International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 05 | May 2023 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 05 | May 2023 www.irjet.net

1,2,3,4 Student, Chemical Engineering, D. Y. Patil College of Engg & Tech, Kolhapur Maharashtra, India

5* Professor, Chemical Engineering, D. Y. Patil College of Engg & Tech, Kolhapur Maharashtra, India

***

Abstract - In recent year the demand of food has been increased by increasing population. Our basic need is to be consume food from plants. But our plantsarenot safebecause, lots of bugs and insects damage and destroy our plant. Solution on this problem is natural pesticide. Due to increases in the industrialization use of synthetic product has been increased. But they give adverse healtheffect andalso damage our environment. Now, in this situation we needto usenatural pesticide and they obtain from natural resources like aswaste leaves, cow urine, and various extracted oil from leaves and seeds. In this paper we use method of extraction of oil from custard apple seeds. After extraction of oil purify and separation of solvent with the help of distillation. And finally, we manufacture the pesticide using purified oil with the help of emulsifier as Labolene soap.

Key Words: Oil Extraction, Distillation, Custard apple seed, Pesticide.

Pesticide:

Pesticideassubstancesthatweareappliedtokillundesired organisms.Inadditionaltohelpingtomaintainsoilfertility and boost agricultural yield, pesticides are essential for protecting crops from insect assault. In other term “Pesticide” refers to any substance used to prevent, eliminate, repel, attract or diminish pest organisms. Pesticidebothnaturalandsynthetic,naturalpesticidesare thosepesticidewhichweusefromancienttime.Peopleswho are constantly exposed to pesticide during use they can benefit from using natural pesticides, which are less expensive and more secure. It is created from natural ingredientssuchascowurine,wasteleaves,seedoilandso on. It benefits soil fertility as well as biodegradable. Synthetic pesticide has become more popular in recent years. As agricultural productivity increases, soil fertility decreases. Bio control is the most effective method for dealing with chemical losses. Oil extracted from custard appleseedusingvarioussolventlikehexane,benzene,ethyl acetate etc. Further studies focused for the formulation, modificationanddeterminationofsomepossibleproperties ofoil.

Custard Apple Seed:

Annonasquamosa(Custardapple),alsoknownas“Sitaphal”, is one of the most delicious fruits brought to India from

tropical America. It is widely available in various parts of India,includingAndhraPradesh,Assam,Bihar,Karnataka, Maharashtra,Orissa,TamilNadu,andWestBengal.Custard appleseedsare toxic,bitter andcan be used aspesticides and fish poison. Cancer treatment involve the use of seed pest. Custard apple seed have confirmed that the major active chemical constituents are annonaceous acetogenins and cyclopeptides. Seed have been shown to have strong antibacterial, anti-ovulatory, anti-inflammatory, anti-thyroidal and other properties.Duetoacetogeninsgroupofpowerful respiratoryinhibitingtoxiccomponentwhichisresponsible foroilactaspesticide.

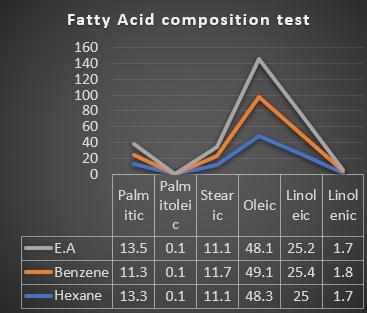

Custardappleseedoilcontainfollowingacidswhichshows antioxidantpropertiesasshowninfollowingTable(1)

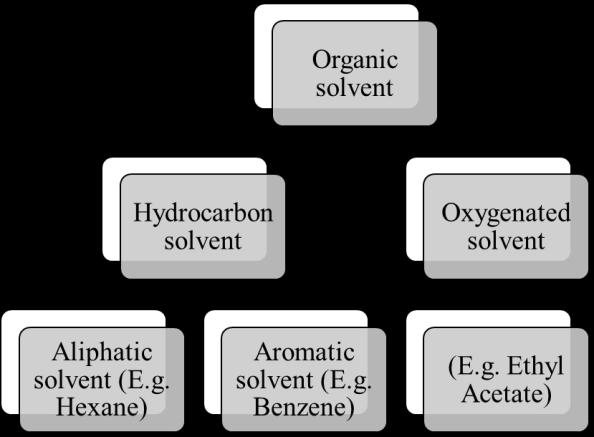

Solvent Selection:

Itisnecessarytoselecta propersolventfor extraction. In thispaper,wehavecarriedoutcomparativelystudyofthree differentsolvents.Whichiseconomicalforenvironment.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

dependingonthematerialsandcomponentsinvolvesaswell asthedesiredoutcomeofthextraction.

Tincture:

Tincture isan extraction processinvolvesusinga solvent, typicallyalcohol,toextracttheactivecompoundsfromplant material.Tincturesareconcentratedliquidextractthatare commonly used in medicine, pharmaceutical and otherapplications.

Solvent extraction:

Cost of solvent:

Cost is one of the important factor while choosing the solvent. We have to choose the solvent which is less expensiveandhavingmoreefficiencyofextractionofoil.

2. Review of various methods of oil extraction

Cold pressing:

Coldpressingisamechanicalextractionprocess,alsocalled as mechanical separation process. Cold pressing is an extraction method in that method we extracting oils from varioussourcesincludingolives,fruits,seedsorgroundnuts without any external heat and chemical solvents. Cold pressingprocessiscarriedoutatlowtemperatures,typically below120°F.Itisalsousedintheproductionoffreshjuices fromfruitsandvegetables.

Maceration:

Maceration extraction process is a simple and traditional method used to extract desired compounds from solid materialusingaliquidsolvent.Itinvolvessoakingthesolid material in the solvent for a certain period, allowing the solventtodesiredandextractthecomponentsitisrelatively straightforwardandiscommonlyfortheextractionoffood andbeverageindustries

Percolation:

Percolationextractionprocessisamethodusedtoextract desired compounds from solid material using a liquid solvent.Itinvolvestheflowofthesolventthroughthesolid material.Itiscommonlyusedinvariousindustriesincluding pharmaceutical,foodproduction.

Infusion:

Infusionisanextractionprocessinvolvesextractingdesired components from a solid material using a liquid medium. Thistechniqueiscommonlyusedtoextractflavor,aromas, and other natural ingredients. This process may vary

Solvent extraction is the process in which a compound transfersfromonesolventtoanotherowingtothedifference in solubility or distribution coefficient between thus two immiscible(orslightlysoluble)solvents.

Oil Extraction (Soxhlet apparatus method):

Raw materials and apparatus:

Round bottom flasks, condenser, thermometer, heating mental, beaker (500ml), measuring cylinder, weighing balance, seed crusher, seed powder, filter paper, hexane, benzene,ethylacetate.

Solvents

Procedure:

Takethecustardappleseedswashanddryandcrushed them.

Take40gofseedpowder.

Take300mlsolventinroundbottomflask.

InsertitintoSoxhletApparatus.

Set the circular round bottom flask on the heating source.

Roundbottomflaskshouldbeconnectedatthebottom withtheSoxhletapparatusaboveitandthecondenser atthetop.

For the starting extraction process Firstly, heat the round bottom flask according to the boiling point of respectivesolvents.

Whenheatingprocessbegan,vapourstobegenerated andmovedupward,andfinallycondensed.

The condensed solvent is drip in to the Soxhlet apparatus.

After filling the siphon tube with solution (solvent) comingintotheroundbottomflask.

Thisextractionprocessiscontinuouslyworkfor2 –3 hrsafterthatweremovethemixtureandfiltered.

Thisfilteredsolutionisuseforfurtherprocess.

Thenflaskisattachedwithcondenser.

Afterthatitisheatuptosolventboilingpoint.

After solutionis heated, vapoursare formed and thus vapourspassthroughthecold-watercondenser.

Condensedvapourisoursolventwhichiscollectedin thebeakerandremainingsolutionintheroundbottom flaskisanoil.

.

Production of natural pesticide from oil:

Raw material & Apparatus:

Custard apple seeds oil, Labolene soap, water, measuring flask,spraygun.

Procedure:

Firstly,takeanoilsampleinvariousquantity.

Mix the specific quantity of the water with specific sampleofoilandLabolenesoap.

Thenwellmixedthemixtureofoilandwater.

Afterthatmixtureistakeintothespraygun.

Thismixtureissprayonaplantasapesticidewhichare harmfulforthebugsandinsects.

Weobservethepesticidesprayedplantforfewdays.

Analysetheoilpropertiesbyusingfollowingformulae

Simple distillation

Firstly,filteredmixtureisaddedinroundbottomflask.

Chemical properties of

Afterapplyingpesticideonaplant.Weobservetheeffectof thepesticideonplantfor5days.Inthesedayswelearnthat ourpesticideiseffectonplantisslowly.Fordestroythebugs andinsectsweneed5 days.Thoseare the result ofthat 5 days.

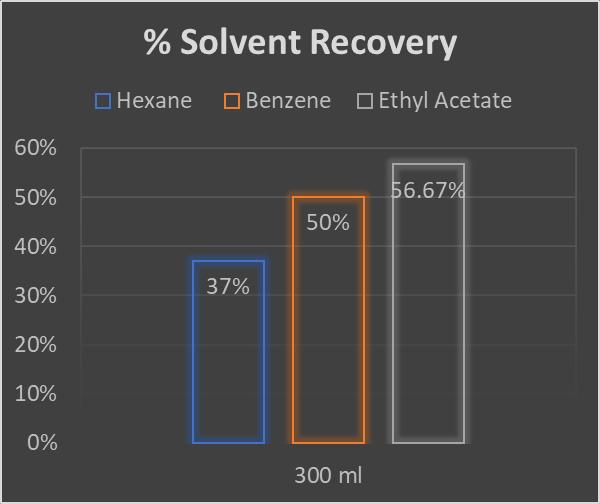

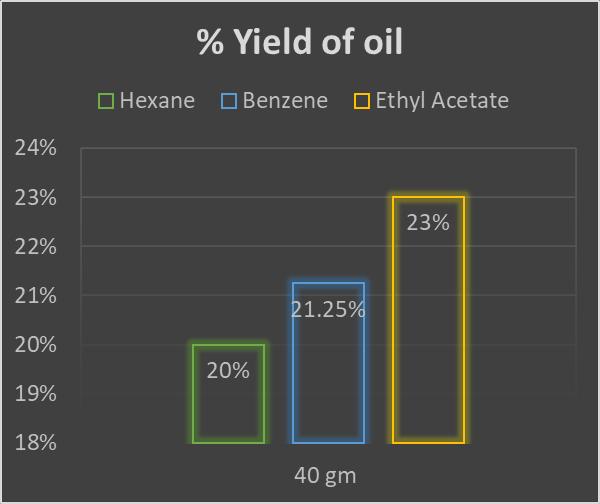

oilyieldisabout20–23%andsolventrecoveryofbenzene is 61 – 64 %. This raw material will be very inexpensive, loweringtheoverallprocessingandsolventrecoverycost.

[1].ShubhamM.Patil,RohanD.Gaykar,“Manufacturingof naturalpesticidefromcustardappleseeds”Departmentof Chemical Engg, Bharati Vidyapeeth college of Engg, Navi Mumbai,April2022,IJIRT,Vol.8issue11,ISSN:2349–6002

[2].PrashantBhosale,DhirajDevikar,RutikGodase,Aniket Jhondhale,“Extractionandseparationofcustardappleseed oilasanaturalpesticide”DepartmentofChemicalEngg,P. Dr V. V. Patil, Poly college, Loni, Dist – Ahmednagar, May 2022,IJSREM,Vol.6issue05,ISSN:2582–3940

[3].VedantLal,SwapnilBansi,RugvedDeshpande,“Custard appleseedoilasapesticide”DepartmentofChemicalEngg, Thadomal Shahani Engg college, Mumbai, August 2021, IJOEAR,Vol.7issue8,ISSN:2454–1850

[4].RajSuryawanshi,VikasKusalkar,MaheshBhabad,“Bio–pesticidefromcustardappleseed”DepartmentofChemical Engg, Pravara Enggcollege, Loni,Ahmednagar,May 2022, IJARSCT,Vol.2issue7,ISSN:2581–9429

[5].SikdarD.C,SushmitaKushary,RoshneeDas,“Evaluation ofeffectivenessofecofriendlybiopesticideextractedfrom custard apple seed on white mealy bugs” Department of ChemicalEngg,DayanandaSagarcollegeofEngg,Bangalore, March–April2016,IJTRA,Vol.4issue2,ISSN:2320–8163

[6].VaishaliS.Ghoderao,“Effectofbiopesticidefromcustard appleseedsonwhitemealybugs”DepartmentofChemical Engg, J.D.I.E.T, Yavatmal, May 2020, IRJET, Vol.7 issue 05, ISSN:2395–0056

[7]. Ajay V. Gawali, Sapna K. Deotale, Tousf Y. Shaikh, “Annona Squamosa: A source of natural pesticide” DepartmentofChemicalEngg,A.E.C,Chikhli,January2017, IARJSET,Vol.4issue3,ISSN:2393–8021

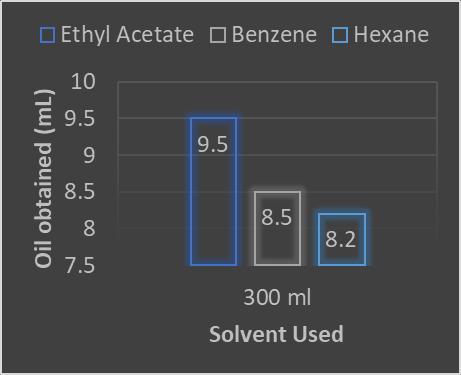

Natural pesticide made from custard apple seed oil has shown to be effective, affordable, and non-toxic. By using differentsolventsthataresoldinthemarket,weareableto recover the pesticide from the seed. Without much additionalwork,thisnaturalpesticidematerialcanbemade easilyaccessibletoallformercitizensofIndia.Thecostof theraw material will be extremelylow, whichwill reduce theoverallprocessingandsolventrecoverycosts.Thiswill be for a different synthetic option. Manufacturing is more affordablethanothernaturalpesticides.

Wecanconcludethatcustardappleoilderivedfromcustard appleseediscosteffectiveandeasytomanage.Itrecovered toabout63 – 65 % while using ethyl acetateasa solvent. Ethylacetateoilisrecoveredduringextractionisaround25 –29%.Aswellasifweusebenzeneasasolventthanweget

[8]. Kalpesh P. Borole, Jayprakash R. Sirsath, Swapnil M. Bhonde,RushikeshD.Sable,“Extractionofoilfromcustard apple seeds” Department of Chemical Engg, J.D.I.E.T, Yavatmal,IJFEAT,Vol.4issue1,ISSN:2321–8134

[9] ShamsulMazalan,“Extractionofcustardappleseedoil to produce natural pesticide” Politeknik & Kolej Komuniti Journaloflifelonglearning,Vol.5issue1,ISSN:2600-7738