International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

1Mangesh Anil Deshmukh

1

Senior Project Manager, Tata Technologies Ltd, Pune

***

Abstract - The Four-Wheel Steering (4WS) system is an advanced automotive technology designed to enhance vehicle stability, maneuverability, and handling by enabling the rear wheels to steer in conjunction with the front wheels. Unlike conventional steering systems, where only the front wheels turn, 4WS adjusts the rear wheels' steering angle based on vehicle speed and driving conditions. This paper presents a comprehensive analysis of the 4WS system, focusing on its design principles, operational mechanisms, and mathematical calculations. The design ofthe 4WS systemintegrates complex control algorithms that determine the optimal rear wheel steering angle to minimize the turning radius at low speeds and enhance stability at higher speeds. The mathematical model derived in this study calculates the turning radius as a function of both front and rear steeringangles, wheelbase, and vehicle dynamics. The analysis demonstrates that at low speeds, the rear wheels turn in the opposite direction to the front wheels, significantly reducing the turning radius and improving maneuverability. Conversely, at high speeds, the rear wheels turn in the same direction as the front wheels, enhancing directional stability. The findings highlight the effectiveness of 4WS in improvingoverallvehicle performance, making it a valuable addition to modern automotive design.

The handling performance of contemporary production vehicleshasreachedanadvancedstagewhereanyfurther enhancements require innovative approaches. To address thischallenge,weinvestigatedafour-wheelsteering(4WS) systemandidentifieditspotentialtosignificantlyimprove drivercontrolandsteeringperformance,especiallyinhighspeedscenarioswhereprecisehandlingiscrucial.Thekey advantageof4WSliesinitsabilitytosteertherearwheelsin thesamedirectionasthefrontwheels,enhancingstability andreducingtheturningradiusathighspeeds.

Atlowspeeds,however,differentconsiderationscomeinto play.Toimprovemanoeuvrabilityandmakeparkingintight spaceseasier,itisbeneficialfortherearwheelstosteerin the opposite direction to the front wheels. This countersteeringeffectreducestheturningradius,makingthevehicle more agile and easier to handle in confined areas. The challenge in developing an effective 4WS system lies in balancingtheseopposingrequirements ensuringthatthe rear wheels steer oppositely at low speeds for better manoeuvrabilityandinthesamedirectionathighspeedsfor improvedstability.

Toachievethis,thesystemmustadjusttheratiooftherear wheelsteeringanglerelativetothefrontwheelanglebased onvehiclespeedandsteeringinput.Athigherspeeds,where thefrontwheelsteeringangletendstobesmaller,steering the rear wheels in the same direction as the front wheels providessimilarbenefits.However,whenthesteeringwheel angle exceeds a certain threshold, the system should automaticallyreverse therearwheel steering direction to maintaincontrolandstability.

This report explores the optimal rear wheel steering characteristics for a 4WS system, delving into the key considerations and principles underlying its design. The effectivenessofthisinnovativesteeringsystemisvalidated through extensive testing, demonstrating its significant impact on vehicle performance across different driving conditions

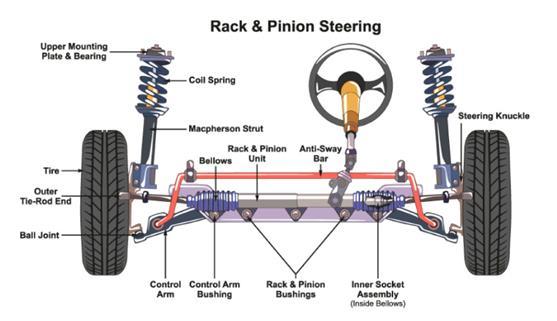

Thefront-wheelsteeringsystemisthemostcommontypeof steeringmechanisminvehicles,controllingthedirectionof thecarbyturningthefrontwheels.Theprocessbeginswhen thedriverturnsthesteeringwheel,whichisconnectedtoa steeringcolumn.Thiscolumn,essentiallyashaft,transmits the rotational input from the steering wheel down to the steeringmechanism.Therotationofthesteeringcolumnis crucial as it converts the driver's manual input into mechanicalforcethatdirectsthewheels.

At the heart of this system is the steering gearbox, also known as the steering rack or steering gear. The steering gearbox'sprimaryroleistoconverttherotationalmotionof thesteeringwheelintolinearmotion,whichmovesthefront wheels left or right. There are two main types of steering gearboxes.Therackandpinionsystem,whichiscommonin mostpassengervehicles,involvesaroundgear(thepinion) meshing with a flat gear (the rack). As the steering wheel turns, the pinion rotates, moving the rack sideways and steering the wheels. The recirculating ball system, often found in trucks and heavier vehicles, uses ball bearings to reduce friction as the steering wheel turns a worm gear, whichthenmovesasectorgearconnectedtothepitmanarm.

Thesteeringgearboxisconnectedtothewheelsthrougha seriesoflinkages,includingtierodsandcontrolarms.These linkagesensurethatthemovementgeneratedbythesteering gearisaccuratelytransmittedtothewheels.Thetierodsplay

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

acriticalroleinthisprocess,connectingthesteeringgearbox to the steering knuckles, which are attached to the front wheels. When the steering gear moves the tie rods, the steeringknucklespivot,causingthewheelstoturn.

In the context of wheel alignment, three angles caster, camber,andtoe affectthesteeringsystem'sperformance.

1:DavisSteeringSystemLinkages

When viewed from the side of the vehicle, angle of the steeringaxisisknownasCaster.Itisthetiltofthesteering axisforwardorbackward,anditplaysasignificantroleinthe stabilityandsteeringresponseofthevehicle.Positivecaster, wherethetopofthesteeringaxistiltstowardtherearofthe vehicle,improvesstraight-linestabilityandhelpsthesteering wheel return to center after a turn. However, excessive positivecastercanmakesteeringheavier,especiallyatlow speeds.

Camberreferstotheangleofthewheelswhenviewedfrom thefrontofthevehicle.Ifthetopofthewheeltiltsinward,it's callednegativecamber;ifittiltsoutward,itspositivecamber. The camber angle affects tire wear and cornering performance. Negative camber is often preferred in performancecarsbecauseitkeepsthetireflatontheroad during cornering, improving grip. However, too much negativecambercancauseuneventirewear.

Toeistheangleatwhichthetirespointinwardoroutward whenviewedfromabove.Toe-inoccurswhenthefrontofthe tires point toward each other, while toe-out is when they pointawayfromeachother.Thetoesettingaffectstirewear, handling,andstraight-linestability.

Toe-ingenerallyenhancesstraight-linestabilitybutcanlead to increased tire wear. Toe-out can improve cornering responsebutmightmakethevehiclefeellessstableathigh

speeds.ThusToeinisusuallyusedinvehiclesdesignedfor highspeedstabilitylikesedansorhighwayvehicleswhereas Toe out is used in vehicle having requirement of high maneuverability.

1.2.1 Davis steering mechanism

TheDavissteeringmechanism,reliesonaconfigurationthat introduces friction and weardue to its use of sliding pairs instead of turning pairs. This results in a system that can becomeinaccurateovertime,whichisasignificantdrawback.

DetailedDescriptionoftheDavisSteeringMechanism:

1. SlidingPairs:Themechanismemploysslidingpairs, whichinherentlygeneratemorefrictioncompared toturningpairs.Thisfrictioncauseswearandtear onthecomponents,leadingtodecreasedaccuracyin thesteeringovertime.

ComponentLayout:

1. Cross-Link CD: This is a sliding link that moves paralleltoanotherlink,AB.

2. BellCrankLevers(LACandMBD):Thecross-linkCD isconnectedtothestubaxlesofthefrontwheelsvia twobellcranklevers,LACandMBD.Theseleversare pivotedatpointsAandB,respectively.

3. SlidingPairsatEndsCandD:Theendsofthecrosslink CD (points C and D) are designed as sliding pairs,allowingthelinktoslidewithinitsbearings.

OperationalMechanics:

1. Mid Position of Gear: When the vehicle is moving straightahead,thesteeringgearisconsideredtobe in its mid position. This is a crucial position, as it represents the neutral state of the steering mechanism.

2. CrossArmAngle(��):Theaccuracyandeffectiveness of the Davis steering mechanism depend on the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

appropriate selection of the cross arm angle, denotedby��.Thecorrectvalueofthisangleensures thatthesteeringremainspreciseandeffectiveunder normaloperatingconditions.

The correct steering depends on selecting a suitable cross arm angle (��). This angle determines how effectively the mechanismcanmaintainproperwheelalignment,ensuring that the vehicle steers accurately even as the components experiencewear

Where,cisthedistancebetweenpivotsoffrontaxleandbis wheelbase.��liesbetween11.3°and14.1°.

TheDavissteeringmechanismistheoreticallycorrectbutis inefficient in practical due to presence of more sliding membersthewearisincreased,thusbecominginaccurate. Hence,thissystemisnotusedcommonly.

1.2.2

TheAckermansteeringmechanismiswidelyusedinvehicles due to its simplicity and effectiveness in ensuring proper wheel alignment during turns. This steering mechanism is designed togeometricallyarrange thesteeringlinkagesso thattheinnerandouterwheelsturnatappropriateangles. Thisalignmentallowsthewheelstofollowthecorrectpath duringaturn,reducingtirewearandimprovinghandling.

ComponentConfiguration:

1. Cross-LinkCD:Thislinkconnectstheshortarmsof the two front wheels. It plays a critical role in maintaining the correct relationship between the wheelsduringsteering.

2. ShortAxlesALandBM:Theshortaxlesofthefront wheelsareconnectedtothecross-linkCDthrough theshortarmsACandBD.

3. BellCrankLevers(LACandMBD):Theshortarms ACandBDformbellcrankleversLACandMBDwith thecross-linkCD.Theselevershelpintransmitting themotionfromthesteeringsystemtothewheels.

4. AnglesandAlignment:Whenthevehicleismoving straight,thecross-linkCDisparalleltothelinkAB. Both short arms AC and BD make an equal angle, denotedby��,withthehorizontalaxisofthechassis.

OperationalMechanics:

1. Straight-LineMotion:Inastraight-linemotion,the anglesmadebytheshortarmsACandBDwiththe chassis are equal, ensuring that the wheels are alignedparalleltoeachother.

2. Turning Motion: During a turn, the mechanism adjusts the angles of the inner and outer wheels, allowing them to turn at different angles. This ensuresthateachwheelfollowsitscorrectcircular path,aprinciplederivedfromthegeometryofthe Ackermansteeringmechanism.

3. Fundamental Equation of Corrected Steering: To ensureaccuratesteering,thelengthsofthelinksAC and BDand the angle ��are carefully selectedand proportioned. This proportionality is crucial for satisfying the fundamental equation of corrected steering,ensuringthatthewheelsturnatthecorrect anglesrelativetoeachother.

Forcorrectsteering,

Relationbetween��,��and∅isgivenby-

Four-WheelSteering(4WS)isanadvancedvehiclesteering technologydesignedtoenhancemaneuverability,stability, andoveralldrivingexperience.Unlikeconventionalsteering systems that control only the front wheels, 4WS systems allow both the front and rear wheels to turn, albeit at differentangles,dependingondrivingconditions.Thisdual controloverallfourwheelssignificantlyimprovesavehicle's handling,especiallyintightspaces,high-speeddriving,and duringsharpturns.

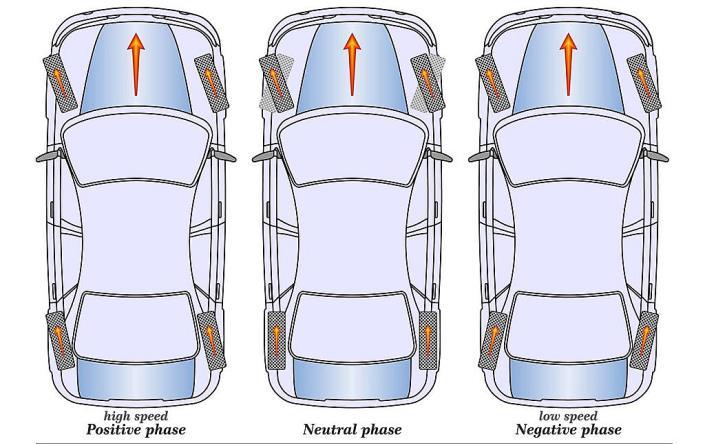

In low-speed situations, such as parking or navigating throughnarrowstreets,therearwheelsturnintheopposite direction to the front wheels. This counter-steering effect reduces the vehicle's turning radius, making it easier to

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

maneuver.Conversely,athigherspeeds,therearwheelsturn inthesamedirectionasthefrontwheels,enhancingstability by reducing the lateral forces acting on the vehicle. This coordinatedmovementprovidesbettertractionandcontrol, particularlyduringlanechangesorsuddenswerves.

The4WSsystemisparticularlybeneficialinlargevehicles, suchastrucksandSUVs, wheremaneuverabilityisoftena challenge. By improving both low-speed agility and highspeed stability, 4WS offers a significant advancement in automotivesteeringtechnology.

2.1.1 Passive Rear-Wheel Steering

PassiveRear-WheelSteeringisasimplertypeof4WSsystem wheretherearwheelsadjusttheiranglesautomaticallyin responsetolateralforcesduringcornering.Thisadjustment happens without active control, providing a slight improvementinhandlingandstability.Thepassivenatureof this system means it requires less complexity and maintenance, but it also limits the level of precision and adaptability, making it less effective compared to active systems.

2.1.2 Active Rear-Wheel

Active Rear-Wheel Steering systems are more advanced, using electronic controls to actively adjust the rear wheel angles based on inputs such as steering wheel position, vehicle speed, and road conditions. This type of system enhances both low-speed maneuverability and high-speed stability.Byactivelycontrollingtherearwheels,thevehicle canrespondmoreeffectivelytodifferentdrivingscenarios, thoughthiscomeswithincreasedcomplexityandcost.

2.1.3

In Opposite-Phase Steering, the rear wheels turn in the oppositedirectiontothefrontwheels.Thisconfigurationis particularlyusefulatlowspeeds,asitreducesthevehicle’s turningradius,makingiteasiertonavigatetightspacessuch asparkinglotsornarrowcitystreets.Thecounter-steering effect allows for sharper turns, greatly improving the vehicle’smaneuverabilityinconfinedareas.

2.1.4

Same-Phase Steering is used primarily at higher speeds, wheretherearwheelsturninthesamedirectionasthefronT wheels.Thisalignmentenhancesthevehicle’sstabilityduring high-speed maneuvers, such as lane changes or sharp cornering,byreducingthelateralforcesactingonthevehicle. The in-phase steering helps the vehicle maintain better controlandreducesbodyroll,contributingtoasmootherand saferdrivingexperienceathigherspeeds.

Hybrid Steering Systems combine the benefits of both opposite-phase and same-phase steering. These systems automaticallyswitchbetweenthetwomodesbasedonthe vehicle’s speed and driving conditions. At low speeds, the system employs opposite-phase steering to improve maneuverability,whileathigherspeeds,itswitchestosamephasesteeringforenhancedstability.Thisversatilityoffers thebestofbothworlds,thoughitalsoaddstothesystem’s complexityandcost.

The Four-Wheel Steering(4WS) system comprises several crucial components that work together to enhance vehicle performance:

1. Vehicle Speed Sensors: Located within the speedometerandatthetransmissionoutput,these sensors measure the speed of the vehicle’s wheel rotationandsendaccuratesignalstotheElectronic ControlUnit(ECU).

2. SteeringPhaseControlUnit:Thisunitsendssignals to the power steering cylinder booster valve, conveying the direction and stroke of rear wheel steeringbyadjustingthecombinedmovementofthe controlyokeangleandbevelgearrevolutions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

3. Electric StepperMotor:Thiscomponentaltersthe yoke angle and bevel gear phasing, allowing for preciseadjustmentstotherearwheelsteering.

4. Rear Steering Shaft: It transmits the front wheel steeringanglebyturningasmallbevelgearinthe steeringplacementcontrolunit,whichthenrotates themainbevelgearintheassembly.

5. Control Valve: This valve regulates hydraulic pressuretothesteeringactuator,ensuringthatthe rear wheel steering is optimized according to the requiredphaseandstroke.

6. HydraulicPowerCylinder:Itdrivestherearwheels using hydraulic pressure and includes a centering lock spring and solenoid valve that lock the rear wheels in a neutral (straightforward) position in case of failure, reverting to a normal two-wheel steeringsystem.

7. Hydraulic Pump: This pump provides hydraulic pressuretoboththefrontandrearsteeringsystems, ensuring consistent performance across different drivingconditions.

TheFour-WheelSteering(4WS)systemfeaturesarack-andpinionfrontsteeringsystem,whichishydraulicallypowered byatwintandempump.Therearwheelsteeringmechanism isalsohydraulicallypowered,usingthemainpump,andis electronicallycontrolledtooptimizeperformancebasedon thefrontsteeringangleandvehiclespeed.Keycomponentsof therearsteeringsysteminclude:

1. RearSteeringShaft:Extendsfromtherackbarofthe front steering gear assembly to the rear steering phasecontrolunit.

2. VehicleSpeedSensors:Measurethevehicle’sspeed tohelpthesystemadjusttherearwheelsteering.

3. Steering Phase Control Unit: Manages the rear steeringsystembyprocessinginputfromthespeed sensorsandcontrollingtherearwheelmovement.

4. Power Cylinder and OutputRod: Operate the rear wheelsusinghydraulicpressuretoensureprecise steeringadjustments.

5. Centering Lock Spring: Locks the rear steering systeminaneutral(straightforward)positionifthe hydraulicsystemfails.

6. Solenoid Valve: Disengages hydraulic assist and activatesthecenteringlockspringintheeventofan electricfailure.

The steering phase control unit is responsible for adjustingthedirectionanddegreetowhichtherearassembly issteered.Keycomponentsandoperationsinclude:

1. Stepper Motor:Controls the rearsteering ratio by adjustingtheangleofthecontrolyoke.

2. ControlYoke:Itsangleisoptimizedbythestepper motor,affectingthesteeringresponse.

3. Swing Arm and Main Bevel Gear: The main bevel gearisattachedtotherearsteeringshaftthrougha smallbevelgear.

4. Control Rod: Connected to the control valve, it translatesthemovementofthemainbevelgearinto steeringadjustments.

5. Control Valve: Function: Receives input from the control rod to regulate hydraulic pressure for the rearsteering.

Operation:Theinputrodofthecontrolvalvemovestothe rightbasedonthecontrolrod'smovement,positioningitto moveupwardsandtotheright.Thisadjustmentresultsinthe rearwheelsbeingsteeredtotheleft,oppositethedirectionof thefrontwheels.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

1. OppositePhaseSteering(Under30kilometersper hour):

When the front wheels are steered to the right, the small bevelgearrotatesinthe“X”directionduetotherearsteering shaft’srotation.

This rotation causes the main bevel gear to turn, which movesthecontrolrodtowardsthecontrolvalve.Thecontrol valvethendirectshydraulicpressuretosteertherearwheels intheoppositedirectionofthefrontwheels,tighteningthe vehicle’ssteeringlock.

2. NeutralPhase(At30kilometersperhour):

Thecontrolyoke’sangleishorizontal(neutral),sotheinput tothecontrolvalveremainsunaffectedbythecontrolrod’s movement.

Inthismode,therearwheelsarenotsteered,maintaininga neutralsteeringalignment.Thisuniteffectivelymanagesthe rearwheelsteeringtoensureoptimalvehiclehandlingunder varyingspeedsandconditions.

3. CALCULATION FOR TURNING CIRCLE DIAMETER OPPOSITE

This is the line diagram for correct four wheel steering mechanism,where

R=radiusofthevehiclefromthepointCGtotheConcurrence point

R1=Distanceb/wtheconcurrencepointandtheaxisofthe vehicle

Φf=Angleoftheouterfrontwheel

Φr=Angleoftheouterrearwheel

Θ

f=Angleoftheinnerfrontwheel

Θr=Angleoftheinnerrearwheel

FrontWheelbase(L_f):Distancebetweenthefrontaxleand thefrontsteeringpivotpoint.

RearWheelbase(L_r):Distancebetweentherearaxleandthe rearsteeringpivotpoint.

Fig 6: IcenterDiagram

ForavehicleequippedwithFour-WheelSteering(4WS),the turningcirclediametercanbesignificantlysmallercompared toavehiclewithonlyfront-wheelsteering.Thisisbecause 4WSsystemsallowforenhancedmaneuverabilitybysteering therearwheelsinadditiontothefrontwheels.

The turning radius RRR in a 4WS system depends on the steering angles and the wheelbase. The effective turning radiuscanbeapproximatedbycombiningtheeffectsoffront andrearsteering.Here’sasimplifiedapproach:

Front-WheelSteeringRadius(R_f):

Rear-WheelSteeringRadius(R_r):

CombinedTurningRadius(R):

TurningCircleDiameter(D)D=2R

4. ADVANTAGES OF 4 WHEEL STEERING ON CONVENTIONAL STEERING SYSTEM

1. EnhancedManeuverability

The Four-Wheel Steering (4WS) system significantly improves maneuverability compared to conventional front-wheel steering systems. By allowing the rear wheels to steer in the opposite direction of the front

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

wheels at low speeds, the 4WS system reduces the vehicle's turning radius. This capability is especially advantageous when making tight turns in confined spaces,suchasparkinglotsornarrowstreets.

2. ImprovedStability

Athigherspeeds,the4WSsystemsteerstherearwheels in the same direction as the front wheels, which enhancesvehiclestabilityduringlanechangesandhighspeed cornering. This coordinated steering helps to maintainastabledrivingtrajectory,improvingoverall handlingandreducingthelikelihoodofskiddingorloss ofcontrol.

3. IncreasedCorneringPerformance

The 4WS system enhances cornering performance by increasing the cornering force when the rear wheels steerinthesamedirectionasthefrontwheelsathigh speeds. This results in better grip and reduced understeer, allowing for more precise and controlled cornering. The improved cornering performance contributestoamoreenjoyableandconfidentdriving experience.

4. ReducedTireWear

Byreducing the turningradius andimproving vehicle stability,the4WSsystemhelpstodistributestressmore evenlyacrossallfourtires.Thisleadstomoreeventire wear during sharp turns and high-speed maneuvers, potentially extending the lifespan of the tires and reducingthefrequencyofreplacements.

5. EnhancedVehicleControl

The4WSsystemimprovesvehiclecontrolbyensuring that all four wheels are optimally aligned for better traction.Thisenhancedtractionisparticularlybeneficial in challenging driving conditions, such as slippery or unevensurfaces,wheremaintaininggripiscrucialfor safedriving.

6. BetterParkingandLow-SpeedManeuvering

Oneofthenotablebenefitsofthe4WSsystemistheease ofparkingandmaneuveringatlowspeeds.Thereduced turning radius makes parallel parking and navigating tightspacesmuchsimplerandmoreefficient,whichis particularly useful for urban driving where parking spacecanbelimited.

7. IncreasedDriverConfidence

Withtheimprovedstabilityandcontrolprovidedbythe 4WS system, drivers experience greater confidence behind the wheel. The enhanced handling and predictable vehicle behavior contribute to a more

comfortable driving experience, allowing drivers to handle various driving conditions with greater assurance.

8. EnhancedSafety

The 4WS system reduces the risk of oversteer and understeerbyoptimizingthesteeringanglesofboththe front and rear wheels. This leads to a safer driving experience by helping to maintain better control and stability during turns and high-speed maneuvers, ultimatelyenhancingoverallroadsafety.

The4WSsystemsignificantlyreducestheturningcircle diametercomparedtoconventionalsteeringsystems.By steeringtherearwheelsintheoppositedirectionofthe frontwheelsatlowspeeds,the4WSsystemallowsfora muchtighterturningradius.Thisreducedturningcircle diameterfacilitateseasiermaneuveringintightspaces and improves the vehicle’s overall agility and parking efficiency.

5. DISADVANTAGES OF 4 WHEEL STEERING ON CONVENTIONAL STEERING SYSTEM

1. IncreasedComplexity

The4WSsystemismorecomplexthantraditionalfrontwheel steering systems. It involves additional components such as rear steering actuators, sensors, andcontrolunits,whichcanincreasethecomplexityof thevehicle'sdesignandmaintenance.

Duetotheaddedcomplexityandtheneedforspecialized components, 4WS systems can be more expensive to manufactureandrepair.Thishighercostcanbereflected in the vehicle's purchase price and maintenance expenses.

3. PotentialforIncreasedMaintenance

Withmorecomponentsinvolved,the4WSsystemmay require more frequent maintenance and inspections

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

comparedtoconventionalsteeringsystems.Issueswith anypartofthesystem,suchassensorsoractuators,can leadtomorecomplicatedrepairs.

4. LimitedOff-RoadCapability

4WS systems are typically optimized for on-road performance and may not be as effective in off-road conditions.Theadditionalsteeringmechanismscanbe more susceptible to damage from rough terrain, potentiallylimitingthevehicle’soff-roadcapabilities.

5. DriverAdjustmentPeriod

Drivers who are accustomed to conventional steering systemsmayneedtimetoadjusttotheuniquehandling characteristicsofa4WSsystem.Thedifferentsteering responses at various speeds might initially feel unfamiliarorrequireaperiodofadaptation.

6. PotentialforMalfunctions

The increased number of components and electronic controlsina4WSsystemintroducesadditionalpointsof potential failure. If a malfunction occurs, it can affect boththefrontandrearsteeringmechanisms,potentially leadingtounpredictablehandlingorreducedsafety.

7. IncreasedWeight

Theadditionalcomponentsrequiredforthe4WSsystem canaddweighttothevehicle.Thisaddedweightmay impactfuelefficiencyandoverallvehicleperformance, although advancements in technology have aimed to minimizethiseffect.

8. ComplexCalibration

Proper calibration of the 4WS system is crucial for optimalperformance.Incorrectcalibrationcanleadto handling issues, such as improper steering angles or reduced effectiveness of the rear-wheel steering, affectingthevehicle'sstabilityandmaneuverability.

Although the 4WS system can reduce tire wear by improving handling, improper system calibration or malfunctioning components can lead to uneven tire wear, particularly if the rear wheels are not aligned correctly.

Four-WheelSteering(4WS)systemsrepresentasignificant advancementinautomotivetechnology,offeringarangeof benefits over traditional front-wheel steering systems. By allowing both the front and rear wheels to steer, 4WS systemsenhancemaneuverability,stability,andcornering performance. However, despite these advantages, the technology also presents several challenges and disadvantagesthatmustbeconsidered.

Oneoftheprimarybenefitsof4WSsystemsistheirabilityto reducethevehicle'sturningcirclediameter.Thisisachieved bysteeringtherearwheelsintheoppositedirectionofthe frontwheelsatlowspeeds,whichallowsformuchtighter turns and easier maneuvering in confined spaces. This feature is particularly useful for urban driving, where parking and navigating tight spaces can be challenging. Additionally,athigherspeeds,therearwheelssteerinthe same direction as the front wheels, enhancing vehicle stability and improving handling during lane changes and high-speedcornering.

Theimprovedcorneringperformanceandreducedtirewear areother notableadvantages.Byincreasingthecornering forceandreducingundersteer,4WSsystemscontributetoa more precise and controlled driving experience. The even distributionofstressonthetiresalsoleadstomoreuniform tirewear,potentiallyextendingtheirlifespanandreducing thefrequencyofreplacements.Enhancedvehiclecontroland increaseddriverconfidencearesignificantbenefitsof4WS systems.Theimprovedtractionandstabilityprovidedbythe systemmakeiteasierfordriverstohandlevariousdriving conditions, including slippery or uneven surfaces. This enhancedcontrolhelpstoreducetheriskofoversteerand understeer, ultimately contributing to a safer driving experience.

Despite these advantages, the implementation of 4WS systems comes with certain drawbacks. The increased complexityofthesystemmeansthatitinvolvesadditional components, such as rear steering actuators, sensors, and control units. This complexity can lead to higher manufacturing and repair costs, as well as potentially increased maintenance requirements. The need for specialized components and calibration also introduces additionalpointsofpotentialfailure,whichcanimpactthe system'sreliability.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Moreover, 4WS systems may be less suitable for off-road driving. The additional steering mechanisms, while beneficialforon-roadperformance,maybemorevulnerable todamagefromroughterrain.Thislimitationcanrestrictthe vehicle’sversatilityandoff-roadcapability.

Anotherconsiderationistheadjustmentperiodrequiredfor driversaccustomedtoconventional steeringsystems.The uniquehandlingcharacteristicsof4WSsystemsmayinitially feel unfamiliar, requiring a period of adaptation to fully utilize the system's benefits. Additionally, improper calibrationormalfunctionscanleadtohandlingissuesand uneventirewear,whichcannegativelyaffectthevehicle's performanceandsafety.

Insummary,Four-WheelSteeringsystemsofferarangeof benefitsthatenhancemaneuverability,stability,andoverall drivingperformance.Theabilitytoreducetheturningcircle diameter, improvecornering,andincreasevehiclecontrol makes 4WS a valuable technology for modern vehicles. However, the increased complexity, higher costs, and potentialmaintenancechallengesmustbecarefullyweighed against these advantages. As automotive technology continues to evolve, ongoing advancements and improvementsin4WSsystemswilllikelyaddresssomeof thesedrawbacks,furtherenhancingtheireffectivenessand practicality.

1. Soni, Aayush, Chhattisgarh Durg, and Shubhrata Nagpal. "Study of four-wheel steering systems viabilityinfutureautomobiles."(2021)

2. Rehan, Ansari, et al. "Design & Synthesis of FourWheel Steering Mechanism." International Refereed Journal of Engineering and Science 6.4 (2017):17-20.

3. Sundar, S., T. Sudarsanan, and Radha Krishnan. "Review of Design and Fabrication of four-wheel Steering system." International Journal of Recent Trends in Engineering & Research (IJRTER) 4.10 (2018):1034-1049.

4. Arunsingh,AbhishekkumarandRajivChaudhary,” Study of 4 Wheel Steering Systems to Reduce Turning Radius and Increase Stability” https://www.researchgate.net/publication/281450 446_Study_of_4_Wheel_Steering_Systems_to_Reduce _Turning_Radius_and_Increase_Stability

5. T.Hiraoka,O.Nishihara,H.Kumamoto,Automatic path-tracking controller of a four”wheel steering vehicle, Vehicle System Dynamics, 47(10), 12051227,2009

6. M.Kreutz,M.Horn,J.Zehetner,“Improvingvehicle dynamics by active rear wheel steering systems”, VehicleSystemDynamics,47(12),1551-1564,2009