THE EMPIRICAL INVESTIGATION OF LIGHTWEIGHT CONCRETE VIA THE UTILIZATION OF VARIED WASTE MATERIALS

Kamal Kumar Singh1, Mr. Ushendra Kumar2

1Master of Technology, Civil Engineering, Lucknow Institute of Technology, Lucknow, India

2Head of Department, Department of Civil Engineering, Lucknow Institute of Technology, Lucknow, India

Abstract - Foam is used in the production of Cell Lightweight Concrete (CLWC) with a density ranging from 400 kg/m3 to 1950 kg/m3. CLWC is suitable for non-load bearing applications due to its lightweight nature and insulatingproperties.Toenhanceitsstrength,materialslike fly ash and silica fume are added during production. Lightweight concrete requires a mix of concrete, fine aggregates, coarse aggregates, silica fume, fly ash, and aluminum powder as an air-entraining agent. It offers compressive and flexural strengths comparable to standard concrete. The advantages of lightweight concrete include reduced need for additional weight, increased productivity, and lower costs in handling and transportation. It is considered a versatile material in the construction industry, suitable for various applications such as multi-story buildings, floors, partition walls, and roof structures. Key features of lightweight concrete include compressive strength, water absorption, optimal material thickness, and the precise water content needed for cohesion between water and cement. It maintains its integrity under significant stresses and environmental changes. The limited understanding of CLWC properties and safety aspects has hinderedits widespreaduse. Excessivewaterusagecanlead to runoff from aggregates, potentially compromising structural integrity. Lightweight concrete is seen as a valuable material in construction, offering efficiency and versatilityinvariousbuildingcomponents.

Key Words: Lightweight concrete, Waste materials, Sustainability, Empirical investigation ,Fly ash, Recycled aggregates.

1.INTRODUCTION

Lightweight concrete, an innovative material in construction,offersa compellingalternativetotraditional concrete. Composed of lightweight aggregates such as expanded clay, shale, or slate, it possesses a reduced densitywhilemaintainingstructuralintegrity.Thisunique composition makes it ideal for various applications, from building foundations to architectural elements. One of its primary advantages lies in its weight-saving properties, significantlyreducingthestructuralloadonbuildingsand thus minimizing the need for extensive foundation systems. Additionally, its thermal insulation properties contribute to energy efficiency in structures, reducing heating and cooling costs. Moreover, lightweight

concrete's ease of handling and placement enhances construction efficiency, speeding up project timelines and reducinglaborcosts.Assustainableconstructionpractices gain momentum, the use of lightweight concrete further alignswithenvironmentallyconsciousbuildinginitiatives, owing to its lower carbon footprint compared to traditional concrete. In essence, the adoption of lightweightconcreterepresentsasignificantstepforward in modern construction, offering a versatile, efficient, and eco-friendly solution for building projects of varying scales.

1.1.Importance of Lightweight Concrete

Lightweight concrete plays a pivotal role in modern construction due to its numerous benefits and applications. Its importance lies in its ability to address key challenges faced in the construction industry. Firstly, lightweight concrete significantly reduces the overall weight of structures, thereby easing the burden on foundations and structural supports. This characteristic notonly enhancesthestructuralintegrityofbuildingsbut alsoallowsformoreinnovativeandcost-effectivedesigns. Additionally, the thermal insulation properties of lightweight concrete contribute to improved energy efficiency, leading to reduced heating and cooling expensesoverthelifespanofabuilding.Moreover,itsease of handling and placement streamlines construction processes, leading to shorter project timelines and decreased labor costs. As sustainability becomes increasinglyimportantinconstruction,the environmental benefitsoflightweightconcrete,includingitslowercarbon footprint compared to traditional concrete, further highlight its importance. In essence, lightweight concrete representsavaluablesolutionforaddressingtheevolving needs of the construction industry, offering versatility, efficiency, and sustainability in building projects worldwide.

1.2.Purpose of Lightweight Concrete

The purpose of lightweight concrete is multifaceted, serving various needs and objectives within the realm of construction.Primarily,its mainobjectiveistoreducethe overall weight of structures. By utilizing lightweight aggregates such as expanded clay, shale, or slate, lightweightconcreteachievesalowerdensitycomparedto

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

traditional concrete while maintaining its strength. This decrease in weight significantly eases the structural load on buildings, resulting in more cost-effective designs and minimizing the necessity for extensive foundation systems. Another essential function of lightweight concrete is its thermal insulation properties. Its composition enables enhanced energy efficiency in buildings by offering superior insulation against heat transfer. This feature aids in regulating indoor temperatures, lessening the requirement for excessive heating or cooling and subsequently reducing energy consumption and operational costs throughout the lifespan of a structure. Lightweight concrete facilitates easy handling and placement during construction. Its reduced density makes it simpler to transport, lift, and maneuver on-site, leading to quicker construction processes and decreased labor expenses. Moreover, its malleabilityallowsformoreintricatearchitecturaldesigns and versatility in construction methods. Lightweight concrete is in line with sustainability objectives in the construction industry. Its utilization contributes to diminishing the overall carbon footprint of buildings due to the decreased energy consumption during transportationandconstruction,aswellasitspotentialto integraterecycledmaterials.

2.IMPROVEMENT OF THE LIGHTWEIGHT CONCRETE

Lightweight concrete has seen significant improvements inrecentyears,enhancingitsperformanceandexpanding itsapplicationsinconstruction.Keyadvancementsinclude the development of high-strength lightweight aggregates, which provide better load-bearing capabilities while maintaining reduced density. Innovations in mix design haveoptimized the balance between weight and strength, incorporating supplementary cementitious materials like fly ash and silica fume to improve durability and sustainability. Additionally, the use of advanced admixtures has increased workability and reduced water

demand, leading to better curing and reduced shrinkage. These enhancements make lightweight concrete an attractive option for modern construction, offering benefits such as improved thermal insulation, reduced structuralload,andgreaterseismicresistance.

3.STRENGTH OF LIGHTWEIGHT CONCRETE

Thestrengthoflightweightconcretehasbeensignificantly enhanced through various technological advancements and material innovations. Historically, lightweight concrete was primarily valued for its reduced density, which provided advantages in terms of weight reduction and insulation. However, recent developments have enabledtheproductionoflightweightconcretewithmuch higher strength, making it suitable for a broader range of structural applications. Key factors contributing to the improvedstrengthoflightweightconcreteinclude:

3.1.High-Strength

Lightweight Aggregates

The use of high-strength lightweight aggregates such as expanded clay, shale, and slate has been pivotal. These aggregates have a porous structure that reduces the overall density of the concrete while maintaining or even enhancingcompressivestrength.

3.2.Optimized

Mix Designs

Advances in mix design have allowed for a better balance between strength and weight. Incorporating supplementary cementitious materials like fly ash, silica fume, and slag not only enhances the strength but also improvesdurabilityandsustainability.

3.3.Advanced Admixtures

The introduction of high-performance admixtures has significantly improved the properties of lightweight concrete. Superplasticizers, for instance, enhance workability without increasing water content, leading to higher strength. Additionally, the use of air-entraining agentscanimprovefreeze-thawresistance,contributingto long-termdurability.

3.4.Innovative Curing Techniques

Improved curing techniques, such as steam curing and autoclaving, have been employed to accelerate the strength gain and improve the overall quality of lightweight concrete. These methods help achieve higher early strength, which is beneficial for construction timelines.

3.5.Fiber Reinforcement

The incorporation of fibers (such as steel, glass, or syntheticfibers)intolightweightconcretecansignificantly

Figure-01: Lightweight Concrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

enhanceitstensilestrengthandductility,providingbetter performance under load and reducing the likelihood of cracking.

4.UTILIZATION OF THE WASTE MATERIAL FOR LIGHTWEIGHT CONCRETE

The utilization of waste materials in the production of lightweight concrete has gained significant attention due to its environmental benefits and potential cost savings. By incorporating waste products, the concrete industry can reduce its environmental footprint, promote sustainability, and create innovative materials that enhance the properties of lightweight concrete. Here are severalkeywastematerialsbeingusedeffectively:

4.1.Fly Ash

Abyproductofcoalcombustioninpowerplants,flyashis widely used as a partial replacement for cement in concrete. It improves workability, reduces water demand, enhances strength, and increases durability. Its use also helps in reducing the environmental impact of cement production.

4.2.Blast Furnace Slag

Thisbyproductoftheironandsteelindustrycanreplacea portion of the cement in concrete. Slag improves the compressiveandtensilestrength,increasesdurability,and enhancesresistancetochemicalattack.Italsocontributes to a lower carbon footprint compared to traditional cement.

4.3.Recycled Concrete Aggregate (RCA)

Crushedconcretefromdemolishedstructurescanbeused asaggregateinnewconcrete.RCAcansignificantlyreduce waste in landfills and decrease the demand for virgin aggregates. Whenusedinlightweightconcrete,RCAhelps tomaintainstructuralintegritywhilereducingweight.

4.4.Expanded Polystyrene (EPS) Beads

Waste EPS, commonly found in packaging materials, can be ground into beads and used as lightweight aggregate. This addition provides excellent thermal insulation propertiesandreducestheoveralldensityoftheconcrete. However, care must be taken to ensure proper bonding andstrength.

4.5.Rice Husk Ash

Theashproducedfromburningricehuskscanbeused as a supplementary cementitious material. It improves the strength and durability of concrete and enhances resistance to chemical attack. Utilizing rice husk ash also addresseswastedisposalissuesinrice-producingregions.

4.6.Crushed Glass

Waste glass, when crushed and used as aggregate, can enhancetheaestheticappealanddurabilityoflightweight concrete.Italsocontributestothereductionofglasswaste inlandfills.Properprocessingisnecessarytoavoidalkalisilica reaction (ASR) that can compromise concrete integrity.

4.7.Plastic Waste

Recycled plastic materials, including polyethylene terephthalate (PET) and polypropylene (PP), can be used as aggregates in lightweight concrete. These plastics help reducethedensityand improve the thermal properties of the concrete. The challenge lies in ensuring adequate bonding between the plastic aggregates and the cement matrix.

4.8.Paper Sludge Ash

Generated from paper recycling processes, paper sludge ash can be used as a partial replacement for cement. It enhances the workability and reduces the environmental impactofconcreteproduction.

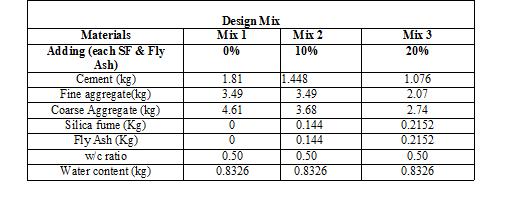

5.MIX DESIGN FOR CUBE

The form that was constructed out of cast iron and included a design that allowed for the projection of a sizeable variety of distinct iterations in a variety of contexts was that which we are referring to here. It is a vital factor to consider when figuring out the concrete's compressive strength because of the function it plays in theprocess.

6.RESULT AND ANALYSIS

Byincorporatingadditivessuchassilicafumeandflyash, one can obtain a premium and cost-effective fundamental element that is lightweight, commonly known as lightweight cement, post completion of all essential production inspections. Moreover, this fundamental element can be denoted as lightweight cement. In the event that all other options have been exhausted without

Table-1: Mix Design for Cube

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

success, high compressive strength can be achieved by blendingpreciseproportionsofconcrete,sand,silicafume, aggregates,andflyash.Comparedtoconventionalcement, it will offer reduced overall cost, diminished dead load in the central region, enhanced fire resistance and strength, as well as improved environmental friendliness. Furthermore, itwillexhibitgreaterdurability.Therugged natureofconcreteisinfluencedbyvariousfactors,suchas properquantities,blending,andmixingofcomponents,as well as the collection, transportation, and placement of said constituents. It has been observed that the water-tocement ratio plays a vital role in the required blend, strength, setting duration, and usability of the mixture. The lower the amount of water and heat utilized during the curing process, the more advantageous and timeeffectiveitwillbefromtheoutset.Water-to-cementratios rangingfrom0.45to0.5arecommonlyemployed,asthey fallwithintheoptimalrange.

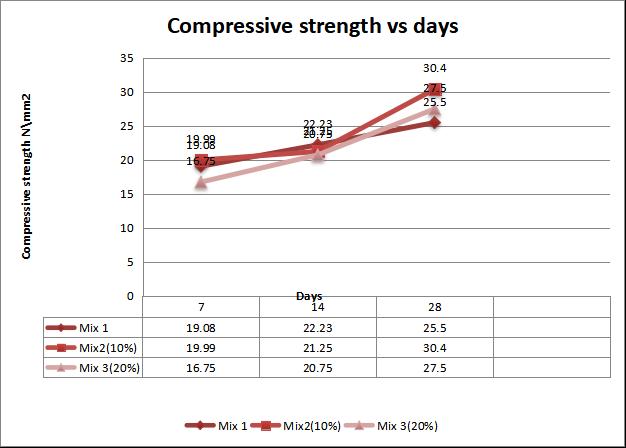

6.1.Compressive Strength Test

Concrete provides virtually solid surfaces, which makes it easier to apply pressure to the material. The stage in the process of quality control known as "the process of determining the substantial compressive strength of concrete" is an important one, and the Compression TestingMachineisoneoftheinstrumentsthatareusedin this step of the process. For the testing of hardened specimens at 7, 14, and 28 days following the initial testing, the form type that has a diameter of 15 centimeters, a distance across 150 millimeters, and a heightof300millimetersis theonethatisemployed.The next paragraphs illustrate the preliminary results of compressive strength tests conducted on conventional concrete and lightweight concrete. These tests were carriedouttocomparethetwotypesofconcrete.

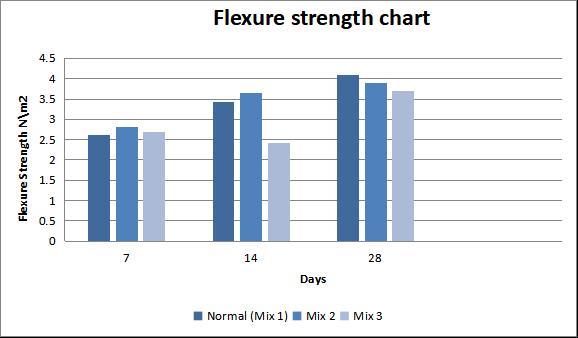

6.2.Flexure Strength

Thesupportpointsizeof500mmx100mmx100mmisused to choose the flexural strength of concrete. The testing of concrete changing IS 516, for the method for the testing procedure. The flexural test evaluates the flexibility of concrete by suggestion. It tests the limit of unreinforced concrete footers or lumps to get through disillusionment inturning.

7. CONCLUSION

In comparison to traditional cement, Cell Lightweight Concrete offers cost savings through waste reduction, increasedfireresistanceandstrength,andalowercarbon footprint. The durability of concrete is derived from its aggregates, mixing ratios, blending, transportation, and curing process. The crucial mix design, strength characteristics, curing time, and overall quality of the concretearesignificantlyinfluencedbythewatercontent. Additionally, Cell Lightweight Concrete is typically lighter thanregularcement duetotheincorporationoffrothasa base,aswellastheadditionof10%to20%silicafumeand fly ash to enhance its properties. The total admixtures incorporated into Mix 2 account for 10% of the total weight, while in Mix 3 it is 20%, with silica fume and fly ash contributing 10% and 20% of the total weight, respectively. Due to the higher number of admixtures in Mix 2, and the fact that both silica fume and fly ash are accelerating admixtures, this results in a shorter initial setting time, faster development of compressive strength, greater durability, and exceptional workability compared toMix3.

REFERENCE

1) Potential of Waste Material as Coarse Aggregates for Lightweight Concrete Production: A Sustainable Approach. Potential of Waste Material as Coarse Aggregates for Lightweight Concrete Production: A SustainableApproach.

Figure-02: Compressive Strength Test

Figure-03:Flexure Strength Test

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

2) The Effect of Expanded Glass and Crushed Expanded Polystyrene on the Performance Characteristics of Lightweight Concrete. The Effect of Expanded Glass and Crushed Expanded Polystyrene on the PerformanceCharacteristicsofLightweightConcrete. AppliedSciences.

3) Exploring the Effect of Different Waste Fillers in Manufactured Sustainable Plastic Aggregates Matrix on the Structural Lightweight Green Concrete. Exploring the Effect of Different Waste Fillers in Manufactured Sustainable Plastic Aggregates Matrix on the Structural Lightweight Green Concrete. Sustainability.

4) Lightweight Heat Resistant Concrete Panels Using Recycled Materials. Lightweight Heat Resistant Concrete Panels Using Recycled Materials. IOP ConferenceSeries:EarthandEnvironmentalScience.

5) Experimental investigation and optimization of lightweight concrete bricks developed using vermiculite. Experimental investigation and optimization of lightweight concrete bricks developedusingvermiculite.FrontiersinMaterials.

6) A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar. A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar. OpenEngineering.

7) Utilization of waste materials as a substitute for the sand drain in clayey soil. Utilization of waste materials as a substitute for the sand drain in clayey soil.InternationalJournalofGeo-engineering.

8) Study on Properties of Concrete After Incorporating Waste Materials. Study on Properties of Concrete After Incorporating Waste Materials. IOP Conference Series.

9) A Sustainable Alternative for Green Structural Lightweight Concrete: Performance Evaluation. A Sustainable Alternative for Green Structural Lightweight Concrete: Performance Evaluation. Materials.

10) UtilizationofRecyclableConcreteandCeramicWaste as Filling Material in Hot Mix Asphalt. Utilization of Recyclable Concrete and Ceramic Waste as Filling Material in Hot Mix Asphalt. Periodica PolytechnicacivilEngineering.

11) Utilization of modified plastic waste on the porous concrete block containing fine aggregate. (n.d.). Utilization of modified plastic waste on the porous

concreteblockcontainingfineaggregate.85(4),143–151.

https://doi.org/10.11113/jurnalteknologi.v85.19219

12) Study of the Compressive Properties of Heavy Calcium Carbonate-Reinforced Epoxy Composite Spheres (HC-R-EMS) Composite Lightweight Concrete. (n.d.). Study of theCompressive Properties of Heavy Calcium Carbonate-Reinforced Epoxy Composite Spheres (HC-R-EMS) Composite Lightweight Concrete. 15(5), 1278–1278. https://doi.org/10.3390/polym15051278

13) The Use of Lightweight Aggregate in Concrete: A Review. (2022). The Use of Lightweight Aggregate in Concrete:AReview.28(11),1–13.

14) Recycled Construction and Demolition Waste as Supplementary Cementing Materials in Eco-Friendly Concrete. (n.d.). Recycled Construction and Demolition Waste as Supplementary Cementing Materials in Eco-Friendly Concrete. 8(4), 54–54. https://doi.org/10.3390/recycling8040054

15) Analisis Pengaruh Penambahan Kaolin Sebagai SubtitusiSemenTerhadap KuatTekanBetonRingan. (n.d.).AnalisisPengaruhPenambahanKaolinSebagai SubtitusiSemenTerhadap KuatTekanBetonRingan. 11(1).https://doi.org/10.36982/jtg.v11i1.2804

16) Experimental Investigation on Mechanical and Thermal Properties of Concrete Using Waste Materials as an Aggregate Substitution. (n.d.). Experimental Investigation on Mechanical and Thermal Properties of Concrete Using Waste Materials as an Aggregate Substitution. 15(5), 1728–1728.https://doi.org/10.3390/ma15051728

17) Uso de materiales ligeros para la producción de hormigón de baja densidad: una revisión literaria. (2022). Uso de materiales ligeros para la producción dehormigóndebaja densidad:unarevisiónliteraria. 12(1), 90–101. https://doi.org/10.22320/07190700.2022.12.01.06

18) Experimental Investigation of Recycled Fine Aggregate from Demolition Waste in Concrete.(n.d.). Experimental Investigation of Recycled Fine Aggregate from Demolition Waste in Concrete. 14(17), 10787–10787. https://doi.org/10.3390/su141710787

19) Alkali Activated Concrete using Industrial and Agro Waste-Mix proportioning and Experimental Investigation. (n.d.). Alkali Activated Concrete using Industrial and Agro Waste-Mix proportioning and Experimental Investigation. 1, 1327–1331. https://doi.org/10.38208/acp.v1.659

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN:2395-0072

20) Alkali Activated Concrete using Industrial and Agro Waste-Mix proportioning and Experimental Investigation. (n.d.). Alkali Activated Concrete using Industrial and Agro Waste-Mix proportioning and Experimental Investigation. 1, 1327–1331. https://doi.org/10.38208/acp.v1.659

21) The Effect of Finely-Grinded Crushed Brick Powder on Physical and Microstructural Characteristics of Lightweight Concrete. (n.d.). The Effect of FinelyGrinded Crushed Brick Powder on Physical and Microstructural Characteristics of Lightweight Concrete. 12(2), 159–159. https://doi.org/10.3390/min12020159

22) Sustainable Materials Used as Lightweight Aggregate :(An Overview). (n.d.). Sustainable Materials Used as Lightweight Aggregate :(An Overview). 961(1), 012027–012027. https://doi.org/10.1088/17551315/961/1/012027

23) Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber. (2022). Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber. 11(1), 58–70. https://doi.org/10.1515/nleng-2022-0008