International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:11Issue:05|May2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:11Issue:05|May2024 www.irjet.net p-ISSN:2395-0072

Atharv S Siddeshwarmath1 , Girish Kammar V2 , Omkar M K3 ,

Prof.Vishwanath.M.Khadakbhavi4 , Dr. Ashok M Hulagabali5 , Dr.Rajendra M Galagali6

1234Students, Department of Mechanical Engineering S.G. Balekundri Institute of TechnologyEngineering Belgaum, Karnataka, India

5Professor and Project Guide, Department of Mechanical Engineering S.G. Balekundri Institute of Technology Engineering Belgaum, Karnataka, India

6Professor and HOD, Department of Mechanical Engineering S.G. Balekundri Institute of TechnologyEngineering Belgaum, Karnataka, India

Abstract- The integration of the Internet of Things (IoT) into industrial settings has revolutionized the monitoring and control of various parameters crucial for efficient operations. Thispaperpresents acomprehensive IoT-based system designed to monitor and control industrial parameters such as temperature, humidity, pressure, and machinery status in real-time. Utilizing a network of sensors andmicrocontrollersconnectedthroughwireless communication protocols, the system collects and transmits data to a centralized cloud platform. Advanced data this is processed by machine learning and analytics algorithms. data, providing actionable insights and predictive maintenance alerts to prevent equipment failuresandoptimizeperformance.

1.Introduction

The advent of the Internet of Things (IoT) has ushered in a new era of connectivity and intelligence, significantly transforming various sectors, including industrial operations. Industrial environments are characterized by complex processes that require precise monitoring and control of numerous parameters such as temperature, humidity, pressure, and machinery status. Traditionally, these parameters have been monitored manually or through isolated automated systems, often resulting in inefficiencies, delayed responses to anomalies, and increased operational costs.

IoT-based industrial monitoring and control systems offer a revolutionary solution to these challenges by leveraging interconnected sensors, actuators, and advanced communication technologies. These systems enable real-time data collection, analysis, and response, facilitating proactive maintenance, enhanced operational efficiency, and reduced downtime. The integration of IoT with industrial processes not only ensures the seamless flow of information across different levels of operations but also empowers industries to implement predictive maintenance strategies, optimize resource utilization, andachievehigherlevelsofautomation.

This research paper explores the design, implementation, and impact of an IoT-based system for monitoring and controlling industrial parameters. By deploying a network of smart sensors and leveraging cloud computing and data analytics, the proposed system provides a comprehensive solution for real-time monitoring and management of industrial environments. The introduction of such a system is poised to address the limitations of conventional methods, providing a scalable, secure, andefficientapproachtoindustrialautomation.

The integration of IoT in industrial parameters monitoring and control has garnered significant attention in recent research, highlighting its potential to revolutionize traditional industrial processes. Several research papers have investigated different aspects of this technology,

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:11Issue:05|May2024 www.irjet.net p-ISSN:2395-0072

focusing on its implementation, benefits, and challenges.

1. Implementation and Architecture: Research by Gubbi et al. (2013) outlines the foundational architecture for IoT systems, emphasizing the importanceofsensornetworks,dataprocessing, and cloud computing in creating a cohesive IoT framework. Similarly, Lee and Lee (2015) discuss the integration of IoT with existing industrial systems, proposing a multi-layered architecture to facilitate seamless data flow and control.

2. Benefits and Efficiency: Many studies have documented the efficiency gains from IoT implementation. For instance, Qin et al. (2016) demonstrate how real-time monitoring and predictive maintenance enabled by IoT can significantly reduce downtime and maintenance costs in manufacturing.Furthermore, Kang et al. (2016) highlight improvements in operational efficiency and product quality through continuous monitoring and data-driven decision-making.

3. Challenges and Solutions: Despite its advantages, IoT adoption in industrial settings faces challenges such as data security, interoperability, and scalability. Research by Sicari et al. (2015) addresses security concerns, proposing robust encryption and authentication mechanisms to protect sensitive industrial data. Additionally, Thibaud et al. (2018) explore the issues of interoperability and propose standardized communication protocols to ensure seamless integration across diverse systems.

4. Case Studies and Applications: Real-world IoT applications across a range of industries offer insightful information about the technology's efficacy. For instance, a case study on the application of IoT for smart manufacturing is presented by Bagheri and Yang (2018), showing notable gains in flexibility and efficiency. In a similar vein, Al-Fuqaha et al. (2015) explore IoT applications in the energy industry and present improved smart grid monitoring and control capabilities.

5. FutureDirections:Emergingresearchisfocusing on enhancing the capabilities of IoT systems through advanced technologies such as artificial intelligence and machine learning. Studies by Wang et al. (2020) suggest that integrating AI with IoT can further optimize industrial processes by enabling predictive analytics and autonomousdecision-making.

The rapid advancement of the Internet of Things (IoT) presents a transformative opportunity for enhancing industrial processes through real-time monitoring and control of critical parameters. Traditional industrial systems often rely on outdated, manual, or semi-automated methods that can lead to inefficiencies, delayed responses to anomalies, and increased operational costs. These conventional approaches are inadequate in addressingthegrowingcomplexityanddemandsfor higher precision, safety, and efficiency in modern industrialenvironments.

In industries such as manufacturing, energy, and chemical processing, parameters such as temperature, pressure, humidity, vibration, and chemical concentrations are critical to maintaining optimal operational conditions and ensuring product quality and safety. However, the lack of real-time dataacquisition and analysis capabilities can result in undetected deviations from optimal parameters,leading to equipment failures, product defects, andsafetyhazards.

The integration of IoT technologies into industrial settings promises to revolutionize the way these parameters are monitored and controlled. By leveraging IoT sensors, data analytics, and automated control systems, industries can achieve continuous, real-time monitoring and proactive management of their processes. This integration can increase operational effectiveness, decrease downtime, improve safety, and lead to significant costsavings.

The deployment of Internet of Things (IoT)-based monitoring and control systems is packed with challenges, even while its potential. These include controlling the enormous volumes of data

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:11Issue:05|May2024 www.irjet.net p-ISSN:2395-0072

produced, guaranteeing the security of IoT networks, assuring the dependability and precision of sensors, and fusing new technologies with the infrastructure already in place in the industrial sector. Furthermore, scalable solutions that can be tailored to match the unique needs of various industrialsectorsarerequired.

4.1.IOT

The Internet of Things (IoT) represents a paradigm

4. shiftinthewayindustrialsystemsoperate,enabling seamless interconnectivity and real-time data exchange between machines, sensors, and control systems. By embedding sensors and actuators in industrial equipment, IoT facilitates continuous monitoring and precise control of critical parameters such as temperature, pressure, and humidity. This link improves the effectiveness of operations., predictive maintenance, and decisionmaking processes, reducing downtime and operational costs. Moreover, IoT-drivenanalytics provide valuable insights that drive innovation and optimization in industrialprocesses, aligning with the goals of Industry 4.0 to create smarter, more responsive,andagilemanufacturingenvironments

4.2.SENSOR

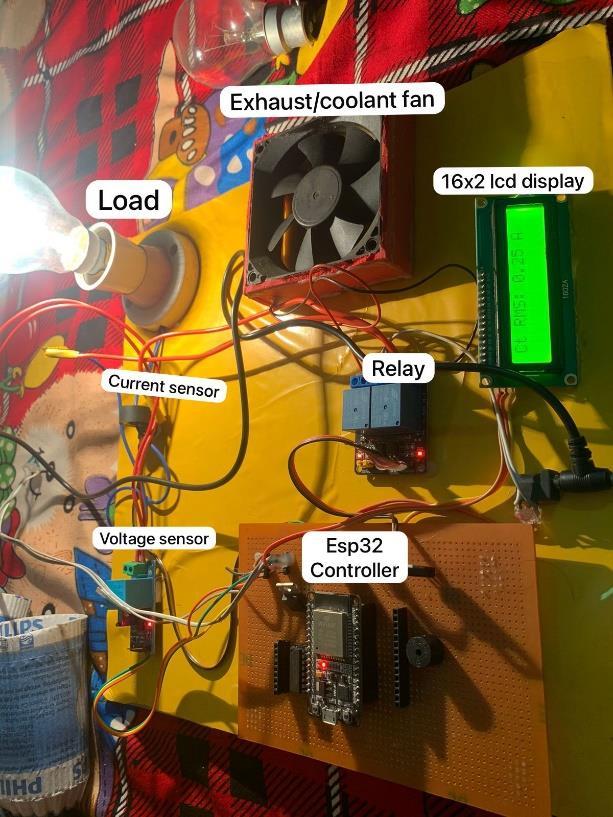

As thevitallink between digitalcontrol systems and physical processes, sensors are essential parts of contemporary industrial systems. Temperature, pressure, humidity, vibration, and chemical concentrations are just a few of the physical factors that these sensors detect and monitor. They then translate these observations into electrical signals so that they may be processed and evaluated. Since sensors offer the real-time data required for monitoring and managing industrial activities, their accuracy and dependability are crucial. High-tech sensors, frequently combined with Internet of Things technologies, allow for constant data gathering and smooth connection with centralized controlsystems. This makes predictive maintenance easier, increases operational effectiveness, and guarantees safety and compliance in industrial settings.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:11Issue:05|May2024 www.irjet.net p-ISSN:2395-0072

4.3.WORKINGPRINCIPLE

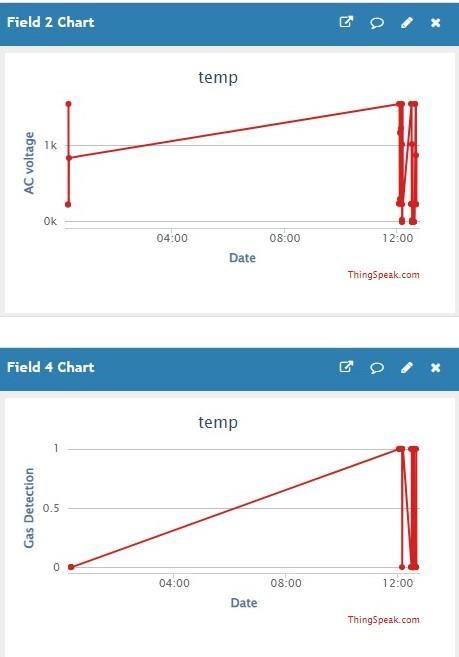

The data collection, transmission, processing, and feedback processes are all incorporated into the operation of the Internet of Things-based industrial parameter monitoringandcontrolsystem.Important variables like temperature, pressure, and humidity are measured by sensors placed in industrial settings, and these readings are translated into electrical impulses. Using protocols like MQTT or HTTP, these signals are wirelessly sent to cloud platforms or central processing units. Real-time data analysisisdonebysophisticatedalgorithmsthatspot trends and abnormalities. Actuators receive control signals based on this analysis, which are used to automatically modify process settings. The feedback loop in the system ensures constant monitoring and real-time modifications, and the user interfaces offer alerts and dashboards for manual intervention as needed. This method improves industrial operations' dependability,safety,andoperationalefficiency.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:11Issue:05|May2024 www.irjet.net p-ISSN:2395-0072

The integration of IoT in industrial parameters monitoring and control represents a significant advancement in modern industrial operations. By leveraging real-time data acquisition, advanced analytics, and automated control mechanisms, IoT systems enhance operational efficiency, safety, and reliability. The comprehensive framework of IoTbased solutions enables continuous monitoring, predictive maintenance, and immediate response to deviations, thereby minimizing downtime and optimizingresourceutilization.

Despite the clear benefits, the adoption of IoT in industrial settings is not without challenges. Issues related to data security, interoperability, and scalability need to be addressed to ensure robust and seamless integration. ongoing investigation and improvement are focused on overcoming these hurdles, with promising advancements in encryption, standardized protocols, and AI-driven analytics.

In conclusion, IoT-based industrial parameters monitoring and control systems hold the potential to revolutionize industrial processes, aligning with the objectives of Industry 4.0. The future of industrial operations lies in the successful deployment of these technologies, fostering innovation and maintaining competitive advantage in the global industrial landscape. Continued research and collaboration among industry stakeholders will be crucial in realizing the full potentialofIoTinindustrialapplications.

ThefuturescopeofIoT-basedindustrial parameters monitoring and control is expansive and promising, driven by continuous technological advancements and increasing industry demands for efficiency and precision. Key areas for future development and researchinclude:

1. Integration with Advanced Technologies: The Internet of Things' (IoT) convergence with machine learning (ML) and artificial intelligence (AI) will greatly improve predictive analytics and the capacity for independent decisionmaking. Large volumes of data produced by Internet of Things (IoT) devices can be analyzed

by AI algorithms to forecast equipment breakdowns, enhance maintenance plans, and boostworkflowefficiency.

2. Enhanced Data Security and Privacy: As IoT devices proliferate in industrial environments, ensuring data security and privacy becomes paramount. Future research will focus on developing robust encryption methods, secure communication protocols, and comprehensive cybersecurity frameworks to protect sensitive industrialdatafromcyberthreats.

3. Scalability and Interoperability: Taking on the difficulties of scalability and interoperability is crucial for the widespread adoption of IoT systems. Standardization of communication protocols and development of scalable IoT architectures will enable seamless integration across diverse industrial systems and facilitate the deployment of IoT solutions in large-scale industrialoperations.

4. Edge Computing: The implementation of edge computing in IoT systems will reduce latency and bandwidth usage by processing data closer to the source. This will enhance real-time monitoring and control capabilities, particularly in environments where immediate response timesarecritical.

5. Energy Efficiency: IoT systems in the future will have to focus on energy efficiency to ensure sustainable operations. Research will likely explore low-power IoT devices and energyharvestingtechnologiestoextendthebatterylife of sensors and reduce the overall energy footprintofIoTdeployments.

6. Smart Manufacturing and Industry 4.0: IoT will play a crucial part in advancing the principles of Industry 4.0, driving the development of smart factories where interconnected machines and systems operate autonomously. This will lead to greater customization, flexibility, and efficiency inmanufacturingprocesses.

7. IoT Analytics and Visualization: Enhanced data analytics and visualization tools will provide deeper insights into industrial operations. Future developments will focus on user-friendly interfaces and real-time visualization

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:11Issue:05|May2024 www.irjet.net p-ISSN:2395-0072

dashboards that allow operators to monitor system performance and make data-driven decisionsquickly.

8. Regulatory Compliance and Standards: As IoT technology evolves, so will the regulatory landscape. Making sure that industry norms are followed and regulations will be vital to the safe and effective deployment of IoT systems. Future research will contribute to the development of comprehensive regulatory frameworks that support innovation while ensuring safety and reliability.

We would like to express my gratitude to all those who assisted us finish this study paper on the monitoring and control of industrial parameters usingIoTtechnology.

First and foremost, we would want to express our sincere gratitude to our research mentor/advisor for all of their help and support during the process. Their knowledge and perceptions have greatly influenced the course and emphasis of this investigation.

We also express our gratitude to the organizations and participants who so kindly shared their resources, knowledge, and experience with us, making it possible for us to collect the information andunderstandingweneededforourstudy.

We also like to thank our peers and colleagues for their contributions, since they offered insightful criticism and recommendations throughout this project.

1. Gubbi, J., Buyya, R., Marusic, S., & Palaniswami, M. (2013). Internet of Things (IoT): A vision, architectural elements, and future directions. Future Generation Computer Systems, 29(7), 1645-1660.

2. Lee, I., & Lee, K. (2015). The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Business Horizons, 58(4), 431440.

3. Qin, J., Liu, Y., & Grosvenor, R. (2016). A Categorical Framework of Manufacturing for Industry4.0andBeyond.ProcediaCIRP,52,173178.

4. Kang, H. S., Lee, J. Y., Choi, S., Kim, H., Park, J. H., Son, J. Y., Kim, B. H., & Do Noh, S. (2016). Smart manufacturing: Past research, present findings, and future directions. International Journal of Precision Engineering and Manufacturing-Green Technology,3(1),111-128.

5. Sicari, S., Rizzardi, A., Grieco, L. A., & CoenPorisini, A. (2015). Security, privacy and trust in Internet of Things: The road ahead. Computer Networks,76,146-164.

6. Thibaud, M., Chi, H., Zhou, W., & Piramuthu, S. (2018). Internet of Things (IoT) in high-risk Environment, Health and Safety (EHS) industries: A comprehensive review. Decision SupportSystems,108,79-95.

7. Bagheri, B., & Yang, S. (2018). Cyber-physical systems architecture for self-aware machines in industry 4.0 environment. IFAC-PapersOnLine, 51(11),1625-1630.

8. Al-Fuqaha, A., Guizani, M., Mohammadi, M., Aledhari, M., & Ayyash, M. (2015). Internet of Things: A survey on enabling technologies, protocols, and applications. IEEE Communications Surveys & Tutorials, 17(4), 2347-2376.

9. Wang, Y., Ma, H., Wang, L., Zhang, H., & Zhao, W. (2020). Towards a framework for data-driven intelligent manufacturing based on the integration of IIoT, cloud, and AI. Journal of Manufacturing Systems, 56, 251-261.