International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Akhil Nema1 , Kriparam Banshkar2

1Guest Faculty, Dept. of Civil Engineering, UIT, Barkatullah University, Bhopal, Madhya Pradesh, India.

2 Guest Faculty, Dept. of Civil Engineering, UIT, Barkatullah University, Bhopal, Madhya Pradesh, India

Abstract - Now days, Solid waste management (SWM) isone of the foremost environmental apprehensions in our country. In recent years a significant expansion in the utilization of plastic is noted worldwide, which led to enormous quantities of waste related to plastic. Reprocessing of plastic waste to turn out new materials like concrete is one of the logical methods of setting out wastes, due to its financial and environmental benefits. Numerous works have been carried out or are under execution to assess the properties of concrete including plastic waste. In this project, study on the fractional replacement of sand with High DensityPolyethylenepowderis done. An assessment between traditional concrete and concrete with HDPE powder is accomplished to study the strength and durability parameters. In the present work different percentage replacements of sand with HDPEpowder is examined.

Key Words: High Density Polyethylene powder (HDPE), Solid waste management, Sand, Recycling plastic waste, Compressive Strength, Split tensile Strength and UPV.

Since many years, research pertaining to the use of byproductstosupplementthepropertiesofconcretehasbeen goingon.Inthelasttwodecades,adeterminedattempthave beenmadetoemployindustryderivativessuchasflyash, ground granulated blast furnace slag (GGBS), glass cullet, silica fume, etc. in civil constructions. The possible applicationsofindustryderivativesinconcreteareaspartial aggregatesubstitutionoraspartialcementreplacementrely ontheirchemicalcompositionandgrainsize.Theutilization of these materials in concrete comes from the ecological constraintsinthesafediscardingoftheseproducts.

One of the various waste materials used in the concrete industry is recycled or reprocessed plastic. In order to disposehugeamountofrecycledplasticmaterial,reprocess of plastic in concrete manufacturing is considered as the mostviableapplication.Recycledplasticcanbeemployedas coarseaggregateorfineaggregateinconcrete.Though,itis important to emphasize that re-using of wastes is not yet economicallybeneficial,duetothecostsoftransportandits resultonthetotalcostofproduction.

The aim of the experimental program is to study the behaviour of concrete in which fine aggregate is partially replacedbyHDPEpowder.Inthischapteradetailhasbeen explained about the material used and different tests conducted.

2.1 Materials

1. Cement

OrdinaryPortlandcementofspecificgravity3.15(IS40311988 part II) is used in this research program. To assess someparameterslikefineness,consistencyandsettingtime test.Differenttestshavebeenconducteddoneoncement.

Table 1.1 Properties of Cement

2. Fine Aggregate: In this experimental program, sand is used as fine aggregate. Sand passing through sieve IS 4.75mmisutilizedforavarietyoftests.

Table 1.2 Properties of Sand

3. Coarse Aggregate: 20mm maximum size coarse aggregates have been used in this research program. Propertiesofcoarseaggregatesaretabulatedbelow.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

4. Water: Normal tap (Potable) water has been used for castingandcuring.Thewaterisfreefromchemicals,organic matterandacids.

5. High Density Polyethylene (HDPE) Powder: HDPE powderisusedforthepartialreplacementoffineaggregate inthisproject.HDPEpowderisknownforitslargestrength todensityratio.

3.2 Mix Design

Calculationofmixproportionlikecement,coarseaggregate, admixture,water,fineaggregatesandotherconstituentsto formulateconcreteasperrequiredstrength,workabilityand durabilityisknownasConcreteMixDesign.

1. Requirements

a)Specifiedminimumstrength=20N/Sqmm

b)Durabilityrequirements:ExposureModerate&Minimum CementContent=300Kgs/cum

c)Cement(ReferTableNo.5ofIS:456-2000)

BirlaCement,TypeOPC&Grade43

d)Degreeofqualitycontrol:Good.

2. Test Data For Materials Supplied

A.CEMENT

i)Specificgravity=3.05

ii)Avg.comp.strength7days=46.5morethan33.0 (OK)

iii)Avg.comp.strength28days=55.0morethan43.0 (OK)

B.COARSEAGGREGATE

i)20mmGraded

ii)TypeCrushedstoneaggregate

iii)Specificgravity=2.68

iv)Waterabsorption=1.46

v)Free(surface)moisture=0

C.FINEAGGREGATE(Coarsesand)

i)TypeNatural

ii)Waterabsorption=0.5

iii)Specificgravity=2.6

iv)Surfacemoisture=1.4

3. Target Mean Strength (TMS)

a)StatisticalconstantK=1.65

b)StandarddeviationS=4.6

Thus,TMS=27.59N/Sq.mm

4. Selection of W/C Ratio

a)AsrequiredforTMS=0.5

b)Asrequiredfor‘Moderate’Exposure=0.55

AssumeW/cratioof0.5

5. Determination of Water & Sand Content For W/C = 0.5

a)Watercontent=186Kg/cum

b)Sandaspercentageoftotalaggregatebyabsolutevolume =35%,C.F.=0.8

Max. Aggregate Size = 20 mm Thus, Net water content = 180.42Kg/cumNetsandpercentage=33%.

6. DETERMINATION OF CEMENT CONTENT W/C Ratio = 0.5

Watercontent=180.42Kg/cum

Thus,Cementcontent=360.84Kg/cum

AdequateformoderateexposureSay360Kg/cum

7. DETERMINATION OF COARSE AND FINE AGGREGATE CONTENT Assume Entrapped Air As 2 %

0.98cum=[180.42+360/3.05+{1/0.33}*{FA/2.6}]/1000 &0.98cum=[180.42+360/3.05+{1/0.67}*{Ca/2.68}]/1000 Hence,

FA=584Kg/cumCa=1223.8Kg/cum

ThefinalmixproportionsofM-20gradeofconcretebecome:

Test conducted in two categories i.e. fresh and hardened concrete.

A. Tests on Fresh Concrete:

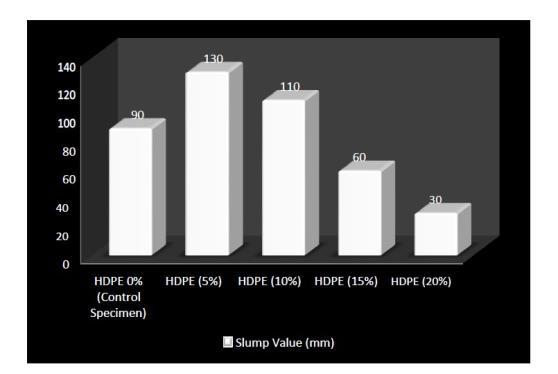

1. Slump cone test

Fordeterminingtheconsistencyorworkabilityofconcrete mix,slumpconetestisthemostpopulartestusedatboth laboratory in situ conditions. In order to obtain uniform quality,slumpischeckedatintervalsi.e.frombatchtobatch duringconstruction.

B. Tests on Hardened Concrete:

Foranappropriatetimeintervalafterdemouldingofmoulds, specimens are kept in curing tank to lessen the heat of hydration. The specimens should be tested by standard testingprocessconfirmingIS:516-1959.

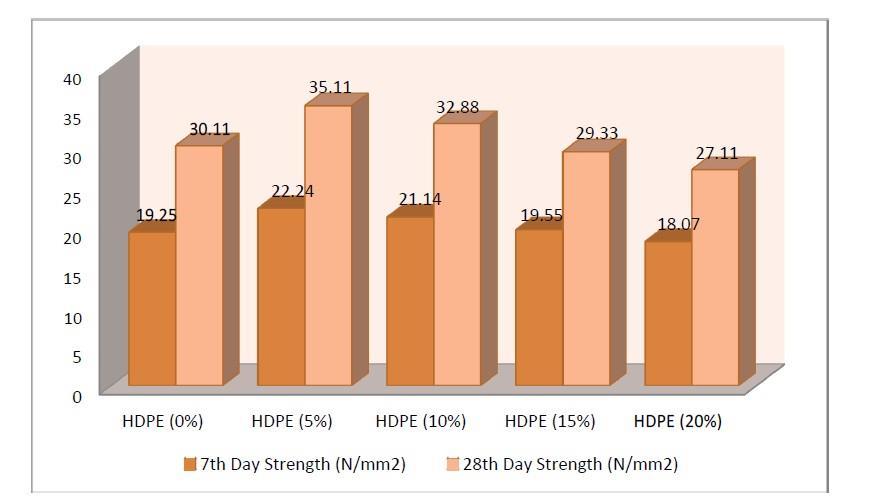

1. Concrete compressive strength

Concrete is known for its good compressive strength and resilience. Concrete is mostly used in construction where loadconveyedismostlyviacompressivestrength.Samples havebeenpreparedofstandardsizei.e.150mmx150mmx 150mmandkeptinthecuringtankfor7and28daysand thentestedunderCTM.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

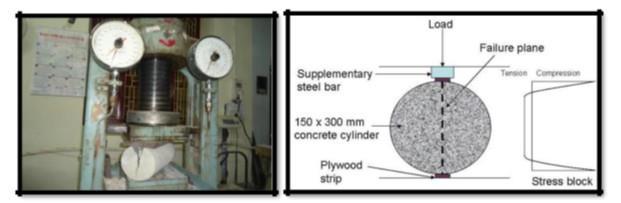

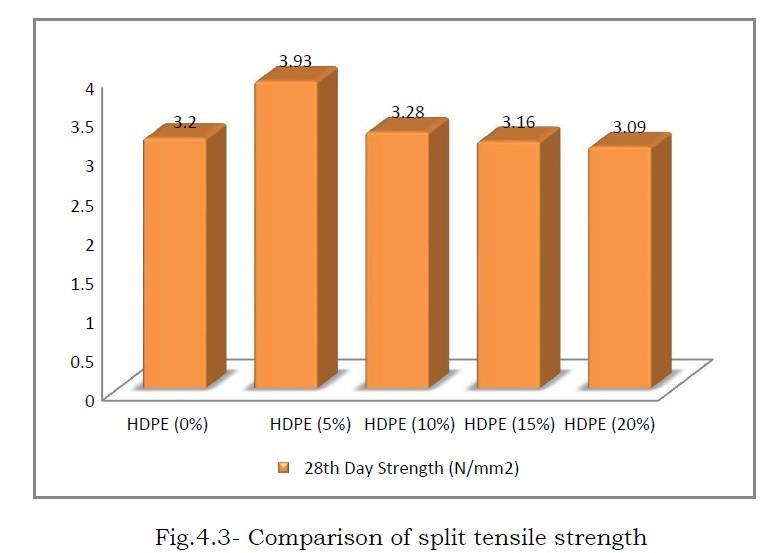

2. Split tensile strength

Concrete may also be subjected to tension in some cases and it is never designed to resist direct tension. Nevertheless, the load at which cracking would occur is significantandneedstobefindout.Thetensilestrengthof concreteascompared toits compressivestrengthisvery less and it is found to be only 10-14 % of the crushing strength.Therearesomeparameterswhichmanipulatethe tensilestrengthofconcretelikeage,curing,aggregates,airentrainmentandmethodoftesting.

3. Flexural strength:

Inordertoevaluatetheindirecttensilestrengthofconcrete, Flexural strength test is adopted. This test evaluates the capacityofconcretebeamorslab(withoutsteel)toresist failureinbending.

4. Ultrasonic Pulse Velocity Test

For examining the quality of concrete, Ultrasonic Pulse Velocity (UPV) method is the worldwide adoptable NDT Technique.Inthistechniqueultrasonic wavesare passed from one end to another end of concrete element and velocity of these waves is noted. In case of good quality

higher velocities will be received which shows higher density,homogeneityanduniformity.Whereas,incaseof poor-qualityconcrete,lowvelocitiesarereceived.

4. RESULTS:

This chapter presents various results obtained in the experimental program. The results obtained by the experimentsconductedaregraphicallyrepresented.

Slump cone test is conducted to check the workability of concretewithorwithoutreplacingHDPE.Therearevarious ways of determining workability but slump cone test is worldwideacceptedasthismethodisquickandeasytodo. In the present experimental program effect of partial substitutionofHDPEonconcreteisstudied.HDPEPowderis replacedwithfineaggregatesinfollowingpercentagesi.e.0, 5,10,15,20%.Theresultsofreplacementonworkabilityare discussedbelow.

Table 4.1- Slump values and workability of concrete

(0%) Control Specimen

International Research Journal of Engineering and Technology (IRJET)

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net

The compressive strength shown below is the average of compressivestrengthobtainedfromthreeidenticalcubesi.e. 150mmX150mmX150mm.

Table 4.2- Compressive Strength Test Result

Theflexuralstrengthtestisconductedonabeamofsize100 mm×100 mm×500 mm. The average flexural strength of threeidenticalsamplesisshownbelow.

4.3 Split tensile strength test

Thetensilestrengthshownbelowistheaverageoftensile strengthobtainedfromthreeidenticalcylindersi.e.150mm X300mm.

Table 4.3- Split tensile Strength Test Results

Table 4.4- Flexural Strength Test Results

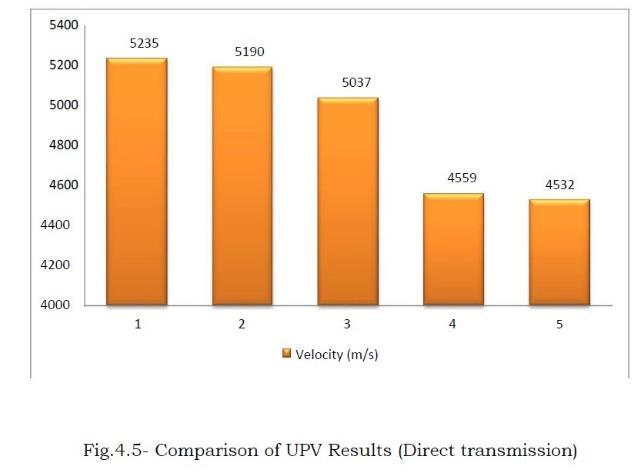

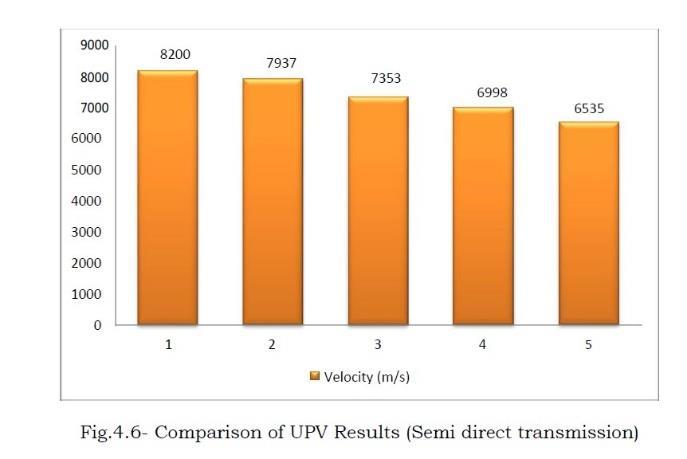

TheUPVtestisconductedonconcretecubeshavingsame size150mmX150mmX150mmwithdissimilarsubstitution ofHDPEpowdertocheckitseffect.TheresultsofUPVtest arediscussedbelow.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

5.0 Discussion and Conclusion

5.1 Discussion:

Followingaretheimportantpointsofdiscussion:

1. Results indicate that with increase in HDPE powder workability decreases. Optimum percentage of HDPE powder replacement is 5% with fine aggregates. At Replacementrangesbetween5to10%inconcreteshows highlyworkableconcrete.

2. If the replacement range is in between 5 to 10%, compressivestrengthincreaseswhenitkeptsidebysidedto controlled specimen. Nevertheless, at 5% replacement, compressivestrengthenhancesby16%.

3.Forsplittensilestrength,thebestvalueisobtainedat5% replacementoffineaggregatebyHDPEpowder.Howeverit hasbeennoticedthatthesplittensilestrengthreduceswith increaseinpercentageofHDPEpowdermorethan5%.Split tensilestrengthincreases by22.9%at 5% replacement of HDPEpowder.

4.Also,incaseofflexuralstrength,decreasewithincreasein percentage of HDPE powder has been noticed. 46.34% increment has been observed at 5% optimum value. However,atanyreplacementofHDPEpowderstrengthis morethancontrolspecimen.

5.ReductioninUPVhasbeenobservedwiththeincrementin UPVvalues,butstillitfallsundergoodqualityconcreteat anyreplacementpercentage.

5.2 Conclusion

Followingpointsofconclusioncanbedrawnfromtheresults ofexperimentalwork:

1.Itisfoundthatplasticwastemaybedisposedbyusingit asaconstructionmaterialinconcrete.

2. All the properties such as workability, compressive strength, flexural strength and split tensile strength of concreteareaffectedbytheinclusionofHDPEpowder.

3.Compressivestrength,flexuralstrengthandsplittensile strength of concrete decreases with increase in HDPE powder.

4.TheoptimumreplacementofHDPEpowderisfoundtobe 5%.

5.Atoptimumreplacementcompressivestrengthincreases by16.6%.Splittensilestrengthincreasesby22.815%and Flexuralstrengthincreasesupto46.34%

6. Density of cubes measured by UPV decreases with increaseinHDPEpowder.

7.AsHDPEisthewastematerials,hencebytheuseofthis materialinconcretemakesenvironmenteco-friendly.

8.Byutilizingthesematerialseconomicalconstructionmay bedone.

[1]. E. Ghafari, Y. Yuan, C. Wu, T. Nantung and N. Lu, “Evaluation the compressive strength of the cement paste blendedwithsupplementarycementitiousmaterialsusinga piezoelectric-based sensor”. Construction and Building Materials,Volume171,20May2018,Pages504-510.

[2]. A. Bagheria, m. Alipour, o. E.ozbulut and d. K.harris (2018).“Anondestructivemethodforloadratingofbridges without structural properties and plans”. Engineering structures,volume171,2018,pages545-556.

[3]. G.Villan, V. Garnier, Z. M. Sbartaï, X. Dérobert and J.P. Balayssac (2018). “Development of a calibration methodology to improve the on-site non-destructive

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

evaluationofconcretedurabilityindicators”.Materialsand Structures,April2018,51:40

[4]M.R.Polimen,I.RoselliV.LupranoaM.Mongelli,A.Tatì, G. Caniob, “A non-destructive testing methodology for damage assessment of reinforced concrete buildings after seismic events”. Engineering Structures., Volume 163, 15 May2018,Pages122-136.

[5] S. Shams, A. Ghorbanpoor, S. Lin and H. Azari (2018). “Nondestructive Testing of Steel Corrosion in Prestressed Concrete Structures using the Magnetic Flux Leakage System”. Journal of Transportation Research Board. May 2018.

[6] M. Prakash, .B.Hemalatha, “Replacement Of Waste Material In Concrete Using Recycled Plastic”, SSRG International Journal Of Mechanical Engineering, March 2017

[7]ManhalAJibraelandFarahPeter,“StrengthandBehavior of Concrete Contains Waste Plastic” Journal of Ecosystem &Ecography,May31,2016

[8]PreetiSaini,DeepakarKr.Ashish“AReviewonRecycled Concrete Aggregates”SSRG International Journal of Civil Engineering(SSRG-IJCE),April-2015,

[9] P. Saravanakumar and G. Dhinakaran“Mechanical and Durability Properties of Slag Based Recycled Aggregate Concrete”IJST,Feb2015

[10]A.Pawer,A.GabgurdeandK.Vikram,“GreenConcrete using Plastic Waste”, International Journal of Engineering TrendsandTechnology(IJETT)–Volume19Number4–Jan 2015

[11] Y. Ghernouti, B. Rabehi, B. Safi and R. Chaid, “Use of Recycled Plastic Bag Waste in the Concrete”, Journal of InternationalScientificPublications:Materials,Methodsand TechnologiesVolume8,ISSN1314-72692015.

[12]RaghatateAtulM,“USEOFPLASTICINACONCRETETO

IMPROVE ITS PROPERTIES” International Journal of AdvancedEngineeringResearchandStudiesE-ISSN2249–8974,2015

[13] Jitender Sharma, Sandeep Singla, “Study of Recycled ConcreteAggregates”,InternationalJournalofEngineering TrendsandTechnology(IJETT),July-2014.

[14] M. K. Singh, D. Kumar “Physical Properties of Construction & Demolished Waste Concrete”, IJSRDInternationalJournalforScientificResearch&Development, 2014

[15]Ferrari,Surico,Brocchi,Banfi,Maltese,Squinzi,“Method forrecyclingconcrete”EuropeanJournal,June-2012.

[16.] Saradhi R, Tabin-Rushad S, Bhavesh KR, Duggal SK, 2012,‘Studyofwasteplasticmixconcretewithplasticizer’, InternationalScholarlyResearchNetwork,ISRNCivEng,pp. 1–5.S

2025, IRJET | Impact Factor value: 8.315 |