International PetFoodVolume 6Issue 2February 2024 www.internationalpetfood.com www.perendale.com As A Source Of Nutrients For Petfood - World Feeds At Its Best - Petfood After Cop28 February 2024 Up-coming International PETFOOD conferences Download your online version:

YOUR RELIABLE PARTNER

A reliable team for a reliable project

Projects in 150 countries

55 million m3 built

New pendular and rotative sensors

ATEX 20 certified, the zone with the highest risk

· SY-DP1 Pendular . Robust and simple. It does not require power and maintenance.

· SY-DR1 Rotative . Sensitive. It has 2 operating modes depending on the density of storage material.

Top Project worldwide

Flexibility and adaptability

symaga.com • +34 91 726 43 04 • symaga@symaga.com

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 01242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor

Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor Prof Simon Davies simond@perendale.co.uk

Editorial team

Shannon Parsons

Tel: +44 (0)1242 267706 shannonp@perendale.co.uk

Niamh Cassidy

Tel: +44 (0)1242 267704 niamhc@perendale.co.uk

Community Manager

David Harvey

Tel: + 44(0)1242 267700 davidh@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 (0)1242303792 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta clarissag@perendale.com

Turkey, Eurasia and Middle East

Marketing Team

Mehmet Ugur Gürkaynak

Tel: +90 537 364 64 57 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng

Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor

Tel: +44 (0)1242303791 jamest@perendale.co.uk

Production Assistant

Cristina María Roldán Otero

Tel: +44 (0)1242 267700 cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 (0)1242 303790 tutit@perendale.co.uk

Development Manager

Antoine Tanguy

Tel: +33 6 78 57 76 45 antoinet@perendale.co.uk

February

10 Industry News

COLUMNS

6 Roger Gilbert

7 Joseph P Kearns

8 Professor Simon Davies

Perendale Publishers Ltd

International Petfood - Volume 6 - Issue 2 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 2754-4680 www.internationalpetfood.com 26 Training 27 Troubleshooting 28 Production focus 9 The PetFood Journal REGULAR ITEMS 24 Industry Profiles 31 Industry Events 39 The Market Place 40 The Interview 42 Industry Faces

FEATURES

14 As A Source Of Nutrients For Petfood

18 World Feeds At Its Best

22 Petfood After Cop28

What should you expect …

It’s not always clear what are the likely benefits from attending an exhibition, particularly one that focuses on poultry and meat production with feed manufacturing in support.

That’s the focus of the annual IPPE show that takes place at the end of January each year in Atlanta, USA. It attracts large numbers of Latin Americans and this year just fell short of having 30 percent of its visitors attending from outside the USA.

Roger Gilbert Publisher – International Petfood

Roger Gilbert Publisher – International Petfood

IPPE hosts one of the most important petfood conferences this country has access to

In fact, this is a global event and one that is protein production focused. And where you will find manufacturers and suppliers of the technology to produce feedstuffs for all livestock species and of course you will find pet interests.

A keynote presentation on the opening one-day American Feed Industry Association (AFIA) Pet Food Conference was delivered on Nourishing Companions: Emerging Trends in the Global Pet Food Market by Lynn Dornblaser, Director, Innovation and Insight at Mintel.

We will be reporting this and a number of presentations in our next edition, but it’s worth stating here that this is a worthwhile day and one that connects our industry to the wider animal food production business.

The production of petfoods demand special attention in their preparation, processing and delivery to retail shops and ultimately to the customer. Where else is it possible to gain so much information in such a concentrated space and in such a timely way?

It may be that we as a magazine spend too much time attending these types of events, but all yield benefits to the visitors as well as the companies that exhibit.

For example, another standout presentation at the AFIA event was on packaging - Packaging Regulations and Possibilities: The Ongoing Pursuit of Sustainable Pet Food Packaging by Dr Rafael

Auras, Professor, School of Packaging, Michigan State University, USA.

We announce the winner of the 2023 AFIA Friend of Petfood Award on page 10.

Of course, there are major international petfood exhibitions that are massive and show us everything that is commercially available to pet shops, retails and pet owners alike. Often, they are overwhelming in their coverage of petfood is displayed throughout. This is not a shortcoming, but if your focus is the production processes then other events might also be on your short list for consideration to attend.

I encourage you to look to the efforts being made in your local regions by organisers of exhibitions that involve livestock and aqua feeds and enquire about their focus on petfood production. Or encourage them to host and/or develop seminars or conferences on this increasingly important topic.

In this issue we have our report on feeds of ornamental fish (see page 16) which the IPF team were honoured to be invited to tour and out thanks go to World Feeds for a great day at their feed production plant.

On page 20, we look at the implication COP 28 has for the petfood industry and we follow with our usual columns of an Industry Profile, industry Training, Production Focus and Trouble Shooting before we get into Events and show reports.

Please don’t overlook our upcoming event in Bangkok Thailand which is called Petfood & Aquafeed Extrusion conference, which the magazine hosts on March 11, 2024 - one day prior to the opening of the Victam Asia/VIV Nutrition and Health co-located exhibitions in the BITEC halls.

There’s our Market Place on page 34 and our Interview with Riccardo Concetti, the director of sales and marketing at Concetti SPA, Italy which is well worth the time to read and consider.

There’s much more in this issue that should have been highlighted above. Enjoy the voyage of discovery!

Our last edition

Did you miss our January 2023 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from the Apple Store, Google Play or online at: https://magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

What you may have missed…

Alternative Protein Solutions for Furry Family Members by Jennifer

Adolphe, Pet Technical Sales Manager, ADM,

USA

Alternative protein sources have risen as an essential factor in the global food system for both humans and their pets. Plant- and yeast-based proteins are options

that can be used in pet food and treats to supplement or replace animal protein ingredients. Even insect protein, like black soldier fly meal, is being used in some pet foods today.

To read more, go to: https://issuu.com/international_aquafeed/docs/ ipf2401_web/18

Revolutionising Pet Nutrition Inside the Innovative Approach of a Petiva by

Mehmet Uğur Gürkaynak, International Petfood Magazine, Türkiye

International Petfood was fortunate to visit Petiva, a leading brand dedicated to delivering highest-quality products aimed at enhancing the health and wellbeing of pets, in December and understand its unique approach to petfood production.

To read more, go to: https://issuu.com/international_aquafeed/docs/ ipf2401_web/24

THE PUBLISHER

Joseph

Joseph

Reviewing the articles in this issue it became apparent that the petfood industry is really on one of those up turns in exponential development and growth periods. Development of so many new and unique ingredients, additives, processing equipment diversity and the ranges of products for pets. Formulas developed to assist in all life stages with health natural and well- balanced formulas. It is an exciting time to be in this expanding and developing growth industry.

In this issue there are topics of interest and reviewing these articles remind me of my collection of pets, mostly dogs, over the years. It is amazing how this industry has developed and advanced with new and revolutionary ideas and approaches. Access to information via the internet allows amazing search possibilities in today’s times. Googled ‘best petfood for dogs’ and you see sponsors and adds but a few clicks down you see ‘People also ask’ and these are interesting. Best brand, worst brands, No1 brand, why rice, brown or white, what dog food do vets give their dogs and on and on. The point being people ask and are concerned about their pets and they want knowledge and information on these topics and companies are responding, a few examples.

How great is it that a company, Myos Corp, has received a patent on improving mobility in aging pets. All my dogs lived good long lives and yes when they achieved their senior year’s they did have reduced mobility, congrats on this development, one I am sure many pet owners will enjoy.

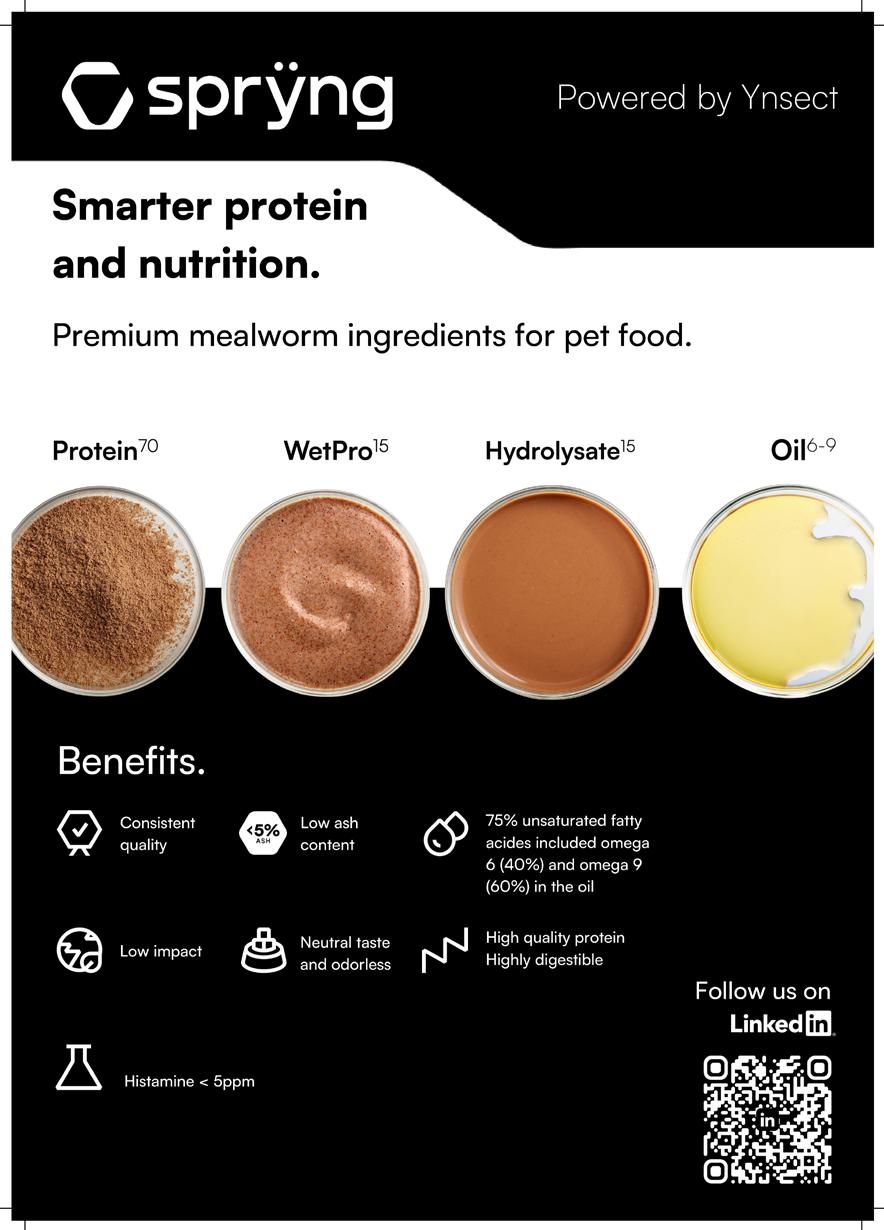

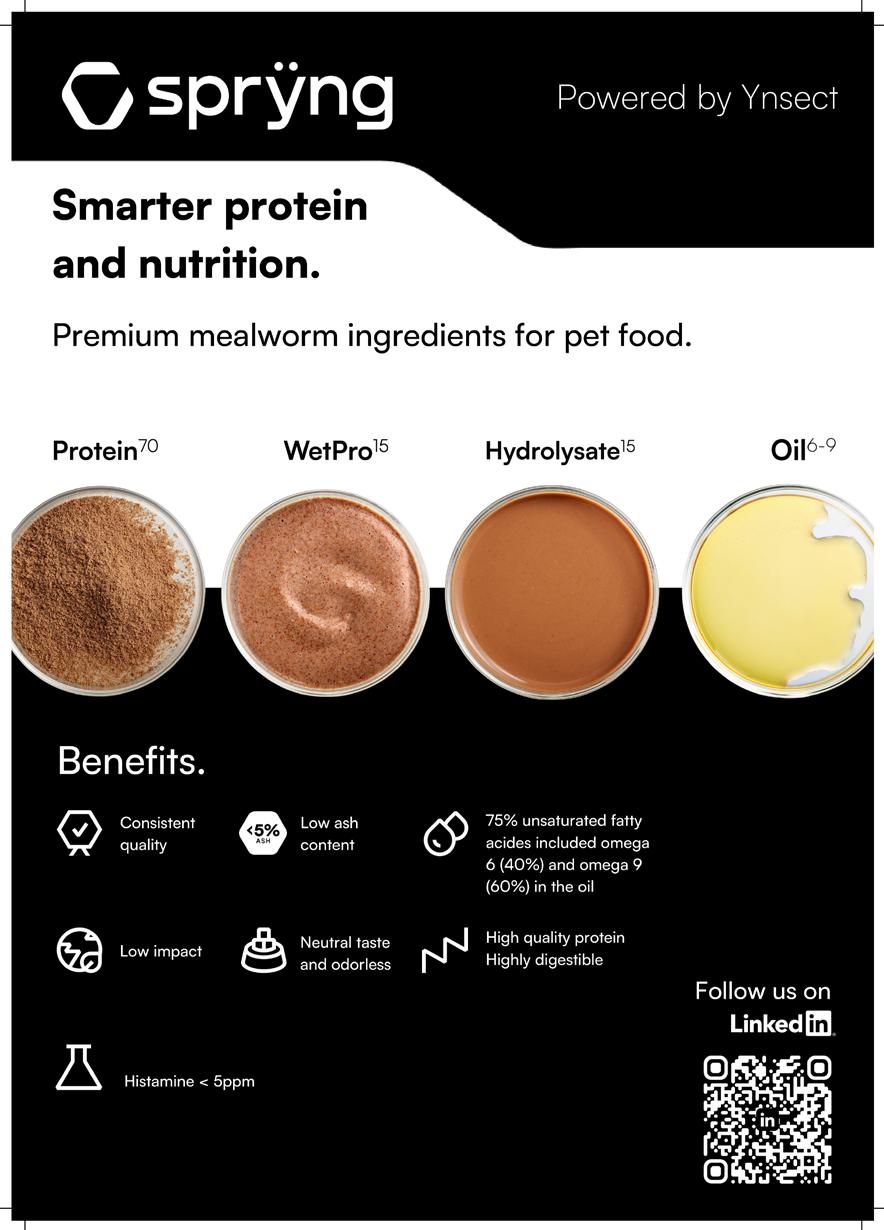

Lorena Sanchez of Ynsect France has reported the benefits of mealworm proteins for obesity in pets. I never had this problem with my dogs due to fact their goal was to run and run hard chasing wild birds, pheasants and quail to be exact. Absolutely have seen many cats and dogs which are obese and developments like these are definitely going to be of interest to pet owners of less active dogs.

Ok, years ago when pet foods started to change from basic products to more advanced nutritional formulas, we changed our pet’s diets. It was not an easy decision having been conditioned to feeding them the low cost traditional brown and round products. Being involved in the industry and seeing what was happening an assessment or review on my approach for this decision was in order. Big 40 kilo bags of brown and round was a huge volume, fed the dogs about four cups each based on the guidelines. Looking at the more premium diets and understanding feeding in a volumetric fashion it was noted the higher nutritional products were just as heavy bag wise but the volume was less. When you add fat and meat into a petfood the density can increase but the nutrient and ingredient sources and content changed and on a per volume went way up. Only need to feed 2 cups instead of four with the advanced formulas. My study was to see if we could justify the additional cost of the improved diets. Basically, it proved the cost of the feed was

nearly the same since the nutrient density in two cups of higher quality product was the same or similar as seen in a four-cup serving of brown and round. We changed and an additional benefit was less work to keep the yard in order! I believe many pet owners changed products but didn’t reduce the feeding volume. Lorena reports the huge increase in pet obesity and it is a pleasure to see their work in assisting pet owners to improve the quality of life for their pets with mealworm protein. Who would have guessed? When you are on the leading edge in the ingredient field you need to do testing to see what the results yield and in many cases the results are amazing.

The review continues with an article on alternate proteins for pets by Jennifer Adolphe of ADM. Nice article and one that is spot on how the protein ingredients used has and is changing in pet food production.

Prof. Simon Davies continues to keep us informed of details necessary even on the micro nutrients and this month riboflavin is the topic. In continuation of the discussion on micro ingredients, Dr. Cinzia Boggino Scavone and Dr. Allison Millican of Zinprop Corp. prepared an in- depth article on inflammation in pets and the important of attention to trace minerals.

An article on Petiva petfood production in Turkey points out the combination of ingredient selection and equipment yielding the desired innovation with scientific data and advanced techniques to achieve the quality final products. Another confirmation the advancements in processing and in ingredient development where their use is advancing the science and art of pet food production.

The interview with Thomas Runde of Tietjen, Germany is most interesting based on the fact that grinding is an important step in pet food production. Their innovative approach to problem and situation solving to advance developing is based on actually testing products to be ground individually or a mixed formula with in-depth discussion on what is expected and what is the range possibilities of what is to be ground to specific finesses. If you do the work up front in defining what is to be achieved then this or other devices do not become bottlenecks. I always felt a percentage of production over the need is not a bad idea in some cases.

This well-rounded issue does show just a few examples of how and why this industry is so dynamic. Attendance to the conferences around the world supporting this industry are promoting and sharing developments in all sectors. The list is endless and too long to list so let’s hope that we cross paths at some shows in the near future and share our developments and experiences to all friends and clients for the growth of the industry and benefits to our beloved pets. We would be glad to assist and hear as it is all interesting. Countless times discussions have shown that these new unique approaches are useful and worthy of review to see if it assists petfood production and development.

THE

EDITOR

International Petfood - February 2024 | 7

P Kearns Editor, International Petfood Magazine

Professor Simon Davies Nutrition Editor, International Petfood

Professor Simon Davies Nutrition Editor, International Petfood

Niacin the essential micronutrient for cat health

A modern cat food is well balanced in terms of protein and the ten essential amino acids constituting the optimal or ‘ideal’ protein requirements for maintenance and growth. Along with the essential fats and oils delivering the omega-3 fatty acids and lipids for energy as typical of a carnivorous diet we must include vitamins and minerals in commercial diets for the companion feline sector. Vitamins of course can be divided into the water soluble vitamins and the fat soluble vitamins A, E, D and K. The water soluble vitamins for cats are the important B-vitamins that work synergistically as co-factors for a myriad of enzymes involved in intermediatory metabolism within animal cells making up tissues and organs. We have discussed some of these previously for both dogs and cats. As individual key vitamins, each have a specific function.

The metabolic role of niacin in animals, including cats, is essential for various physiological processes. Niacin functions as a precursor to coenzymes nicotinamide adenine dinucleotide (NAD) and nicotinamide adenine dinucleotide phosphate (NADP), which play critical roles in cellular metabolism. Niacin, also known as vitamin B3, is a vital vitamin nutrient for cats, playing a crucial role in various physiological processes that contribute to overall health and wellbeing. It is vital for the proper functioning of the immune system, metabolism, and the maintenance of healthy skin and coat. Here, I critically review the nutritional requirements of niacin for cats and its importance in their health and relation to the petfood industry.

Energy Metabolism

Niacin is a key component in the electron transport chain, a crucial process in cellular respiration. NAD and NADP act as coenzymes in redox reactions, facilitating the transfer of electrons and the generation of ATP, the cell’s primary energy currency. Niacin is involved in the metabolism of carbohydrates by participating in glycolysis, the breakdown of glucose to produce energy. It helps convert pyruvate into acetyl-CoA, a crucial step in the TCA (tricarboxylic acid) cycle. Niacin is essential for lipid metabolism, playing a role in the synthesis and breakdown of fatty acids. It contributes to the formation of NADPH, which is critical for fatty acid biosynthesis and lipid storage. It is also involved in the metabolism of amino acids, serving as a cofactor for enzymes involved in protein synthesis and degradation. NADPH, derived from niacin, is crucial for cellular detoxification processes, including the reduction of reactive oxygen species (ROS) and the regeneration of antioxidant molecules.

Nutritional Requirements of Niacin for Cats

Cats are obligate carnivores, meaning their diet primarily consists of meat. Unlike some other animals, cats cannot efficiently convert tryptophan (an amino acid) into niacin. As a result, they have a higher dietary requirement for preformed niacin compared to many other species.

The National Research Council (NRC) recommends a daily intake of around 12.5 mg of niacin per kilogram of dry matter for adult cats. The Association of American Feed Control Officials (AAFCO) recommends a minimum of 40 mg niacin per kilogram of cat food on a dry matter basis.

Niacin is essential for the metabolism of proteins, fats, and carbohydrates. It plays a key role in converting food into energy, contributing to the overall metabolic health of cats. Niacin is crucial for the proper functioning of the immune system. It supports the production and function of immune cells, helping cats to defend against infections and diseases.

Deficiencies in Cats

Niacin deficiency in cats can lead to various health issues, including Poor Growth. Kittens may experience stunted growth and development. Dermatitis - Skin problems, such as lesions and inflammation, can occur. Digestive Issues - Niacin deficiency can affect the digestive system, leading to diarrhoea and other gastrointestinal problems. Neurological Issuessevere niacin deficiency can result in neurological symptoms. It is of paramount importance that cats are fed animal rich diets and the growing fad for higher inclusion of plant based ingredients must be very carefully assessed and cautioned.

Foods Rich in Niacin for Cats

Since cats are obligate carnivores, meat is a primary source of niacin in their diet. Chicken, turkey, beef, and fish are all good choices. Liver and other organ meats are rich in niacin. These should be included in a cat’s diet in moderation to provide essential nutrients. High-quality commercial cat foods are formulated to meet the nutritional needs of cats, including niacin. It is imperative to always choose well-balanced, complete cat foods as part of nutritional management.

In summary, niacin is a vital nutrient for cats, and meeting their dietary requirements is crucial for overall health, immune function, and metabolism. Providing a balanced diet with appropriate amounts of meat and organ meats, or feeding high-quality commercial cat food, is essential for preventing niacin as well as other B-Vitamin deficiencies in cats. Regular veterinary check-ups can help ensure that your cat’s nutritional needs are being met and any potential issues are addressed promptly for early action.

8 | February 2024 - International Petfood

The PetFood Journal

Petfood Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with a distinguished track record of technical and trade magazines in the agricultural sciences. This new peer-reviewed scientific journal will serve academia and the commercial petfood industry with high quality papers relating to the science and technology of petfood development and production for the rapidly expanding companion animal sector. It is envisaged to address fundamental and applied nutritional research addressing requirements for advanced feed production manufacturing for dogs, cats and many other species such as guinea pigs, rabbits, rats and exotics e.g. reptiles, amphibia and fish (aquatics). The journal will embrace information on essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to maintenance, growth, feed utilisation efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to traditional sources. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of pet animals are attractive. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Petfoods play a significant role in animal behaviour due to palatability and smell. Research on these interactions would be welcome and of interest to the scientific community and stakeholders. Given the diversity of different types of commercial diets ranging from wet, canned and extruded dry diets as well as treats and speciality diets, there is much scope to provide information on these advances. We also cover papers on feed production manufacture such as milling, pelleting, shaping and texture of petfoods such as extrusion.

The journal recognises that petfood science & manufacturing technology plays a vital role in promoting the health and well-being of our pets. Optimal feed management and environmental impact of diets are worthy of inclusion.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Petfood Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral, researcher, being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief.

These OA papers will be available on our official website Internationalpetfood.co.uk and printed as well as being downloadable. Links will be provided within our existing International Petfood magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2024

International Petfood - February 2024 | 9

Protix receives funding for new plant

The European Investment Bank (EIB) has signed an EU€37 million loan agreement with Protix to support the expansion of its sustainable protein production. This funding, backed by the InvestEU program, will aid Protix in constructing a new production plant in Poland. The collaboration aligns with InvestEU’s objectives of Sustainable Bioeconomy and Circular Economy, aiming to stimulate over EU€372 billion in additional investment in the European Union from 2021 to 2027.

EIB Vice-President Teresa Czerwińska expressed satisfaction in supporting innovative solutions and collaboration with Protix. Protix CFO Lynn De Proft highlighted the agreement’s significance, emphasising the industry’s growth potential. Protix, a leader in alternative protein for Petfood and agriculture plans to scale internationally, with the new plant in Poland being three to four times larger than its existing facility.

The EIB emphasises the importance of investing in innovation and development for economic growth, with global support to these sectors amounting to EU€17.93 billion in 2022. Protix exemplifies successful use of targeted European Commission funds to support innovative companies in key EU policy areas.

AFIA announces PetFood Award winner

The American Feed Industry Association (AFIA) announced Angele Thompson, PhD, founder and president of Thompson PetTech as the 2023 Friend of PetFood Award winner. Jerry May, vice president of government and trade affairs at Freshpet, presented the award today during the AFIA PetFood Conference, happening in conjunction with the International Production & Processing Expo this week.

“Dr Thompson has contributed to the advancement of innovation, product development and nutrition in the Petfood industry,” said Louise Calderwood, AFIA’s director of regulatory affairs. “She continues to be a proactive voice in the industry, and we are excited to

present this award in recognition of her leadership.”

In her current role as an independent consultant, Thompson draws upon her extensive experience in the petfood industry and offers nutrition, product development and regulatory services, and guides companies toward innovative solutions that prioritise pet health and wellbeing. In addition, she has served many roles with the Association of American Feed Control Officials (AAFCO), including speaking on expert panels for developing the Nutrient Profiles and Protocols, and as an industry advisor to the AAFCO Ingredient Definitions Committee and AAFCO PetFood Committee.

“I am very lucky to have gotten into the petfood industry at the beginning of my career and continue to contribute to the lives of pets and those who love them,” said Thompson.

Thompson began her career as a nutritionist with Heinz Pet Products and rose to the role of technical services manager of nutrition, analytical laboratory and animal feeding laboratory. In 1997, she started her independent consulting firm, Thompson PetTech.

Thompson earned a bachelor’s degree in biochemistry from the University of California, Los Angeles and a doctorate in nutritional biochemistry from the University of Arizona.

THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED:

� CHIEF COMMERCIAL OFFICER

� GENERAL MANAGERS

� MANAGING DIRECTORS

� CHIEF MILLERS

RECRUITING GLOBALLY

� FEED & POULTRY MANAGERS

� MAINTENANCE MANAGERS

� R&D NEWPRODUCT DEVELOPMENT

� SALES & MARKETING

� PLANT MANAGERS

BOURNE AES R C H & RECRUITMENT SELE C T I NO

�

���� bournerecruitment.co.uk ���� +44 7764 465 897

CFO’S

10 | February 2024 - International Petfood N

Globe Buddy introduces new sustainable dog food

Danish petfood company Globe Buddy has introduced a super-premium dog food based on a novel and sustainable source of proteininsects. The brand wants to inspire a positive change and help dog owners live a greener pet life.

“We have made it easy to feed your furry friend a healthy and tasty diet while doing some good for the planet, simply by reducing the climate impact of dog food,” said Bjarne Gravesen Jensen, CEO and co-founder of Globe Buddy.

The insect-based dog food Globe Buddy Brown features protein from the black soldier fly larvae, which is good for all dogs, especially those with sensitive digestion or intolerances to traditional meats.

It is also a win for the climate. Using insect protein in petfood reduces carbon emissions. The carbon footprint of the ingredients in Globe Buddy’s new product is just over half that of the ingredients used in the market’s average dogfood, according to calculations performed by the consultancy firm Viegand Maagøe on behalf of Globe Buddy.

The insect-based product comes with a thirdparty verified carbon footprint, something that is still rarely seen in the petfood industry.

“While many companies have brought what are claimed to be green petfoods to market, we saw a need among pet-parents for increased transparency in the environmental sustainability of their dog’s food. Our brand aims to address this unmet need,” said Bjarne Gravesen Jensen.

Besides the climate-friendliness, insect larvae are a petfood ingredient that advances the circular economy and minimises waste because insects are fed on by-products from the food industry.

Globe Buddy’s commitment to sustainability also extends to their packaging, with a fully recyclable and perfectly-sized box designed for direct-toconsumer distribution.

International Petfood - February 2024 | 11 N Come and see us at

Demand for quality petfood remains high despite inflation

New research results show that despite inflation and price increases on petfood, owners continue to want the best for their pets. As a result, delivering added value such as nutritional, health or sustainability benefits is key to retaining consumer interest in times of tighter budgets. This new global survey has been conducted by the market research agency FMCG Gurus, on behalf of Beneo, with 2500 dog and cat owners in the US, Brazil, UK, Germany and China.

The research demonstrates that even though almost nine in ten surveyed pet owners feel that petfood prices have risen in the last year, only one in six pet parents globally has turned to cheaper products or brands as a result. Most are staying loyal to their brand of choice by taking greater advantage of promotional offers or bigger packs. In fact, price is considered less important when buying petfood compared to ingredient quality, nutritional value, taste and health claims. And over half of respondents are even willing to pay a price premium for petfood with health-promoting ingredients that have been scientifically proven.

Pet parents are very concerned about their pet’s health and the survey results reflect this, with more than four in five owners considering their pet’s health to be as important as their own. The link between their pet’s digestive health and overall health is also more widely recognised by pet owners, with over three in four cat and dog owners understanding that the digestive system has a positive influence on many aspects beyond the gut, such as bone condition, mental and physical wellbeing and the immune system. It is not surprising therefore that the on-pack claims most likely to influence purchasing of petfood products include ‘promotes digestive health naturally’ and ‘east-todigest’.

Most pet owners opt for a proactive and natural approach to nurturing their pet’s digestive health, with more than one in three saying that their pet’s food that features claims to support digestive health, showing the importance of highlighting specific benefits on pack.

The digestive health claims with the biggest effect on pet owners’ purchase interests are: ‘digestive comfort and well-being’, ‘promotes digestive health naturally’ and ‘supports a healthy and balanced digestive system’. In addition, almost half of pet owners associate prebiotics with gut health, making this a key ingredient in petfood manufacturers’ toolbox.

The survey also reveals that protein quality and content are important for seven in ten respondents. Additionally, sustainability claims are considered by some extent by four in five owners when choosing food for their pets. With more than half of cat and dog owners considering plant-based proteins to be better for the environment, it is no surprise that vegetal ingredient sources with sustainability credentials are of increasing relevance. For instance, more than 80 percent of pet owners associate faba beans with being sustainable. Natural and high-quality vegetal proteins are therefore a valuable resource for manufacturers, allowing them to cater to pet owners’ interests, whilst formulating nutritious petfood recipes.

Dr Maygane Ronsmans, Product Manager Animal Nutrition at BENEO says: “The findings of this latest pet owner survey highlights that even in times of inflation, nutritional value and health remain a priority for petfood purchases. Scientifically proven prebiotics like BENEO’s Orafti Insulin and Oligofructorse from chicory root, are providing popular with petfood producers as they naturally support digestive health, whilst allowing for appealing on-pack communication. Also, with pet owners more attentive to sustainability, BENEO’s vegetal proteins, derived from faba bean, wheat or rice, are valuable assets in petfood producers’ toolboxes.Thanks to a versatile range of plant-based ingredients with technical, nutritional and healthpromoting benefits, as well as longstanding expertise in healthy nutrition, BENEO is well equipped to help manufacturers bring to market innovative and relevant petfood products that meet consumer demand, even in a tough economic climate.”

N 12 | February 2024 - International Petfood

Vafo Group acquires Dagsmark

Vafo Group, a Czech family company that manufactures petfood, has bought the Finnish Dagsmark Petfood. The acquisition took place on January 31, 2024. Dagsmark will continue to operate as an independent company and all its personnel will be transferred to the new owner.

Vafo Group already owns Prima Pet Premium Oy in Finland and Vafo Finland Oy, a dry petfood factory completed for Nokia in spring 2023. With the acquisition, Dagsmark becomes a sister company of Prima Pet Premium and Vafo Finland in Finland. The companies will continue to operate separately but will intensify their cooperation. The companies’ productions naturally complement each other, as Dagsmark produces wet food for dogs and cats at its own factory in Mellilä.

“Dagsmark has done an excellent job. The company’s growth has been tremendous and the products are of high quality. We see considerable growth potential in the Dagsmark brand in Finalnd and the opportunity to expand to other Nordic countries,” says Timo Pärssinen, a member of Vafo Group’s management team.

Nokia’s dry food factory is Vafo Group’s previous big investment in Finland. The factory, which cost about 20 million euros, was completed in 2023. Vafo Group also manufactures products of other brands in its factories. The company is known for the high and consistent quality of its products.

PETFOOD INTERNATIONAL

International Petfood comes to you either in print or digitally.

Whichever way you want to receive, please sign up on our MagStand for your personal copy which will give you access, from your desktop, to our back-issue library. https://store.magstand.com/petfood

The App can be downloaded from your favourite app store.

We invite you to use the code below for a free edition of our March magazine either mailed to you or via our App Use coupon code:

“For us, the acquisition is an absolutely positive thing. With the new owner, we get more resources and knowhow and the opportunity to invest more in product development than before,” says Riikka Koskenohi, CEO of Dagsmark

The acquisition does not affect the domesticity of Dagsmark’s products. The dry and wet petfood sold under the Dagsmark brand will continue to use domestic raw materials whenever possible. Wet food production continues at Dagsmark’s own factory in Mellilä, and dry food production at Vafo Finland’s factory in Nokia.

The most advanced software solutions for pet food production from intake to finished product.

Download your online version

Scan the QR-code and learn more! International Petfood - February 2024 | 13 N

ATLANTA24

AS A SOURCE OF NUTRIENTS FOR PETFOOD

Yeast & yeast-based feed additives

by Márcia Villaça, Technical and Sales Manager & Melina Bonato, Technical and R&D Manager, ICC, Brazil

Although the use of yeast and yeastbased feed additives as a source of nutrients in animal diets is well-known worldwide, there are still some doubts about their use in petfood. Therefore, we have listed the main benefits of formulating Standard, Premium, Premium Special, and Super Premium diets, considering various techniques and their uses. Learn more about the benefits of ICC Animal Nutrition’s line of solutions for animal nutrition.

First, it is worth noting that commercial pet food is classified according to the segmentation instituted by the industry itself as Standard or Economy, Premium, Premium Special, and Super Premium. There is a significant qualitative difference between these formulations, which involves selecting raw materials and their analysis, evaluating animal digestibility, and nutrient absorption.

In addition to nutritional factors, the costs of the ingredients are considered through formulation programs to formulate a diet. Including functional additives or yeast as a source of nutrients in diets is a common practice and often used to give them some exclusive benefit, adding quality and value to the final product. Therefore, the most appropriate choice for pet food must consider economic and nutritional factors and the specific benefits sought.

Standard diets

These diets have lower-quality protein sources and less biological value, requiring higher animal consumption to meet their nutritional needs.

For this type of food, yeasts, as a source of nutrients from ethanol or brewery production processes, are an excellent option to increase its nutritional quality since these are protein sources with an interesting amino acid and vitamin profile. Yeasts are also excellent sources of glutamic acid, making it possible to reduce the use of palatants. That is why the inactive dried yeast (StarYeast®) can also be used in Standard diets.

Considering the use of feed additives, ImmunoWall® is an excellent option. For diets that use fewer noble ingredients in their formulation, the inclusion of ImmunoWall® as a source of MOS and β-glucans is highly positive since it provides benefits on gut integrity, reduction of pathogens, and acts as an immunomodulator, resulting in an excellent value for money.

These are diets with a greater diversity of ingredients, a better protein profile, and higher digestibility. From an economic point of view, it allows the use of brewers and inactive dried yeast

F 14 | February 2024 - International Petfood

(StarYeast®) as nutritional yeast and feed additives such as MOS and β-glucans (ImmunoWall®), autolyzed yeast (LysCell®) and mycotoxin adsorbents (StarFix®).

Super Premium and Veterinary diets

The Super Premium and Veterinary diets are made up of even more noble ingredients with high digestibility. They provide better use of nutrients, requiring less consumption to meet the animal’s needs. Another essential characteristic of Super Premium diets is that their composition is usually fixed; replacing any components is prohibited.

In these diets, the main goal is to have high-quality ingredients and provide maximum animal welfare, so using feed additives is almost a rule. It is also possible to consider the inclusion of a yeast-based solution, such as a source of MOS and

β-glucans present in ImmunoWall® – which are focused on improving gut health and modulating the immune response of animals, making them less susceptible to diseases; mycotoxin adsorbing additive, such as StarFix®, which reduce the risk of mycotoxin contamination that may be present in the diet, added to traditional brewer’s yeasts, such as Brewer’s EXL®, and autolyzed yeast, LysCell®

It is worth mentioning that LysCell® and Hilyses® are ideal for diets intended for animals with dermal sensitivity or allergic problems since they have a high concentration of short-chain peptides, which are not detected as allergens by the immune system. The autolysis process also contributes to excellent palatability and digestibility. Hilyses® also contributes with nucleotides and nucleosides, essential for demands like allergic control, hepatic problems, and animal recovery.

4B DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS Engineering Solutions Since 1888 Improving the Safety & Efficiency of Your Plant www.go4b.com A Worldwide Manufacturer www.go4b.com ELEVATOR COMPONENTS HAZARD MONITORS & SENSORS CONVEYOR CHAIN #23399 Global Ad Styles.indd 8 07/06/2023 10:07:25 Highly recommended Recommended Allowed

International Petfood - February 2024 | 15 F

atitsbest

Tailoring the process to meet the needs of the ornamentals

by Jyothsna Nelloolichalil, International Petfood, UK

Imagine a world where fish feed isn’t just a commodity but a precision-engineered nutritional and tailored package for life below water.

This visionary approach was designed and brought into reality and is today at the heart of World Feeds, a pioneering aquarium feed producing company nestled in Thorne, Doncaster, UK.

International PetFood had an opportunity in late autumn to visit the company and understand its unique approach to aquafeed production.

Welcomed by Peter Kersh the CEO, Mark Wilson founder and technical director and Tom Noble, the sales director, our

experience began with an introduction to the company’s ethos and its flagship brands - VAF and Vitalis.

Vitalis, the jewel in the crown of World Feeds, and caters to the diverse dietary needs of aquarium fish. Peter explained that Vitalis feeds are used by leading public aquariums worldwide.

Some of the largest exhibits worldwide have been reaping the many nutritional and practical benefits of the company’s feeds over many years.

For example, Sea Sentosa of Singapore features a 45 million litre tank, which is home to over 100,000 marine animals of 1000 different species is one such aquarium and another is the 11 million litre multi-species exhibit at the Dubai Aquarium and

International Petfood Tuti Tan amazed by 3D printing

Peter Kersh, CEO; Mark Wilson, technical Director and Founder and Tom Noble, Sales Director (From left to right)

The warehouse

International Petfood Tuti Tan amazed by 3D printing

Peter Kersh, CEO; Mark Wilson, technical Director and Founder and Tom Noble, Sales Director (From left to right)

The warehouse

F 16 | February 2024 - International Petfood

Head office in Thorne, Doncaster, UK

Underwater Zoo that trust the feeds this company produces.

The secret behind the company’s success lies not just in using high-quality ingredients but also in employing scientifically precise formulas and utilising proprietary machinery. And herein lies the crux of its innovation — crafting feeds that are malleable, stable and highly digestible, aligning perfectly with the natural feeding habits of the fish in question.

The market scope of these remarkable feeds extends far and wide. While VAF dominates markets in Scotland and Norway, Vitalis enjoys global distribution.

The Genesis

Founded in 2004 by Technical Director Mark Wilson, World Feeds is a South Yorkshire-based company built on the simple premise of improving the way fish are fed.

Mark’s history in ornamental aquaculture, including conservation and breeding programmes, steered him into forming the world’s first commercial clownfish hatchery. His research led to a discovery that deeply concerned him - the food on the market at the time simply did not fulfil the nutritional requirements of the ever-growing diverse range of fish.

Species representative of the different regions from around the globe each have an equally diverse range of dietary needs. These were certainly not being met with the catch-all approach of products available in the market at that time. Change was necessary.

Coming together with Managing Director Peter Kersh in 2005, together formed a team of fish experts, scientists and engineers to

Our wide range of value-added services and understanding of production and market challenges worldwide, allows us to find the right technology and the most cost-effective solutions for your business in Livestock, Aquaculture/ Aquafeed and Pet industries.

E S E has developed and manufactures its own line of innovative and specialized equipment and systems, with exclusive and worldwide technical services for different processing situations in several capacities, from unique components to full line and complete solutions ENGINEERED SYSTEMS & EQUIPMENT, INC 1564 Hwy.166 E. Industrial Park. P.O. Box 99, Caney, Kansas 67333 USA - Phone: + 1 (620) 306-4100 – Fax: +1 (620) 840-2087 Email: info@eseintec.com - www.eseintec.com Carretera Córdoba a Veracruz Km 342, Zona Industrial, C.P. 94690 Cordoba, Veracruz, México Tel: (+52) 271 751 7350; (+52) 271 751 7396 www.intecmx.com - contacto@intecmx.com INTEC – INTERNATIONAL FEED & FOODS TECHOLOGIES S.A. DE C.V. Supported and Guaranteed with its own very complete and equiped Laboratory with latest Technologies Offers customized development, formulation and manufacturing services for efficient and effective Vitamin and Mineral Premixes, Additives, Farmac, Organic Acids, Pigments, Organic Bypass Fats, etc with the highest quality standards and according to the needs of its customers in animal nutrition, with exclusive Technical, Professional and Personalized Consulting worldwide. DISCOVER HOW WE CAN HELP WITH YOUR NEXT PROJECT

Peter Kersh with feeds and feed ingredients

The feeds

The company primarily produces its fish feeds in either flakes, soft pellets or blocks.

The ingredients used are sustainably sourced and meet the highest specifications.

The company also has a unique way of manufacturing its flakes, which are produce as sheets with less than one percent moisture and later broken down into smaller flakes.

Our journey through the hallowed halls of the factory was a further revelation.

Witnessing the intricately designed machines that craft flakes, pellets and elongated feed blocks was akin to peeking behind the curtain of innovation.

World Feeds’ custom-made extruders are at the very heart of its process to produce fish feeds that aligned with the nutritional needs of fish. They even make their own wear parts on 3D prints

bring about their vision of creating the best fish food in the world to fruition.

Vitalis Aquatic Nutrition is exported to over 40 countries, supplying retailers and public aquariums around the world.

“Our innovative formulation and engineering developments with VAF (Vita Aqua Feeds) are embraced by international aquaculture operations - all formulated, manufactured, packaged and distributed from one location in Thorne, just outside Doncaster, UK,” says Tom, who has a background in Zoology and a prior association with Mark, who was later to join the team.

Additionally, John Adron, a Biochemist specialising in aquaculture and marine nutrition, has continuously supported World Feeds as a consultant since its inception. He has worked for the Natural Environment Research Council and has been the author of 75 published scientific papers in the field of marine biochemistry.

The crux of their innovation lies in a fundamental paradigm shift.

Unlike conventional companies that tailor feed to fit machines, World Feed alters and ‘tailors’ its machinery to make fish feeds that meets the needs of the fish. World Feeds engineers its machinery constantly to craft feed that aligns with the feeding characteristics and dietary needs of the fish.

inhouse which includes their own cutters.

The machines have a production capacity of 120kg per batch, and the packaging is done manually but gradually moving to automation as demand dictates.

World Feeds’ unwavering dedication to designing feeds tailored for aquatic residents stands as a beacon of innovation in the industry.

In essence, World Feeds isn’t merely a company — it’s a testament to visionary leadership, unyielding passion and an unwavering commitment to transforming the way we nourish aquatic life.

With every flake meticulously crafted and every pellet scientifically formulated, World Feeds continues to be the epitome of excellence in aquatic nutrition — a beacon guiding the industry toward a future where fish thrive on tailored nutrition.

Production of flakes Production of pellets Feed blocks for cleaner fish

International Petfood team with Peter, Mark and Tom

Fish feed being moved for packaging Fish feed

Production of flakes Production of pellets Feed blocks for cleaner fish

International Petfood team with Peter, Mark and Tom

Fish feed being moved for packaging Fish feed

F 18 | February 2024 - International Petfood

With over 150 years of combined experience, we help you find your individual packaging solution. Over the years, we have delivered highly versatile and innovative machines operating at high production rates for the international pet food industry. In addition, we

vironmental challenges without compromising on performance.

The Packaging Group GmbH · Germany · www.tpg-packaging.com

you

en-

If you can think it, we can pack it! Let’s create your perfect pet product packaging solution!

help

meet global

PETFOOD AFTER COP28

by John Harvey, Veterinary Surgeon and MSc Student, University of Exeter; Dr Peter Alexander, Senior Lecturer in Global Food Security & Prof. Dominic Moran, Professor of Agricultural and Resource Economics, University of Edinburgh

by John Harvey, Veterinary Surgeon and MSc Student, University of Exeter; Dr Peter Alexander, Senior Lecturer in Global Food Security & Prof. Dominic Moran, Professor of Agricultural and Resource Economics, University of Edinburgh

Despite accounting for around 30 percent of global greenhouse gases, emissions from food systems have not received as much political attention as those from energy, transportation, and other industrial sectors. But that changed at COP28, where the final agreement made specific reference to food.

Taking a leaf out of the ‘big oil’ playbook, there has been some push-back from ‘big meat’, but it now seems inevitable that food systems will eventually be included within national emissions allowances; and this is likely to have direct and indirect consequences for pet food production as a subsidiary part of that system. What might these be and how might related environmental impacts be mitigated?

In terms of direct effects, the trends that we see in human food consumption, largely away from meat and ultra-processed foods, will likely be mirrored in pet food sector. Consumer preferences can change rapidly, and growing consumer awareness of climate change and other sustainability challenges will be reflected in the choices they make or themselves and their pets. Changing demand will in turn drive more sustainable pet food compositions.

In addition, an on-going protein transformation of the human food system, mainly away from red meat, will likely have indirect impacts for pet food producers. Changing patterns of meat production will influence the production costs and supply of animal by-products (ABPs), often used as pet food ingredients.

Other potential policy interventions in the meat and livestock sector could include a meat tax and a variety of voluntary or mandatory measures to reduce meat in public procurement for schools, hospitals and other public bodies. Such measures will also have an indirect effect on livestock production, and in turn, the likely availability of ABPs. ABP prices could also be driven up by increased use in human diets or alternative competing uses such as for manufacture of pharmaceuticals, biodegradable plastics, or biofuels.

Can pets be fed in environmentally friendly ways?

There is currently considerable debate about how pets can be fed in a more environmentally friendly way. A simple approach might be to encourage ownership of fewer and smaller pets. Feeding dry instead of wet food has been suggested to have a significantly lower carbon footprint. Some also argue that a move to plant-based diets is essential for environmental sustainability, and healthy for pets; the potential for nutritional completeness of plant-based foods now being accepted, at least for dogs, by some mainstream veterinary nutritionists. Others maintain that ABPs are still a low waste protein source with less climate impact. The veterinary profession, meanwhile, has health concerns about plant-based pet feeding, especially for cats. Elsewhere, proponents of insect-based foods highlight their sustainability attributes. Advocates of more raw food or ‘natural’ diets, typically with high meat content, argue that ingredients can be sourced in a more ethical and environmentally friendly way. While there is little evidence to support the environmental benefits of the latter, these arguments suggest that a common position on pet feeding

20 | February 2024 - International Petfood F

sustainability performance metrics has not been reached.

Consumer interest in sustainable pet foods is growing, from a historically low level, and ingredient sourcing as a product sustainability attribute is a focus of industry research and innovation. This includes research to understand consumer preferences for ABPs as healthy and sustainable protein sources. It seems clear that consumer demand will increase through better information about ingredients, primarily better labelling – detailing content percentages rather than generic descriptions of ‘meat and animal derivatives’. This suggests that labels should initially provide information beyond current regulatory requirements.

Trust in labelling is a key product attribute. Unilever are currently being investigated for ‘a range of concerning practices’ including possible misrepresentation of product sustainability credentials.

Might petfood come under similar scrutiny?

Reconnaissance in one supermarket showed two ‘premium’ pet food products from one manufacturer being separately marketed for health and improved sustainability but with almost identical ingredients. Previous studies have suggested that ‘main market’ products generally have lower environmental impacts than the ‘premium’ segment, due the quantity of the meat content. This could be the case here, although it would be hard to assess as the manufacturer only lists ‘meat and animal derivatives’ as the ingredients of their main-market branded product. Might regulators regard this as ‘misleading’? Either way, more transparency of ingredients

Revolutionizing batching with unmatched precision Easy maintenance Track & trace Reporting Continuity Employee shortage Health safety and environment Accuracy Short batch times Micro dosing and weighing equipment for: Offering a solution to your challenges such as: ALFRA - Part of KSE Group www.ksegroup.com Advertentie International Petfood (IPPE uitgave) – Print – NEW FORMAT_NO_STAND 190x132mm.indd 1 06/12/2023 11:20

F International Petfood - February 2024 | 21

would be a positive step.

The biggest players in the pet food industry are gaining experience offering plant-based and alternative protein, including insect, recipes. This includes purchasing or launching ‘niche’ brands, adding such products into their main ranges, and including plant-based recipes in their main offerings without specifically promoting this feature (for example Purina HA hypoallergenic which is vegan except for fish oil). At the same time, market demand for high-meat diets is met under alternative branding from the same companies. It seems likely that major players have the expertise, brands and supply chains that would allow them to adapt rapidly to market demand or ingredient supply changes. However, this might be different for smaller manufacturers who may have a smaller range of brands. They also may struggle to adapt formulations or may face supply chain challenges, especially accessing ingredients (such as alternative proteins), which may not be available through established agricultural practices.

Ingredients are only part of the sustainability picture. As environmental impact assessments improve, ingredient sourcing, animals (or insect) feeding, transportation, packaging, storage (e.g. cold chain) requirements, and other factors will come under increasing scrutiny. As with human food supplies, the development of life cycle assessment (LCA) methodologies (for example foundation-earth.org) will likely evolve into standardised front of pack ecolabels.

Lack of clarity

At present, the environmental impacts of different pet feeds are still disputed. But the scale of the global impact of pet food is substantial. Impacts related to ingredients are estimated as 56-151 Mt CO2 annual global emissions (dry food alone) - equivalent to 6-17 percent of aviation emissions. Variation in estimates arise when determining the ingredients of different products, grouping a wide range of ingredients as having similar impacts (for example treating all meat as chicken), and disagreements in attributing environmental impacts to ABPs.

The correct calculation of ABP impacts is still unresolved. Currently, LCA of ABPs apportions their impacts in proportion to their economic contribution to carcass value. This results the assignment of a relatively low environmental impact. But an alternative approach would be to assign the same environmental impacts, by weight, to other parts of the carcass. To understand the impacts of ABPs as pet food ingredients, it is insightful to consider what would happen if they were not used in pet food; that is, considering the likely changes would then occur in the food system and the associated the environmental impacts of alternatives.

For example, if ABPs would otherwise be waste that had to be incinerated, with little impact on the number of animals produced for meat, use in pet food would be environmentally negligible. On the other hand, if ABP use in pet food is economically supporting increased meat production, the impacts might be far greater.

There are gaps in the research evidence on the sustainability of pet foods. An increasing focus on food chain sustainability metrics is likely to extend to increased scrutiny of the pet food sustainability claims. Changes in consumer preferences as well as changes to ingredient supply linked to market and regulation pressures seem likely. In the coming years, the pet food industry will evolve due to sustainability pressures. How quickly this occurs, what this means for businesses along the supply chain, and the costs to consumers who may already be experiencing a ‘cost of living crisis’, are key future challenges for the industry.

22 | February 2024 - International Petfood F

PALATE+

Palate Positive, Planet Positive.

Maltento’s PALATE+ Pet

A functional hypo-allergenic digest inclusion, inspired by insects to improve palatability and gut health.

Minebea Intec

Minebea Intec is a leading manufacturer of industrial weighing and inspection technologies. Their mission is to increase the reliability, safety and efficiency of our customers’ production processes and they provide high-quality products, solutions and services that ensure a high level of safety.

Minebea Intec’s excellent performance is based on 150 years of experience, distinct German Quality and continuous investments in the development of innovative technologies. Their strong global presence and an extensive network of distribution partners ensure that our customers can rely on top Minebea Intec quality – anytime, anywhere. Their goal is to set strong standards in all areas of the company, which is reflected in the brand slogan, ‘the true measure’.

By purchasing Minebea Intec products, customers all over the world are choosing more than just innovative technologies: they are also choosing top-quality service performance and comprehensive support throughout the entire life cycle of their product. The company’s aim is to fulfil customers’ requirements no matter what the industry, and to be the first port of call for weighing and inspection technologies.

In Petfood

Ensuring products are safe and contamination-free has always been the most important premise for the pet food industry. However, new trends in pet food production are forcing manufacturers to be flexible whilst complying with regulations and sustaining supply. With its broad product portfolio of weighing and inspection solutions, Minebea Intec offers manufacturers the right solution for future-proofing their business.

Metal detectors, Vision systems, X-ray inspection equipment as well as software are used at

several points in pet food production to exclude contamination by foreign bodies made of metal, stones, plastic or other materials. This starts even before processing, where the basic ingredients are examined for possible contamination. During later processing steps, such as mixing the ingredients, product contamination can be caused by rubbing from containers or machines and finally, packaging is also checked by inspection solutions. Dynamic Checkweighers such as Flexus® and Synus® are equipped with electromagnetic force compensated load cells for most accurate weighing which in turn can also automatically adjust fill levels to reduce give-away.

Minebea strongly invest in developing Leading Technologies and new products. To ensure that these investments truly support our customers in optimising the safety, reliability and efficiency of their processes, we encourage and facilitate a company culture of systematic and sustainable creativity and innovation.

At the basis of this culture is our attitude of putting customers at the center of our thinking and acting. Through methods such as Customer Process Monitoring, they obtain a clear understanding of their current and future needs. The process of finding innovative solutions for fulfilling these needs, includes both technical research as well as applying structured creativity. In many phases of this process, Minebea involve internal and external specialists from a variety of disciplines, partners and customers.

The company’s well established Quality Management System provides us with the necessary procedures and tools for effectively managing our innovation process and ensuring that they fulfill the requirements regarding time-to-market and returnon-investment.

Industry Profile 24 | February 2024 - International Petfood IP

International Petfood - February 2024 | 25 World Leaders in Microwave Moisture Measurement Oil Animal Feed Coffee Rice Grain Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Milling and Grain-Advert Mar 2023 215x140mm.indd 1 28/02/2023 13:55

Industry Training

Aquafeed & Dry Petfood Extrusion Technology, Europe (Norway)

Core aspects of extrusion technology will be discussed and developed in this short course, taking into consideration the nuances of the processing of both petfoods and aquatic feeds.

The three-day course covers the principles of extrusion, the design of extrusion processes for both aquatic feeds and petfoods, as well as how the formulation interacts with the extrusion process. Principles learned will be demonstrated using the extruder in the Centre for Feed Technology pilot plant.

The program provides an in-depth background in general extrusion technology. The course is relevant to both single and twin-screw extrusion technology.

The course will cover topics from the basics of extruders and their configuration, through what is happening chemically and physically inside the extruder barrel, to an understanding of extruder dies and extruder instability.

Topics covered include: Principles of extruder configurations (single and twin screw)

• Role of rheology in extrusion

• Die types and effects, die design

• Extrusion chemistry – Recipe design

• Product density control

• Preconditioning for Extrusion

• Causes and effects of extruder instability

• Screw, barrel, and die-plate wear

• Extrusion troubleshooting

Examples in product formulation and the design of extrusion processes will be included to demonstrate application of the theory. Principles learned will be applied during the practical demonstration on Day two. Important aspects of peripheral systems (e.g. raw materials pre-processing, preconditioning) are also covered.

This program is relevant to technical staff interested in the formulation of extruded aquafeeds and dry petfoods and the use of extrusion technology for the production of these products. The program takes participants from the basics of what extrusion is and what it can do, through to a detailed understanding of the design of formulations and processes, and the operation and troubleshooting of extrusion systems.

This short course is presented by Dennis Forte & Associates in conjunction with The Centre for Feed Technology (Fortek), Norway, and is taking place 15 April – 17 April, from 9am to 5:30pm at the Norwegian University of Life Sciences.

For more details visit:

Your industry training platform

TRAINING

https://www.dennisforte.com.au/events/aquafeedextrusion-norway2024-2pm94-nyahb-d6bjj

The Online Milling School provides a comprehensive 12-week remote learning experience covering all aspects of feed milling, from raw material handling through to final packaging and dispatch. www.onlinemillingschool.com FISH FARMING TECHNOLOGY

26 | February 2024 - International Petfood

Troubleshooting

Die and knives are one of the areas in extrusion that has many possibilities and the choices define the results in the final product appearance. To start for safety dies should be bolted on with a minimum of grade 8 bolts. The combination of the die strength and the use of grade 8 bolts is the design which hold the pressure behind the die and keeps it together under high pressures. Note there are differences in how these grade 8 bolts are made and quenched and tempered designs hold higher pressures. As far as dies go there are considerations with regards on how many openings in a die, their spacing and still have the needed strength to hold the pressure.

Hole placement can change the final product shape. Wedged products for example, thicker on one side then the other in a kibble is typically caused by the velocity of the material flowing out the die. It just so happens in this case that one side of the hole has higher flow resulting in non-uniform kibble thickness or a wedged shape. Looking at the area or the bore behind the die which is flowing and full of product towards the back side of the die, this flow is fairly constant except for the friction force seen near the sides inside this area where steel meets the product. The die openings need to be fed evenly which is basically an even area of this mass flowing forwards. To each opening. If a die opening or part of a hole receives more flow then the others then the product will most likely be uneven in shape. This can be seen in variations of product thickness off the die.

Capacity of the extruder has an effect; typically, single screw extruders can run at different capacities or what is referred to as extruder capacity turn down. The designs usually allow for a three to one turn down which means as an example, nine tonne per hour extruder should be able to run at 3 tons per hour and make the same product. However, the die needs to be modified. The number of openings used at nine tonnes per hour will not operate correctly at three tonnes per hour to achieve the same product specs. Yes, you guessed it, you need 1/3 of the die openings equally spaced for three tonnes per hour. On a more scientific basis, typical expanded product dies have a total open area in the die of about 200 to 250 mm sq. per tonne per hour. Heavier density products have more open area per ton which reduces expansion. The total open area is adjusted to get the density at a given capacity.

Ok, a die can be designed where the holes are exactly evenly spaced but at lower rates produce an acceptable product. When pushed for maximum rate then you can potentially see different product densities out of various holes as these increased rates can show these slight die imperfections. The question then becomes do we run at lower rates or improve the die for the increased capacity control the product quality? The higher capacities require more exacting dies for exacting product specifications. All of these factors do relate to the final product parameters defined. Having said this, you can have different hole designs making multiple shapes at the same time as long at the holes have the same basic open area. If the open area of each shape is different then you will see a difference in each shapes length or size or expansion rate.

The cutting blade design needs to be such that each die hole is not completely covered on a micro second basis. Knife blades normally have angles so the product can grow in size behind the blade at it rotates over every hole. Slow motion videos show this effect and confirm correct design reduces fines at the die due to tails which can be caused by not taking these angles into consideration. An adjustable strobe light can freeze frame what is happening in the die area to define the holes which are not flowing correctly or evenly allowing for corrections so as to achieve maximum capacity.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The extruder barrel - Part 1

Forming extruders are used for some select products – thus this part of the discussion centres on single and twin designs.

6. Cook in the extruder barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - February 2024 | 27

Unique synergy!

Innovations this month February 2024

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk

PEGASUS® 5-IN-1 MIXER by Dinnissen

The Pegasus® 5-in-1 Mixer is a true multiprocessing machine. It allows you to mix, vacuum coat, dry, germinate and acidify your product. The mixer produces flavored products with a high hygiene requirement and a fresh-sour taste sensation, such as tea, cereals, (crispy) sweets, and snacks. In sectors such as the food industry, there is an increasing need for multiprocessing machines. Production must become ever faster and more efficient, to produce the best possible product using the least number of materials and resources possible.

By combining several process steps in one machine, the Pegasus® 5-in-1 mixer saves on both cost and energy. The dual axis mixing mechanism airily tosses powders, pellets and granules during mixing. Then the finely atomized liquid particles mix homogeneously with the dry raw materials. The 5-in-1 mixer can also dry, germinate and acidify the product. No transport is needed between the different process steps, saving time and manpower. www.dinnissen.com

PRODUCTION

Download your online version We invite you to use the code below for a free edition of our magazine either mailed to you or via our App Use coupon code: ATLANTA24

–Brewers’ yeast bound to functional f ibres! | dietetic and prebiotic active ingredients

digestion

promotes skin and coat quality | technological advantages Available with different fibre carriers like spent grain, DDGS or apple pomace. Visit our website: leibergmbh.de

Leiber YeaFi®

| supports

|

Leiber GmbH | Franz-Leiber-Straße 1 | 49565 Bramsche Germany | info@leibergmbh.de 140823_International Petfood_90 mm x 270 mm + 3 mm Beschnitt.indd 1 14.08.23 16:25 28 | February 2024 - International Petfood

FOCUS

Touchswitch by 4B Group

The Touchswitch is an electromechanical limit switch with no moving parts, which detects tracking and misalignment problems on bucket elevators and conveyors. When a belt misaligns or a pulley moves over and contacts the sensor, the built in solid-state electronic circuitry detects the lateral force of the belt or pulley and activates a voltage free solid state relay output. This output signal is used to immediately alarm and ultimately shutdown the machine.

The face of the sensor is made from hardened and annealed stainless steel, not soft brass or aluminium, so wear life is longer when a belt contacts it. The Touchswitch is not affected by dust or material build up and will still work when completely covered by material. An external test wheel allows for quick and simple sensor/system testing. The sensors are usually installed in pairs on opposite sides of the machine.

www.go4b.com

Healthy Heart by Butchers

Butchers Healthy Heart recipes are Vet Recommended and are carefully created by their Nutritionist. Every recipe has the right amount of naturally active ingredients to support heart muscle function, helping to keep your beloved friends healthy and happy. These complete & balanced, grain free recipes contain a combination of key ingredients to support a healthy heart and help your dog thrive.

Plant based omega-3 is algae oil naturally rich in the omega 3 fatty acid DHA to help support a healthy heart.

Vitamins C & E are antioxidants to help strengthen natural immune defences and vegetables such as spinach and butternut squash are a great source of omega 3 fatty acids, antioxidants & fibre.

www.butchersdogfood.co.uk

NHP200 by TekPro

The full Holmen range of Pellet Durability Testers are exclusively Made in Britain by Tekpro, and offer a fast and reliable method of testing PDI or Mechanical Durability. From feed pellets to wood pellets, either manual or automatic testing, TEKPRO provides the solution whatever the size of your mill!

The NHP200 is preferred by quality focused feed mills due to its ease of use and repeatable accuracy of the test process, its other benefits include:

• Suitable for Animal Feed & Wood Pellets between 3mm and 12mm

• Semi-Automatic – less need for human input

• Quicker than alternative methods

• Ideal for laboratories in busy testing environments

• Reproducible accuracy of ± 0.1%

• PDI results are stored and displayed on Colour LCD touchscreen, and can be printed or sent to other software by Ethernet socket

• Daily test results can be sent by email to staff, even if working remotely

• Digital Self Calibration built in

• Now includes dedicated Fines Calculation feature

• 1PH 110V-115V or 1PH 220V-240V www.tekpro.com

SEE YOUR PRODUCTS IN THIS MAGAZINE

If you produce a product that you think we should feature in International Petfood magazine, please get in touch

To be considered for inclusion in the magazine please; Email: editorial@perendale.co.uk

Include 75 words about the product along with a high resolution image and a web link to more information about the product in your email

Adult Chicken & Rice Gluten Free Dog Food by Oscar

To help combat dental disease

Oscar’s Chicken & Rice dog food recipe includes a special herb pack containing parsley to help freshen breath alongside antioxidants such as Vitamin C, E and BetaCarotene to support the immune system and reduce the risk of bacterial gum disease. When it comes to optimum nutrition they use hydrolysed Chicken which is less allergenic and highly digestible as well added fruits and vegetables to support general health and wellbeing.

Their Gluten Free Chicken & Rice dog food is often chosen for its delicious flavour but is ideal for dogs needing to avoid gluten.

www.oscars.co.uk

International Petfood - February 2024 | 29

BITEC , BA NGKOK , TH AIL A ND 12-14 MARCH

TOTA L A N I M A L

FE

E D A N D H E A LT H

E V E N T FO R A S I A

in co-location with

ORGANIZED

NUTRITION

HEALTH &

ASIA 2024

BY SUPPORTED BY

Scan here to register

Industry Events

2024 February

25- 26

Anido Kortrijk, Belgium www.anido.be

2024 March

4-5

Animal Health, Nutrition, and Technology Innovation Europe 2024 London, England www.events.kisacoresearch.com/ahi-europe-2024

9-10

ExpoZoo Paris Animal Show Paris, France www.parisanimalshow.fr

11

Petfood & Aquafeed Extrusion Conference Bangkok, Thailand

www.lp.constantcontactpages.com

11

Aquatic Asia Bangkok, Thailand www.databadge.net

12-14

VICTAM ASIA Bangkok, Thailand www.victamasia.com

13

Build My Feedmill Bangkok, Thailand

www.internationalpetfood.com/companies/build-my-feedmill// 12-14

HEALTH & NUTRITION ASIA Bangkok, Thailand www.vivhealthandnutrition.nl/

14