Successful intralogistics is all about building smart and staying agile throughout every stage of facilities management. With our engagement model that helps you ideate, activate and adapt innovative solutions, combined with the power of our family of companies, we can help you optimize your facilities for whatever tomorrow brings. Tackle the challenges of today and make the most of the opportunities of tomorrow.

ONE TRUSTED PARTNER THREE STAGES OF OPTIMIZATION ENDLESS OPERATIONAL ADVANTAGE

By now I’ve gotten used to the futuristic hum of electric vehicles as they drive down my street. While I still drive a traditional internal combustion engine (ICE) vehicle, I’m increasingly aware of how many EVs there are on the roads.

Just how big the market share for EVs in North America will be in the short- to mid-term seem unclear. Long term, we’ll likely see this rise and competition become stiffer. Technology has shifted rapidly in recent decades and the auto sector is no exception.

This shift, along with society’s overall digital transformation, highlights the importance of critical minerals, with companies and countries vying to get control of them. Canada can benefit from this demand.

Critical minerals are elements and compounds like lithium, cobalt, nickel, and rare earth elements. They are strategically important, have limited substitutes, are vulnerable to geopolitical unrest, and are essential to the clean energy transition.

They’re also used in industries far beyond the EV space. They’re crucial in technologies ranging from smartphones to solar panels to computer chips and medical devices. Critical minerals like lithium, nickel and graphite are used in batteries, renewable energy technologies, and other advanced technology. Access to them will be essential in our tech-driven economy. They’re also essential for transitioning to a low-carbon economy.

Turns out, Canada has a fair bit of the stuff. The federal government’s official list of critical minerals (updated last year) says we have 34 minerals and metals identified as critical. Six of them – lithium, graphite, nickel, cobalt, copper, and rare earth elements – are crucial for technology manufacturing. Capitalizing on this is a challenge. Yet the benefits far outweigh any such challenges.

Many regions that have critical minerals, such as Ontario’s Ring of Fire region, lack sufficient infrastructure like roads and power. Developing these areas can affect forests and wetlands, harm water sources and biodiversity. As well, any development must occur with First Nations, as many areas are located in Indigenous territories. It’s a crucial partnership.

We also risk losing out economically. The global race is on to secure supply chains for these minerals, and we could fall behind if we don’t act. A report by the Canadian Climate Institute estimates that failing to meet domestic demand for critical minerals would see us lose $12 billion a year by 2040.

Finally, global trade is more volatile and less predictable than it was even a few years ago. Trade relations with some of our most reliable partners, most notably the US, are uncertain to put it mildy.

Diversifying our critical mineral supply chains helps to protect us against this volatility. We can’t be overly dependent on other countries for such essential resources.

Canada faces multiple challenges regarding critical minerals. Yet the risks are greater if we underutilize what will be one of our most coveted and useful natural resources.

EDITOR MICHAEL POWER 416-441-2085 x7 michael@supplypro.ca

PUBLISHER

FARIA AHMED 416-441-2085 x 5 faria@supplypro.ca

DESIGN

Art Direction ROY GAIOT Design Consultation BLVD AGENCY

iQ BUSINESS MEDIA INC.

Vice President STEVE WILSON 416-441-2085 x3 swilson@iqbusinessmedia.com

President & Executive Publisher ALEX PAPANOU

PUBLICATION MAIL AGREEMENT NO. 43096012 ISSN 1497-1569 (print); 1929-6479 (digital)

CIRCULATION

Mail: 126 Old Sheppard Ave, Toronto ON M2J 3L9

SUBSCRIPTION RATES

Published six times per year

Canada: 1 Year $ 99.95 CDN

Outside Canada: 1 Year $ 172.95 USD Single price per copy $18.00 CDN

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised.

Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. © 2021 iQ Business Media Inc. All rights reserved. Printed in Canada.

Supply Professional is the Official Magazine for NISCL

I’ve always been fascinated by black holes. They form when massive stars die and collapse. Black holes are invisible. They neither emit nor reflect light. But perhaps their distinguishing feature is their immense gravitational pull. It is due to the concentration of all the star’s mass into a single point. What does that mean practically? Nothing can escape it, not even light. And I think of Donald Trump as the black hole of global economics because of his immense pull in so many different domains.

Three of my previous four columns have focused on tariffs. This is understandable, given the importance of the US as Canada’s trading partner. In 2024, about 75 per cent of our exports headed south. That same year, just under 50 per cent of our imports came from the USA. But Trump’s economic significance extends far beyond tariffs which is why I won’t be mentioning them again in this column.

Let’s start with his immigration policy. He has been explicit in his desire to deport all illegal, or undocumented, immigrants –whether or not they’ve committed crimes while in America. In order to understand immigration under Trump’s predecessor, Joe Biden, it’s critical to differentiate between the globalist and nationalist perspectives on this issue. Let me steelman both positions. Globalists (Biden) start with recognizing the essential humanity all of us share. If I need a blood transfusion, the country of birth or the amount of the donor’s melanin is unimportant. By way of contrast, the nationalist

(Trump) perspective says that we are tribal beings and live in a world where resources are finite.

There have been protests and riots, particularly in California, because of the multiple arrests. This could seem like a law-and-order issue, but at its core this conflict is economics-based. Uncontrolled immigration in the US has devastated the wages for those workers we would understand as low or lower-skilled. It’s a simple matter of supply and demand: Everything else being equal, you increase the supply of anything, and its price will drop. It’s one of the primary reasons why so many American-born Latinos voted for Donald Trump. And if my Black Hole theory holds, I think that in the near future we will see a very different approach with respect to immigration not only in Western Europe, but here at home as well. In fact, it’s already started. In 2023, Canada welcomed 464,265 new permanent residents. The target for 2024 was supposed to be 480,000 and it has been pared to 395,000 for the current year.

One of the other issues that Donald Trump brought to the fore is the importance of rare earth minerals. At the end of April, the US and Ukraine signed a historic deal to establish a joint investment fund that will assist in Ukrainian reconstruction. That fund will be capitalized from future natural resource extraction, including rare earth minerals. Trump was the first Western leader – at least to my recollection – who recognized the importance of this natural resource, and this is great news for Canadians.

Virtually every province and territory in this country possesses at least some rare earth minerals. According to our own federal government, Canada has some of the largest known reserves in the world, estimated at 15.2 million tonnes. Given present demand, that would serve the entire globe for the next 50 years. Our country can be slow to the party at times, but I feel confident that in the longer run we’ll get our act together, given our mining tradition, and the extraction of rare earth minerals will be an economic boon.

On June 24 and 25 the 2025 NATO Summit was held in the Netherlands. Trump got the win he was looking for. Virtually every NATO ally committed to spend five per cent of its gross domestic product on defense spending within 10 years. Spoiler alert: it will not happen. Currently most of the biggest, therefore most important, NATO members, are at around two per cent. The reason why these countries committed to five per cent over the next decade is because they know Donald Trump won’t be around at that time.

Yet, to give the devil his due, many NATO countries have already started spending more on defense. It’s Trump’s “Art of the Deal” in action. Demand the whole loaf, accept half as a “compromise” and get all that you had hoped for in the first place.

Donald Trump is unquestionably a divisive figure. However, what everyone I know agrees on is that his impact on international affairs is significant, earning him the monicker of “Black Hole.” SP

His website is www. michaelhlinka.com

“I

think of Donald Trump as the black hole of global economics because of his immense pull in so many different domains.”

One of the biggest complaints arising from vendors after a bid event is predictable, completely avoidable, and yet occurs at least 70 per cent of the time. What is that you may ask? Complaints about not knowing why they lost, how their submission was scored, and a feeling that unless they won the bid, the game was rigged against them from the start. In worst-case scenarios, you award the bid, and the winner immediately goes belly up, rendering them unable to perform.

Every procurement professional has experienced some version of this, a dread that after hitting the submit button, the complaints will pour in, and that the winner will fail, ensuring senior leadership retains their opinion that procurement just isn’t up to the job.

In the myriad award contracts that my team and I have negotiated, I’ve found the only way to minimize the above, and maximize results, is to begin the communication process early and to be transparent. Too many teams try to be cute, treating the whole ordeal as though they were buying a car at a used car lot, with four trips to “see the finance guy,” and both sides walking away feeling ripped off.

Some will say that’s a solid outcome – everyone is a little disgruntled and the dollars saved have been hard won. I believe that the best business relationships and results, particularly for ongoing business continuity for customer and supplier, come from deals where everyone walks away a little happy, a little guilty that they

might have just pulled one over on the other, and with a commitment to perform.

What are the steps my teams and I have taken? Number one is to ask for service-first bids, and then costfirst bids. Don’t allow a change in business priorities to force you to start from scratch when you eliminate all the high-cost, high-service bids in round one only to learn the SVP has declared the theme for next quarter to be “zero failures.” Send weekly updates on status to your bid group beginning no less than six weeks before a comprehensive bid launching. These updates force you and your team to think through what is changing, what you’re seeing, and most importantly, create a situation where your bidders will show their cards.

What do I mean? It’s easy to listen to a suave salesman on a call pitch a bid, run the numbers, and only after awarding them, realize the guy never considered X, Y, or Z , which means the rates are entirely fictional. Or listen to the sweet tones of sales promising the world in service, only to learn that the pivot to cost only meant that the great deal you got on the new kitting requires assembly at your site. Invariably, that learning comes only after the first container arrives, and usually on a day when the president of the company happens to be visiting.

Quick communication, experienced procurement folks, and solid business relationships can help you recover from nearly any poor bid, but the goal is to avoid

those pitfalls in the first place. Here are some best practices to help you do just that:

Always get bids for low cost and best service separately. You can’t predict which one will win, and too often selecting for one at the outset means you have to start anew. And, contrary to the firmly held beliefs of many CFOs, there is no such thing as the lowest cost provider also being the absolute best quality.

Start your communication with potential suppliers six weeks prior to the bid opening and continue until the selectees are announced. Then, explain what made the winner win. Tell people how to be successful in the future. This will not be the only bid you ever get.

Ensure your selection criteria is not driven solely by finance. Manufacturing, operations, and quality should be at a minimum aware of the new bid, but ideally involved in the selection updates.

Share your updates with senior leadership no less than eight weeks prior to the bid start. Do not avoid telling them in hopes that this will go easier. Well, don’t do that unless you enjoy your name being thrown around negatively in rooms you’re not in later.

Find your bid collector. You know, the new person you’ve put on the team who has to collect all of the responses and answer questions they don’t know the answer to. Sometimes, that’s an intern.

“Complete a post-mortem on any bid that either represents more than 10 per cent of your spend or is business critical.”

Educate that person on when to respond and how to answer questions. If your bid collector is an employee, ensure that they’re actually answering questions, and providing real answers.

Complete a post-mortem on any bid that either represents more than 10 per cent of your spend or is business critical. Finding out what went well and what went wrong will help. Embrace the mini bid for anything less than the above. Do not force your suppliers or partners to suffer through an eight-week process for a single part. No one has unlimited time, so value theirs. Use your learnings from post-mortems on big bids to inform your small ones and watch efficiency roll through the team. SP

Photonic quantum computing company Xanadu has opened a $10-million advanced photonic packaging facility in Toronto. The facility will enable secure production of high-performance quantum components for quantum computers, the company says. Photonic quantum computing uses photons (individual light particles) to represent and process quantum information.

While supporting Xanadu’s internal hardware roadmap, the facility will also serve as a resource for advanced manufacturing, open to external customers.

The facility adds manufacturing capacity to Canada’s quantum ecosystem, the company said, reducing reliance on international packaging providers. It also contributes to the growth of a sovereign quantum supply chain, spanning chips, cryogenics, electronics, and control systems.

Cascades Inc. has announced that its corrugated medium manufacturing facility in Niagara Falls, New York will be permanently closed as part of the optimization of the company’s packaging production platform. Production will end no later than September 3, 2025.

The company said that the closure aligns with its commitment to support strategic growth by focusing on profitability and customer service levels. The Niagara Falls production site has an annual production capacity of 200,000 short tons. A second machine at this facility was closed in 2023. Closure costs are estimated at approximately $5 million.

The Canadian economy will face further headwinds amid uncertainty over US trade policies, says research from The Conference Board of Canada. GDP is forecast to increase by 1.5 per cent in 2025.

Following two years of growth, the US economy contracted in the first quarter of 2025. Given the trade conflict, Canada’s trade sector will have a rough ride. While Canadian exporters have turned to new markets, these gains are insufficient to offset the sharp decline in exports from the US. Import growth will be held back as Canadians and businesses rein in spending.

Canada’s labour market is showing weakness. Fragile business sentiment is dampening hiring, slowing job growth, and pushing the unemployment rate up. The effects of the federal government’s 2024 migration policy changes are taking hold, with employment growth outpacing labour force growth in the first quarter of 2025.

Concerns over the Canada-US trade relationship are dampening spending. Policies to make Canada attractive for investment could boost capital spending. However, uncertainty in the EV space is adding downside risk.

SEMI, an association serving the global semiconductor and electronics design and manufacturing supply chain, has reported findings from its latest 300mm Fab Outlook report. The report shows global front-end semiconductor suppliers are accelerating expansion efforts to support the surging demand for generative AI applications.

According to the report, the global semiconductor manufacturing industry is expected to maintain strong momentum, with capacity projected to grow at a compound annual growth rate (CAGR) of seven percentage points from the end of 2024 through 2028, reaching a record high of 11.1 million wafers per month (wpm).

The UN Global Compact has launched the Coalition for Sustainable Procurement, an initiative designed to elevate procurement as a lever for advancing sustainable business. Anchored in the UN Global Compact’s Sustainable Supply Chains & SMEs Programme, the Coalition brings together companies committed to embedding sustainability across their procurement practices.

The coalition plans to convene chief procurement officers (CPOs), chief sustainability officers (CSOs) and public sector leaders to align procurement with the sustainable development Goals (SDGs).

The founding member companies will be announced on September 25 2025 at the Chrysler Building in New York. The event will gather procurement and sustainability leaders to identify challenges, opportunities, and pathways for strengthening sustainable procurement practices. This will mark the first in a series of engagements to accelerate knowledge sharing, foster innovation, and drive action.

Driving this growth is the expansion of advanced process capacity, which is expected to increase by about 69 per cent. AI inference is another catalyst, the report says. Market expansion is further fuelled by AI’s integration into system software for personal assistants and innovative applications.

BY CHRISTIAN SIVIÈRE

What are the main risks in supply chain and logistics? Global financial services company Allianz provides us with solid data in their yearly Risk Barometer published at the beginning of every year. In the 2025 edition, cyber, business interruption and natural catastrophes were the first risks of concern for businesses globally. Their study surveyed 3,778 companies from 106 countries. With a larger proportion than ever before (38 per cent), cyber incidents consolidated its position as the most important risk, while a related one made its entry in the top 10 at number 10: the risk impact of new technologies and developments in artificial intelligence. Closely linked to cyber, business interruption ranked second (31 per cent), just ahead of natural catastrophes at number three (29 per cent). Climate change was another standout result, the bigger mover in the top 10 risks globally, climbing two places to number five (19 per cent), achieving its highest ever position in the survey. Changes in legislation and regulations also drew a bigger response this year, retaining number four globally (25 per cent).

The survey’s findings specific to Canada show similar concerns

in a slightly different order. Business interruption came first at 38 per cent, natural catastrophes, including extreme weather events, came second at 37 per cent, cyber risks came third at 35 per cent and climate change, for example disruptions resulting from global warming, came fourth at 23 per cent. They are followed by change in legislation and regulation in fifth position, equally with shortage of skilled workforce (both at 19 per cent), fire and explosion (16 per

cent), macroeconomic developments (15 per cent) and critical infrastructure blackouts or failures (11 per cent).

Recent history taught us lessons on dealing with business interruption, including disruptions caused by the COVID-19 pandemic. Then we learnt that, from an operational viewpoint, successful companies need flexibility, creativity, social responsibility, and ample resources to stay in business. From a more basic risk management,

financial point of view, companies that had purchased business interruption insurance, fared better that those that hadn’t. Business interruption insurance compensates businesses from losses derived from unexpected disruptions and can cover lost income, rent or payroll when outside, unforeseen events force a business to temporarily close. Of course, this has costs and it’s impossible to know with certainty if the benefits will outweigh them.

Natural catastrophes, including losses caused by storms, floods, earthquakes, wildfires, and similar extreme weather events could be grouped with climate change and disruptions from global warming, if you believe they are more frequent, and are caused by human activity. On the other hand, the MAGA movement in the US refutes that and many environmental regulations have been curtailed south of the border, including cuts in government agencies and services like the National Weather Service, education, universities, research institutes, and so on. This is a dangerous trend because some countries may do the same, to stay competitive with the US

Cyber risks include cybercrime, IT network and service disruptions, malware/ransomware, and data breaches. These risks are growing as fast as progress in technology. The more information we share, the more exposed we become. In June, it was revealed that 16 billion passwords had been exposed in a record-breaking data breach, opening access to Facebook, Google, Apple, and many other services used by businesses. It’s apparently the largest data breach in history. Records are scattered across 30 databases and the data is recent, not just recycled from older breaches. Cybercriminals now can exploit these credentials for account takeovers, identify theft and phishing attacks. How to protect yourself: reset passwords regularly, select strong, unique passwords that are not reused for multiple platforms, enable multi-factor authentication when possible, and monitor your accounts closely. And ultimately, control and limit how much data you give out. Changes in legislation and regulations, including new directives,

protectionism, environmental, social, governance and sustainability requirements is a broad topic. One popular belief is that excessive regulations lead to inefficiencies, restrain innovation and economic growth. Some philosophers argue that a proliferation of rules makes us dumber and less happy, and that we could be better off with fewer rules. But we also know that rules are needed to protect consumers, workers, the public, the environment and generally speaking, the common good.

Protectionism is an interesting issue. For years, the free and democratic world, led by the US, has been championing free and open trade, promoting a rules-based world order, while dictatorships with controlled economies were erecting trade barriers. The MAGA movement has turned the tables and the US is now the champion of protectionism, erecting tariff barriers

against many countries, contradicting international trade rules. It is difficult for Canadian businesses to insulate ourselves from this highly abnormal situation south of the border, given than 75 per cent of our exports go to the US, slightly over 50 per cent of our supplies come from there and our economies are closely integrated. An essential tool to lessen our dependence on the US is to diversify both our export markets and our sources of supplies, turning to other parts of the world like Europe, Asia and Latin America, while promoting internal Canadian trade, but this takes time.

Shortages of skilled workforce is a known problem deriving from population aging, that may only be solved with immigration, but this poses other challenges. Limiting fire and explosion risks requires reducing the quantity and movement of dangerous substances to a minimum, having proper safety procedures in place. This points to more regulations

25_007012_Supply_Professional_AUG_CN

or a better enforcement of existing regulations. We see this issue coming up regularly with electric vehicles and the increased use of highly flammable lithium-ion batteries. Macroeconomic developments refer to inflation, deflation, unemployment, government programs, monetary policies, austerity programs, larger issues that are beyond the control of individual companies, hence addressed case by case, as they arise. Critical infrastructure blackouts refer to power disruption or failures, for example aging dams, power plants, bridges, roads, rail tracks and the like that play a role in a smooth and efficient energy distribution across the country. These also tend to be associated with government policies and priorities, although some, like rail tracks, are often privately owned. Ultimately, resilience comes from raising awareness of these issues through sharing of information, constant monitoring of changes,

education, adaptation and collaboration with customers, suppliers and other stakeholders, in our uncertain, dangerous, and sometimes unpredictable world. And with respect to increased cyber risks, we must take them more seriously and limit the data we give out. SP

BY MICHAEL POWER

Many struggle to find meaning in their careers. Yet not everyone can give back while making a living. Nicola Raycraft is one such person. While she’s worked in multiple supply chain environments, it’s been her current position as customer experience director, strategic sourcing, at HealthPRO Canada, that has allowed her to make the biggest positive difference.

Yet her procurement journey began outside healthcare. She has worked in sectors like automotive, food manufacturing, packaging, and CPG. She eventually transitioned to public procurement, where she has spent the last 18 years. Healthcare has allowed her to focus affecting the world for the better. Yet each position has presented unique challenges that have helped her to foster a strategic mindset and work on operational agility, she says. In the automotive sector, for example, Raycraft learned the discipline required for lean manufacturing and just-in-time logistics. Through her stint in the dairy industry, which uses a quota-managed system, she learned about compliance, quality assurance, and risk

management under tight timelines. From packaging, she learned the value of innovation, especially as it applies to potential suppliers.

“Public procurement instilled the importance of transparency, fairness and the stewardship of public funds,” Raycraft says. “Those early experiences laid the foundation and gave me a well-rounded view of how procurement functions in different sectors. It taught me how to manage complex supplier networks and navigate volatile markets, building resilience, and sourcing strategies. I began seeking a more purposeful, driven path, and I think that’s where it took me to healthcare. We all work for a paycheque. But we all work for something much more. The ability to put out procurement documents and make procurement decisions that could directly impact lives was very impactful for me. That’s probably one of the big reasons why I went into it.”

Raycraft began her supply chain career in 1998 at Volvo Motor Graders. From there she worked in several supply chain positions,

including as purchasing manager at Schaeffler Canada, and logistics and planning manager at Parmalat Canada. In 2010, she landed a position as director of supply chain management at Jones Packaging. Raycraft then entered healthcare the next year, where she has spent 18 years in supply chain leadership roles. She began at a company called MedBuy, which has since rebranded as Mohawk MedBuy. She then worked for Baxter Canada as director of health systems for Ontario. In 2022, she joined HealthPro Canada, a group purchasing organization focusing on public procurement.

Along the way, Raycraft earned a supply chain education. After she got married, her first occupation as a stay-at-home mother. But when her children began school, she decided she needed something else to occupy her. She did her Certified Professional Purchasing (CPP) designation, which became the CSCMP designation through the Purchasing Managers Association of Canada (PMAC). Following that, she earned a graduate diploma in management from Athabasca University before ultimately getting an MBA in 2008, also from Athabasca.

Raycraft now lives in the small town of Mitchell, about a 20-minute drive northwest of Stratford, Ontario. She’s originally from Fleur-de-lys, Newfoundland and Labrador but moved after finishing high school. She met her future husband in Ontario, who is from a small farming community not far from Mitchell.

Like many in the field, Raycraft’s workday is anything but typical. Yet she stresses that it’s the unpredictability that makes her position so dynamic and fulfilling. When she first joined HealthPRO, she led national sourcing and contract management across five non-clinical portfolios. She looked after capital equipment, signature services, supportive services, food and nutrition, as well as energy management.

Each area has its complexities, stakeholder expectations, and supplier dynamics, she says. Back then, her day was a blend of strategic planning, market analysis, data analysis, and cross-functional collaboration. The company dealt with 3,000 hospitals across Canada and the position involved a lot of problem solving beyond the technical and operational elements.

“It was more about building strong relationships, especially trust relationships with suppliers and our members as well,” Raycraft says.

Her role now involves a large element of leadership, or mentorship, as she prefers to call it, which has been central to her roles throughout her career. Health PRO, where she now works, will soon be 30 years old, and many

of its employees have worked there for decades. One of Raycraft’s team members just celebrated a 25th anniversary, for example. Such long tenures show how much its employees value working at the company, she notes.

As a somewhat recent hire, Raycraft feels that she brings a fresh point of view. It’s a perspective developed from the variety of positions she held before starting at HealthPRO.

“Mentorship and leadership have been central,” she says. “Supporting and growing high

performing teams, that’s a personal priority for me as well. And I also still remain actively engaged with my professional education – contributing as a lifelong learner, staying attuned to market trends, emerging technologies, and health systems. Just recently, I just did six courses on circular economy, because that’s something that’s super important to us as an organization, and also in healthcare.”

Last January, Raycraft stepped into a new leadership role, which she says represents the

vision of her and another colleague. The organization created a customer excellence department, with Raycraft as the director of customer experience and strategic sourcing.

The new department and position represent a structural change within the organization, she says. It’s a vision that includes a segregation of duties and a strategic view of how things work. There’s a philosophical shift in which suppliers are treated as customers. There’s also a contract management approach with a shift away from a transactional view. This approach is more grounded in strategic and value-based engagement. That shift is similar to the one Raycraft’s career took across her years in the field.

“My whole career has been in supply chain, with the early years more supply chain, but now I’m more deeply embedded from a strategic sourcing standpoint,” she says. “But all of those things, as our economy and as our work became more global, the knowledge of that end-to-end supply chain benefited me very well.”

A long career is bound to have highlights, and Raycraft’s is no exception. A defining aspect, she says, has been leading sourcing and supply chain operations during three pandemics, along with recovery from a natural disaster. The first pandemic was the 2009 H1N1 influenza pandemic, also known as swine flu, which was a global outbreak of an influenza A virus. The second pandemic was the 2014 Ebola outbreak. The recent COVID-19 pandemic represents the third pandemic. Meanwhile, she also worked through Hurricane Maria, a Category 5 hurricane of September 2017, which caused widespread destruction and a significant humanitarian crisis.

While these were major global events, they were especially impactful to those working in healthcare, Raycraft says. The urgency was real, and the stakes were high. A lack of basic items like surgical masks and gloves for frontline workers hampered their ability to provide care. Traditional procurement models aren’t always adequate in such situations.

“It forces you to rethink everything, how you source, how you allocate,” she says. “We now have procedures in place with Health Canada on how to escalate bringing, say, a product or a drug into Canada. And I was part of all of those teams. In fact, I still sit on a national committee for shortages and supply disruption, and that’s across Canada. And Health Canada is the chair of that, but it represents healthcare across the country.”

Raycraft has also earned recognition during her supply chain tenure. A particularly meaningful honour came 15 years ago, when she received the 2010 Supply Chain Canada Outstanding Achievement Award. Raycraft considers the award not only important from a professional standpoint, but also a personal milestone, as it represents her commitment to both operational excellence and thought leadership.

A second award that also represents her commitment to thought leadership was when she received the Canada’s Procurement Research Foundation’s best research paper.

“Both of those awards were recognition of sustained performance, leadership, and impact in the field,” she says. “And that award to me, what I really took away from it, what resonates through to today, is that it acknowledged not just results delivered, but the way those results were achieved, through innovation, mentorship, and collaborative engagement with a focus on strategic value.”

The award also demonstrated to Raycraft that procurement professionals should strive to be system change makers, rather than simply placing orders and negotiating prices. Those accolades also highlight what she considers her dual roles in the field: that of practitioner and educator.

“I’ve never seen procurement as simply a function of execution,” Raycraft notes. “These awards validated that perspective and pushed me further to bridge that gap between theory and practice.”

Regardless of the industry, whether healthcare, automotive, food manufacturing, packaging, or another area, supply chain and procurement professionals must navigate a complex world, Raycraft says. Geopolitics, climate change, cybersecurity, and other factors are reshaping the field. They’re also testing the boundaries of legacy procurement models originally designed for efficiency, not volatility.

This shift has been noticable in healthcare, Raycraft says. In the past, it offered stability with events like cold and flu season happening at the same time each year. But global volatility has upended that consistency. A strict focus on low costs and siloed supplier relationships won’t cut it. These days, a more reliable path lies to building supply chain resiliency while recognizing procurement as a strategic enabler.

Professionally, Raycraft says she will continue to focus on pushing boundaries for her healthcare supply chain. That includes championing innovation – she was, for example, part of the team that created an innovation accelerator program at HealthPRO. For her, innovation

“I also still remain actively engaged with my professional education – contributing as a lifelong learner, staying attuned to market trends, emerging technologies, and health systems.”

is what helps to create long-term value, especially with regards to sustainability and equity.

And while there may be discussion of valuebased procurement, organizations must focus more on carrying out such policies. Ensuring that organizations look at the long-term societal impacts of procurement decisions is an important challenge for professionals.

“We’re at a point in procurement where we can evolve from that primary cost focus to becoming true strategic drivers of better patient outcomes, population health and system efficiency,” Raycraft says. “That’s my main focus.”

Another recent focus for her is artificial intelligence. The technology is starting to play a more pivotal role in procurement’s transformation. Raycraft says that she and her team are investigating how to build the technology into processes. AI can help organizations become more efficient in their operations, she notes, for example by doing scoring within the RFP process. It can also help with risk mitigation.

“I don’t think AI is ever going to replace what we do, but it’s going to help us be more strategic and identify risk and what’s important to us,” she says.

A final area that Raycraft says she plans to work on is mentorship and supporting the next generation of supply chain professionals. Beyond her day-to-day tasks, she will work to build strong relationships and enable others to grow and lead with confidence.

“I personally think that great leadership begins at home,” she says. “So having that strong, loving home creates the clarity and emotional resilience that good leadership demands. As I continue to grow professionally, I’m equally committed to living with intention and to lead with both a strategic focus and personal integrity.”

Outside of work, Raycraft enjoys gardening. It’s a pastime that allows her to connect with nature. Yet she considers it more than a hobby – it’s a personal ritual that offers connection

to her late mother who taught Raycraft the joys of getting nutrients and life from the earth.

“When I garden, I feel her presence, and it’s a quiet, sacred space where I reflect on the lessons that she passed on to me and the value of patience, the importance of care, and the beauty of tending to something that’s greater than yourself,” she says.

That passion carries over into the kitchen, where Raycraft loves to cook with fresh, locally sourced ingredients. Cooking is another way for her to express creativity and foster connections, especially with her family. Eating together, especially using herbs grown in her garden, is a way for her family to remain close. It’s also an opportunity for the family to discuss their day.

“My family are my foundation, inspiration and compass, and the love and stability I found shapes the kind of leader I strive to be – grounded, compassionate and resilient,” she says.

Raycraft notes that she’s a firm believer in the adage, “knowledge is power.” While the foundation of knowledge is education, she recommends that professionals stay curious, adaptable, and commit to continuously improving their craft.

For her, procurement and supply chain are more than just business functions. They’re forces for transformation, and one of the few professions with the power to influence outcomes at every level of a business. That includes innovation, sustainability, cost efficiency, and others. Every decision along the chain matters.

Also important are soft skills, Raycraft says. Emotional intelligence, the humility to actively listen, and the courage to act even when it’s inconvenient are important attributes for a transformational leader.

“Surround yourself with mentors,” she says. “Seek out those who challenge you, and who see your potential even when you don’t and push you to grow with both wisdom, and grace,” she says. “It was very beneficial to have a mentor who saw something in me before I even saw it in myself. It’s a gift I carry forward and try to offer others in turn.”

Above all, Raycraft recommends leading with a mindset that’s focused on service to others. “Strive to be remembered for what you gave,” she says. “Not what you took, but what you contributed. Not for the titles, but the legacy of building one’s generosity and integrity. Impact where your work speaks not just to what you achieve, but the difference you made.” SP

BY SAM MANNA

The supply chain world never stands still. The past few years have shown how fast it can shift under pressure from tariffs, global disruptions, labour shortages, and technological change. Whether you’re an early-career planner, an experienced procurement lead, or an operations director, one thing remains true: staying competitive means continually upskilling.

At ThreeLinx Search, we hear from hiring managers every day about what they need most. More and more, clients are telling us they’re not just looking for experience on paper – they’re looking for people who can adapt, collaborate across departments, and bring fresh thinking to solve challenges we couldn’t have imagined a few years ago.

So, where should supply chain professionals focus their learning and development time? Here’s a practical look at the skills that keep you ahead, and the associations and strategies to help you get there.

Data literacy and analytics: Data now drives every supply chain decision, from forecasting demand to managing inventory and optimizing distribution. Many companies still have data sitting unused or scattered across spreadsheets. Increasingly, our clients want people who can not only run the numbers but translate them into clear, actionable decisions.

Analysts are no longer just a support function. Many companies now see their analysts as strategic partners – key people who can surface trends, spot risk early, and help leadership teams make smarter choices.

Candidates who can confidently work with tools like Power BI, Tableau, or advanced Excel stand out. Senior professionals who know how to ask the right questions – and apply insights to real operations –are in high demand.

Where to learn: APICS/ASCM (CPIM, CSCP) modules with strong analytics content. CSCMP (Council of Supply Chain Management Professionals) data workshops.

Risk management and resilience: Clients tell us risk management has become non-negotiable. With supply chains impacted by global events, political shifts, and natural disasters, they want professionals who can build resilience into supplier networks and pivot quickly when needed.

Skills in supplier diversification, nearshoring, and risk mapping are all areas we see in job descriptions again and again. The ability to communicate risk plans and lead teams through disruptions is equally critical.

Where to learn: Institute for Supply Management (ISM); CIPS (Chartered Institute of Procurement & Supply).

Trade compliance and cross-border knowledge: Trade compliance expertise is one area that consistently comes up when we talk to clients with cross-border operations, especially in North America. Tariffs, shifting trade agreements, and customs rules can mean the difference between smooth deliveries and costly delays.

“Senior professionals who know how to ask the right questions – and apply insights to real operations – are in high demand.”

Employers want candidates who know how to classify goods, manage brokers, and keep documentation airtight. It’s one of the best ways to stand out, especially for roles that touch global logistics.

Where to learn: Canadian Society of Customs Brokers (CSCB) –Certified Customs Specialist (CCS). NISCL events and workshops.

Sustainability and ESG awareness: Many companies have moved sustainability out of the boardroom and into daily operations. Clients want procurement and operations professionals who know how to balance cost, efficiency, and environmental impact. Sourcing responsibly, managing supplier audits, and supporting ESG reporting are now core parts of many supply chain roles. More companies want to see real knowledge in this area when they hire.

Where to learn: ISM sustainability and sourcing training, CSCMP sustainability webinars.

Leadership and people management: This one is a common theme in our calls with clients: technical skills will get you in the door, leadership skills will get you promoted. Many professionals reach a ceiling because they haven’t developed the people side of the job.

Employers want professionals who can mentor others, manage teams through change, and build strong relationships internally and externally. Being able to present ideas clearly and resolve conflict effectively is a real advantage.

Where to learn: APICS/ASCM leadership tracks. Local NISCL or CSCMP workshops.

Embracing automation and AI: From robotics to machine learning, technology is transforming supply

chains. Clients regularly ask us for candidates who understand automation basics and can bridge the gap between tech teams and operations. No one expects you to code, but employers do value people who can spot opportunities for automation and help roll out new tools successfully.

Where to learn: Coursera or LinkedIn Learning; ASCM and ISM conferences.

Find a mentor and learn across industries: One thing that often surprises new candidates? Supply chain skills are universal, but each sector is unique. What works in automotive may look very different in food, pharma, or consumer products. Our most adaptable candidates talk to peers outside their industry and bring fresh solutions back to their own teams. Mentorship is equally important. Having someone in your corner who’s navigated economic shifts, supply crises, and career turning points can help you stay focused and confident.

Where to connect: CSCMP, CITT, ASCM cross-industry events. Webinars, panels, or local meetups. From what we hear every day; companies aren’t just filling jobs. They’re building teams that can handle whatever tomorrow brings. They want supply chain professionals who blend technical know-how with strategic thinking, data fluency, strong communication, and resilience.

Pair those skills with a mentor and a strong industry network, and you’ll be ready for whatever comes next – and stand out in a market that needs skilled supply chain talent more than ever. SP

BY JOHN MCCLYMONT

The path to a sustainable last-mile network isn’t about waiting for a technological saviour. It’s about retailers taking ownership of the problem. This requires a shift in mindset and operations, and an acceptance of the current system’s limits. Retailers must then establish density within their sales base, moving from a passive to an active role.

The conventional model is time-based, meaning orders are processed as they arrive. A sustainable model uses volume-triggered fulfillment. This doesn’t mean retailers should take on the monitoring themselves. Instead, it requires better collaboration, leveraging carrier partners to manage these volume triggers across a broader client base.

By aggregating orders from various retailers heading to the same area, carriers can meet density thresholds quicker, limiting negative impact on consumers’ delivery times while ensuring profitability.

The rules governing these thresholds – the correct volume for different predefined geographies – are a joint effort between retailers and service providers. Just as traditional pricing uses “zones” based on time and distance, this approach establishes a new “activity zone” model. This prioritizes network-wide efficiency over processing orders in isolation.

Currently, expectations for “fast and free” delivery drive up costs. Retailers absorb these costs into pricing models, which made sense with

higher-margin goods and healthier basket sizes. But, with the growth of commoditized and lowvalue goods, average order values (AOVs) have plummeted. This practice can no longer apply.

Retailers can shift the value proposition away from speed and toward reliability and transparency. This requires a “what’s-in-it-for-them” approach. Instead of removing popular options and creating a sense of loss for consumers, retailers must create offers that entice customers to choose more sustainable, density-building delivery windows. By creating incentives (like direct price discounts, exclusive access to promotions, or other perks), retailers allow customers to justify a different choice, reframing it as a gain. Being explicit at checkout empowers customers.

Single-family home delivery is inefficient. Moving the final collection point to consolidated locations is a powerful strategy. Buy Online, Pick-up In-Store (BOPIS) eliminates the last-mile cost by shifting the final leg to the customer. Automated parcel lockers and staffed pick-up/drop-off (PUDO) points solve the two problems of low density and high failure rates. A courier can deliver dozens of packages to a single locker in one stop with a near-100 per cent first-time success rate.

Spreading volume across multiple carriers to “rate shop” atomizes volume so no single partner can achieve profitable density. The stra-

tegic alternative is to shift from a transactional to a relational approach.

Use diversification to build deeper partnerships with fewer carriers and consider awarding exclusive rights for a specific region to one carrier. Guaranteeing them a critical mass of volume gives you the leverage to demand better service and collaborate on long-term efficiency. Free shipping should not be a default expectation. It must be positioned as either an earned reward for non-members or a benefit of a paid membership program. For the general customer base, minimum order thresholds are essential to ensure that smaller, less profitable orders don’t erode margins. For loyal customers, free shipping can be a powerful retention tool, but it should be bundled into a membership program.

This creates a value proposition: non-members are incentivized to increase their basket size, while the benefits of the membership program become an attractive alternative for those who order more frequently. For customers who need a product in a rush, a premium charge for the delivery is justified. Walmart has used this approach successfully. Failed deliveries multiply costs. Address validation at checkout is not enough. Retailers must monitor and validate why deliveries fail. It’s unrealistic to assume a carrier partner can track and resolve every exception. Retailers must therefore implement systems to surface recurring issues tied to individual customers, specific

geographies, or even product types. Those who manage the quality of their data and delivery instructions are in a stronger position to negotiate and establish partnerships.

Global e-commerce growth is built on a broken logistical foundation. The system is squeezed by shifts in consumer expectations and the rise of low-cost, commoditized goods. With last-mile expenses accounting for 50-to-55 per cent of shipping costs, the path to profitability and sustainability demands more than cost-cutting. Getting deliveries done on time while keeping costs from spiraling means a more resilient strategy.

The problem is a misunderstanding of logistics economics. Traditionally, the movement of goods benefited from economies of scale; shipping large volumes to a few centralized locations lowered per-unit cost. Direct-to-consumer (D2C) e-commerce shattered this model. It forces unitary orders and small shipments to geographically dispersed doorsteps. This creates a reality in which the driver of profitability in the last mile is not total aggregate volume, but delivery density, meaning the number of packages delivered per hour within a specific geographic area.

A retailer that doubles its sales by acquiring customers spread thinly across new territories doesn’t make its delivery network more efficient. It forces its carrier partners to run more low-density, money-losing routes.

To grasp the importance of density, you must deconstruct the profit-and-loss statement of a single delivery route. A last-mile route is a fixedcapacity and largely fixed-cost asset for the day. The driver’s shift time and the vehicle’s physical capacity are rigid constraints. Once a truck leaves the depot, most of its costs are locked in.

This debunks the myth that a “light” day with low package volume translates to a shorter, and cheaper, carrier workday. If the deliveries are scattered across the same geography, the driver travels a similar distance in less time. Fixed costs remain the same. In this model, package volume is not a cost driver; it is a revenue generator. The carrier only profits after the revenue from delivered packages surpasses the fixed daily operating cost.

This is where the gig economy comes in, which can theoretically operate at a lower cost. While crowdsourced models avoid many of the fixed overheads of legacy carriers, they’re not immune to the laws of last-mile economics. They must still hit a critical number of transactions per hour to be profitable. The model also carries risks, as a growing number are unwilling to do demanding delivery work for low pay.

This discourages the professionalism needed to maximize route density and operational excellence. To lower shipping expenses, retailers can adopt a multi-carrier strategy, spreading

“By aggregating orders from various retailers heading to the same area, carriers can meet density thresholds quicker.”

their volume among several providers to find the lowest rate. This means difficult regions are forced onto national networks, while the deeper density in urban areas is siphoned to cheaper regional or gig-work carriers. This fragments the delivery density of any single carrier.

Route optimization software is essential, yet its impact is limited. It works on a pre-existing set of packages already on a vehicle. It can make an inefficient, low-density route more efficient, but it can’t create density. If the software saves a driver 30 minutes, but there are no more packages to deliver in that rescued time, it generates no new revenue. It preserves margin but doesn’t add value.

Decentralizing inventory through micro-fulfillment centres (MFCs) seems like a sound principle.

Placing inventory closer to customers shortens the final delivery leg. But, for most brands, this is a strategic trap. The focus on last-mile transportation savings obscures the total cost of ownership. The high price of urban real estate, technology maintenance, increased middle-mile costs to replenish numerous facilities, and the complexity of managing fractured inventory offset last-mile gains. It only works for the largest retailers with massive, predictable volume.

Some tout autonomous vehicles as a solution. But these technologies face challenges from technological limitations and infrastructure costs. They ignore the blind spot of the physical capacity of urban infrastructure. A delivery truck might make 150 deliveries. In an autonomous future, those deliveries could require 15 or more smaller autonomous vehicles. This would unleash a flood of new ‘vehicles’ onto already clogged roads.

The path forward demands a radical shift. It begins with retailer accountability, engineering density, recalibrating customer expectations, and strategic partnerships with carriers. Success will come to those who build the most intelligent, resilient, and economically sustainable delivery ecosystem. The time for strategic action is now. SP

TRAINING NEEDS & GAP ANALYSIS WITH DIGITAL ACADEMY: Make succession planning easier by understanding individual skill gaps and assess your bench strength with a cumulative analysis.

ALL-ACCESS CORPORATE SUBSCRIPTION PROGRAM: Get Cost-efficient, scalable and hassle-free access to 50+ training courses, to ensure high impact teams with smart investment.

CUSTOMIZED CORPORATE TRAINING: Tailor your training to bridge your talent gaps or build project-specific or enterprisespecific capabilities.

For further information contact:

TANAYA JAIN at tjain@niscl.ca or 416.977.7566 x2142

NISCL-CSCL & MCIPS DUAL DESIGNATION: Two Powerful Designations – Certified and Chartered.* One Seamless Path to Global Recognition. For the first time ever get the Global and Canadian Designations – ROI driven curriculum that offers easy payment plans.

NISCL & CIPS DUAL MEMBERSHIP: Get associated with prestigious global organization and get access to robust resources and a community of 60,000 members globally to build a global network.

NISCL LEARNING & DEVELOPMENT: Get access to leadingedge training and development, on industry-leading topics and through 5 certifications.

*The Chartered status is attained within 1 year of attaining the MCIPS Designation.

For further information contact: KATIE CHESHIRE at kcheshire@niscl.ca or 416.977.7566 x2149

Public Sector & Healthcare Conference

SEPTEMBER 25, 2025

Infrastructure & Healthcare Conference DECEMBER 4, 2025

Leadership Series: Digital Transformation in Supply Chain FEBRUARY 26, 2026

SPONSORSHIP: Speaking opportunity for visiblity to 15,000+ supply chain professionals across Canada. Contact: HIMANI DUREJA, Senior VP, Strategic Partnerships and Learning I hdureja@niscl.ca

Leadership Series: Sustainability & ESG APRIL 30, 2026

REGISTRATION

Book your seat early. Limited seats.

NOMINATION DEADLINE Friday, August 29, 2025

NISCL AWARDS EARLY-BIRD DEADLINE Friday, August 29, 2025

SPONSORSHIP DEADLINE Wednesday, October 29, 2025

ELEVATE YOUR IMPACT: BUILD CREDIBILITY, VISIBILITY, AND STRATEGIC RELEVANCE

NOVEMBER 13, 2025 Toronto Congress Center, Mississauga

SPONSOR THE AWARDS: Elevate your brand awareness and build industry relations. Contact: HIMANI DUREJA, Senior VP, Strategic Partnerships and Learning I hdureja@niscl.ca

CHRIS MITCHELL Chief Procurement Officer Province of Nova Scotia

NISCL AWARDS JUDGES PAUL GIAMBERARDINO Chief Supply Chain Officer Staples Canada

MURAD AL KATIB President and Chief Executive Officer AGT Food and Ingredients Inc.

FERNANDO J. PICA

CFO & VP, Strategic Business Services Vancouver Coastal Health

Contact: HIMANI DUREJA, Senior VP, Strategic Partnerships and Learning I hdureja@niscl.ca

BY MATHEW ZARZYCKI

In an era of fast decisions and volatile headlines, it’s easy to lose sight of the long game. And yet, logistics professionals – especially those in trucking – know that the real work of trade isn’t reactive. It’s generational.

Trucking doesn’t make the news when things run smoothly. It’s only when lanes shut down, tariffs spike, or border delays choke production schedules that supply chains get attention. But behind every efficient delivery is a network of operators, dispatchers, and drivers translating policy into physical movement.

This is the reality of the industry we’re in. And if we want to future-proof it, we need to think beyond freight rates and fuel surcharges. We need to treat trucking as what it truly is: the connective tissue of a cooperative economy.

Canada has built its brand on openness to global trade. Yet we often overlook how internally closed our logistics system remains.

Interprovincial inconsistencies – mismatched weight limits, conflicting emissions rules, and province-specific permitting headaches – create friction that isn’t just inconvenient. It’s economically costly. Add to that the lack of harmonized enforcement around driver classification (like the ongoing “Driver Inc.” issue), and you have a fragmented system that undercuts the very trade corridors we depend on.

These barriers aren’t imposed by foreign governments or geopolitical rivals. They’re selfinflicted. And they mean that Canadian goods often navigate more red tape domestically than they do internationally.

Logistics professionals see this every day: they’re not just moving product, they’re navigating policy. If Canada wants to compete globally, it has to start by cooperating internally.

With US election cycles heating up and protectionist rhetoric returning, it’s no surprise that Ottawa is quick to respond with reciprocal tariffs. But too often, these measures serve more as polit-

ical optics than protection. They feel good in the short term but rarely address the structural issues that weaken our trade resiliency in the long run.

Canadian tariffs on US goods, from steel and aluminum to household items, may send a political message, but they often lack strategic follow-through. Meanwhile, the freight flows affected by those decisions become less predictable and more expensive. It’s rarely the pressure that breaks a supply chain. It’s the lack of a plan when pressure hits.

Logistics resilience doesn’t come from dodging volatility. It comes from planning through it. The shippers and logistics providers best positioned today are those who diversified their routing strategies, invested in trade compliance, and understood policy risk not as a one-off but as a constant variable.

There’s still a prevailing mindset in many boardrooms that trucking is a commodity –a simple cost to be minimized. But that thinking misses the point.

Trucking is how trade manifests. Every bilateral agreement, every tariff revision, every policy shift becomes real the moment a truck hits the road. And increasingly, that truck must navigate a patchwork of rules, politics, labour dynamics, and infrastructure gaps to get to its destination. We can’t expect strategic outcomes if we treat transportation as transactional.

Leading supply chains are doing more than reacting. They’re integrating transportation intelligence into planning cycles. They build trusted partnerships across their carrier network. They anticipate regulatory changes and design routing strategies that reflect more than cost –they reflect resilience. They embed compliance expertise into their dispatching and planning processes, not just their quarterly reviews.

In logistics, we’re trained to act fast: expedite the load, reroute the trailer, pull in a team. And sometimes that’s the right move. But the most resilient supply chains I’ve worked with – especially post-COVID-19 – aren’t built on hustle. They’re built on patience and systems thinking. Speed moves product. Endurance builds systems. And in a volatile trade environment, systems are what carry you through the storm.

“We should be at the table when supply chain-affecting regulations are discussed, not just reacting after they’re written.”

It’s tempting to see every new policy or tariff as a threat. But what if we treated these shifts as invitations? When tariffs rise, it’s a signal to revisit supplier footprints and shipping corridors. When the US political winds shift, it’s a chance to refine trade compliance protocols. When provinces debate clean fuel standards or carbon taxes, it’s a cue for logistics professionals to engage, not just observe.

We should be at the table when supply chain-affecting regulations are discussed, not just reacting after they’re written. Because too often, policies aren’t designed with logistics in mind until there’s a disruption.

That’s the problem. Canada doesn’t need more trucks. It needs more coordination – between provinces, between regulators, and across the industry. Better roads, harmonized rules, and

investment in digital and physical infrastructure build trade. That’s how we create resilience that isn’t just reactive, it’s foundational. As Foreign Affairs wrote in 1932: “Nothing in recent history has so strikingly emphasized the need for international coöperation in the economic field as the business depression which now for over two years has weighed down upon the world.”

Substitute “pandemic,” “trade war,” or “supply chain disruption,” and the lesson still holds. Cooperation isn’t a luxury. It’s the only viable model.

This is not a time for panic. It is a time for clarity. If we want Canadian supply chains to thrive, we must first look inward. We must dismantle the barriers between our own provinces, enforce standards that protect workers and competition, and start treating freight not just as a cost, but as a strategic force for resilience, diplomacy, and growth.

Trade is hopeful. So is trucking. It connects communities. It moves economies. It carries more than freight—it carries possibility. And the more intentionally we build it, the more powerful it becomes. SP

Supply chain management (SCM) is undergoing a seismic shift. Let’s be real – if your strategy still relies on spreadsheets and gut instincts, you’re swinging for the World Series with a tee-ball bat. The 2020 pandemic exposed major vulnerabilities, and today’s escalating protectionist policies are adding layers of complexity, pushing supply chain professionals into a whirlwind of outdated benchmarks and chaotic decision-making. There are reasons why the old scorecards are striking out. Baseball fans can think back to the early 2000s Oakland A’s. The team’s former general manager Billy Beane’s data-driven approach revolutionized baseball talent evaluation. While tradition held most teams back, the A’s leveraged analytics to rewrite the game. Today, supply chain management faces a similar crossroads. The reliance on conventional metrics, like cost

per unit and on-time delivery percentage, obscures the broader strategic impact of modern supply chain challenges and hurdles.

Sticking to old KPIs in today’s volatile environment is like trying to navigate a hurricane with a paper map (remember those?). The pandemic shattered assumptions, geopolitical tensions rewrote trade dynamics, and customer expectations soared. Traditional metrics fail to account for these shifts, for example:

Days sales outstanding (DSO):

Once a gold-standard financial metric, DSO now falls short by ignoring currency fluctuations, trade policies, and the new popular, geopolitical risks.

Inventory turnover ratio: Previously useful but outdated in the era of real-time rapid demand shifts and global visibility. On-time delivery percentage: A supplier’s punctuality doesn’t equate to agility, especially amid disruptions like extreme weather or changing trade agreements.

Cost per unit produced: Focusing solely on production cost overlooks sustainability, ethical sourcing, and resilience. Total cost of ownership (TCO) now holds the strategic edge.

Now artificial intelligence (AI) has stepped up to the plate, and it’s proving to be a game-changer for supply chain management. And AI isn’t just a buzzword. It’s transforming supply chain management through predictive analytics, realtime decision-making, and automation. AI-driven strategies are delivering game-changing results.

These results include a morethan 15 per cent reduction in logistics costs, through optimizing routes, happier carriers, and leaner warehouses. Think of logistics optimization reducing fuel costs, minimizing empty miles, and enhancing fleet efficiency through real-time traffic and weather analysis.

There has also been a 35 per cent-plus boost in inventory efficiency, for example through hyper-accurate demand sensing for superior inventory control, by analyzing real-time demand patterns, reducing stockouts, and preventing overstocking. Machine learning models predict purchasing trends, ensuring optimal stock levels while minimizing storage costs and waste.

Service levels have also surged by over 65 per cent. Real-time adaptability has translated to delighted customers by enabling businesses to swiftly adjust to disruptions, ensuring seamless fulfillment and proactive customer engagement.

The real influence of AI extends far beyond cost-cutting. It’s your all-star power hitter unlocking next-level capabilities. It can accelerate time to market through optimized production and distribution networks. AI-driven risk assessments and forecasting models can enhance supplier collaboration. The technology can also improve customer satisfaction through dynamic inventory and logistics adjustments. Finally, it can help to reduce environmental impact through smarter transportation routes and waste minimization.

Furthermore, AI grants unprecedented transparency into cost progression, revealing smarter pricing strategies:

Manufacturer to distributor: Markups of 15-to-30 per cent, to address production costs and profit margins using tools like dynamic pricing models, predictive demand forecasting and AI-driven supplier negotiations.

Distributor to wholesaler: An additional 10-to-20 per cent for storage and transport, think of route optimization, as well as smart load balancing and warehouse automation to gain deeper insights.

Wholesaler to retailer: Prices climb 20-to-50 per cent, driven

by bulk agreements and market trends like real-time market trends analysis, automated supplier matching and even AI-powered inventory allocation.

Retailer to consumer: Markups range from 50-to-100 per cent, factoring in branding, operations, and perceived value employing demand prediction for stock optimization, AI-powered consumer sentiment analysis and even personalized pricing strategies, which could be a real gamechanger.

Just as Moneyball revolutionized baseball strategy, AI-powered supply chain management is redefining supply chain value. This shift isn’t optional, it’s a strategic imperative. Companies must embrace AI-driven intelligence to remain competitive in an increasingly volatile and interconnected economy.

Artificial intelligence isn’t just improving supply chains. It’s also redefining and elevating them to new heights. The question isn’t if AI will transform SCM – it’s how fast companies can adopt it. It’s time to play ball. The future of supply chain management isn’t just about efficiency – it’s also exhilarating. AI is the catalyst for this next revolution. Are you ready to step up to the plate and hit it out of the park? SP

By Michael Power

Like many industries, there is a shift underway within fleet management brought on by transformative technology. Today’s fleets still face many of the same challenges they always have, but the tools available to deal with those challenges are changing.

The goal is to use technology to make things easier, cheaper, and more efficient. Yet some organizations struggle to adopt these technologies. Once the process is underway, however, organizations stand to reap the benefits that technology offers.Technology has the potential to improve fleet safety, reduce the costs, and help decision making.

It can also boost sustainability, says Aditya Nath, head of sales, North America for Mobilisights, the Stellantis data-as-a-service company (DaaS).

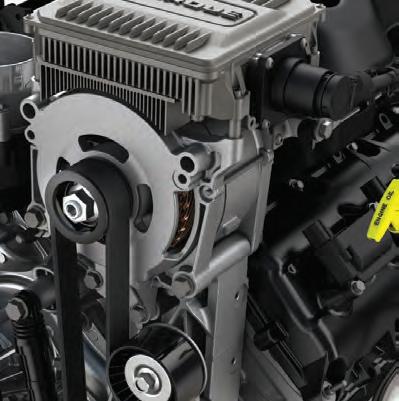

“The biggest driver for sustainability is obviously fuel usage, because at least in North America, we’re seeing electrification of fleets is still a very small percentage of the overall fleet size,” Nath says. “For internal combustion engine fleets, fuel usage drives the biggest positive or negative impact on sustainability, and this can be achieved in many ways. Obviously, by keeping your vehicle in tip-top shape, you burn less fuel.”

Mobilisights takes data from connected vehicles, cleans and har-

monizes it, then provides data service subscriptions to fleets.

The preventive and predictive maintenance that’s available through data and analytics helps to forecast when vehicles may need oil changes, filter changes, or require repairs, Nath says. Proper maintenance of fleet vehicles impacts fuel usage directly. As well, ensuring those vehicles have the correct tire pressure can save between three-tofive per cent on fuel.

The data provided by technology makes all this data visible to fleet managers, he says. As well, GPS tracking allows for route optimization, which can minimize the distance that vehicles drive.

Access to data is a great first step but sifting through it is inefficient and time consuming. The sheer volume of data available to fleet managers poses a challenge. AI can help, as it can absorb a lot of content, says Bob Bradley, associate vice-president, data science and AI engineering at Geotab. It can then highlight insights to help fleet managers make decisions.

For example, sensors in a device located on vehicles can collect data about collisions. But other events, like hitting a pothole or even kicking the device, can mimic a collision.

“This is where AI can help,” says Bradley. “We can feed into an AI

algorithm or an ML algorithm many, many different inputs. We can train those algorithms to try and weed out some of the noise so that we can arrive at those pieces of information that are most important for a fleet manager to deal with. Whether that’s using AI to recognize a collision and then take that information to look at risky driving behaviours that contribute to collisions, then use that information to help a fleet manager prioritize their coaching opportunities within the fleet.”

Organizations are adopting AI to move beyond traditional analytics and dashboard-driven insights, says Brian Antonellis, CTP, Fleet Advantage’s senior vice-president of fleet operations. For example, some companies use data analytics and consolidate multiple platforms into a single, AI-powered solution to optimize route planning. That can mean using agentic AI – artificial intelligence systems that can act autonomously, without human oversight.

“By analyzing historical traffic patterns, weather data, and delivery schedules, the system can reduce fuel consumption and improve on-time deliveries, all without manual intervention at every decision point,” says Antonellis. “This is the kind of operational lift agentic AI makes possible.”

Systems propelled by agentic AI can also aid predictive maintenance, Antonellis says. Such sys-

tems can monitor telematics data to forecast component failures and schedule maintenance. This reduces unplanned downtime and extends asset life.

Telematics, connected vehicles and analytics continue to drive improvement for most fleet operators, says Frank Daccardi, manager, telematics solutions, at Holman. A recent advance in telematics is the addition of cameras in various telematics devices, he says. Fleet operators can capture footage of vehicles in use as well as the driver behind the wheel. They can monitor drivers for high-risk behaviours and provide alerts or coaching to improve performance.

“Fleet operators are now exploring how they may be able to use AI to better analyze and leverage the data telematics provides,” says Daccardi. “The effectiveness of any telematics program is determined by the speed at which you can effectively analyze data and implement change based on that information. AI can accelerate analytics, allowing you to act on the information much faster. Additionally, AI and machine learning can make it much more efficient to explore various data elements and assess the impact of multiple underlying data points to deliver insight.”

Cost remains a barrier to adopting such technologies. But understanding the ROI of having the data

access helps put that cost in perspective, says Nath of Mobilisights. “In the bigger scheme of things, the cost of data is a very, very small cost element, but the benefits are great,” he says. “The ROI is huge, so education is number one.”

While agreeing it can be a barrier, those costs are also dropping rapidly, says Geotab’s Bradley. As well, the company works to use only the technology that’s needed to deliver the right insights to users.

Yet another barrier to overcome is learning to use tech properly to get the results you’re looking for. As everyone gets better at employing these tools, that issue will fade rapidly, he notes.

The common fear that AI will replace humans on the job is also misplaced, Bradley says. Rather, such technologies will help fleet managers make more strategic decisions.

“It’s important with any new technology to start small and look at those small wins,” he says. “Focusing on a safety program and delivering safety ROI is a great way to get started. Then expand that reach to other pillars of the program, whether it be operational efficiency or predictive maintenance and things like that.”

Many organizations still hesitate to go all-in on AI for procurement decisions with only 19 per cent noting they’re “very confident” in this area according to a recent industry survey, says Antonellis of Fleet Advantage. Most likely, this is due to concerns about data accuracy from AI systems. As a solution, “gated data,” meaning highquality, verified information that’s been curated and protected, can help ease this worry.

“It’s critically important to have access to trusted partners that can continue to oversee the impact these machines have on decision

By analyzing historical traffic patterns, weather data, and delivery schedules, the system can reduce fuel consumption and improve on-time deliveries.

making, as well as access to only the most trusted, gated data for extreme accuracy,” he says.

Getting driver buy-in and handling change management are further considerations, says Liz Klein, director of regional sales, Canada, at Samsara. While technology can offer benefits like enhanced safety, increased efficiency and productivity, reduced operational costs, and improved driver experience, drivers may resist change while seeing tech as intrusive or overly complex.

It’s important to communicate the benefits from the drivers’ perspective, for example by emphasizing how they can enhance safety and simplify their daily tasks.

To make the process of incorporating more advanced technolo-