International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Alfiya Easa2 , Asna Shaji3 , Athil A A4, Adila Abdulla kunju5

1234UG student, Department of Civil Engineering, Ilahia College of Engineering and Technology, Kerala, India

5Assistant professor, Department of Civil Engineering, Ilahia College of Engineering and Technology, Kerala, India ***

Abstract- Concrete is one of the most commonly used materialsincivilengineering, madeupofcement,aggregates, water,andvariousadmixtures.However,withtherisingcosts and dwindling natural resources, there’s an urgent need to focus on recovering and reusing these materials, as well as developing alternatives. Cement, which is the main binding agent in concrete, is in high demand due to the rapid pace of infrastructure development. Consequently, scientists and researchers around the world are actively looking for alternative binders and materials that can partially replace cement, aiming to boost sustainability without sacrificing strength and durability. Coarse aggregates also make up a significant part of concrete, so findingsuitable substitutes for natural stone is crucial. By using alternative materials like industrial by-products, recycled aggregates, or additives derived from waste, we can greatly aid in resource conservation and promote environmental sustainability. By embracing innovative materials and sustainable practices in concrete production, the construction industry can lessen its ecological impact while ensuring long-lasting durability and cost-effectiveness. This study explores the durability of concrete that incorporates ceramic waste as a partial replacement for fine aggregate and mica as a mineral admixture, using specific ratios. The goal of including these materialsistoenhancethemechanicalpropertiesandlifespan of concrete, while also supporting sustainability through the use of industrial waste.

Key Words: Ceramic waste, Fine aggregate replacement, Mica, Chemical Admixture, Strength characteristics, Durability test

The construction industry is grappling with some serious environmentalissues,largelybecauseofthehighdemandfor concrete, which is notoriously resource-intensive. This projectdivesintosomecreativesolutionsbyusingceramic waste as a partial substitute for fine aggregate and incorporating mica as an additive in concrete production. Ceramicwaste,whichcomesfrombrokentilesandsanitary ware, often ends up in landfills; by repurposing it in concrete,wenotonlycutdownonwastebutalsosupport sustainabilityinconstruction.Mica,amineralknownforits helpfulproperties,isaddedtoimprovetheperformanceof theconcretemix,potentiallyenhancingbothworkabilityand durability.Themaingoalsofthisprojectincludeevaluating

mechanical properties like compressive and flexural strength,analyzingworkability,andperformingdurability tests such as the Rapid Chloride permeability test. Plus, microstructuralexaminationswillshedlightonhowthese materials interact. By showcasing the practicality and benefits of using waste materials, this project aims to encourage sustainable construction practices that lessen environmental impact while keeping the strength and performance of concrete intact. Ultimately, the research aspirestopavethewayforamoresustainablefutureinthe concrete industry, promoting innovative strategies for resourcemanagement.

TheMainScopeofthestudyis

The study focuses on M40 grade concrete, with a target compressive strength of 40 MPa after 28 days.

Thestudyevaluatescompressivestrength,splitting tensilestrength,andelasticmodulustoassessthe impact of ceramic waste and mica on the performanceanddurabilityofM40concrete.

To evaluate the potential of ceramic waste as a partialreplacementforfineaggregateandmicaasa mineral admixture by analyzing strength characteristics.

To assess the importance of incorporating waste materials in concrete production to enhance sustainabilityinconstruction.

Tominimizeconcreteproductioncostsbyutilizing locallyavailablealternativematerials.

TopromoteSustainableConstructionPractices. Theprimaryobjectiveofthisexperimentalinvestigation is to evaluate the effectiveness of ceramic waste and micaasmineraladmixturesinconcreteproduction.The objectivesare

ToinvestigatetheRoleofMicaasanAdmixture.

ToanalyzetheCombinedEffectofCeramicWaste.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Toanalyzethecompressivestrength,flexibility,split tensile strength by partially replacing fine aggregatebyceramicwaste.

To compare Performance Against Conventional Concrete.

TopromoteSustainableConstructionPractices.

ToconductRapidChloridepermeabilityTest.

• Sustainability: By recycling industrial by-products like ceramic waste and mica, we can significantly lessen our environmentalfootprint.

• Waste Management: Tackling the growing amounts of ceramicwasteandmicabyintegratingthemintoconcrete provides an effective way to dispose of these materials. • PerformanceImprovement:Exploringhowthesematerials canboostconcretepropertiessuchasstrength,durability, andworkabilitymightleadtothedevelopmentofsuperior andmoreaffordablebuildingmaterials.

•EconomicBenefits:Findingbudget-friendlyalternativesto traditional fineaggregatescanhelpcut construction costs andencouragemoresustainablebuildingpractices.

• This study meets both the environmental and practical demandsoftheconstructionindustry.

A. Cement:

For this project, we used Portland Pozzolana cement. This type of cement is crucial in concrete as it helps create strengthanddurabilitythroughthehydrationprocesswhen mixed with water. We chose Portland Pozzolana cement (PPC)becauseit’sconsistent,widelyavailable,andhasasolid trackrecordinstructuralconcreteapplications.PPCisknown for providing high early strength and dependable performance, which makes it ideal for evaluating how ceramic waste and mica affect concrete properties. Essentially,PortlandPozzolanaCement(PPC)isa blended cementthatcombinesOrdinaryPortlandCement(OPC)with pozzolanicmaterialslikeflyash,silicafume,volcanicash,or calcined clay. These pozzolanic materials improve certain characteristicsofthecement,makingitsuitableforvarious construction projects, especially where durability and sustainabilityarekey.

B. Coarseaggregate:

Coarseaggregate,whichconsistsofparticleslargerthan4.75 mm,playsacrucialroleinconcretebyboostingitsstrength, durability,andstability.Typically,coarseaggregatesaccount

for about 60-70% of the total volume in concrete mixes, serving as the primary load-bearing element. These aggregates are irregular, granular materials such as sand, gravel, or crushed stone, and they are commonly used in concreteproduction.Theyareusuallysourcedfromnatural depositsthroughquarryblastingormanualandmechanical crushing,whichhelpsenhancethecompactnessofconcrete mixes.Byusingcoarseaggregates,wecanreducetheamount of cement and water needed while also improving the mechanicalstrengthoftheconcrete,makingthemvitalfor buildingandmaintainingdurablestructures.Forthisproject, weselectedcoarseaggregateswithmaximumsizesof12mm and20mm,sourcedfromanearbyshop.

C. Fineaggregate:

Fine aggregate, often referred to as natural sand, is a key ingredient in concrete. It fills the gaps between larger aggregates,addsbulk,andenhancestheoverallstrengthand durabilityoftheconcrete.Commonlyknownas"sand,"fine aggregateisanessentialcomponentthatplaysasignificant role in the concrete mix. concrete, mortar, and other constructionmaterials Itconsistsofsmallerparticlesthan coarseaggregates andtypically passes througha 4.75mm sieve.Fineaggregatesprimarilyfillthevoidsbetweenlarger particles, contributing to the concrete mix's workability, strength,anddurability.Itiscollectedfromnear-byshop.

D.Water:

It'sabsolutelyessentialintheconcrete-makingprocess becauseitkickstartsthehydrationofcement,whichiswhat binds all those aggregate materials together into a solid structure.Inthisstudy,we’reusingfresh,cleanwaterthat’s free from impurities to ensure that all our samples have consistenthydrationandbondingquality.Thepropertiesof thewaterweusearevitalforachievingtherightworkability, setting time, and strength in the concrete. Water is an inorganic,clear,tasteless,andodorlesssubstance,makingup asignificantpartofEarth'shydrosphereandthefluidsinall known living organisms.It’s crucial forlife, even thoughit doesn’tprovideanycaloriesororganicnutrients

E.Ceramicwaste:

Ceramictilewastereferstodiscardedorbrokenceramic tiles generated during the manufacturing process, installation, or demolition of buildings. As a significant contributortoconstructionanddemolitionwaste,ceramic tile waste has attracted attention for its potential as a sustainablematerialforconstruction,especiallyinconcrete production. Using ceramic waste can help reduce landfill space, conserve resources, and lower the environmental impact of traditional concrete materials. Ceramic isa nonmetallic,inorganicmaterialmadefromclayandothernatural minerals, shaped and then hardened by high-temperature firing. Ceramics are highly durable, resistant to heat and chemicals,andhavelowelectricalconductivity,whichmakes

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

them suitable for a wide range of applications, including construction,householdproducts,electronics,andmedical implants.Ceramicwastetakenintheformoffinepowder[1].

F.Mica:

Micaisanaturallyoccurringmineralknownforitsunique properties,includingitsshinyappearance,excellentthermal stability,flexibility,andinsulatingcapabilities.Mica’slayered structure allows it to be split into thin sheets, making it valuableacrossindustriessuchasconstruction,electronics, cosmetics,andautomotive.Insustainableconstruction,mica can be used as a partial substitute in cement or concrete mixtures. It enhances the thermal insulation properties of concreteandimprovesitsdurability,potentiallyreducingthe need for cooling and maintenance. This reduces overall energycostsandcontributestoresourceconservation[2].

G.Superplasticizer:

Fosroc Auramix 400 Fig-3 is an advanced, highperformance superplasticizer specifically designed for concretemixesthatrequirehighstrengthandworkability. Thisproduct,iscommonlyusedintheconstructionindustry to produce highly workable concrete with reduced water content while maintaining flow and durability. The typical dosageofAuramix400variesbasedonthemixdesignand specificprojectrequirementsbutgenerallyrangesfrom0.5% to 1.5% by weight ofcement. Adjustmentsmay be needed based on the desired workability and environmental conditions[3]

5. EXPERIMENTAL METHODOLOGY

5.1 TESTING OF MATERIALS

Toexaminethebasicpropertiesofthematerialschosenthe followingtestswerecarriedout.

5.1.1 TESTS ON CEMENT

Cement is the most important ingredient in concrete. Therefore,qualityofcementshouldbecheckedbeforeusing it. Various tests on cement are performed to evaluate the specificgravity,standardconsistencyandinitialsettingtime.

5.1.1.1 Specific gravity of cement

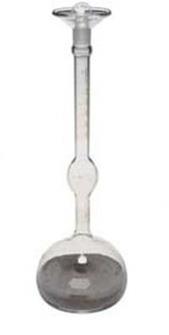

AsperIS4031,thespecificgravityistheratiobetweenthe weightofagivenvolumeofmaterialandweightofanequal volumeofwater.ThedryLeChatelierFlask[4]wascleaned andfilledwithkeroseneuptothemark.60gofcementwas taken.Theinitialreadingofflask(V1)wasnoted.Add60gof cementintotheflaskwithcare.Careshouldbetakensothat cementisfallingproperlyintotheflask.Shaketheflaskwith stopper so that no cement is stick to walls of flask. The cementwasallowedtosettle.Thefinalreadingofflask(V2) wasnoted.

Specificgravityofcement=��������ℎ������������ ����/��������ℎ�� ����equalvolumeofwater

5.1.1.2 Standard Consistency of Cement

AsperIS4031&IS269,about400gofcementwasweighed accuratelyandplacedinanenameltrough.Tostartwith,add clean water and mixed it thoroughly with cement. The gaugingtimeshouldbecarefullymaintainedbetween3to5 minutes,startingfromthemomentwaterisaddedtothedry cementuntilthemouldfillingbegins.TheVicat’smould[5] was filled with this paste. Make the surface of the cement paste in level with the top of the mould. The mould was placedundertherodbearingtheplunger.Theindicatorwas adjustedtoshow0-0readingwhenittouchedthesurfaceof thetestblock.Theplungerwasreleasedquickly,allowingit to sink into the plate. The trial paste was prepared with

International

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

varying%ofwaterandthetestwasrepeatedasdescribed aboveuntiltheneedlepenetrates5mmto7mmabovethe bottomofthemould.Theamountofwaterwasexpressedas percentagebyweightofthedrycement.

5.1.1.3

According to IS 4031 & IS 269, the initial setting time of concrete is the time when cement paste starts hardening while the final setting time is the time when the cement pasteisconsideredtohavehardenedsufficientlywhena1 mmneedleleavesanimpressiononthepasteinthemould, whilea5mmneedledoesnotanyimpression.Takeabout 400gramsofcementwasweighed.Aneatcementpastewas prepared by adding 0.85 times the percentage of water required for standard consistency. The stopwatch was startedattheinstantwhenwaterwasaddedtothecement. TheVicat’smouldwasfilledwiththecementpasteprepared. Gaugingtimeshouldnotbe lessthan3minutesand more than 5 minutes. Filled the mould completely and smoothenedthesurfaceofpastemakingitlevelwiththetop ofthemouldtogiveatestblock.Thetestblockwasplaced confined in the mould under the load bearing medium. Lowered the needle gently till it came in contact with the surfaceoftestblockandwasquicklyreleased,allowingitto penetratethetestblockandnotedpenetrationafterevery twominutes.Thisprocedurewasrepeateduntiltheneedle failedtopiercetheblockforabout5mm,measuredfromthe bottomof the mould. Thestopwatchwasstoppedand the initialsettingtimewasnoted.

Fine aggregates play a crucial role in concrete, so their qualityisreallyimportant.Toensurethisquality,various testslikespecificgravityandsieveanalysisareconducted on fine aggregates. The specific gravity test helps us measurethestrengthoftheseaggregates.

AccordingtoIS2386(part3),thePycnometer[6]needsto be cleaned, dried, and weighed accurately with its cap securelyinplace(W1).Next,wetakeabout300gto500gof anoven-driedsampleandweighitagain(W2).Afterthat, weadddistilledwatertothePycnometerandstiritwitha glass rod to eliminate any trapped air. We then fill the Pycnometerwithdistilledwateruptotheholeintheconical cap and weigh it (W3). Once that’s done, we empty and cleanthePycnometer,thenfillitwithdistilledwateragain uptotheholeintheconicalcapandweighitonemoretime (W4).Theformulaforspecificgravityis:

Specificgravity=W2/(W2-(W-W1))

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

AccordingtoIS2386(part3)about2kgofaggregatesample is taken in a wire basket and immersed in water at a temperatureof22ºCto32ºC.Entrappedairisremovedfrom thesamplebyliftingthebasket25mmabovefor25times. The basket with sample kept completely in water for 24 hours.Thebasketandaggregateareweighedareweighed while suspended in water. The basket and aggregate are removedfromwateranddriedwithdryabsorbentcloth.The surface-driedaggregatesarealsomeasuredbyweight.

Westartedwithabout1kgoffineaggregate,usingISsieves [7] with sizes of 4.75mm, 2.36mm, 1.18mm, 600µ, 300µ, 150µ,andapan,allarrangedfromlargesttosmallest.After placing the fine aggregate in the sieves, we sieved the materials,collectingtheamountthatpassedthrougheach larger sieve and retaining what was left on the next one. Finally,weplottedagraphshowingthepercentageoffiner material against the sieve size, based on the results we gatheredfromourtests.

5.1.3 TESTS ON COARSE AGGREGATE

Coarse aggregates play a crucial role in concrete, so their qualityisessential.Toensurethisquality,severaltests,like specificgravityandsieveanalysis,areconductedoncoarse aggregates. The specific gravity test, in particular, helps gaugethestrengthoftheseaggregates.

5.1.3.1 Specific gravity of Coarse aggregates

About 2kg of thoroughly washed coarse aggregate was placedinthewirebasketandimmerseditindistilledwater. Theweightofthesaturatedaggregatesuspendedinwater with the basket [8] was weighed and noted as (W1). Removed the basket and aggregate from the water and allowed it to drain. Immerse the basket in water and the emptyweight (W2) was taken. Oven dried the aggregates for a temperatureof110°Cfor24hours.Theweightofovendried aggregate(W3)wasnoted.

Specificgravity=W3/W3-(W1-W2)

5.1.3.2 Water Absorption on Coarse aggregates

AccordingtoIS2386(part3),youstartbytakingabout2kg ofaggregateandplacingitina wirebasket.Thisbasketis thenimmersedinwaterthat’sbetween22ºCand32ºC. To getridofanytrappedair,youliftthebasketabout25mm abovethewatersurfaceanddothis25times.Afterthat,the basketwiththesampleneedstostaycompletelysubmerged

inwaterfor24hours.Oncethat’sdone,youweighthebasket andtheaggregatewhilethey’restillunderwater.Finally,you takethebasketandaggregateoutofthewateranddrythem offwithacleanabsorbentcloth.Afterthey’vedriedonthe surface,youweightheaggregatesagain.

5.1.3.3 Sieve analysis of coarse aggregates

About1kgofcoarseaggregatetakeninISsieve[9]sizeof 25mm,20mm,16mm,12.5mm,10mm,4.75mm.Thesieves werearrangedinthe decreasingorderofsizeand putthe aggregate taken. Sieved the aggregates and the amount whichispassingthroughgreatersizewastakenandretained onthenext.Thelaboratorytestonsieveanalysisofcoarse aggregatewasconducted.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

AmixforM40gradewasdesignedasperIS10262:2009and the same were used to prepare the test samples. The variation of strength of hardened concrete using ceramic wastepowderaspartialreplacementofFINEaggregateand Micaasmineraladmixtureisstudiedbycasting3cubes,3 cylindersand3prismsforeachandeveryreplacement.The specimens were tested for compression, split tensile and flexuralstrengthsaftercuringperiodof7days,14days,28 days as per the mix design. The quantities required for casting3cubes,3cylindersand3prismsforeachpercentage replacement are computed. The design mix proportion is givenintable1.

anyvoids. After24hours,themoldsareremoved,andthe testspecimensareplacedinwaterforcuring.

Compressivestrength=

Concretetensilestrengthreferstoitsabilitytowithstand tensileforcesorstressesappliedtoit.Thetensilestrengthof concrete is measured by the split cylinder test [11] of concrete method. The tensile strength of concrete is measured in units of force per cross-sectional area. ASTM D638isusedtomeasurethetensilepropertiesofplastics, including ultimate tensile strength, yield strength, elongation, and Poisson's ratio. The universal testing machineisthemostcommonlyusedequipmentfortensile testing.Tensilestrengthisacriticalpropertyofconcrete,as concretestructuresaresusceptibletotensilecrackingdueto various effects and applied loads. However, the tensile strengthofconcreteissignificantlylowercomparedto its compressive strength. This test is allotted as per the rule giveninIS:5816-1959.Concretetensilestrengthrefersto itsabilitytoresistappliedtensileforcesorstresses.Itis commonly measured using the split cylinder test method. Thetensilestrengthisexpressedinunitsofforcepercrosssectionalarea(N/Sq.mm.orMPa).

TensileStrength=

Thecompressivestrengthtestisamechanicalassessment that measures the maximum compressive load a material canwithstandbeforefracturing.Thetestspecimen,typically shapedasacube,prism,orcylinder,isplacedbetweenthe platensofacompression-testingmachineandsubjectedtoa graduallyappliedload. This testisallottedaspertherule giveninIS3495-1992.Compressiontestisthatthemainand vital test and this test was dispensed by a Compression Testing Machine [10]. This test was carried out on the seventh,fourteenthandtwentyeighthdayfromthedayof casting.Formostapplications,cubicmoldsmeasuring15cm ×15cm×15cmarecommonlyused.Thisconcreteispoured inthemoldandappropriatelytemperedsoasnottohave

Flexuraltestingisperformedtoassessamaterial'sabilityto resistbendingorflexuralstress.Alsoknownasatransverse beam test [12], it involves placing a sample between two supportsandapplyingaloadeitheratasinglecentralpoint (3-Point Bend Test) or at two points (4-Point Bend Test). Flexural strength is an indicator of the tensile strength of concrete,measuringitsabilitytoresistbendingorflexural stress. Thistestisallottedaspertherulegiven in IS:5161959.It is measured by loading 100 x 100mm concrete beams with a span length 500mm. In most cases, the specimenisplacedonasupportspan,andtheloadisapplied at the center using a loading nose, creating three-point bending at a specified rate. Key parameters for this test includethesupportspan,loadingspeed,andthemaximum deflectionduringthetest.

Flexuralstrength=

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

The Rapid Chloride Permeability Test (RCPT) [13], standardizedunderASTMC1202andAASHTOT 277,isused to assess the resistance of concrete to chloride ion penetration, which is crucial for durability in structures exposed to marine environments, de-icing salts, and aggressivechemicals.Thetestinvolvesa50mmthickand 100 mm diameter cylindrical concrete specimen, which is firstvacuum-saturatedtoensureuniformmoisturecontent. It is then placed between two acrylic cells, with one containing0.3Nsodiumhydroxide(NaOH)solutionandthe otherfilledwith3.0%sodiumchloride(NaCl)solution A60 VDCpotentialisappliedacrossthespecimenforsixhours, forcingchlorideionstomigratethroughthe concrete.The totalchargepassed,measuredincoulombs(C), indicatesthe permeability of the concrete, with higher values representing greater chloride penetration. According to ASTMclassification,valuesexceeding4000Cindicatehigh permeability,whilethosebelow100Crepresentnegligible permeability.

Although RCPT provides a quick assessment of chloride penetration resistance, it primarily measures electrical conductivityratherthantruediffusion,meaningfactorssuch as pore structure, water-to-cement ratio, admixtures, and supplementarycementitiousmaterials(SCMs)significantly influencetheresults.Despiteitslimitations,RCPTremainsa widely used durability indicator for concrete mix optimization and quality control in chloride-exposed environments.

8. RESULT AND DISCUSSIONS

8.1.1 Cement

The specific gravity of cement is a crucial property that indicatesthedensityofcementrelativetowater.According

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

toIS455:1989,PartII,theacceptablerangeforthespecific gravity of cement is between 2.9 and 3.15. The obtained value of 3.05 falls within this range, suggesting that the cementisofgoodqualityandfreefromexcessiveimpurities or moisture. Specific gravity is important in concrete mix designasithelpsincalculatingthecorrectproportions of materials,ensuringthedesiredstrengthanddurabilityofthe final structure. It also aids in determining the volume of cementrequiredforaparticularmix.Inadditiontospecific gravity, other essential properties of cement include fineness, consistency, setting time, and compressive strength.Finenessaffectstherateofhydrationandstrength development, while consistency ensures uniform mixing. Settingtimeindicateshowquicklythecementhardens,and compressive strength reflects the material's load-bearing capacity. If these properties are within the specified standards, the cement can be considered suitable for constructionpurposes.

Table 2.Propertiesofcement

SI No. Tests conducted Values obtained ISSpecificationand Allowablelimit Inference

1. Standard Consistency 37%

2. Specific gravity 2.85

3. Initial SettingTime 30 minutes

IS;4013(PART5) 1988,limitbetween 25%–35% Theobtained valueis37%

IS;455-1989,limit between2.9-3.15 Theobtained valueis 2.85

IS;4301-1968,Not lessthan30 minutes Theobtained valueisnot lessthan30 minutes

Table 4. PropertiesofCoarseaggregates

SINo. Tests conducted Results ISSpecification andAllowable limit Inference

1 Specific Gravity 2.78 IS2386 (part 3), limitisbetween 2.5-3 The obtained valueis2.78

2 Sieve analysis Fineness modulus =3.13 IS2386 (Part 3), limitisin between4-8 The obtained valueis3.13

3 Water absorption 0.1% IS2386(Part3) limitislessthan 2% The obtained valueisless than 2%

9.1 Compressive strength of M40 grade concrete

The compressive loading test on concrete were conducted on a compression testing machine of capacity 2000kN.The readingsfrom thedial gauge wererecorded, and the compressive strength was calculated accordingly. Thetestwasconductedon150mmcubespecimenat7,14 and28days.

Table 5. CompressivestrengthtestresultonM40concrete

8.1.2 Aggregates

Table 3. PropertiesofFineaggregates

SI No. Tests conducted Results ISSpecification andAllowable limit Inference

1. Specific Gravity 2.64

IS;2386 (Part 2)-1963, limitisbetween 2.65–2.67 The obtained valueisin between 2.65-2.67

2. Sieve analysis Fineness modulus=3 .89 IS 3831970, limit is between2-3.5 The obtained valueisin between 3.1-3.6

Split tensile strength test of M40 concrete

Thesplittensilestrengthtestonconcretewere conducted on a compression testing machine of capacity 2000kN.Thereadingsondialgaugewererecordedandsplit tensilestrengthwascalculated.Thetestwasconductedon 150mmdiameterand300mmheightcylinderspecimenat7, 14and28days.

Table 6. SplittensilestrengthtestresultonM40concrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Theflexuralstrengthtestonconcretewereconducted onaflexuralstrengthtestingmachineofcapacity2000kN. The readings on dial gauge were recorded and flexural strength was calculated. The test was conducted on 500×100×100mmbeamspecimenat7,14and28days.

Table 7. FlexuralstrengthtestresultonM30concrete

9.6 Compressive strength of M40 grade concrete of 30% Replacement

Table 11. CompressivestrengthtestresultonM40concrete

9.4 Compressive strength of M40 grade concrete of 20% Replacement

Table 8. CompressivestrengthtestresultonM40 concrete

9.5 Split tensile strength test of M40 concrete of 20% Replacement

Table 9.SplittensilestrengthtestresultonM40concrete

9.7 Split Tensile strength of M40 grade concrete of 30% Replacement

Table 12. SplitTensilestrengthtestresultonM40concrete

9.6 Flexural strength test of M40 concrete of 20% Replacement

Table 10. FlexuralstrengthtestresultonM40concrete

9.8 Split Tensile strength of M40 grade concrete of 30% Replacement

Table 12. SplitTensilestrengthtestresultonM40concrete

9.9 Flexural strength test of M40 concrete of 30% Replacement

Table 10. FlexuralstrengthtestresultonM40concrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

9.10 Compressive strength of M40 grade concrete of 40% Replacement

Table 11. CompressivestrengthtestresultonM40concrete

9.11 Split tensile strength test of M40 concrete of 40% Replacement

Table 12. SplitTensilestrengthtestresultonM40concrete

Table 14. Strengthresultsofconcreteafter28days

9.12 Flexural strength test of M40 concrete of 40% Replacement

Table 13. FlexuralstrengthtestresultonM40concrete

10. Final result

Thetableshowsthestrengthpropertiesofconcreteafter28 days ofcuring.Threedifferentconcrete mixes weretested. The mix with a compressive strength of 42 N/mm², split tensile strength of 4.1 N/mm², and flexural strength of 7.2 N/mm² achieved the highest values, indicating superior performance. The other two mixes showed slightly lower strengths,withcompressivestrengthsof40N/mm²and39 N/mm²,splittensilestrengthsof4N/mm²and3.9N/mm², andflexuralstrengthsof7N/mm²and6N/mm²,respectively.

FIGURE14

Figure 14 illustrates the compressive strength of three concrete categories after 28 days of curing. Category 2 achieved the highest compressive strength of 42 N/mm², markingitastheoptimumpointforstrengthenhancement. Category1recordedaslightlylowerstrengthof40N/mm², whileCategory3showedtheloweststrengthat39N/mm².

TheRapidChloridePermeabilityTest(RCPT)measuresthe resistanceofconcretetochlorideionpenetration.Inthistest, aconcretesampleisplacedbetweentwocells,onefilledwith a sodium chloride solution and the other with a sodium hydroxide solution. A 60V DC voltage is applied across the samplefor6hours,andthetotalchargepassed(incoulombs) isrecorded.Lowerchargevaluesindicatebetterresistanceto chlorideionpenetration.

Table 15 ClassificationofChlorideIonPenetrabilityBased onChargePassed(ASTMC1202)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

higherreplacementsreducedperformance.Excessiveceramic wastecouldweakentheconcrete'sstructure.

<100 NEGLIGIBLE

Qualitativeindicationsofthechlorideionpenetrabilitybased onthemeasuredvaluesfromthistestmethodareprovidedin theTable18.Thesevalueswereobtainedfromdatacollected fromslicesofcoresextractedfromlaboratoryslabsmadewith differenttypesofconcrete.

Table 16. RCPTtestresultinference

CURRENT1(mA) CURRENT2(mA) SPECIMEN 1(M40) C(30%replaced)

Coulombs 473.9 520.2

Thetablecategorizeschlorideionpenetrabilitybasedonthe chargepassedincoulombs,rangingfromhigh(>4,000C)to negligible (<100 C). The results show that M40 concrete withoutreplacement(Sample1)recordedanRCPTvalueof 473.9 C, while M40 concrete with 30% replacement using ceramic waste and mica (Sample C) registered a slightly highervalueof520.2C.Bothvaluesfallwithinthe"VeryLow" category,definedbytherangeof100to1,000C.Thisindicates that the inclusion of ceramic waste and mica as partial replacements does not significantly compromise the concrete'sresistancetochlorideionpenetration.Thus,itis inferredthatbothconcretemixesexhibitverylowchloride permeability,enhancingtheirdurabilityinchloride-exposed environments.

The experimental study evaluated concrete using ceramic waste as a fine aggregate replacement and mica as an admixture. Among the tested levels, replacing 30% of fine aggregateswithceramicwastegavethebestresults.Thismix achieved the highest compressive strength of 42 N/mm², alongwithsplittensileandflexuralstrengthsof4.1N/mm² and7.2N/mm²,respectively.TheRapidChloridePermeability Test(RCPT)showedthatboththeconventionalandmodified mixeshad"VeryLow"chlorideionpenetrability,withvalues of 473.9 C and 520.2 C. This indicates strong resistance to chloride-inducedcorrosion,improvingdurability.

Thestudyfocusedonenhancingconcrete'sperformanceand sustainabilitybytestingreplacementlevelsof20%,30%,and 40%. The 30% replacement level gave the best results, outperforming the 20% and 40% mixes, which reached compressive strengths of 40 N/mm² and 39 N/mm², respectively.The30%mixalsoshowedbettersplittensileand flexuralstrengths.Graphsconfirmedthat30%replacement wastheoptimallevelformaximumstrength,whilelowerand

In terms of durability, the RCPT results showed that both conventionalandmodifiedmixeshadexcellentresistanceto chlorideingress,reducingtheriskofreinforcementcorrosion andincreasinglong-termdurability.Usingceramicwasteand micanotonlyimprovesconcretestrengthbutalsosupports environmentalsustainabilitybyreducingindustrialwasteand minimizingtheneedfornaturalsand.

[1] RanaB.Alshahwany,OmarM.AbdulKreemandRifaD. Shlla,“Influenceofceramicwastesasarecycledcoarse aggregate with different maximum sizes on the concrete,” The Open Civil Engineering Journal, 3 (9), 2024,pp.349-370,

[2] SaraswathiPawar,ShreyaGrudandShrunaliOhal,“Use of Mica in concrete to resist geopathic stress,” InternationalJournalofAdvancedResearchinScience, communication and Technology, 4 (6), 2024, pp 251254.

[3] Dr.K.Ramadevi,Thepurposeofconcretewithceramic wastereplacedforfineaggregate”,InternationalJournal CivilEngineeringandTechnology,8(8),2024,pp17301737.

[4] RajKumarandReteeshaKhare,Experimentalanalysis onreplacementofaggregatebybrokenceramictilesin concrete,InternationalJournalofAdvancedResearchin CivilEngineering,7(4),2023,pp53-58.