The design and construction of a lever wheelchair can be improved. There are a large number of people with disabilities due to accidental injuries. Various methods are used to create a wheelchair to help those people. These methods change the existing design but therearemanypeople who cannot afford an improved model. Therefore, inthis deign we change the chain linking mechanism with a ratchet pawl machine to transfer the wheelchair power.

Wheelchairs are an excellent tool for these patients, empoweringthemtoliveanormallifebyallowingthemto domostoftheirdailyactivities.Thiscanrangefrombeing able to move from one place to another to compete in sportingevents.Wheelsofbicycleareusedinsteadofpush edges. The wheels will be rotated with the help of lever whichwillbeusedtopropagatefurtherwitheaseandless Theefforts.wheelswillberotatedwiththehelpofaleverthatwill beusedforcontinuousdistributionwithminimaleffort.by using Ratchet and pawl mechanism which used in normal bicycleshelptoreduceeffortsappliedbypatientwheelsof bicycleareusedinsteadofpushedges.Thewheelswillbe rotated with the help of lever which will be attached to wheels by means of lever operated mechanism. The main mottoofthisprojectistogivethereplicawhichwillrequire lesseffortthantheconventionalwheelchairanditwillhave low cost in comparison with the advanced wheelchairs availableinthemarket.Therearepeople whocannotbuy the Automatic power wheelchairs for daily use. So, this wheelchairwillbethebetteroptionforthosepeople.

2. PROBLEM STATEMENT

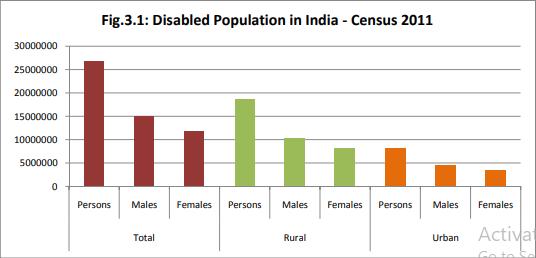

According to the 2011 Census, in India a population of Cr 121,2.68Crpeopleare'disabled'whichis2.21%ofthetotal population.Amongpeoplewithdisabilities56%(1.5Cr)aremen and 44% (1.18 Cr) are women. In the general population, menandwomenmakeup51%and49%respectively.The majority(69%)ofpeoplewithdisabilitiesliveinruralareas (1.86Crpeoplewithdisabilitiesinruralareasand0.81Crin urbanareas).Intermsofpopulationagain,69%comefrom ruralareasandtheremaining31%liveinurbanareas.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 01 | Jan 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page671 Design and Development of Lever Operated Wheelchair Aniket Vidyagar1 , Prof. Ganesh D. Korwar2 , Sumedh Kulkarni3 , Nikhil Gund4 , Sreeraj Karpe5 , Somnath Hirole6 1UG Scholar, Dept. of Mechanical Engineering, V.I.T, Pune, Maharashtra, India 2Professor, Dept. of Mechanical Engineering, V.I.T, Pune, Maharashtra, India 3,4,5,6UG Scholar, Dept. of Mechanical Engineering, V.I.T, Pune, Maharashtra, India *** Abstract

The wheelchair is designed in such a way that it requires little user effort to operate and be economically accessible compared to other high quality wheelchairs

Fig. 1:Traditionalwheelchair

Key Words: Lever Wheelchair, Wheelchair Design, Active Wheelchair Design, Ratchet and pawl mechanism.

TheproposedLeverwheelchairsystemcanbeusedtomove itwithverylittlepower

.

1.INTRODUCTION

3. SURVEY

Modernwheelchairsforpeoplewithphysicaldisabilitiesare difficult to operate. This requires great strength to move Forforward.thedisabled person living in a developing country, wheelchairsarenottobemissedastheyreducetheuser's levelofspaceandsmoothness.

Typically,membersarearrangedsothatthelinkstravelon thesameplane,andtheassemblyiscalledaplanarfour bar

Ratchet and Pawl mechanism

Fig 2 Disabledpopulationbytypeofdisability2016

Fig.5:Ratchetandpawlmechanism

About69%oftheoverall disabledIndianpopulationlives ruralareas.Thistellsusthat37,51,410locomotordisabled peopleliveinruralareas.Onlyabout16,85,416locomotor disabledpeopleliveinurbanareas.

TheCensus2011revealedthat,InIndia, 20% of the disabled persons are having disability in movement,19%arewithdisabilityinseeing,andanother19 %arewithdisabilityinhearing.8%hasmultipledisabilities.

Therearerattsonsomescrewdriversthatallowtheuserto effortlessly turn to one side and back without turning the Whenscrew.thegearshiftsinonedirection,thepawlslidesupand

Fig. 3:Mechanismof4barlinkage Input:ReciprocalLink Output:Rotatinglink(wheelhub) Theconnectionofthefourbars,alsocalledthefourbars,isa simple portable connection closure. It consists of four bodies,calledbarsorlinks,attachedtoaloopbyfourjoints.

Fig.4:CADmodelof4BarMechanismdesignedinSolid works

PROPOSED

4. OVERLOOK OF MECHANISM

Typesofdisability

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 01 | Jan 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page672 Chart -1:

DisabledpopulationinIndia

2011

Fourlinkage.line connections can be used for many mechanical purposes,including:convertingrotationalmovementsinto repetitive movements (e.g., pumpjack models) converting repetitivemovementsintorotatingmovements(e.g.,bicycle models) rotating movements (e.g., knee models and suspensions).

Ideal condition for such mechanism: Inputlink:Rotary Outputlink:Reciprocating So, this mechanism is discarded as it may fail sometimes whileperformingmotion.Itmaygetstopped.

Mechanism of 4 bar linkage

:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 01 | Jan 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page673 overthegearteeth,sendingthepawlintoplacebeforethe nexttooth.Thepawlhasbeentightenedagainstthepressure between the gear teeth, preventing any backward Ratchetmovement.machinesareveryusefuldevicesthatallowdirector rotatingmovementononlyoneside. Typicalexamplesofratchetwatches,jackets,andhoists Forward Stroke: Pawlallowsforwardmotionofsprocket. Backward Stroke: Pawldoesnotallowbackwardmotionofsprocket. Redportion Pawl Hence, to and fro motion of lever results in travelling forwarddistance. Reason to choose Ratchet and pawl mechanism Theratchetandpawlmechanismispreferredforthisproject becauseduringtheprocessofconnectingthemotion4barit may be suspended or reversed when power is applied. A practicesimilartoasewingmachinemaybepossible. Butontheratchetandpawlmovementswillbegivenonly oneside 5. ROUGH SKETCH Fig. 6: Roughsketchofdesignforleveroperated wheelchair 6. LITERATURE REVIEW 7healthymalevolunteers(UnskilledWheelchairusers): - Meanheight:175.8(+/ )4.11cm - Meanmass:72.62(+/ )5.88kg Meanage:26.0(+/ )3.46years 4disabledmalevolunteers(SkilledWheelchairusers) Meanheight:173.75(+/ )7.68cm Meanmass:67.75(+/ )11.76kg - Meanage:42.5(+/ )8.58years Standard wheelchair sizes: - Drivewheelsizeindiameter 24’’(61cm) - Casterwheels 4’’to6’’(10to15cm) - Propulsion Torque (Rear wheel torque of the Wheelchair). - Maximumpropulsiontorque: - Heavy fastcondition:Unskilled 19.21(+/ )1.99 Nm,Skilled 15.98(+/ )2.25Nm - Light slow condition: Unskilled 12.47 (+/ ) 1.08 Nm,Skilled 9.23(+/ )1.13Nm Fig. 7: Meanpropulsiontorquesfor(a)unskilledand(b) skilledgroupsduringmanualwheelchairpropulsion underfourdifferentconditions 7. CALCULATIONS FOR DESIGN Force calculation Therearethreeforcesresistingthemotionofwheelchair: •Rollingresistanceforce •Inertialforce •Aerodynamicforce(neglected) Forrollingresistanceforce,Fr=µ*N Therefore,Fr=µ*mg

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 01 | Jan 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page675 Fig. 9:Sprocketdesign Smaller sprocket design Fig. 10: Smallersprocketcalculations Bigger sprocket design Fig. 11:Biggersprocketcalculations 8. MATERIAL SELECTION Themostcommonusesintheframe/wheelchairstructure Solidare:Steel(AISI1018Mild/LowCarbonSteel): Thedensityis7.87g/ccandthecostisestimatedatRs.60/ kg. Strength=370MPaandModulusofElasticity=205GPa Aluminum(Al6061 T6): Thedensityis2.7gm/c.c.andthecostisRs.275/kg. Strength=276MPaandModulusofElasticity=68.9GPa Titanium(Ti 6Al 4V)(Grade5)alloy: Thedensityis4.512g/ccandthecostisestimatedatRs. 1600/ Strengthkg.=862MPaandModulusElasticity=110GPa 9. CAD MODEL OF DIFFERENT PARTS Fig. 12. RatchetPawlMechanism Fig. 13. FreeWheel

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 01 | Jan 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page676 Fig. 14. Frame Fig. 15. Chain Fig. 16. WheelchairModel 10. ANALYSIS USING ANSYS Fig. 17. TotalDeformation Fig. 18. EquivalentStress • For the analysis of pawl, it is considered as a cantileverbeam. • Radiusofinternalteeths=38mm. • Torqueonsprocket=40Nm. • So,Forceononepawl=520N. • Therefore,Mb=520*0.026=13.52Nm • Shearstress=F/A =520/(0.003*0.0061)= 28.415 MPa 11. FINAL WORKING MODEL

ThanksPROF.G.D.KORWAR'sguidance,supportandinput intothisstudyprojectwouldnothavebeenpossiblewithout Thanksit.toProfM.B.ChaudhariistheheadoftheDepartment ofMechanicalEngineeringwithhissupportandadditionof suchkindprojectstoourcurriculum.Weexpressoursincere gratitudetothemanagementoftheVishwakarmaInstitute of Technology, Pune for allowing us to undertake such educationalprojects. Weexpressourfeelingsandrespecttoourparents,without their blessings, help and inspiration this work would not havebeencompletedanditwouldhavebeenjustadream for us. We thank all those who may have unintentionally failedtoidentifythembutwhocontributedpositivelytothe successfulcompletionofthisproject.

[4]SeonhongHWANG,SeunghyeonKIM,JongsangSONand YounghoKIM.Manual WheelChairPropulsion Torqueand PowerOutputsinDifferentSkillGroups;Vol.7,No.4,2012.

REFERENCES

[3]WijitDrivingandBrakingSystem USERMANUAL

[5]https://wdo.org/site project/leveraged freedom chair

[7]TaylorandFrancis,StandardHandbookofChains,Chains for Power Transmission and Material Handling, Second Edition,2006 [8] V. B. Bhandari, Design of Machine Elements, Tata McGraw HillEducation,2010 [9] Ronald A. Walsh, Handbook of Machining and Metalworking Calculations, Tata McGraw Hill Education, [10]2001Lucas H.V. Vander Woude, Ingrid vriend, Mechanical Advantage in Wheelchair Lever Propulsion, Journal of RehabilitationResearchandDevelopment 1997

[1] Ahmad Rifai Sarraj and Raphael Massarelli. Design History and Advantages of a New Lever Propelled WheelchairPrototype;13May2011.

The aim of this project is to provide a clear and complete presentationoftheoreticalandpracticalinformationonthe construction of a wheelchair. To achieve this goal, team membershaveneverworkedaloneastheseideasarebuilt onthecomments,suggestionsandacceptanceprovidedby PROF.G.D.KORWARMechanicalEngineeringDepartment.

[6]SeonhongHWANG,SeunghyeonKIM,JongsangSONand YounghoKIM.Manual WheelChairPropulsion Torqueand PowerOutputsinDifferentSkillGroups;Vol.7,No.4,2012

[2]JagdishP.Choudhary,PoonamG.Choudhary,KedarM. Kulkarni. Design and Fabrication of Lever Operated WheelchairforDisabledPersonwithNoLegs;Vol.6,Issue1, January2019.

ACKNOWLEDGEMENT

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 01 | Jan 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page677 Fig. 19 Developedwheelchair 12. COST ESTIMATION 13. CONCLUSIONS 1. Designisfeasible,itcanbescaledup. 2. Costeffective,simpleandefficient. 3. It saves human efforts which is very essential especiallyfordisabled. 4. Theincreaseinspeedandtorqueinpercentagesis 53%and40.35%respectivelyforthiswheelchair ascomparedtotraditionalwheelchair. 5. Mechanismispurelymechanical,hencereliable. 6. Universaldesignmakesitapplicationoriented. 7. It can be used on different terrains if some more modificationsaredoneinthiswheelchairsuchas usinghydraulicsforthelaunchofwheelchair.