Comprehensive Diploma Design

Department of Real estate development & Construction management

By : Issam Alabdullah

H22N2O

By : Eng Attila Pém

By : Issam Alabdullah

H22N2O

By : Eng Attila Pém

1

Prepared

Neptun Code:

Supervised

1.Introduction:

The new cultural and social center in the Jewish court in Budapest is incorporates a seminar & cinema hall, library, Vegan Food Court, and Workshop & meeting rooms,. The task is to combine various cultural and Social functions as compact and efficient as possible and to create spaces that facilitate synergies, multi use and attractive meeting places. It should be inviting and inspiring and build further on Hungarians identity.

It is a place that can serve the locals by providing all necessary facilities from reading to meeting watching movies studying and eating. this place is a place that connects people from different generations from young teenagers to elderly people.

This place well attracts foreigners especially the increasing number of students who can use the workshop rooms and the public spaces as a place for study the thing the can strengthen the relations and melt the ice between them and the locals.

1.1. Site Analysis:

2

The plot area is locating in one of old Budapest’s neighborhoods and it is surrounding with many old and famous buildings, for Example Synagogue in Dob utca and the Dohany Utca famous Synagogue on the other hand the location is very accessible because of the roads surrounding it, Moreover, there is an empty piece of land just next to the project plot that we can use to put all the building pieces of equipment. The nearest hospital is just 900 m far ( 4 minutes by car )

1.2. Constrains and Assumption

- Executing Time : the period must be no more than 12 months

- Delivery Time: 1 1 2022

- Estimated cost : no more than 2,500,000 $

1.3. Aim of the project:

Providing a suitable public building that can serve the community in 7th district to be the spot for gathering and different activities for people from different generations

Providing a good example into the borders of scientific academic, health and Urban identity

3

1.4. Project Scope:

Establishing a public cultural & social center 3 stories

1.5. Project Goals

• Establishing a new cultural & social center in Budapest to reflect the Hungarian culture

• The ability to link the internationals and the Hungarian citizens by opening the center to give the internationals more information about Hungarian culture

• The mixture of different aspects and users will give extra value to this important area (students, employees, tourists , public, etc. )

• According to the functions in the project we can recognize work time as the government institutions ( 08:00 20:00)

1.6. List of primary risks:

Exceeding the specified delivery date (requires delay fines) dealing with the surrounding narrow roads

High prices during the implementation phase. (Estimated budget change) Bad weather conditions.

1.7. Difficulties:

1. the building is located in a central area of the city and there are two existing surrounding buildings from both sides of the plot the thing that can affect the flexibility of construction work.

2 The noise of the building will affect the surrounding buildings.

4

2.Investment plan:

2.1. Professional conclusion

The Project is a cultural & social center in the 7th district.

The project is situated in the middle of Budapest near Klauzal ter , in the famous historical Jewish court.

The proposal is to give a building that can serve the community and attracts people to strengthen the social connections and reflects the Hungarian culture, through the different facilities that it has.

It is a place that can serve the locals by providing all necessary facilities from reading to meeting watching movies studying and eating. this place is a place that connects people from different generations from young teenagers to elderly people.

This place well attracts foreigners especially the increasing number of students who can use the workshop rooms and the public spaces as a place for study the thing the can strengthen the relations and melt the ice between them and the locals.

The plot area is locating in one of old Budapest’s neighborhoods and it is surrounding with many old and famous buildings, for Example Synagogue in Dob utca and the Dohany Utca famous Synagogue on the other hand the location is very accessible because of the roads surrounding it,

Moreover, there is an empty piece of land just next to the project plot that we can use to put all the building pieces of equipment. The nearest hospital is just 900 m far ( 4 minutes by car )

Project Location:

Hungary | Budapest | 7th D

-Category: Public Building “Cultural & Social center ”

Site Area: 1100 m2

-Built Area: 1665 m2

-Project Year: 2021 Project Users: all society

5

Functional schema of the building

6 2.2. Project Facilities Function Number Area | Each M2 total 1. Lobby 1 134 134 2. Reception 3 5 8 18 3. Public gathering & meeting Areas 3 - 410 4. Workshops 5 15 75 160 5. Library 1 185 185 6. Roof bar 1 160 160 7. Vegan Food Court 1 120 120 8. Seminar & movies hall 1 103 103 9. Administration 2 - 65 10. Services (W.C) 70 70 11. Circulation 12-18% 12. Total 19 1665

Structural engineer: . Eng. Alaa Kanaan

Civil engineer : Eng. Mouaz Nabaa

Individual

Individual

Mechanical engineer Eng. Alaa Shatila

Individual

Electrical engineer: Eng. Ahmed Hammad

Individual

7 • This building will add value to this important area due to the brilliant design and the visitors number, Where the center can accommodate up to 150 300 people / hour divided for 3 floors. • The plan is a two rectangles linked together with bridges and staircases 2.3. Project Participants: Client : Ministry of culture Quality Surveyor: Dr. Wager Peter Financing company : firm Municipality Authorities : Contractor: General contractor: DCTC construction company (firm ) Sub contractors Suppliers Designer : Architect Issam Alabdullah Engineering Office ( Individual )

(

)

(

) -

(

)

(

) Turnkey method (participants connections) Characteristics Single point responsibility • Can be overlapped • Client can be sure of maximum cost before final commitment • Thus costs should be lower shorter time on site

Connections between the participants

8

Participants roles and tasks

1. Participants and tasks

Considering that it is a public building of social and cultural interest, built with Governmental funding, there are specific procedures that must be followed in order to meet the demands required. Thus, understanding background and I will mention these rules due to the lectures of Construction Management 4 in Budapest university of Technology & Economics

First step they will announce an Architectural Competition to choose the best design by a Jury of famous and well skilled designers.

Competition:

Organizer roles:

Defining aim and type of competition

Ensuring the financial background

Invitation of the jury

Defining the assignment of the competition

Making the competition announcement

Organizing the competition

Announcing the results, offering awards

Utilization of the plans

Jury roles:

Selection of the most valuable plans (according to the aim of the competition)

Evaluation with justification

Opening the „envelops” of the awarded plans

Recommendations for the future design phases

Participants roles :

Submission of the plans

Now I will speak about the duties for the main Participants

Client

In our case it is a governmental institution

o Provide financial background, liquidity of the project

Dispose with the construction site

Procure the rights to build (attain building consent)

Establish contract with the architect, consultant, contractor, etc.

Share rights and risks

Attain permission of use

Designer - architect

Help the client in professional way to attain building permit

Prepare documentations according the national/international standards and legal prescriptions

Coordinate the work of the co operative designers and professionals

9

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

Other designers and professionals

Tasks and duties:

Prepare documentations according the

standards and legal prescriptions

Continuous co operation and communication with the designer architect

Consultants

and duties:

Depend on their contract

Contractor

and duties:

Participate in the tendering process

Contract with the client and with sub contractors and the suppliers

Construct the building according the national/international standards and legal prescriptions

Co operation and communication with the designer team, the authority and the client/PM

Authorities Tasks and duties:

Provide building permit

Provide permission of use

Give consent for the plans, for the technical solutions, etc., according to to legal prescriptions

Public utilities, public services

Tasks and duties:

Give a consent for the plans (capacity, standards, etc.)

Verify the finished wor

Quality surveyor Tasks and duties:

Control the plans in accordance with the

the legal

Control the assignment of the building

Ensure the prosecution of the prescribed tests (e.g. soil mechanics)

Control the construction: the construction logbook, hidden structures, quality, used materials, the volume of the completed work

Inform the client if the completed work is according to the contract

Financing institute

Consider the requests for credit

Grant credit by schedule for the project

Control the use of money

plans

10

o

national/international

o

Tasks

o

Tasks

o

o

o

o

o

standards and

prescriptions o

o

o

o

o

o

o

o

o

o

o

o

o

Technical information:

The new center in the Dob utca is a 3 stories Cultural & Social Building, with another facilities, the basement is a smart parking, storages and technical rooms .

The land was used by the Vegan Garden area where people come to taste vegan food from different caravans and kiosks , so the ground floor is the Vegan food court with the lobby and information

The upper floors contains different facilities from library to movie hall ,administration, workshops and meeting rooms

The roof of one of the two masses is a sky bar provides a beautiful view towards the neighboring green park.

area

11

Cultural AdminMoviesFacilities & Services Garden

Technical description of the planned construction

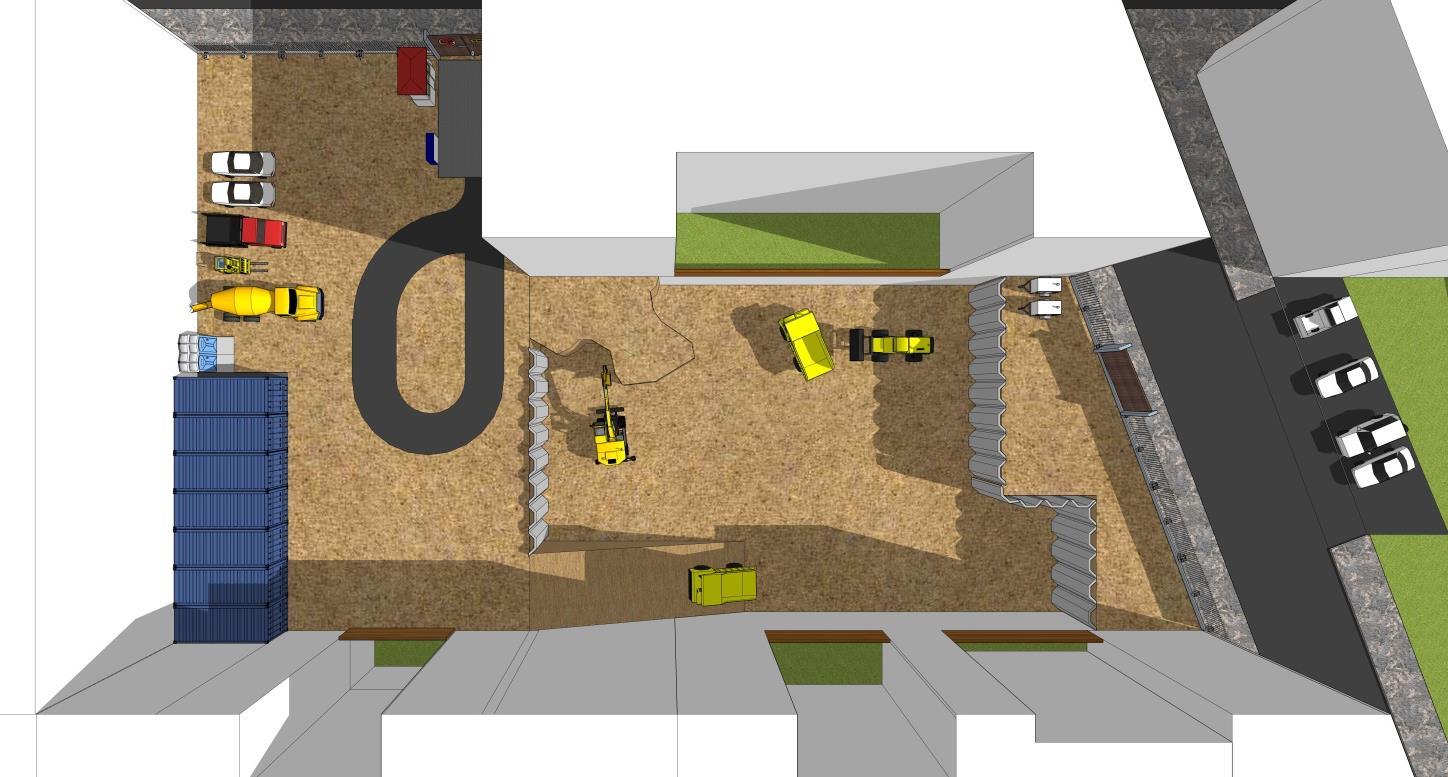

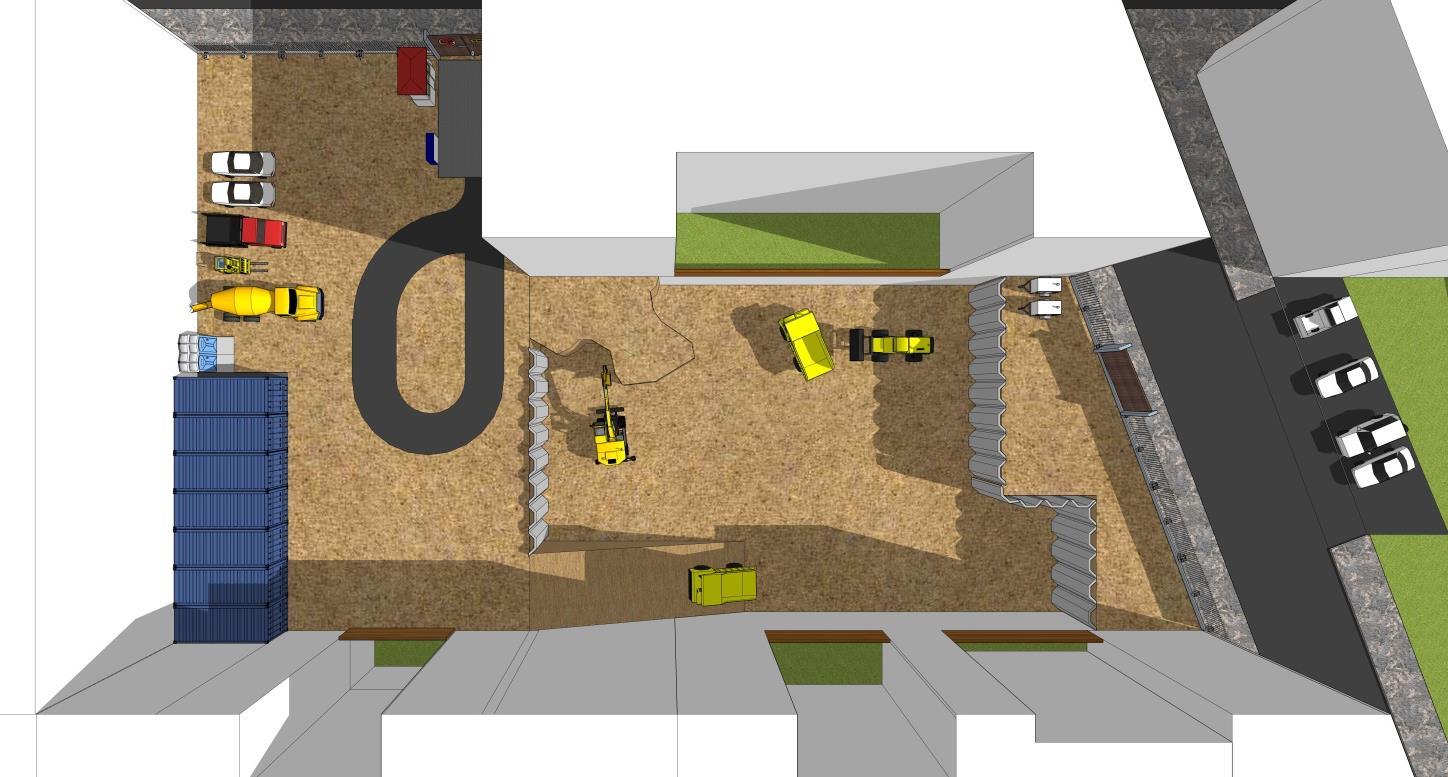

Preparation of the site

We should prepare a geotechnical report as a first step before construction begins, in order to certify the conditions of the site. The site cleaning should be given afterwards, before the building begins properly.

Secondly, we have to rent the empty neighboring plot to place the facilities in it.

We should locate the gate and position fences at a height of 2.0 m. The demolition works for a particular section of the adjacent building( just a wall ) , which will also be integrated into the project's construction site, will also be required.

Following this first phase, temporary facilities such as the supply of electricity would have to be prepared in order to provide the necessary infrastructure for the start of the work. It is also necessary to provide the staff with containers. Containers should be distributed as follows:

1. Office

2. Changing rooms

3 Kitchen and food area

4 warehouses for materials

5 Storage for formwork

There should also be temporary toilets and guard (control) cabins installed on the site. Considering that 80 % of the total area of the site will be used by the house, it will be necessary to expand the site to a a neighboring empty plot space. Or even using small part of the public space opposite the street ( huge public park ) to put Storage for building materials and the vehicles.

Demolishing:

As I mentioned above there are some kiosks selling vegan food in the plot all of these kiosks are light weight

12 2.

and can be moved or demolished easily as it can be seen in the photo below

Excavation

The excavated material should be loaded into truck and will be send to the appropriated destination. As soon as the excavation of the soil is concluded, the foundation works can start.

First, in order to start the excavation for the potential installation of the foundation (considering that we have a basement floor), the exact boundary of the building should be demarcated. We will need a loader, an excavator and a dump truck for the excavation. Provided that the site is flat, and the water level is below the lower level of the base, the excavation can be achieved in just one stage.

The lowest level of excavation is 425, because I have only one basement floor.

It is important to load the excavated material into a truck and send it to the appropriate destination. The foundation works will begin as soon as the excavation of the soil is completed.

Installation of the crane

The most suitable technical solution for the construction of this building is to use one small size mobile crane, also a small size tower crane and sometimes we need support of other smaller cranes taking in consideration that the size of the plot and the location of the building in relation to the storage areas. The mobile crane will be placed on the edge of the rented area in the neighboring empty plot and will have the radius of 30.00 m. Crane will be installed before foundation work. At the end of the load bearing constructions, The crane is movable due narrow passages. As far as space limitation is an issue in this construction site, the Tower crane can be installed inside the court yard of the building after finishing the basement works which could be enough space . the crane is suitable to install the scaffolding around the building. Because of limited place on the construction site, crane will be place inside the court yard, cooping one of the halls of the building which is 3 story high. All Storages will be within reach in the construction site

Foundation

A strip foundation scheme has been selected for this construction. We have to transport concrete to the exact location required for its construction by concrete mixer and it will be pureed with the support of concrete pump or with the mobile crane. Construction process steps:

1. Earth works: the project site compaction

2. Preparation of a site, setting the gravel

3. Placing Formwork

4. Protection mesh Reinforcement positioning

13

5. Pouring, flattening and vibrating concrete

6. For the curing of the concrete, the foundation should be watered for

7. Layer positioning for waterproofing

Structural Works

A skeleton frame system consists of the following components: pillars and beams, shear walls, slabs and wall beams, all made of reinforced concrete. The framework of the building is a skeleton frame system. This structural approach made the use of space more versatile, taking into account that this would require a technology that would allow for wider spans. To prevent thermal bridges, the elements exposed to the outside will be properly enveloped with thermal insulation.

The walls are made of brick with insulation between the house and the surrounding buildings, while the inner external side walls are manly curtain walls. The inner walls of clay brick mortars

Interior Walls : Knauf Gypsum partition walls with different thicknesses ,

Modern Knauf drywall system offer huge benefits compared to solid constructions, for example , with regard to sound insulation , space gains and lower weights.

And these benefits are really important for the project especially the walls of the workshops that needs some sound insulation

Moreover this system has many pros for the project .

1 Special gypsum core for highest degree of sound insulation

2. Very good performance at low frequency range

3. Fire resistance . DIN 18180 non combustible

4 Easy application

5. Bendable

And it is easy to construct with metal stud partitions also we can add cladding to the wall

Shear walls:

Shear walls are vertical components of the resisting structure of horizontal force. They are made of 30 cm of RC as well. From base to roof, they cross the house. In order to have no opening, these walls were built to retain their load bearing capacity.

Flooring & Slabs

There are numerous types of slabs in this building, as there are four kinds of technological solutions needed to make architectural planning feasible. Depending on the form of usage that will decide the constitution, the types vary. between apartments, terrace, balcony or roof slab, it may be an internal

14

slab. In all circumstances, the RC slab has the same thickness, differing only from the other required layers above. The slab components in the most general situation are:

Concrete Structure: concrete, mixed in a 3:2:1 ratio, is made from cement, aggregate , and water.

To form a fluid mixture, ingredients are combined, which can be quickly spread across various areas. Damp Proof Membranes (DPMs) are used to prevent the screed and final floor from being damaged by rain water. These membranes are made of polyurethane and are placed on top of the concrete base to resist dampness, especially when impermeable floor finishes are used to prevent the natural dispersion of moisture.

Insulation of the Building

1 Exterior walls An EPS / XPS insulation sheet of at least 15 mm thickness envelops the exterior of the house.

2 Roofs : There are two styles of roofs in the building: a walk able roof terrace and a non walkable roof that will only be available for maintenance or repair. The non walk able roof is made up of:

* 5 cm of gravel ballast Ø16 32 mm and layer protection

* synthetic filter of 1 layer with a specific density of 125 g / m2

* 20 cm of extruded thermal insulation polystyrene foam (XPS), with spaced joints

* 1 layer of 4 mm bitumen waterproofing membrane (reinforced polyester fiber), completely bonded by torch welding.

* 1 layer of 4 mm modified bitumen waterproofing membrane (reinforced glass fiber), completely bonded compound cold layer of bitumen patching (approximately 300 g / m2)

* 4 cm concrete inclination layer (substructure), expansion joints at 50m2 each

* 20 cm reinforced concrete monolithic slab.

Curtain wall System:

Since all the inner part of the elevations are made of Schuco FWS 60 CV curtain wall system I will speak about it.

Curtain wall systems are non-structural cladding systems for the external walls of buildings. They are generally associated with large, multi storey buildings.

Curtain walls separate the interior from the exterior, but only support their own weight and the loads imposed on them (such as wind loads, seismic loads, and so on) which they transfer back to the primary structure of the building. This is in contrast to many forms of traditional construction in which the external walls are a fundamental part of the primary structure of the building.

15

Typically curtain wall systems comprise a lightweight aluminum frame onto which glazed or opaque infill panels can be fixed. These infill panels are often described as 'glazing' whether or not they are made of glass.

Fixing of the System :

This system is a prefabricated system we move it to the site and then with the help of crane we can fix it in the exact façade

Installation sequence

The high degree of prefabrication of the Schüco Façade FWS 60 CV allows particularly efficient installation. The system is based on the reliable and proven mullion/transom construction method.

1 Attachment to the building structure Brackets are positioned on the building structure at defined distances, and are connected to the base profile of the system.

2. Installing opening units ,Units prefabricated in the workshop are placed on the aligned base profile from the outside and fixed in place .

3. T r a n s o m p r o fi l

es and fixed glazing . Transom profiles from the Schüco FWS 60 system are placed in the adjoining fixed fields to fit between the opening units. For an opening unit with a basic depth of 65 mm, a 70 mm deep transom is used; and for a unit with a basic depth of 85 mm, a 90 mm transom is used. After the fixed fields have been glazed, the glass is secured using pressure plates, onto which cover caps are fitted. Adjoining opening units have so far not been possible.

16

2 1 3

17

Flooring:

Parquet Floor preparation &installation

First of all, it is always necessary to ensure that the required working standards are enforced.

The concrete slab must be as flat as required by the requirements of the manufacturer of wood flooring. In a 6 foot radius and or 3/16 "in a 10 foot radius, manufacturers would usually define a flatness tolerance of 1/8".

The dry subfloor must be test by adding drops of water to the slab for the presence of sealers. If the water beads up, sealers or oils may exist.

Checking if the concrete slab is not chalky or soft before installation is necessary.

Ensure that the concrete is well applied to the sub floor. Check for hollow spots, loose areas and cracks. The concrete needs to be clean, smooth and dry to specification.

Before proper installation, it is also necessary to provide adequate storage conditions for parquet flooring in order to preserve the desired material characteristics, given that wood is a material that needs special attention, particularly when it comes to humidity. According to the manual available at oldwoolltd.com, below are some of the most critical things that must be taken into account when storing these constructive elements:

1. Do not store wood floors under unregulated environmental conditions at the work site.

2 Check the moisture content of wood flooring with a moisture meter upon delivery to create a baseline for acclimation. Check the material of several boards for moisture. For a 1,000 square feet of flooring, a good representative sample is usually 40 boards.

3. The optimal wood moisture content only reflects the base line from which to start and does not reflect the final EMC needed for the indoor setting. In order to adjust the moisture content of the wood flooring to the interior climate in which it is expected to function, acclimatization is also needed. Excessive expansion, shrinkage, dimensional distortion or structural damage can be caused by insufficient acclimatization of wood flooring.

Parquet floor Installation:

1. Wood subflooring test for humidity

2 Testing concrete for humidity

3 " The minimum expansion area of 1⁄2" around the perimeter and all vertical obstructions must be left.

4 Lay blocks and/or individual bits of glue parquet.

5. Use the adhesive approved by the wood manufacturer. Follow the spread rate, size of the trowel and installation technique as recommended by the manufacturer of the adhesive.

18

Layout of parquet:

The "wall side" is the selected parquet layout for the installation of this constructive layer and the criteria for its effective installation procedure are:

1. Measure and create a chalk line parallel to and 24 1/2 "(62 cm) away from the starting wall opposite the entrance doorway in at least two places from the corner, if the room dimensions allow. The 1/2" (12.7 mm) is for expansion space.

2. away from the right angle wall, snap a second chalk line 90 degrees to the first chalk line. The 1⁄2" is for room for expansion.

3. Make the necessary changes to allow for square walls before continuing.

The last thing is to spread the adhesive

Other floor covering:

1. Marble : Vetrite marble with the size of 53 * 114 cm

Subfloor preparation is similar cement board underlayment installed over a sturdy plywood subfloor is the best base for marble tiles , just as it is in ceramic tile.

Tiles are glued down with a thin set adhesive a mortar based product that now is the standard for stone and tile products

Joints between the tile are grouted with a fie mortar product

2. Tiles & Ceramic Tiles : Kerateam Fliesenproduktions / NOUV RIWAL

Ceramic Tiles used in the project only in kitchen and WC

As for tiles and ceramics the similar way of establishing marble tiles can be applied to make these floors

3. Epoxy coating layers :

for basement & mechanical rooms .

We use these materials usually in factories , workshops , warehouses and garages…etc. so they can protect the floor from mechanical ware and chemical damage and in order to make it easy to clean.

The products of are usually a 2 component solvent free epoxy system , mixed together and layed above the final surface and after some time the floor is ready.

19

Plaster : plaster layers on the interior and exterior surfaces / Knauf

I chose plaster finishing because it is clean beautiful and easy to paint above it . also it is flixibe in such kind of buildings when we are speaking about a public center we don’t need to provide expensive materials on the walls

Doors : Daloc Wooden doors with different sizes

SD 4210 steel doors for Technical rooms

Many doors are used in the project depending on the function for example the workshop doors are heave doors made of steel and they includes acoustic insulation .

The rooms doors are wooden doors easy to construct and has good thermal and acoustic insulation impacts

20

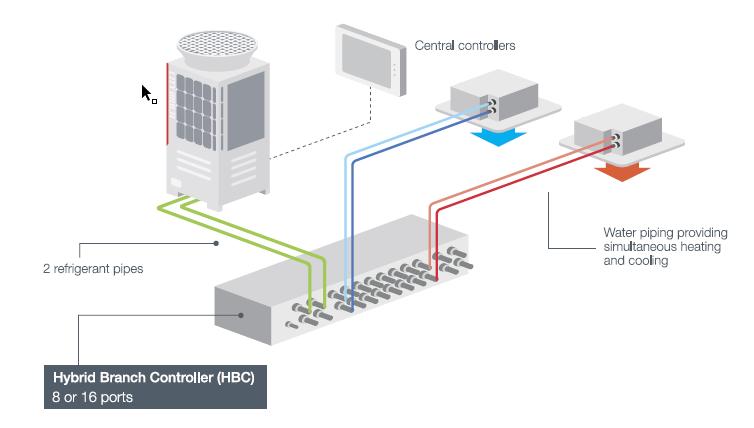

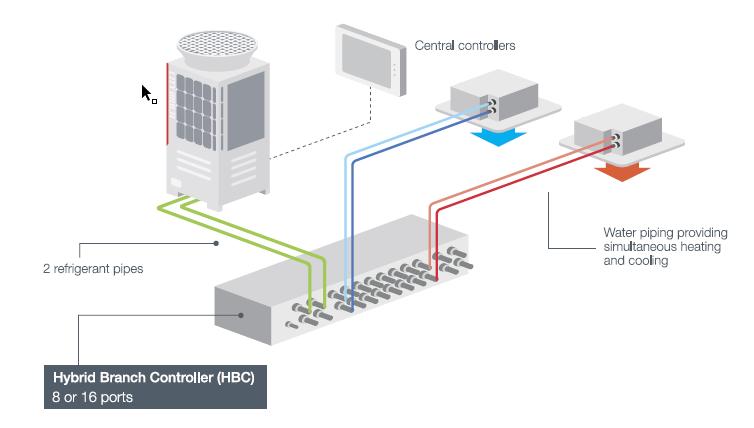

21 Building Systems : Heating & Cooling System: The outdoor units are two units and it is an Air Source unit Mitsubishi City Multi Model Number: PUHY P650YSNW A Master Branch Controller Model : CMB WM108V AA CASETTE MODEL : 4 WAY BLOW CASETTE PLFY P 100VEM E The Heating system consists of an: Outdoor Unit, an Indoor Master Branch Controller, system remote control, and Cassettes

22

23

Master

Branch Controller Model: CMB WM108V AA:

24

25

Cassette Model: PLFY P100VEM E

System Example:

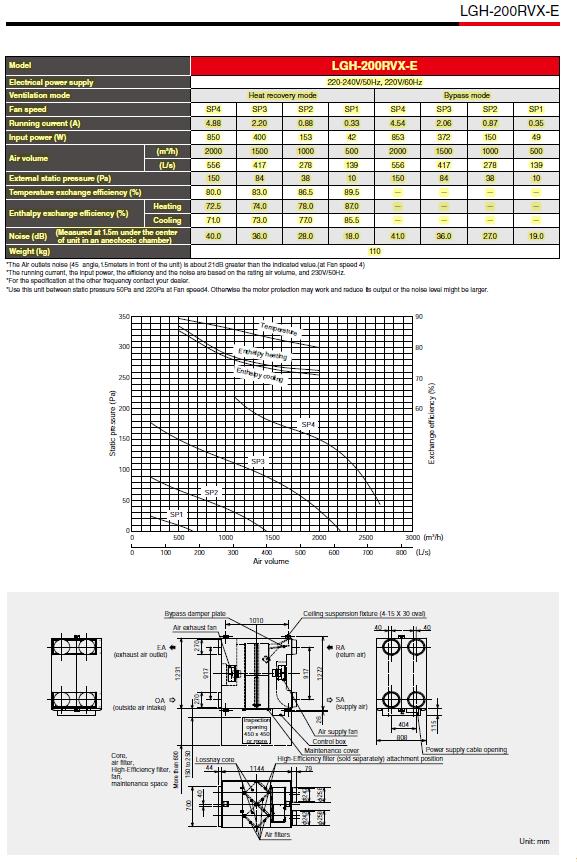

Ventilation System :

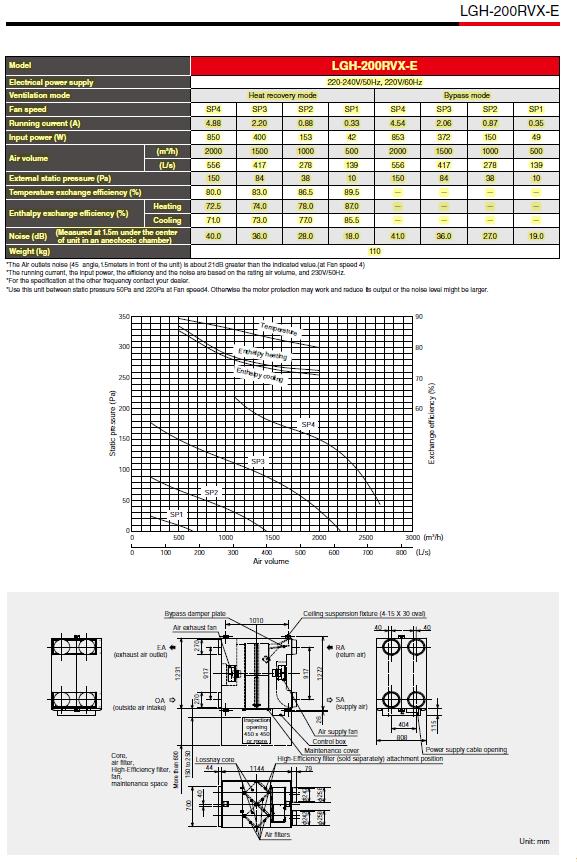

Ventilation system used is designed by Mitsubishi ( Lossnay Ventilation system). The building is ventilated both mechanically and naturally. all around the building, built in windows are positioned within the curtain wall systems to allow the users to utilize natural ventilation through windows natural air. Mechanical ventilation is provided in the building through compact ventilation units. Vair <2500m3/h, the compact ventilation units can be mounted on ceilings. Ventilator Unit used: Lossnay LGH-200 RVX-E. 6 Lossnay units were used in design due to capacity needed.

26

27

The system is a centralized controller unit:

The Duct system uses Grills for ventilating:

28

BUILDING'S ARCHITECTURAL ECONOMICS

Competitive Advantages:

1

Modern, contemporary design

2 Fresh and distinctive architecture, making the property stand out in the area.

3. High grade materials.

4 Immediate surroundings that provide a range of activities.

5 Decent mobility on foot or by public transport.

6. Reliable public transport.

Supply and Demand Analysis:

When it comes to District 7 then all people in Budapest knows how important because it is the heart of the city the district that never sleep since it has many famous restaurants and bars also it includes sport and cultural facilities , adding a new place in a well marketed area will guarantee a vast number of customers especially when we are talking about a multi functional building that can be used from all the people in the community whether young or old no matter if they are citizens or foreigners

Based on the facilities in the building:

The Vegan court: 10 Euro / Person

Movies and seminar hall: 7 Euro / Person

The Library and Bookshop: approximately 2 Euros / Book

Roof Bar: 10 Euro / Person

Meeting rooms: 20 Euro / Hour

Workshops: 20 Euro / Hour

Vending Machines: 1 Euro /Person

Financial Analysis:

Income (Positive)

Outcome (Negative)

Vegan Court Operations ( Gas, Electricity, Security , Management)

Movies hall Maintenance

Library and Bookshop Insurance

Roof Bar Facility management Workshops & meeting rooms Marketing

Economic Analysis:

Income (Positive)

Energizing the neighbourhood economy

Outcome (Negative)

Noise

Higher income for parking and shops Waste Job Vacancies Maintenance for the surroundings

30

Higher land value

Higher prices pf the neighbouring flats

Governmental Income (Tax)

Risk Analysis:

More crowded roads

1. the building is located in a central area of the city and there are two existing surrounding buildings from both sides of the plot the thing that can affect the flexibility of construction work.

2. The noise of the building will affect the surrounding buildings.

3 Local acceptance and municipality approval are required for the project.

Cost Calculation:

Construction cost

Construction cost appears to be one of the main factors for design growth, with the employer and in some instances the contractor wanting to understand the measured price effect of decisions taken in respect of design. The cost assessment processes and simple cost planning are used to notify the employer and the design/construction team of the effect of certain decisions on the price. This data in turn feeds back into the phase of design creation.

There is also an on going concept creation and cost planning mechanism to ensure that:

The employer can finance their venture, and

It reflects value for money.

Factors affecting the cost :

1. The location in the old city will effect the flexibility for the trucks to enter the project area

2 Timing: Environmental conditions vary at various times of the year and availability can impact material costs. The general economic conditions at the time of the compilation of the averages may vary from those of today.

3. And there are several other factors (like the quality of the used materials, political issues, etc.

Project Cost divided according to ( DIN 276 )

The Construction process will start in 2021 and it is expected to end in 2022 so the period of the project is one year .

Due to a report of construction prices published in 2019 from Cushman & Wakefield company the construction price for one square meter in Budapest is around 1500 Euros

Moreover, the range of property prices in district 7 is 300,000 400,000 Huf / Sqm

All the prices that I used in the cost estimation brought from a report of THE EUROPEAN COUNCIL OF CONSTRUCTION ECONOMISTS published in 2018 to compare the prices between different countries in the EU

31

000 HUF/m

000 HUF/m

000 HUF/m

for

for

for no 1

000 HUF/m2 for no2

HUF/m2 forno 3

HUF/m2 forno 2

HUF/m2 for no 1

000 HUF/m2 for no 3

000 HUF/m2 for no 2

000 HUF/m2 for no 1

000 000

000

000 000

000 000

000 000

000 000

000 000

000 000

750 000

000 000

000 000

450 000

000

000 000

32 The facilities in the building is different and I will classify them in three main categories: 1 Basement : storage , Technical rooms , and Parking areas ( total area : 450 M2 ) 2 Public Cultural Facilities : Library , seminar Hall , Meeting areas and food areas ( 1000 M2 ) 3. Offices , and workshop rooms ( 200 M2 ) Note that I raised the additional expenses percentage because I will rent a new plot to place the equipment also a compensation money for vegan food restaurants owners in the plot due to the suspension of their work Cost group Percent of 300+400 or cost 100 Plot 300 000 000 HUF 300 000 000 HUF 300 000 000 HUF 200 Infrastructure 5% 44290000HUF 300 Building construction 320 000 HUF/m2 for no 3 430 000 HUF/m2 for no 2 242 000 HUF/m2 for no 1 80, ,000,000 HUF 430,000,000 HUF 118,918,000 HUF 628918000 HUF 400 Construction of building installations and electrical 212 592 000 HUF 410 Water, sewage, gas 30 000 HUF/m2 for no 3 35

2

no 2 20

2

no 1 6

000 35

9

53148000 420 Heating 40

2

45

8

45

53148000 430 Ventilation and AC 10000

12000

6000

2

12

2

17716000 440+450 Electricity, Telecommunication and IT 30

40

30

6

40

13

17716000 460 Transportation equipment (elevator) Car elevator 12

HUF/pcs 20 000 000 HUF/ Pcs 17160

20

17716000 500 Outdoor constructions (landscaping , setting areas) 40 000 HUF/m2 22 000 000 22 000 000 HUF 600 Installation and artwork 0 100% 2% 17 716 000 HUF 700 Additional expenses 10% 10% 88 580 000 HUF Construction cost for the project = 885,800,000 HUF Total Project Cost = 1,101,504,000 HUF

33 Construction Cost Group 300 Estimated Percent Estimated cost 310 Earthwork 5% 44290000 320 Foundation 8% 70864000 330 External Walls 20% 177160000 340 Internal Walls 9% 79722000 350 Slabs & Roof 20% 177160000 360 Built in appliances 2% 17716000 370 Other 5% 44290000 69% 628918000 Construction Cost Group 400 Estimated Present Estimated cost 410 Water, Sewage, Heating 6% 53148000 420 Ventilation & AC 2% 17716000 430 Electricity 5% 177160000 440 Telecommunication and IT 2% 17716000 450 Transportation Equipment 2% 17716000 460 Technology Equipment 2% 17716000 470 Integrated Building management and service management 3% 26574000 480 Heating 6% 53148000 490 Other 4% 35432000 DIN 276 1 100 Plot 300 000 000 200 Infrastructure 5% 44 290 000 300+400 Construction cost 628 918 000 500 Outdoor Construction 22 000 000 600 Installation & artwork 17 716 000 700 Additional expenses 88 580 000 Total 1,101,504,000 Construction cost for the project = 885,800,000 HUF Total Project Cost = 1,101,504,000 HUF

Construction Site :

Information about the project:

1. The project has two gates from two different streets

2. The main storage area ,the offices and the vehicles movement are in the rented plot on the left

3. There is a security spot next to the gate with a machine or washing the trucks and the concrete mixers from dust and concrete before leaving the site

4. The electricity and the water main lines are in the neighboring streets and I draw it to the site from the kiss diofa utca on the corner of the plot and as it is shown in the plan these lines are reaching all the facilities based on needs .

5. The tower crane in the central area in the court yard has to be set up after finishing the basement woks , and it can be moved out from the plot by the Dob utca ( the road is open under the bridge the height is 3.5 m the same thing also for the mobile crane.

6. There are many courtyards and shafts ( doesn’t includes windows between the building and the neighboring buildings ) I placed a fence between them and the plot during the construction

34

35 Excavation

36

37 Structural Activities :

38

39

40 Time Schedule:

Quantities and Resources :

Basement :

Excavation Area = 850 M2

Excavation Height = 5 M

Excavation Volume = 4250 M3

Total Foundation Volume = 66 M3

Ground Beams Volume = 30.24 M3

Necks of the Columns and the Columns in Basement Volume = 27.5 M3

Shear wall Volume = 32.23 M3

Gravel Volume 755 * 0.2 = 151 M3

Basement Slab Concrete Volume = 755 * 0.15 = 113 M3

Ground Floor :

Ground Floor Area = 385 M2

Concrete slab Volume = 100 M3

Ground Floor Columns Volume = 16.36 M3

Ground floor shear walls = 23.83 M3

Ground Floor Beams volume = 48.95 M3

First Floor:

Floor Area = 750 M2

Floor slab Volume = 182 M3

Beams Volume = 52.36 M3

Columns Volume = 16.36

floor shear walls = 23.83 M3

Second Floor:

Floor Area = 750 M2

Floor slab Volume = 182 M3

Beams Volume = 52.36 M3

Columns Volume = 16.36

floor shear walls = 23.83 M3

Roof Floor

Floor Area = 750 M2

Floor slab Volume = 182 M3

Beams Volume = 52.36 M3

floor shear walls = 23.83 M3

Staircases & Ramps

1.Entrance stairs volume = 4 M3

2. staircase in every floor volume = 2.4 M3

I hve 6 staircases in 3 floors

Total staircase Volume = 14.4 M3

3. front bridges stairs volume = 2 * 3.68 = 7.37 M3

4. back bridge stairs = 2*04.1 = 8.2 M3

5. Entrance Ramp Volume = 1.34 M3

6. Bridges Ramps = 2.7 M3

Water Insulation :

Slabs = 1583 M2

Walls = 564.9 M2

Total = 2148 M2

Thermal Insulation

Basement = 433 M2

Slabs = 2665 M2

Walls = 240 M2

Total = 3338 M2

Curtain Wall Elevations

Ground Floor = 294 M2

First Floor = 402 M2

Second Floor = 381 M2

Total = 1077 M2 = 178 Panels

Drywall System ( Gypsum boards )

Basement = 453 M2

Ground Floor = 24.2 M2

First Floor = 78 M2

Second Floor = 178 M2

Roof Floor = 83 M2

Total = 817 M2

Block Walls :

Area = 69.1 M2

Number of Blocks = 69.1 / 0.0741 = 933 Blocks

Plaster

Slabs = 1744 M2

Partition Walls = 138 M2

Cover Walls = 824 M2

Total = 2706 M2

Paint

Total = 2245 M2

Reinforcement Steel for Concrete

Foundations & Ground Beams = 2680 Kg

Columns = 3025 Kg

Shear Walls =5156 Kg

Ground Floor Beams = 3916 Kg

Ground Floor Slab = 1400 Kg

Ground Floor Columns = 1799 Kg

Shear Walls in Ground Floor = 3812.8 Kg

First floor beams = 4712 Kg

First floor Slab 2600 Kg

First Floor Columns = 1799 Kg

Shear Walls in first Floor = 3812.8 Kg

Second floor beams = 4712 Kg

Second floor Slab 2600 Kg

Second Floor Columns = 1799 Kg

Shear Walls in Second Floor = 3812.8 Kg

Labor

Note: the work will be on the site for 2 3 shifts every shift is 8 hours and it has the ability to be 10 hours as 2 extra hours work in case of need.

1. Gravel Leveling :

V= 151 M3 for a group of 8 workers every one finishes 1.14 M3/H

We will need 2 shifts of working for two different groups of workers every group have to work 8.25 hours ( 16 workers by two shifts )

2. Foundations and Ground Beams Steel Fixing :

Every steel fixer finishes 20 Kg / h with the group of 6 skilled steel fixers 120 Kg /h

For 8 hours working 960 Kg

The steel amount is 2680 Kg so we need 3 shifts to finish the work 22.4 hours of Work in Two Working days

3. Shuttering for ground beams & foundations :

A carpenter finishes 2.5 M2/h while a worker finishes 1.7 M2/h a group of 1 carpenter and 4 workers finishes 9.3 M2/h

Coverage total area = 161.9 M2 thus 161.9 / 9.3 = 17.4 h

We need two groups to finish the works and they can finish in one working day

4. Concrete casting for foundations , necks and ground beams :

A concrete pump can cast 15 M3 / h with the help of 6 workers

115 / 15 = 7 working hours so we finish in one day one shift

5. Steel fixing for columns and shear walls in Basement :

Steel amount = 8181 Kg / 960 ( amount per shift ) = 8.5 shifts

So we need two groups working together for 4 shifts and thus the duration 3 working days

6. Shuttering of columns and shear walls :

322.6 / 9.3 = 34.6 hours. so we need 2 groups 4 shifts every group 2 carpenters and 10 workers

7. Concrete casting :

49.2 /15 = 3.28 h with 6 workers and concrete pump.

8. Ground Floor steel fixing :

Beams = 8 steel fixers working for 3 shifts in two working days

Slap = 1 group for 2 shifts in one working day

Columns = 2 groups working together for 10 hours in one working day)

9. Ground floor shuttering :

Beams (244.8 M2 ) = 2 groups for 1.5 shifts

Slab ( 385) = 2 groups/shift for 2 working days

Columns (191 M2) = 2 groups working for 10 hours/shift in one working day)

10. Ground floor concrete casting :

with a pump and 6 workers

Beams = 3.2 hours

Slab = 6.6 Hours

Columns = 2 hours

11. First floor Steel fixing :

Beams = two working days

Slap = two working day

Columns = 2 groups working together for 10 hours in one working day

12. First floor shuttering :

Beams (261 M2 ) = 2 groups for two shifts

Slab ( 750) = 2 groups/shift for 4 working days

Columns (191 M2) = 2 groups working for 10 hours/shift in one working day)

13. First floor concrete casting :

with a pump and 6 workers

Beams = 3.49 hours

Slab = 6.6 Hours with using two pumps and 12 workers

Columns = 2 hours

14. second floor Steel fixing :

Beams = two working days

Slap = two working days

Columns = 2 groups working together for 10 hours in one working day

15. second floor shuttering :

Beams (261 M2 ) = 2 groups for two shifts

Slab ( 750) = 2 groups/shift for 4 working days

Columns (191 M2) = 2 groups working for 10 hours/shift in one working day)

16. second floor concrete casting : with a pump and 6 workers

Beams = 3.49 hours

Slab = 6.6 Hours with using two pumps and 12 workers

Columns = 2 hours

17. shear walls in repeated floors :

Steel = 2 groups for 2 working days 2 shifts

Shuttering = 2 groups in one shift one working days

Concrete casting : 1.5 hours with pump and 6 workers

18. water insulation : using Bituminus felt double coat the skilled worker finishes 230 M2/h

total area = 2148 M2 / 230 = 9.3 Hours 1 working day

19. Heat insulation :

Using gas silicate insulation tile size 79.5 * 24 cm

The skilled worker finishes 5 m2/h for vertical surfaces and 11.11 m2/h for horizontal

3098/11.11 = 278.8 hours

240/5= 48 hours

For 6 skilled workers = 54.4 h/ worker and thus we need

12 workers to work for 3.5 working days every group works for one shift / day

20. Curtain wall panels :

Two skilled workers needs 0.5 hours to establish one panel

174 panels in the project so we need 10 workers for three days with the help of the crane.

cultural & Social Center Dec 15, 2020 Hungarian company http:// Project manager Issam Alabdullah Project dates Jan 1, 2021Jun 25, 2022 Completion 0% Tasks 120 Resources 47

Duration

463

End date

6/24/22

Begin date

1/1/21

Name

Social & Cultural centre

3/23/21

1/1/21

1-Preparation Phase

2/4/21

70 Project Preparation and analysis

1/1/21

2/16/21

30 Analysis

2/5/21

3/5/21

10 Fesability study

138

2/17/21

3/23/21

15 Financing

9/16/21

3/6/21

4/9/21

15 2-Planning Phase

5/13/21

4/9/21

Architectural competition announce

5/15/21

30 jurey evaluation

5/14/21

5/17/21

2 choosing the Architect

5/17/21

6/21/21

1 Concept plan

5/18/21

8/12/21

30 Documintation for Implementation

30

9/16/21

6/22/21

8/13/21

45 Building Permit

12/7/21

9/17/21

3-Preperation for implementation

10/21/21

70 Documintation for tendering

9/17/21

11/13/21

30 Construction plan

20

10/22/21

12/7/21

149

11/15/21

20 Tendering , contracting

5/30/22

6

12/14/21

2

12/9/21

12/8/21

12/8/21

4-Construction Work

Temporary construction site work

12/8/21

Installing fence and security contatiners

12/10/21

12/10/21

installing temporary officees

1

12/11/21

1 Installing temporary Wc in the site

12/13/21

1

12/14/21

12/11/21

12/13/21

1 Installing the crane

12/14/21

Placing the depo storages area in the site surrounded by fence

1/21/22

12/15/21

Basement Construction Work

1/1/22

33 Foundation Work

10

12/25/21

12/15/21

12/15/21

16 Excavation Work

cultural & Social Center Dec 15, 2020 Tasks 2

date

6/6/22

6/3/22

6/6/22

6/2/22

6/14/22

Begin date

6/22/22

6/24/22

Name

5/31/22

5/31/22

6/4/22

5/31/22

6/7/22

6/15/22

6/23/22

5-Exterior Works

Landscaping

fixing exterior furniture in place

6-cleanning after all construction is done

7-obtain permits

8-evaluation of Progress

9-Hand over

End

Duration

6

4

2

3

7

7

2 cultural & Social Center Dec 15, 2020 Tasks 6

Default role

Name

Issam Alabdullah

project manager financial manager

undefined competition supervisors

undefined architectural competition jurey

undefined architect

undefined civil Engineer

undefined feild preparation group

undefined excavation contractor

undefined transporters

undefined

undefined steel fixing group 2

Steel fixing group 1

undefined formwork group 1

undefined formwork 2

undefined

undefined concrete casting group 1

concrete casting pump driver

undefined concrete casting group 2

undefined wall builders group

undefined water insulation group

undefined thermal insulation group1

undefined thermal insulation group 2

undefined Tiler group

undefined Parquet installation group

undefined screed workers

undefined drywall installation group 1

undefined drywall installation group 2

undefined suspended ceiling installation group

undefined Doors & Windows carpenter

undefined Mason + Labourer group 1

undefined Mason + Labourer group 2

undefined

cultural & Social Center Dec 15, 2020 Resources 7

Name

Default role electricity group 1

undefined electricity group 2

undefined Ventilation group 1

undefined Ventilation group 2

undefined plumber

undefined curtain wall fixers 1

undefined curtain wall fixers 2

undefined farmer group

undefined installation workers 1

undefined installations workers 2

undefined cleanning group

undefined quality survior

undefined client

undefined mechanical Engineer

undefined electrical engineer

undefined contractor

undefined studying team

undefined lawer

undefined

cultural & Social Center Dec 15, 2020 Resources 8

cultural & Social Center Dec 15, 2020 Gantt Chart 9 Name Begin date End date Duration Social & Cultural centre 1/1/21 6/24/22 463 1-Preparation Phase 1/1/21 3/23/21 70 Project Preparation a... 1/1/21 2/4/21 30 Analysis 2/5/21 2/16/21 10 Fesability study 2/17/21 3/5/21 15 Financing 3/6/21 3/23/21 15 2-Planning Phase 4/9/21 9/16/21 138 Architectural compet... 4/9/21 5/13/21 30 jurey evaluation 5/14/21 5/15/21 2 choosing the Architect 5/17/21 5/17/21 1 Concept plan 5/18/21 6/21/21 30 Documintation for Im... 6/22/21 8/12/21 45 Building Permit 8/13/21 9/16/21 30 3-Preperation for implem... 9/17/21 12/7/21 70 Documintation for te... 9/17/21 10/21/21 30 Construction plan 10/22/21 11/13/21 20 Tendering contracti... 11/15/21 12/7/21 20 4-Construction Work 12/8/21 5/30/22 149 Temporary constructi... 12/8/21 12/14/21 6 Installing fence a... 12/8/21 12/9/21 2 installing tempor... 12/10/21 12/10/21 1 Installing tempor... 12/11/21 12/11/21 1 Installing the crane 12/13/21 12/13/21 1 Placing the depo ... 12/14/21 12/14/21 1 Basement Constructi... 12/15/21 1/21/22 33 Foundation Work 12/15/21 1/1/22 16 Excavation W... 12/15/21 12/25/21 10 transporting t... 12/27/21 12/27/21 1 assembling th... 12/28/21 12/29/21 2 installing the ... 12/30/21 12/30/21 1 pouring the c... 12/31/21 12/31/21 1 Removing For... 1/1/22 1/1/22 1 Basement RC Col... 1/3/22 1/10/22 7 install the rei... 1/3/22 1/5/22 3 Install the for... 1/6/22 1/7/22 2 concrete pou... 1/8/22 1/8/22 1 Removing the... 1/10/22 1/10/22 1 Stair case Constru... 1/19/22 1/20/22 2 Building Partition... 1/19/22 1/21/22 3 Ground floor Constru... 1/11/22 2/12/22 29 RC Ground Floor ... 1/11/22 1/18/22 7 install the rei... 1/11/22 1/13/22 3 Install the for... 1/14/22 1/15/22 2 concrete pou... 1/17/22 1/17/22 1 Removing the... 1/18/22 1/18/22 1 RC Columns & Sh... 1/19/22 1/26/22 7 install the rei... 1/19/22 1/21/22 3 Install the for... 1/22/22 1/24/22 2 concrete pou... 1/25/22 1/25/22 1 Removing the... 1/26/22 1/26/22 1 Building walls in ... 2/11/22 2/11/22 1 Stair case Constru... 2/11/22 2/12/22 2 First Floor Constructi... 1/27/22 3/5/22 33 RC first Floor Slab 1/27/22 2/10/22 13 install the rei... 1/27/22 1/31/22 4 Install the for... 2/1/22 2/7/22 6 concrete pou... 2/8/22 2/8/22 1 Removing the... 2/9/22 2/10/22 2 First Floor RC Col... 2/11/22 2/18/22 7 install the rei... 2/11/22 2/14/22 3 Install the for... 2/15/22 2/16/22 2 concrete pou... 2/17/22 2/17/22 1 Removing the... 2/18/22 2/18/22 1 Building walls 3/4/22 3/5/22 2 Stair case Constru... 3/4/22 3/5/22 2 Second Floor Constru... 2/19/22 3/26/22 31 RC Second Floor ... 2/19/22 3/3/22 11 install the rei... 2/19/22 2/23/22 4 Install the for... 2/24/22 3/1/22 5 concrete pou... 3/2/22 3/2/22 1 Removing the... 3/3/22 3/3/22 1 Second Floor RC 3/4/22 3/11/22 7 install the rei... 3/4/22 3/7/22 3 Install the for... 3/8/22 3/9/22 2 concrete pou... 3/10/22 3/10/22 1 Removing the... 3/11/22 3/11/22 1 Building walls 3/25/22 3/26/22 2 Stair case Constru... 3/25/22 3/26/22 2 Roof Slab Constructi... 3/12/22 3/28/22 14 install the reinfor... 3/12/22 3/16/22 4 Install the formw... 3/17/22 3/22/22 5 concrete pouring 3/23/22 3/23/22 1 Removing the for... 3/24/22 3/24/22 1 essambling the g... 3/25/22 3/25/22 1 Building Roof flo... 3/25/22 3/26/22 2 finishing layers 3/26/22 3/28/22 2 Internal finishing wor... 3/29/22 5/24/22 49 Floor Finishing 3/29/22 5/6/22 34 Sceed layer a... 3/29/22 3/30/22 2 parquet cover... 3/31/22 4/5/22 5 Tiles covering 3/31/22 4/11/22 10 carpet coveri... 5/5/22 5/6/22 2 walls & Openings 3/29/22 5/21/22 47 Internal Dry w... 3/29/22 4/26/22 25 Internal Susp... 4/27/22 4/30/22 4 Doors & Win... 5/2/22 5/3/22 2 Plastering 5/5/22 5/21/22 15 other finishing w... 5/5/22 5/24/22 17 Toilet Fixture 5/5/22 5/6/22 2 exterior doors 5/23/22 5/23/22 1 internal doors 5/23/22 5/24/22 2 Mechanical Electric... 3/25/22 5/25/22 53 Electricity infrastr... 3/25/22 4/11/22 15 Ventilation infrast... 4/12/22 4/25/22 12 ventilation visible... 5/2/22 5/3/22 2 Plumbing installa... 4/26/22 5/4/22 8 plumbing tapes a... 5/23/22 5/24/22 2 Lights and Electri... 5/23/22 5/25/22 3 elevation works 5/26/22 5/30/22 4 elevation insulati... 5/26/22 5/27/22 2 Curtain walls 5/26/22 5/28/22 3 windows installat... 5/30/22 5/30/22 1 plastering and fin... 5/28/22 5/30/22 2 5-Exterior Works 5/31/22 6/6/22 6 Landscaping 5/31/22 6/3/22 4 fixing exterior furnitu... 6/4/22 6/6/22 2 6-cleanning after all cons... 5/31/22 6/2/22 3 7-obtain permits 6/7/22 6/14/22 7 8-evaluation of Progress 6/15/22 6/22/22 7 9-Hand over 6/23/22 6/24/22 2 2021 2022 January February March April May June July August September October November December January February March April May June July August September 1-Preparation Phase

cultural & Social Center Dec 15, 2020 Resources Chart 10 Name Default role Issam Alabdullah project ma... financial manager undefined competition supervisors undefined architectural competition jur... undefined architect undefined civil Engineer undefined feild preparation group undefined excavation contractor undefined transporters undefined Steel fixing group 1 undefined steel fixing group 2 undefined formwork group 1 undefined formwork 2 undefined concrete casting pump driver undefined concrete casting group 1 undefined concrete casting group 2 undefined wall builders group undefined water insulation group undefined thermal insulation group1 undefined thermal insulation group 2 undefined Tiler group undefined Parquet installation group undefined screed workers undefined drywall installation group 1 undefined drywall installation group 2 undefined suspended ceiling installatio... undefined Doors & Windows carpenter undefined Mason + Labourer group 1 undefined Mason + Labourer group 2 undefined electricity group 1 undefined electricity group 2 undefined Ventilation group 1 undefined Ventilation group 2 undefined plumber undefined curtain wall fixers 1 undefined curtain wall fixers 2 undefined farmer group undefined installation workers 1 undefined installations workers 2 undefined cleanning group undefined quality survior undefined client undefined mechanical Engineer undefined electrical engineer undefined contractor undefined studying team undefined lawer undefined 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 200% 2021 2022 January February March April May June July August September October November December January February March April May June July August September

By : Issam Alabdullah

H22N2O

By : Eng Attila Pém

By : Issam Alabdullah

H22N2O

By : Eng Attila Pém