KOLLMORGEN INTRODUCES THE AKMA SERVO MOTOR FOR MEDIUM- TO HEAVY-WASHDOWN APPLICATIONS 21 EMERSON LAUNCHES FIRST COMBUSTION SAFETY SHUTOFF VALVES CERTIFIED FOR BIODIESEL USE IN AMERICAS AND ASIA 48 WHAT LIES AHEAD FOR AI AND MACHINE LEARNING 4 02 | JULY 2023 IN DUSTRY USA ■ ASIA ■ EMEA TELEDYNE FLIR INTRODUCES PREMIUM E8 PRO EDITION FOR POINT-AND-SHOOT THERMOGRAPHY INSPECTION 108 INTERNATIONAL INDUSTRIAL MARKET MAGAZINE

4 WHAT LIES AHEAD FOR AI AND MACHINE LEARNING

10 STRONG HIGH FEED GEOMETRY

11 PRODUCTIVE SHOULDER MILLING

12 SOFTING LAUNCHES THE CABLEMASTER 210 ETHERNET CABLE TESTER

13 COPLEY CONTROLS INTRODUCES COMPACT, EFFICIENT NANO DRIVES WITH ETHERCAT AND CANOPEN SUPPORT

14 A RELIABLE EYE ON HEALTH

18 COMAU IS DEVELOPING A FULLY AUTOMATED SYSTEM FOR SUSTAINABLE BATTERY RECYCLING AND SECOND-LIFE REPURPOSING

20 SOPHISTICATED DATA SCIENCE TOOL FOR OPTIMIZED OPERATIONS

21 KOLLMORGEN INTRODUCES THE AKMA SERVO MOTOR FOR MEDIUM- TO HEAVY-WASHDOWN APPLICATIONS

22 DELTA ELECTRONICS’ AMERICAS HEADQUARTERS BECOMES THE FIRST LEED ZERO ENERGY-CERTIFIED GREEN BUILDING IN FREMONT, CA

24 COMAU’S MATE-XT WEARABLE EXOSKELETON SUPPORTS ERGONOMIC WELL-BEING AT JOHN DEERE’S PARTS DISTRIBUTION CENTER IN BRAZIL

26 HISTORICAL TEXTILES IN FOCUS

30 HMS NETWORKS PRESENTS NEW EWON REMOTE CONNECTIVITY SOLUTIONS WHERE HARDWARE MEETS SOFTWARE

31 NEW OPTIONS FOR

CARBON APPLICATOR

45 ROLLON INTRODUCES HIGHLY ADAPTIVE BEARING FOR LIGHT-TO-MODERATE LOADS IN LINEAR MOTION APPLICATIONS

46 ONE SWEET MACHINE

48 EMERSON LAUNCHES FIRST COMBUSTION SAFETY SHUTOFF VALVES CERTIFIED FOR BIODIESEL USE IN AMERICAS AND ASIA

49 ANELLOTECH WELCOMES JEAN-PIERRE BURZYNSKI AS TECHNICAL ADVISOR AND BOARD MEMBER

50 NEW TELEDYNE GAS AND FLAME DETECTION WEBSITE LAUNCH

51 THE LEADER IN STRIP LEVELLING TECHNOLOGY UNGERER GMBH WILL BE FULLY INTEGRATED INTO REDEX GROUP

52 27 STAGEMAKER ELECTRIC CHAIN HOISTS FROM VERLINDE NOW EQUIP THE NEW LIGHTING SYSTEM OF THE FAMOUS KEISTUOLIAI THEATRE IN LITHUANIA

54 FPT INDUSTRIAL CHOSEN BY MASERATI FOR ITS NEW FULL-ELECTRIC GRAN TURISMO FOLGORE

56 PROACTIVE EQUIPMENT MEASURES VITAL TO OFFSHORE WIND DEVELOPMENT

57 NEW FAMILY MEMBER FOR THE MEDIUM POWER RANGE

58 DRIVES FOR SPEED IN INTRALOGISTICS

60 WHY A STRATEGIC PARTNERSHIP IS THE PERFECT MEDICINE FOR PERMEDICA

ADVERTISERS: • MEPAX 8

www.magazine-industry-usa.com

ECONOMICAL FACE MILLING 32 STAY FLEXIBLE SAFELY 34 COMAU TO DEVELOP NEW MOBILE ROBOTICS SOLUTION 35 CONTA-CLIP GROWS 36 ORBEX GROUP OFFERS NEW CUSTOM BRUSHLESS DC MOTORS 37 HILSCHER’S NETX 90 AND NETRAPID 90 RECEIVE CC-LINK IE FIELD NETWORK BASIC SLAVE CERTIFICATION 38 HART MULTIPLEXER SOFTWARE FROM SOFTING INDUSTRIAL NOW SUPPORTS SIEMENS CONTROLLERS 39 MITSUBISHI ELECTRIC AUTOMATION INTRODUCES POWERFUL MODULE ALLOWING USERS

NETWORKS USING ONE MODULE 40 DELTA HONORED WITH THE ENERGY STAR® PARTNER OF THE YEAR SUSTAINED EXCELLENCE AWARD FOR THE SIXTH CONSECUTIVE YEAR 42 FREE UPDATE MAKES THIRD DEEP LEARNING METHOD AVAILABLE FOR IDS NXT 44 PHOENIX LABELING E-COMMERCE LOGISTIC SOLUTIONS: VOLT770 FULL-ELECTRIC

TO CONFIGURE TWO

02 | Industry USA-ASIA-EMEA | July 2023

INTERNATIONAL INDUSTRIAL MARKET MAGAZINE

62 UNDERSTANDING THE ROI OF VISUALIZATION

66 CONTINUED GROWTH FOR INDUSTRIAL ETHERNET AND WIRELESS NETWORKS - INDUSTRIAL NETWORK MARKET SHARES 2023 ACCORDING TO HMS NETWORKS

68 HMS NETWORKS EXPANDS RANGE OF NEXT-GENERATION GATEWAYS WITH ANYBUS COMMUNICATOR ETHERCAT MAIN DEVICE

70 HMS NETWORKS PRESENTS NEW EWON REMOTE CONNECTIVITY SOLUTIONS WHERE HARDWARE MEETS SOFTWARE

71 SECO JS754 STUB SERIES BRINGS VERSATILITY AND VALUE WHEN MILLING TOUGH MATERIALS

72 SECO IS MOVING TOWARDS A SUSTAINABLE FUTURE AND SWITCHING TO RECYCLABLE PACKAGES

74 EMERSON’S NEW ALUMINUM FILTER REGULATORS ENHANCE PROCESS EFFICIENCY AND STREAMLINE SUPPLY CHAINS

75 QVI ANNOUNCES KEITH E. POLIDOR AS PRESIDENT AND CHIEF EXECUTIVE OFFICER

76 ROUTECO AND CORETIGO ENGAGE IN PARTNERSHIP TO REVOLUTIONIZE UK FACTORY AUTOMATION

77 CORETIGO RECEIVES INVESTMENT FROM AMAZON INDUSTRIAL INNOVATION FUND TO ACCELERATE INDUSTRIAL CONNECTIVITY

78 MOXA JOINS AVNU ALLIANCE AS PROMOTER MEMBER TO FUEL THE FUTURE OF INDUSTRIAL AUTOMATION WITH TIME-SENSITIVE NETWORKING

79 THREE CODESYS-BASED MOTION CONTROLLERS, INCREASING AX-3 SERIES SCALABILITY

80 CASE COMPLETES ENVIRONMENTAL BEACH CARE CLEAN-UP PROJECT

82 KOMATSU INTRODUCES A MEDIUM-SIZED HYDRAULIC EXCAVATOR WITH HYDROGEN FUEL CELL SYSTEM

83 ENABLING LI-ION BATTERY MANUFACTURERS TO TURN DATA INTO EFFICIENCY GAINS 84

TO JUPITER: EXXELIA HIGH RELIABILITY PASSIVE COMPONENTS READY TO WITHSTAND EXTREME SPACE

JUICE

CONDITIONS 85 SMART COCOA PROCESSING THAT

86 PORTABLE JUST GOT MORE POWERFUL 88 KOMATSU ANNOUNCES SWITCH TO HVO AS FACTORY-FILL FUEL 90 PEPPERL+FUCHS FACTORY AUTOMATION: INNOVATIVE TECHNOLOGY REVOLUTIONIZES 3-D MEASUREMENT 92 EXXELIA EXPANDS ITS HIGH-PERFORMANCE DIELECTRIC RESONATORS AND FERRITES CAPABILITIES FOR MICROWAVE APPLICATIONS 93 LEMO PRESENTS 12G-SDI 4K ULTRA HIGH DEFINITION TRANSMISSION PUSH-PULL CONNECTORS 94 FUZZY LOGIC AND VISIONIC, PARTNERS IN AUTOMATING THE CLEANING OF COMPLEX PARTS IN AERONAUTICS 96 WEAV3D AWARDED NATIONAL SCIENCE FOUNDATION GRANT FOR NATURAL FIBER POLYPROPYLENE ENHANCEMENTS 97 ROTACHROM RCPC PLATFORM ADHERES TO CGMP GUIDELINES FOR PHARMACEUTICALS 98 EMITECH GROUP INVESTS €10M IN VEHICLE HOMOLOGATION AND QUALIFICATION OF LARGE SYSTEMS 100 VERLINDE OFFERS ELECTRIC BELT HOISTS FOR A BRINING PROCESS 102 PLANT DOCUMENTATION 4.0 – AN ESSENTIAL ENABLER FOR INDUSTRY 4.0 106 KEYENCE INTUITIVE VISION SYSTEM ENABLES ALPHR TECHNOLOGY TO DELIVER RELIABLE, CUSTOMISED AUTOMATION TESTING SOLUTIONS 108 TELEDYNE FLIR INTRODUCES PREMIUM E8 PRO EDITION FOR POINT-AND-SHOOT THERMOGRAPHY INSPECTION 110 DAHL AND FRIGA-BOHN PARTNERSHIP WILL DELIVER HIGH-QUALITY REFRIGERATION SOLUTIONS IN SWEDEN 112 POTENTIAL WATER RESTRICTIONS SHOULD SPARK COOLING CONVERSATIONS IN EUROPEAN MANUFACTURING SECTOR 113 AGGREKO INVESTS £150M INTO EUROPEAN FLEET OVER 2022-23 114 PCVUE INTRODUCES THE PCVUE 16 PLATFORM INDUPORTALS MEDIA PUBLISHING Send your press releases to: editor@ipmediaonline.com To receive ours newsletters, please subscribe online: https://induportals-media-publishing.com/ Industry USA-ASIA-EMEA is the magazine for engineers, published by INDUPORTALS MEDIA PUBLISHING. It contains the latest product and company news for industrial markets. Industry USA-ASIA-EMEA edits its articles with the greatest of care, however we cannot guarantee the accuracy of the information presented in them. Our teams disclaim all responsibility concerning the content of this media or how it might be used. Our magazines are published on ISSUU.

MISSION

HITS THE PRODUCTIVITY SWEET SPOT

By K.A. Gerardino.

WHAT LIES AHEAD FOR AI AND MACHINE LEARNING

The advent of Artificial Intelligence (AI) has been a key game-changer across many industries. The leading approach to AI is machine learning, in which programs are trained to pick out and respond to patterns in large amounts of data. -

By K.A. Gerardino.

By K.A. Gerardino.

AI and Machine Learning are already transforming the way people interact with technology, making it easier and more efficient to perform tasks, such as data analysis and predictive modelling. This technology is also being used to automate mundane tasks, enabling companies to save time and resources. With the global AI and Machine Learning market anticipated to grow exponentially, the market is expected to expand at a compound annual growth rate (CAGR) of over 20% between 2023 and 2033, according to International Data Corporation (IDC). This growth is being driven by advancements in the technology, including more sophisticated algorithms and better data processing capabilities, IDC reported.

Today, most of us encounter AI every single day. From the moment we wake up to check our smartphone to asking Siri to help find our AirPods or telling Amazon Alexa to turn on the lights and music. AI has quickly made its way into our everyday lives. In fact, AI and machine learning have been around for a long time. The earliest successful AI program was written in 1951 by Christopher Strachey, later director of the Programming Research Group at the University of Oxford. Strachey’s checkers (draughts) program ran on the Ferranti Mark I computer at the University of Manchester, England. By the summer of 1952 this program could play a complete game of checkers at a reasonable speed.

So, What’s The Setback?

With the existing state of things, some people argue that AI will displace occupations and increase unemployment. One application of AI is a robot. Therefore, they claim that there is always a chance of unemployment as a result of chatbots and robots replacing humans. For example, robots are often utilized to replace human resources in manufacturing businesses in some more technologically advanced nations like Japan. AI offers both the promise to improve the safety and health of workers, and the possibility of placing workers at risk in both traditional and non-traditional ways.

In a world still dealing with the impact of an unprecedented pandemic, combined with an increasing amount of industrial automation, the “new normal” has generated significant demand for applications capable of ensuring worker safety. These applications include physical identification and compliance for sensitive environments like cleanrooms used in silicon production, monitoring of industrial settings with heavy machinery in use, keeping track of security zones with restricted personnel access, and more. Enforcing compliance with policies for the appropriate use of personal protective equipment (PPE) and limiting personnel to the locations for which they are equipped results in reduced work-related accidents, thus improving employee safety while also supporting steady productivity. These practices also enable organizations to avoid expensive and reputation-damaging citations from government agencies monitoring industrial environments.

02 | Industry USA-ASIA-EMEA | July 2023 4

MARKET OVERVIEW

Worker safety is not to be taken lightly, as safety concerns have become an issue of widespread concern around the world. Many are turning to AI-powered machine visionbased applications to ensure compliance and maintain enforcement using a centralized architecture. By doing so, these organizations have successfully automated their systems via a combination of smart cameras, sophisticated machine vision applications, and industrial computing solutions that do not require human resources to ensure compliance. These systems are better equipped than humans to complete tasks of this kind. For example, smart monitoring solutions ensure employees are wearing the appropriate PPE when required, ensure the right people are allowed in the correct zones, and enable real-time implementation of corporate policy where it is needed.

However, there are also concerns regarding the use of AI in the workplace. This is especially true if the data used are incomplete, inappropriate, or insecure; the methods are not easily explained or understood; or if the systems operate without the oversight of a human agent. Integration of this technology, using systems which are predictable and reliable, has been shown to improve performance and acceptance. The opposite also appears to be true, demonstrated by failures associated with the Maneuvering Characteristic Augmentation System (MCAS), an AI system designed to activate and assist the pilot under circumstances, which resulted in the two crashes of Boeing 737 Max airplanes.

Trends in AI and Machine Learning

Although research gaps exist regarding the use and impact of AI and machine learning, the use of this technology is already very much part of modern living. Rather than worrying about a future AI and machine learning takeover, let us focus on some of the AI-specific trends that will help us in the next couple of years:

Adoption of cloud computing for machine learning applications: The growing adoption of cloud computing for machine learning applications is also set to be one of the major trends in AI in 2023. With cloud computing, businesses can benefit from improved scalability and flexibility when it comes to their machine learning projects. By leveraging cloud-based services such as Amazon Web Services (AWS) or Microsoft Azure, companies can quickly scale up or down depending on their needs while also taking advantage of advanced technologies like artificial intelligence (AI) and deep learning. As a result, more businesses are turning to cloud computing for their machine learning needs in order to take advantage of its many benefits.

Improved language modelling: ChatGPT demonstrated a new way to think about engaging with AI in an interactive experience that is good enough for a wide range of use cases in many fields, including marketing, automated customer support and user experiences. In 2023, expect to see a growing demand for quality control aspects of these improved AI language models. There has already been a

02 | Industry USA-ASIA-EMEA | July 2023 5

MARKET OVERVIEW

Image courtesy of Microsoft Azure

backlash against inaccurate results in coding. Over the next year, companies will face pushback on inaccurate product descriptions and dangerous advice, for example. This will drive interest in finding better ways to explain how and when these tools generate errors.

Chiplets: AI acceleration has been one of the main drivers for heterogeneous compute in the last few years, and this trend will certainly continue as Moore’s Law slows. Heterogeneous compute refers to the system design technique whereby accelerators for specific workloads are added to more general computer hardware like CPUs, whether as separate chips or as blocks on an SoC. This trend is obvious in the data center, but endpoint SoCs for everything from household appliances to mobile phones now have specific blocks dedicated to AI acceleration. For large-scale chips, such as those used in the data center, chiplets are a significant enabling technology. Chiplets allow huge chips to be built by connecting multiple similar reticle-sized die through a silicon interposer, but they also enable heterogeneous compute by enabling the connection of CPU, memory, and accelerator die at high bandwidth. Chiplet technologies are maturing and will continue to do so in the next two years as we see chips like Intel’s Ponte Vecchio hit the market.

Human and machine collaboration: In the coming years, we can expect to see an increasing trend towards human and machine collaboration in the field of AI. As AI technologies become more advanced and sophisticated, they will be able

to work with humans in order to achieve greater results. This could take many forms, from machines providing assistance with tasks or decisions that are too complex for humans alone, to humans teaching machines new skills and knowledge. By leveraging the combined strengths of both human intelligence and AI technology, businesses will be able to unlock a wealth of possibilities for improved efficiency and productivity.

Transformer networks have been widely used for naturallanguage processing for some time, with impressive results. Today’s large language models (LLMs) can be used to power chatbots, answer questions, and write essays, and the text they produce is often indistinguishable from what a human might have written. These networks use a technique called attention to explore relationships between words in a sentence or paragraph. The trouble is that to really understand language, LLMs need to consider relationships between words that are further apart in the text. The result is that transformer models are rapidly growing, and so are the computers needed to train them. Training of GPT-3 was estimated to cost millions of dollars — that is to train one model, one time. Despite huge costs, the demand for accelerated compute from transformer networks is not slowing down. Economic or practical limits to transformer size – if they exist – have not yet been sighted, let alone reached.

02 | Industry USA-ASIA-EMEA | July 2023 6

MARKET OVERVIEW

Freepik imagerawpixel.com

Generative AI has already been used in creative applications such as music composition and video game design. In 2023, we can expect this trend to continue as generative models become even more sophisticated and powerful. This could lead to new possibilities for creative expression and innovation across a variety of industries. Generative AI models use neural networks to generate new content from existing data. This type of AI can be used for a wide range of applications – from creating images or video effects to generating natural language text and music. Generative models offer an efficient way to generate large amounts of artificial data, allowing organizations to save time and resources in the creative process. For example, generative AI can help developers create virtual environments for video games by automatically generating textures and patterns based on pre-existing data. Generative AI is also helping businesses better understand their customers’ preferences and tailor products accordingly. Companies such as Amazon are increasingly using generative AI technologies to recommend products that customers may like based on past behaviour – resulting in improved customer experiences and better sales.

AI industry regulation: As the use of AI becomes more widespread, governments worldwide are beginning to take steps toward regulating its use to protect consumer privacy and ensure ethical practices are followed. We can expect this trend toward regulation to continue in 2023 as governments look for ways to ensure that companies using AI technology

do so responsibly. Heightened AI industry regulation is already being implemented across the world. In Europe, for example, the General Data Protection Regulation (or GDPR) sets strict standards for companies that collect and use consumer data.

AI-driven technologies such as facial recognition are also increasingly falling under governmental scrutiny – with some countries passing laws to ban their use or restrict its application in certain areas.

In the coming year, we can expect even more regulations to come into effect worldwide – making sure organizations using AI technology do so ethically and responsibly. Such regulations could be critical to protecting public safety and privacy while continuing to allow businesses access to powerful AI toolsets reaping rewards without creating a risk of harm.

AI to make ethical decisions: In 2023, Explainable AI (XAI) is set to be a major trend in the world of Artificial Intelligence. XAI can help machines make ethical decisions by providing humans with an explanation of how a decision was made and why it was taken. This will enable humans to better understand the machine’s decision, thus enabling them to take corrective action if needed. XAI also allows for greater accountability, as humans can review and reject decisions that are not in line with company policies or public safety regulations. XAI makes use of techniques such as natural language processing and machine learning to analyze data and provide meaningful explanations for AI-generated decisions. By using explainable AI, companies can ensure that their AI systems are making ethical and responsible decisions without compromising on accuracy or speed. As such, XAI technology will be essential for businesses looking to deploy AI systems responsibly in 2023 and beyond. Furthermore, explainable AI can be used to promote transparency when it comes to data privacy and usage practices. By providing users with detailed explanations about how their data is being used – including what kinds of algorithms are being employed – companies can ensure that users have full control over their own personal data while still benefitting from the advantages of AI technologies. As a result, explainable AI looks set to become an important tool in helping businesses achieve greater levels of trustworthiness when it comes to protecting user data in 2023 and beyond.

Brain-inspired computing: Neuromorphic computing refers to chips that use one of several brain-inspired techniques to produce ultra-low–power devices for specific types of AI workloads. While “neuromorphic” may be applied to any chip that mixes memory and compute at a fine level of granularity and utilizes many-to-many connectivity, it is more frequently applied to chips that are designed to process and accelerate spiking neural networks (SNNs). SNNs, which are distinct from mainstream AI (deep learning), copy the brain’s method of processing data and communicating between neurons. These networks are extremely sparse and can enable extremely low-power chips. Our current understanding of neuroscience suggests that voltage spikes travel from one neuron to the next, whereby the neuron performs some form of integration of the data (roughly analogous to applying neural network weights) before firing a spike to the next neuron in the circuit. Approaches

02 | Industry USA-ASIA-EMEA | July 2023 7

MARKET OVERVIEW

OPTIMIZE YOUR INTERNATIONAL PR AND ADVERTISING FOR THE INDUSTRIAL MARKET!

International capability

More than 80 employees in 35 different countries, ensuring a strong relationship with main local media.

Mepax distinguishes itself through its extensive media knowledge and ability to select the best international online/print advertising options.

PR can be translated into 35 languages.

Outstanding results

50,000 published articles in 2022: EMEA: 48% - Asia: 31% - Americas: 21%. Most of the articles are published in the top 1000 media worldwide.

Optimized process

With a proven process set for more than 200 active customers, we can adapt to all specific client needs with the highest reliability. We have developed in house the most advanced PR dedicated ERP, enabling transparency and real-time full online reporting. International media management is then made easy, fast, and efficient for optimal results.

THE MOST INNOVATIVE PR AGENCY

www.mepax.com info@mepax.com

to replicate this may encode data in spike amplitudes and use digital electronics (BrainChip) or encode data in timing of spikes and use asynchronous digital (Intel Loihi) or analog electronics (Innatera). As these technologies (and our understanding of neuroscience) continue to mature, we will see more brain-inspired chip companies, as well as further integration between neuromorphic computing and neuromorphic sensing, where there are certainly synergies to be exploited. SynSense, for example, is already working with Inivation and Prophesee on combining its neuromorphic chip with event-based image sensors.

Voice and language-driven intelligence: is set to be a major trend in AI in 2023, as the technology gets better at understanding natural language. This will enable machines to interact with humans more naturally, allowing for more efficient conversations and greater accuracy when it comes to interpreting user commands. By utilizing voice recognition and natural language processing technologies, businesses can provide their customers with an enhanced level of customer service that is both faster and more accurate than ever before. Furthermore, this type of AI technology can be used for a wide range of applications such as automated customer support systems, virtual assistants, and even conversational agents that can help users’ complete tasks or make decisions quickly. As such, voice and language-driven intelligence looks set to revolutionize the way we interact with computers in 2023.

Conclusion

2023 is set to be a year of major advancements in the world of AI and machine learning. From AI-driven text, speech and vision to explainable AI, these trends will shape how businesses interact with their customers. It is prepared to function at scale. Its full application cannot be predicted at this point, but it ensures real-time actionable insights and offers newfound responsiveness in an uncertain world. We can expect increased investment in quantum computing research and development as companies look for ways to take advantage of its powerful capabilities. Additionally, edge computing is ready to become more important for low power devices, such as wearables or IoT sensors due to faster response times and lower energy consumption. Meanwhile, cloud computing is on the rise for machine learning

applications because it provides improved scalability and flexibility when compared to traditional methods.

Although innovation has unintended side effects and too much of a good thing can still be damaging, it is important to criticize with basis. Yes, history is scattered with bad technology calculations, but early adopters of AI should involve judgements with an open mind. The opportunities for AI and machine learning are infinite. While moral, ethical, and legal questions are important for society to answer, the technology needs principled direction and smart engineers to support the implementation. Integrating AI and machine learning into core functions will help companies become more resilient and recession-proofed.

When leveraged correctly, this technology can help save time, streamline processes, efficiently access organizational knowledge, and provide masterful insights. But it is about more than just disregarding mistakes and inefficiencies— it is customizing our preferences and work out complex problems as they happen. In ways we cannot yet imagine, AI will help make us more human and help humans interact in more natural ways. It just needs our help getting started. AI will help individuals, companies, and government to navigate through the emerging risks and uncertainties of the future if applied smartly.

With all these developments taking place over the next few years, one thing is certain: AI and machine learning has an exciting future ahead!

02 | Industry USA-ASIA-EMEA | July 2023 9

MARKET OVERVIEW

Freepik imagerawpixel.com

STRONG HIGH FEED GEOMETRY

Dormer Pramet is introducing new products for use in various die and mold machining.

The international cutting tool manufacturer is releasing a new strong HM geometry within its popular doublesided Pramet SNGX 11 high feed milling range. The HM geometry is ideally suited for use on hardened steels and cast irons.

This addition extends the application range of the Pramet SSN11 cutter family, which already includes the versatile M geometry for steels and cast steels, and the MM for stainless steels, soft steels, and superalloys.

The new HM geometry has a highly negative and narrow T-land, as well as a positive rake to reduce vibration and enable a smoother cutting action. Together, these improve the durability and process security, prolonging tool life in the relevant materials by up to 50%, compared to the existing assortment.

www.dormerpramet.com

02 | Industry USA-ASIA-EMEA | July 2023 10 MORE INFORMATION METAL WORKING

PRODUCTIVE SHOULDER MILLING

A new assortment of Pramet LNEX 12 negative tangential inserts, with four cutting edges, provides a highly productive solution for a wide range of applications.

The LNEX 12 is a robust insert designed for shoulder milling with a maximum depth of cut up to 10 mm. It features a positive rake angle and narrow T-land to provide a smooth cutting action with lower demands on spindle torque.

The peripherally ground insert offers improved wall accuracy and straightness and creates a true 90° corner. The LNEX12 also featuring a patented U-groove segment on all four cutting edges which provide a good surface finish and expand its application range to low-power machines and small depths of cut.

In addition, the two-sided design supports performance by making ramping possible.

The insert comes in two different geometries, F- for machining of various workpiece materials in light and medium applications. While M- is suited for medium to semiroughing in steels and cast irons.

Alongside the new insert is a line of perfectly matched cutters. The Pramet SLN12X series is available in Cylindrical, Weldon and Shell styles, with all featuring internal coolant systems for improved surface quality.

Its improved body strength and thick core offers enhanced rigidity, giving a reliable cutting process with low vibrations and long tool life for both the insert and cutter. Easily accessible large clamping screws provide simple indexing and handling of inserts.

The combination of the Pramet LNEX 12 inserts and the SLN12X cutters give operators a smooth cut with a clean finish, reducing the need for additional operations, such as deburring.

LNEX 12 negative tangential inserts provide a highly productive solution for a wide range of applications.

www.dormerpramet.com

02 | Industry USA-ASIA-EMEA | July 2023 11 MORE INFORMATION METAL WORKING

SOFTING LAUNCHES THE CABLEMASTER 210 ETHERNET CABLE TESTER

Softing extends its portfolio of professional Ethernet cable testers to include the CableMaster 210, the most economical cable tester — less than $100 — that fits in your pocket.

Softing introduces the CableMaster 210, a professional, economical Ethernet cable tester that’s small enough to fit in your pocket. CableMaster 210 is part of a complete portfolio of professional Ethernet cable testing solutions offered by Softing including the flagship WireXpert copper cable certifier, FiberXpert fiber cable certifier, the award-winning NetXpert XG2 Ethernet cable BERT (bit error rate tester) and the award-winning LinkXpert active network tester.

For years, Softing has offered globally recognized, professional, cable testing solutions and continues to innovate, providing a portfolio of complete solutions to meet the needs of IT network managers, professional cable installers and industrial network managers. Softing now offers a small, easy-to-use cable tester, affordable enough for everyone to carry in their pocket or toolbox.

“Most cable testers less than $100 are large and have LED readouts that look more like science projects,” says Deane Horn, Director, Marketing.

“The CableMaster 210 is a professional cable tester, distinguished from other cable testers by its large LCD, backlit display that makes results easy to see and understand, and by its remote that neatly docks inside the local tester making this an economical solution that fits in your pocket.”

For troubleshooting Ethernet cable or testing after cable installation, the CableMaster 210 solution includes a local and remote cable tester to connect to each end of a cable. A click of the large “OK” button starts the cable test. The results show pass/fail, resulting wiremap diagram, shorts, opens, mis-wires and length of cable. And for finding wires in a bundle of cables, CableMaster 210 includes a tone generator compatible with optional tone receiver Cable Probe (CP15) from Softing and optionally up to 24 cable identifiers.

https://itnetworks.softing.com/cabling-testers/copper/ cablemaster210/

02 | Industry USA-ASIA-EMEA | July 2023 12 MORE INFORMATION INDUSTRIAL COMMUNICATIONS

COPLEY CONTROLS INTRODUCES COMPACT, EFFICIENT NANO DRIVES WITH ETHERCAT AND CANOPEN SUPPORT

These compact units integrate easily into autonomous guided vehicles (AGVs), autonomous mobile robots (AMRs), robotic joints and other automated equipment that need precise speed and position control despite limited space.

Copley Controls has introduced the Nano Series of digital servo drives. “Designed with precision and performance in mind, the Copley Controls Nano Series of servo drives represents the next generation of motion control technology, enabling our customers to achieve unparalleled accuracy and efficiency in their applications,” said Dennis Sykes, VP of Copley Motion.

The Nano Series comes in a small footprint of 35 x 30 x 23.4 millimeters, operates from 9 to 180V DC input voltage and delivers up to 35A of continuous current and 70A peak current to provide exceptional power density and efficiency. The Nano Series’ compact size also gives integrators the flexibility to mount the units directly onto the motor or within robot joints. The optional connectorized PCB and CME commissioning software facilitates setup and tuning.

The Nano Series supports the EtherCAT or CANopen communication protocols for real-time data exchange.

Additional features and specifications include:

• Safe Torque Off (STO) capability with Sil 3, Category 3, PL e conformance

• Six digital inputs and four digital outputs

• Four voltage/current combinations

• One ±10V 12-bit analog input

• BiSS-C unidirectional and SSI absolute encoders (primary)

• Dual encoder feedback support

• Digital incremental encoder (primary and secondary)

• Digital Halls

• 32-bit floating point filters and multiple advanced filters

• Frequency analysis tools

Nano Module EtherCAT NES and Nano Module CANopen NPS models are available with an EZ Board option to simplify mounting.

www.copleycontrols.com

02 | Industry USA-ASIA-EMEA | July 2023 13 MORE INFORMATION ELECTRONICS

A RELIABLE EYE ON HEALTH

Automatic visual inspection of rigid endoscopes.

Rigid endoscopes are used in medical diagnostics and therapy to examine body cavities and hollow organs and to perform minimally invasive procedures. In order to avoid risks for patients and medical staff, it is essential that the devices function perfectly. Reliable quality testing is intended above all to exclude risks from infections and injuries, but also misdiagnoses. In many countries, hospitals are required by law to regularly check and maintain their endoscopes to ensure that they function properly and do not contain any germs that are harmful to health. In addition, there are European guidelines and standards that regulate the quality assurance of rigid endoscopes. These checks are carried out by specially trained staff and include endoscopy tests and sterilization tests as well as extensive visual inspections.

The Dutch company Dovideq Medical Systems B.V. specializes in measuring instruments for minimally invasive surgery. The current product range is aimed at central sterilization departments in hospitals, endoscope manufacturers and endoscope repair companies. For the inspection of rigid endoscopes, Dovideq Medical Systems has developed various automated and networked systems. Particularly handy, small, light, cost effective and fast is the automatic endoscope tester LightControl. Using six test and measurement parameters, detailed data on the condition of the endoscope is recorded and evaluated. This ensures that only flawless endoscopes reach the operating theatre.

The LightControl system ensures a high degree of efficiency and reliability with the help of IDS cameras from the LE camera family. For the safety of all, for the well-being of the patients and ultimately also for the benefit of the hospital balance sheet.

The COVID 19 pandemic has brought the importance of hygiene and sterility of endoscopes and other medical devices even more to the fore, leading to a greater awareness of the need for automated inspection procedures. An endoscope that has not been properly cleaned and disinfected can cause the transmission of

02 | Industry USA-ASIA-EMEA | July 2023 14 MORE INFORMATION OPTICS

infection, and a defective endoscope can lead to injury during patient examination or treatment. No less serious are the consequences of a misdiagnosis or incorrect treatment if an endoscope does not function properly or is damaged, resulting in incorrect images.

Quality defects and the associated impaired functioning of an endoscope can have various origins. In addition to incorrect handling and lack of maintenance, these include factors such as material fatigue and contamination. Improper transport or unsuitable storage can also lead to damage, as can the simple ageing of the medical device. Lenses and other optical components can wear out over time, resulting in blurred or distorted images. To prevent bacteria or other pathogens from settling on the endoscope and thus not only impairing the quality of the images but, in the worst case, also harming the person being treated, they are regularly sterilized. However, the sterilization process can also affect the quality and accuracy of medical devices, as the high temperatures and chemical substances used in the process can be potentially harmful to the sensitive components of the endoscope. In particular, heat and steam can trap moisture in the lenses and cause damage. In addition, some sterilizing substances, such as formaldehyde, can have a corrosive effect on metal parts.

As complex as the possible causes are, as versatile are the possible damages of an endoscope. In order to efficiently deal with the complexity of the required inspection criteria,

Dovideq Medical Systems has developed the patended LightControl visual inspection system. “With the help of the camera, it sees far more than the human eye of a surgeon, for example dirt particles, lens fractures, impurities or colour deviations,” explains Chielant de Wit, Managing Director of Dovideq Medical Systems.

LightControl runs the automated visual inspection with the aid of a uEye LE camera from IDS. Price, sensor and size were decisive factors in the choice of model. The built-in USB3 Vision industrial camera U3-3860LE Rev.1.2 is reduced to essential functions and has a light-sensitive Sony sensor. The integrated IMX290 with BSI technology (“back-sideillumination”) ensures excellent image quality with clean colour separation and enables true-to-life reproduction of the subject, which is so important here - even under poor or fluctuating lighting conditions. The camera is small and versatile; the lightweight, coated plastic housing is nevertheless robust. This makes it ideal for integration into small devices and embedded systems and predestines it for use in medical technology.

For the automated quality inspection of endoscopes, Dovideq has identified six test and measurement parameters that the camera examines and about whose status the system provides detailed feedback in real time:

• The “Lens Fracture” algorithm measures whether one or more internal lenses have a fracture. The “Particle Detection”

02 | Industry USA-ASIA-EMEA | July 2023 15 MORE INFORMATION

algorithm finds out whether fine dirt particles, moist or other contaminations have entered the internal areas of the endoscope. For both measurements, the camera takes several pictures and makes a histogram from them. The system references the images in relation to previous images and feeds this data into a neural network.

• “Light fibers” are measured in lux and are based on light emission. The light fiber measurement uses reference values to ensure that the fibers or fiber bundles of the endoscope allow enough light to pass through. This prevents the endoscope from providing unclear images.

• The “light transmission” through the lenses is determined on the basis of individual images from the integrated IDS camera. For this purpose, the measuring device uses a calibrated light source that falls on a pixel plane. Each pixel is assigned a specific RGB value of a colour spectrum. The combination of all pixels is converted into a luminance value and referenced with the help of a specially developed algorithm.

• The “focus measurement” uses the scientific Harr wavelet transformation to check whether the lenses are intact and not contaminated or whether the endoscope provides a clear image. During the measurement, the system takes several pictures to get an idea of the condition of each lens. In the optimal case, the camera looks through the endoscope and shows sharp contours.

• “Colour Correction” is performed to detect discolouration due to the sterilisation process. The system warns against misinterpretation of images due to colour deviations. The unit takes images and measures deviations in colour transmission using the HSV model, which describes the colour of a pixel based on the 3 values Hue (hue), Saturation (saturation) and Value (brightness). Colour Correctness ensures that the actual colours of organs or tissues are reproduced to avoid incorrect diagnosis or treatment.

“With the help of the test and measurement details, information about the performance of the tested endoscopes can be evaluated and history and trend analyses can be created,” explains Chielant de Wit. “LightControl stores all details of the endoscope measurements, together with the test results, in a database called EndoscopeManager for reporting and management purposes, enabling dedicated management and quality reporting.”

According to Chielant de Wit, the customer benefits are obvious. “The automated visual inspection of endoscopes serves quality assurance, efficiency, cost-effectiveness and patient safety in hospitals and medical practices. Systems like LightControl make a significant contribution to this by providing objective results and detecting even the smallest defects, scratches or wear on endoscopes. Moreover, they always work with the same accuracy and consistency, regardless of factors such as fatigue or human

02 | Industry USA-ASIA-EMEA | July 2023 16 MORE INFORMATION

error, and are much faster. This saves time and costs, leads to higher equipment availability and improved resource utilisation. Potential defects or damage are detected at an early stage, which can avoid costly repairs or replacement of endoscopes. The resulting images or videos are available as proof of inspection and can be used for fault analysis and training purposes if required.

Outlook

“Endoscopes are vital medical devices that enable doctors to diagnose and treat a variety of conditions by providing a clear, internal view of a patient’s body. However, like any medical device, endoscopes are subject to wear and tear, and over time they may need to be repaired or replaced”, says Chielant de Wit. Already now, the demand for automated intelligent visual inspection of endoscopes is high and is expected to increase further in the coming years. In particular, due to the increasing number of endoscopy procedures and the growing sensitivity to infection risks, the demand for automated inspection technologies will become stronger. In addition, artificial intelligence will help improve the efficiency and accuracy of inspection processes and minimise human error.

The needs of the health sector are evolving as fast as the technologies used in this field. The use of IDS cameras is increasingly proving its worth here. “In medical technology, the demand for our products has increased particularly in the past year, which pleases us not only from an economic point of view,” explains IDS Managing Director Jan Hartmann. More and more IDS cameras are thus making a contribution to health promotion worldwide.

Camera

Our cost- and space-saving project camera: The uEye LE

• Interface: USB 3

• Model: U3-3860LE-C-HQ Rev.1.2

• Sensor type: CMOS

• Manufacturer: Sony

• Frame rate: 135 fps

• Resolution: 1936 x 1096 px

• Shutter: Rolling-Shutter

• Optical class: 1/3”

• Resolution: 1,31 MPixel

• Dimensions: 47,0 x 46,0 x 23,9 mm

• Weight: 36 g

• Connector: USB Type-C

• Applications: Machine Vision, Medical technology and Laboratory automation, Inspection application

Client

Dovideq Medical Systems specializes in measuring instruments used in minimally invasive surgery. The current product range is aimed at central sterilisation and biomedical engineering departments, as well as professional hospital OR managers concerned with endoscope use and quality. Dovideq solutions lower total cost of ownership, reduce surgery downtime and increase efficiency, predictability and traceability by automating key processes, including repairs.

https://en.ids-imaging.com/

02 | Industry USA-ASIA-EMEA | July 2023 17 MORE INFORMATION

COMAU IS DEVELOPING A FULLY AUTOMATED SYSTEM FOR SUSTAINABLE BATTERY RECYCLING AND SECOND-LIFE REPURPOSING

Comau has renewed its commitment to the EU’s Flexible Battery Dismantling (Flex-BD) project for the second year, to help deliver a fundamental pillar on the path towards a truly circular economy.

Comau continues its participation in the renewed EU project “Flex-BD” for which it is developing a robotized electric battery dismantling cell as part of its on-going commitment to advancing sustainable electric mobility solutions.

With a view to the circular economy, Comau will test and validate the solution as a first step towards cost-effective second life repurposing of automotive batteries.

The Comau-designed cell will facilitate the manipulation of low-charge batteries while minimizing risks to operators and equipment.

Flex-BD is a robotized system that automates the entire process of dismantling worn-out electric batteries using a highly flexible, repeatable and standardizable process. Now, having validated the proof-of-concept, Comau has expanded the scope to include second life repurposing of automotive batteries. In doing so, Comau, in collaboration with other partners within the EU EIT Manufacturing community, is taking an important step towards greater sustainability within eMobility.

Comau estimates, based on the predicted electric battery production volumes within Europe over the next several years, that the EU could easily have over 1 million discarded batteries to be reused by 2030. To this end, Comau is helping anticipate what it believes will be a growing market demand for powerful electric battery recycling and repurposing solutions. In tandem, it will enable businesses to reduce waste and optimize the reuse of raw materials contained within battery packs.

Flex-BD represents a significant improvement to manual handling processes that often include repetitive and heavy tasks in addition to contact with potentially harmful substances. It therefore makes the recovery of battery modules and their components more efficient and sustainable while having a positive impact on workers’

02 | Industry USA-ASIA-EMEA | July 2023 18 MORE INFORMATION ROBOTICS

health and safety. With second-life battery repurposing, on the other hand, the fully automated manipulation of low-charge batteries minimizes risks to both operators and the dismantling equipment. Unlike the materials recovery and recycling process, in which the battery is completely discharged and destroyed, second-life battery repurposing is done while maintaining a low but active battery charge.

The way the Flex-BD cell works is as intuitive as it is innovative. One by one, battery packs are introduced into the specialized cell where a high-payload Comau NJ industrial robot automatically executes its path and changes its end-effectors based on the required application. In a typical recycling application, for example, the robot unscrews the battery cover, changes grippers to remove the cover, re-attaches the screwdriver to unscrew the modules and then using its gripper moves the pieces to a dedicated storage area. What’s more, Flex-BD is designed around a highly flexible programming approach based on a reduced use of codes, state-of-the-art environmental perception techniques and the robot’s reactive capacity, the entire dismantling cycle is defined through CAD. The use of LowCode programming also allows operators to quickly and easily redefine the cycle with no need to reprogram the robot.

Comau’s efforts to advance green energy deployment extend beyond its expertise in automated manufacturing systems for batteries, electrical motors and drive units,

competencies that are key to enabling the mass production of electric vehicles. At the same time, the company is addressing several key technical and development aspects of the automation process for battery cell manufacturing, including process design and assembly of rechargeable cells, as well as the use of renewable energy and second-life strategies for automotive batteries.

“Our work with the Flex-BD project leverages Comau’s long standing automation expertise in the development of flexible, scalable and sustainable processes,” said Pietro Gorlier, CEO at Comau. “By expanding our smart automation solution to include second life repurposing of high-power batteries, many of which have a residual capacity of up to 80%, Comau is making a concrete contribution to the realization of truly sustainable mobility.”

www.comau.com

02 | Industry USA-ASIA-EMEA | July 2023 19 MORE INFORMATION

SOPHISTICATED DATA SCIENCE TOOL FOR OPTIMIZED OPERATIONS

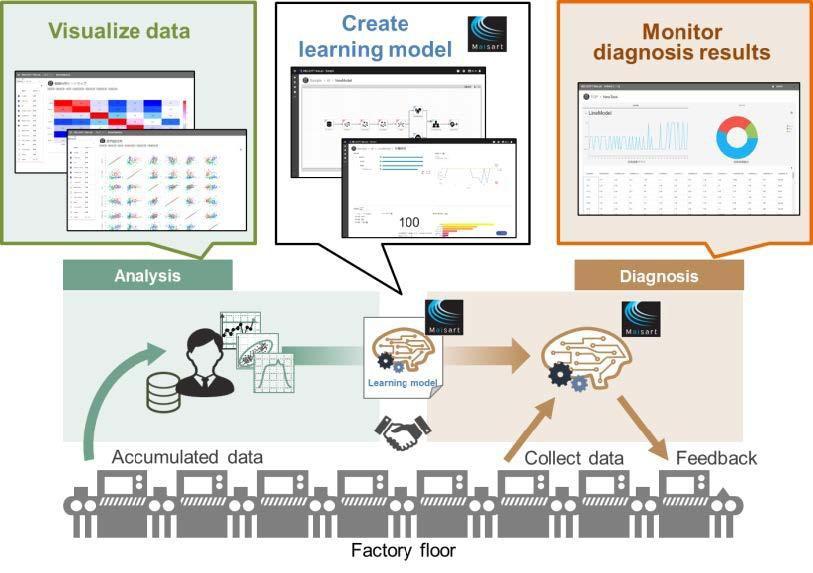

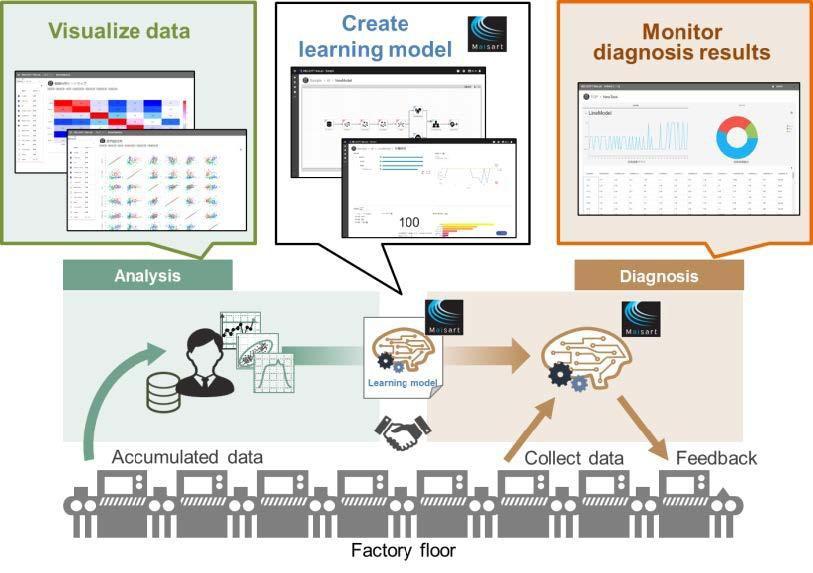

MELSOFT MaiLab enables users to effortlessly navigate and experience data analytics with minimal training to save on costs, optimize operations, and drive overall business success.

Mitsubishi Electric Automation, Inc. announces its MELSOFT MaiLab software that uses the company’s Maisart intelligent technology to enable companies to easily analyze and diagnose factory data. Through analysis of past manufacturing data, the software makes sophisticated data decisions, akin to skilled workers, requiring less investment of time and expertise in a company’s workforce. As the global economy continues to navigate through the challenges brought by the COVID-19 pandemic, the issue of labor shortages has become a critical concern for businesses and consumers alike. In this context, the use of the software to replace more experienced operator personnel is becoming an increasingly attractive option for many companies.

MaiLab’s sophisticated software design with a user interface includes single-tool capability, enabling both offline analysis and real-time diagnostics, with direct feedback to the production site. Its integrated open concept, such as the Python programming language or web-based environment, ensures the software’s longevity and future-proof design.

“MaiLab provides an exceptional data analytics user experience by offering a range of licensing options to meet the varying requirements of different industries. With the support of predictive analytics, plant managers can receive alerts regarding necessary maintenance, streamline their production processes, and enhance the overall quality of their products,” said Agnieszka Zupancic, product manager at Mitsubishi Electric Automation, Inc.

https://us.mitsubishielectric.com/fa/en/products/edge/ edgsw/rda/mailab/index/

02 | Industry USA-ASIA-EMEA | July 2023 20 MORE INFORMATION INDUSTRIAL COMMUNICATIONS

KOLLMORGEN INTRODUCES THE AKMA SERVO MOTOR FOR MEDIUM- TO HEAVY-WASHDOWN APPLICATIONS

Kollmorgen has extended its highly regarded AKM™ servo motor portfolio with a new highperformance motor that delivers durability, cleanability and versatility.

Kollmorgen has launched the AKMA servo motor built specifically for durability, cleanability, and versatility. The motor employs a hardened anodized aluminum surface to offer machine designers a cost-effective hygienic option to stainless steel in medium- to heavy-washdown applications.

The lightweight design of the AKMA motor makes it easy to install and maintain, and its high torque density offers machine builders more performance in a smaller footprint. The motor is ideally suited for precision motion applications in food & beverage processing, and in pharmaceutical & medical packaging operations. The AKMA’s IP69k rating enables it to deliver high performance even in wet and rugged environments, supporting critical applications like tracking and positioning for antenna pedestal systems.

An anodized aluminum surface offers strong resistance to chemicals across a wide pH range. Since the motor’s smoother and hardened surface is more scratch resistant and will not flake like a painted motor, it can be used above the food line. The AKMA’s stainless steel shaft meets functional safety requirements, while its “one-piece” rounded housing structure eliminates the need for a seal between the flange and housing to prevent puddling and water ingress. The AKMA motor also features a vented design to equalize pressure inside and outside for increased OEE and motor durability.

“We are excited to offer the AKMA servo motors to engineers searching for an affordable motor choice in wash-down environments where stainless steel surfaces are not necessarily required,” said Ross McMillan, Vice President of Engineering at Kollmorgen. “Now, it’s possible to balance performance with value and avoid overspending for a surface quality you may not need.”

https://www.kollmorgen.com/en-us/products/motors/ servo/akma

02 | Industry USA-ASIA-EMEA | July 2023 21 MORE INFORMATION MECHANICS DRIVES

DELTA

ELECTRONICS’

AMERICAS HEADQUARTERS BECOMES

THE FIRST LEED ZERO ENERGY-CERTIFIED GREEN BUILDING IN FREMONT, CA

Delta has announced its Americas regional headquarters (HQs) has become the first green building in Fremont, CA, and second in the Silicon Valley Bay Area, to achieve the LEED Zero Energy certification from the U.S. Green Building Council.

The accolade, granted to green buildings that generate as much electricity as they consume, has been attained thanks to the further implementation of Delta’s own solutions on this originally LEED Platinum facility. A new solar PV carport, supported by a 330kWh Delta energy storage system, now helps to increase the building’s annual green electricity generation to over 1.4 million kWh. With 32 green buildings(1) enabled worldwide, Delta’s solutions are nurturing sustainable cities.

“Just as Fremont leads the way in clean technology, Delta Electronics continues to set the industry standard for building performance. The company’s built-to-suit Americas HQ in Fremont previously laid claim to being one of the earliest private sector LEED Platinum facilities in California. Delta Electronics sets another milestone as only the second facility in the entire Bay Area to achieve LEED Zero-Energy.”, said Lily Mei, Mayor of Fremont. She added, “As one of the greenest cities in the nation, we’re proud that Delta Electronics continues to showcase sustainability through thoughtful application of technology, including using its Fremont facility as a proving grounds for many of its own products while working through pandemic disruptions to invest even further in our community.”

Kelvin Huang, President of Delta Electronics (Americas), said, “Fremont has been Delta’s home in the Americas for over 30 years, so it is an honor for us to contribute to our community with the environmental and social benefits of the city’s very first LEED Zero Energy green building. With its net-zero energy capabilities, our Americas HQs green building will contribute even further to Delta’s RE100 initiative, which is a promise to power our worldwide operations with renewable electricity by 2030. By developing smart energy-saving solutions capable of fostering green buildings and sustainable cities, Delta demonstrates that its ESG-embedded business model can bolster mankind’s environmental goals.”

Aided with an energy-conscious design that utilizes geographical advantages unique to Fremont while considering the productivity and needs of its operations, the Delta Americas HQs building is an example of what a total integrated solution can look like. The most recent upgrades made possible with Delta’s own IoT-based Smart Green Solutions are:

• The facility generates over 1.4 million kWh of renewable electricity through a 616kW rooftop solar PV system and a recently constructed 504kW bi-facial PV carport system, both supported by Delta’s high-efficiency PV inverters.

02 | Industry USA-ASIA-EMEA | July 2023 22 MORE INFORMATION GREEN BUILDING

That green energy output covers 100% of its consumption needs over a full calendar year.

-The recent addition of a 330 kWh Delta energy storage system helps to optimize energy management in the facility.

• A recent enhancement of Delta’s data center cooling solution, featuring a dedicated economizer supported by our own DC brushless electronically commutated (EC) fans and variable frequency drives for HVAC applications, have contributed significantly in lowering the annual power usage effectiveness (PUE) of the building’s data center from 1.5 originally to as low as 1.25.

• Optimized energy management is also attained by the implementation of Delta’s next-generation SCADA system and building control platform. The former is VTScada, the industry’s most powerful SCADA system, developed by Canadian-based Trihedral, a Delta Group Company; the latter is the enteliWEB building control platform, developed by Canadian-based Delta Controls, also a Delta Group Company. These platforms integrate seamlessly with the existing building sub-systems, such as HVAC, LED lighting and other energy-intensive applications, to create set points, collect data and track trends, create reports, and manage alarms, remotely. With unlimited scalability, this solution grows with the facility as new solutions are integrated to ensure lower energy consumption.

(1) Delta has created 32 green buildings worldwide since 2006 to promote the environmental, social and health benefits of green buildings. Several of these green buildings have been donated to academic institutions to inspire next generations to foster sustainable development.

Here are some of the original integrated solutions that made Delta Americas’ HQs a LEED Platinum green building back in 2018, and that have certainly contributed to the new LEED Zero Energy certification:

HVAC

Host to one of the largest geothermal systems in Silicon Valley, Delta’s unique location in the Bay Area takes advantage of the natural underground warm springs. With over 20 miles of horizontal piping at 15 and 30 feet depths, a Delta VFD circulates water in a closed-loop system to exchange heat for an HVAC system estimated to be 70% more efficient than a cooling tower.

92 miles of piping is embedded in the facility’s floors and ceilings for radiant heating and cooling, providing stable and comfortable temperatures, efficiently. Working in collaboration with CBE Berkeley, this system has been a case study to determine optimal operations and controls for maximum energy efficiency.

Lighting

With LED lighting systems in the parking lot and around the office, Delta’s lighting controls integrates with its building management system to ensure smooth operations at all hours. Taking advantage of the floor-to-ceiling panoramic windows, the open floor plan, and low-e windows, zones are created to minimize waste from excessive lighting. Light meters placed around the office ensure sufficient lightlevels for safety and productivity.

Additional Green Features

-(19) Delta Level II EV Chargers, free for employee-use

-Delta elevator regenerative drives

-Bioswale for natural filtration of rainwater and pollutants to the Baylands

-140,000 gallon rainwater harvesting tank for landscaping and agriculture

-Native, drought-tolerant plants and trees

-100% fresh air unit, improving IAQ

https://www.deltaww.com/en-US/index

02 | Industry USA-ASIA-EMEA | July 2023 23 MORE INFORMATION

COMAU’S MATE-XT WEARABLE EXOSKELETON SUPPORTS ERGONOMIC WELL-BEING AT JOHN DEERE’S PARTS DISTRIBUTION CENTER IN BRAZIL

Comau has equipped John Deere with multiple MATE-XT wearable exoskeletons to help sustain worker well-being, alleviate physical stress and reduce the ergonomic risk within its parts logistics operations. MATE-XT accurately replicates all movements of the shoulder, helping employees perform their jobs comfortably by reducing muscle fatigue without limiting mobility or adding bulk. Its ergonomic design can be easily adjusted to fit different people with different body types – changing the length of the shoulder straps and the required level of assistance based on the worker or the job at hand is quickly achieved in a few simple steps. Working closely with John Deere to implement the exoskeleton within its daily operations, Comau provided a hands-on training course held at John Deere’s 75,000m2 parts distribution center in Campinas, in the state of São Paulo.

As parts are often required for next-day delivery, John Deere’s employees must select, sort and package hundreds of parts per day, a task that involves repetitive movement of the arms, shoulders and back.

MATE-XT’s highly breathable design is worn like a backpack, providing comfortable, all-day ergonomically-assisted support aimed at increasing the quality and precision of manual tasks. In addition to offering highly effective postural support, MATE-XT is EAWS-certified (Ergonomic Assessment Work-Sheet), which enables John Deere to acquire an objective measurement of ergonomic improvement and projected benefits in terms of reduced muscle fatigue and execution speeds.

Even when working with small and lightweight objects, the apparently minimal effort of repeated manual movements can take a toll on the body. To help John Deere quantify the benefits of using MATE-XT, Comau performed an electromyographic analysis of the ergonomic risk factor.

02 | Industry USA-ASIA-EMEA | July 2023 24 MORE INFORMATION LOGISTICS

MATE-XT kept the muscle at a rest stage for 98.5% of the activity time (compared to only 2.4% of the time without MATE-XT).

Furthermore, Comau’s MATE-XT ensures proper muscular balance while optimizing the energy expenditure needed to stabilize and sustain the weight of the arm. Wearing the exoskeleton, arm stability can be maintained using only 10% of the operator’s maximum force capacity. This translates to an improved feeling of well-being in addition to tangible performance-based results such as process optimization and productivity gains. All said, MATE-XT is helping John Deere to mitigate ergonomic risks and achieve a 68% reduction in muscle overload.

“Our efforts to provide customers with innovative automation technologies extends to finding new ways to ensure their workers stay safe during their day-to-day activities, in different applications and markets,” said Laerte Scarpitta, Comau Leader for the Americas. “MATE-XT is an easy-to-use wearable exoskeleton that allows John Deere to provide greater added value and measurable benefits in terms of reducing perceived muscle fatigue and as a consequence, the mechanical stress on a worker’s back, lumbar region, arms and shoulders. It is yet another example of the value that robotics can bring.”

https://www.comau.com/en

02 | Industry USA-ASIA-EMEA | July 2023 25 MORE INFORMATION

HISTORICAL TEXTILES IN FOCUS

New approaches to investigate damage due to environmental fluctuation on textile artefacts by image processing.

Preventive conservation plays an important role in the preservation of art and cultural assets. In order to preserve their condition for as long as possible, it is essential to slow down ageing processes and evaluate factors that alter materials. To do this, it is necessary to grasp and have an holistic understanding of the artefact. Cultural heritage science and engineering methods for understanding material behaviour require an interdisciplinary approach. Textiles are among the most sensitive art and cultural heritage objects. In the course of their production and handling, their presentation and storage, they are often exposed to influences that can have a damaging effect. The French start-up company S-MAC-H has studied the Bayeux Tapestry as part of a research project and, with the help of IDS cameras, has developed a system that provides valuable insights for the conservationoptimised storage and presentation of this delicate and extraordinary artefact. The expertise of conservators, combined with state-of-the-art technology, helps to identify potentially damaging factors at an early stage, to minimise them or, at best, to exclude them altogether.

The system was designed for a comprehensive study looking at the mechanical behavior of the Bayeux Tapestry - commissioned and funded by the Normandy Regional Office for Cultural Affairs. “We contributed our expertise in mechanical engineering by fully monitoring the stress and strain on the tapestry. In addition to monitoring, we helped to devise conservation solutions. This involved classifying and assessing the degree of risk and sensitivity of the tapestry in its surrounding indoor climate,” explains Cécilia Gauvin, co-founder and managing director of S-MA-C-H.

A multidisciplinary team of textile and preventive conservators as well as heritage conservation scientists characterized the artefact’s response to appropriate environmental fluctuations. “The project addressed two main questions: what are the optimal parameters for a presentation on sloping supports and how does the tapestry react to its microclimate?”

To be able to answer these questions, the tapestry was monitored by temperature and humidity sensors as well as by force sensors to record the gravity pressure. The heart and brain of the system: a non-contact 2D full-field Digital Image Correlation (DIC), consisting of an IDS camera and specially developed software for digital image correlation.

02 | Industry USA-ASIA-EMEA | July 2023 26 MORE INFORMATION VISION SYSTEM

“Digital image correlation is an image processing technique that can be used to analyze movements and deformations of objects. For this purpose, high-resolution images of the object’s surface are captured and then evaluated with the help of software algorithms to detect changes in the shape, position or size of the object,” explains Patrick Schick, IDS Product Marketing Manager. In the search for the right camera model for the system, parameters such as interface, sensor and price-performance ratio were the main deciding factors. “For the analysis of the tapestry, extremely highresolution images with low image noise are required to capture the smallest details.” The USB 3 uEye CP meets these requirements thanks to the particularly light-sensitive IMX183 rolling shutter CMOS sensor from Sony’s STARVIS series. With BSI technology (“back-side illumination”), this sensor ensures outstanding image quality even under difficult lighting conditions. “The camera is thus ideally suited for demanding image evaluations such as this monitoring, which takes place in low light for conservation reasons. The USB3 Vision camera records high-resolution images at a very low frequency over a longer period of time,” adds Patrick Schick. For the research project, for example, the monitoring ran around the clock for a month, with only one image capture per hour.

“The Python interface of the IDS peak API allowed us to quickly and easily develop software to parameterise the camera and capture images,” explains Cécilia Gauvin. The images are then processed with DEFTAC3D, a software

developed by the French Pprime Institute specifically for digital image correlation. This results in full-surface measurement data of the object’s surface based on thousands of 2D or 3D coordinates with very high resolution. The displacement of the image points within the examination period is interpreted as a deformation that is due to a mechanical load or stress on the object. Based on the results, full-field strain maps as well as deformation maps are generated. Full-field strain maps illustrate the strains in a material over the entire surface. They therefore show whether and how the tapestry has deformed as a whole. Deformation maps, on the other hand, provide information about the local deformations in a material. They provide S-MA-CH staff with information on whether and how the tapestry has deformed at specific points.

The full-field strain maps are processed together with the environmental variation findings to understand the hygromechanical behaviour of the Bayeux Tapestry. Hygromechanical behaviour refers to the interplay between moisture and the mechanical properties of the textile. This can be influenced by a number of factors, including the type of yarn used to make the fabric and the type of weaving or embroidery technique used to make the tapestry, which adds to the complexity of the study.

In order to incorporate scientific data into the decisionmaking process, tests were carried out on both facsimiles and the tapestry itself. On the facsimiles, the full-field strain

02 | Industry USA-ASIA-EMEA | July 2023 27 MORE INFORMATION

Figure 1: A calibration plate is used to calculate the 2D position of the camera in relation to the object and to correct any kind of distortion caused by the camera and lens.

maps were combined with the stress results from the force sensor measurement and the climate measurements (temperature and humidity). The results allow conclusions to be drawn about the climate regulation for optimal storage of the artefact.

The data collected by the sensors and camera system was documented in real time to analyse long-term trends. With the help of the information provided, it can be ensured that the climatic conditions in the Bayeux Museum are within the optimal limits to avoid damage to sensitive art objects or historical exhibits, such as the Bayeux Tapestry.

Outlook

The market for the protection and preservation of cultural heritage is slowly opening up to structural diagnostic procedures. “Our goal is to develop appropriate systems for conservators in a plug-and-play system,” explains Cécilia Gauvin. In addition, the French start-up wants to use vision systems to monitor structural damage to paintings in museum galleries and historical monuments in the future. This approach across disciplines makes it possible to assess the condition of exhibits so comprehensively that the appropriate conservation measures can be taken.

“Our knowledge of mechanical engineering, combined with industrial image processing, opens up new approaches, expands the range of actions and produces innovative solutions.”

An elaboration of the conservation conditions for handling, storage or presentation of artefacts based on these interdisciplinary research results offers protection against further damage. Historical as well as modern products of textile art can thus be preserved in the best possible way for the future. Image processing components make a valuable contribution to this.

Data and facts about the exhibit

• 68 meters long

• 52 cm high

• 9 panels of woven linen fabric

• 4 seams

• 10 colors of woolen yarn

• 58 individual scenes

• 623 people

• 202 horses

• 55 dogs

• 505 other animals

• 27 buildings

• 41 ships and boats

• 49 trees

The Bayeux Tapestry, is an embroidered work created in the second half of the 11th century on a strip of cloth about 52 centimeters high. Depicted in images and text over 68 meters in 58 individual scenes, the Conquest of England is considered one of the most remarkable pictorial monuments of the High Middle Ages because of its

02 | Industry USA-ASIA-EMEA | July 2023 28 MORE INFORMATION

Figure 2: IDS camera point of view for 2D strain analysis.

abundance of detailed individual depictions, well thoughtout iconography and quality of craftsmanship. Despite its name, the Bayeux Tapestry is not actually a tapestry but a narrative embroidery. It consists of images and text inscriptions and comprises nine interconnected linen panels.

Camera

GigE uEye CP - Incredibly fast, incredibly reliable, incredible sensors

• Interface: USB 3 Vision

• Model: U3-3800CP-C-HQ

• Sensor type: CMOS

• Manufacturer: Sony

• Frame rate: 19,5 fps

• Resolution (h x v): 5536 x 3692

• Shutter: Global-Shutter

• Resolution: 20,44 MPixel

• Dimensions: 29 x 29 x 29 mm

• Weight: 49 g

• Connector: USB 3.0 micro-B, screwable

Applications: e.g. industrial image processing, surface inspection, metrology, medical technology, biotechnology and life sciences quality assurance, etc.

Client S-MA-C-H is an innovative start-up based in France that promotes the introduction of mechanical engineering into heritage conservation research. The experimental approach is to the interface between art and technology. The mechanical behavior of complex and aged materials (including stress and damage) focuses on controlling the deformation and damage of artworks and is tested at different levels using innovative and non-invasive optical and mechanical techniques. For this, the start-up offers simple and accessible solutions to concrete conservation questions.

www.s-ma-c-h.com

“The Bayeux municipality and the Bayeux Museum team gave us access to the tapestry and helped us with logistic.”

(Cécilia Gauvin, S-MA-CH) Bayeux Museum: https://www.bayeuxmuseum.com/en/ the-bayeux-tapestry/ Bayeux Municipality: https://www.bayeux.fr/fr

The study was commissioned by the Regional Office of Cultural Affairs of Normandie (financial support).

Author Silke von Gemmingen +49 7134 96196-0 silke@gemmingen.de www.ids-imaging.us

© 2023 IDS Imaging Development Systems GmbH

02 | Industry USA-ASIA-EMEA | July 2023 29 MORE INFORMATION

HMS NETWORKS PRESENTS NEW EWON REMOTE CONNECTIVITY SOLUTIONS WHERE HARDWARE MEETS SOFTWARE

HMS Networks reinforces its remote connectivity solutions by presenting the recently acquired software solutions WEBfactory i4connected and i4scada under the Ewon® brand.

The new offering gives machine builders and their customers an end-to-end IIoT solution which gathers data from machines and presents it in an easy-to-use web interface.

The Ewon offering from HMS Networks features the world’s most used solutions for remote machine connectivity, enabling secure remote machine access and data collection for proactive and efficient maintenance of machines.

With the new i4 software solutions, machine builders and their customers will be able to visualize data from connected machines in a web interface to help improve decisionmaking, control and service – minimizing the risk of costly machine and system downtime.

How it works

As soon as an Ewon gateway – Flexy or Netbiter – has been installed to a machine, the Ewon i4connected software can go to work. i4connected gathers data from Ewon gateways and presents it to the user in an easy-to-understand graphical user interface. Complex industrial processes are displayed in a straightforward way, enabling the user to securely connect and get data from plants, buildings, machines, equipment,

and sensors. In i4connected, the data can be visualized and analyzed in real-time, helping the user to make data-driven decisions and perform predictive maintenance.

Additionally, with Ewon i4scada factory owners and system integrators benefit from a fully web-based SCADA software to help improve the efficiency of complex on-site industrial processes in real-time. i4scada enables data-driven decisions for better productivity and cost optimization.

“This integrated approach combines our successful Ewon gateways Flexy and Netbiter with the state-of-the-art i4connected software. Machine builders and their clients will be able to easily unlock and leverage precious data from their machines to improve operational efficiency and reduce costs. HMS stands for ‘Hardware Meets Software’ and this integration is a perfect demonstration of that,” says Alexander Hess, General Manager of HMS Networks’ Business Unit Ewon.

https://www.hms-networks.com/products-solutions/ewonby-hms-networks

02 | Industry USA-ASIA-EMEA | July 2023 30 MORE INFORMATION INDUSTRIAL COMMUNICATIONS

NEW OPTIONS FOR ECONOMICAL FACE MILLING

A new highly economical face milling family from Dormer Pramet has launched, covering a wide range of applications with negative octagonal and square inserts, along with a variety of shell mills.

The latest Pramet range includes three variants of a 16-edged ONMX insert for depths of cut up to 0.157” (4mm). The standard geometries include the F for light operations, M for versatile use, and R for rough cuts in a variety of materials. Additionally, the 8-edged ONMX-W is a specific wiper insert for high-quality surface finish with large cutters and high feed rate.

Along with the Pramet ONMX inserts, the global manufacturer has added a range of 8-edged SNMX inserts for higher metal removal rate. This includes an M chip breaker for medium machining and an R geometry for roughing, both for depths of cut up to 0.275” (7mm) in various materials.

All the new face milling inserts can be used with our new shell cutter body. The Pramet ISON06 is available in sizes 2-6 inches, and the metric family SON06 is available in range 1.968”–9.843” (50–250mm).

The assortment is made of high-quality hardened tool steel, to improve durability and process security. Combined with internal coolant systems on the entire range, these tools improve chip evacuation to achieve a high surface quality.

www.dormerpramet.com

02 | Industry USA-ASIA-EMEA | July 2023 31 MORE INFORMATION METAL WORKING

ONMX06 ECO Face milling B9763

ONMX06 ECO Face milling B9754

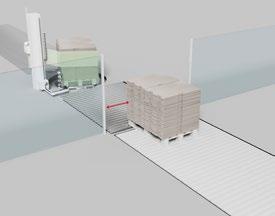

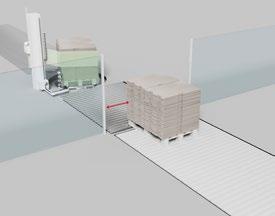

STAY FLEXIBLE SAFELY

Different material widths, varying material positions or partially loaded pallets pose special challenges for transfer station access guarding. For this, Leuze relies on the concept of dynamic format adaptation. In this way, productivity and safety can be optimally harmonized.

Variation becomes a safety risk

Access monitoring on conveyor lines can be implemented with classic tried and tested safety concepts if the dimensions of the goods remain constant. These are mostly based on muting functions for automatic temporary bridging of the safety function. However, the area of application of the access guarding with muting function is limited. If the width or position of the goods on the pallet or the position of the pallet on the conveyor varies, unmonitored safety gaps directly next to the goods can emerge. A person would then be able to access the danger zone. However, these gaps can be reliably closed with a safety solution tailored to them. The Leuze safety solution with dynamic format adaptation provides the right concept for this purpose.

Just triggering is not enough

A look at three examples of real-world situations illustrates the challenges of access guarding. The initial situation in all three cases: Pallets are automatically conveyed into or out of a danger zone using a conveyor line.

- Example 1: The space next to the goods on the conveyor is larger than 200 mm.