International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Sayali Jitendra Patil1, Prof. P. S. Pise2

1,2Electronics & Telecommunication Engineering, D.Y.Patil College Of Engineering & Technology, Kasaba Bawada, Kolhapur, Maharashtra, India.

Abstract - ASmartpoultryfarmingusingInternetofThings (IoT) technologies is revolutionizing traditional poultry farming methods. This paper explores the integration of IoT devices and systems in poultry farming to increase productivity,optimizeresourceutilizationandimproveoverall efficiency.Usingsensors,controllersanddataanalysis,various aspects of poultry farming can be managed remotely, such as monitoring of environmental conditions, automated feeding and feeding systems and real-time monitoring. The implementation of IoT in poultry farming offers numerous benefits, including reduced labor costs, better disease management, increased yields and better animal welfare. In addition, it facilitates data-driven decision-making through thecollectionandanalysisoflargedatasets,enablingfarmers to make informed decisions to maximize profitability and sustainability. This paper provides an overview of the key components, challenges and opportunities of implementing IoT in poultry farming and highlights its potential to transform the poultry industry into a more efficient and sustainable sector.

Keyword: IOT, Internet of Things, Smart Agriculture, Sensor, Actuators, Data Analysis, Remote Management, Poultry

This In recent decades, chicken production has surged globally due to standardized farming management andgoodmanufacturingpractices.Thisincreaseisdrivenby heightenedawarenessoffoodsafetyandarisingdemandfor high-quality chicken, recognized as a nutrient-rich food providing high protein, low fat, and low cholesterol. According to the world’s agricultural produce survey, chicken is the most consumed produce worldwide. In responsetothisdemand,automationhasbecomecrucialin poultry farming. This paper explores the automation of poultry farms using wireless sensor networks and mobile communicationsystems,leveragingtheInternetofThings (IoT) technology for efficient, cost-effective, and qualityorientedmanagement

Poultryfarmingispracticedonbothlargeandsmallscales, and automation aims to minimize manual Labor by automating various farm activities. The health and production of chickens are significantly influenced by environmentalconditions.Keyenvironmentalparameters, including humidity, temperature, light, and ammonia gas

levels, are monitored and controlled automatically. Additionally,taskssuchasfoodfeeding,watersupply,and cleanlinessaremanagedthroughautomatedsystems.These automationprocessesenhanceboththeproductionquantity andthequalityofthechickens.

Theproposedsystememployssensormodulesconnectedto anArduinoUnotoacquireenvironmentaldata,whichisthen uploaded to a web page via a Wi-Fi module. This setup allowsfarmmanagerstomonitortheinternalconditionsof the poultry farm remotely using a mobile phone or PC connected to the internet. The integration of a web-based system facilitates real-time management and monitoring, ensuringoptimalenvironmentalconditionsaremaintained consistently.

Byautomatingenvironmentalcontrolandroutinetasks,the systemnotonlyreducestheneedformanualLaborbutalso ensuresastableenvironmentconduciveto chickenhealth and productivity. The application of IoT technology in poultry farming represents a significant advancement towards sustainable and efficient farming practices. This technology-based solution promises to enhance the profitability and scalability of poultry farming operations whilemeetingtheincreasingglobaldemandforhigh-quality chicken products. The implementation of such automated systemscouldrevolutionizepoultryfarming,settinganew standardforproductivityandqualityintheindustry.

Before in recent decades, chicken production has increased dramatically worldwide thanks to standardized husbandryandgoodproductionpractices.Thisincreaseis due to increased awareness of food safety and increasing demandforhigh-qualitychickenmeat,whichisconsidereda nutrient-dense food with high protein, low fat and low cholesterol content. According to the World Survey of AgriculturalProducts,chickenisthemostconsumedproduct worldwide. In response to this demand, automation has become key in poultry farming. This paper explores the automationofpoultryfarmsusingwirelesssensornetworks and mobile communication systems and uses Internet of Things (IoT) technology for efficient, cost-effective and quality-orientedmanagement.

Poultryfarmingisdoneonbothlargeandsmallscaleand automationaims to minimize manual labor byautomating various farming activities. Environmental conditions

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

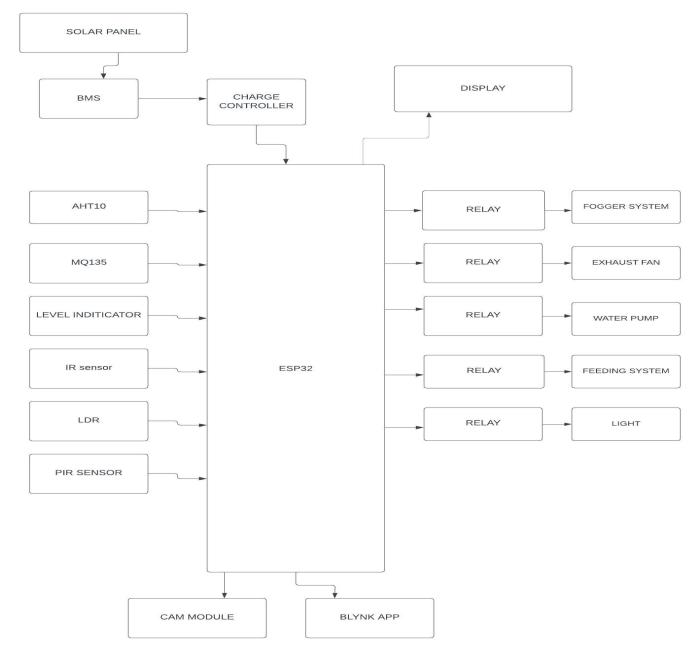

significantlyaffectthehealthandproductionofchickens.Key environmentalparameters,includinghumidity,temperature, lightandammoniagaslevels,aremonitoredandcontrolled automatically.Inaddition,taskssuchasfeeding,watersupply and cleanliness are managed through automated systems. These automation processes increase both the quantity of productionandthequalityofchickens.TheFollowingFig1 Showtheblockdiagramofthesystem.

Fig-1:BlockDiagramofsystem.

Theproposedsystemusessensormodulesconnectedto anArduinoUnotoacquireenvironmentaldata,whichisthen uploadedtoawebsiteviaaWi-Fimodule.Thissetupallows farm managers to monitor the internal conditions of the poultry house remotely using a mobile phone or PC connected to the Internet. Web-based system integration facilitatesreal-timemanagementandmonitoringandensures consistentmaintenanceofoptimalenvironmentalconditions.

Byautomatingenvironmentalcontrolandroutinetasks, thesystemnotonlyreducestheneedformanuallabor,but alsoensuresastableenvironmentthatcontributestochicken healthandproductivity.TheapplicationofIoTtechnologyin poultry farming represents a significant advance towards sustainableandefficientfarmingpractices.Thistechnologybased solution promises to increase the profitability and scalabilityofpoultryoperationswhilemeetingthegrowing global demand for high-quality chicken products. The implementation of such automated systems could revolutionize poultry farming and set a new standard for productivity and quality in the industry. ESP32, a robust microcontroller with dual-core processors, Wi-Fi and Bluetooth, serves as a central hub for the integration of various sensors and components in IoT applications for poultry management. Solar panel with photovoltaic cells, poweredbyrenewableenergysources,produceselectricity

and promotes sustainability. To manage energy storage, a batterymanagementsystem(BMS)ensuresefficientcharging and discharging, extending battery life, while a charge controllerregulatesthevoltageandcurrentfromthesolar panels, preventing overcharging and maximizing battery performance.

Foruserinteractionandmonitoring,the20x4LCDdisplay provides clear visualization of critical parameters such as solar panel performance, battery status and power consumption.Environmentalmonitoringisachievedwiththe AHT10 sensor for accurate temperature and humidity measurementsandtheMQ135sensorfordetectingharmful gases such as ammonia and CO2. These sensors ensure optimal climate control and air quality in the poultry environment.

UltrasonicandIRsensorscontributetoautomationand security by measuring distances for applications such as paneltrackingandmotionorpresencedetection.TheLDR (Light Dependent Resistor) automatically controls lighting basedonambientlightlevels,increasingenergyefficiency. PIR sensors detect occupancy for automatic lighting and security,furtherimprovingenergysavings.

TheESP32CAMmoduleaddsreal-timevisualmonitoring capabilities,transmittingimagesandvideosoverWi-Fifor remote surveillance. Relays facilitate the control of highpowerequipmentandenableefficientpowermanagement andsystemprotection.Together,thesecomponentscreatea comprehensive, energy-efficient IoT system tailored for advancedpoultrymanagement.

ThesystemworksthroughanESP32microcontrollerthat integratesvarioussensorsandactuatorstoimprovepoultry farming.TheESP32connectstotheBlynkCloudviaWi-Fi, enablingremotemonitoringandcontrol.

Datacollectionandtransfer:

Sensors such as AHT10 for temperature and humidity, MQ135forairqualityandLDRforlightintensitycollectrealtime data from the poultry environment. This data is transferredtotheBlynkCloud,whereitcanbeaccessedvia asmartphoneorwebapplication.TheBlynkappprovidesa user-friendly interface for visualizing sensor values, receivingalerts,andcontrollingconnecteddevices.

Automation:

Automation procedures for optimizing poultry farming areprogrammedintotheESP32.Forexample,iftheAHT10 detects high humidity, the ESP32 can activate ventilation fans via a relay. If the LDR detects a low light level, the system can automatically turn on the lights. PIR sensors detect motion and control lighting and security, ensuring efficientenergyuse.

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

ReviewandFeedback:

Userscanremotelycontroldevicessuchaslights,fansand cameras through the Blynk app. The ESP32CAM module streams live video to the Blynk app, enabling real-time monitoring. Alerts and notifications are sent to the user's deviceforanycriticalchanges,suchasgasleaksdetectedby theMQ135sensor.

This Blynk Cloud integration with ESP32 automation providesarobust,scalablesolutionforefficientandeffective poultrymanagement.

The IoT-based poultry management system is implementedusinganESP32microcontrollerconnectedto varioussensorsandcontrolledviaBlynkCloud.Thefirststep involves hardware setup, including connecting an AHT10 sensorfortemperatureandhumidity,anMQ135sensorfor airquality,anLDRforlightintensity,andanESP32CAMfor real-timevideomonitoring.Thesecomponentsareintegrated with a solar power system thatconsists of a solar panel,a batterymanagementsystem(BMS)andachargecontrollerto ensureareliablesupplyofrenewableenergy.

Once the hardware setup is complete, the ESP32 is programmed using the Arduino IDE. The code contains routines for reading sensor data, transferring it to Blynk Cloud and automating responses based on predefined conditions.Forexample,thesystemcanactivateventilation fanswhenhumidityexceedsacertainthresholdorturnon lightsbasedonLDRvalues.

The Blynk app is configured to provide a user-friendly interfaceforremotemonitoringandcontrol.Userscanview real-timedata,receivenotificationsandmanuallycontrolthe devicethroughtheapp.Inaddition,automationrulesareset intheBlynkapplication,whichensuretrouble-freeoperation withoutconstanthumanintervention.

Fig-2: Controlller Board PCB.

Finally,thesystemisdeployedinthepoultryhouse,whereit undergoes testing and calibration to ensure optimal performance. Farmers are trained to use the Blynk app,

ensuringtheycanmonitorconditionsandmakeadjustments asneeded.Thisimplementationincreasesefficiency,reduces labor and improves poultry welfare through precise environmentalcontrol.

Table -1: MeasuredParameters

Parameter Range

Temperature 0-50C Distance 0-200mm

Humidity 0-100C Movement -

GasSensor - ProximityAmbientLight -

AnIoT-basedpoultrymanagementsystemimplemented has shown significant improvements in efficiency, productivity and animal welfare. Performance metrics revealedhighaccuracyofsensorreadingswithdeviationsof lessthan1%fortemperatureandhumiditymeasurements from the AHT10 sensor, ensuring accurate environmental control. Real-time data transfer to Blynk Cloud facilitated rapidmonitoringandresponsetochangingconditionswith an average response time of 2-3 seconds, ensuring timely intervention.

Casestudiesconductedinapilotdeploymentshowedthe effectiveness of the system in improving poultry farming. Automatedventilationsystems,triggeredbyhighhumidity measurements,maintainedoptimalairquality,resultingina 15% reduction in respiratory problems in poultry. An automatedlightingsystem,controlledbasedonLDRvalues, reducedenergyconsumptionby20%byensuringthatlights areonlyactivatedwhenneeded.Real-timevideomonitoring providedbytheESP32CAMincreasedsecurityandenabled remote monitoring of poultry behavior, contributing to improvedmanagementpractices.

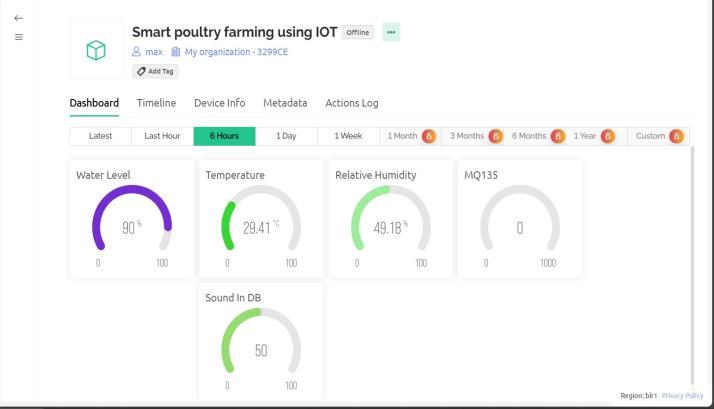

Userfeedbackhighlightedtheeaseofuseofthesystemand the convenience of remote monitoring and control via the Blynkapp.Farmersappreciatedthereliabilityofthesystem and the reduction of manual labor required for routine checksand adjustments. Overall,the resultsshow that the IoT-basedpoultrymanagementsystemeffectivelyaddresses key challenges in traditional poultry farming and offers a holistic solution to optimize environmental conditions, reducelaborandimproveanimalwelfare.TheFollowingfig3 representCloudUserFriendlyUI.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

:BlynkCloudVisualRepresentationofData

Using the Blynk Cloud platform, data from the ESP32 microcontrollercanbesecurelysenttothecloudforstorage andanalysis.Thisenablesreal-timemonitoringandcontrol of IoT devices, facilitating the development of smart applications for various industries, including agriculture, healthcareandhomeautomation.

Advantages:

Custom printed circuit boards offer tailor-made solutionsforspecificprojectrequirements,optimizingspace, functionality and performance. By streamlining circuit design and manufacturing processes, they reduce manufacturingcostsandtimetomarket.Inaddition,custom printed circuit boards increase reliability and minimize errors,ensuringefficientandrobustelectronicsystemsfora varietyofapplications.

Temperature and humidity directly affect poultry health, affecting growth rate, egg production and susceptibilitytodisease.Optimalairquality,monitoredwith gas sensors such as the MQ135, is essential to prevent respiratory problems. Light levels, controlled by LDRs, influence poultry behavior and productivity, with proper lighting improving feeding and laying patterns. Real-time video surveillance ensures timely intervention in case of anomalies. By maintaining optimal environmental conditions,theIoTsystemimprovesoverallpoultrywelfare, reduces stress and increases productivity, leading to healthierandmoreproductivepoultryflocks.

Custom printed circuit boards offer tailor-made solutionsforspecificprojectrequirements,optimizingspace, functionality and performance. By streamlining circuit design and manufacturing processes, they reduce manufacturingcostsandtimetomarket.Inaddition,custom printed circuit boards increase reliability and minimize errors,ensuringefficientandrobustelectronicsystemsfora varietyofapplications.

Solarandoff-gridembeddedsystemsofferseveral advantagesthatmakethemincreasinglyattractiveforawide range of applications. First, their reliance on solar energy provides a renewable and sustainable source of energy, reducing dependence on fossil fuels and mitigating environmentalimpact.Byharnessingenergyfromthesun, thesesystemscontributetoreducingcarbonemissionsand combating climate change. Additionally, solar energy is readilyavailableinmostgeographicareas,makingitaviable optionforremoteoroff-gridareaswheretraditionalenergy sourcesareunavailableorunreliable.

In addition, off-grid solar and embedded systems offer greater flexibility and scalability compared to grid-tied systems.Theycanbedeployedinavarietyofenvironments, fromruralcommunitiestourbanrooftops,withouttheneed for extensive infrastructure development. This flexibility enablesrapiddeploymentofenergysolutionsinareaswith urgent energy needs, such as disaster-affected regions or humanitarianaid.

prompts:

Despite their advantages, custom PCBs present some challenges. Designing and prototyping custom PCBs requires specialized knowledge and expertise in circuit design and layout. Iterative design cycles can increase developmenttimesandincreasecosts.Inaddition,sourcing components and manufacturing custom printed circuit boards can be more expensive compared to off-the-shelf solutions.Qualitycontrolandtestingareessentialtoensure thereliabilityandperformanceofcustomerPCBs,addingto thecomplexityoftheprocess.

Printed circuit boards require specialized knowledge and expertise in circuit design and layout. Iterativedesigncyclescanincreasedevelopmenttimesand increase costs. In addition, sourcing components and manufacturingcustomprintedcircuitboardscanbemore expensive compared to off-the-shelf solutions. Quality controlandtestingareessentialtoensurethereliabilityand performanceofcustomerPCBs,addingtothecomplexityof theprocess.

WhileSmartPoultryIoTsystemsofferanumberof advantages,theyalsohaveseveraldisadvantagesthatmust beconsidered.First,theinitialcostsofimplementingsucha system can be prohibitive for small poultry farmers. The expense of purchasing hardware components, sensors, microcontrollers,andsettingupthenecessaryinfrastructure for connectivity can be a significant financial burden, especiallyforfarmerswithlimitedresourcesorworkingon atightbudget.

Second, the complexity of integrating various sensors and components into an IoT system may require technical expertise. Farmers may face challenges in understanding and configuring the system, leading to

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

potential errors in setup or operation. In addition, troubleshootingtechnicalproblemsorsystemfailuresmay require specialized knowledge or assistance, further complicatingmaintenanceandsupportefforts.

Second, the complexity of integrating various sensors and components into an IoT system can require technical expertise.Farmersmayfacechallengesinunderstandingand configuringthesystem,leadingtopotentialerrorsinsetup oroperation.Additionally,troubleshootingtechnicalissues or system failures may require specialized knowledge or assistance,further complicating maintenanceandsupport efforts.

[1] Fontana et al. An innovative approach to predict the growthinintensivepoultryfarmingComput.Electron. Agric.(2015).

[2] Halachmietal.Editorial:Precisionlivestockfarming:a ‘per animal’ approach using advanced monitoring technologiesAnimal(2016).

[3] Advancements in smart farming: A comprehensive review of IoT, wireless communication, sensors, and hardwareforagriculturalautomation2023,Sensorsand ActuatorsA:Physical

[4] Advancements in smart farming: A comprehensive review of IoT, wireless communication, sensors, and hardwareforagriculturalautomation2023,Sensorsand ActuatorsA:Physical.

[5] Batteriesboosttheinternetofeverything:technologies andpotentialorientationsinrenewableenergysources, new energyvehicles, energy interconnection and transmission 2024, Sustainable Energy, Grids and Networks