International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 06 | Jun 2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 06 | Jun 2024 www.irjet.net p-ISSN:2395-0072

Suryakant Maurya1, Mr. Ushendra Kumar2

1Master of Technology, Civil Engineering, Lucknow Institute of Technology, Lucknow, India

2Head of Department, Department of Civil Engineering, Lucknow Institute of Technology, Lucknow, India

Abstract - The construction industry is perpetually in pursuit of sustainable strategies to mitigate environmental impact and decrease resource consumption. This review delves into the incorporation of waste materials in the construction of rigid pavements, focusing on the environmentaladvantagesandengineeringefficacy.Diverse waste materials, such as industrial by-products, recycled aggregates, and plastic waste, are examined for their viability as substitute construction components. The paper consolidates insights from recent research on the mechanical characteristics, longevity, and overall performance of rigid pavements integrated with waste materials. Furthermore, it scrutinizes the economic ramificationsandpotentialregulatoryhurdleslinkedtothe implementation of these sustainable methods. The review underscores that integrating waste materials in rigid pavement construction not only fosters resource preservation and waste disposal but can also result in improved pavement performance under specific circumstances. Nevertheless, it also acknowledges the necessity for standardized testing protocols and guidelines to ensure the uniform quality and safety of pavements. In essence, this paper furnishes a thorough examination of current trends, advantages, and obstacles in the utilization ofwastematerialsforrigidpavementconstruction,withthe aimofsteeringfutureresearchandpracticalapplicationsin sustainableinfrastructureadvancement.

Key Words: - Waste materials, Rigid pavement, Sustainable construction, Recycled aggregates, Industrial by-products,Plasticwaste,Pavementperformance

1.HISTORY

The incorporation of waste materials in the construction of rigid pavement has undergone significant advancementsinrecentdecades,drivenbyenvironmental and economic considerations. Initially, the construction sector heavily relied on traditional components like cement, sand, and gravel. However, increased awareness of environmental issues and the necessity for sustainable development prompted researchers and engineers to investigate alternative materials. In the 1970s and 1980s, significant efforts were made to introduce industrial byproductssuchasflyash,slag,andsilicafumeintoconcrete mixes, primarily to enhance concrete properties and mitigate waste disposal challenges. The 1990s and early

2000s witnessed a wider acceptance and application of these materials, supported by extensive research demonstrating their effectiveness in enhancing pavement durability and performance. The incorporation of a broader range of waste materials, including recycled concrete aggregates, rubber from discarded tires, and plasticwaste,markedanewerainthe21stcentury.These innovations were not only aimed at reducing environmental impact but also at optimizing costs and resource utilization in pavement construction. Presently, the integration of waste materials in rigid pavements is acknowledged as a feasible practice, with ongoing technological advancements and developments in materials science continually expanding its potential applicationsandadvantages.

Rigid pavement is a specialized road or pavement constructionthatisengineeredtoprimarilydisperseloads through a solid surface layer. This layer is commonly composed of Portland cement concrete, offering exceptional strength and resilience. In contrast to flexible pavements, which depend on a layered configuration to distribute loads, rigid pavements utilize the robustness of the concrete slab to evenly spread loads across a broad expanse. This feature leads to reduced deformation and maintenance requirements in the long run. The design of rigid pavements incorporates joints to manage cracking and facilitate thermal expansion and contraction, guaranteeing longevity and optimal performance even in high-trafficconditions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 06 | Jun 2024 www.irjet.net p-ISSN:2395-0072

The primary function of rigid pavement is to furnish a robust and enduring surface for roadways, expressways, airport runways, and various other transportation structures. These pavements are meticulously engineered to evenly disperse the weight of vehicles, aircraft, and other forms of traffic across a broad surface, effectively reducing deformation and averting the emergence of fracturesandothertypesofstructuraldeterioration.

Load Distribution: Rigid pavements are designed to efficientlydistributetheheavyloadsgeneratedbyvehicles andtrafficacrossabroadsurfacearea.Thisdistributionof weight helps to minimize the pressure and stress exerted on the soil and subgrade beneath the pavement. By spreading out the load, rigid pavements can effectively prevent cracking, rutting, and other forms of damage that can occur when the weight is concentrated in a smaller area. This design feature notonly enhances the durability and longevity of the pavement but also contributes to the overall stability and safety of the road infrastructure. In essence,rigidpavementsplayacrucialroleinmaintaining theintegrityoftheroadnetworkandensuringsmoothand reliabletransportationforallusers.

Durability: Rigid pavements, which are commonly constructed using Portland cement concrete, are known for their exceptional durability and ability to withstand heavy traffic and harsh environmental conditions. Due to their strong resistanceto wearandtear, these pavements are often chosen for use in high-traffic areas such as highways, airports, and industrial facilities. The rigid structure of these pavements provides long-lasting support and stability, making them a reliable choice for infrastructure projects that require a sturdy and reliable surface. Overall, rigid pavements are a popular choice for areas that experience high levels of use and require a durable,long-lastingsolution.

Longevity: Rigid pavements, when designed and constructed correctly, can offer a significantly extended service life with minimal maintenance needs in comparison to other types of pavements. This means that properlylaidoutrigidpavementscanwithstandthetestof time and prove to be a cost-effective and durable option forinfrastructureprojects.Byensuringthatthedesignand construction processes are carried out meticulously, the longevity and performance of rigid pavements can be maximized, resulting in reduced maintenance costs and prolonged usability for roads, highways, and other transportation systems. Therefore, investing in welldesignedandwell-constructedrigidpavementscanleadto long-term benefits in terms of efficiency, safety, and overallinfrastructurequality.

Smooth Surface: Rigid pavements are a type of road surface that offers a durable and stable foundation for

vehicles to drive on. These pavements are known for providing a smooth and even surface, which in turn enhances driving comfort, safety, and fuel efficiency for motorists. By minimizing bumps and unevenness in the road, rigid pavements help to reduce wear and tear on vehicles, improve handling and stability, and increase overall driving performance. Additionally, the solid constructionofrigidpavementshelpsto preventcracking and deterioration over time, making them a long-lasting and cost-effective choice for road infrastructure. Overall, rigid pavements play a crucial role in ensuring a smooth andsafedrivingexperienceforallroadusers.

Structural Integrity: Rigid pavements are designed to withstand heavy loads and harsh weather conditions, allowing for safe and dependable transportation routes. Thesepavementsareconstructedusing durablematerials that provide structural integrity, preventing cracks and damage from occurring. With their strong foundation, rigidpavementsofferstabilityandlongevity,makingthem a preferred choice for roads, highways, and other infrastructure projects. By maintaining their strength and resilience over time, rigid pavements ensure the safety andefficiencyoftravelforbothmotoristsandpedestrians alike.

Resistance to Environmental Factors: Rigid pavements are carefully engineered structures that are built to endure various environmental challenges, including changes in temperature, moisture levels, and exposure to chemicals. These pavements are specifically designed to minimize the risk of deterioration over time, ensuring theirlongevityanddurability.Byconsideringfactorssuch as material selection, design specifications, and construction techniques, rigid pavements are able to withstand the harsh conditions they are exposed to, providing a reliable and long-lasting surface for transportationandotherpurposes.Theuseofhigh-quality materials and proper maintenance practices further contribute to the resilience of rigid pavements, making them a cost-effective and sustainable solution for infrastructureprojects.

Cost-effectiveness: Although the initial costs for constructing rigid pavements may be higher compared to flexible pavements, the durability and longevity of rigid pavementsoftenleadtosignificantcostsavingsinthelong run.Thisisbecauserigidpavementshavealongerservice lifeand require less maintenance, ultimately reducing the overall expenses associated with pavement upkeep and repairs over the course of its lifespan. Despite the higher upfront investment, choosing rigid pavements can prove to be a more cost-effective option in the grand scheme of things.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 06 | Jun 2024 www.irjet.net p-ISSN:2395-0072

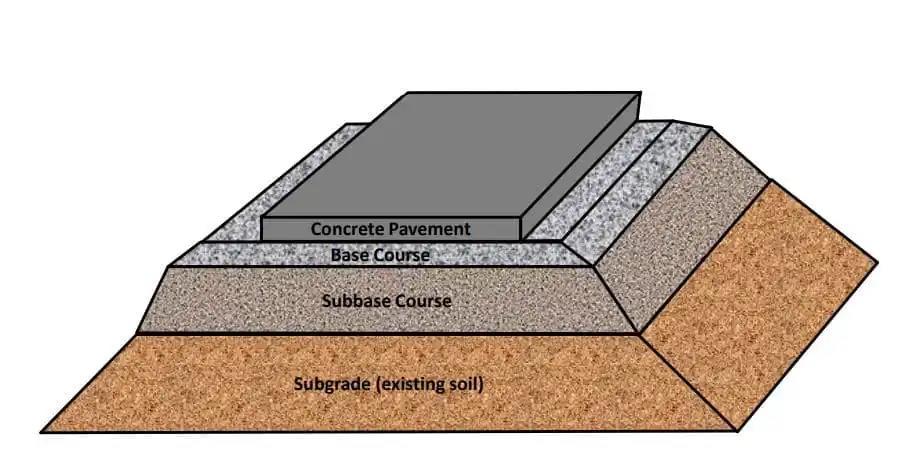

The structure of rigid pavement consists of several key components designed to work together to provide a durable and long-lasting surface for transportation. The mainelementsofrigidpavementinclude:

3.1.Concrete Slab

Theprimaryload-bearinglayer,typicallymadeofPortland cementconcrete(PCC).Thisslabprovidestherigidityand strengthneededtodistributeloadseffectively.Itisusually reinforced with steel to enhance its structural integrity andcontrolcracking.

3.2.Subbase

A layer of material placed between the concrete slab and the subgrade to provide additional support and stability. The subbase improves drainage, reduces the effects of frost heave, and helps to distribute loads more evenly. Common materials used for the subbase include granular aggregatesorstabilizedmaterials.

3.3.Subgrade

Thenaturalsoillayerbeneaththepavementstructure.The subgrade must be properly prepared and compacted to provideastablefoundationforthepavement.Itsstrength and stability are critical to the overall performance of the pavement.

3.4.Joints

Rigid pavements are a type of road surface that is built with intentional joints to help prevent cracking and allow for movement caused by factors such as changes in temperature, variations in moisture levels, and stresses from heavy loads. These joints are strategically placed to provide flexibility and prevent the pavement from becoming damaged over time. By incorporating these design elements, rigid pavements are able to better withstand the wear and tear of daily use, ultimately leadingtoalongerlifespanandimprovedperformancefor motorists.

3.5.Load Transfer Devices

In the construction and maintenance of roads and pavements, it is essential to use devices such as dowel barsandtiebarsatjoints.Thesedevicesplayacrucialrole in transferring loads across joints and ensuring proper alignment between adjacent slabs. Dowel bars are specifically designed for use in contraction joints to effectivelytransferverticalloadsandprovidestability.On the other hand, tie bars are utilized in longitudinal joints to secure adjacent slabs together, preventing any separation and maintaining the overall integrity of the

structure. By incorporating these devices into the design and construction process, engineers can ensure the durabilityandlongevityoftheroadorpavementsystem.

3.6.Surface Texturing

The concrete surface is often textured to improve skid resistance and provide a safe driving surface. Techniques includetining,grooving,orapplyingabroomfinish.

4.ADVANTAGE

Rigid pavement offers several significant advantages, making it a preferred choice for various high-traffic and critical infrastructure applications. One of the primary benefits is its durability and long lifespan. Rigid pavements, typically made of Portland cement concrete, can withstand heavy loads and adverse environmental conditions with minimal maintenance, leading to reduced lifecyclecosts comparedto flexiblepavements.Their high load-bearing capacity ensures that they can support substantial traffic volumes, including heavy trucks and machinery, without significant deformation or rutting. Additionally, the smooth surface provided by rigid pavementsenhancesdrivingcomfortandsafetywhilealso improving fuel efficiency. The ability to maintain structural integrity over long periods, even under harsh conditions, makes rigid pavements a cost-effective and reliable choice for roads, highways, and airport runways. Furthermore, their resistance to weathering, chemical spills, and temperature fluctuations contributes to their longevity and performance, ensuring consistent service withfewerinterruptionsforrepairsandmaintenance.

5.WASTE MATERIALS IN THE CONSTRUCTION OF RIGID PAVEMENT

Incorporating waste materials into the construction of rigidpavementsisanincreasinglypopularpractice,driven by environmental and economic benefits. These materials can improve the sustainability of pavement construction by reducing waste, lowering costs, and sometimes enhancing the properties of the concrete. Common waste materialsusedinrigidpavementconstructioninclude:

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 06 | Jun 2024 www.irjet.net p-ISSN:2395-0072

5.1.Fly Ash

A byproduct of coal combustion in power plants, fly ash canreplaceaportionofthePortlandcementinconcrete.It improves workability, reduces the heat of hydration, and enhancesthedurabilityandstrengthofthepavement.

5.2.Slag Cement

Also known as ground granulated blast-furnace slag (GGBFS), this byproduct from steel manufacturing can partially substitute for Portland cement. It improves the concrete's resistance to sulfate attack, alkali-silica reaction,andthermalcracking.

5.3.Recycled Concrete Aggregate (RCA)

Crushedconcretefromdemolishedstructurescanbeused as aggregate in new concrete mixtures. RCA reduces the demand for virgin aggregate, promotes recycling, and minimizesconstructionwaste.

5.4.Reclaimed Asphalt Pavement (RAP)

While more commonly used in flexible pavements, RAP can also be incorporated into rigid pavement as a partial replacement for natural aggregates, contributing to resourceconservationandwastereduction.

5.5.Silica Fume

A byproduct of silicon and ferrosilicon alloy production, silicafumeisahighlyreactivepozzolanthatenhancesthe strength and durability of concrete. It also reduces permeability,improvingresistancetochemicalattack.

5.6. Rice Husk Ash

Generated from the combustion of rice husks, this ash is rich in silica and can serve as a supplementary cementitious material. It improves the mechanical propertiesanddurabilityofconcrete.

5.7.Plastic Waste

Shredded plastic waste can be used as a partial replacement for fine aggregate in concrete, helping to reduce plastic pollution and improve certain concrete properties,suchastoughnessandimpactresistance.

6.LITERATURE REVIEW

In this section of the literarure review, we have studied theimprovementoftherigidpavement byusing different material,wheresummaryofthepreviousresearchworkis given:

Clrino et al. In this article , the authors evaluate the effects of incorporating plastic waste in construction materials, including economic, environmental, human health, performance and social impacts, and compare known impacts of these treatments for plastic waste and provide recommendations for future research. Plastic waste in construction materials exacerbates negative impacts.

Silvina et al. In this article , the effects of including complete walls of ceramic blocks (including masonry mortars)assupplementarycementingmaterials(SCM)on the physical, mechanical, and transport properties (water absorption and permeability) of concrete were analyzed. CBW stimulates hydration physically and chemically. Concrete with CBW has comparable mechanical properties.

Ramashankar et al. In this article,theauthorsproposed asolutiontoreducetheamountofnaturalresourcessuch as natural coarse aggregate and bitumen by blending alternate recyclable waste materials such as construction demolition waste aggregate and plastic waste shredded from waste bottles.UtilizationofCDWAand plasticwaste inpavementconstructionissustainableandcost-effective. Optimummixproportion:10%plasticwasteblendedwith 15%CDWA.

Mohsen et al. In this paper , the authors used concrete, bricks,andglassas100%aggregatesofchipseal,whichis acorrectiveorpreventivepavementmaintenancemethod, andacationicrapidsetting(CRS-2)bitumenemulsionwas also used to prepare the chip seal. Novel chip seals were developed using construction and demolition waste materials. Concrete aggregates showed the best performanceinchipsealdevelopment.

Anita: In this article , a literature review on the use of waste cooking oil to produce composite materials for constructionpurposes,addressingtheprocessparameters of tipping solid materials comprising vegetable oil as a binder and examining their strength and absorbability. Wastecookingoilcanbeusedasabinderforconstruction materials. Producing and using "green" materials has advantages.

Yara et al. In this paper , the authors identified the optimum acceptable plastic waste content to be involved in the construction material in order to enhance its thermal resistance without jeopardizing the compressive strength, and a comparative analysis was conducted on theeligiblepapersfocusing ontheusedtype,particlesize and percentages of the applied PW and the impact on the thermal conductivity and the compressed strength. Reusing plastic waste in construction materials is a sustainable solution to reduce plastic pollution. Plastic waste can enhance thermal resistance but may reduce compressivestrength.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 06 | Jun 2024 www.irjet.net p-ISSN:2395-0072

Aparna & Bindu. In this paper , the authors used waste products like quarrydust, coir pith (CP),fly ash(FA),and rice husk ash (RHA) as the vertical drain in clayey soils. Quarry dust and coir pith can be better alternatives to sanddrain.Densityofdrainaffectsconsolidationrateand permeability.

Radmila et al. Inthisarticle,theuseofsolidifiedfractions of industrial hazardous waste obtained by mixing with inert materials in construction was investigated. But the results showed that the investigated mixtures cannot be used for structural building elements, but their usage is recommended for elements such as pavements, roadside, pathcubes,concretehaberdashery,etc.Investigatedwaste can't be used for structural building elements. Recommended for pavements, roadside, path cubes, concretehaberdashery.

Hasan et al. In this article , an experimental study of unbound granular material using recycled concrete aggregate for pavement subbase construction was conducted, where five percentages of aggregate were obtained from two different sources with an originally designed compressive strength of 20-30 MPa as well as 31-40 MPa at three particle size levels. Recycled concrete aggregate can replace ordinary gravel materials for pavement subbase construction. Using recycled concrete aggregate enhances the bearing capacity and rigidness of thepavementstructure.

Rachida et al. In this article , experimental laboratory tests were carried out on the waste rock produced from theextractionofthephosphateintheKef-Essenounmine, to study the performance of road pavement foundations built with these types of material. Waste rock materials from phosphate mining can be used in pavement construction. The materials need to be treated with hydraulicbindersforimprovedproperties.

Kuok: In this article , the authors present the latest advances in the valorization of plastic waste as construction and building materials through a review of 60relevantscholarly papersanda contentanalysisofthe papers.Plastic waste can be valorizedasadditivesor raw materials for construction materials. Plastic-based construction materials have desirable properties but may posefiresafetyconcerns.

Paulo & Silva. In this paper , the authors provide a literaturereviewontherelevantengineeringpropertiesof different types of recycled aggregates coming from C&D waste, a comparison with the properties of natural aggregates,andhowtheseaggregatesperforminthelongterm when used in unbound pavement applications. Recycled aggregates are suitable alternatives to natural aggregates in unbound pavement layers. The use of recycled aggregates can mitigate the environmental impactsoftheconstructionindustry.

Chalyaput et al. In this article , high calcium waste dust from asphalt concrete manufacturing was utilized to stabilize low-quality lateritic soil as a subbase course material in road structures, which achieved a sufficiently high California bearing ratio, optimized plastic index, liquidlimit,andswellingindexofsoilabovetheminimum standard requirements for a sub base course material. Asphalt waste dust can be used to stabilize low-quality lateritic soil as a subbase course material in road structures. The addition of asphalt waste dust improves thestrengthandperformanceofthesoil.

Zemeng & Zong. In this article , a new method of preparing construction waste into powder and using recycledpowder(RP)asasphaltfillerisproposedinorder to promote the convenient and low-cost utilization of construction waste. RA properties don't meet requirementsforasphaltpavementaggregates.RPwithPC achieves satisfactory engineering performance in asphalt concrete.

Gallya et al. In this paper , the authors developed environmentally clean construction materials for stabilizing natural loam (NL) using red mud (RM), blast furnaceslag(BFS),andlimeproductionwaste(LPW).The combinationofRM,BFS,andLPWshowedpositiveresults in the strength and durability of NL in both dry and wet environments. The developed construction materials may have a good application in the market for construction materialsbecauseoftheirlowercostsincurrentprocesses andmayplayanimportantroleineliminatingthestorage ofproductionwasteinKazakhstan.

John et al. In this paper , aggregates from four types of recycled materials are being subjected to study for unbound and cemented pavement layers, and the results showed that despite the weaknesses arisen from weak components such as masonry and elongated tiles, the stabilized distribution of the particle size can accelerate reaching to final compaction of unbound aggregates with roller passing. Different recycled materials exhibit similar behavior with different extent in vibrating roller compaction. Supplementary tests and methods may be required to determine the number of vibratory roller passesforcompactingtheunboundlayer.

The incorporation of waste materials in the construction of rigid pavements presents a promising avenue for sustainable development in the construction industry. This review has highlighted various waste materials, includingflyash,slag,recycledconcreteaggregate,plastic waste, and rubber tires, each demonstrating significant potential in enhancingtheperformanceandsustainability of rigid pavements. The utilization of these materials not only addresses the pressing issue of waste management but also contributes to the conservation of natural

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 06 | Jun 2024 www.irjet.net p-ISSN:2395-0072

resources and reduction of environmental impact. Key findings from the reviewed studies suggest that waste materials can improve the mechanical properties of concrete, enhance durability, and provide cost-effective solutions for pavement construction. For instance, fly ash and slag have been shown to improve workability and strength,whilerecycledconcreteaggregatesofferaviable alternative to natural aggregates, reducing the need for virgin materials. Moreover, the incorporation of plastic and rubber waste can enhance the flexibility and crack resistance of concrete pavements. In conclusion, the utilization of waste materials in rigid pavement construction offers a sustainable solution that aligns with global efforts to promote environmental stewardship and resource efficiency. By embracing these innovative approaches, the construction industry can significantly contributetoacirculareconomy,reduceitsenvironmental footprint,andpavethewayforgreenerinfrastructure.

1. Al-Mosawe,H.,Albayati,A.,Wang,Y.,&Mashaan,N.S. (2022). An experimental study of granular material using recycled concrete wastefor pavement roadbed construction. Buildings, 12(11), 1926. https://doi.org/10.3390/buildings12111926

2. Alzhanova, G. Z., Aibuldinov, Y. K., Iskakova, Z. B., Khabidolda,S.M.,Abdiyussupov,G.G.,Omirzak,M.T., Murali, G., & Vatin, N. I. (2022). Development of environmentally clean construction materials using industrial waste. Materials, 15(16), 5726. https://doi.org/10.3390/ma15165726

3. Aparna, R. P., & Bindu, J. (2023). Utilization of waste materials as a substitute for the sand drain in clayey soil. International Journal of Geo-engineering, 14(1). https://doi.org/10.1186/s40703-022-00180-9

4. Chaiyaput, S., Sertsoongnern, P., & Ayawanna, J. (2022). Utilization of Waste Dust from Asphalt Concrete Manufacturing as a Sustainable Subbase Course Material in Pavement Structures. Sustainability, 14(16), 9804. https://doi.org/10.3390/su14169804

5. Cirino, E., Curtis, S., Wallis, J., Thys, T., Brown, J., Rolsky, C., & Erdle, L. M. (2023). Assessing benefits and risks of incorporating plastic waste in construction materials. Frontiers in Built Environment, 9. https://doi.org/10.3389/fbuil.2023.1206474

6. El-Metwally, Y. S., Dewidar, K. M., Ismail, M. R., & ElMahallawi, I. S. (2023). A review on Sustainable disposal of plastic waste by integration in construction materials. Civil Engineering and Architecture, 11(2), 714–725. https://doi.org/10.13189/cea.2023.110213

7. Guo, Z., & Chen, Z. (2022). Utilization of construction waste recycled powder as filler in asphalt concrete. Materials, 15(16), 5742. https://doi.org/10.3390/ma15165742

8. Malaoui, R., Harkati, E. H., Soltani, M. R., Djellali, A., Soukeur, A., & Kechiched, R. (2023). Geotechnical characterizationofphosphateminingwastematerials for use in pavement construction. Engineering, Technology and Applied Science Research/Engineering, Technology and Applied Science Research, 13(1), 10005–10013. https://doi.org/10.48084/etasr.5493

9. Pereira, P. M., & Vieira, C. S. (2022). A Literature review on the use of recycled construction and demolition materials in unbound pavement applications. Sustainability, 14(21), 13918. https://doi.org/10.3390/su142113918

10. Ramshankar,P.,Sukumar,B.,Aishwarya,R.,Darshan, P.R.,&Hrithik,H.(2023).Experimentalinvestigation on bituminous pavement using construction demolitionwasteandplasticwaste.IndianJournalof Science and Technology, 16(21), 1546–1554. https://doi.org/10.17485/ijst/v16i21.1792

11. Serovic, R., Jelic, I., Matic, B., & Savic, A. (2023). Utilizationofsolidifiedindustrial hazardouswastein construction: A case study. Hemijska Industrija, 77(2), 137–146. https://doi.org/10.2298/hemind222610001s

12. Shamsaei, M., Carter, A., & Vaillancourt, M. (2023). Usingconstructionanddemolitionwastematerialsto develop chip seals for pavements. Infrastructures, 8(5), 95. https://doi.org/10.3390/infrastructures8050095

13. Staroń, A. (2023). Composite materials based on waste cooking oil for construction applications. Buildings, 13(4), 994. https://doi.org/10.3390/buildings13040994

14. Sustainable recycling techniques of pavement materials. (2022). In MDPI eBooks. https://doi.org/10.3390/books978-3-0365-6200-1

15. Tang, K. H. D. (2022). Valorization of Plastic Waste through Incorporation into Construction Materials. Civil and Sustainable Urban Engineering, 2(2), 96–109.https://doi.org/10.53623/csue.v2i2.141

16. Zito, S. V., Irassar, E. F., & Rahhal, V. F. (2023). Recycled construction and demolition waste as supplementary cementing materials in Eco-Friendly concrete. Recycling, 8(4), 54. https://doi.org/10.3390/recycling8040054