International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Sejal Pawar1 , Shreya Patil2 , Arshad Shaikh3

123Research Scholar, Dept. of Electronics&ComputerScience Engineering, Padmabhooshan Vasantraodada Patil Institute of Technology, Budhgaon, Maharashtra, India ***

Abstract: - The programming language most frequently used in programmable logic controllers (PLCs), which operate around 80% of industrial automation systems. Developed from traditional relay bases, it provides a simple and visual way to manage complex industrial processes. Because of its reliability and ease of use, AllBradleyPLCusesparalyzedlogicincontrolmachinessuch asassemblylinesandmanufacturingdevices.Intheageof Industry 4.0, conductor logic is increasingly integrated intoIIOTandcloud-basedsystems,andisstillessential to ensure efficient, accurate and intelligent automation. In this paper, the fundamentals of PLC programming are discussedinconductorlogic

Keywords:

PLC Programming, Ladder Logic, Allen-Bradley PLC, IndustrialAutomation,Industry4.0.

1.INTRODUCTION

A Programmable Logic Controller (PLC), also appertained to as a programmable sense controller, is a technical digital computer used primarily in artificial robotization systems. Unlike conventional computers that bear input bias similar as a keyboard or examiner, PLCs operate by entering input data from detectors or switches, recycling this data, and also transferring commands to control bias similar as motors, lights, or faucets. These small computers are used in colorful diligence, including manufacturing, automotive, food and libation processing, and chemical processing, where they automate processes for bettered effectiveness, thickness, and safety. PLCs are programmable, meaning they can be configured to perform specific tasks grounded on the requirements of the system. The most common programming languages usedforPLCsareLadderLogic(LLD)andC.LadderLogic, which visually resembles electrical relay circuits, is the mostextensivelyusedprogramminglanguageinPLCsdue to its ease of understanding and graphical format. The program structure in Ladder Logic consists of two perpendicular lines, called rails, and vertical lines, called rungs, which represent control sense. This setup mimics the physical wiring of control circuits, making it intuitive for masterminds familiar with electrical systems. The graphical representation of this program is known as a HeadSenseIllustration(LLD),whereeachpealeddefinesa specificcontroloperation.

WhileGraduationsense ismostcommon,someadvanced PLCs also support programming in C, a more flexible language suitable for complex control algorithms, fine operations,anddatahandling.PLCsservebycontinuously cycling through three main way entering input from detectors,recyclingthedatausingtheprogrammedsense, and transferring affair commands to control selectors or another ministry. This cycle enables PLCs to control processes similar as assembly lines, robotic arms, or fluid controlsystemsinchemicalshops.Byautomatingartificial processes, PLCs significantly reduce the need for homemade intervention, increase product effectiveness, andameliorateoverallsafety.

The evolution of Programmable Logic Controllers (PLCs) has been a significant milestone in the development of industrialautomationsystems.PLCswerefirstintroduced in the late 1960s as an alternative to relay-based control systems. As noted by Moubray (2001), the primary motivation behind the creation of PLCs was to replace hard-wired relay logic systems, which were inflexible and difficult to modify. The first PLC, the Modicon 084, used Ladder Logic (LL) as its primary programming language due to its simplicity and resemblance to traditional relay diagrams(Bailey&Wright,2003). Ladder Logic (LLD)isa graphical programming language that mimics electrical circuits, which made it easier for electrical engineers to adopt PLCs without requiring extensive programming expertise(Boddy,2012).

PLC programming has been applied across various industries to improve the efficiency, accuracy, and safety of manufacturing processes. Nof (2009) highlighted that PLCs are pivotal in sectors such as automotive, food and beverage processing, and chemical production, where precise control over machinery and processes is necessary. Chang (2011) demonstrated the effectiveness of PLCs in controlling production lines, where real-time adjustments could be made based on input signals from sensors. PLC systems enable continuous monitoring, reducing human intervention and enhancing operational efficiency.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

The flexibility of PLCs has also allowed for complex control processes. For instance, Siew et al. (2018) detailed the use of PLCs in traffic light control systems, where Ladder Logic was employed to manage the sequenceof red,yellow,andgreenlights.Thisapplication highlighted how PLCs are capable of managing multiple outputs and handling time-based operations with ease. Similarly, Gao (2015) explored the use of PLCs in packaging automation, where sensors and actuators, controlled by Ladder Logic, managed tasks such as packaging,labelling,andsealingwithhighefficiency.

As we enter the era of Industry 4.0, PLCs are increasingly being integrated with cutting-edge technologies such as the Internet of Things (IoT), cloud computing, and edge computing. According to Baur & Reinhardt (2020), the integration of PLCs with IoT allows for real-time data collection and remote monitoring of industrial processes. This provides engineers and operators with detailed insightsintomachineperformance,allowingforpredictive maintenance and optimized operations. Zhang et al. (2019) emphasized how PLCs can be connected to cloudbasedsystems, enablinglarge-scaledata analyticsandthe application of artificial intelligence (AI) for process optimization.

Recent advances have seen the expansion of PLC capabilities, with more sophisticated systems capable of running complex algorithms. Bertolini et al. (2018) discussed how newer PLC models, including those from brands like Allen-Bradley, have added features such as support for Structured Text (ST) and Function Block Diagram (FBD) programming, offering greater flexibility for more complex applications. However, despite the introduction of these advanced languages, Ladder Logic remains the most widely used language for PLC programming due to its simplicity and visual appeal, especially for control engineers with an electrical background.

The increasing connectivity of PLCs in smart factories introduces a range of cybersecurity concerns. Bishop et al. (2017) discussed how the integration of PLCs into larger networked systems exposes them to cyber threats, such as malware, hacking, and unauthorized access. As PLCs become more integrated with enterprise-level IT systems, ensuring their security has become paramount. Several authors, including Harris & Miller (2020), have emphasized the importance of adopting robust cybersecurity measures, such as encrypted communication protocols, intrusion detection systems,

and regular software updates to protect PLCs from cyberattacks.

The future of PLC programming looks toward increasing automation, intelligence, and connectivity. Johnson et al. (2021) discussed how artificial intelligence (AI) and machinelearning(ML)areexpectedtoplayalargerrolein PLC-controlled systems, offering more autonomous decision-making capabilities. By analysing data in real time, AI algorithms can predict system failures, optimize operations, and even adjust control parameters autonomously. Furthermore, the widespread adoption of edgecomputingisexpectedtoenhancetheperformanceof PLC systems by processing data closer to the source, reducing latency, and improving real-time decisionmaking(Al-Dahashetal.,2022).

Another promising development is the use of blockchain technologyinPLCsystemsforsecureandtransparentdata sharing. Patel & Wang (2020) proposed that integrating blockchain with PLCs could ensure the integrity and traceabilityofdataexchangedbetweenmachines,enabling moresecureandefficientindustrialprocesses.

Ladder - Logic Diagrams (LLDs) are graphical programminglanguagesusedinPLCs,usedinrealtimeby processing input signals and performing corresponding outputactions.ItconsistsoftwoverticallinescalledRails. The left rail normally represents the power source, while the right rail isconnectedtothe neutral line. Performance flowsfromlefttoright,passingthroughallthebudsinthe diagram. Each rung contains a number of switches and output coils. The bud switch can perform basic logic operations such as or not. These logical operations are fundamental to creating complex control logic within a PLC. If the conditions of the rung are met, i.e., if the H. switchisinthecorrectstate,theconnectedoutputcoilsare supplied with energy, which triggers the action in the actualsystem.Thismeans,forexample,theengineisonor off depending onthe full range of conditions. This process iscontinuouslyscannedbythePLCinrealcyclestoensure that the control system operates seamlessly. By repeating this cycle, the PLC automates the operation of the system andmaintainsefficientandaccuratecontrolofthemachine orprocess.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Programming PLCs and comprehending the operation ofcontrolcircuitsrequiretheuseofladderlogicdiagrams, or LLDs. These diagrams provide a straightforward and understandable visual representation of how control circuits function. Understanding the essential elements of a ladder logic diagram is essential when programming systemslikeAllen-BradleyPLCsorothers.Railsandrungs arethemainparts,alongwithNO(NormallyOpen)andNC (NormallyClosed)contacts,whichserveasthefoundation forthecontrolsystem'slogicprocesses.

The rails in a Ladder Logicdiagram are represented by two vertical lines. These rails serve as the circuit's power supply wires. Usually, the neutral line or output is representedbytherightrail,andtheactivepowersource is represented by the left rail. Certain control logic processes are represented by the rungs, which are the horizontallinesthatjointherails.Considereachrungasa control sequence that determines, according on the input conditions,whetheradeviceshouldbeturnedonoroff.As the PLC scans the schematic, it assesses each rung to decideif theoutputcoil attachedto that rung needsto be powered. The logic runs from the left rail (power supply) totherightrail(output).

2. NO (Normally Open) and NC (Normally Closed) Contacts

Switches or inputs that regulate the system's current flow are represented by contact symbols in ladder logic. Depending on the switch's condition, these contacts are crucial for identifying whether a circuit is open or complete. Normally Open (NO) and Normally Closed (NC) connections are the two primary contact types utilized in ladderlogic.

Normally Open (NO) Contact:

When not triggered, a NO contact stays open (nonconducting).

Itcompletesthecircuitbyclosingthecircuitwhenitis engaged, allowing current to flow through. ANOcontactinladderlogicisshownasanopenspace betweentwolines.Thegapcloseswhenitisengaged, such as when a switch is pressed, enabling current to passthroughthecircuit.

When not triggered, an NC contact stays closed (conducting), permitting current to flow through. The circuit is broken and the current flow is interrupted when the NC contact opens upon activation.

An NC contact in ladder logic is represented as a continuous line that runs between two places; when thelineisactivated,thecurrentstopsflowingand the outputisdeactivated.

3. Output/Coil

InLadderLogic,theoutput orcoilcontrolsdeviceslike motors,lights,valves,oralarms.Itisplacedatthefar-right end of the rung and is shown as a circle or parentheses withthenameofthedeviceinside.Whentheconditionsin the rung are met (such as certain switches being activated), the coil is "energized," which means it sends power to the connected device, making it work. For example, if the logic tells the PLC that everything is in order, the coil could turn on a motor or light. The PLC constantlycheckstheconditionsintheprogramandkeeps theoutputdevicesworkingasneeded.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Fig -3: PartsofaLadderLogicDiagram

1. Examples of Some Ladder Logic Programming

a) Creating AND Gate Ladder Logic Diagram

In Ladder Logic, the AND gate logic is used to represent situationswheretwoconditions(inputs)mustbetrue for an output to be activated. The logic for an AND gate is representedas:

Y = A. B (where A and B are the inputs, and Y is theoutput).

In a Ladder Logic diagram, the two inputs (A and B) are represented as Normally Open (NO) contacts. Both of these contacts must be closed (activated) for the output coil(Y)tobeenergized.Here'showitworks:

1. TheinputAisconnectedtoaNOcontact.

2. TheinputBisconnectedtoanotherNOcontactin serieswiththefirst.

3. The output coil Y is placed at the far-right end of therung.

b) Truth Table

The truth table for an AND gate shows all possible combinations of the inputs (A and B) and the correspondingoutput(Y):

WhenA=0andB=0,theoutputY=0.

WhenA=0andB=1,theoutputY=0.

WhenA=1andB=0,theoutputY=0.

WhenA=1andB=1,theoutputY=1.

In an AND gate, the output is 1 (true) only when both inputsare1(true).Forall othercombinations,theoutput is 0 (false). This truth table directly reflects how the Ladder Logic diagram would behave in real-world applications

Fig -4: LadderLogicImplementationofANDGateinRS Logix500

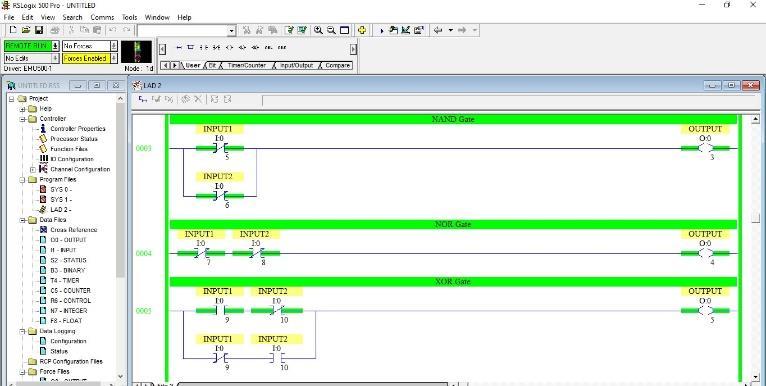

Examples of Some Other Ladder Logic Programming

Fig -5: LadderLogicImplementationofAND,OR&NOT Gate

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

4. Applications

1. Conveyor System Control: Controls conveyor beltsusingsensorsandtimers.

2. Start/Stop Motor Control: Manages motor operationusingstartandstopbuttons.

3. Level Control in Tanks: Maintains liquid levels usingsensorsandpumps.

4. Traffic Light Control: Automates traffic light sequencesusingtimers.

5. Safety Interlocks: Ensures machinery operates onlyundersafeconditions.

6. Packaging Machine Control: Automates packaging,labelling,andsealingprocesses.

7. Temperature Control: Regulates temperature usingsensorsandheaters.

8. Conveyor Sorting Systems: Sorts items using sensorsandactuators.

9. Bottling and Canning Systems: Controls bottle filling,capping,andsealing.

10. Material Handling Systems: Manages cranes, hoists,andlifts.

11. Automatic Door Control: Operates doors using motionsensors.

12. Elevator Control Systems: Manages floor selectionandsafetyfunctions.

13. Batch Processing Systems: Controls mixing and chemicalreactions.

14. Industrial Ovens and Furnaces: Maintains temperatureprofiles.

15. HVAC Systems: Controls temperature, humidity, andairflow.

16. Escalator and Moving Walkways: Manages speedandsafetysystems.

The future of Ladder Logic programming and AllenBradley PLCs will focus on integrating advanced technologies like IoT, cloud connectivity, AI, and edge computing. This will enable smart factories, real-time monitoring, and predictive maintenance. Programming tools will become more intuitive, and AI could help optimize control processes. Cybersecurity will be critical as PLCs become more connected, and energy efficiency will be prioritized for sustainability. Collaborative robots (cobots) will work alongside humans, enhancing automation. Overall, the future will bring smarter, more efficient,andmoreinterconnectedindustrialsystems.

PLC programming using Ladder Logic is essential for industrial automation, offering reliability, flexibility, and ease of troubleshooting. This paper explored the fundamentals of Ladder Logic with a focus on AllenBradley PLCs, highlighting their role in efficient control systemdesign.AsautomationadvanceswithIndustry 4.0, masteringLadderLogicfor Allen-BradleyPLCsprovidesa strong foundation for developing intelligent and scalable industrialsolutions.

[1] M. Moubray, Reliability-Centered Maintenance: The Handbook,2nded.NewYork:IndustrialPress,2001.

[2] D. Bailey and E. Wright, Practical Programmable Controllers: An Introduction to PLCs and Their Applications,3rded.Oxford:Newnes,2003.

[3] A. Boddy, Programmable Logic Controllers: An Introduction,4thed.Oxford:Elsevier,2012.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

[4] Y. Nof, Handbook of Industrial Robotics, 2nd ed. Hoboken,NJ:Wiley,2009.

[5] J. Chang, “Applications of PLC in industrial automation,” Journal of Automation and Control Engineering,vol.3,no.2,pp.45-49,2011.

[6] L. Siew, M. Zain, and A. Yusuf, “PLC applications in real-time traffic light control systems,” International Journal of Electrical Engineering & Technology,vol.10, no.5,pp.320-328,2018.

[7] J. Gao, “PLC-based control systems in industrial automation: Case studies in manufacturing,” International Journal of Advanced Manufacturing Technology,vol.60,pp.19-28,2015.

[8] J. Zhang, D. Li, and F. Sun, “Integration of PLCs with IoTforsmart manufacturing,” International Journal of Industrial Control Systems, vol. 5, no. 3, pp. 105-113, 2019.

[9] A. Bertolini, R. S. P. Ribeiro, and M. A. B. Ribeiro, “AdvancementsinPLCprogramming:StructuredText and Function Block Diagram,” Journal of Control and Automation Engineering, vol. 6, no. 2, pp. 212-218, 2018.

[10] C.Bishop,R.Miller,andA.Harris,“Securingindustrial PLCs in a connected world,” Cybersecurity for Industrial Control Systems, vol. 2, no. 1, pp. 45-58, 2017.

[11] M. Johnson, K. Patel, and S. Wang, “Artificial Intelligence and Machine Learning applications in PLC-based control systems,” IEEE Transactions on Industrial Informatics, vol. 17, no. 8, pp. 1234-1243, 2021.

[12] M.Al-Dahash,Z.Al-Kassab,andF.Al-Sakran,“Therole of edge computing in enhancing PLC performance in Industry 4.0,” Journal of Automation and Digital Control,vol.11,no.2,pp.76-85,2022.