Shot Peening

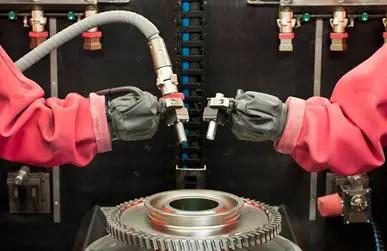

Shot peening is a controlled mechanical process where small spherical media known as shots are blasted against the surface of a component. component. This actually creates a high velocity impact, and this process increases the material’s resistance to fatigue, stress and cracking. It’s an essential process for components to enhance their durability.

when it comes to high-performance environments, this process prevents fatigue failure and stress corrosion cracking.

Shot peening also enhances the surface finish and eliminates microscopic cracks that may lead to early part failure. As a result, components last longer, operate more reliably, and require less frequent replacement.

we start the shot peening process, we analyse the component’s geometry, material type and operational stress factors

Steel Shot – Durable and commonly used for heavyduty applications

Glass Beads – Ideal for delicate surfaces or cosmetic finishing

Ceramic Beads – Used when high precision and nonferrous compatibility are needed

Almost all materials like steel, aluminium, titanium, and other industrial metals can be shot peened.

Shot peening is mostly used to create compressive stresses that improve material fatigue resistance.

On average, most shot peening jobs get completed within 24 to 72 hours.