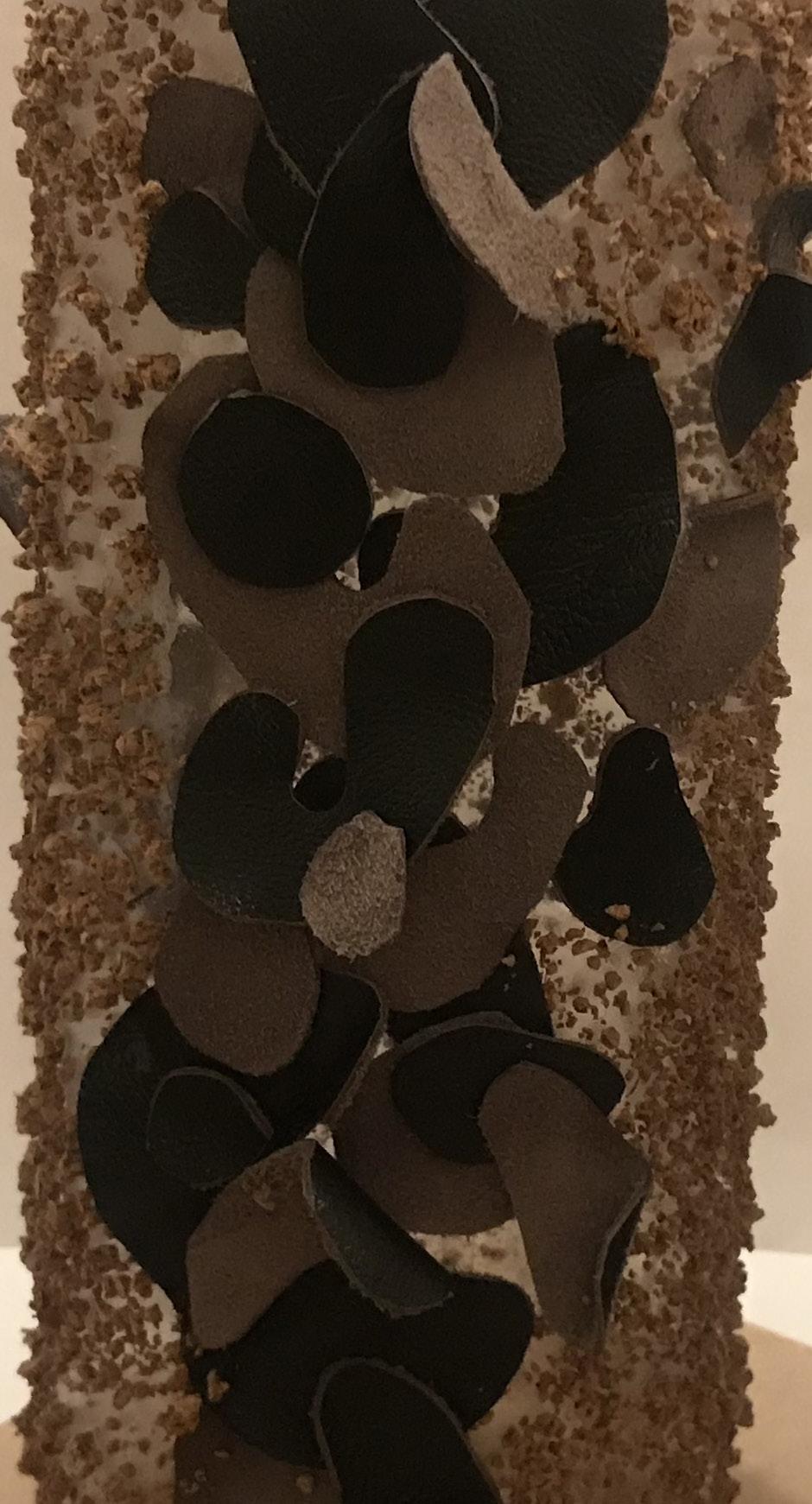

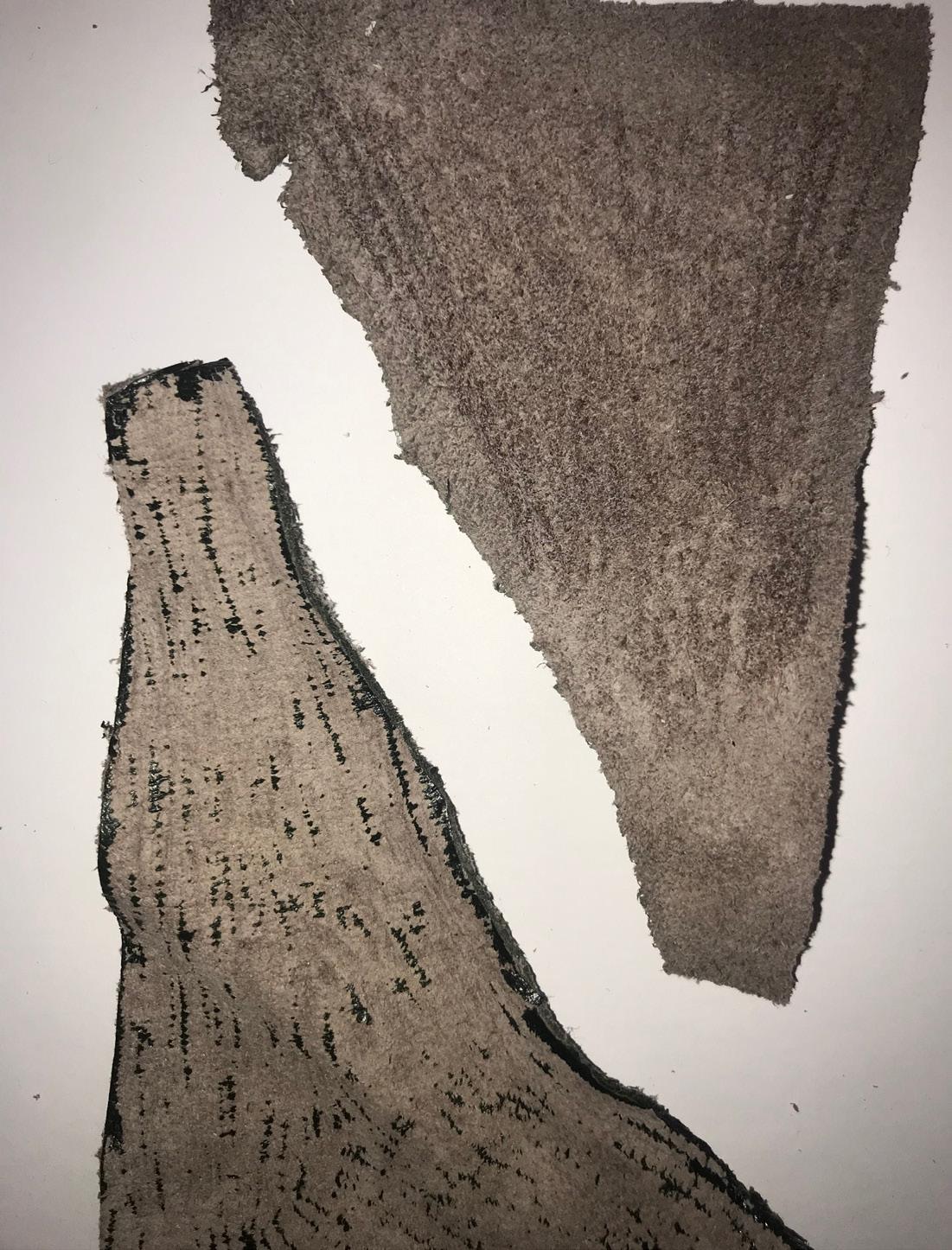

CUTTING AND STICKING

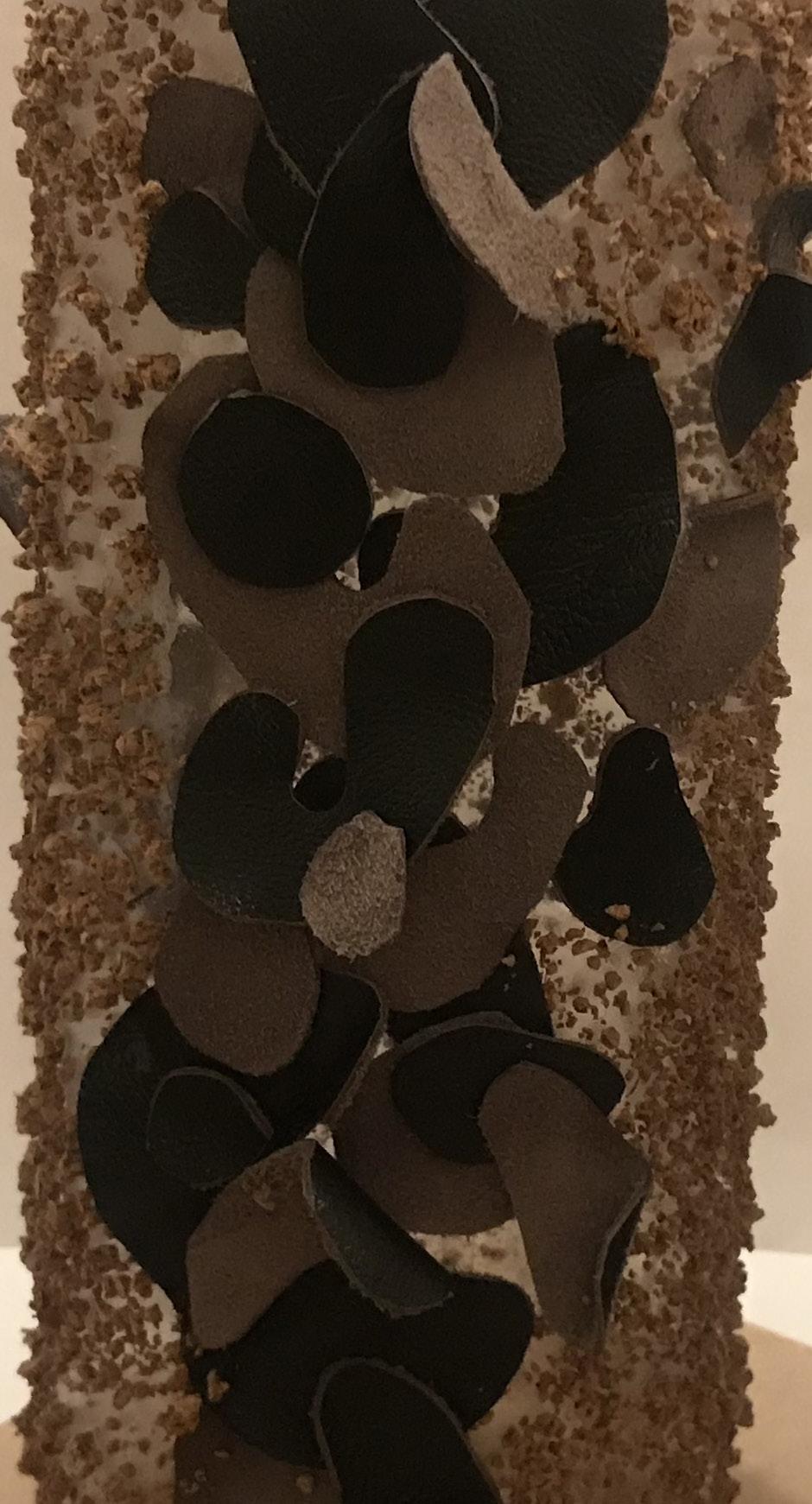

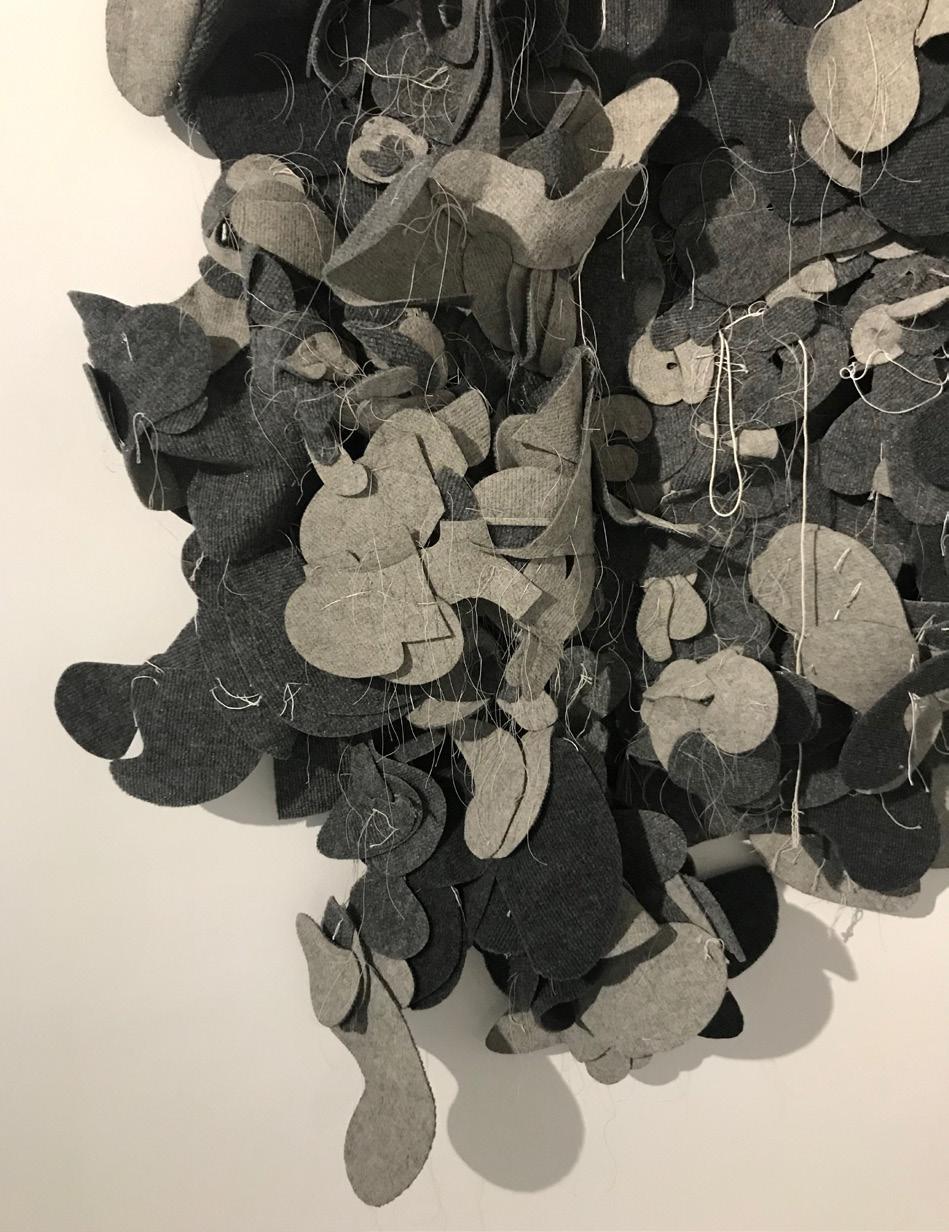

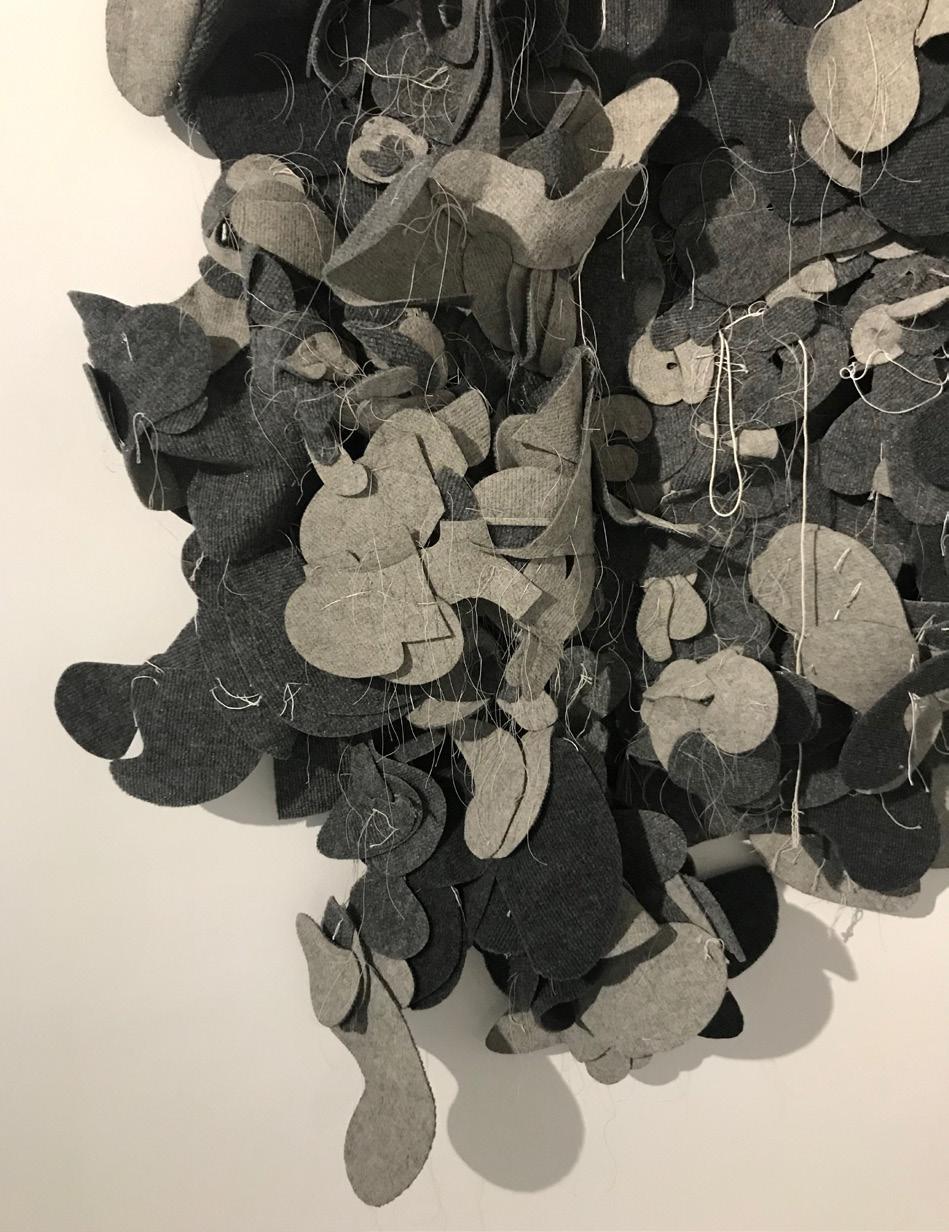

After seeing a contemporary artwork in Morocco whereby the fabric felt had been cut into var ious shapes and then sewn and glued together to form a cascading wall piece; it made me think that it would be worth attempting this with leather. Due to it being such a crude material, the organic shapes and forms may allow it to be directed away from this. After piecing the shapes together I added very small details using a soldering iron.

DECORATIVE THROUGH DECONSTRUCTION

57

Art found in the Museum of Modern and Contemporary Art, Rabat, Morocco. Artist Unknown.

I then decided to add the scraps of the cut off to ensure most of the material was used and not disposed of.

I think that adding to the leather a sewing method whereby threads are visible would be affective too. As shown below.

Art found in the Museum of Modern and Contemporary Art, Rabat, Morocco. Artist Unknown.

I then decided to add the scraps of the cut off to ensure most of the material was used and not disposed of.

I think that adding to the leather a sewing method whereby threads are visible would be affective too. As shown below.

58

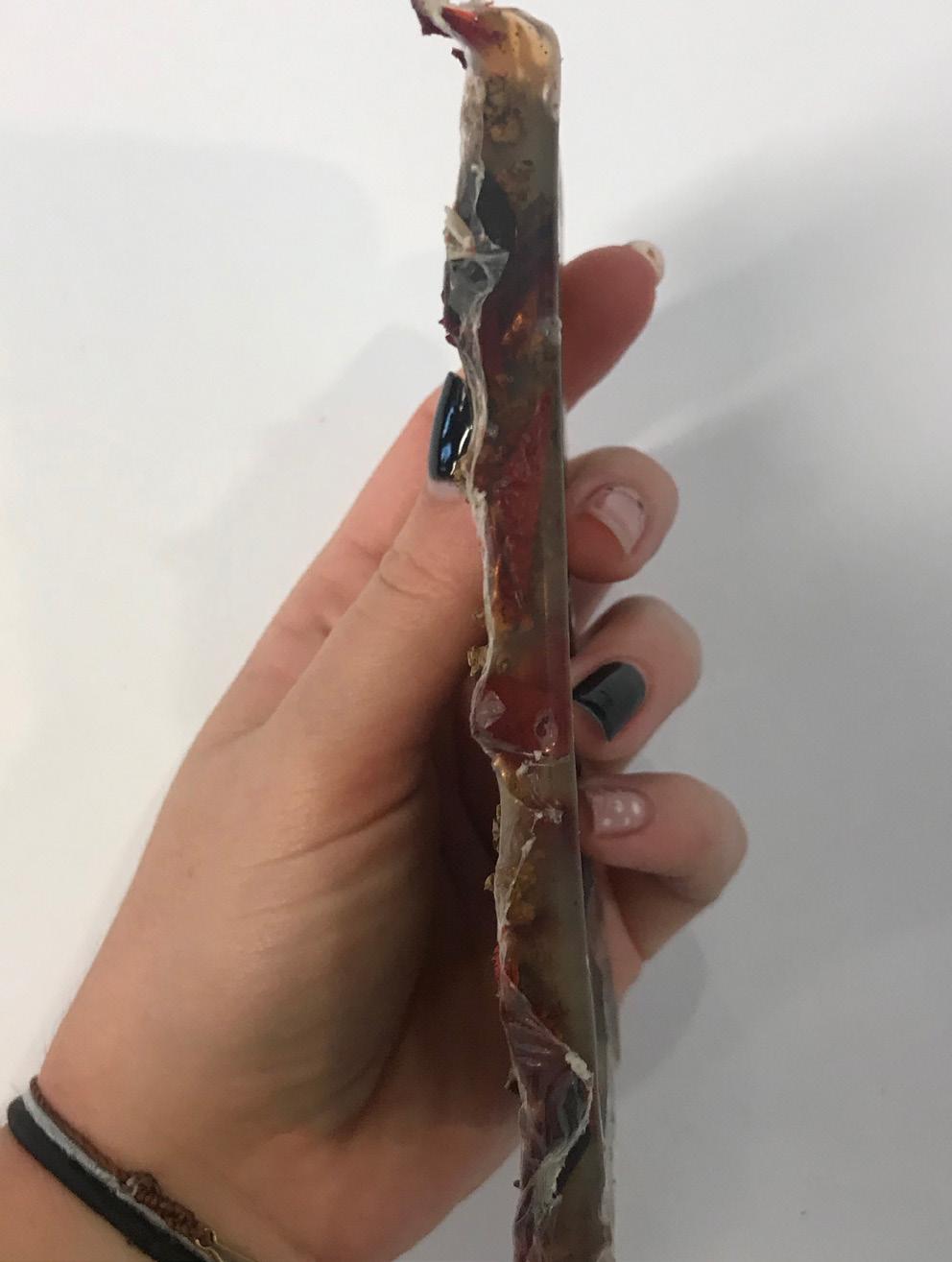

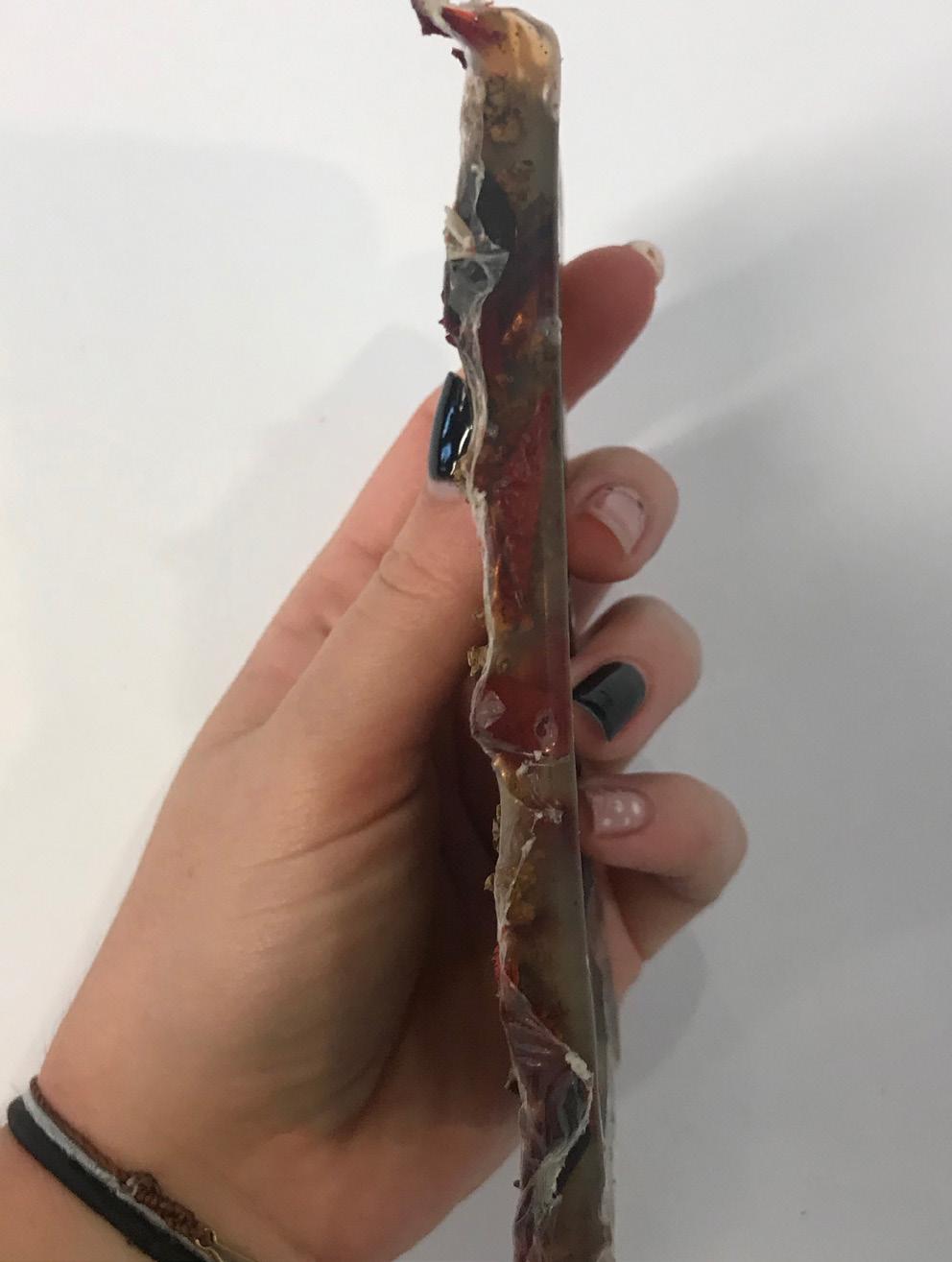

I wanted to explore making the leather forms have more dimension in a space and with success of the transparent cork granule tree trunk, I thought I would try a transparent tube for this effect. This way it follows a curve and has option of flowing around on different height levels whilst being visible from any side whether it is the back of it in the background or the front in the foreground. It also follows the same organic form of the piece before which could encourage ethical solutions in products using leather.

Eunsuk Hur created such modular textiles in order for users to create a piece of clothing or interior accessory which promote sustainable design. They are multifunctional and emotionally durable.

CUTTING AND STICKING

59

Eunsuk Hur, Transformable Modular Textile Design.

Eunsuk Hur, Transformable Modular Textile Design.

60

EXPERIMENTING WITH BOTH MATERIALS TOGETHER

After carrying out experiments with the materials individually, it is important to find a relationship between the two materials. In this chapter I will find which works best in creating a prototype of such a matter.

I hope to find a more organic and delicate approach than the material I bought give off.

Showing the relationship with tension between cork and leather. Cork is great in compression but hopeless in tension, whereas leather is great in tension but not as successful in compression.

MATERIAL EXPERIMENTS PART 2

61

SIMPLIFYING

THICKER FORM

GRANULES AND STRIPS

FOREST DEBREE

RETHINKING AESTHETIC RETHINKING MEANING

62

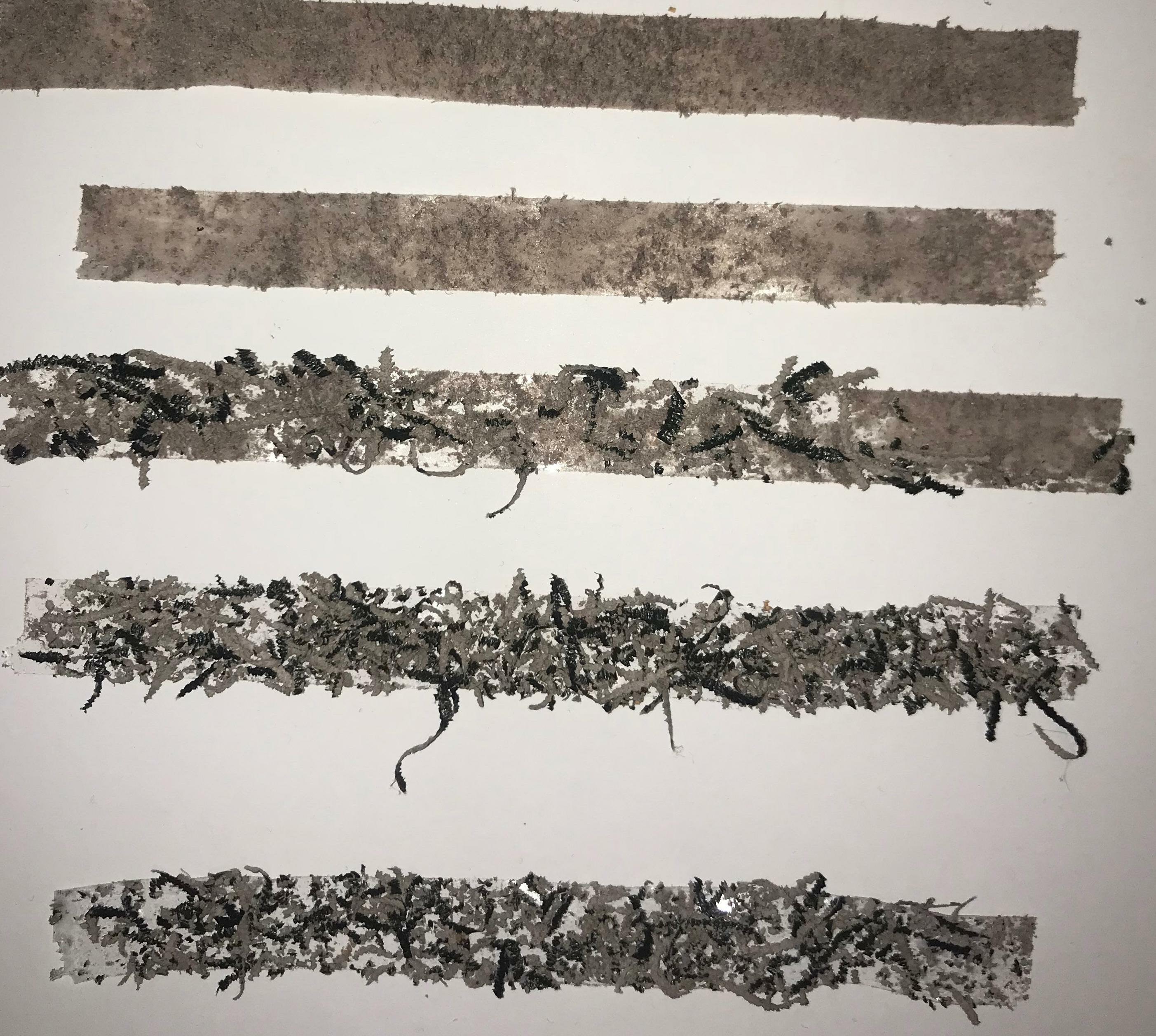

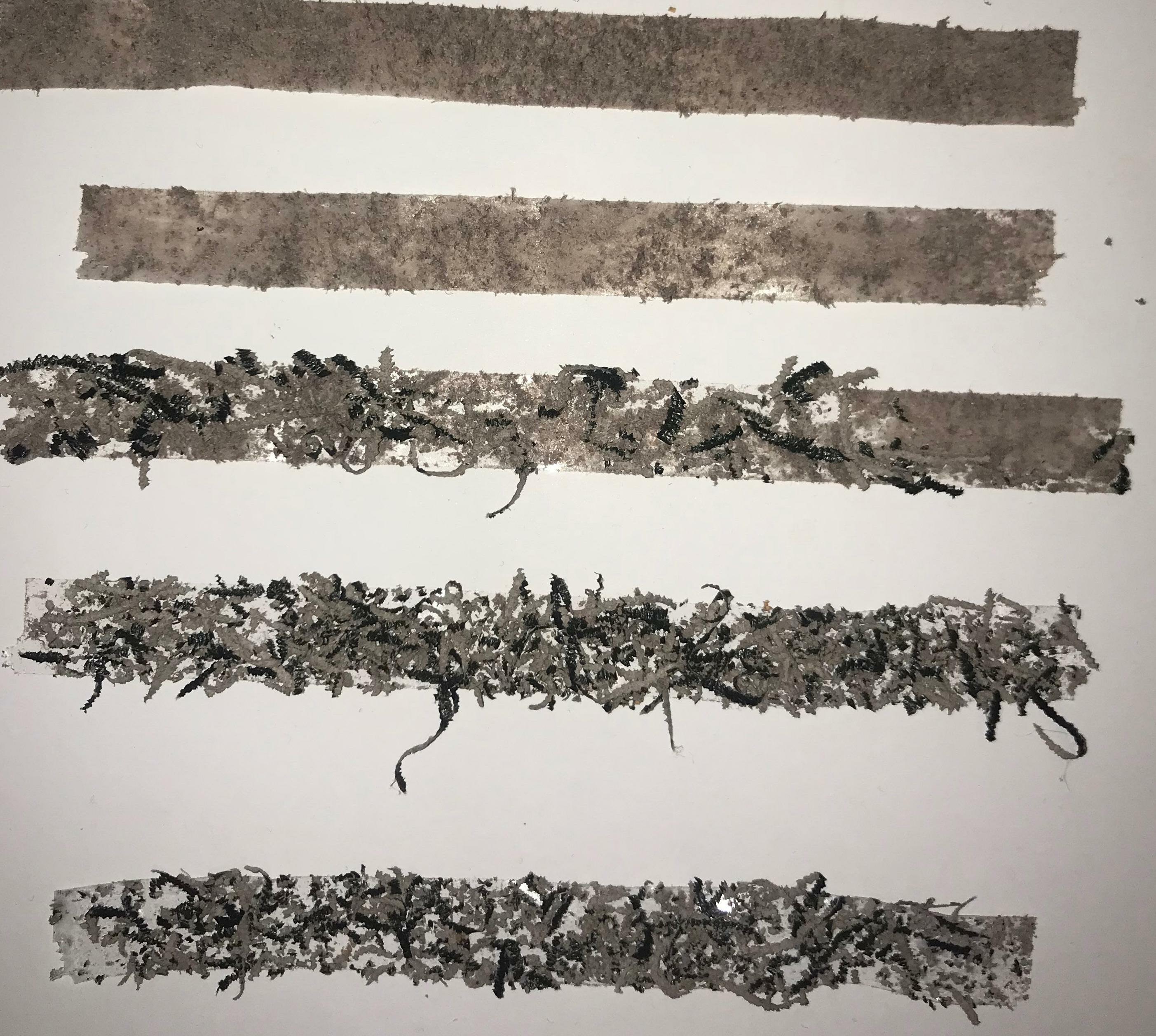

CORK AND LEATHER STRIPS

In this test, I simply placed strips of leather and cork on-top of latex. The result was that they successfully stuck to the latex and the under side had a better aesthetic to the intended top side.

I did this to try something more simple.

On the right with the binding experiment, I was testing the durability of this finish. The conclusion was that it was a tough fabric finish that would work well as a rug which reminded me of FairTrade rugs. However the cork was not very strong in this binding technique as once I tied the leather tightly around it usually tore.

SIMPLIFYING

63

64

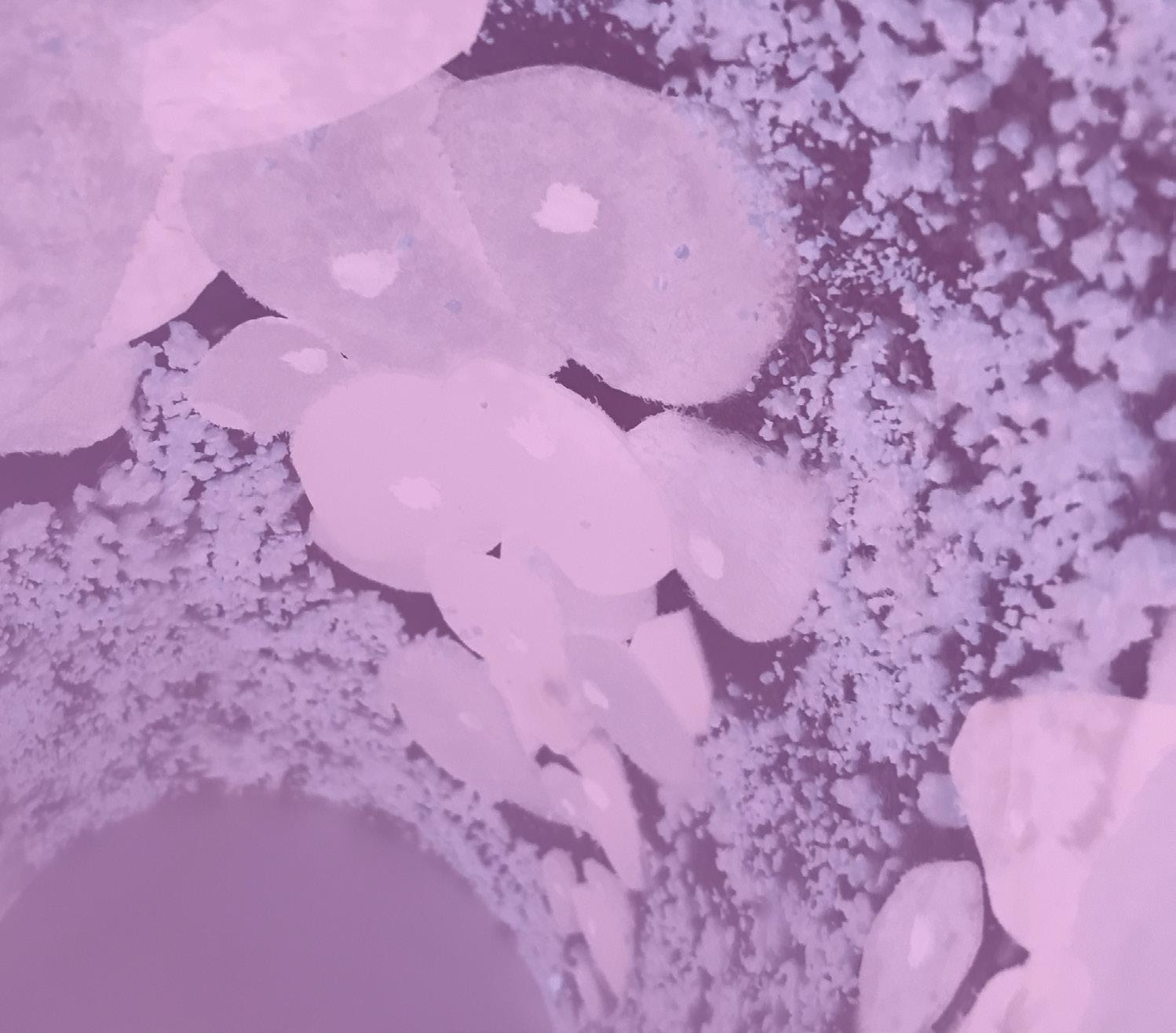

WITH

From this experiment, I personally found success in the contrast of the small red leather strips with the cork granules; which unexpectedly bled out into the latex. The material became more solid and strong due to setting it in a plastic box. As seen in the last photo above, it does not want to fold further than what is shown. This is due to the density of the cork and leather in the thick rubber.

A THICKER FORM COMBINING

LATEX

65

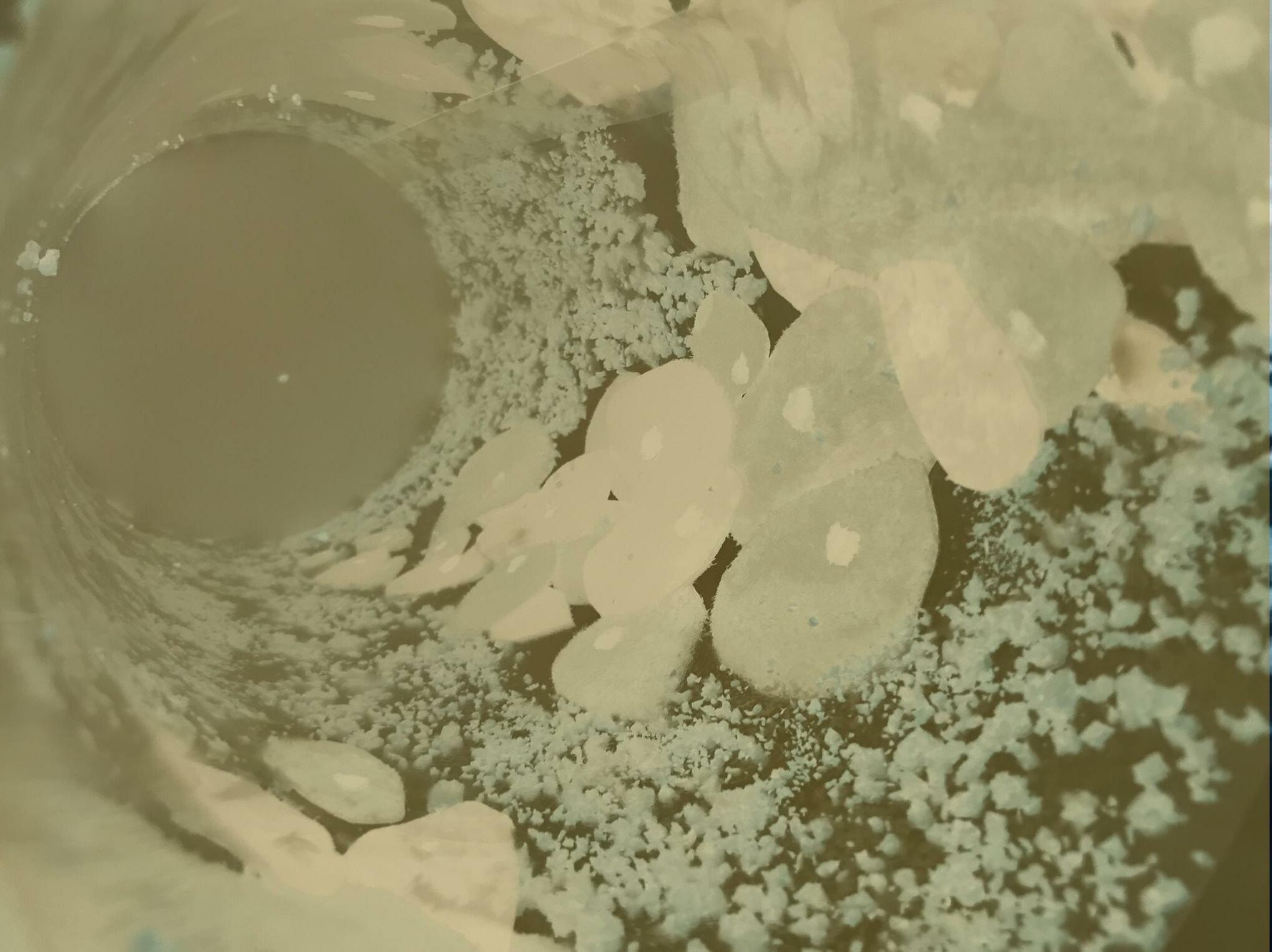

Material particles before latex was added.

Before latex dried

Material particles before latex was added.

Before latex dried

66

From this experiment, the hand crushed cork was successful in the latex as it successfully sticks together strongly and allowed the light to pass through in some areas, however maybe it would be better if they were crushed more finely. The leather strips are a great contrast to the cork granules, next I will try making them into smaller pieces as-well.

This latex material combination was stronger than expected. The fabric only wanted to fold as far as my hand shows in the above photo. This may be due to the granules being large and stuck well to the adhesive or the large span of it, or simply the strengthening of the latex on the cork as I applied the materials and latex in layers.

GRANULES AND STRIPS COMBINING WITH LATEX

67

Before latex

After latex dried

Before latex

After latex dried

68

The leather and cork particles have been stuck to a piece of sellotape. The cork is hand crushed from a cork sheet and the leather is scrapings off a piece of died hide. The look reminds me of the ground, whereby debree of natural particles is found. Therefore this to me appears more natural.

When they are held into the light, the sellotape becomes almost invisible, and the debree appears as if it is floating or suspended mid air. It looks like a pause in a moment of time where the particles are forming or falling.

The particles give enough weight to the sellotape which allow it to fall gently over a surface.

Cork and Leather on separate pieces of sell otape and then stuck together.

FOREST DEBREE

CRUDE MATERIAL IN A DELICATE STATE

69

Cork and Leather on one piece of sellotape.

I collaged the strips into pictures of forests to show how they can be seen as natural debree and there fore very organic due to the fine particles of the cork and leather on a transparent strip.

70

When the cork bark is drying, it sits in stacks in its beautiful curved form.

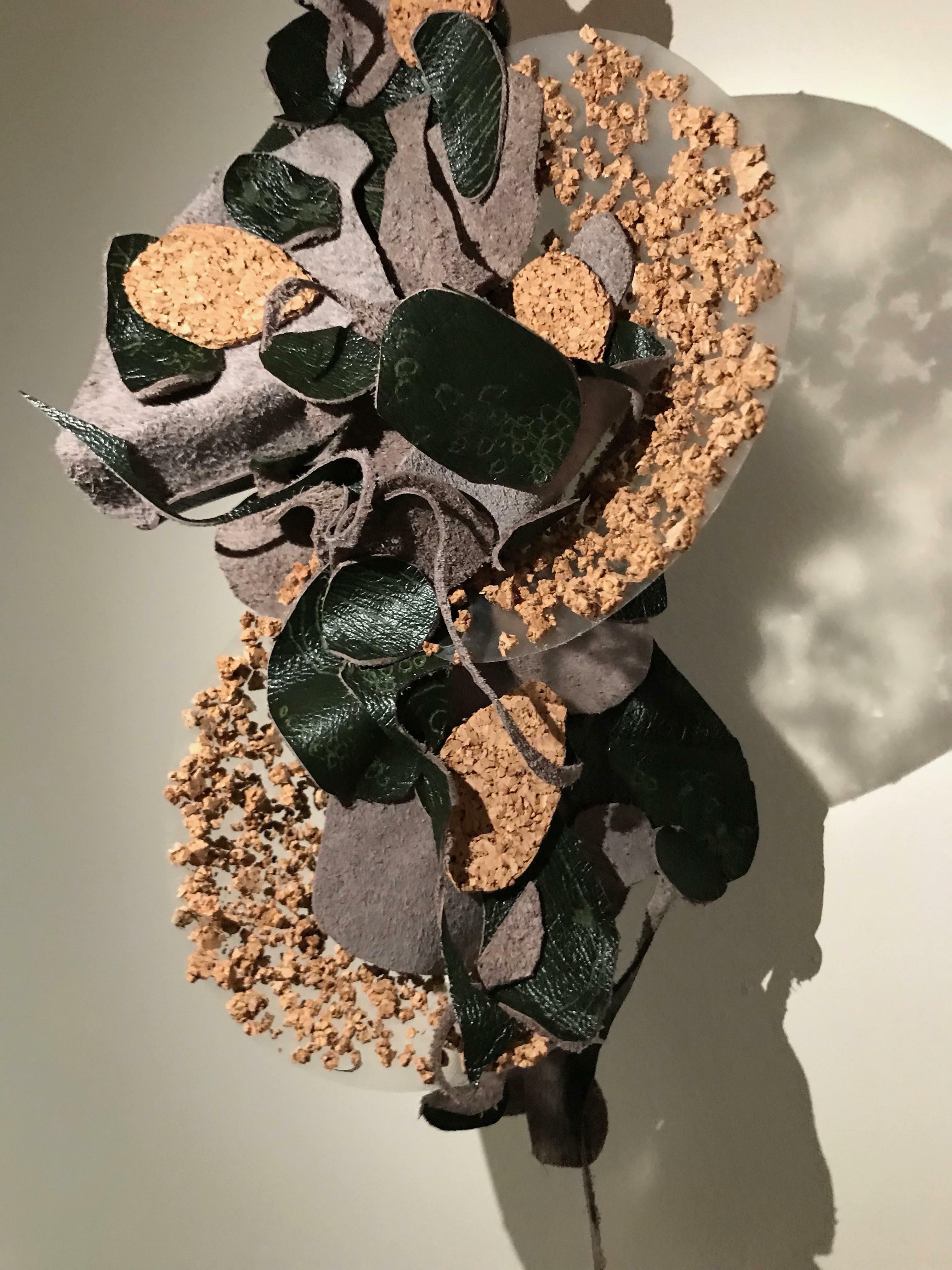

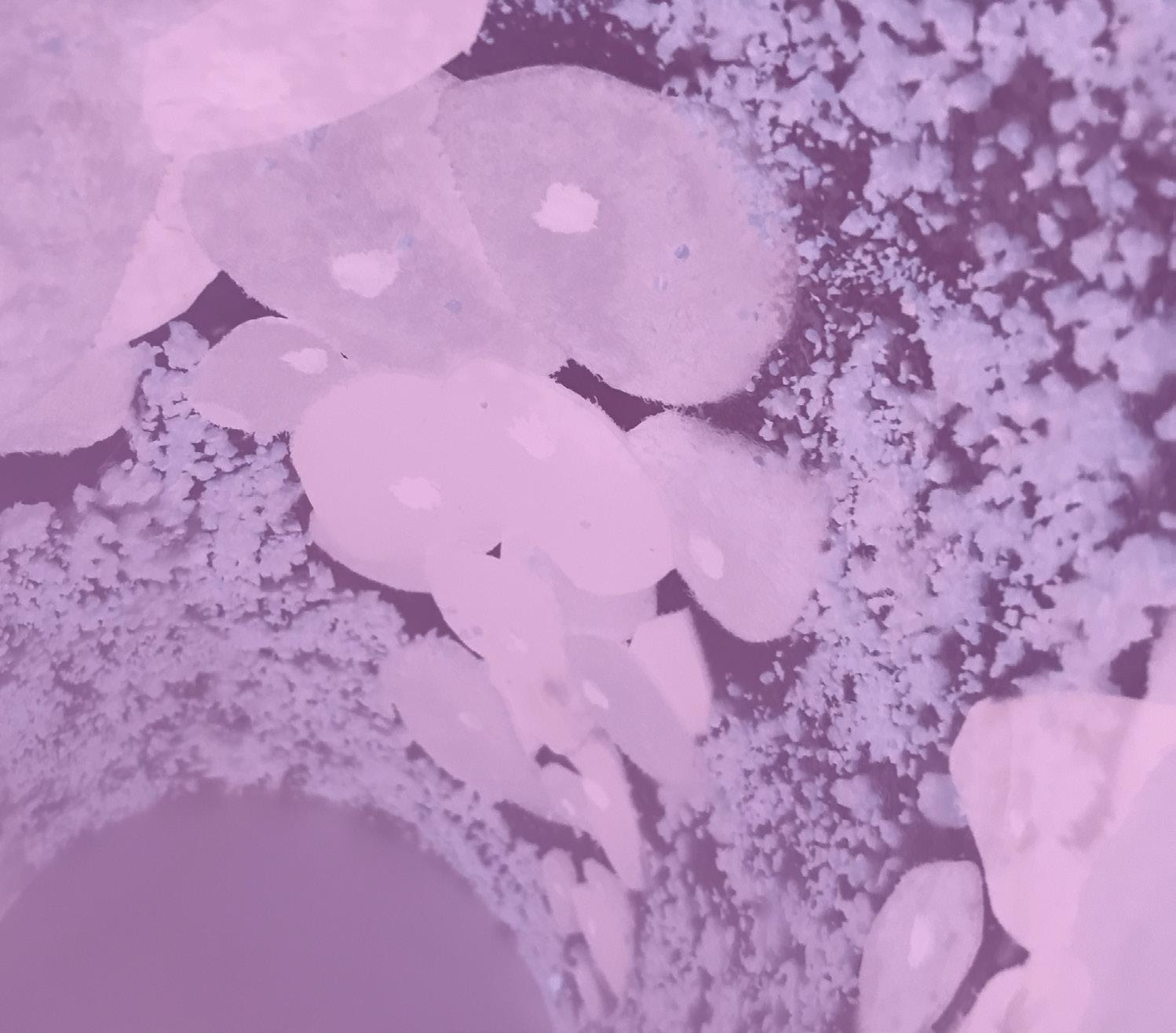

With the cork granules reminding me of the bark, I wanted to create a curved look with them. I decided to add my own form of curve to the leather wall piece created in earlier experiments. I have done this with acrylic which came from the success of the tube in earlier experiments.

By doing this, it also gave the piece more structure.

RETHINKING THE AESTHETIC DECONSTRUCTION TO RECONSTRUCTION

71

72

CHANGE OF DIRECTION AND DIMENSION

After producing these experiments, and comparing them, I wandered if they could be integrated into one thing. This is when I decided to add cork to the cylinder and play with the light in and around the tube. The light coming from above the tube was the best effective on the surrounding space. I also wan der if this could be of a large scale in a space whereby people can be amongst the tube.

Once I added the cork and the light, it really came to life. The cork really starts to be seen in a different perspective. As if it were back to the tree where the bark is forming around the trunk. This reminded me of the great value of cork and how it has to be 9 years of growing the bark before it can be harvested.

However the leather against the cork becomes a contrast between ethical and non ethical, yet how they are both taken from nature as form of a skin. Here they pose as the skin to the harmful plastic tube but remind us of the value of our natural environment surrounding us but our affect as humans on such spaces.

The leather is placed in an organic floral manner to enhance its natural beauty but also to represent the harmful effects of producing such a material on the natural organisations around us.

RETHINKING AESTHETIC AND MEANING

73

74

Both materials appear to me as rather dull and harsh in their first form in which I bought them. The Cork House is an example where the raw material does give the opposite effect. But I found that with both the leather and cork individually together, they perform beautifully through first being de-constructed.

I suppose that I would like to create a prototype that follows the theme of reconstruction through deconstruction. With the hidden analogy between the workings of nature and those of human societies.

After experimenting and testing both materials, I have concluded that the most simple forms of experiments were more successful in terms of creating an influence on experience with the mind and body. These may include the simplistic form of the cork granules on a transparent material which play a significant role with light and are able to look more delicate and natural than the product in which was originally bought. I did not do many experiments with the wine corks, this is due to me finding more interested in the form and process behind the agglomerated cork sheets. Of which these are formed from the waste product of the cork bark. This is interesting as then the whole bark of the tree is being used entirely and nothing is wasted. This can then be crushed down and used over and over again making it all in all a sustainable material.

The cork granules were most interesting to experiment with because I was able to test different binding adhesives, and delicacy in the material. However the cork sheets were successful in terms of creating structural elements such as the spacial cork sheet. This is different in the case of the cork tubes whereby the agglomerated cork becomes a structure due to the support of the acrylic. However, this does allow it to show case the more delicate side of the fabric and its natural form.

CONCLUSION THE EXPERIMENTS

Structurally reli

Rigid form in a fluid state

Delicately in your hands

A melt-able structure

75

The leather became the most challenging material to experiment with. The tests implemented were unsuccessful, this was due to me testing the durability of the material and hoping to caus some element of deconstruction to them. However the material is proven to be a rather strong and versatile due to their being no obvious or extreme effect of the solutions tested on it. Although the soldering iron did create some deconstruction to the top coat however this did give a decorated finish.

I found that the simple method of cutting and rejoining the leather the most aesthetically pleasing. This is because I was hoping to successful create more beautiful forms with the leather as it can be seen as a rather harsh and dull material. This may come from the knowing of the harmful implications it has on the environment during its manufacturing process.

Resistant

Burnt decor Piece Pieceto

Images attempting to convey the natural organisms in the materials being brought back to life in the final

Resistant

Burnt decor Piece Pieceto

Images attempting to convey the natural organisms in the materials being brought back to life in the final

76

THE OUTER APPEARANCE OF THE BODY

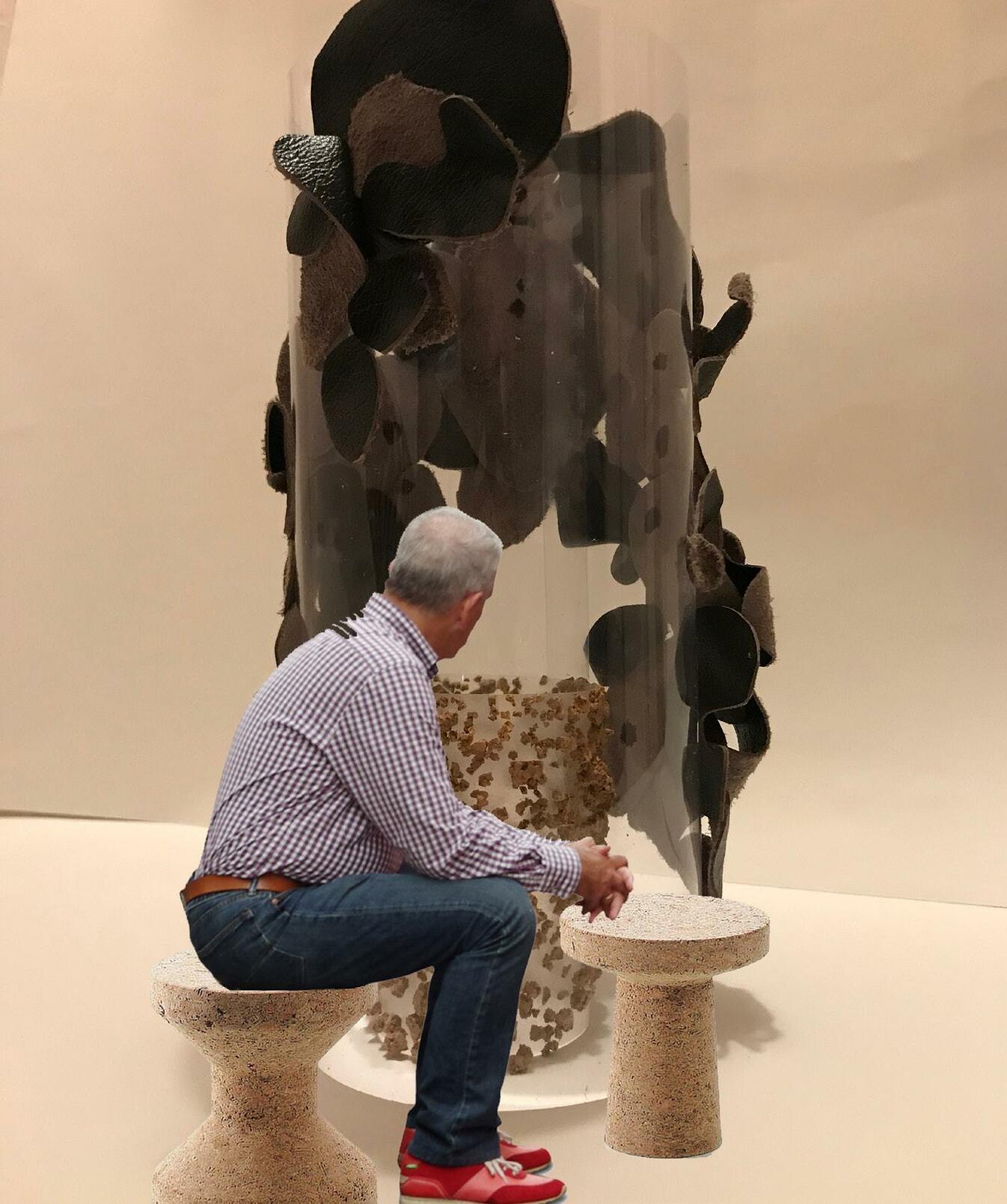

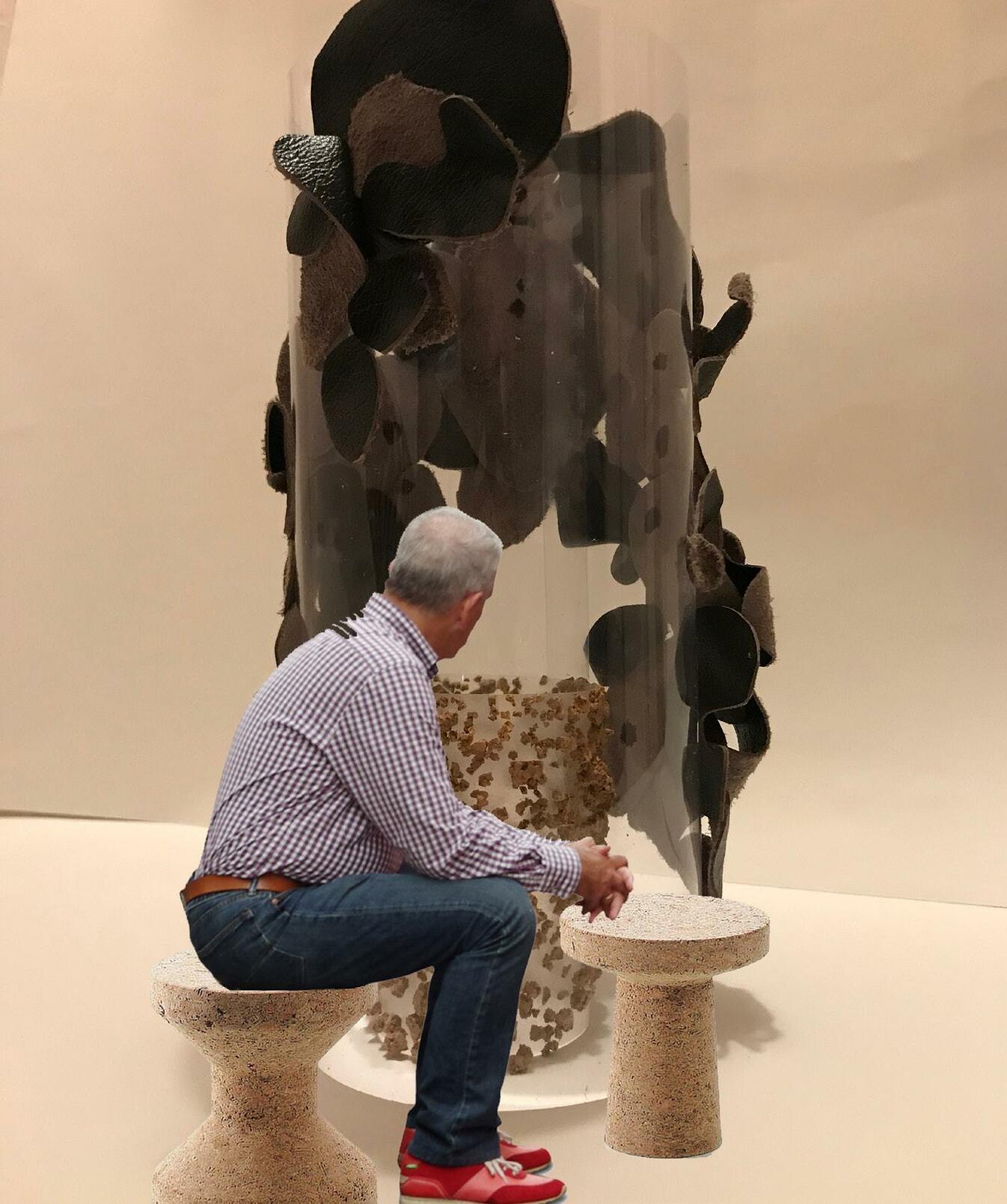

I have decided to create spacial dividers in the form of columns. They will be constructed of acrylic or glass in life scale and bolted to the floor, clad in the cork granules and leather with an artificial light shining down through the acrylic body for the darker times.

The natural light will reflect on the body of the columns giving it a raw look but delicate approach to the materiality, when the artificial light is being shined down the centre, the granules will become more suspended with the leather in silhouette forms whilst casting shadows of natural shapes. All in hope to create a tranquil surrounding with the light capturing the materials in an elipsical form.

It will become a space for users as a resting point in public spaces or can be used as other spacial dividers and zoning in private locations whilst promoting greener and more sustainable choices to peoples lives. Encouraging them to do the next right thing, preserving the natural environment.

The columns will vary in height to enhance the space and modular format.

THE PROTOTYPE

77

COMPRESSION

Weight of lid will add compression with the use of gravitational pull and act as a paper weight on the tube creating a more steady structure. This will support the tension of the cylinder.

TENSION

Clamps can be added for extra support and security at the bottom.

By using columns, the space around is easily created due to them working as a modular system. The format of the columns can be structured to the program of the space.

PRODUCEDBYANAUTODESKSTUDENTVERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

78

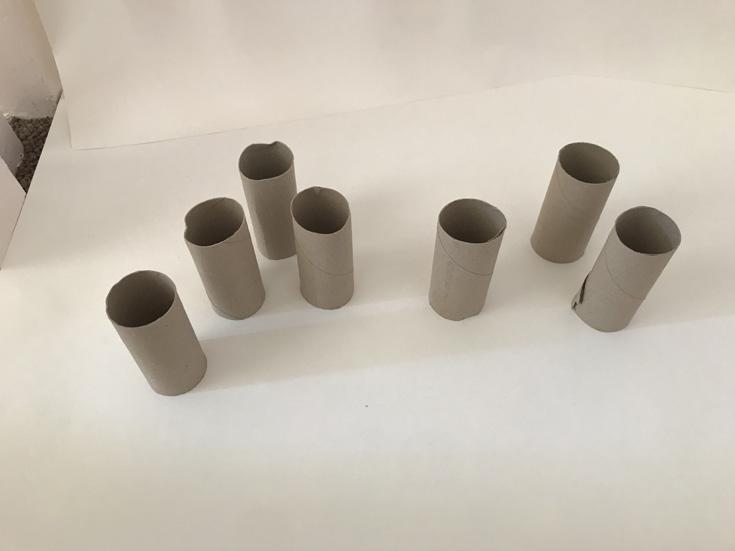

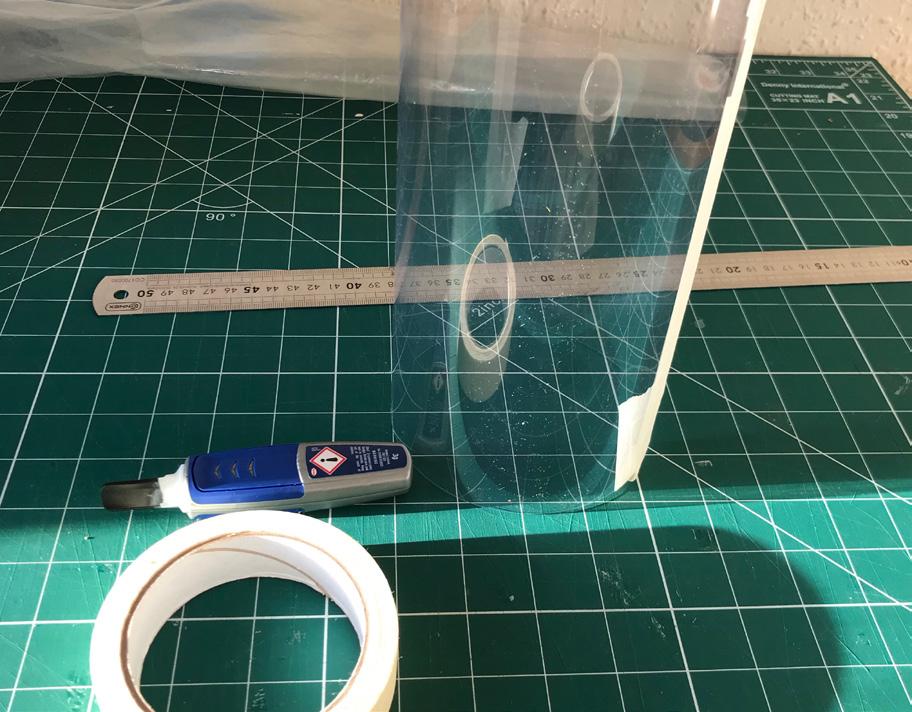

MAKING THE PROTOTYPE

MAKING THE TUBES

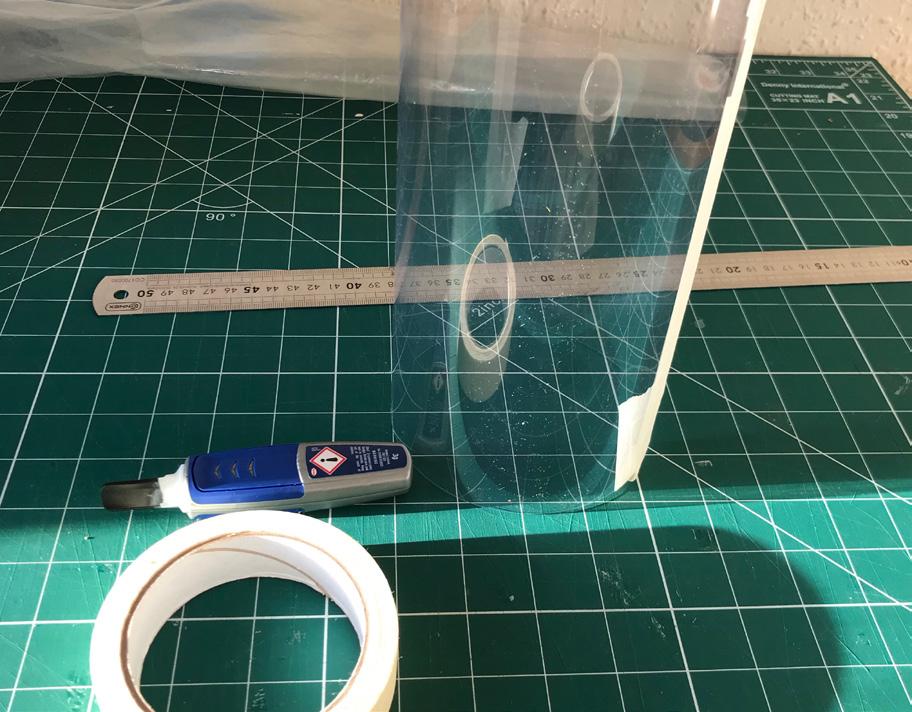

I sourced acrylic sheets and glued them together with super glue and used white tape to hold them together whilst it dried.

CREATING DIFFERENT HEIGHTS AND THICKNESSES.

I decided to create a range of heights and slight difference in dimension.

You should draw a circle around the tubes onto card so you have the correct dimensions for creating the lids later on.

CREATING THE WEIGHTED LIDS AND LIGHTS

Cut out the circles drawn out from the earlier stage, then trace onto an agglomerated cork sheet. You can cut this out and stick to the card ensuring the white side of the card is showing. I used wood glue for this. Then stick your lights to the white side, this will help reflect the light downwards and outwards.

ARRANGE THE TUBES

Once the tubes have the cork and leather on them, arrange and stick them down to the base. I used uhu but you could use bolts if it is at a bigger scale.

THE PRODUCTION PROCESS

79

CUTTING PIECES OF LEATHER

This takes the most time in the making. The leather will need to be cut smoothly in different shapes and sizes ensuring creases in the leather are kept as this adds good effect to the finish. Fabric scissors to the best job.

STICK THE CORK TO TUBE

I then sprinkle cork on the tube and roll the tube in the cork so that the granules stick to the acrylic.

FIXING THE GRANULES TO TUBE

Once the cork is crushed you should use a glove or some form of protection so that you can spray the adhesive on the tube.

PIECING THE PIECES

The leather should then be arranged and stuck to the tube. Super glue works best. It is important to not put glue over the whole piece as having only a bit stuck down allows it to create more folds and depth.

I left some tubes without.

BREAKING UP THE CORK

I then used a blender to crush up the cork into smaller pieces, the smaller the pieces the more likely they are to stick; but too small allows less light through the tube.

80

FORMS OF NATURE A TRANSPARENT FOREST

PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION

ANAUTODESKSTUDENTVERSION

PRODUCED BY AN AUTODESK STUDENT

Are

you destroying the natural environment?

81

PRODUCEDBYANAUTODESKSTUDENTVERSION

PRODUCED BY AN AUTODESK STUDENT VERSIONPRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCEDBYANAUTODESKSTUDENTVERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCEDBYANAUTODESKSTUDENTVERSION

PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCEDBY

STUDENT VERSION

PRODUCEDBYANAUTODESKSTUDENTVERSION

PRODUCED BY AN AUTODESK STUDENT VERSIONPRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCEDBYANAUTODESKSTUDENTVERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCEDBYANAUTODESKSTUDENTVERSION

PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCEDBY

STUDENT VERSION

82

Can

THE SPACIAL EFFECT DAY AND NIGHT

you choose more sustainable materials? 83

84

LIGHT QUALITIES 85

86

I am happy with the play on light and spacial effect with the prototype. I think that this would sit well in many spaces especially those trying to promote sustainability and to be more involved with nature.

For improvements, the leather would possibly be more effective if it cascaded off the tubes more maybe a bit onto the floor whereby it could be moved around to create different forms. Maybe even adding more holes to the leather parts and the leather itself to allow more clear light through. Otherwise I think the form of the leather is rather effective with its organic shapes and flow around the cylinder body.

The cork is very delicate to the eyes but also to the touch. This is great as it represents how delicate and fragile our earth can be and vulnerable to many factors. However this practically may be too much, and there would end up being too much fall off. A better glue maybe used in construction would be more ideal so that there is no fall off and people are able to interact more with it.

The surroundings of the prototype could be accompanied with compressed cork stools or tensile leather stools to allow visitors a place to stop and take it in.

The overall cost came to a large amount which was surprising due to the little amount of material used. The materials and costs listed are the whole package of the sourced product, therefore there are a lot remaining from some of it, making the cost less due to it not all being used.

REPORT CONCLUSION

87

THE COSTS OF THE MATERIALS USED FOR THE PROTOTYPE

MATERIALCOST

ACRYLIC

SUPER GLUE

WHITE TAPE

LEATHER FABRIC SCISSORS CORK SPRAY ADHESIVE

UHU CARD

LIGHTS

WOODEN BASE£2.00 £5.00 £5.00 £0.75 £2.00 £8.00 £5.00 £4.95 £6.00 £2.00 £12.00 £57.70

OVERALL COST

88

TEXTURES.COM. Materials. Available at: https://www.textures.com (Accessed 3 September 2019)

MJANDSTUFF. Through Suzaan Heyns Doors Of Perception. Available at: https://mjandstuff.wordpress.com/2013/04/04/throughsuzaan-heyns-doors-of-perception/ (Accessed 14 September 2019)

WINEANORAK. How cork is made. Available at: https://wineanorak.com/corks/howcorkismade.htm (Accessed 4 October 2019)

THE LEATHERSELLERS COMPANY. Leather Manufactoring Process. Available at: https://leathersellers.co.uk/leather-industry/ leather-manufacturing-process/ (Accessed 4 October 2019)

EUNSUKHUR. Wonderland Collection. Available at: https://www.eunsukhur.com/homeware?lightbox=dataItem-ipken3hl3 (Accessed 20 October 2019)

Morby, A. (2015) DEZEEN. Jorge Penades creates furniture from waste leather. Available at: https://www.dezeen.com/2015/06/16/ jorge-penades-creates-furniture-from-waste-leather/ (Accessed 2 December 2019)

RIBA. Cork House. Available at: https://www.architecture.com/awards-and-competitions-landing-page/awards/riba-regionalawards/riba-south-award-winners/2019/cork-house (Accessed 2 December 2019)

LEATHER DICTIONARY. Leather colour - Leather dye. Available at: https://www.leather-dictionary.com/index.php/Leather_ dye_-_Leather_color_-_Leather_colour (Accessed 4 January 2020)

KEIKO SATO. Metamorphosis. Available at: https://www.keikosato.nl/projects/157.php (Accessed 6 Jan 2020)

THE GUARDIAN. David Nash. Available at: https://www.theguardian.com/artanddesign/2019/may/02/david-nash-exhibitionopens-at-national-museum-cardiff (Accessed 20 Jan 2020)

IMAGE REFERENCES:

Most images are taken by myself, those including photographs taken in Morocco and of experimental process. Others taken from websites as referenced in the bibliography.

BIBLIOGRAPHY

89

90

Leather Tannery in Fes, Morocco.

Leather Tannery in Fes, Morocco.

CORKS ARE THEN PLACED INTO BINS ACCORDING TO THEIR GRADE, READY FOR SHIPMENT.

WASTE CORK AND VIRGIN CORK IS PASSED THROUGH A MACHINE BREAKING IT INTO SMALL PIECES.

AGGLOMERATED CORK IS FORMED THROUGH DIFFERENT WAYS OF BINDING THESE CORK PARTICLES TOGETHER.

CORKS ARE THEN PLACED INTO BINS ACCORDING TO THEIR GRADE, READY FOR SHIPMENT.

WASTE CORK AND VIRGIN CORK IS PASSED THROUGH A MACHINE BREAKING IT INTO SMALL PIECES.

AGGLOMERATED CORK IS FORMED THROUGH DIFFERENT WAYS OF BINDING THESE CORK PARTICLES TOGETHER.

The production process of the cork used in the Cork House.

The production process of the cork used in the Cork House.

COW GOAT

CAMEL

Common leather found in Morocco.

Hard Thick Thin

Soft

COW GOAT

CAMEL

Common leather found in Morocco.

Hard Thick Thin

Soft

A MORE SUSTAINABLE LEATHER

A MORE SUSTAINABLE LEATHER

RIGID CORK IN THE FOLD

RIGID CORK IN THE FOLD

Keiko

Keiko

Brunhilde Asleep by Margaret Fernie Eaton 1902.

Brunhilde Asleep by Margaret Fernie Eaton 1902.

The ‘fur’ scraped off from the back of the leather

The ‘fur’ scraped off from the back and front of the leather

The ‘fur’ scraped off from the front of the leather

The ‘fur’ scraped off from the back of the leather

The ‘fur’ scraped off from the back and front of the leather

The ‘fur’ scraped off from the front of the leather

Art found in the Museum of Modern and Contemporary Art, Rabat, Morocco. Artist Unknown.

I then decided to add the scraps of the cut off to ensure most of the material was used and not disposed of.

I think that adding to the leather a sewing method whereby threads are visible would be affective too. As shown below.

Art found in the Museum of Modern and Contemporary Art, Rabat, Morocco. Artist Unknown.

I then decided to add the scraps of the cut off to ensure most of the material was used and not disposed of.

I think that adding to the leather a sewing method whereby threads are visible would be affective too. As shown below.

Eunsuk Hur, Transformable Modular Textile Design.

Eunsuk Hur, Transformable Modular Textile Design.

Material particles before latex was added.

Before latex dried

Material particles before latex was added.

Before latex dried

Before latex

After latex dried

Before latex

After latex dried

Resistant

Burnt decor Piece Pieceto

Images attempting to convey the natural organisms in the materials being brought back to life in the final

Resistant

Burnt decor Piece Pieceto

Images attempting to convey the natural organisms in the materials being brought back to life in the final