International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Pranjal Gupta1 , Shyam Ji1 , Ankit Kumar1 , Zahir Ansari1 , Dr. Rahul Shukla2

1 B .Tech Mechanical Engineering final year , Goel Institute of Technology &Management, Lucknow 2 Assistant Professor, Department of Mechanical Engineering, Goel Institute of Technology &Management, Lucknow ***

Abstract - This paper explores the development and implementation of a electric tiller, designed to enhance agricultural productivity while minimizing environmental impact. Traditional tillers rely on fossil fuels, leading to emissionsandhighoperatingcosts.Theproposed,whichis stored in batteries to power the tiller’s motor. This design offersasustainable,cost-effective,andeco-friendlyalternative forfarmers,especiallyinoff-gridareas.Theobjectiveofthis studyistoassesstheoperational efficiency,energystorage capacity, and long-term viability of the tiller in real-world agriculturalconditions.Bypromotingrenewableenergyusage infarming,thisinnovationsupportssustainableagricultural practices.

Key Words: Soil prepration ,energy efficiency , smart farmingtools,mentanencereduction,sustainablefarming

1.INTRODUCTION

Thedesignandfabricationofanelectricitybasedtillermachine focusoncreatingasustainable,efficienttoolforsoilcultivation. Poweredbyelectricity,itreducesemissionsandofferseaseof operation.Usingelectricmotors,thetillerprovidesconsistent powerwithreducedmaintenance,whileitsergonomicdesign enhancescomfortandsafety,makingitanaccessiblechoicefor small to medium-scale farmers. This project addresses the demand for eco-friendlyagricultural equipment,combining compact design with effective soil preparation for diverse farmingneeds.

1.1

Theelectrictilleroffersseveralkeyfeaturesthatenhanceits appealinmodernagriculture.Itoperatesonelectricpower storedinhigh-capacitybatteries.

Eliminatingtheneedforfossilfuelsandreducingemissions. Thissustainabledesignsignificantlylowersoperatingcosts andmaintenancerequirementscomparedtotraditionalfuelpowered tillers. The machine is lightweight, easy to maneuver,andengineeredforoptimalsoilpenetrationand tillingefficiency.

Toreducethepolutionofsoilandavoidepreservativesand chemicalfromfarmingofMenthaoil.anelectrictillerinrealworldagriculturalsettings.Theresearchaimstodemonstrate howtheelectrictillercanenhanceagriculturalproductivity, reduce environmental impact, and support sustainable farmingpracticesthroughrenewableenergyuse.

Electric tiller machines are ideal for step farming in mountainousregions,suchasAssam'steaplantations.They navigatesteep,narrowterraces,looseningsoilandmanaging weedsefficiently.Theireco-friendly,quietoperationbenefits sensitiveecosystems,promotingsustainableagricultureintea farms and high-altitude terrains, enhancing productivity withoutharmingtheenvironment.

Theearlydevelopmentofpowertillersdatesbacktothemid20thcenturywhenmanufacturersbeganexperimentingwith small engine-powered machines that could provide the benefits of mechanization to smallholder farmers. Diesel engines became the preferred power source due to their reliability,fuelefficiency,andabilitytooperateinavarietyof conditions.Bythe1950s and1960s,JapanandotherAsian countries were pioneers in developing diesel-powered tillers,primarilyforricecultivation.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

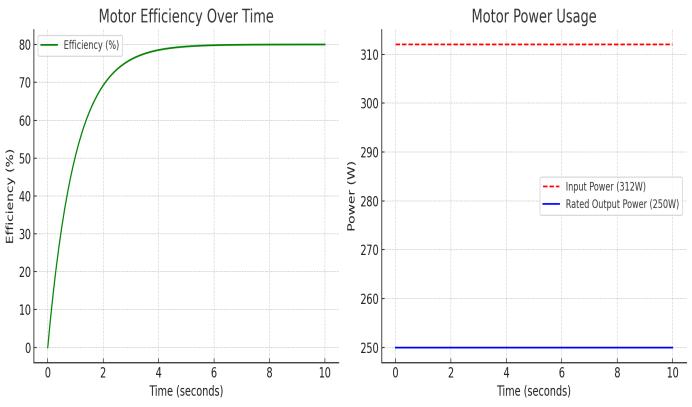

To make the electricity-based tiller machine, weconstruct theframeusing welding toassemblemetalpartsand drilling tocreatemountingpointsforthecomponents.A 24V, 250W DC motor ismountedsecurelyontheframeandconnectedto thetillingbladesviaa sprocket and chain drive foreffective powertransfer.Thebladesaredesignedandmountedona rotating shaft for efficient soil tilling. A 24V rechargeable battery ishousedinaprotectivecompartmenttopowerthe motor,withathrottleinstalledforspeedcontrol

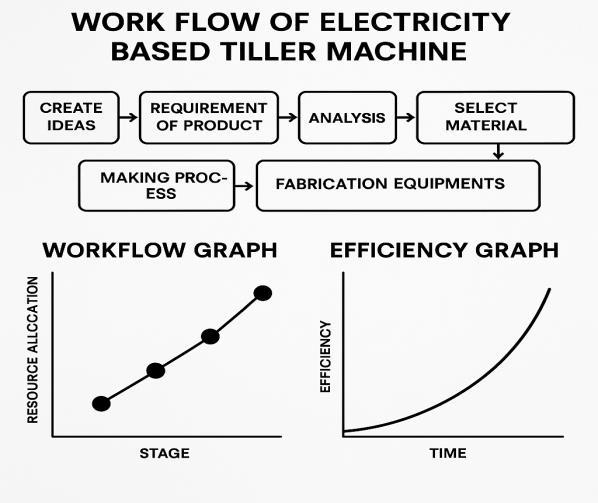

5.METHODOLOGY

Create Ideas – Brainstorm innovative and ecofriendlytillerconcepts.

Requirement of Product –Identifypowersource, functionality,terraincompatibility.

Analysis – Study feasibility, mechanical design, powerload,andmarket.

Making Process – Develop CAD model, prototype electricalandmechanicalsystems.

Select Material –Choosedurable,lightweight,and cost-effectivematerials.

Fabrication Equipment – Use welding tools, CNC, cutters,andtestingsetups.

6.EXPERIMENTEL SETUP

An electric tiller machine poweredbya 24-volt, 250-watt DC motor isacompactandefficienttoolforsoilpreparation, ideal for small farms and gardens. It is driven by a 24-volt rechargeable battery connected to the motor, ensuring a cleanandeco-friendlyoperation.

The DC motor transferspowertothetillingbladesthrougha sprocket and chain mechanism, offering smooth torque delivery.Thissystemensuresreliableperformanceforlightto mediumsoiltillingtasks.The blades aredesignedtorotate efficiencygood

A fully adjustable acceleration control system enablesthe usertoregulatethebladespeed,allowingflexibilitybasedon soil typeand working conditions. This feature ensures precisionandenergyefficiency.

The design is lightweight and portable, with minimal maintenance requirements compared to petrol or dieselpoweredtillers.Iteliminatestheneedforfuel,makingitan environmentally friendly choice, with reduced noise and vibrationduringoperation.

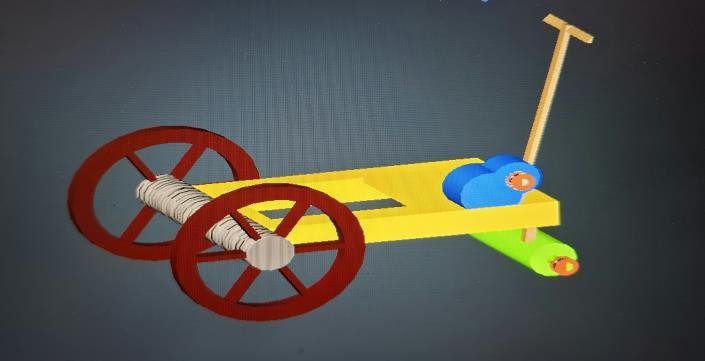

Fabricatedanelectricity-basedtillermachinebyperforming cutting,drilling,andlathemachiningtocreateacentralhole in the disc. Forged blades in the blacksmith shop, shaped them precisely, and welded all components together. The process combined mechanical and fabrication skills to developafunctionaltoolforagriculturaluse. Fabricatedan electricity-basedtillerbycutting,drilling,andusing alathe fordiscmodification.Forgedbladesintheblacksmithshop andcompletedtheassemblywithprecisewelding.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Thisfabricatedimageillustratesamanuallyoperatedelectric tillermachine,highlightingthemotorandrotavatorassembly. Italsoshowcasestheelectronicconnections,providingaclear viewoftheintegrationbetweenmechanicalcomponentsand electricalsystemsforefficientagriculturaluse.

One of the most notable advantages of an electricity-based tiller machine is its environmental friendliness. Unlike conventionalgasolineordiesel-poweredtillers,electrictillers do not emit harmful gases such as carbon dioxide, carbon monoxide,ornitrogenoxides

The electricity-based tiller machine marks a significant advancementinmodernagriculturaltechnology,providinga cleaner,moreefficient,andcost-effectivesolutioncompared to traditional fuel-powered alternatives. As global farming trendsmovetowardsustainabilityandenergyefficiency,the relevanceofelectrictillerscontinuestogrow.

One of the key benefits of an electric tiller is its environmentallyfriendlyoperation.

Futureworkontheelectricity-basedtillermachinecanfocus on several significant upgrades to improve its efficiency, functionality,andeaseofuse.Enhancingbatterycapacityand reducing charging time will allow for longer and more productive field operations. Integrating solar charging systemscanmakethemachinemoresustainableandsuitable forremoteareas.Theadditionofautomationfeaturessuchas GPS-based navigation and obstacle detection will enable precision farming and reduce manual labor. Incorporating smartcontrolsthroughIoTandmobileapplicationswillallow farmerstomonitorandcontrolthetillerremotely.

The manually operated electric tiller has significant future scope in sustainable and precision agriculture. With rising demandforeco-friendlyandcost-effectivefarmingsolutions, thiscompacttillercanbefurtherdevelopedusingadvanced battery technologies, solar charging options, and smart sensors for soil analysis. It can be adapted for small-scale farmers in remote or resource-limited areas, reducing dependency on fossil fuels and large machinery. Modular designscanmakeitcompatiblewithvariousattachmentsfor different farming tasks. Additionally, integrating IoT and automationcouldenhanceefficiency,makingitsuitablefor modern smart farming practices while maintaining affordabilityandeaseofuse.

1. Mehta, R. (1998). "Design Challenges in Diesel Tillers for Small Farms." Agricultural Mechanization Journal, 14(4), 210-216.

2. Ogawa,Y.(1975)."ComparativeStudyofFuel-Powered Tillers in Southeast Asia." Journal of Mechanized Agriculture, 2(4), 198-204.

3. Khurana,M.,&Yadav,T.(2002)."OptimizationofDiesel Power Tillers for Dryland Farming." International Journal of Agricultural Science and Technology, 19(3), 67-73.

4. Mandal,S.K.,&Maity,A.(1988). PerformanceEvaluation of Power Tillers, National Agricultural Mechanization ConferenceProceedings,18(3),319–325.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

5. Kawamura, H. (1992). Energy Consumption in DieselBased Tillage,JournalofEnergyinAgriculture,8(1),55–62.

BIOGRAPHIES

Pranjal Gupta

B.TechMechanicalEngineering finalyear

Ankit Kumar

B.TechMechanicalEngineering finalyear

Shyam Ji

B.TechMechanicalEngineering finalyear

Zahir Ansari

B.TechMechanicalEngineering finalyear

Mr Rahul Shukla, AssistantProfessorGITM

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008