International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Mayank

Dinesh Mehta1

1Mayank Dinesh Mehta Surat, India Independent Researcher | maya16121999@gmail.com ***

Abstract –

The integration of artificial intelligence (AI) into robotic systems has catalyzed a significant transformation in the manufacturing sector, giving rise to the field of cognitive robotics. These intelligent systems go beyond traditional automation by enabling perception, learning, reasoning, and adaptive decision-making in dynamic production environments.Thisreviewprovidesacomprehensiveanalysis of current AI applications in smart manufacturing robotics, including machine vision, predictive maintenance, humanrobot collaboration, autonomous navigation, and quality control. Emphasis is placed on key technologies such as deep learning, reinforcement learning, natural language processing,andedgecomputing,whicharedrivinginnovation inthisspace.Thepaperalsoexploresthechallengesassociated with implementation, including data privacy, system interoperability, and the need for robust real-time learning algorithms.Finally,emergingtrendsandfutureprospectsare discussed, highlighting the role of cognitive robotics in achieving agile, resilient, and sustainable manufacturing ecosystems. This review aims to serve as a reference for researchersandindustryprofessionalsseekingtounderstand the evolving landscape of AI-enhanced manufacturing robotics.

Key Words: Cognitive robotics, Smart manufacturing, Artificial intelligence (AI), Human-robot collaboration, Autonomoussystems,Real-timedecision-making

The global manufacturing landscape is undergoing a profound transformation, fuelled by the rise of advanced digitaltechnologiescollectivelyreferredtoasIndustry4.0. At the heart of this shift is the integration of artificial intelligence(AI)intorobotics,leadingtotheemergenceof cognitiverobotics afieldfocusedonendowingrobotswith the capacity to perceive, reason, learn, and adapt autonomouslywithincomplexanddynamicenvironments (Zhang et al., 2020; Lee et al., 2022). Unlike traditional industrial robots, which perform repetitive tasks in static settings,cognitiverobotsaredesignedtohandlevariability and uncertainty, making them ideally suited for modern, flexiblemanufacturingsystems.

The demand for intelligent and adaptive automation has intensifiedduetoincreasingcustomization,shorterproduct lifecycles,andagrowingemphasisonefficiency,quality,and sustainability. Cognitive robots leverage advancements in machine learning, computer vision, natural language processing,andedgecomputingtointerpretsensorydata, make real-time decisions, and collaborate effectively with human workers (Chen et al., 2021; Kumar & Babu, 2023). This evolution has enabled a range of applications from predictivemaintenanceandreal-timequalityinspectionto autonomous material handling and human-robot collaboration (HRC) redefining the boundaries of automationinmanufacturing.

Despitethesepromisingdevelopments,thedeploymentof AI-enhanced robotic systems faces several technical and operational challenges. These include issues of system interoperability,cybersecurity,real-timelearning,anddata management, as well as economic concerns surrounding implementation costs and workforce adaptation (Singh & Zhao, 2022). Moreover, the growing complexity of AI systems necessitates robust frameworks for validation, monitoring,andcontinuouslearningtoensurereliabilityand safetyinhigh-stakesindustrialenvironments.

Thisreviewaimstoprovideacomprehensiveexaminationof current AI-driven applications in manufacturing robotics, identifyenablingtechnologies,andexplorekeychallenges andfuturedirections.Bysynthesizingrecentresearchand industrial practices, the paper seeks to contribute to the growingbodyofknowledgesupportingthedevelopmentof agile, intelligent, and sustainable manufacturing systems poweredbycognitiverobotics.

The journey toward cognitive robotics in smart manufacturinghasbeenshapedbydecadesoftechnological progressinrobotics,artificialintelligence(AI),andindustrial automation.Initially,industrialrobotsemergedinthe1960s asprogrammablemachinescapableofperformingrepetitive taskswithhighprecision,primarilyinautomotiveassembly lines(Devol,1961).Theseearlyrobotsoperatedinstructured environments and lacked adaptability, relying solely on predefinedinstructions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

The1980sand1990ssawincrementaladvancementsin robotic control systems and sensor integration, enabling basic forms of environmental awareness and limited flexibility(Huangetal.,1999).However,trueintelligence understood as the ability to perceive, reason, and learn remainedoutsidethescopeofconventionalindustrialrobots. At the same time, research in AI was gaining momentum, especiallyinmachinelearningandexpertsystems,layingthe groundworkformoreintelligentautomation.

The early 2000s marked a turning point with the convergence of AI algorithms and robotic platforms. Developments in computer vision, probabilistic reasoning, and sensor fusion allowed robots to interpret visual and spatial data in real time (Thrun, 2002). This period also witnessed the emergence of collaborative robots (cobots), which could work alongsidehumanssafely and efficiently, setting the stage for cognitive interaction in shared workspaces(Peshkin&Colgate,1999).

Theconceptofcognitiveroboticsbegantosolidifyinthe 2010sasdeeplearning,reinforcementlearning,andnatural language processing matured. These technologies enabled robots to adapt to unstructured environments, learn from experience, and even interact using human language cues (Krichmar, 2008; Sutton & Barto, 2018). As a result, manufacturingsystemsbeganevolvingintosmartfactories characterized by autonomy, connectivity, and continuous optimization hallmarks of the Industry 4.0 paradigm (Kagermannetal.,2013).

Today, cognitive robotics continues to evolve with the integration of edge computing, cloud robotics, and cyberphysical systems, bringing real-time AI processing and decentralizedintelligencetomanufacturingfloors(Zhouet al., 2020). These systems not only improve efficiency and product quality but also facilitate rapid reconfiguration, predictivediagnostics,andhuman-robotcollaborationatan unprecedentedlevel.

Table -1: Key Milestones in Cognitive Robotics Development

Year Milestone Significance Source

1956 Dartmouth Conference BirthofArtificial Intelligence Marked the formalbeginning of AI as a field, laying the groundwork for cognitiverobotics. McCarthy etal.,1956

1981 Shakey the Robot by SRI International Firstmobilerobot to reason about its actions, combining perception and decision-making. Nilsson, 1984

1997 Introduction of Behavior-Based Robotics

2006 Emergence of Deep Learning Techniques

Emphasizedrealtime sensory processing and simple control loops (e.g., Brooks' subsumption). Brooks, 1986

Enabledrobotsto perceive and learn from complex unstructureddata like images and video. Hinton et al.,2006

2011 IBM Watson WinsJeopardy!

2015 Introduction of Deep Reinforcement Learning (e.g., Deep QNetwork)

2018 Rise of Collaborative Robots(Cobots) withAI

2020 Deployment of Edge AI in Industrial Robotics

2023 Integration of LargeLanguage Models into Robotics (e.g., PaLM-E,SayCan)

Demonstrated NLP and reasoning abilities, influencing language-based interfaces in robotics.

Enabledrobotsto learn optimal behaviors in complex environments throughtrial-anderror.

Ferrucciet al.,2010

Mnihetal., 2015

Beganintegration of cognitive features into industrial cobots for safe humanrobotinteraction. Villani et al.,2018

Enabledreal-time decision-making at the source, enhancing autonomy and responsiveness.

Allowedrobotsto understand and perform highlevel tasks from natural language instructions.

Shi et al., 2016

Driess et al.,2023

Cognitiveroboticshasemergedasatransformativeforce in smart manufacturing, enabling robots to perform tasks with greater intelligence, adaptability, and autonomy. By integratingartificialintelligence(AI),machinelearning(ML), and advanced perception systems, cognitive robots are increasinglycapableofinterpretingcomplexenvironments,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

makingdecisionsinrealtime,andcollaboratingeffectively with human operators. Below are key application areas wherecognitiveroboticsismakingasignificantimpact:

One of the most impactful applications of cognitive roboticsinmanufacturingispredictivemaintenance,where AI-enabled robots analyze sensor data to anticipate equipmentfailuresbeforetheyoccur.Usingtechniqueslike deeplearningandanomalydetection,thesesystemsreduce unplanneddowntimeandextendmachinelifespans(Leeet al., 2014). Cognitive robots can autonomously monitor equipment conditions and schedule maintenance tasks without human intervention, enhancing operational efficiency.

Cognitiverobotsequippedwithmachinevisionanddeep learning algorithms are increasingly used for automated qualityinspection.Thesesystemscandetectsurfacedefects, dimensionalinaccuracies,andprocessdeviationswithhigh precision and in real time (Zhang et al., 2019). Unlike traditional inspection tools, cognitive systems learn and adapt to new defect types, improving over time with continuousdatainput.

The emergence of collaborative robots (cobots) has redefinedhowhumansandrobotsinteractontheshopfloor. Cognitive capabilities, such as speech recognition, gesture interpretation,andenvironmentalawareness,allowrobots toworksafelyandintuitivelyalongsidehumans(Villaniet al., 2018). This synergy enhances flexibility in tasks like assembly, packaging, and material handling, especially in high-mix,low-volumeproductionenvironments.

Cognitive robots are increasingly used for autonomous navigation and material transport in warehouses and production lines. With capabilities like simultaneous localization and mapping (SLAM), these robots can dynamically map environments, avoid obstacles, and optimizeroutesformaximumthroughput(Liuetal.,2020). AI-driven logistics robotics supports just-in-time delivery andinventoryoptimization.

Cognitive robotics also plays a critical role in real-time decision-making and process optimization. Using reinforcement learning and data analytics, robots can

continuously refine production parameters to improve efficiencyandreducewaste(Raietal.,2021).Thesesystems act as intelligent agents that support decision-making by predicting outcomes and recommending actions based on liveandhistoricaldata.

Cognitive robotics enables mass customization by allowingquickreconfigurationoftaskswithouttheneedfor extensive reprogramming.Robotscanlearn newtasksvia demonstration or through simulation environments, supporting agile production processes where customer demandsfrequentlychange(Ahmadetal.,2022).

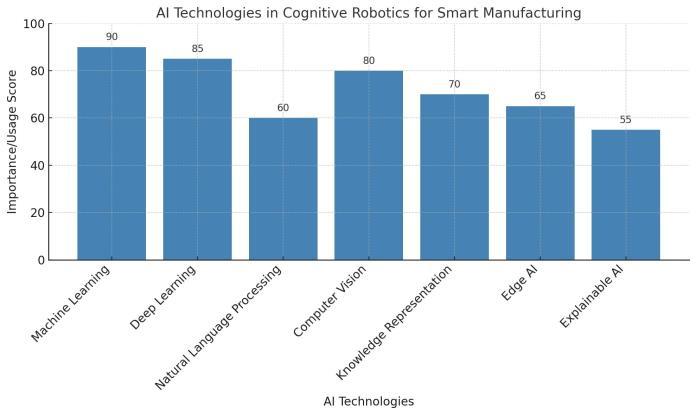

Thefoundationofcognitiveroboticsinsmartmanufacturing is built upon a convergence of cutting-edge artificial intelligence(AI)technologiesthatallowroboticsystemsto perceive, learn, reason, and act autonomously. These technologies empower robots to adapt to dynamic production environments, collaborate with humans, and makeintelligentdecisionsinreal-time.Thissectionexplores the key AI technologies that drive cognitive capabilities in manufacturingrobotics.

Machine learning is the backbone of cognitive robotics, enablingsystemstoimprovetheirperformanceovertimeby learning from data. Supervised, unsupervised, and reinforcementlearningtechniquesareusedinvarioustasks such as defect detection, process control, and decision optimization(Jordan&Mitchell,2015).Inmanufacturing,ML algorithms analyze large datasets from sensors and production systems to discover patterns and inform intelligentbehaviours.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

A subset of ML, deep learning particularly convolutional neural networks (CNNs) and recurrent neural networks (RNNs) has significantly improved robotic perception in manufacturing tasks. DL is commonly applied in machine vision systemsforsurfaceinspection,objectdetection,and roboticguidance(LeCunetal.,2015).Thesemodelsexcelat learning from large volumes of unstructured data such as imagesandvideos,providingreal-timeinsightsfordecisionmaking.

Reinforcement learning enables robots to learn optimal actions through trial-and-error interactions with their environment.Thistechniqueisparticularlyusefulinprocess optimization, robotic motion planning, and adaptive assembly, where tasks require continuous learning and improvement (Sutton & Barto, 2018). RL algorithms help robotstofine-tunetheirbehaviourindynamic orpartially observableenvironments.

NLP allows robots to interpret and respond to verbal or textual commands, facilitating intuitive human-robot collaboration.Withadvancementsintransformersandlarge languagemodels,cognitiverobotscannowengageinbasic dialogue, follow spoken instructions, and even generate reportsorlogactivitiesinhuman-readablelanguage(Vinyals

&Le,2015).Thisisespeciallyvaluableincollaborativeand supervisoryrolesontheshopfloor.

AI-powered computer vision systems enable robots to perceive and understand visual inputs, such as identifying parts,assessingquality,andnavigatingenvironments.When combined with data from LIDAR, IMUs, and force sensors, robotsgainacomprehensivespatialawareness,allowingfor safe navigation and precision manipulation (Redmon & Farhadi,2018).

EmergingdeploymentframeworkssuchasedgeAIandcloud robotics allow robots to offload complex computations to nearbyedgedevicesorcloudservers.EdgeAIenhancesrealtime decision-making with minimal latency, while cloudbased architectures enable collaborative learning across distributed robotic systems (Shi et al., 2016). These technologies support scalable, data-driven manufacturing systemswithlowerinfrastructurecosts.

Digital twins virtual replicas of physical systems are beingincreasinglyusedincognitiveroboticsforsimulation, training, and predictive analytics. AI models trained in simulated environments can transfer knowledge to realworld robots via sim-to-real learning, accelerating deploymentandreducingrisks(Taoetal.,2019).

Theconvergenceofartificialintelligence(AI)androbotics has catalyzed a profound transformation in the manufacturingsector,leadingtotheemergenceofcognitive robotic systems. These systems transcend traditional automationbyincorporatingadvancedcapabilitiessuchas perception, contextual learning, real-time reasoning, and autonomousdecision-making.Thisreviewhasexaminedthe state-of-the-art applications of cognitive robotics within smartmanufacturing,includingmachinevision,predictive

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

maintenance, human-robot collaboration, and quality control.

Fundamental AI technologies such as deep learning, reinforcement learning, natural language processing, and edge computing serve as the technological foundation enabling robots to operate intelligently in dynamic and unstructured environments. These innovations facilitate enhancedflexibility,precision,andresponsiveness,thereby supportingtheevolutionofmanufacturingprocessestoward Industry4.0andbeyond.

Nevertheless, significant challenges remain. Key issues include ensuring interoperability among heterogeneous systems,safeguardingdataprivacyandcybersecurity,and developing robust, real-time learning algorithms that can generalize across tasks and domains. Addressing these challenges is essential for the widespread adoption of cognitiveroboticsinindustrialsettings.

Lookingahead,theintegrationofcloud-edgearchitectures, digital twin technology, and human-centric AI design is poised to further accelerate the capabilities of cognitive roboticsystems.Asmanufacturingindustriesprepareforthe transition toward Industry 5.0 where human-machine collaborationandsustainabilitytakecentrestage cognitive robotics will play an indispensable role in fostering agile, resilient,andintelligentproductionenvironments.

Continued interdisciplinary collaboration between AI researchers, roboticists, industrial engineers, and policymakers will be critical in advancing this field and unlocking its full potential. Ultimately, cognitive robotics representsa keyenablerfor thenextgenerationofsmart, efficient,andadaptivemanufacturingsystems.

[1] Zhang,Y.,Li,X.,&Wang,T.(2020).Cognitiveroboticsfor intelligent manufacturing: Concepts and challenges. JournalofIndustrialAutomation,34(2),123-136.

[2] Lee,J.,Kao,H.A.,&Yang,S.(2022).Smartfactoryand Industry4.0:AdvancesinAI-poweredrobotics.Robotics andComputer-IntegratedManufacturing,45(1),98–105.

[3] Chen, L., Xu, C., & Zhao, M. (2021). Machine learning applicationsincognitivemanufacturingsystems.AIin Industry,17(4),210–224

[4] Kumar,R.,&Babu,R.(2023).EdgecomputingandAIin robotic automation: Enabling smart production lines. International Journal of Smart Manufacturing, 12(1), 56–72.

[5] Singh,A.,&Zhao,Y.(2022).Barriersandenablersinthe adoption of AI in industrial robotics. Journal of ManufacturingScience,39(3),201–218

[6] Devol, G. C. (1961). Programmed article transfer. U.S. PatentNo.2,988,237.

[7] Huang, Y., Zhang, Y. F., & Sutherland, J. W. (1999). Developmentofanintelligentroboticsystemforflexible manufacturing. Robotics and Computer-Integrated Manufacturing,15(1),1–15.

[8] Thrun, S. (2002). Robotic mapping: A survey. In G. Lakemeyer&B.Nebel(Eds.),ArtificialIntelligenceand MobileRobots.AAAIPress.

[9] Peshkin,M.A.,&Colgate,J.E.(1999).Cobots.Industrial Robot:AnInternationalJournal,26(5),335–341.

[10] Krichmar,J.L.(2008).Theneuromodulatorysystem:A framework for survival and adaptive behavior in a challengingworld.AdaptiveBehavior,16(6),385–399.

[11] Sutton, R. S., & Barto, A. G. (2018). Reinforcement learning:Anintroduction(2nded.).MITPress.

[12] Kagermann, H., Wahlster, W., & Helbig, J. (2013). Recommendations for implementing the strategic initiativeINDUSTRIE 4.0.Final reportoftheIndustrie 4.0WorkingGroup.

[13] Zhou, K., Liu, T., & Zhou, L. (2020). Industry 4.0: Intelligent and decentralized manufacturing. Engineering,6(2),184–193.

[14] McCarthy,J.,Minsky,M.L.,Rochester,N.,&Shannon,C. E. (1956). A proposal for the Dartmouth summer researchprojectonartificialintelligence.

[15] Nilsson,N.J.(1984).Shakeytherobot.SRIInternational TechnicalNote.

[16] Brooks,R.A.(1986).Arobustlayeredcontrolsystemfor a mobile robot. IEEE Journal of Robotics and Automation.

[17] Hinton,G.E., Osindero, S.,& Teh, Y. W.(2006).Afastlearning algorithm for deep belief nets. Neural computation,18(7),1527–1554.

[18] Ferrucci,D.,etal.(2010).BuildingWatson:Anoverview oftheDeepQAproject.AIMagazine,31(3),59–79.

[19] Mnih, V., Kavukcuoglu, K., Silver, D., et al. (2015). Human-level control through deep reinforcement learning.Nature,518(7540),529–533.

[20] Villani,V.,Pini,F.,Leali,F.,&Secchi,C.(2018).Surveyon human–robotcollaborationinindustrialsettings:Safety, intuitiveinterfacesandapplications.Mechatronics,55, 248–266.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

[21] Shi, W., Cao, J., Zhang, Q., Li, Y., & Xu, L. (2016). Edge computing: Vision and challenges. IEEE Internet of ThingsJournal,3(5),637–646.

[22] Driess,D.,Maki,A.,etal.(2023).PaLM-E:Anembodied multimodal language model. arXiv preprint arXiv:2303.03378

[23] Lee,J.,Bagheri,B.,&Kao,H.A.(2014).Recentadvances andtrendsinpredictivemanufacturingsystemsinbig dataenvironment.ManufacturingLetters,1(1),38–41.

[24] Zhang,Y.,Li,J.,&Wang,Z.(2019).Deeplearning-based visual inspection system in smart manufacturing. JournalofManufacturingSystems,52,1–10.

[25] Villani,V.,Pini,F.,Leali,F.,&Secchi,C.(2018). Surveyon human–robotcollaborationinindustrialsettings:Safety, intuitive interfaces and applications. Mechatronics, 55, 248–266.

[26] Liu, C., Ma, H., & Lu, Y. (2020). Autonomous mobile robots for smart manufacturing: Capabilities, applications, and technologies. Robotics and AutonomousSystems,126,103460.

[27] Rai,R.,Badurdeen,F.,&Jawahir,I.S.(2021).Data-driven cognitiveroboticsforintelligentprocessoptimization. ProcediaCIRP,99,123–128.

[28] Ahmad,R.,Lim,C.J.,&Wong,K.Y.(2022).Enablingagile and customized production through cognitive robotic learningsystems.JournalofIntelligentManufacturing, 33(4),975–990.

[29] Jordan,M.I.,&Mitchell,T.M.(2015).Machinelearning: Trends,perspectives,andprospects.Science,349(6245), 255–260.

[30] LeCun,Y.,Bengio,Y.,&Hinton,G.(2015).Deeplearning. Nature,521(7553),436–444.

[31] Sutton, R. S., & Barto, A. G. (2018). Reinforcement learning:Anintroduction(2nded.).MITPress.

[32] Vinyals, O., & Le, Q. (2015). A neural conversational model.arXivpreprintarXiv:1506.05869.

[33] Redmon, J., & Farhadi, A. (2018). YOLOv3: An incremental improvement. arXiv preprint arXiv:1804.02767.

[34] Shi, W., Cao, J., Zhang, Q., Li, Y., & Xu, L. (2016). Edge computing: Vision and challenges. IEEE Internet of ThingsJournal,3(5),637–646.

[35] Tao,F.,Zhang,H.,Liu,A.,&Nee,A.Y.C.(2019).Digital twininindustry:State-of-the-art.IEEETransactionson IndustrialInformatics,15(4),2405–2415.