FIXING DESIGN GUIDE

MECHANICAL, CHEMICAL and LIGHT duty ANCHORS

2023-2024

Safe Anchoring

EDITION

With

ACCURATE CODE-COMPLIANT DESIGNS

Secure your work

Can be used according the different calculation rules and standards

ETA documents

BIM

WITH ALL BROWSERS

Always up to date Tablet, computer, smartphone

INTUITIVE

Easy 6 step process

For all kind of users

2D / 3D Interface for clear views

WWW.SPIT.COM/I-EXPERT @

FREE SOFTWARE

ENILNO

LIBRARY EMBEDED AUTOCAD & REVIT EN1992-4 BIM YSAE

FOREWORD

The design of fasteners are covering by European Standard EN 1992-4. In this technical guide, we propose technical sheets dedicated to each product with following data:

¬ General technical data on the product, ie. Dimensions, installation data, drawing, application, field of use, mechanical properties

¬ Minimum thickness of base material, minimum spacing and edge distance, characteristic spacing and edge distance.

¬ Characteristic resistances given in the ETA

¬ Recommended loads determined from performances and partial safety factors given in the ETA

¬ Design resistance Rd for each type of actions, ie. Static, Seismic, Fire depending on the scope of the approval All performances are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr

¬ Performances for tensile load are given for the decisive failure for decisive failure type i.e. Pull-out failure, Concrete cone failure and Steel failure

¬ Performances for shear load are given for steel failure

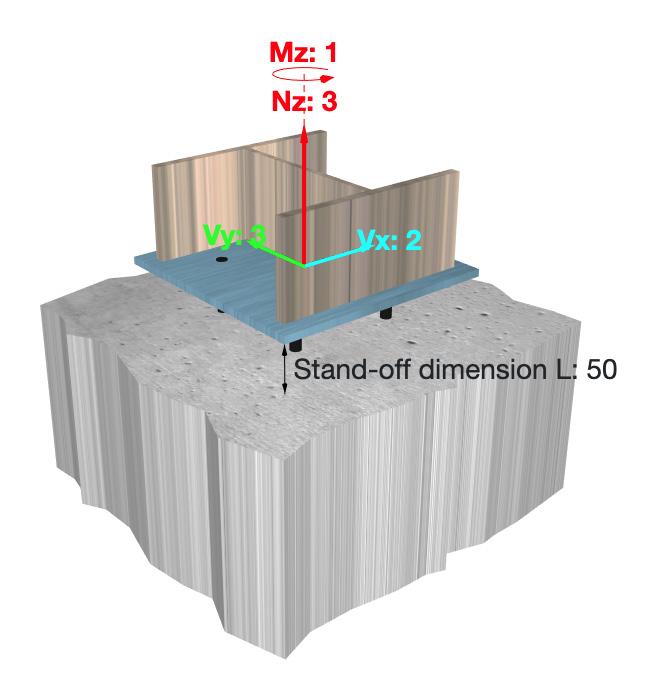

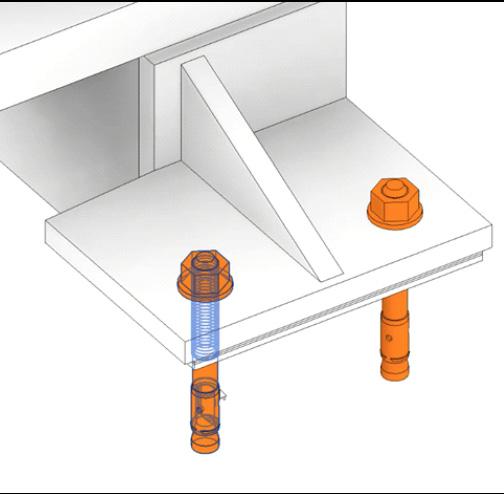

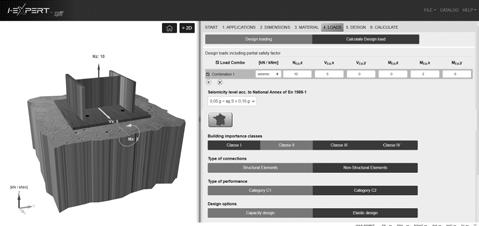

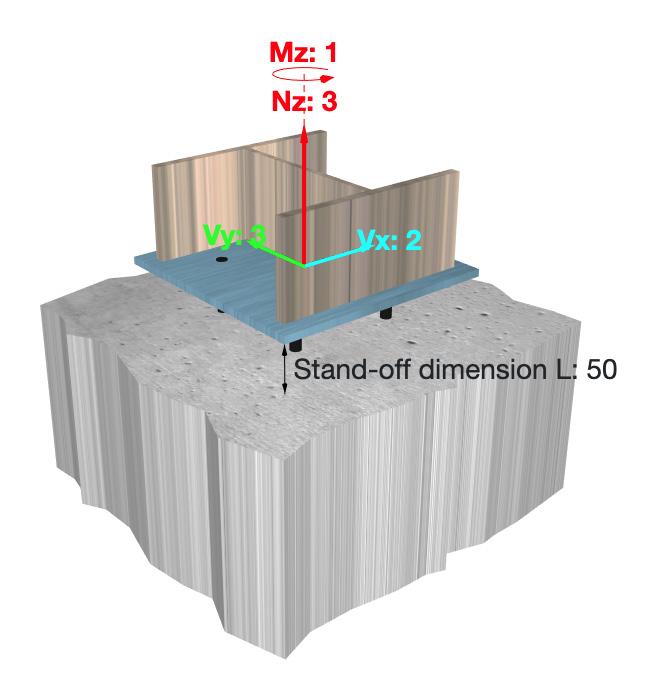

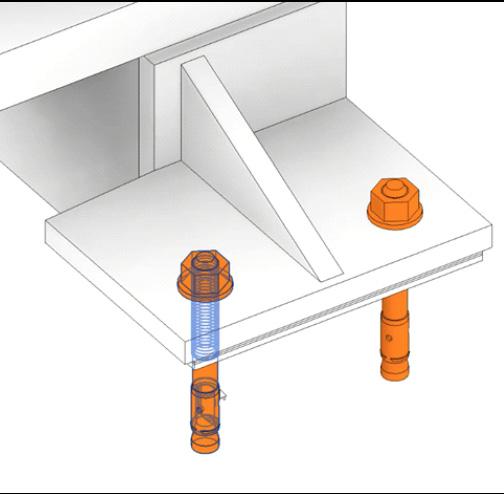

To design easily your project, we recommend to use SPIT i-Expert software according to EN 1992-4

index

i-Expert Software

17

18

21 MECHANICAL ANCHORS 22 - 57 CHEMICAL ANCHORS 58 - 86 LIGHT DUTY ANCHORS 87 - 94

CONTENTS GENERALItY 02 -

product selection chart

-

GENERALITY

TYPE OF ANCHORS

TORQUE CONTROLLED EXPANSION ANCHOR - TYPE A

The expansion is achieved by a torque acting on the screw or bolt, the intensity of the anchorage is controlled by this torque.

HAMMER SET EXPANSION ANCHOR - TYPE B

The expansion is achieved by impacts acting on a sleeve or cone. In the case of the SPIT GRIP anchor, the sleeve is expanded by driving in the cone, the anchorage being controlled by the length of travel of the cone.

UNDERCUT ANCHORS - TYPE C

Undercut anchors are anchored by mechanical interlock provided by an undercut in the concrete. The undercutting can be achieved by hammering or rotating the anchor sleeve into a drilled undercut hole, or by driving the anchor sleeve onto the tapered bolt in a cylindrical hole.

BONDED ANCHORS - TYPE D

Bonded anchors are anchored in drilled holes by bonding the metal parts to the sides of the drilled hole with a resin mortar. Tensile loads are transmitted to the concrete via bond stresses between the metal parts and the resin, and the resin and the concrete face of the drilled hole.

LIGHT DUTY PLASTIC ANCHORS

Plastic sleeves are expanded by hammering or screwing in the expansion element which presses the sleeve against the wall of the drilled hole. The expansion element could be a nail or a screw.

EUROPEAN STANDARDS

TORQUE CONTROLLED EXPANSION ANCHORS

CONCRETE SCREWS

UNDERCUT ANCHORS

HAMMER SET EXPANSION ANCHORS

BONDED ANCHORS

BONDED ANCHORS:

EAD 330747-00-0601

Post-installed rebar connections EAD 330087-00-0601

BONDED ANCHORS: for masonries

* Documents available on website: www.eota.eu DESIGN METHOD

ETA OPTIONS

Applications for

• «actual» risk of loss of human life

• serious economic consequences

• affect fitness of the structure to fulfil its functions

Applications for concrete with limited risk level

• «negligible» risk of human life

• low economic consequences

• localized damages

Anchors for multiple use in non-structural applications (typical example include pipework,ductwork and cable tray)

Application for rebar connections designed in accordance with Eurocode 2

Metal injection anchors for use in masonry

Anchors for fixing external thermal insulation composite systems with rendering

ETAG of plastic anchors for multiple use in concrete and masonry for non-stuctural applications

Design of anchors for use in concrete under quasi-static and seismic actions

OPTION N° CRACKED AND NON CRACKED NON CRACKED ONLY C20/25 ONLY C20/25 TO C50/60 ONE VALUE ACCORDING TO DIRECTION CHARATERISTIC & MINIMUM DISTANCES FOR SPACING, EDGE FRk FRk Ccr Scr Cmin Smin 1 • • • • • • • 2 • • • • • • • 3 • • • • • • • 4 • • • • • • • 5 • • • • • 6 • • • • • 7 • • • • • • • 8 • • • • • • • 9 • • • • • • • 10 • • • • • • • 11 • • • • • 12 • • • • • SUITABLE ANCHORS TYPE EUROPEAN STANDARDS* APPLICATION RANGE TORQUE CONTROLLED EXPANSION ANCHORS EAD 330232-00-0601

concrete

with high risk level

CONCRETE SCREWS UNDERCUT ANCHORS HAMMER SET EXPANSION ANCHORS BONDED ANCHORS EAD

330499-00-0601

EAD 330076-00-0604

EAD 330196-00-0604

INSULATION ANCHORS

EAD

LIGHT DUTY PLASTIC ANCHORS

330284-00-0604

EN 1992-4

2

For the design of anchorages according to the EN 1992-4 standard, the safety concept of partial safety factors shall be applied at the ultimate limit state. It shall be shown that the value of the design action Sd does not exceed the value of the design resistance Rd.

PRINCIPLE OF PARTIAL SAFETY CONCEPT

Case of ultimate limit state

Case of serviceability limit state

According to the EN 1992-4 design method, the proof of the resistance must be carried out for each following types of failures in tensile and shear load. The purpose of differentiating these failure modes, is to be able to apply an appropriate safety factor as a function of the specific failure mode.

CALCULATION OF THE COMBINED LOAD

The combined load FSd with an angle α is obtained by:

FSd = (NSd)² + (VSd)² α = arctan (VSd/NSd)

with: NSd: action in tensile direction (NSd = FSd x cos α)

VSd: action in shear direction (VSd = FSd x sin α)

To verify the resistance for a combined load with the method CC, we proceed as follows :

‣ the tensile resistance: βN = NSd / NRd ≤ 1

‣ the shear resistance: βV = VSd / VRd ≤ 1

‣ the combined load with the following interactive equation: βN + βV ≤ 1,2

Sd ≤ Rd Mean

Characteristic resistance Design resistance Recommended load S< Rrec Design load (ELU) Actual load Sk Sd Rd Rrec Rk Ru,m Rk=Ru.m (1-k.v) Sd=Sk. Rrec = Rd

ultimate resistance

Mean

resistance Characteristic resistance Design resistance Design load Actual load Sk Sd Rk=Ru.m (1-k.v) Rd Rk Ru,m Sd=Sk Rd=Rk / M Sd < Rd GENERAL

ultimate

DIFFERENT TYPES OF FAILURE MODE N Concrete cone failure N Pull-out failure N Steel failure N Splitting failure TENSILE LOAD V Pryout failure V Steel failure V Concrete edge failure SHEAR LOAD

0.2 0.2 1.0 βN + βV ≤1,2 1.0 βV βN NSd FSd VSd

SAFETY CONCEPT 3

Seismic

The static or quasi-static loads are dead loads of the element fixed, permanent and variable actions as wind, snow …

DESIGN

The design actions for tensile and shear load in the ultimate limit state are calculated according to Eurocode 2 or 3.

In the simplest case: (permanent load «G» and one variable load «Q»), the design load is calculated as follows:

The factor 1,35 and 1,5 are the partial safety factor applied on the action. For simplification, in this book we have adopted the safety factor : γF = 1,4:

Sk = G + Q

Other cases:

The variable loads can be influenced by wind, or / and snow.

To calculate these actions in ultimate limit state, we will take the most unfavourable of the following actions combined. Details on Eurocode 1 for the loading codes.

4

TIME LOAD TIME PULSATING SHOCK ALTERNATIVE Static or quasi-static loads Dynamic loads Sd = 1.35 x G + 1.5 x Q Sd = γF . Sk

: G = permanent load QB = imposed load W = wind load Sn = snow load Ψ0 = 0,77 or all premises, except record offices and parking. If the basic variable action is the snow, Ψ0 is increase by 10%

Symbols

loads SEISMIC TIME PERMANENT LOAD VARIABLE LOAD ONE WITH ITS CHARACTERISTIC VALUE OTHERS WITH COMBINATION VALUE U.L.S. 1,35 G + 1,5 QB + 1,2 W 1,35 G + 1,5 W + 1,3 Ψ0 QB 1,35 G + 1,5 Sn + 1,3 Ψ0 QB TYPE OF LOADS

The seismic loads are calculated using the acceleration spectrum of the seismic zone, according to Eurocode 8. ACTION CALCULATION

The dynamic loads are variable actions in time with a medium or high amplitude. For example, motor vibration, regular shock … Some dynamic loads could be considered as quasi-static loads (wind …).

DESIGN ACTIONS

DESIGN RESISTANCE

CALCULATION OF THE DESIGN RESISTANCE

The design value of resistance Rd, in any direction and for all type of failure, is calculated from the characteristic resistance and the partial safety factor.

Rd = Rk γM

Rk : characteristic resistance of the anchor

γM : partial safety factor depends on the type of failure

CHARACTERISTIC RESISTANCE

The characteristic load of the anchor for concrete cone failure, in any direction, is calculated from the average value of the mean failure load for the single anchor, without the effect of spacing and edges. The characteristic load corresponds to the 5% - fractile of failure loads for the level of confidence (90%).

FRk = (1- k.v) . FRu,m

This calculation depends on number of tests (k) and the variation coefficient of tests (v)

Example : for a number of tests equal to 10 anchors, we can take k = 2,568.

The characteristic load of steel failure are calculated as follows:

For tensile load: NRk,s = A0.fuk [N] For shear load: VRk,s = 0,5.AS.fuk[N]

A0: min cross section [mm²]

As: stressed cross section [mm²] fuk: min tensile strength [N/mm²] fuk: min tensile strength [N/mm²]

CALCULATION OF PARTIAL SAFETY FACTOR

For concrete cone failure: γMc = γc γ1 γ2

γc: Partial safety factor for concrete under compression: γc = 1,5

γ1: Partial safety factor taking account of the scatter of the tensile strength of site concrete.

γ1 =1 for concrete produced and cured with normal care (EUROCODE 2 chap. 7)

γ2: Partial safety factor taking into account of the installation safety* of an anchor system

Tensile load:

γ2 = 1 for systems with high installation safety*

γ2 = 1,2 for systems with normal installation safety*

γ2 = 1,4 for systems with low but still acceptable installation safety*

Shear load:

γ2 = 1

For steel failure: γMs

γMs = 1,2 ≥1,4 fyk/fuk

γMs = 1,0 ≥1,25 fyk/fuk

For tensile load: For shear load: with fuk ≤ 800 N/mm² and fyk/fuk ≤ 0,8

γMs = 1,5 with fuk > 800 N/mm² or fyk/fuk > 0,8

* Installation safety means the influence of installation defects, such as diameter of drilled hole, cleaning of the hole, intensity of anchorage and striking the reinforcement during drilling.

5

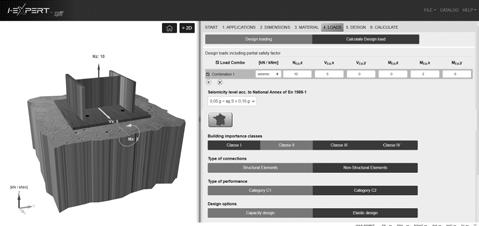

SEISMIC PERFORMANCE

SEISMIC PERFORMANCE CATEGORIES C1 AND C2

The seismic performance of anchors subjected to seismic loading is categorized by performance categories C1 and C2. Seismic performance category C1 provides anchor capacities only in terms of resistances at ultimate limit state, while seismic performance category C2 provides anchor capacities in terms of both resistances at ultimate limit state and displacements at damage limitation state and ultimate limit state.

Table below relates the seismic performance categories C1 and C2 to the seismicity level and building importance class. The level of seismicity is defined as a function of the product ag.S, where ag is the design ground acceleration on Type A ground and S the soil factor both in accordance with EN 1998-1.

The value of ag or that of the product ag.S used in a Member State to define thresholds for the seismicity classes may be found in its National Annex of EN 1998-1 and may be different to the values given in Table below. Furthermore, the assignment of the seismic performance categories C1 and C2 to the seismicity level and building importance classes is in the responsibility of each individual Member State.

Tests

Category

RECOMMENDED SEISMIC PERFORMANCE CATEGORIES FOR METAL ANCHORS

a The values defining the seismicity levels are may be found in the National Annex of EN 1988-1

b Definition according to EN 1998-1:2004, 3.2.1

c ag = design ground acceleration on Type A ground (EN 1998-1:2004, 3.2.1), S = soil factor (see e.g. EN 1998-1:2004, 3.2.2).

d C1 for Type 'B' connections for fixings of non-structural elements to structures

e C2 for Type 'A' connections for fixings structural elements to structures

I Buildings and structures that normally are not subject to human occupancy (e.g., equipment storage sheds, barns, and other agricultural buildings) and that do not contain equipment or systems necessary for disaster response or hazardous materials.

II Most buildings and structures of ordinary occupancy (e.g., residential, commercial, and industrial buildings) except those buildings contained in other categories (less than 300 people, building high ≤ 28 m).

Buildings and structures that:

• Have large numbers of occupants (more than 300 people, building high ≥ 28 m) e.g., high-rise office buildings, sports arenas, and large theaters...

III

• Shelter persons with limited mobility (e.g., jails, schools, andsome healthcare facilities)

• Support lifelines and utilities important to a community’s welfare

• Contain materials that pose some risk to the public if released IV

Buildings and structures that:

• Are essential to post-earthquake response (e.g., hospitals, police stations, fire stations, and emergency communications centers)

• House very large quantities of hazardous materials

CATEGORY EUROPEAN REQUIREMENT ACCORDING TO TR 045 TECHNICAL REPORT ASSESSMENT OF TESTS ACCORDING TO ETAG 001 - ANNEX E

C1 for non-structural applications

tests in cracked-concrete (crack widths 0,5 mm)

Category

Alternative

C2 for structural and non-structural applications

crack

(crack

SEISMICITY LEVELa BUILDING IMPORTANCE CLASS ACC. TO EN 1998-1:2004, 4.2.5 CLASS Ag.Sc I II III IV Very lowb ag.S ≤ 0,05 g No additional requirement Lowb 0,05 g < ag.S ≤ 0,10 g C1 C1d or C2e C2 > Low ag.S > 0,10 g C1 C2

of increased severity with varying

widths, simulating earthquake

widths 0,8 mm)

CLASS BUILDING TYPE

6

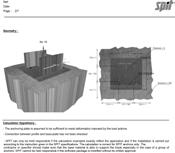

I-EXPERT SOFTWARE I-EXPERT 7

Concrete is classified according to its compressive strength which is based on the classification per strength measured on cylinders as indicated in the NF EN 206-1 standard. For information, the table below gives an equivalence between the characteristic values and average strength on cylindrical and cubic specimens in MPa.

Concrete can be considered as cracked for many reasons. According to the ETA Guideline, we must verify if the concrete is cracked or non cracked by calculation of stresses in the works or part of the works serving as the base material (§4.7 - EN1992-4):

σL: Stresses in the concrete induced by external loads, including anchors loads

σR: Stresses in the concrete due to restraint of instrinsic imposed deformations (e.g; shrinkage of concrete) or extrinsic imposed deformations (e.g. due to displacement of support or temperature variations).

If no detailed analysis is conducted, then σR = 3N/mm² should be assumed, according to Eurocode 2.

If there are no details available to make the above calculation, use the table below. Nevertheless, it is the responsibility of the designer to check the status of the base material (cracked or non cracked).

CONCRETE CLASSES CHARACTERISTIC STRENGTH fck AVERAGE STRENGTH ACCORDING TO EUROCODE 2 ACCORDING TO P18-305 CYLINDER 16 X 32 CM CUBE 15 X 15 X 15 CM CYLINDER (fcm) 16 X 32 CM CUBE 15 X 15 X 15 CM CUBE 20 X 20 X 20 CM C 16/20 B16 16 20 20 25 24 C 20/25* B20 20 25 25 31 29 C 25/30 B25 25 30 30 37 36 C 30/37* B30 30 37 37 46 43 C 35/45 B35 35 45 45 56 53 C 40/50* B40 40 50 50 62 59 C 45/55 B45 45 55 55 69 65 C 50/60* B50 50 60 60 72 68 * The most usual classes WORKS OR PARTS OF WORKS USED AS ANCHORING BASE CONCRETE CONDITIONS NON CRACKED CRACKED Deflected elements (slabs, longitudinal beam, firder, purlin) in reinforced concrete X Deflected elements (slabs, longitudinal beam, firder, purlin) in prestressed concrete X Outside wall of a building in not reinforced (according to BAEL) or with reinforced skin X Outside wall of a building in reinforced concrete X Inside wall of a building X Angle or edge post X Inside post X Base plate paving X Keying areas of a building made from prefabricated elements X Ends of deflected elements (ex: projected balcony noses) X Tanking X CONCRETE STRENGTH FIELD OF USAGE: CRACKED OR NON CRACKED CONCRETE σL+ σR ≤ 0

8

CONCRETE

The following are examples of non-cracked locations in simple structures (issue from the technical report n° CEN/TC250/SC2/WG2 “effect of cracking” published by CEN.

Solid slabs, beams - simply supported

Solid slabs, beams, ribbed floors - Continuous

Cantilever slabs

Cantilever beams

0.15L L L h h h h 0.4h 0.4h 0.4h A A – A A – A A – A B – B B – B 0.15L 0.25L L 0.25L 0.15L1 0.15L2 0.15L3 L1 L2 L3 0.15L1 0.25L2 0.25L1 0.25L3 0.25L2 0.15L2 B AB A A B B A A A A B B C C Non-cracked concrete Non-cracked concrete Non-cracked concrete Non-cracked concrete

CONCRETE 9

MASONRIES

Perforated clay bricks type ECO-30, rendered or not rendered

Rc = 3.7 N/mm² - 57x20x30 (cm)

NF EN 771-1

Rc = 14.5 N/mm² - 20x24x50

NF EN 771-1

Clay bricks

Rc = 55 N/mm² - 22x10x5.5 (cm)

NF EN 771-1

Solid concrete blocs B120 Rc = 13,5 N/mm² - 20x20x50 (cm)

Hollow concrete block type B40, rendered or not rendered Rc = 6,5 N/mm² - 20x20x50 (cm)

NF EN 771-3

Plasterboard type BA13 and BA10 + polystyrene

NFP 72-302

FIXINGS OF REBARS AND THREADED STUDS M8 TO M20 IN CEILING

USING CEILING CAP AND MEASURING CONNECTOR: USING SIEVE

Aerated

concrete

1 - Resin injection (EPOBAR for rebars or VIPER XTREM for studs) with measuring connector

2 - Cap introduction into drilled hole

3 - Installation : the rebar (or the stud) is maintained by the cap blades

d L

The design resistances for stud dimensions M8 to M20 in ceiling are reduced by 20 % for anchoring with resin.

1 - Drill a hole according to the diameter and the selected depth

2 - Carefully clean with metal brush

3 - Remove the dust by blowing with air pump

4 - Cut a length of screen corresponding to the length Lt of the table above and insert the cap

5 - Insert the threaded stud in the cap and push it into the sieve to the length lr of the table above

6 - Fill the remaining volume of sieve with resin

l

7 - Insert the assembly in the hole until the cap locks itself in the hole

8 - Push the stud by hand with a twisting motion through the cap to the bottom of the hole. A slight excess of resin should emerge

STUD DIMENSION MIN. SUPPORT THICKNESS HOLE DIAMETER HOLE DEPTH STUD LENGTH INSERTED INTO SIEVE INTERNAL DIAMETER OF THE SIEVE SIEVE LENGTH SIEVE CODES CAP TYPES CAP CODES (mm) d0 (mm) h0 (mm) lr (mm) dt (mm) lt (mm) M8 120 15 80 10 12,5 75 63400 W5 63460 M10 130 15 90 10 12,5 85 63400 W5 63460 M12 160 18 110 15 15 105 63410 W7 63470 M16 175 22 125 50 20,5 120 63420 W10 63480 M20 220 28 170 65 26 165 63430 W13 63490

Mvn

NF EN 771-3 NF

= 500 kg/m3

EN 771-4

Engineer clay bricks Murbric type T20, rendered or not rendered

9 - Observe loading and tightening torque times

Characteristics of these sieve and installation data :

10

OTHER SUBSTRATE/CEILING

STEEL PROPERTIES

Mechanical characteristics

The steel properties are determined by : - the tensile strength fuk (N/mm²), - the yield strength fyk (N/mm²).

Zinc coated steel: the standard NF EN 20898-1 gives the characteristics of studs and screws depending on the grade of steel. Stainless steel: the standard NF EN 25100-0 gives the stainless steel characteristics.

TORQUE WRENCH SOCKETS / NUTS / WASHERS

NUTS: dimensions for torque wrench sockets

WASHERS: dimensions of the washers used with SPIT Products (some products are available with large washers)

NOMINAL THREAD DIAMETER THREAD PITCH NOMINAL CROSS SECTION STEEL GRADE STAINLESS STEEL GRADE A4 3.6 4.6 4.8 5.6 5.8 6.8 8.8 10.9 12.9 50 70 80 (mm) (mm) As/mm² Minimum failure load Minimum failure load 1.6 0.35 1.27 0.42 0.51 0.53 0.64 0.66 0.76 1.02 1.32 1.55 0.64 0,89 1.02 2.0 0.4 2.07 0.68 0.83 0.87 1.04 1.08 1.24 1.66 2.15 2.53 1.04 1,45 1.66 2.5 0.45 3.39 1.12 1.36 1.42 1.70 1.76 2.03 2.71 3.53 4.14 1.70 2,37 2.71 3.0 0.5 5.03 1.66 2.01 2.11 2.51 2.62 3.02 4.02 5.23 6.14 2.51 3,52 4.02 3.5 0.6 6.78 2.24 2.71 2.85 3.39 3.53 4.07 5.42 7.05 8.27 3.39 4,74 5.42 4.0 0.7 8.78 2.90 3.51 3.69 4.39 4.57 5.27 7.02 9.13 10.70 4.39 6,15 7.02 5.0 0.8 14.2 4.69 5.68 5.96 7.10 7.38 8.52 11.35 14.80 17.30 7.10 9,94 11.35 6.0 1.0 20.1 6.63 8.04 8.44 10.00 10.40 12.10 16.10 20.90 24.50 10.00 14,07 16.10 7.0 1.0 28.9 9.54 11.60 12.10 14.40 15.00 17.30 23.10 30.10 35.30 14.40 20,23 23.10 8.0 1.25 36.6 12.10 14.60 15.40 18.30 19.00 22.00 29.20 38.10 44.60 18.30 25,62 29.20 10.0 1.5 58.0 19.10 23.20 24.40 29.00 30.20 34.80 46.40 60.30 70.80 29.00 40,60 46.40 12.0 1.75 84.3 27.80 33.70 35.40 42.20 43.80 50.60 67.40 87.70 103.00 42.20 59,01 67.40 14.0 2.0 115.0 38.00 46.00 48.30 57.50 59.80 69.00 92.00 120.00 140.00 57.50 80,50 92.00 16.0 2.0 157.0 51.80 62.80 65.90 78.50 81.60 94.00 125.00 163.00 192.00 78.50 109,90 125.00 18.0 2.5 192.0 63.40 76.80 80.60 96.00 99.80 115.00 159.00 200.00 234.00 96.00 134,40 159.00 20.0 2.5 245.0 80.80 98.00 103.00 122.00 127.00 147.00 203.00 255.00 299.00 122.00 171,50 203.00 22.0 2.5 303.0 100.00 121.00 127.00 152.00 158.00 182.00 252.00 315.00 370.00 152.00 212,10 252.00 24.0 3.0 353.0 116.00 141.00 148.00 176.00 184.00 212.00 293.00 367.00 431.00 176.00 247,10 293.00 27.0 3.0 459.0 152.00 184.00 193.00 230.00 239.00 275.00 381.00 477.00 560.00 230.00 321,30 381.00 30.0 3.5 561.0 185.00 224.00 236.00 280.00 292.00 337.00 466.00 583.00 684.00 280.00 392,70 466.00 33.0 3.5 694.0 229.00 278.00 292.00 347.00 361.00 416.00 576.00 722.00 847.00 347.00 485,80 576.00 36.0 4.0 817.0 270.00 327.00 343.00 408.00 425.00 490.00 678.00 885.00 997.00 408.00 571,90 678.00 39.0 4.0 976.0 322.00 390.00 410.00 488.00 508.00 586.00 810.00 1020.00 1200.00 488.00 683,20 810.00 Sw M Ø e d1 d2 s

WASHERS ACCORDING TO NF EN ISO 7091 SPECIAL WASHERS SPIT TRIGA Z XTREM WASHERS SPIT TRIGA Z A4 (mm) d2 d1 s d2 d1 s d2 d1 s M6 12 6,6 1,6 18 6,7 2 18 6,3 2 M8 16 9,0 1,6 20 8,7 2 22 8,2 2 M10 20 11,0 2 26 10,5 3 28 10,5 3 M12 24 13,5 2,5 30 12,5 3 30 12,3 3 M16 30 17,5 3 40 16,7 4 - -M20 37 22,0 3 45 20,7 4 - -M24 44 26,0 4 - - - - -M30 56 33,0 4 - - - - -NUTS ACCORDING TO DIN 934 NUTS ACCORDING TO NF EN ISO 4032 (mm) Sw e M Sw e M M6 10 11,5 5 10 11,05 5,2 M8 13 15 6,5 13 14,38 6,8 M10 17 19,6 8 16 17,77 8,4 M12 19 21,9 10 18 20,03 10,8 M16 24 27,7 13 24 26,75 14,8 M20 30 34,6 16 30 32,95 18 M24 36 41,6 19 36 39,55 21,5 M30 46 53,1 24 46 50,85 25,6

MECHANICAL CHARACTERISTICS STEEL GRADE STAINLESS STEEL GRADE* 3.6 4.6 4.8 5.6 5.8 6.8 8.8 10.9 12.9 50 70 80 Min. tensile strength fuk (N/mm²) 330 400 420 500 520 600 800 1040 1220 500 700 800 Min yield strength fyk (N/mm²) 190 240 340 300 420 480 640 940 1100 210 450 600 * Stainless steel grade A1, A2 & A4

Minimum failure loads (kN) - ISO metric thread to NF EN 20898-1

STEEL MECHANICAL PROPERTIES

11

CHOICE OF STEEL QUALITY ACCORDING TO ATMOSPHERE

Atmospheric corrosion is linked to ambient atmosphere. The agents combined themselves to air components. The mixture of oxygen, moisture and industrial pollutants, mainly chlorous and sulphurous, attacks and destroys metals and alloys. We can indicate 6 principal types of atmosphere.

DRY Clean rooms, heated in winter without condensation. Housing inside, air-conditioned rooms.

HUMID Rooms subjected to condensation, warehouses, stores, cellars...

RURAL Housing in temperate climate and a long way from large cites and factories (country).

URBAN Housing in towns with one or more factories emitting smoke creating atmospheric corrosion.

INDUSTRIAL Factories and their surroundings significant atmospheric corrosion (depending on industrial process).

SALT ATMOSPHERE Atmosphere of seaside or on sea. High corrosion due to presence of relatively high humidity combined with certain contents of sea salt in the air.

Source : NFA 91-102 - Metal surface Quality not suitable for the medium Get into touch with us Possible use

CHOICE OF STEEL QUALITY ACCORDING TO CONTACTS BETWEEN MATERIALS

Electrolytic corrosion may occur when two different metals are in contact with each other. This creates an electrolytic action which causes the gradual destruction of one of the elements.

TYPES OF ATMOSPHERE ZINC DEPOSIT 5-10 µm HOT DIP GALVANIZED 45 µm MINI STAINLESS STEEL A4

INSIDE

OUTSIDE

METAL OF THE PART TO BE FIXED METAL OF THE FIXING STAINLESS STEEL HOT DIP GALVANISED ZINC COATED STEEL ZINK ALLOY BRASS Stainless steel Hot dip galvanised steel Zinc coated steel Mild steel Aluminium alloy No corrosion of the fixing Moderated corrosion of the fixing Corrosion of the fixing

12

CORROSION

COATINGS AND CORROSION RESISTANCE

Type of coating

1600

1400

1200

1000

800

1800 > 5000 FRANCE NF EN 10088-1 ACCORDING TO NFA 35-573 1990 NFA 35-574 1990 (OR NFA 36-209 OR NFA 35-577)

600

Sherardisation (20 µm)

Hot dip galvanised (70 µm)

Electrogalvanised with thickness coating (5-7 µm)

TABLE OF PRINCIPAL AUSTENITIC STAINLESS GRADES

Sherardisation (35 µm)

steel (316L) 400

Stainless 200

USA GERMANY SWEEDEN U.K. ITALY QUALITY GRADE SYMBOL CODE AISI WERKSTOFF DIN SIS BS 970 UNI X2 CrNi 19-11 14306 Z3 CN 18-10 304 L 1.4306 X2 Cr Ni 18-09 2352 304-512 X2 CrNi 18-11 A2L Z3 CN 19-11 X5 CrNi 18-10 14301 Z6 CN 18-09 304 1.4301 X5 Cr Ni 18-09 2332 304-515 X5 CrNi 18-10 A2 Z7 CN 18-09 X10 CrNi 18-8 14310 Z11 CN 17-08 ≈ 302 1.4300 X12 Cr Ni 18-09 2330/31 302-525 X10 CrNi 18-09 A2 Z11 CN 18-08 Z12 CN 18-09 X4 CrNi 18-12 14303 Z5 CN 18-11 305 1.4303 X5 CrNi-19-11 305-519 X8 CrNi 18-12 A2 X6CrNiTi 18-10 14541 Z6 CND 18-10 321 1.4541 X10 CrNiTi 18-09 2337 321-512 A3 X5CrNiMo 17-12-2 14401 Z6 CND 17-12 316 1.4401 X5CrNiMo 18-10 2343 316-516 X5CrNiMo17-12 A4 X6 CrNiMoTi 17-12-2 14571 Z6 CNDT 17-11 316 Ti 1.4571 X10CrNiTi 18-10 2334 320-517 X6CrNiMoTi17-12 A5 X2 CrNiMo 17-13-3 14404 Z3 CND 17-12 316 L 1.4404 X2CrNiMo 18-10 2353 316-512 X2CrNiMo17-12 A4L X2CrNiMoN17-13-3 14406 Z3 CND 17-11 AZ A4L X3CrNiCu 18-9-3 14560 Z4 CNU 19-09 FF A2

CORROSION 13

Dacromet 500 grade A (5 - 7 µm)

Exposure time

saltspray (hours)

to

Dacromet 500 grade B (8 - 10 µm) 0

Length: 1 mm = 0,1 cm = 0,0394 in (pouce)

Force: 1 kN = 100 daN = 1000 N ~ 100 kg

1 kg = 9,81 N

1 N = 0,2248 lbf (livre-force)

Concrete compressive strength:

1 MPa = 1 N/mm² = 10 kg/cm²

1 MPa = 10 bars

1 N/mm² = 149,2 lbf/in² (pound-force per square inch)

METRIC IMPERIAL FACTOR CONVERSION UNITS SYMBOLS UNITS SYMBOLS IMPERIAL/METRIC METRIC/IMPERIAL Concrete strength newton per square mm N/mm2 (=MPa) livre-force per square inch lbf/in2 (=psi) 1 lbf/in2 = 0,00689 N/mm2 1 N/mm2 = 145,0 lbf/in2 Tightening torque newton-meter Nm pound-force foot lbf/ft 1 lbf ft = 1,356 Nm 1 Nm = 0,738 lbf ft Mass ton t pound Lb 1 lb = 0,00454 t 1 t = 220,26 lb ton t ton t 1 t = 1,016 t 1 t = 0,9842 t kilogram kg pound lb 1 lb = 0,4536 kg 1 kg = 2,204 lb Force kilonewton kN ton-force tf 1 tf = 0,10036 kN 1 kN = 9,9640 tf kilonewton kN pound-force lbf 1 lbf = 0,004448 kN 1 kN = 224,8 lbf newton N pound-force lbf 1 lbf = 4,448 N 1 N = 0,2248 lbf Length meter m foot ft 1 ft = 0,3048 m 1 m = 3,2808 ft centimeter cm inch in 1 in = 2,54 cm 1 cm = 0,3937 in millimeter mm inch in 1 in = 25,4 mm 1 mm = 0,03937 in Area square millimeter mm2 square inch in2 1 in2 = 645,16 mm2 1 mm² = 0,0015 in2 Temperature Celsius degree °C Fahrenheit degree °F 1°F = (9/5 °C + 32) 1°C = 5/9 (°F - 32) 0 °C = 32 °F 30 °C = 86 °F 10 °C = 50 °F 40 °C = 104 °F 20 °C = 68 °F 50 °C = 122 °F

UNITS 14

UNITS CONVERSION TABLE

TERMINOLOGY

Actions

Sk Action on the anchor at the serviceability limit state (ELS)

Sd Action on the anchor at the ultimate limit state (ELU)

Resistances of the anchor

Ru,m Mean ultimate resistance

Rk Characteristic resistance

Rd Design resistance

Frec Recommended resistance

Types of resistance

uncr Resistance for non-cracked concrete

cr Resistance for cracked concrete

C1 Resistance for seismic loads category C1

C2 Resistance for seismic loads category C2

fi,R Resistance for fire exposure

Types of load

N Tensile force (NSd, NRu,m, NRk, NRdp, NRds, NRdc, Nrec)

V Shear force (VSd, VRu,m, VRk, VRds, VRdc, Vrec)

F Oblique force (FSd, FRu,m, FRk, FRds, FRdc, Frec)

M Bending moment (MRk, MRec)

Anchor technical data

hef Effective anchorage depth

hnom Embedment depth in the concrete

h0 Drilling depth

d Thread diameter

d0 Drilling diameter

df

Clearance hole diameter in the part to be fixed

dnom External diameter of the anchor

L Total anchor length

l2

Threaded length

Tinst Required setting torque

tfix

hmin

Thickness of the part to be fixed

Minimum thickness of base material

Distances

S Distance between 2 anchors

Scr Spacing for ensuring the realisation of the characteristic resistance

Smin Minimum allowable spacing

Cmin Minimum allowable edge distance

Ccr,N Edge distance for ensuring the realisation of the characteristic tensile resistance

Concrete and steel

fcm Average concrete compression strength

fck

fuk

fyk

Characteristic concrete compression strength

Characteristic steel ultimate strength

Characteristic yield strength

SYMBOLS USED L d0 hef tfix df Tinst hmin h0 d N V F S C V C fck fcm fuk

15

TESTING

SPIT LABORATORY

At SPIT we have our own laboratory to test all types of fixings in any base material. This laboratory is used for new product development, approvals and quality control.

Our laboratory is accredited by COFRAC in accordance with programme 39.2 «testing of mechanical anchors - Part 2 : Expansion Anchors». Tests for metal anchors in concrete are carried out in accordance with TR048 and TR049.

To carry out these tests, the laboratory is equipped with high performance test benches able to apply pull out loads up to 80 tonnes. Shear tests, long term load tests, pulsating load tests, tests in static cracks from 0,3 mm to 0,5 mm, tests in dynamic cracks, and seismic tests for qualification of anchors C1 & C2 categories, are also carried out on these equipments. EQUIPMENT

FOR TESTING IN CRACKED CONCRETE

PULL

OUT EQUIPMENT TEST

OVEN TO TEST THE BEHAVIOUR AT HIGH TEMPERATURE FOR CHEMICAL RESINS

SEISMIC TEST BENCH

16

I-calc

I-CALC App : Resin volume calculator for SPIT Adhesive cartridges

I-CALC App allows you to determine the number of SPIT Adhesive cartridges that you need on your jobsite for installation of reinforcement rebars or studs. The number of cartridges required can be easily adjusted based on the installation quality you choose.

Android app on Available on the

I-CALC APP

17

i-CALC APPLICATION

product selection chart

TYPE OF ANCHORS Anchor diameter Stainless steel Approvals Crack concrete Seismic HEAVY DUTY MECHANICAL ANCHORS TRIGA Z XTREM M6 - M20 ETA 05/0044 TRIGA Z XTREM A4 M8 - M16 GUARDIA - GUARDIA A4 M12 ETA 07/0047 FIX Z XTREM M8 - M20 ETA 15/0388 FIX Z XTREM A4 M8 - M16 ETA 15/0388 FIX3 M6 - M20 ETA 13/0005 TAPCON XTREM Ø8 - Ø14 ETA 16/0276 TAPCON XTREM LT A4 Ø6 - Ø10 ETA 22/0364 TAPCON Ø5 - Ø6 ETA 16/0373 (1) - ETA 16/0276 Ø6 GRIP+ L & GRIP+ A4 M6 - M16 ETA 21/0176 MEDIUM DUTY MECHANICAL ANCHORS PRIMA M6 - M12 SOCOTEC KX 0827 TRINEO/B M6 - M10 ETA 22/0628 - ETA 22/0883 DYNABOLT M6 - M12 CHEMICAL ANCHORS MAXIMA + Studs Zn & A4 M8 - M30 ETA 18/0197 EPCON C8 XTREM - Studs Zn & A4 M8 - M30 ETA 10/0309 - ETA 07/0189(2) EPCON C8 XTREM - Starter bars Ø8 - Ø30 ETA 10/0309 VIPER XTREM - Studs Zn & A4 M8 - M30 ETA 17/0514 - ETA 17/0513(2) VIPER XTREM - Multicone studs M12 - M20 ETA 17/0514 VIPER XTREM - Starter bars Ø8 - Ø20 ETA 17/0514 ATP - ATP A4 M8 - M20 MULTI-MAX - Studs Zn & A4 M8 - M24 ETA 13/0435 - ETA 13/0436(2) MULTI-MAX - Masonry M8 - M12 ETA 13/0437 C-MIX PLUS - Masonry M8 - M16 SOCOTEC 18056808000007 EASYMIX M8 - M10 SOCOTEC 18046808000010 LIGHT DUTY ANCHORS PROLONG Ø10 - Ø16 ETA 17/0202 B-LONG XTREM - B-LONG XTREM A4 Ø8 - Ø10 ETA 13/1068 - ETA 20/0542 HIT M - HIT M A2 Ø5 - Ø8 ETA 06/0032 (1) Non stuctural applications (2) For post-installed rebars applications European Technical Assessment ETA STAINLESS STEEL A4/A2 SOCOTEC

18

Fire resistance Waterproof Concrete Stone/Solid concrete block/ Solid brick Hollow concrete block/ Hollow brick Plasterboard Aerated concrete Beam slab Page 22 25 28 30 33 36 38 41 44 47 50 53 56 58 60 63 66 69 72 75 77 79 81 84 87 89 92 SUITABLE POSSIBLE USE WATERPROOF

chart 19

product selection

OTHER ANCHORS

Technical data sheets for the SPIT products listed below are available on our website: www.spitpaslode.com

TYPE OF ANCHORS Anchor diameter Approvals Crack concrete Fire resistance HEAVY DUTY MECHANICAL ANCHORS TAPCON PLUS Ø10 - Ø14 LIGHT DUTY ANCHORS L M10 ACS Ø10 UDZ Ø6 ETA 05/0038 (1) SDA Ø6 ETA 10/0166 (1) P6 & G8 Ø6 - Ø8 RM6 M6 LAITON M4 - M8 STELLIX M4 - M6 ZENTECH M4 - M6 CC M4 - M6 DRIVA & DRILL Ø4,5 - Ø3 DRIVA CLICK Ø4,5 PRO6 Ø5 - Ø14 COLORTECH Ø5 - Ø8 NYL Ø5 - Ø14 ARPON M6 - M8 INSULATION ANCHORS PTH-KZ Ø8 ETA 18/1103 PTH-S Ø8 ETA 18/1102 PTH-X Ø8 ETA 18/1095 PTH-SX Ø8 ETA 18/1101 ISO Ø10 ETA 04/0076 CB Ø8 ISOMET Ø8 SOCOTEC PT 3043 ISOWOOD Ø4,5 (1) Non stuctural applications European Technical Assessment ETA

SOCOTEC

20

Concrete

Stone/Solid concrete block/ Solid brick

Concrete

Stone/Solid concrete block/ Solid brick

Base material : wood only SUITABLE POSSIBLE USE

21

Hollow concrete block/ Hollow brick Plasterboard Aerated concrete

OTHER ANCHORS

TRIGA Z XTREM

TECHNICAL DATA

RANGE Min. anchor depth Max. thick. of part to be fixed Min. thick. of base material Thread Ø Drilling depth Drilling Ø Clearance Ø Total anchor length Tighten torque Code (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm) h ef t fix h min d h 0 d 0 df L T inst V6-10/5 50 5 100 M6 70 10 12 65 15 050673 V6-10/20 20 80 050674 V8-12/1* 60 1 120 M8 80 12 14 65 25 050677 V8-12/10 10 80 050678 V8-12/20 20 90 050679 V8-12/50 50 120 053001 E8-12/20 20 99 050681 E8-12/55 55 134 050684 V10-15/1* 70 1 140 M10 90 15 17 75 50 050687 V10-15/10 10 95 050688 V10-15/20 20 105 050689 V10-15/55 55 140 053003 E10-15/20 20 114 050691 E10-15/35 35 129 050692 E10-15/55 55 149 050693 V12-18/1* 80 1 160 M12 105 18 20 80 80 053905 V12-18/10 10 105 050696 V12-18/25 25 120 050697 V12-18/55 55 150 053004 E12-18/25 25 132 050698 E12-18/45 45 152 050699 E12-18/65 65 172 050701 E12-18/100 100 207 050702 V16-24/10 100 10 200 M16 131 24 26 130 120 050704 V16-24/25 25 145 050705 V16-24/50 50 170 050710 E16-24/25 25 159 050706 E16-24/55 55 189 050707 E16-24/100 100 234 050708 V20-28/25 125 25 250 M20 157 28 31 170 200 050711 E20-28/25 25 192 050712 E20-28/60 60 227 050713 E20-28/100 100 267 050714 TF V8-12/16 60 16 120 M8 80 12 14 85 25 050686 TF V8-12/26 60 26 120 M8 80 12 14 95 25 053002 TF V10-15/27 70 27 140 M10 90 15 17 105 50 050695 TF V12-18/40* 80 40 160 M12 105 18 20 130 80 050715 E12-18/A* 80 - 160 M12 105 18 - 162 80 050703 E12-18/QC* 80 - 160 M12 105 18 - 178 80 050671

Tinst L hmin L h0 hef Tinst tfix d0 df d d ETA - 05/0044 ETA ANCHOR MECHANICAL PROPERTIES SIZE M6 M8 M10 M12 M16 M20 fuk [N/mm2] Min. tensile strength 800 800 800 800 800 830 fyk [N/mm2] Yield strength 640 640 640 640 640 660 Seq,V [mm2] Equivalent stressed cross-section bolt version 39,2 76,1 108,8 175,3 335,1 520,2 Seq,E [mm2] Equivalent stressed cross-section threaded stud version 35,2 61,8 82,0 104,1 183,3 277,3 Wel [mm3] Elastic section modulus 12,7 31,2 62,3 109,2 277,5 541,0 M0Rk,s [Nm] Characteristic bending moment 12,2 30,0 59,8 104,8 266,4 538,8 M [Nm] Recommended bending moment 5,8 12,4 24,8 43,5 110,7 216,0 SW [mm] Key size 10 13 16 18 24 30

* Do not belong to ETA

INSTALLATION ⁃ Safety critical loads ⁃ Overhead crane rails ⁃ Steel columns and walkways ⁃ Wall plates ⁃ Safety rails APPLICATION CHARACTERISTICS ZINC COATED STEEL Zn

High security, high performance fixing for use in cracked and non-cracked concrete and seismic performance categories C1 & C2

22

MINIMUM THICKNESS OF CONCRETE, CHARATERISTIC & MINIMUM DISTANCES FOR SPACING, EDGE

CHARACTERISTIC RESISTANCES [kN]

Characteristic resistances are shown as informative, and have to be used by application of safety factors.

RECOMMENDED LOADS OF ONE ANCHOR WITHOUT INFLUENCE OF SPACING & CONCRETE EDGE [kN]

Recommended values are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr

SIZE M6 M8 M10 M12 M16 M20 Anchorage depth hef [mm] 50 60 70 80 100 125 Minimum thickness of base material hmin [mm] 100 120 140 160 200 250 Characteristic edge and spacing distance for full anchor capacity Ccr ≥ [mm] 75 90 105 120 150 187,5 Scr ≥ [mm] 150 180 210 240 300 375 Minimum distances for cracked and non-cracked concrete Cmin [mm] 50 60 70 80 100 150 S ≥ [mm] 100 100 160 160 180 300 Smin [mm] 50 60 70 80 100 125 C ≥ [mm] 80 100 100 160 180 300 Nota: The values indicated in italics and underlined correspond to steel failure TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 NRec [kN] 7,6 9,5 13,7 16,8 23,4 32,7 CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 150 NRec [kN] 2,4 5,7 7,6 11,7 16,4 22,9 NRec = min [NRd,p ; NRd,c; NRd,s] / γF ; γF = 1,4 SHEAR CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 Type V/TF VRec [kN] 13,4 18,6 28,1 41,5 67,0 99,1 Type E VRec [kN] 8,2 10,9 17,7 27,1 53,2 62,8 VRec = VRd,s / γF ; γF = 1,4

TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 NRk,p [kN] 17,4 20,0 28,8 35,2 49,2 68,8 CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 NRk,p [kN] 5,0 12,0 16,0 24,6 34,4 48,1 SHEAR CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 Type V/TF VRk,s [kN] 23,4 32,6 49,1 72,7 117,2 173,5 Type E VRk,s [kN] 14,3 19,0 31,0 47,4 93,1 109,9

23

TRIGA Z XTREM

TRIGA Z XTREM

Design resistances for static, seismic and fire loads are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr. For project with reduced spacing and edge distance, we recommend to use SPIT i-Expert software to design your project according to EN 1992-4.

DESIGN RESISTANCE FOR STATIC LOADS IN NON-CRACKED CONCRETE [kN]

DESIGN RESISTANCE FOR STATIC LOADS IN CRACKED CONCRETE [kN]

DESIGN RESISTANCE FOR SEISMIC LOADS CATEGORY C1 [kN]

DESIGN RESISTANCE FOR SEISMIC LOADS CATEGORY C2 [kN]

DESIGN RESISTANCE FOR FIRE EXPOSURE [kN]

TENSILE SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 NRd,uncr [kN] C20/25 10,7 13,3 19,2 23,5 32,8 45,8 C40/50 10,7 18,9 27,2 33,2 46,4 64,8 Distances Scr and Ccr must be fulfilled NRd,uncr = min[NRk,p,uncr / γMc ; NRk,s / γMs,N] γMc = 1,5 SHEAR SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 Type V/TF VRd,s [kN] ≥ C20/25 18,7 26,1 39,3 58,2 93,8 138,8 Type E VRd,s [kN] ≥ C20/25 11,4 15,2 24,8 37,9 74,5 87,9 VRd,s = VRk,s /γMs,V γMs,V = 1,25

TENSILE SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 NRd,fi R30 [kN] 0,9 2,8 4,5 17,6 32,8 51,1 NRd,fi R60 [kN] 0,6 2,1 3,3 11,4 21,3 33,2 NRd,fi R90 [kN] 0,4 1,3 2,1 5,3 9,8 15,3 NRd,fi R120 [kN] 0,3 0,9 1,5 2,2 4,1 6,4 NRd,fi = NRk,s,fi /γM,fi γM,fi = 1,0 SHEAR SIZE M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 VRd,fi R30 [kN] 0,9 2,8 4,5 17,6 32,8 51,1 VRd,fi R60 [kN] 0,6 2,1 3,3 11,4 21,3 33,2 VRd,fi R90 [kN] 0,4 1,3 2,1 5,3 9,8 15,3 VRd,fi R120 [kN] 0,3 0,9 1,5 2,2 4,1 6,4 VRd,fi = VRk,s,fi /γM,fi γM,fi = 1,0 TENSILE SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 NRd,cr [kN] C20/25 3,3 8,0 10,7 16,4 23,0 32,1 C40/50 4,7 11,3 15,1 23,2 32,5 45,4 Distances Scr and Ccr must be fulfilled NRd,cr = min[NRk,p,cr / γMc ; NRk,s / γMs,N] γMc = 1,5

SHEAR SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 Type V/TF VRd,s [kN] ≥ C20/25 18,7 26,1 39,3 58,2 93,8 138,8 Type E VRd,s [kN] ≥ C20/25 11,4 15,2 24,8 37,9 74,5 87,9 VRd,s = VRk,s /γMs,V γMs,V = 1,25

TENSILE SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 NRd,C1 [kN] C20/25 - - 6,1 17,2 24,0C40/50 - - 8,7 24,3 33,9Distances Scr and Ccr must be fulfilled NRd,C1 = min[NRk,p,eq,C1 / γMc ; NRk,s,eq,C1 / γMs,N] γMc = 1,5 SHEAR SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 VRd,s [kN] ≥ C20/25 - - 13,7 22,7 48,4VRd,s,C1 = VRk,s,eq,C1 / γMs,V γMs,V = 1,25 TENSILE SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 NRd,C2 [kN] C20/25 - - 3,5 6,3 11,0C40/50 - - 5,0 8,9 15,6Distances Scr and Ccr must be fulfilled NRd,C2 = min[NRk,p,eq,C2 / γMc ; NRk,s,eq,C2 / γMs,N] γMc = 1,5

SHEAR SIZE M6 M8 M10 M12 M16 M20 hef [mm] 50 60 70 80 100 125 VRd,s,C2 [kN] ≥ C20/25 - - 11,6 22,7 46,5VRd,s,C2 = VRk,s,eq,C2 /γMs,V γMs,V = 1,25 Nota: The values indicated in italics and underlined correspond to steel failure

i-Expert

Software

24

High security, high performance fixing for use in cracked and non-cracked concrete

TECHNICAL DATA

ANCHOR MECHANICAL PROPERTIES

RANGE Min. anchor depth Max. thick. of part to be fixed Min. thick. of base material Thread Ø Drilling depth Drilling Ø Clearance Ø Total anchor length Tighten torque Code (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm) h ef t fix h min d h 0 d 0 df L T inst V6-10/10 50 10 100 M6 70 10 12 70 10 050694 V8-12/30 60 30 120 M8 80 12 14 100 25 050596 E8-12/45 45 124 050598 TF8-12/30 30 100 057902 V10-15/25 70 25 140 M10 90 15 17 115 50 050601 E10-15/45 45 139 050604 V12-18/25 80 25 160 M12 105 18 20 120 80 050605 E12-18/45 45 152 050608 E16-24/20 95 20 200 M16 130 24 26 157 170 052940 Tinst L hmin L h0 hef Tinst tfix d0 df d d ⁃ Safety critical loads ⁃ Overhead crane rails ⁃ Steel columns and walkways ⁃ Wall plates ⁃ Safety rails

SIZE M6 M8 M10 M12 M16 Type V Seq,V [mm2] Equivalent stressed cross-section bolt version 39,2 76,1 108,8 175,3 335,1 fuk [N/mm2] Min. tensile strength 800 800 800 800 800 fyk [N/mm2] Yield strength 600 600 600 600 600 M0Rk,s [mm2] Characteristic bending moment 12,2 30,0 59,8 104,8 266,4 M [mm2] Recommended bending moment 5,8 12,4 24,8 43,5 110,7 Type E Seq,E [mm2] Equivalent stressed cross-section threaded stud version 35,2 61,8 82,0 104,1 183,3 fuk [N/mm2] Min. tensile strength 700 700 700 700 700 fyk [N/mm2] Yield strength 350 350 350 350 350 M0Rk,s [mm2] Characteristic bending moment 10,6 26,2 52,3 91,7 233,1 M [mm2] Recommended bending moment 4,4 10,9 21,8 38,2 97,1 SW [mm] Key size 10 13 16 18 24

INSTALLATION APPLICATION CHARACTERISTICS STAINLESS STEEL

A4

25

TRIGA Z A4

TRIGA Z A4

MINIMUM THICKNESS OF CONCRETE, CHARATERISTIC & MINIMUM DISTANCES FOR SPACING, EDGE

CHARACTERISTIC RESISTANCES [kN]

Characteristic resistances are shown as informative, and have to be used by application of safety factors.

RECOMMENDED LOADS OF ONE ANCHOR WITHOUT INFLUENCE OF SPACING & CONCRETE EDGE [kN]

Recommended values are given for spacing ≥ Scr and edge distance ≥ Ccr

CONCRETE ‒ C20/25 to C50/60

TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/E/TF NRk,p [kN] 17,4 16,0 20,0 25,0 50,0 CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/E/TF NRk,p [kN] 5,0 9,0 16,0 24,6 34,4

SIZE M6 M8 M10 M12 M16 Anchorage depth hef [mm] 50 60 70 80 100 Minimum thickness of base material hmin [mm] 100 120 140 160 200 Characteristic edge and spacing distance for full anchor capacity Ccr ≥ [mm] 75 90 105 120 150 Scr ≥ [mm] 150 180 210 240 300 Minimum distances for cracked and non-cracked concrete Cmin [mm] 50 60 70 80 100 S ≥ [mm] 100 100 160 160 180 Smin [mm] 50 60 70 80 100 C ≥ [mm] 80 100 100 160 180 SHEAR CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/TF VRk,s [kN] 21,5 31,4 49,1 60,1 89,4 Type E VRk,s [kN] 12,6 16,6 27,2 41,4 65,6 TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/TF NRec [kN] 7,1 7,6 9,5 11,9 23,8 Type E NRec [kN] 4,8 7,6 9,5 11,9 23,8 CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/E/TF NRec [kN] 2,4 4,3 7,6 11,7 16,4 NRec = min [NRd,p ; NRd,c; NRd,s] / γF ; γF = 1,4 SHEAR CRACKED AND NON-CRACKED

SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/TF VRec [kN] 11,5 16,9 26,4 32,3 48,0 Type E VRec [kN] 4,5 5,9 9,7 14,8 37,5 VRec = VRd,s / γF ; γF = 1,4

Nota: The values indicated in italics and underlined correspond to steel failure

26

i-Expert Software

Design resistances for static loads are given for spacing ≥ Scr and edge distance ≥ Ccr For project with reduced spacing and edge distance, we recommend to use SPIT i-Expert software to design your project according to EN 1992-4.

DESIGN RESISTANCE FOR STATIC LOADS IN NON-CRACKED CONCRETE [kN]

DESIGN RESISTANCE FOR STATIC LOADS IN CRACKED CONCRETE [kN]

TENSILE SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/TF NRd,uncr [kN] C20/25 10,0 10,7 13,3 16,7 33,3 C40/50 10,0 15,1 18,9 23,6 46,4 Type E NRd,uncr [kN] C20/25 6,7 10,7 13,3 16,7 33,3 C40/50 6,7 12,1 18,9 23,6 46,4 Distances Scr and Ccr must be fulfilled NRd,uncr = min[NRk,p,uncr / γMc ; NRk,s / γMs,N] γMc = 1,5 Type V/TF: γMs,N = 1,60 Type E: M6-M12 γMs,N = 2,40 ; M16 γMs,N = 1,50 SHEAR SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/TF VRd,s [kN] ≥ C20/25 16,2 23,6 36,9 45,2 67,2 Type E VRd,s [kN] ≥ C20/25 6,3 8,3 13,6 20,7 52,5 VRd,s = VRk,s /γMs,V Type V/TF: γMs,V = 1,33 Type E: M6-M12 γMs,V = 2,00 ; M16 γMs,V = 1,25 TENSILE SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/E/TF NRd,cr [kN] C20/25 3,3 6,0 10,7 16,4 23,0 C40/50 4,7 8,5 15,1 23,2 32,5 Distances Scr and Ccr must be fulfilled NRd,cr = min[NRk,p,cr / γMc ; NRk,s / γMs,N] γMc = 1,5 Type V/TF: γMs,N = 1,60 Type E: M6-M12 γMs,N = 2,40 ; M16 γMs,N = 1,50

SHEAR SIZE M6 M8 M10 M12 M16 hef [mm] 50 60 70 80 100 Type V/TF VRd,s [kN] ≥ C20/25 16,2 23,6 36,9 45,2 67,2 Type E VRd,s [kN] ≥ C20/25 6,3 8,3 13,6 20,7 52,5 VRd,s = VRk,s /γMs,V Type V/TF: γMs,V = 1,33 Type E: M6-M12 γMs,V = 2,00 ; M16 γMs,V = 1,25

Nota: The values indicated in italics and underlined correspond to steel failure

27

TRIGA Z A4

GUARDIA

ZINC COATED & STAINLESS STEEL A4

Mechanical anchor, dedicated for safety barriers fixings

CHARACTERISTICS ZINC COATED STEEL Zn STAINLESS STEEL

ETA - 07/0047 ETA ANCHOR MECHANICAL PROPERTIES SIZE 12X105/20 12X110/20 A4 Cone fuk [N/mm2] Min. tensile strength 1000 500 Body fuk [N/mm2] Min. tensile strength 550 700 Wel [mm3] Elastic section modulus 50 50 M0Rk,s [Nm] Characteristic bending moment 33 26 M [Nm] Recommended bending moment 13,7 10,8 SW [mm] Key size 16 13

A4

INSTALLATION ⁃ Safety barriers APPLICATION d0 hef tfix hmin h0 df L Tinst POSSIBLE 6 mm maxi. TECHNICAL DATA RANGE Min. anchor depth Max. thick. of part to be fixed Drilling depth Drilling diameter Min. thickness of base material Clearance diameter Total anchor length Tighten torque Code (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm) h ef t fix h 0 d 0 h min df L T inst 12X105/20 70 20 95 12 150 14 104 35 051061 12X110/20 A4 70 20 100 12 150 14 110 25 055304

28

MINIMUM THICKNESS OF CONCRETE, CHARATERISTIC & MINIMUM DISTANCES FOR SPACING, EDGE

CHARACTERISTIC RESISTANCES [kN]

Characteristic resistances are shown as informative, and have to be used by application of safety factors.

RECOMMENDED LOADS OF ONE ANCHOR WITHOUT INFLUENCE OF SPACING & CONCRETE EDGE [kN]

Recommended values are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr

Design resistances for static loads are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr For project with reduced spacing and edge distance, we recommend to use SPIT i-Expert software to design your project according to EN 1992-4.

DESIGN RESISTANCE FOR STATIC LOADS IN NON CRACKED CONCRETE [kN]

SIZE 12X105/20 12X110/20 A4 Anchorage depth hef [mm] 70 70 Minimum thickness of base material hmin [mm] 150 150 Characteristic edge and spacing distance for full anchor capacity Ccr ≥ [mm] 105 105 Scr ≥ [mm] 210 210 Minimum distances for non-cracked concrete Smin [mm] 70 70 Cmin [mm] 50 50 TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE 12X105/20 12X110/20 A4 hef [mm] 70 70 NRk,p [kN] 28,8 20,0

SHEAR NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE 12X105/20 12X110/20 A4 hef [mm] 70 70 VRk,s [kN] 14,3 12,8 TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE 12X105/20 12X110/20 A4 hef [mm] 70 70 NRec [kN] 12,8 9,5 NRec = min [NRd,p ; NRd,c; NRd,s] / γF ; γF = 1,4

SHEAR NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE 12X105/20 12X110/20 A4 hef [mm] 70 70 VRec [kN] 6,8 5,9 VRec = VRd,s / γF ; γF = 1,4

TENSILE SIZE 12X105/20 12X110/20 A4 hef [mm] 70 70 NRd,uncr [kN] C20/25 17,9 13,3 C40/50 17,9 13,9 Distances Scr and Ccr must be fulfilled NRd,uncr = min[NRk,p,uncr / γMc ; NRk,s / γMs,N] γMc = 1,5 GUARDIA 12X105/20: γMs N = 1,4 GUARDIA 12X115/20 A4: γMs N = 1,87 SHEAR SIZE 12X105/20 12X110/20 A4 hef [mm] 70 70 VRd,s [kN] ≥ C20/25 9,5 8,2 VRd,s = VRk,s /γMs,V GUARDIA 12X105/20: γMs,V = 1,5 GUARDIA 12X115/20 A4: γMs,V = 1,56

i-Expert Software Nota: The values indicated in italics and underlined correspond to steel failure ZINC COATED & STAINLESS STEEL A4 GUARDIA 29

FIX Z XTREM

TECHNICAL DATA

RANGE Letter marking Maximum anchorage depth Minimum anchorage depth Thread Ø Drilling Ø Clearance Ø Total anchor length Tighten torque Code Max. anchor depth Embed. depth Max. thick. of part to be fixed Drilling depth Min. thick. of base material Min. anchor depth Embed. depth Max. thick. of part to be fixed Drilling depth Min. thick. of base material (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm) h ef h nom t fix h 0 h min h ef h nom t fix h 0 h min d d 0 df L T inst 8X65/5 B 46 55 5 65 100 - - - - 8 8 9 65 20 057763 8X75/15 D 15 75 057764 8X90/30 E 30 - 90 057765 8X120/60 G 60 120 057766 10X85/25-5 D 60 68 5 75 120 40 48 25 55 100 10 10 12 85 45 057768 10X90/30-10 E 10 30 90 057769 10X100/40-20 F 20 40 100 057770 10X120/60-40 G 40 60 120 057771 10X140/80-60 I 60 80 140 057772 10X160/100-80 - 80 100 160 057773 12X105/30-10 F 70 80 10 90 140 50 60 30 70 100 12 12 14 105 60 057775 12X115/40-20 G 20 40 115 057776 12X135/60-40 I 40 60 135 057777 12X155/80-60 J 60 80 155 057796 12X180/105-85 L 85 105 180 057779 16X145/45-25 I 85 98 25 110 170 65 78 45 90 130 16 16 18 145 110 057781 16X170/70-50 K 50 70 170 057782 16X180/80-60 L 60 80 180 057783 20X170/30 K 100 113 30 130 200 - - - - 20 20 22 170 160 057785 20X200/60 M 60 - 200 057786 20X220/80 O 80 220 057787 Large Washer (LW) 8X65/5 B 46 55 5 65 100 - - - - - 8 8 9 65 20 057666 8X130/70 I 70 130 057667 10X160/100-80 J 60 68 80 75 120 40 48 100 55 100 10 10 12 160 45 057668 12X135/60-40 I 70 80 40 90 140 50 60 60 70 100 12 12 14 135 60 057669 12X155/80-60 J 60 80 155 057670 12X180/105-85 L 85 105 180 057671 12X220/123* O 123 - - - - - 220 057672 12X255/158* R 158 - - - - - 255 057673 16X180/80-60 L 85 98 60 105 170 65 78 80 105 170 16 16 18 180 110 057675 16X220/100* O 100 - - - - - 220 100 057676 16X250/130* Q 130 - - - - - 250 100 057677 d0 hef tfix hmin h0 df L d hnom Tinst ETA - 15/0388 * ETA - 17/0073 ETA

INSTALLATION ⁃ Steel and timber framework and beams ⁃ Lift guide rails ⁃ Industrial doors and gates ⁃ Brickwork support angles ⁃ Storage systems ⁃ Wall plates ⁃ Safety barriers ⁃ Cladding brackets ⁃ Curtain-walls APPLICATION ANCHOR MECHANICAL PROPERTIES SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 Cross-section above cone fuk [N/mm2] Min. tensile strength 900 830 830 830 720 720 600 fyk [N/mm2] Yield strength 800 670 670 670 580 580 580 As [mm2] Stressed cross-section 22,9 35,3 45,4 45,4 88,2 88,2 165,1 Threaded part fuk [N/mm2] Min. tensile strength 750 730 730 730 600 600 500 fyk [N/mm2] Yield strength 680 580 580 580 480 480 410 As [mm2] Stressed cross-section 36,6 58,0 84,3 84,3 156,0 156,0 245,0 Wel [mm3] Elastic section modulus 31,2 62,3 109,2 109,2 277,5 277,5 540,9 M0Rk,s [Nm] Characteristic bending moment 28,0 52,8 91,3 78,6 194,0 199,8 315,7 M [Nm] Recommended bending moment 8,7 14,7 25,8 22,4 54,4 57,0 90,5 SW [mm] Key size 13 17 19 19 24 24 30 Washer Standard (NF E 25513) Large (DIN 440 / ISO 7094) SIZE M8 M10 M12 M16 M20 M8 M10 M12 M16 Outer Ø [mm] 16 20 24 30 36 28 34 44 56 Thickness [mm] 1,6 2 2,5 3 3 3 3 4 5 ZINC COATED STEEL Zn CHARACTERISTICS Vds CEA 4001 M8 - M12

Torque controlled expansion anchor, for use in cracked and non-cracked concrete and seismic performance categories C1 & C2

30

MINIMUM THICKNESS OF CONCRETE, CHARATERISTIC & MINIMUM DISTANCES FOR SPACING, EDGE

CHARACTERISTIC RESISTANCES [kN]

Characteristic resistances are shown as informative, and have to be used by application of safety factors.

SHEAR

RECOMMENDED LOADS OF ONE ANCHOR WITHOUT INFLUENCE OF SPACING & CONCRETE EDGE [kN]

Recommended values are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr

SIZE M8 M10 M10 M12 M12 M16 M16 M20 Anchorage depth hef [mm] 46 40 60 50 70 65 85 100 Minimum thickness of base material hmin [mm] 100 100 120 100 140 130 170 200 Characteristic edge and spacing distance for full anchor capacity Ccr ≥ [mm] 69 60 90 75 105 97,5 127,5 150 Scr ≥ [mm] 138 120 180 150 210 195 255 300 Minimum distances for non-cracked concrete Cmin [mm] 50 60 60 60 60 90 90 100 S ≥ [mm] 75 120 120 145 145 140 140 160 Smin [mm] 50 55 55 60 60 90 90 130 C ≥ [mm] 90 70 70 100 100 105 105 120 Minimum distances for cracked concrete Cmin [mm] 50 55 55 60 60 80 80 100 S ≥ [mm] 75 90 90 145 145 110 110 130 Smin [mm] 50 55 55 60 60 90 90 100 C ≥ [mm] 65 70 70 100 100 100 100 120

Nota: The values indicated in italics and underlined correspond to steel failure

TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRk,p [kN] 9,0 20,0 30,0 20,0 40,0 35,0 49,2 hef,2 [mm] - 40 50 - 65 -NRk,p [kN] - 12,4 17,4 - 25,8 -CRACKED CONCRETE ‒ C20/25 SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRk,p [kN] 5,0 9,0 16,0 12,0 20,0 25,0 30,0 hef,2 [mm] - 40 50 - 65 -NRk,p [kN] - 8,7 12,2 - 18,0 - -

CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 hef,2 [mm] - 40 50 - 65 -VRk,s [kN] 13,7 16,0 23,0 25,3 45,0 47,1 61,0 TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRec [kN] 4,3 9,5 14,3 9,5 19,0 16,6 23,4 hef,2 [mm] - 40 50 - 65 -NRec [kN] - 5,9 8,3 - 12,3 -CRACKED CONCRETE ‒ C20/25 SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRec [kN] 2,4 4,3 7,6 5,7 9,5 12,0 14,3 hef,2 [mm] - 40 50 - 65 -NRec [kN] - 4,1 5,8 - 8,6 -NRec = min [NRd,p ; NRd,c; NRd,s] / γF ; γF = 1,4

CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 hef,2 [mm] - 40 50 - 65 -VRec [kN] 6,5 9,0 12,9 14,4 25,7 26,9 29,0 VRec = VRd,s / γF ; γF = 1,4

XTREM 31

SHEAR

FIX Z

FIX Z XTREM

Design resistances for static, seismic and fire loads are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr. For project with reduced spacing and edge distance, we recommend to use SPIT i-Expert software to design your project according to EN 1992-4.

DESIGN RESISTANCE FOR STATIC LOADS IN NON CRACKED CONCRETE [kN]

DESIGN RESISTANCE FOR STATIC LOADS IN CRACKED CONCRETE [kN]

DESIGN RESISTANCE FOR SEISMIC LOADS CATEGORY C1 [kN]

DESIGN RESISTANCE FOR SEISMIC LOADS CATEGORY C2 [kN]

DESIGN RESISTANCE FOR FIRE

[kN]

Nota: The values indicated in italics and underlined correspond to steel failure

TENSILE SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRd,uncr [kN] C20/25 6,0 13,3 20,0 13,3 26,7 23,3 32,8 C40/50 8,5 15,3 23,0 18,8 34,0 32,9 46,4 hef,2 [mm] - 40 50 - 65 -NRd,uncr [kN] C20/25 - 8,3 11,6 - 17,2 -C40/50 - 9,5 13,3 - 21,9 -Distances Scr and Ccr must be fulfilled NRd,uncr = min[NRk,p,uncr / γMc ; NRk,s / γMs,N] γMc = 1,5 ; M8 : γMs,N = 1,4 ; M10-M16 : γMs,N = 1,48 ; M20 : γMs,N = 1,5 SHEAR SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 hef,2 [mm] - 40 50 - 65 -VRd,s [kN] ≥ C20/25 9,1 12,6 18,1 20,2 36,0 37,7 40,7 VRd,s = VRk,s /γMs,V M8 : γMs,V = 1,5 ; M10-M16 : γMs,V = 1,27 ; M20 : γMs,V = 1,5; M12-M16 L>220 : γMs,V = 1,25

TENSILE SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRd,C1 [kN] C20/25 3,1 4,9 10,7 5,6 13,3 11,7 20,0 C40/50 4,4 7,0 15,1 7,9 18,9 16,5 28,3 Distances Scr and Ccr must be fulfilled NRd,C1 = min[NRk,p,eq,C1 / γMc ; NRk,s,eq,C1 / γMs,N] γMc = 1,5 ; M8 : γMs,N = 1,4 ; M10-M16 : γMs,N = 1,48 ; M20 : γMs,N = 1,5 SHEAR SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 VRd,s,C1 [kN] ≥ C20/25 4,0 12,6 18,1 14,2 36,0 26,4 40,7 VRd,s,C1 = VRk,s,eq,C1 / γMs,V M8 : γMs,V = 1,5 ; M10-M16 : γMs,V = 1,27 ; M20 : γMs,V = 1,5 M12-M16 L>220 : γMs,V = 1,25 TENSILE SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRd,cr [kN] C20/25 3,3 6,0 10,7 8,0 13,3 16,7 20,0 C40/50 4,7 6,9 12,3 11,3 17,0 23,5 28,3 hef,2 [mm] - 40 50 - 65 -NRd,cr [kN] C20/25 - 5,8 8,1 - 12,0 -C40/50 - 6,7 9,3 - 15,3 -Distances Scr and Ccr must be fulfilled NRd,cr = min[NRk,p,cr / γMc ; NRk,s / γMs,N] γMc = 1,5 ; M8 : γMs,N = 1,4 ; M10-M16 : γMs,N = 1,48 ; M20 : γMs,N = 1,5 SHEAR SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 hef,2 [mm] - 40 50 - 65 -VRd,s [kN] ≥ C20/25 9,1 12,6 18,1 20,2 36,0 37,7 40,7 VRd,s = VRk,s / γMs,V M8 : γMs,V = 1,5 ; M10-M16 : γMs,V = 1,27 ; M20 : γMs,V = 1,5 M12-M16 L>220 : γMs,V = 1,25

TENSILE SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRd,C2 [kN] C20/25 - 1,9 4,0 3,5 12,0 5,9 17,1 C40/50 - 2,1 4,6 4,9 15,3 8,4 24,1 Distances Scr and Ccr must be fulfilled NRd,C2 = min[NRk,p,eq,C2 / γMc ; NRk,s,eq,C2 / γMs,N] γMc = 1,5 ; M8 : γMs,N = 1,4 ; M10-M16 : γMs,N = 1,48 ; M20 : γMs,N = 1,5 SHEAR SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 VRd,s,C2 [kN] ≥ C20/25 - 7,6 11,0 14,2 27,1 26,4 29,8 VRd,s,C2 = VRk,s,eq,C2 /γMs,V M8 : γMs,V = 1,5 ; M10-M16 : γMs,V = 1,27 ; M20 : γMs,V = 1,5 M12-M16 L>220 : γMs,V = 1,25

EXPOSURE

TENSILE SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 NRd,fi R30 [kN] 0,9 2,8 3,6 1,7 6,6 3,1 10,4 NRd,fi R60 [kN] 0,7 2,3 3,1 1,3 5,7 2,4 9,0 NRd,fi R90 [kN] 0,5 1,8 2,6 1,1 4,9 2,0 7,6 NRd,fi R120 [kN] 0,4 1,6 2,4 0,8 4,4 1,6 6,9 NRd,fi = NRk,s,fi /γM,fi γM,fi = 1,0 SHEAR SIZE M8 M10 M12 M12 L>220 M16 M16 L>220 M20 hef,1 [mm] 46 60 70 70 85 85 100 VRd,fi R30 [kN] 0,9 2,8 3,6 1,7 6,6 3,1 10,4 VRd,fi R60 [kN] 0,7 2,3 3,1 1,3 5,7 2,4 9,0 VRd,fi R90 [kN] 0,5 1,8 2,6 1,1 4,9 2,0 7,6 VRd,fi R120 [kN] 0,4 1,6 2,4 0,8 4,4 1,6 6,9 VRd,fi = VRk,s,fi /γM,fi γM,fi = 1,0

i-Expert Software

32

Torque controlled expansion anchor, for use in cracked and non-cracked concrete and seismic performance categories C1 & C2

CHARACTERISTICS

A4

TECHNICAL DATA RANGE marking Maximum anchorage depth Minimum anchorage depth Thread Ø Drilling Ø Clearance Ø Total anchor length Tighten torque Code Max. anchor depth Embed. depth Max. thick. of part to be fixed Drilling depth Min. thick. of base material Min. anchor depth Embed. depth Max. thick. of part to be fixed Drilling depth Min. thick. of base material (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm) h ef h nom t fix h 0 h min h ef h nom t fix h 0 h min d d 0 df L T inst 8X55/5 0 4 8 5565 100 35 42 5 52 100 8 8 9 56 20 058616 8X70/20-7 1 7 20 71 058617 8X90/40 -27 3 27 40 91 058618 10X70/10 1 60 6875 120 40 48 10 55 100 10 10 12 70 45 058619 10X95/35-15 2 15 35 95 058620 10X105/45-25 3 25 4 5 105 058621 10X130/70-50 4 50 70 130 058622 12X95/20 1 70 8090 140 50 60 20 70 100 12 12 14 95 75 058623 12X110/35-15 2 15 35 110 058624 12X120/45-25 3 25 45 120 058625 12X140/65-45 4 45 65 140 058626 16X120/20 1 85 98110 170 65 78 20 90 130 16 16 18 120 110 058627 16X140/40-20 2 20 40 140 058628 d0 hef tfix hmin h0 df L d hnom Tinst ⁃ Safety barriers ⁃ Cladding brackets ⁃ Curtain-walls ⁃ Steel and timber framework and beams ⁃ Lift guide rails ⁃ Industrial doors and gates ⁃ Brickwork support angles ⁃ Storage systems ETA - 15/0388 ETA ANCHOR MECHANICAL PROPERTIES SIZE M8 M10 M12 M16 Cross-section above cone fuk [N/mm2] Min. tensile strength 900 830 720 720 fyk [N/mm2] Yield strength 800 670 580 580 As [mm2] Stressed cross-section 22,9 35,3 52,8 103,8 Threaded part fuk [N/mm2] Min. tensile strength 750 730 730 600 fyk [N/mm2] Yield strength 680 580 580 480 As [mm2] Stressed cross-section 36,6 58,0 84,3 156,0 Wel [mm3] Elastic section modulus 31,2 62,3 109,2 277,5 M0Rk,s [Nm] Characteristic bending moment 25,0 44,9 77,5 187,5 M [Nm] Recommended bending moment 10,0 18,0 31,0 75,0 SW [mm] Key size 13 17 19 24 INSTALLATION APPLICATION STAINLESS STEEL

Vds CEA 4001 M8 - M12

33

FIX Z XTREM a4

MINIMUM THICKNESS OF CONCRETE, CHARATERISTIC & MINIMUM DISTANCES FOR SPACING, EDGE

CHARACTERISTIC RESISTANCES [kN]

Characteristic resistances are shown as informative, and have to be used by application of safety factors.

RECOMMENDED LOADS OF ONE ANCHOR WITHOUT INFLUENCE OF SPACING & CONCRETE EDGE [kN]

Recommended values are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr

SHEAR

SIZE M8 M10 M10 M12 M12 M16 M16 Anchorage depth hef [mm] 48 40 60 50 70 65 85 Minimum thickness of base material hmin [mm] 100 100 120 100 140 130 170 Characteristic edge and spacing distance for full anchor capacity Ccr ≥ [mm] 72 60 90 75 105 97,5 127,5 Scr ≥ [mm] 144 120 180 150 210 195 255 Minimum distances for non-cracked concrete Cmin [mm] 60 60 60 60 60 90 90 S ≥ [mm] 50 120 120 100 145 105 140 Smin [mm] 50 55 55 60 60 90 90 C ≥ [mm] 60 65 65 100 100 105 105 Minimum distances for cracked concrete Cmin [mm] 60 55 55 60 60 80 80 S ≥ [mm] 60 90 90 145 145 110 110 Smin [mm] 60 55 55 60 60 90 90 C ≥ [mm] 60 65 65 100 100 100 100 TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 NRec [kN] 4,3 5,9 8,3 12,3 hef,2 [mm] 48 60 70 85 NRec [kN] 5,7 9,5 14,3 19,0 CRACKED CONCRETE ‒ C20/25 SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 NRec [kN] 1,4 4,1 5,8 8,6 hef,2 [mm] 48 60 70 85 NRec [kN] 1,9 4,3 7,6 9,5 NRec = min [NRd,p ; NRd,c; NRd,s] / γF ; γF = 1,4

CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 hef,2 [mm] 48 60 70 85 VRec [kN] 8,2 12,7 19,2 29,7 VRec = VRd,s / γF ; γF = 1,4 TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 NRk,p [kN] 9,0 12,4 17,4 25,8 hef,2 [mm] 48 60 70 85 NRk,p [kN] 12,0 20,0 30,0 40,0 CRACKED CONCRETE ‒ C20/25 SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 NRk,p [kN] 3,0 8,7 12,2 18,0 hef,2 [mm] 48 60 70 85 NRk,p [kN] 4,0 9,0 16,0 20,0 SHEAR CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 hef,2 [mm] 48 60 70 85 VRk,s [kN] 12,4 18,7 28,2 51,9

Nota: The values indicated in italics and underlined correspond to steel failure

34

FIX Z XTREM a4

FIX Z XTREM a4

Design resistances for static, seismic and fire loads are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr. For project with reduced spacing and edge distance, we recommend to use SPIT i-Expert software to design your project according to EN 1992-4.

DESIGN RESISTANCE FOR STATIC LOADS IN NON CRACKED CONCRETE [kN]

DESIGN RESISTANCE FOR STATIC LOADS IN CRACKED CONCRETE [kN]

DESIGN RESISTANCE FOR SEISMIC LOADS CATEGORY C1 [kN]

DESIGN

TENSILE SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 NRd,uncr [kN] C20/25 6,0 8,3 11,6 17,2 C40/50 8,5 9,5 13,3 21,8 hef,2 [mm] 48 60 70 85 NRd,uncr [kN] C20/25 8,0 13,3 20,0 26,7 C40/50 9,2 15,3 22,1 32,6 Distances Scr and Ccr must be fulfilled NRd,uncr = min[NRk,p,uncr / γMc ; NRk,s / γMs,N] γMc = 1,5 ; M8 : γMs,N = 1,4 ; M10-M16 : γMs,N = 1,48 ; M20 : γMs,N = 1,5 SHEAR SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 hef,2 [mm] 48 60 70 85 VRd,s [kN] ≥ C20/25 8,2 12,7 19,2 29,7 VRd,s = VRk,s /γMs,V M8 : γMs,V = 1,5 ; M10-M16 : γMs,V = 1,27 ; M20 : γMs,V = 1,5

TENSILE SIZE M8 M10 M12 M16 hef,2 [mm] 48 60 70 85 NRd,C1 [kN] C20/25 2,7 4,9 10,7 13,3 C40/50 3,8 5,7 12,3 16,9 Distances Scr and Ccr must be fulfilled NRd,C1 = min[NRk,p,eq,C1 / γMc ; NRk,s,eq,C1 / γMs,N] γMc = 1,5 ; M8 : γMs,N = 1,4 ; M10-M16 : γMs,N = 1,48 ; M20 : γMs,N = 1,5 SHEAR SIZE M8 M10 M12 M16 hef,2 [mm] 48 60 70 85 VRd,s,C1 [kN] ≥ C20/25 3,8 8,3 12,1 19,3 VRd,s,C1 = VRk,s,eq,C1 / γMs,V M8 : γMs,V = 1,5 ; M10-M16 : γMs,V = 1,27 ; M20 : γMs,V = 1,5 TENSILE SIZE M8 M10 M12 M16 hef,1 [mm] 60 55 60 80 NRd,cr [kN] C20/25 2,0 5,8 8,1 12,0 C40/50 2,8 6,7 9,3 15,2 hef,2 [mm] 48 60 70 85 NRd,cr [kN] C20/25 2,7 6,0 10,7 13,3 C40/50 3,8 6,9 12,3 16,9 Distances Scr and Ccr must be fulfilled NRd,cr = min[NRk,p,cr / γMc ; NRk,s / γMs,N] γMc = 1,5 ; M8 : γMs,N = 1,4 ; M10-M16 : γMs,N = 1,48 ; M20 : γMs,N = 1,5 SHEAR SIZE M8 M10 M12 M16 hef,1 [mm] 35 40 50 65 hef,2 [mm] 48 60 70 85 VRd,s [kN] ≥ C20/25 8,2 12,7 19,2 29,7 VRd,s = VRk,s / γMs,V M8 : γMs,V = 1,5 ; M10-M16 : γMs,V = 1,27 ; M20 : γMs,V = 1,5

TENSILE SIZE M8 M10 M12 M16 hef,2 [mm] 48 60 70 85 NRd,C2 [kN] C20/25 - 1,7 4,0 9,7 C40/50 - 2,0 4,6 12,4 Distances Scr and Ccr must be fulfilled NRd,C2 = min[NRk,p,eq,C2 / γMc ; NRk,s,eq,C2 / γMs,N] γMc = 1,5 ; M8 : γMs,N = 1,4 ; M10-M16 : γMs,N = 1,48 ; M20 : γMs,N = 1,5 SHEAR SIZE M8 M10 M12 M16 hef,2 [mm] 48 60 70 85 VRd,s,C2 [kN] ≥ C20/25 - 5,0 7,3 14,5 VRd,s,C2 = VRk,s,eq,C2 /γMs,V M8 : γMs,V = 1,5 ; M10-M16 : γMs,V = 1,27 ; M20 : γMs,V = 1,5

RESISTANCE FOR SEISMIC LOADS CATEGORY C2 [kN]

FOR FIRE EXPOSURE [kN] TENSILE SIZE M8 M10 M12 M16 hef,2 [mm] 48 60 70 85 NRd,fi R30 [kN] 4,9 9,9 9,2 16,1 NRd,fi R60 [kN] 3,2 6,3 6,5 11,3 NRd,fi R90 [kN] 1,5 2,6 3,7 6,5 NRd,fi R120 [kN] 0,7 0,8 2,3 4,1 NRd,fi = NRk,s,fi /γM,fi γM,fi = 1,0 SHEAR SIZE M8 M10 M12 M16 hef,2 [mm] 48 60 70 85 VRd,fi R30 [kN] 4,9 9,9 9,2 16,1 VRd,fi R60 [kN] 3,2 6,3 6,5 11,3 VRd,fi R90 [kN] 1,5 2,6 3,7 6,5 VRd,fi R120 [kN] 0,7 0,8 2,3 4,1 VRd,fi = VRk,s,fi /γM,fi γM,fi = 1,0

DESIGN RESISTANCE

i-Expert Software Nota: The values indicated in italics and underlined correspond to steel failure

35

Torque controlled expansion anchor, for use in non-cracked concrete

TECHNICAL DATA

PROPERTIES

RANGE Letter marking Maximum anchorage depth Minimum anchorage depth Thread Ø Drilling Ø Clearance Ø Total anchor length Tighten torque Code Max anchor depth Embed. depth Max. thick. of part to be fixed Drilling depth Min. thick. of base material Min anchor depth Embed. depth Max. thick. of part to be fixed Drilling depth Min. thick. of base material (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm) h ef h nom t fix h 0 h min h ef h nom t fix h 0 h min d d 0 df L T inst 6X45/5*35 4551 100 25,6 35 5 41 100 6 6 8 45 10 050510 6X55/15* - 5 15 55 050520 6X85/45* - 35 45 85 050530 8X55/540 4860 80 30 38 5 50 80 8 8 9 55 15 057450 8X70/20-10 C 10 20 70 057451 8X90/40-30 E 30 40 90 057452 8X100/50-40 F 40 50 100 057453 8X115/65-55 G 55 65 115 057454 8X130/80-70 H 70 80 130 057455 8X160/110-100 J 100 110 160 057456 10X65/550 6070 100 40 50 5 60 100 10 10 12 65 30 057460 10X75/15-5 C 5 15 75 057461 10X85/25-15 D 15 25 85 057462 10X95/36-26 E 26 36 95 057463 10X110/50-40 F 40 50 110 057464 10X125/65-55 G 55 65 125 057465 10X140/80-70 I 70 80 140 057466 10X160/100-90 J 90 100 160 057467 12X80/565 7790 130 50 62 5 75 100 12 12 14 80 50 057470 12X100/25-10 F 10 25 100 057471 12x115/40-25 G 25 40 115 057472 12x125/50-35 H 35 50 125 057473 12X140/65-50 I 50 65 140 057474 12X160/85-70 J 70 85 160 057664 12X180/105-90 L 90 105 180 057576 12X220/145-130 O 130 145 220 057477 16X100/580 95110 160 65 80 5 95 130 16 16 18 100 100 057480 16X125/30-15 G 15 30 125 057481 16X150/55-40 I 40 55 150 057482 16X170/75-60 K 60 75 170 057483 16X185/90-75 L 75 90 185 057484 16X235/140-125* - 125 140 235 057485 20X150/10 - - 10 150 057490 20X170/30 K - - - - - 100 113 30 130 200 20 20 22 170 160 057491 20X220/80 0 - 80 220 057492 Large Washer (LW) 12X300/200 * - 70 80 200 90 140 - - - - - 12 12 14 300 60 057673 16X300/205 -190* - 85 98 205 110 170 65 78 190 90 130 16 16 18 300 110 057675 * Do not belong to ETA d0 hef tfix hmin h0 df L d hnom Tinst ETA - 13/0005 ETA ANCHOR

SIZE M6 M8 M10 M12 M16 M20 Cross-section above cone fuk [N/mm2] Min. tensile strength 700 750 750 750 700 600 fyk [N/mm2] Yield strength 580 600 600 600 570 580 As [mm2] Stressed cross-section - 23,8 34,7 56,1 103,9 165,1 Threaded part fuk [N/mm2] Min. tensile strength 600 650 650 650 600 500 fyk [N/mm2] Yield strength 420 420 420 420 480 410 As [mm2] Stressed cross-section 20,1 36,6 58 84,3 157 245 Wel [mm3] Elastic section modulus 12,7 31,2 62,3 109,2 277,5 540,9 M0Rk,s [Nm] Characteristic bending moment 9 24 49 85 200 315,7 M [Nm] Recommended bending moment 3,7 9,8 20,0 34,7 81,6 90,5 SW [mm] Key size 10 13 17 19 24 30

MECHANICAL

INSTALLATION ⁃ Steel and timber framework and beams ⁃ Lift guide rails ⁃ Industrial doors and gates ⁃ Brickwork support angles ⁃ Storage systems APPLICATION Washer Standard (NF E 25513) Large (DIN 440 / ISO 7094) SIZE M8 M10 M12 M16 M20 M12 M16 Outer Ø [mm] 16 20 24 30 37 44 56 Thickness [mm] 1,6 2,0 2,5 3,0 3,0 4,0 5,0 ZINC COATED STEEL

FIX3 36

Zn CHARACTERISTICS

MINIMUM THICKNESS OF CONCRETE, CHARATERISTIC & MINIMUM DISTANCES FOR SPACING, EDGE

CHARACTERISTIC RESISTANCES [kN]

Characteristic resistances are shown as informative, and have to be used by application of safety factors.

RECOMMENDED LOADS OF ONE ANCHOR WITHOUT INFLUENCE OF SPACING & CONCRETE

values are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥

SHEAR

EDGE [kN]

NON-CRACKED CONCRETE ‒ C20/25 to C50/60

Design resistances for static loads are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr For project with reduced spacing and edge distance, we recommend to use SPIT i-Expert software to design your project according to EN 1992-4.

DESIGN RESISTANCE FOR STATIC LOADS IN NON CRACKED CONCRETE [kN]

SIZE M8 M10 M10 M12 M12 M16 M16 M20 Anchorage depth hef [mm] 40 40 50 50 65 65 80 100 Minimum thickness of base material hmin [mm] 100 100 100 100 130 130 160 200 Characteristic edge and spacing distance for full anchor capacity Ccr ≥ [mm] 60 60 75 75 97,5 97,5 120 150 Scr ≥ [mm] 120 120 150 150 195 195 240 300 Minimum distances for non-cracked concrete Smin [mm] 45 50 60 100 70 100 90 130 Cmin [mm] 55 65 65 100 70 100 105 120 TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 M20 hef,1 [mm] 25 30 40 50 65NRk,p [kN] 5,7 7,5 12,4 17,4 25,8hef,2 [mm] 35 40 50 65 80 100 NRk,p [kN] 5,7 12,4 17,4 25,8 35,2 49,2

SHEAR NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE M6 M8 M10 M12 M16 M20 hef,1 [mm] 25 30 40 50 65hef,2 [mm] 35 40 50 65 80 100 VRk,s [kN] 3,6 10,0 13,7 27,4 36,5 61,0 TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE M6 M8 M10 M12 M16 M20 hef,1 [mm] 25 30 40 50 65NRec [kN] 1,7 3,6 5,9 8,3 12,3hef,2 [mm] 35 40 50 65 80 100 NRec [kN] 2,7 5,9 8,3 12,3 16,8 23,4 NRec = min [NRd,p ; NRd,c; NRd,s] / γF ; γF = 1,4

Recommended

Ccr

SIZE M6 M8 M10 M12 M16 M20 hef,1 [mm] 25 30 40 50 65hef,2 [mm] 35 40 50 65 80 100 VRec [kN] 1,7 5,7 7,8 15,7 20,9 29,0 VRec = VRd,s / γF ; γF = 1,4

TENSILE SIZE M6 M8 M10 M12 M16 M20 hef,1 [mm] 25 30 40 50 65NRd,uncr [kN] C20/25 2,4 5,0 8,3 11,6 17,2C40/50 2,4 7,1 11,7 16,4 24,3hef,2 [mm] 35 40 50 65 80 100 NRd,uncr [kN] C20/25 3,8 8,3 11,6 17,2 23,5 32,8 C40/50 3,8 11,7 16,4 24,3 33,2 46,4 Distances Scr and Ccr must be fulfilled NRd,uncr = min[NRk,p,uncr / γMc ; NRk,s / γMs,N] γMc = 1,5 ; M8-M12 : γMs,N = 1,5 ; M16 : γMs,N = 1,47 ; M20 : γMs,N = 1,5 SHEAR SIZE M6 M8 M10 M12 M16 M20 hef,1 [mm] 25 30 40 50 65hef,2 [mm] 35 40 50 65 80 100 VRd,s [kN] 2,4 8,0 11,0 21,9 29,2 40,7 VRd,s = VRk,s /γMs,V M8-M16 : γMs,V = 1,25 ; M20 : γMs,V = 1,5

i-Expert Software Nota: The values indicated in italics and underlined correspond to steel failure FIX3 37

Concrete screw anchor for use in cracked and non-cracked concrete and seismic performance categories C1 & C2

TECHNICAL DATA VERSION

RANGE Minimum anchorage depth Maximum anchorage depth Thread Ø Drilling Ø Total anchor length Tighten torque Code Embed. depth Max. thick. of part to be fixed Drilling depth Min. thick. of base material Embed. depth Max. thick. of part to be fixed Drilling depth Min. thick. of base material (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm) h nom,1 t fix h 0 h min h nom,2 t fix h 0 h min d d 0 L T inst HFL 6X50/15 40 10 40 80 - - -7,5 6 50 10 058730 6X80/45-25 40 55 25 60 100 80 058731 6X100/65-45 60 55 45 60 100 100 058732 8X50/5 45 5 55 100 - - -10,6 8 50 20 058733 8X60/15 15 - - - - 60 058734 8X70/25-5 25 65 5 75 120 70 058735 8X80/35-15 35 65 15 75 120 80 058736 8X100/55-35 55 65 35 75 120 100 058737 8X120/75-55 75 65 55 75 120 120 058738 8X140/95-75 95 65 75 75 120 140 058739 10X60/5 55 5 65 100 - - -12,6 10 60 40 058740 10X70/15 15 - - - - 70 058741 10X90/35-5 35 85 5 95 130 90 058742 10X100/45-15 45 85 15 95 130 100 058743 10X120/65-35 65 85 35 95 130 120 058744 10X140/85-55 85 85 55 95 130 140 058745 10X160/105-75 105 85 75 95 130 160 058746 12X80/15 65 15 75 120 - - -14,6 12 80 60 058747 12X110/45-10 45 100 10 110 150 110 058748 14X130/55-15 75 55 85 130 115 15 125 170 16,6 14 130 80 058768 14X150/75-35 75 115 35 125 170 150 058769 CSK 6X60/25-5 40 20 40 80 55 5 60 100 7,5 6 60 10 058773 6X80/45-25 40 25 80 058774 6X100/65-45 60 45 100 058775 6X120/85-65 80 65 120 058776 6X140/105-85 100 85 140 058777 8X80/35-15 45 35 55 80 65 15 75 120 10,5 8 80 20 05 8653 ETA - 16/0276 ETA

df HFL CSK d0 tfix hmin h0 L d hnom Tinst ANCHOR MECHANICAL PROPERTIES SIZE Ø6 Ø8 Ø10 Ø12 Ø14 As [mm2] Stressed cross-section 20,4 39,6 65,0 97,7 134,0 Wel [mm3] Elastic section modulus 13,0 35,1 74,0 134,0 220,0 M0Rk,s [Nm] Characteristic bending moment 10,9 26,0 56,0 113,0 185,0 M [Nm] Recommended bending moment 5,0 13,0 28,0 56,5 92,5 SW [mm] Key size 13 13 15 17 21 INSTALLATION ⁃ Channel, cable tray ⁃ Brackets ⁃ E-Clips, cowhorn ⁃ TRH clip, rod hanging ⁃ Trunking ⁃ Push-pull bars ⁃ Formwork / shuttering APPLICATION CHARACTERISTICS ZINC COATED STEEL Zn

38

TAPCON XTREM

MINIMUM THICKNESS OF CONCRETE, CHARATERISTIC & MINIMUM DISTANCES FOR SPACING, EDGE

CHARACTERISTIC RESISTANCES [kN]

Characteristic resistances are shown as informative, and have to be used by application of safety factors.

SHEAR

RECOMMENDED LOADS OF ONE ANCHOR WITHOUT INFLUENCE OF SPACING & CONCRETE EDGE [kN]

Recommended values are determined from performances given in the ETA, and are guaranteed for spacing ≥ Scr and edge distance ≥ Ccr

SIZE Ø6 Ø6 Ø8 Ø8 Ø10 Ø10 Ø12 Ø12 Ø14 Ø14 Embedment depth hnom [mm] 40 55 45 65 55 85 65 100 75 115 Minimum thickness of base material hmin [mm] 100 80 80 80 80 102 80 120 87 138 Characteristic edge and spacing distances for full anchor capacity Ccr ≥ [mm] 60 82,5 67,5 97,5 82,5 127,5 97,5 150 112,5 172,5 Scr ≥ [mm] 120 165 135 195 165 255 195 300 225 345 Minimum distances for non-cracked concrete Cmin [mm] 35 40 35 50 40 50 50 70 70 70 S ≥ [mm] Smin [mm] 35 40 35 50 40 50 50 70 70 70 C ≥ [mm] Minimum distances for cracked concrete Cmin [mm] 35 40 35 50 40 50 50 70 70 70 S ≥ [mm] Smin [mm] 35 40 35 50 40 50 50 70 70 70 C ≥ [mm]

TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE Ø6 Ø8 Ø10 Ø12 Ø14 hnom,1 [mm] 40 45 55 65 75 NRk,p [kN] 4,0 7,5 12,0 16,0 21,7 hnom,2 [mm] 55 65 85 100 115 NRk,p [kN] 9,0 16,0 26,0 35,2 43,4 CRACKED CONCRETE ‒ C20/25 DIMENSIONS Ø6 Ø8 Ø10 Ø12 Ø14 hnom,1 [mm] 40 45 55 65 75 NRk,p [kN] 2,0 5,0 9,0 12,0 15,2 hnom,2 [mm] 55 65 85 100 115 NRk,p [kN] 4,0 12,0 19,3 24,6 30,4

CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE Ø6 Ø8 Ø10 Ø12 Ø14 hnom,1 [mm] 40 45 55 65 75 VRk,s [kN] 7,0 13,5 22,5 33,5 56,0 hnom,2 [mm] 55 65 85 100 115 VRk,s [kN] 7,0 17,0 34,0 42,0 56,0

TENSILE NON-CRACKED CONCRETE ‒ C20/25 SIZE Ø6 Ø8 Ø10 Ø12 Ø14 hnom,1 [mm] 40 45 55 65 75 NRec [kN] 1,9 3,6 5,7 7,6 10,3 hnom,2 [mm] 55 65 85 100 115 NRec [kN] 4,3 7,6 12,4 16,8 20,7 CRACKED CONCRETE ‒ C20/25 DIMENSIONS Ø6 Ø8 Ø10 Ø12 Ø14 hnom,1 [mm] 40 45 55 65 75 NRec [kN] 1,0 2,4 4,3 5,7 10,7 hnom,2 [mm] 55 65 85 100 115 NRec [kN] 1,9 5,7 9,2 11,7 14,5 NRec = min [NRd,p ; NRd,c; NRd,s] / γF ; γF = 1,4 SHEAR CRACKED AND NON-CRACKED CONCRETE ‒ C20/25 to C50/60 SIZE Ø6 Ø8 Ø10 Ø12 Ø14 hnom,1 [mm] 40 45 55 65 75 VRec [kN] 4,0 7,7 12,9 19,1 32,0 hnom,2 [mm] 55 65 85 100 115 VRec [kN] 4,0 9,7 19,4 24,0 32,0 VRec = VRd,s / γF ; γF = 1,4 Nota: The values indicated in italics and underlined correspond to steel failure TAPCON

39

XTREM

TAPCON XTREM