International PetFoodVolume 6Issue 6June 2024 www.internationalpetfood.com Striking A Balance - Feline Food Dilemma - Source Sustainable Protein - All-Natural Revolution June 2024 Download your online version:

55 million m3 built

New pendular and rotative sensors

ATEX 20 certified, the zone with the highest risk

· SY-DP1 Pendular . Robust and simple. It does not require power and maintenance.

· SY-DR1 Rotative . Sensitive. It has 2 operating modes depending on the density of storage material.

symaga.com • +34 91 726 43 04 • symaga@symaga.com

A reliable team for a reliable project YOUR RELIABLE PARTNER

Projects in 150 countries Top Project worldwide Flexibility and adaptability

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 01242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor

Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor

Joe Kearns joek@perendale.com

Editorial team

Shannon Parsons

Tel: +44 (0)1242 267706 shannonp@perendale.co.uk

Niamh Cassidy

Tel: +44 (0)1242 267704 niamhc@perendale.co.uk

Community Manager

David Harvey

Tel: + 44(0)1242 267700 davidh@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 (0)1242303792 darrenp@perendale.co.uk

Latin America Marketing Team

Cristina María Roldán Otero

Tel: +44 (0)1242 267700 cristinaot@perendale.co.uk

Turkey, Eurasia and Middle East

Marketing Team

Mehmet Ugur Gürkaynak

Tel: +90 537 364 64 57 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng

Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor

Tel: +44 (0)1242303791 jamest@perendale.co.uk

Production Assistant

Cristina María Roldán Otero

Tel: +44 (0)1242 267700 cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 (0)1242 303790 tutit@perendale.co.uk

Development Manager

Antoine Tanguy

Tel: +33 6 78 57 76 45 antoinet@perendale.co.uk

2024 8 Industry News COLUMNS 6 Roger Gilbert 7 Joseph P Kearns 8 Professor Simon Davies

June

International Petfood - Volume 6 - Issue 5 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 2754-4680 www.internationalpetfood.com 28 Training 29 Troubleshooting 30 Production focus 9 The PetFood Journal REGULAR ITEMS 26 Industry Profiles 33 Industry Events 38 The Market Place 40 The Interview 42 Industry Faces

FEATURES 24 All-Natural Revolution 20 Source Sustainable Protein 12 Striking A Balance 16 Feline Food Dilemma

Today we are all thinking in terms of our carbon footprint; making sustainable choices when it comes to everything from food to cars and even being environmentally friendly such as collecting up and disposing of our waste or unwanted products correctly.

However, we should not overlook the impact that our pets are having on all of the above.

Roger Gilbert Publisher, International Petfood Magazine

Roger Gilbert Publisher, International Petfood Magazine

We often don’t consider pets to be ‘unfriendly’ when it comes to environmental issues and carbon footprint, but unfortunately, they can be.

This edition of International Petfood carries an interesting view from Andrew Tindall, a patent attorney for Potter Clarkson in the UK. He was visiting his local veterinarian when he learnt that he might be over-feeding his cat. His feature appears on page 16 and titled: ‘Feeding the Future.’

The article goes on to provide some much welcome information on what the issues might be surrounding petfoods and their impact not only on the pet in question but on the environment in general.

It reminds us that all pet parents need to be cognisant of their pet’s needs and how best to meet them in these environmentally friendly times.

We know that petfood manufacturers are more aware of their responsibilities than ever before in what materials are included in the rations they produce. They are on the same journey as other feed producers such as aqua and livestock feed manufacturers.

Identifying the carbon footprint of a raw material is now becoming an essential part of the food production process for all our domesticated animals including pets. And the cost is falling to the producer and not always passed on the consumer, nor the pet parent at the retail outlet.

It has been quoted at conferences I attend that the cost of becoming more sustainable is not one that can be

automatically passed to the end purchaser but must be absorbed by industry itself. That’s a hard concept to grasp, but we should not be seeing ‘sustainable’ raw materials as having additional costs in the production of either our foodstuffs or our feeding stuffs.

If we are to reduce our carbon footprint, halt temperature increases and bring about a more sustainable life cycle for all of us on this planet then we must participate in that process - and we should include our pets within that equation as well.

Elsewhere in this edition

First, I must congratulate and welcome Joseph Kearns to the role of Editor of International Petfood magazine. Joe is a long-standing editor within the magazine itself on the technical side of things but is now stepping up to direct the editorial content of the full magazine.

He brings a wealth of knowledge from a long career in the production of petfoods via the extrusion process and is widely regarded for his understanding and insights when dealing with the wide variety of raw materials, ingredients and additives the industry has available to itself.

His selection of news topics will have interest for all readers and, being a dog lover, he has highlighted the nutritional article from dsm-firmenich in the USA, that looks at health and sustainability in ’Striking a balance,’ as his lead feature. Sustainability also takes centre stage in the article on page 20 when sourcing proteins for cat and dog feeds. And we take a close look at what seaweed has to offer on page 24 as well. Overall, there is much to read in this issue once again and I would be interested in your comments and suggestions on other topics we should be covering in up-coming editions.

Happy reading.!

Our last edition

Did you miss our May 2024 edition? If so, don’t panic! We published last mont on our App –which you can download from the Apple Store, Google Play or Online at: https://store.magstand. com/petfood - with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

What you may have missed…

Canine Nutrition and Health Unlocking the Power of Brewers’ Yeast by Maike Rakebrandt, Senior Product Management Equine & Pet, Leiber GmbH, Germany

Brewers’ yeast is a sustainable by-product from breweries, which is produced in compliance with strict food guidelines. It is rich in many

bioavailable active ingredients and nutrients like proteins, amino acids, B vitamins, minerals and trace elements. As an autolysed brewers’ yeast, CeFi®pro undergoes a special production process that leads to the availability of valuable components for the animal in an open structure, and therefore is significantly more readily available.

Moving Beyond Break Prevent Downtime of Pet Food Conveyors by Dell Williams, Technical writer on behalf of Cablevey Conveyers, USA

Petfood processors often rely on tubular drag cable conveyors to move sensitive materials and powders; therefore, it is important to properly design, install, and proactively maintain these systems to minimise production downtime and maximise longevity.

THE PUBLISHER

6 | June 2024 - International Petfood

Reports are showing a shift in petfood purchases as the economy seems to have finally caught up and the dollar spending on petfoods is leveling as customers look at value for cost.

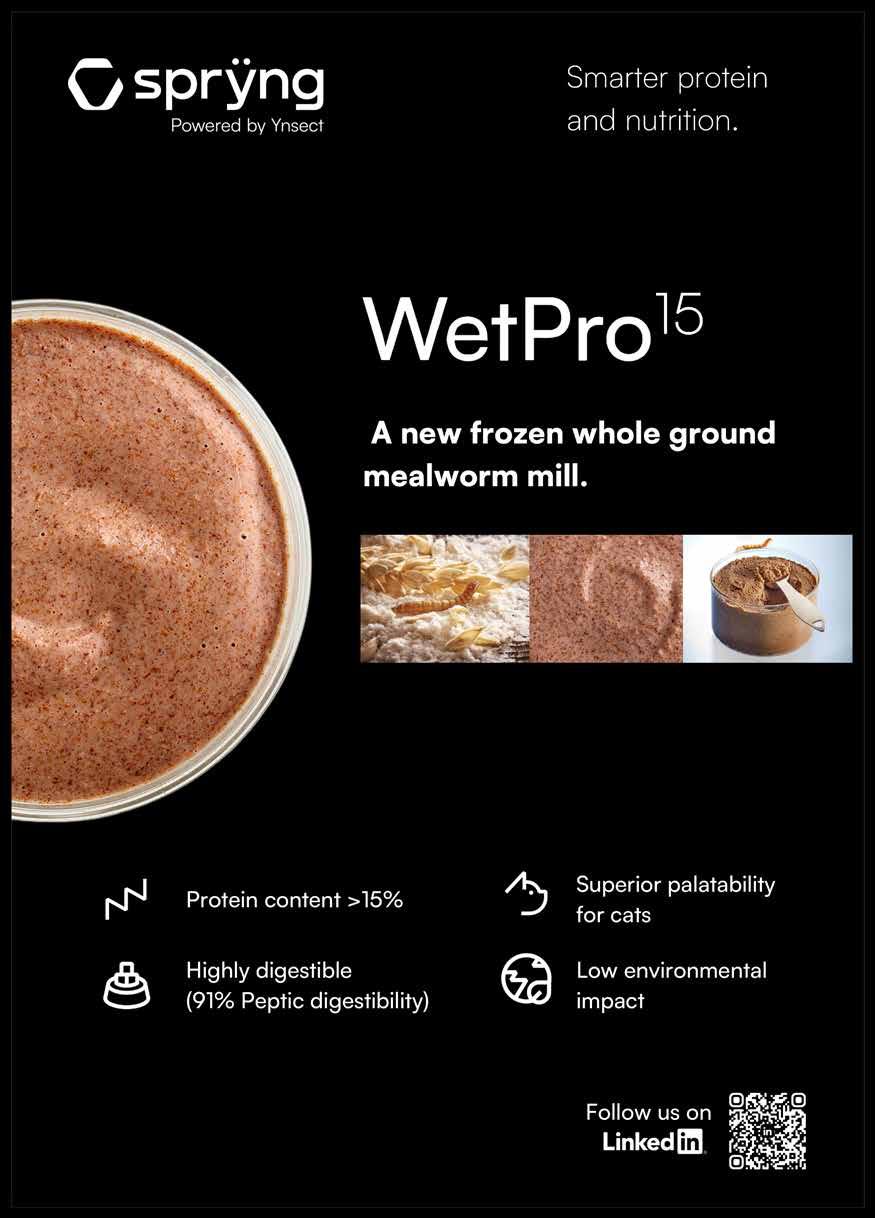

An article in this issue on Entomeal and their insect meal reports good acceptance and results. These two topics might go together but having not looked into costs of insect meal versus the standard type of protein sources this needs to be evaluated. Following the idea of four areas of extrusion, raw materials, system configuration, running conditions and final product specifications it might be interesting to discuss if the system or running conditions with insect meal added will change the final specs of the product.

Joseph P Kearns Editor, International Petfood Magazine

Joseph P Kearns Editor, International Petfood Magazine

seen to have 50 to 60% protein and 20 to 30% lipid dry matter. Looking at this lipid level at a 25% inclusion it would be adding 7.5% fat. Depending on the rest of the total fat level this might become limiting or the need to deal with density adjustments. For reference chicken meal dried to 10% moisture has 65% protein and 12% fat. Regular chicken meat is 70% water, 18% protein and 5% fat. There are many options and at the levels it now appears to be used with insect meals there should be no situations with regards to production.

From the article mentioned above it shows testing at 5, 10, and 20 percent inclusion levels for pets. Acceptability and consumption levels looked good. Ok, have to assume somebody made the test feed without issues. However, I like to play with the numbers to see the effect from a production point of view. For discussions, let’s assume the insect meal is dried to a similar level as poultry meal, fish meal and other proteins of animal origin about 10 percent.

Considerations in extrusion for production besides the nutritional aspects is moisture level, fat or lipid level and starch levels as these can affect the process. What is the limiting factor? It is doubtful that the formula will be short on starch. With fresh meats the first limiting factor in standard style extrusion cookers is the moisture level. There are some exceptions where machines can use higher levels of meats, but for this review let’s consider mainly single and twin screws where mechanical energy is the driving force to cook the food. These machines, when equipped with enough conditioning cylinders and or designs that allow high levels of high moisture ingredients should yield a free-flowing material to the extruder barrel. If not consistent then this becomes a limiting factor. Single screw extruders can handle about 20 percent of 65 percent moisture meat while twin screws can handle about 25 percent. This is equivalent to adding about 10 and 16 percent moisture respectively. If the other ingredients have approx. 10 percent moisture and some is added in the process via water and steam, we are near the moisture limit for these kinds of machines and products from them. The second consideration is lipid or fat levels in the feed before extrusion. For little or no effect in the density the limit is about 15 percent fat total and above this the product has lower expansion or heavier density. At 20 and 25 percent inclusion levels the lipids associated with these kinds of meat at 12 percent lipid in the meat is a 2.4 to three percent lipid addition so generally no negative effects for the extrusion process. This review sets a general base line of what is in the industry for comparison.

Now looking at insect meal what needs to change if anything if insect meal replaces some or all of the normal protein sources. Looking up some details on the internet it appears that black soldier fly meal has general specs of 50% protein, 9% to 15% fat and 10% moisture. Mealworm is

Mentioning possibilities of higher-level inclusions of meats, some systems can now approach nearly 75 to 80% meat inclusion at 65% moisture levels. The success in these is based on handling the moisture and getting the cook needed in petfood production. This requires increases in thermal energy usage in addition to the mechanical energy as well as special handling of these wet nuggets post the extruder die. Logic, at least in my case, it seems that using fresh higher moisture ingredients especially with the ingredients that yield palatability results are the land animal meat inclusions. Using these fresh ingredients in conjunction with the dried meals yield super premium products. These fresh products are not dried so how much energy is saved in the process to dry, rewet, process and redry? Nutrient losses? Costs of raw wet ingredients would be higher no doubt but manageable as seen in the industry.

Now will we see a time where the insect meal uses and availability is such that perhaps a liquified form much like the ground smooth meats used in petfoods will be available? It would be something of interest in my opinion as having seen the ease of operation or production when liquified ingredients are pumped and metered into the process. The modern petfood plant with computer controls, loss in weight dry feed systems and accuracy of pumps and the quality of flow meters make adding high moisture ingredients in place of water quite simple. Meats need to be kept chilled and or frozen, thawed, checked for metals, ground, moisture adjusted and then pumped into the system. Do insect products need the same at higher moistures? Are stabilization products out there? Will this possibly eliminate the need for the expensive meat handling systems? Most likely it will not change but a similar duplicate system for handling insect ingredients might be in order. Not having a chance to discuss insect meal storage in vertical bins and its flow characteristics at this point we need to assume it is OK, but you never know. At the above referenced lipid level of mealworm meal it should be noted most issues in bins are associated with hydroscopic ingredients or ingredients with elevated lipid levels which require “max time in bin management” as well as special discharge devices, live or vibratory.

The industry is in motion and advancing in a number of different ways involving ingredients, machinery designs, novel new processes and advancements in existing systems. All developing to improve the process of petfood production at reasonable cost and for good value to the customers.

THE EDITOR

International Petfood - June 2024 | 7

New report shows pet industry undergoing a shift

The pet industry is undergoing a significant shift, with value becoming a key competitive strategy for businesses. As outlined in Packaged Facts’ latest report, ‘US Pet Market Outlook, 2024-2025’, macroeconomic and industry-specific factors are driving this change, making it essential for businesses to prioritise value for pet parents. David Lummis, report analyst, notes, “The promise of money savings and added value is possibly the oldest promotional manoeuvre, but with the economic trauma of

the pandemic and its aftermaths still rippling through, there may be no better time to focus on value to attract shoppers and engender customer loyalty.”

The National Retail Federation predicts slower consumer spending growth in 2024 due to tighter credit conditions, higher borrowing costs, a cooling labour market and political uncertainty. Although gas prices are down and inflation has been moderating, normalisation isn’t expected until 2025. Additionally, dog population growth, which accounts for two-thirds of pet industry sales, remains flat.

Data from Packaged Facts’ January 2024 Survey of Pet Owners reveal that nearly one third of pet owners have had their ability to buy non-

Layn Natural Ingredients studies shelf-life extension for petfood

Layn Natural Ingredients, a global leader in innovation and manufacturing of natural botanical extract ingredients and solutions, conducted a study to evaluate the efficacy of TruGro AOX+ as a natural preservation solution to enable shelf-life extension for petfood.

Juan Javierre, Senior Nutrition Scientist at Layn Natural Ingredients, stated, “The tests were done following the Oxidative Stability Index, or OSI, method using a Rancimat device. As substrates, we tested oils and fats common in petfood diets, such as fish and chicken oil, assayed at the temperatures most adequate for these substrates. We found a highly protective effect on fat stability, and compounding the data to ambient temperature, TruGro AOX+ demonstrates excellent

Side by Side Pet blends ancient wisdom with AI innovation

Side by Side Pet, a leader in whole-food nutrition, unveiled its latest AI Balance Indicator. Rooted in the time-tested practice of Eastern Food Therapy (EFT), this cutting-edge technology provides pet parents with nutritional guidance tailored to the pet’s needs. In collaboration with experts in veterinary medicine, nutrition, data science and Eastern holistic practices, Side by Side Pet has developed the Balance Indicator. This AI software analyses a dog’s unique constitution and metabolic function by evaluating an image of the tongue. Pet parents simply upload a photo of the pup smiling, playing, or any image that shows its tongue to the Balance Indicator. The patented AI software analyses the tongue’s hue, tint, tone and shade to determine whether the dog is balanced (neutral) or imbalanced

essentials negatively impacted by the economic environment. As a result, three-fourths are actively seeking lower prices, special offers and sales.

While pet owners are costconscious, their priority remains the health of their pets. Product quality tops the lot of important factors in pet care spending choices, followed by good value for prices, convenience in shopping/buying and low-priced products.

In response to these trends, pet industry marketers, manufacturers, retailers and service providers have an opportunity to offer lowerpriced products, facilitate do-ityourself pet care, provide adorable pet insurance and wellness plans and offer flexible payment options.

potential to extend the shelf life of petfood products up to a full year.”

Polyphenols play an important role as technological antioxidants. Trugro AOX+ combines several polyphenol-rich extracts in potent concentrations to help preserve petfoods naturally. Among its active ingredients, TruGro AOX+ contains rosemary extract, which is rich in diterpenes, and tea extract which contains high levels of catechins. In addition to these primary antioxidants, the solution also includes pomegranate extract to provide metal ion chelation. These potent antioxidants help to prevent iron and copper from initiating the oxidative degradation of fats and vitamins. The combination and concentration of these plant-based compounds enable TruGro AOX+ to provide long-term protection against the oxidative rancidity of petfoods, thereby naturally extending shelf life.

(warm or cool). Based on its assessment, the Balance Indicator provides personalised diet recommendations to counterbalance or maintain a healthy equilibrium. Combining the wisdom of EFT with the power of AI, Side by Side Pet empowers pet parents to confidently promote wellness with nutritious whole-food diets crafted to fit its pet’s unique physiology.

“We’re thrilled to introduce this groundbreaking solution to pet parents worldwide,” said Carol Bramson, CEO at Side by Side Pet. “Our AI-powered Balance Indicator combines the best of Eastern and Western approaches to nutrition, providing dogs with all-natural, whole-food diet recommendations, synthetic-free diets that are delicious and tailored to their needs. My mission is to share the immeasurable benefits of whole-food nutrition with pets and their people to help our four-legged family members live longer, happier and healthier lives together with us, side by side.”

8 | June 2024 - International Petfood N

Our wide range of value-added services and understanding of production and market challenges worldwide, allows us to find the right technology and the most cost-effective solutions for your business in Livestock, Aquaculture/ Aquafeed and Pet industries

E

Offers customized development, formulation and manufacturing services for efficient and effective Vitamin and Mineral Premixes, Additives, Farmac, Organic Acids, Pigments, Organic Bypass Fats, etc. with the highest quality standards and according to the needs of its customers in animal nutrition, with exclusive Technical, Professional and Personalized Consulting worldwide

International Petfood - June 2024 | 9 N

S E has developed and manufactures its own line of innovative and specialized equipment and systems, with exclusive and worldwide technical services for different processing situations in several capacities, from unique components to full line and complete solutions ENGINEERED SYSTEMS & EQUIPMENT, INC 1564 Hwy.166 E. Industrial Park. P.O. Box 99, Caney, Kansas 67333 USA - Phone: + 1 (620) 306-4100 – Fax: +1 (620) 840-2087 Email info@eseintec.com - www.eseintec.com Carretera Córdoba a Veracruz Km 342, Zona Industrial, C.P. 94690 Cordoba, Veracruz, México Tel: (+52) 271 751 7350; (+52) 271 751 7396 www.intecmx.com - contacto@intecmx.com INTEC – INTERNATIONAL FEED & FOODS TECHOLOGIES S.A. DE C.V. Supported and Guaranteed with its own very complete and equiped Laboratory with latest Technologies

WE CAN HELP

YOUR

DISCOVER HOW

WITH

NEXT PROJECT

The Nutriment Company acquires Totally Natural Pet Products

The Nutriment Company, a leading provider of premium natural petfood, announced that they have acquired ‘Totally Natural Pet Products’, a renowned Scottish raw dog food manufacturer. The acquisition expands the Nutriment Company’s portfolio of premium natural petfood brands and further strengthens its position in the Central European market.

Totally Natural Pet Products (TNPP) specialises in the production of raw dog food and natural dog treats, operating from a production facility close to Glasgow, Scotland. With over 30 years of experience, TNPP prides itself on an ethical approach to sourcing high-quality ingredients and using human-grade cuts of meat. Its products are predominantly sold to pet specialists across the United Kingdom in a freeflow format, enabling customers to swiftly defrost and conveniently portion them to meet their dog’s nutritional requirements. TNPP’s range of products uses only 100 percent natural ingredients and is free from artificial additives, grains and fillers, offering a wide range of flavours and recipes to meet the nutritional requirements and preferences of various dog breeds.

Campbell Kyle and William Stewart, Co-CEOs of Totally Natural pet products, expressed their excitement about joining The Nutriment Company: “We look forward to working together and expanding opportunities for our

team and customers alike.”

Anders Kristiansen, CEO of The Nutriment Company, commented on the acquisition: “Totally Natural Pet Products has rapidly expanded in the UK over the last few years, and their unique free-flow product fills a gap in our portfolio. We are thrilled to welcome them to our group and are certain that together we will be even more successful.”

The acquisition of TNPP by The Nutriment Company marks an important step in the strategy of both companies to further consolidate and expand their position in the growing market for high-quality, natural petfood.

Simple pet food design

Efficient raw material sourcing Integrated formulation with quality control BESTMIX® Feed Formulation, Quality Control, Ration Calculation and ERP solution.

The most advanced software solutions for pet food production:

Scan to learn more: www.bestmix.com

10 | June 2024 - International Petfood N

Bulk Sampling? You could buy a sampler or, Invest in a Samplex… The Choice is simple... The Solution is International Petfood - June 2024 | 11 N 4B DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS Engineering Solutions Since 1888 Improving the Safety & Efficiency of Your Plant www.go4b.com A Worldwide Manufacturer www.go4b.com ELEVATOR COMPONENTS HAZARD MONITORS & SENSORS CONVEYOR CHAIN #23399 Global Ad Styles.indd 8 07/06/2023 10:07:25

STRIKING A BALANCE

Does health and sustainability go hand in hand in petfood?

by George B. Josef, Global Head Marketing & Nutritional Lipids for petfood, dsm-firmenich, USA

Pet parents have always wanted the best for their furry friends but what is considered ‘best’ is undergoing a radical shift. Nearly 70 percent of global pet owners say they are “worried about climate change” and are “trying to have a positive impact on the environment through my everyday actions”. In fact, pet owners are more concerned about sustainability than nonpet owners.1 This is partly what led to many consumers seeking out petfood products that were made using by-products from meat processing for human consumption. But this practice is declining in popularity as pet owners want more premium and human-grade options for their pets.

At the same time, consumers are increasingly aware that good nutrition can help people live longer and healthier lives and they’re applying this same ethos to cats and dogs. It’s no surprise then that trending human nutrition topics like gut health and immunity are influencing pet nutrition. In one study, three out of five pet owners said they looked for pet food featuring vitamins and nutrients to support immune health at the peak of the Covid-19 pandemic.

So how can modern petfood companies balance the needs of discerning pet parents? Read on to discover the latest ingredients that give pets a taste they love and the nutrition they need all while reducing the environmental impact and protecting petfood producers from volatile supply chains.

What to do when there aren’t plenty more fish in the sea?

Omega-3s – particularly EPA (eicosapentaenoic acid) and DHA (docosahexaenoic acid) – are critical to cat and dog health. EPA and DHA support a wealth of pet parent priorities including healthy joints and brain development in puppies and kittens and enhanced immunity, organ health, and cognition into a pet’s senior years. But omega-3s are heavily associated with overfished oceans and unsustainable practices – 930 billion fish are removed from the oceans each year, just to supply the pet food industry with fish oil and meal. Fluctuations in the availability and price of fish oils also expose pet food manufacturers to supply chain disruption and rapidly increasing costs. But there is a better way to give cats and dogs the essential nutrients they need – by going straight to the source with algal-based omega-3s.

For example, with DHAgold™ petfood companies can easily add the nutritional benefits of DHA to any food, treat or supplement. This easy-to-use powder is made from fermented algae that is carefully dried to produce a robust ingredient with a high DHA content and superior sensory properties. DHAgold™ also has a scientifically proven claim to support brain health in dogs. In one study a group of 8- to 11-year-old dogs were fed food containing DHAgold™ for 6 months and displayed significantly improved memory and visual performance.

For petfood brands who want to offer both EPA and DHA then Veramaris® Pets may be the answer. Containing 60 percent EPA and DHA, this is the world’s most potent and complete omega-3 solution suitable for cats and dogs at all life stages. It offers more

12 | June 2024 - International Petfood F

COMPLETE PLANT

UNDERSTANDING YOU. STANDING BY YOU. NEVER STANDING STILL. We provide complete plant solutions for dry pet food production to your exact specifications and with industry-leading cost efficiency by leveraging our extensive processing expertise and experience. By harnessing the power of automation and digitalization, we ensure continuous innovation to keep you at the forefront. AND with the industry’s most trusted services, we are always there for you.

ANDRITZ FEED & BIOFUEL andritz.com/feed-and-biofuel-en

For more information, visit our website.

SOLUTIONS FROM START TO FINISH, WE ENSURE YOUR PROJECTS DEVELOP SEAMLESSLY

International Petfood - June 2024 | 13 F

than double the potency of equivalent fish-oil alternatives as well as a better taste. These two ingredients highlight just how efficacious algal-based omega-3 ingredients can be in petfood applications. Both are inherently safe with assured freedom from ocean-borne contaminants, offering true consistency, reliability, and scalability with an infinite source of quality omega-3s that does not impact global fish stocks.

Maximizing taste – minimizing impact

Pet parents want their furry friends to enjoy their food and treats, just like any other member of the family. But eco-conscious pet owners are increasingly aware of the high carbon footprint associated with meat- and dairy-based petfood ingredients. For petfood manufacturers as well, animal-based ingredients are associated with volatile costs and often unreliable supply chains –hitting profitability in a highly competitive market.

Fortunately, ingredient science is working to tackle all of these challenges. New solutions can optimize a smaller amount of animal-derived raw materials to create delicious flavors that pets love while also providing a lower environmental impact and less exposure to fluctuating supply and costs. These truly innovative meat-optimizing flavor ingredients therefore help petfood

producers use valuable resources more efficiently, appeal to sustainably minded pet parents and support better pet nutrition through consumption.

One example of this in action is dsm-firmenich’s cheddar cheese flavor concentrate. This spray dried powder is made with genuine Wisconsin cheddar and whey and can be supplemented into dry dog food. The ingredient is created using enzyme modification, which intensifies the natural cheese flavor and aroma that dogs love, transforming a standard dry food application into an experience worthy of wagging tails and happy smiles.

On-trend fortification

In 2024, it’s hard to talk to anyone not actively trying to improve their gut health or immunity – and pet owners have the same priorities for their cats and dogs. In one recent study, 63 percent of pet owners say they want to see “helps aid digestive health” and 51 percent want to see “helps aid immune health” on pet products.

Ingredients like dsm-firmenich’s Leva-Mos® can provide a dual function here by supporting gut and immune health in one easy to use spray dried powder. Rich in mannan oligosaccharides (MOS) and beta-glucans, this upcycled ingredient supports gastrointestinal health by stabilizing the gut microflora, maintaining gut health during microbial enteric challenges, binding to food pathogens in the GI tract, and supporting intestinal barrier function. Meanwhile, the branched glucan structures also support a balanced immune function. And on-trend fortification doesn’t have to come with a hefty price tag. LevaMos® is produced through dedicated baker’s yeast fermentation under strict hygienic conditions and offers pet nutrition brands a cost-effective way to tap into trending health claims that drive brand value.

Finding the balance

Whether it's sustainable and infinite sources of omega-3s, meatoptimizing flavor ingredients to lower emissions, human grade vitamin premixes with custom CO2 calculations, or valorizing waste-streams while supporting pets’ microbiome – the right pet nutrition partner can help you find the balance in taste, health, cost and sustainability.

F 14 | June 2024 - International Petfood

With over 150 years of combined experience, we help you find your individual packaging solution. Over the years, we have delivered highly versatile and innovative machines operating at high production rates for the international pet food industry. In addition, we help you meet global environmental challenges without compromising on performance. If

The Packaging Group GmbH · Germany ·

www.tpg-packaging.com

pack

Let’s create your perfect pet product packaging solution!

you can think it, we can

it!

Feline Food Dilemma

Balancing Nutrition and Sustainability in Pet Diets

by Andrew Tindall, Patent Attorney, Potter Clarkson, UK

Ihad a rather rude awakening recently at the vet’s office. When taking my cat for her annual jabs, I was told that we needed to talk about her ‘condition.’

This, of course, is the polite way of saying that my cat was, well, fat. Whilst embarrassing, this is not uncommon, as half of dogs and over a third of cats are reportedly overweight or obese. Nevertheless, I walked away with a sense of shame, and a prescription for a new, high-protein diet for the family moggy.

Sticking to this recommendation comes with its own challenges, however. Like many households, mine tries to limit the amount of meat we consume for environmental reasons, and I started thinking about how the changes in my cat’s diet would affect our carbon footprint. I’m not alone in this problem. With over 49 percent of adults in the UK owning a pet, the environmental impact of all those sachets of meaty chunks in gravy is staggering. Indeed, 22 percent of all meat produced is consumed by pets, and contrary to public belief relatively little of this is made from upcycling in-demand abattoir waste.

As high protein diets are required for the health of our pets, there remains an unmet need to provide environmentally friendly feeds to satisfy the protein demand, simultaneously improving the health of both companion animals and the planet.

One solution that has already emerged is the use of insect-based protein and the black soldier fly larvae (BSFL). Their capacity to convert organic waste into high protein feed is impressive and has been harnessed by reptile and poultry keepers for decades. When dried, BSFL contain up to 50 percent high-quality protein,

and uses 80 percent less land than beef per kilo of protein. Insect protein remains an attractive option for pet feed, and I was surprised to see multiple brands harnessing this technology on the shelves of my local shop, with both Yora and Lovebug appearing to fit the profile recommended by my vet.

One challenge for insect proteins is the source of waste. Whilst BSFL will happily eat almost any organic substrate, including slaughterhouse waste, manure, and kitchen scraps, these can spread disease. Current regulations restrict insect feedstocks to pre-consumer, non-meat, waste. Whilst this is still a significant waste stream, it limits scalability, as profitability depends on access to cheap and plentiful substrate. Additionally, at present, the law effectively means that flies must eat food that could otherwise feed hungry people (or, indeed, their pets). Moreover, even a small risk of contamination might hinder acceptance in a sector where

16 | June 2024 - International Petfood F

Are you ready for substantial reduction in batch time ? alfraequipment.com/en/Intro-ADA

Group specializes in dosing & weighing systems and smart automation software for the nutrition and solids industry. International Petfood - June 2024 | 17 F

KSE

public perceptions of food safety are already poor.

Even if these challenges can be overcome, the question remains - will the public at large feel comfortable with their pets eating bugs? Given my cat’s fondness for hunting spiders, moths, and beetles, I suspect she will be unbothered either way. However, many pet owners won’t share her enthusiasm. Anecdotally, many owners feel uncomfortable feeding their pets foods they would not eat themselves, but additional processing to disguise the provenance of insect feed is in tension with recent moves away from ‘ultra processed foods’.

Another emerging technology which might hold the key to healthier and more sustainable pet food is mycoprotein. Once again, this is not so much new as a repurposing, as mycoprotein will be familiar (especially to those of us in the UK) as the concept behind vegetarian staples like Quorn. By growing microscopic fungi on feedstocks such as maize starch, it is possible to upcycle cheap substrates into high nutritional value proteins.

Mycoproteins are beginning to find use in pet foods. Pawsible Foods, a startup in Singapore, has launched their mycoprotein dog food in the city-state as well as India. Similarly, Finnish biotech eniferBio have developed their own mycoprotein powder, and attracted significant buzz with their successful EU€11 million series A funding round in April 2023. Their protein PEKILO is now approved in the EU for pet food and has a projected market launch in 2026.

Mycoproteins have an advantage in that they have a long history in the food industry, and regulatory systems for ensuring their safety are already established in most jurisdictions. Additionally, this is a business model that investors understand, and will therefore know whether their investment is likely to be safe, and what IP and business strategies are needed to protect their market exclusivity. Moreover, there is significant untapped innovation potential, as the number of investigated fungal species remains small. As this work expands, it will likely become increasingly easy to source desirable and improved mycoproteins, for countless applications.

Stepping beyond the current supermarket shelves, the technologies shaping the future of human food might also one day influence what our pets eat.

Cultivated meat – the process of growing animal cells in culture, without the need for slaughter – has been steadily growing over the last decade. Once the preserve of science fiction, the technology is now firmly rooted in reality, with regulatory approval being granted in the US and limited public tastings taking place throughout 2023. As the end result is identical to conventional meat, it neatly bypasses fears of UPFs whilst, by avoiding land-use and abattoir wastage, may even be greener too.

In the UK, cultivated meat could make its way onto our pets’ plates before ours. The first cultivated meat to hit the shelves in

the UK may well be for cats, with UK company Meatly poised to launch their chicken product following investment by Pets At Home. Hot on their heels, Czech start up Bene Meat is poised to release their first cultivated product in 2024, this time for dogs. Meanwhile, if my cat fancies fish rather than fowl, Singapore’s Umami Bioworks have developed ‘Marina Cat’, a treat that incorporates cultivated ocean snapper.

This degree of interest may be because, technologically and economically speaking, pet food could be a more attractive initial product than meat for human consumption. As the buyers are not consumers, marketing based on environmental benefits may be more effective than it would with meat for human consumption, where the significant challenge of perfectly replicating taste and texture is more important. In addition to less fussy end-consumers, the regulatory framework around pet food is far less complex.

Once mature, cultivated meat has the potential to go further than nature ever could. Perhaps one day, through canny cell selection or gene editing, it will be possible to adjust the composition of food for different animals – for instance, to produce medicinal, probiotic, or more digestible foods without the need for downstream fortification of processing.

However, the technology remains some distance away, and the large number of innovators in both the animal and human markets means competition is likely to be stiff. Indeed, with multiple competing proprietary platforms covered by strong patent protection, cultivated meat may be the site of costly legal battles, and the risk of litigation may have a chilling effect unless a collaborative approach is developed. That said, it may be possible for innovators to forge these relationships and avoid stepping on any toes by limiting themselves to the domain of pet food.

Advances in pet food have the potential to enable real customer choice. For a long time, consumer preference in this sector was driven primarily by the interplay between price and perceived quality. New technologies could enable owners to make decisions about sustainability, enhanced nutrition, or ethical considerations like veganism. Whilst there remains some tension between new food technology and current trends towards ‘clean’ or ‘natural’ pet food, it remains to be seen whether an appetite for sustainability can be converted into market share.

Food is an emotive, and opinionated subject, where public acceptance is as important as it is fragile. Whilst pets themselves have little choice in the matter, their owners are nevertheless likely to be discerning customers and will require convincing before new protein sources can break through into the mainstream.

Fortunately, my cat isn’t that fussy. No matter what the future brings, I’m sure she’ll eat anything – indeed, that’s partly how we ended up in this situation in the first place.

18 | June 2024 - International Petfood F

World Leaders in Microwave Moisture Measurement Oil Animal Feed Coffee Rice Grain Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Milling and Grain-Advert Mar 2023 215x140mm.indd 1 28/02/2023 13:55 YOUR PARTNER FOR BAGGING & PALLETIZING FULLY AUTOMATIC FORM-FILL-SEAL MACHINE bag filling weight: 10-50 kg sturdy and compact design for woven PP, PE and paper bags 2800 bags per hour up to www.statec-binder.com International Petfood - June 2024 | 19 F

SOURCE SUSTAINABLE PROTEIN

For dogs and cats nutrition

by Presanthi Sithapthi, Senior Sales Manager, Veolia, South East Asia

With more than 471 million dogs kept as pets worldwide, dogs remain the most popular pet choice followed by cats with over 373 million in the world (according to the World Animal Foundation, 2024). Over the years there has been a major shift from pet ownership to pet parenting and this trend to pet humanisation has led to increased demand for high nutritional quality and dietary benefits in pet food. Pet parents are looking for natural, organic and sustainable ingredients to ensure that their pets receive a healthy and balanced diet.

This has created an opportunity for the pet food industry to incorporate alternative protein sources such as insect-based ingredients, a novel source of protein that provides functional benefits to pet’s gut health and skin.

Several studies have shown that insect meal is an acceptable alternative protein source in pet diets. Pet food companies always want the reassurance that the ingredient itself is validated by scientific research, such as feeding trials, when it comes to palatability and digestibility.

This is why Veolia, in collaboration with Chulalongkorn University in Bangkok, Thailand has recently conducted a study to assess the acceptance, general performance (feed intake and body weight maintenance) and digestibility of EntomealTM (black soldier fly larvae meal) in twenty beagle dogs and fifteen mongrel cats.

The dogs and cats were given two dry food formulations containing 10 percent and 20 percent EntomealTM, and five percent and 10 percent EntomealTM, respectively. These diets were compared to a standard commercial control diet containing poultry meat as the primary source of protein.

EntomealTM is a defatted high-quality protein made from black soldier fly larvae (Hermetia illucens) grown on traceable side streams of the food and beverage industry.

Veolia Bioconversion Malaysia Sdn Bhd, one of the largest producers of black soldier fly larvae in the Asia Pacific region, has its facility located in the north of Kuala Lumpur, Malaysia with a production capacity of 3000 tons of insect-based products per year. This industrialscale facility, which is ISO 22 000, GMP+ certified, ensures safe and consistent quality with reliable supply of EntomealTM.

In both canine and feline trials, all diets were well accepted, and body weights and feed consumption were maintained throughout the trial duration.

20 | June 2024 - International Petfood F

Acceptance and Preference

Results for the one-bowl test on dogs showed a good acceptance of dry food containing an inclusion level 10 percent EntomealTM and 20 percent EntomealTM

Although cats are known for adapting slowly and being picky to any new diet, they consumed all the dry food presented at both inclusion levels of 5 percent EntomealTM and 10 percent EntomealTM

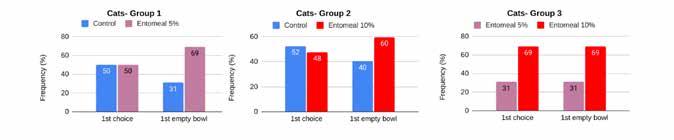

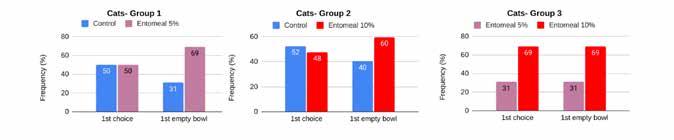

In the two-bowl testing, ‘first choice’ and ‘first empty bowl’ were observed among the three groups of paired diets. This experiment consists of placing simultaneously two bowls before the pet and we monitor which of the two foods have been approached first which is defined as the first choice. Then the bowls are left with pet until one of the bowls has been completely consumed which is referred as first empty bowl.

Results showed that dogs had no preference between the control diet and 10 percent or 20 percent EntomealTM for either ‘first choice’ or ‘first empty bowl.’

However, dogs preferred dry food containing 10 percent Entomeal over 20 percent EntomealTM (refer to figure 1).

Cats also had no preference between control diet and 5 percent or 10 percent EntomealTM, and emptying the bowl was much higher for both EntomealTM diets compared to the control diet (refer to figure 2). When comparing EntomealTM diets, cats preferred 10 percent EntomealTM inclusion versus 5 percent EntomealTM

Digestibility

In the digestibility study, eighteen beagle dogs and fifteen mongrel cats underwent a seven-day washout period before being fed the EntomealTM diets for five days. Faecal samples were collected from the dogs and cats for analysis. The Apparent Total Tract Digestibility coefficients (ATTDC) were obtained using two methods, the total faeces collection (TFC) and chromium oxide (Cr2O3) marker, which was added at a final concentration of 0.25 percent of the diet dry matter basis.

The results showed that ATTDC of crude protein is comparable to the commercial control diet containing poultry meat, which were around 94 percent for dogs and 88 percent for cats.

Conclusion

Overall, the results of this study indicate that the palatability and digestibility of EntomealTM are comparable or better than a standard commercial pet foods for both dogs and cats.

At an inclusion level of 20 percent in dogs and 10 percent for cats, EntomealTM has an equivalent palatability to a standard commercial pet food. As a high-quality protein, EntomealTM can be easily incorporated into dry food formulations for puppies, adults and seniors to achieve optimal nutritional profiles, in addition to its sustainable benefits.

Veolia is also conducting further research with other partners to continuously improve the knowledge and positive impact of EntomealTM in pet nutrition.

Figure.2

Figure.2

22 | June 2024 - International Petfood

Figure.1

All-Natural Revolution

Seaweed-Based Nutrition in Petfood

by Jyothsna Nelloolichalil and Costa Skotidas, International Petfood, UK

In the evolving landscape of animal nutrition, the use of innovative and sustainable solutions has never been more critical. Ocean Harvest Technology (OHT), a pioneering feed company with its headquarters in London, stands at the forefront of this transformation, leveraging the potent properties of seaweed to enhance animal health and productivity.

OHT was established with a clear mission to research and commercialise the diverse applications of seaweeds. Initially focused on various sectors, the company has now honed in on animal and fish nutrition. The driving force behind OHT’s products is extensive research demonstrating that polysaccharides and other bioactive compounds in different types of seaweed act as prebiotics in animals.

Their petfood product, OceanFeed Pet, distinguishes itself by being an all-natural product with no added preservatives, carriers, or emulsifiers. This commitment to purity ensures that pets receive a diet free from potentially harmful additives, which is increasingly important to pet owners who are concerned about the long-term health effects of synthetic ingredients.

One of the standout features of OceanFeed Pet is its impressive shelf life. Despite the absence of preservatives, the product boasts a shelf life of up to three years. This long shelf life is a testament to the quality and stability of the ingredients used, providing convenience and peace of mind to pet owners.

Consumer-Driven Business

Pet food is a consumer-driven industry, with pet owners continuously seeking products that deliver tangible health benefits for their animals. The feedback from pet owners using OceanFeed Pet has been overwhelmingly positive, highlighting significant improvements in their pets’ health and well-being.

“Nearly 90 percent of customers report that their pets experience improved digestive health after switching to food with OceanFeed Pet. This improvement manifests as fewer incidents of diarrhoea and other digestive issues, and also does influence skin condition in a positive way”, says Mark Williams, CEO of OHT.

A healthy digestive system is crucial for the overall wellbeing of pets, as it affects nutrient absorption and energy levels. A healthy coat and skin are indicators of overall health and can reduce the frequency of veterinary visits related to skin problems. The natural ingredients in Ocean Pet Food contribute to these benefits, making pets look and feel healthier.

Half of the users report increased energy and stamina in their pets. This is especially significant in the context of rising global temperatures, where maintaining energy levels can be challenging. Active pets are happier and more engaged, which enhances the bond between pets and their owners. A notable 50 percent of users have observed an improvement in their pets’ breath. Bad breath is a common issue, particularly in dogs, and it can be indicative of underlying health problems.

24 | June 2024 - International Petfood F

Competitive Advantage

Recently, OHT gained a new patent for its OceanFeed brand of products. This patent covers the unique blended seaweed ingredient used in OceanFeed Pet, which has been shown to have a prebiotic effect on the microbiome. The patent details the specific bacterial changes and the composition of these changes in the gut, explaining how they lead to improved health outcomes for pets.

The prebiotic effect of the seaweed ingredient supports a healthy microbiome, which is essential for optimal digestive health. A balanced gut microbiome enhances nutrient absorption, supports immune function, and contributes to overall health and vitality.

Sustainable Sourcing and Global Reach

Sustainability is at the core of OHT’s operations. The seaweeds used in their products are sourced globally and are predominantly invasive wild-blooming varieties. These seaweeds, which thrive on excess nutrients from agricultural and human activities, can be ecologically damaging if left unchecked. By harvesting these invasive species, OHT not only mitigates environmental damage but also creates a sustainable supply of raw materials.

“It protects pretty much the whole scope of the business that we have. It represents to me, because its such a wide ranging patent, as close as you can get to an external verification of first mover advantage”, says Mark.

The company’s initial manufacturing facility in Vietnam has expanded its sourcing to other parts of Southeast Asia, including Indonesia and the Philippines, as well as Eastern Africa. This global diversification of the supply chain ensures a steady and sustainable supply of seaweed, enabling OHT to meet growing demand while maintaining environmental integrity.

OceanFeed Pet, a flagship product of OHT, offers a unique and all-natural option for pet owners seeking the best for their animals. With its impressive shelf life, absence of harmful additives, and proven health benefits, it stands out in the competitive petfood market. As more pet owners recognise the value of high-quality, natural pet food, OceanFeed Pet is poised to become a staple in pet care routines worldwide.

International Petfood - June 2024 | 25 F

Industry Profile

Famsun - an integrated solution provider

Famsun Group Co., Ltd., headquartered in Yangzhou, China, is a global technology partner and the integrated solution provider of plant, equipment and services in feed manufacturing, grain milling, grain handling and storage, oilseed processing, food processing, steel structure construction and industrial automation. Famsun has over 2,800 employees, including 900 technicians and engineers. Backed by its strong R&D capabilities, Famsun has developed more than 120 series (700 models) of quality feed and grain processing machines and is capable of delivering a wide range of turnkey projects from farm to table and in associated industries.

Famsun operates five production sites as well as over 50 agencies, sales & service stations, and spare parts warehouses around the world. Famsun has successfully completed over 8600 referenced projects in more than 140 countries. Famsun’s vision is to provide optimal technology solution and make life better for all. Famsun value innovation, hard work, dedication, integrity, quick response and team work. As world’s demand for quality and safe foods grows, food supply chains have become more connected. Most of their customers diversify their businesses and extend to upstream and downstream links in order to boost productivity, efficiency and sustainability. To meet with customer’s expectations of becoming a single-source supplier, which shares knowledge, experience and resource, provides convenient, flexible and consistent technical supports to customers and help them grow businesses, Famsun develop businesses along the value chains of their customers

with four segments: 1) Feed Tech; 2) Oil/Fat Tech; 3) Grain Tech; and 4) Food Tech.

Cutting edge technologies to manufacture excellent products. By cooperating with leading manufacturing tool companies, Famsun introduces such advanced manufacturing technologies as CNC machining centers, welding robots, automatic painting lines, and semi-automatic assembly lines in its workshops to produce extra precision and high quality for every piece of Famsun product from material processing to machining, painting and assembly. Famsun will speed up production flexibility and increase its local and regional production capabilities by launching an investment plan with several Industry 4.0 manufacturing plants built in some strategic markets of the world.

The success of Famsun as a leading solution provider in agri-food industry resides in its great research and development efforts. To maintain its innovation edge for a changing market demand, Famsun invests an average of more than five percent of annual revenue in basic research and applied development every year. With a stand of R&D Institutes in Asia, Europe and America, Famsun sophisticated specialists work around the clock in the development of existing products and solutions plus exploiting new terrain and unlock new business fields. Additionally, they cooperate with outstanding partners, inventive customers, renowned universities and institutes to constantly bring know-how together on technologies and transfer them to leading production systems in their customers’ facilities.

26 | June 2024 - International Petfood IP

Industry Training

Aquafeed & Petfood Extrusion Technology, South America (Chile)

This short course is presented by Dennis Forte & Associates in conjunction with The Faculty of Natural Resources, Catholic University of Temuco, Chile, and is sponsored by Clextral.

This three-day course covers the principles of extrusion, the design of extrusion processes for aquatic feeds, as well as how the formulation interacts with the extrusion process. Principles learned will be demonstrated through an exercise run on a pilot extruder.

The program provides a good background in general extrusion technology but is specifically directed at aquafeed extrusion. The course is relevant to both single and twin-screw extrusion technology and will be help form 21 – 23 October 2024 at UC Temuco

Continuing Education Centre Avenue Rudecindo Ortega, Temuco, Chile.

The course will cover topics from the basics of extruders and their configuration, through what is happening chemically and physically inside the extruder barrel, to an understanding of extruder dies and extruder instability.

Topics covered include:

Principles of extruder configurations (single and twin screw)

• Role of rheology in extrusion

• Die types and effects, die design

• Extrusion chemistry – Recipe design

• Product density control

• Preconditioning for Extrusion

• Causes and effects of extruder instability

• Screw, barrel, and die-plate wear

• Extrusion troubleshooting

Examples in product formulation and the design of extrusion processes will be included to demonstrate application of the theory. Principles learned will be applied during the practical demonstration on day two. Important aspects of peripheral systems (eg raw materials pre-processing, preconditioning) are also covered.

TRAINING

28 | June 2024 - International Petfood BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY

Troubleshooting

Let’s take a different approach this month in trouble shooting. First off one of the situations in plants is to get the product right and in spec. Yes, in most cases this is corrected at the extruder. Density is a topic as a critical spec and in review open area in the die is important. Hard to exactly predict but here we go with some basics.

Dog food 250 mm2 per ton per hour yielding an approx. expansion rate of 1.5 percent. Cat food starts in the 220 mm2 per ton per hour range with an expansion rate of 1.4 percent generally. If a higher expansion rate is needed the 150 to 250 mm2 or less open area is used. Medium expansion would have a bit more open area as in 300 to 400 mm2. Slight expansion has you up in the 450 to 550 mm2 open area.

When running, the density at the extruder can be adjusted generally with adjustments to the conditions. Steam injection into the extruder barrel, more added more expansion, less added lower expansion. Secondly, more or less water and/or steam in the conditioner. The head temperature can affect density, lower the head temperature increase density. These are a few options in addition to extruder speed control and/or a die flow restriction device are used. Higher extruder speed higher expansion due to more energy input, Flow restriction when decreased will hold or increase barrel fill inserting more energy into the material. These two options show the quickest results in the product post die.

Let’s look at some situations. Fat level in the formula increased by let’s say three to five percent to a total in the 10 to 12 percent range and the density increased by about 30 grams per litre over spec. How to lower the density? First adjust screw speed and flow control device, most likely will work but if not, then decreased water (less water more friction increased cook and/or expansion), possible die open area adjustment (less open area more restriction more pressure more cook expansion), but most likely if can’t be done the screw set up is changed to achieve more energy or frictional inputs.

Product has light and dark area and the shape is not so good with wedging or angle cut ends of product. Out of spec and needs correction. For the colour situation adding some steam or water can increase slippage enough in the barrel to get the needed mixing to avoid this. If not then mixing elements greatly assist in this effect such as a cut flight screw slightly forward of half the distance to the die on the barrel. Mixing lobs are also a possibility, usually a set replaces a screw and can be set according to the cook needed. Wedging can be decreased by increasing water and/or steam, cooling the extruder barrel, readjust the blade setup to get a faster speed for a better cut. Blades could be too wide or cover the hole to long when rotating.

Sticking or clumping at the die and the blades are good and system is stable. Need to eliminate the clumping. Adjust moisture or water input slightly lower with a possible increase in steam injection. This would increase thermal energy input. Die hole location can do this if they get too close together and if the knife speed is lowered to get desired length the speed might be too slow scooping the pellets into each other and sticking. So hole arrangement and umber of blades at the right speed greatly assists.

These kind of situations and others can be solved with adjustments either mechanically or in operations conditions. Keep in mind every change to a formula you have specific running conditions for can cause something to be adjusted to keep the same specifications. Save the records and what you did for future reference, you are generating the trends to solve your specific situations as well as learn what to expect and be prepared to do as required.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The extruder barrel - Part 1

Forming extruders are used for some select products – thus this part of the discussion centres on single and twin designs.

6. Cook in the extruder barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - June 2024 | 29

Unique synergy!

Innovations this month

June 2024

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk

PEGASUS® 5-IN-1 MIXER by Dinnissen

The Pegasus® 5-in-1 Mixer is a true multiprocessing machine. It allows you to mix, vacuum coat, dry, germinate and acidify your product. The mixer produces flavored products with a high hygiene requirement and a fresh-sour taste sensation, such as tea, cereals, (crispy) sweets, and snacks. In sectors such as the food industry, there is an increasing need for multiprocessing machines. Production must become ever faster and more efficient, to produce the best possible product using the least number of materials and resources possible.

By combining several process steps in one machine, the Pegasus® 5-in-1 mixer saves on both cost and energy. The dual axis mixing mechanism airily tosses powders, pellets and granules during mixing. Then the finely atomized liquid particles mix homogeneously with the dry raw materials. The 5-in-1 mixer can also dry, germinate and acidify the product. No transport is needed between the different process steps, saving time and manpower.

www.dinnissen.com

PRODUCTION

Download your online version We invite you to use the code below for a free edition of our magazine either mailed to you or via our App Use coupon code: ATLANTA24

Brewers’

|

|

|

|

Available

Visit our website: leibergmbh.de

Leiber YeaFi® –

yeast bound to functional f ibres!

dietetic and prebiotic active ingredients

supports digestion

promotes skin and coat quality

technological advantages

with different fibre carriers like spent grain, DDGS or apple pomace.

Leiber GmbH | Franz-Leiber-Straße 1 | 49565 Bramsche Germany | info@leibergmbh.de 140823_International Petfood_90 mm x 270 mm + 3 mm Beschnitt.indd 1 14.08.23 16:25 30 | June 2024 - International Petfood

FOCUS

Touchswitch by 4B Group

The Touchswitch is an electro-mechanical limit switch with no moving parts, which detects tracking and misalignment problems on bucket elevators and conveyors. When a belt misaligns or a pulley moves over and contacts the sensor, the built in solid-state electronic circuitry detects the lateral force of the belt or pulley and activates a voltage free solid state relay output. This output signal is used to immediately alarm and ultimately shutdown the machine. The face of the sensor is made from hardened and annealed stainless steel, not soft brass or aluminium, so wear life is longer when a belt contacts it. The Touchswitch is not affected by dust or material build up and will still work when completely covered by material. An external test wheel allows for quick and simple sensor/system testing. The sensors are usually installed in pairs on opposite sides of the machine.

www.go4b.co.u

Single screw extruders by Andritz ANDRITZ places a high level of importance on the advancement and innovation of our processing line technology in order to meet the ever changing needs of aqua feed and pet food producers. The results are a generation of high-capacity, versatile extruders. The EX Series of single screw extruders represents state-of-the-art technology, ensuring unique quality feed at minimum operating costs with a high degree of processing flexibility

www.andritz.com

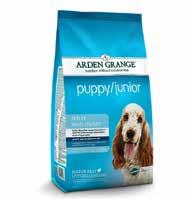

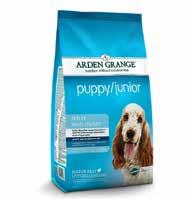

Arden Grange Dry Dog Food Puppy/Junior Fresh

Chicken

Arden Grange Dry Dog Food is for Medium breed puppies 2 to 9 months but can also be used for Larger breed puppies with a low appetite Fussy eaters Pregnant or lactating bitches Weaning. The Small kibble size is ideal for small and medium breeds and is extremely palatable, perfect for fussy eaters. It also boasts a high proportion of fresh chicken meat protein of a very high biological value and a balanced calcium : phosphorous ratio with the correct level of vitamin D to support healthy growth and skeletal development. Added antioxidants and nucleotides support the developing immune system and dental hygiene

www.grovelypetsupplies.co.uk

SEE YOUR PRODUCTS IN THIS MAGAZINE

If you produce a product that you think we should feature in International Petfood magazine, please get in touch

To be considered for inclusion in the magazine please;

Email: editorial@perendale.co.uk

Include 75 words about the product along with a high resolution image and a web link to more information about the product in your email

Chronos OML-1140 B

by Bühler

Bühler, in partnership with Premier Tech, introduces the Chronos OML-1140 B automatic open-mouth bagging station. Engineered to accommodate an array of products such as animal and aqua feed pellets, aqua and feed mash, and free-flowing products, this fully automatic bagging station enhances productivity by ensuring consistent operation, precise bagging performance, as well as the highest product and operational safety standards. The system’s advanced bagging precision – with accuracy of ±0.2 percent at 2 sigma for 25 kg bags – is a direct result of its sophisticated dosing and weighing technologies paired with smart control systems. The station’s robust design for bag management contributes to its impressive estimated production capacity, handling up to 1200 bags per hour for 25 kg bags, thus ensuring maximum uptime. Additionally, its hygienic construction and extensive safety measures align with Bühler’s commitment to superior food and human safety protocols. The Chronos OML-1140 B completes the OML-B Series, enhancing efficiencies and profitability for food and feed production sectors globally.

www.buhlergroup.com

International Petfood - June 2024 | 31

ZMRK23R2 094/2023

2024 June

4-5

Industry Events

Petcare Innovation Europe Berlin, Germany www.petcareinnovationeurope.com

10-12

Animal Health, Nutrition, and Technology Innovation USA Boston, Lincolnshire, USA www.animalhealtheventusa.com

27-28

Pet Food Pet Forum 2024 Guadalajara, Mexico www.petfoodforumevents.com

2024 August

14-15

SuperZoo 2024 Las Vegas, USA www.superzoo.org

14-16

Pet South America 2024 Sao Paulo, Brazil www.home.petsa.com.br

2024 September

24-26

PPMA 2024 Nec, Birmingham, Uk www.ppmashow.co.uk

25-28

Pet Izmir 2024 Konak/İzmir, Türkiye www. petizmir.net/en

29- 1

PATS 2024 Telford, England www.patshow.co.uk

2024 October

7- 9

10th Nordic Pet Food Conference Ålgård, Norway www.nordicpetfood.com

9-12

Global Pet Expo İstanbul, Türkiye www.petfuari.com

30-1

Petfair SE Asia Bangkok, Thailand www.petfair-sea.com

International Petfood - June 2024 | 33

Build My Feedmill Conference 2024

by Shannon Parsons and Niamh Cassidy, International Petfood, UK

The latest technology of a feedmill, broken down into each piece of equipment used to create the nutritious feed we give our livestock, pets, aquatic animals, discussed during the two-hour conference of Build My Feedmill (BMFM) at Health and Nutrition Asia 2024. Held on March 13, 2024 at BITEC, Thailand, Bangkok, Perendale Publishers gathered some of the top people in the feed industry to share their knowledge on their most recent technically-advanced innovations regarding machinery and it was an incredibly informative conference.

Starting off the conference is a warm welcome for the International Petfood’s CEO and Publisher, Roger Gilbert, who explains the process of BMFM. It is a two-hour conference structured on the flow chart of a feedmill where each speaker has ten minutes to discuss their topic/machine that correlates with a part of the flow chart.

Presenting first on the topic of dosing and weighing was Sebastiaan Van Dijk from KSE with his presentation ‘Fast dosing, precise weighing & increased production

capacity’. Sebastiaan dove into the recent and innovative solutions that are transforming dosing and weighing in the milling process, giving valuable insights into achieving exceptional accuracy, optimizing ingredient tracking, eliminating industry challenges like product damage, and boosting productivity.

After we had grinding which was covered by Olaf Naehrig from Amandus Khal discussing ‘The role of the roller mill in the feedmill’. Olaf gave an in-depth introduction to KAHL’s roller mills, their applications, and benefits.

Continuing onto micro-dosing was Marco Prati from PLP Systems with his presentation ‘Handling minor ingredients and additives used for feed production’. Marco covered how additives can be dosed, the role of the Premix Plant, and a way of handling micro ingredients in the mill.

Circling back to a previous speaker, Olaf Naehrig presented ‘Expander technology in the feedmill’ in relation to expander conditioning. He explained how KAHL’s expander plays a key role in the production of high-quality feed.

Jonathan Zheng from ZhengChang then covered high meat addition with his presentation ‘High meat

E 34 | June 2024 - International Petfood

Ms.Haidee Wang

Tel: +86 138 1775 2961

E-mail: haidee.wang@globusevents.com

Mr.Philippe Verstuyft (based in Europe)

Tel: +31 6 1517 3564

E-mail: philippe@vnueurope.com

Ms.Chanitprapa Menasuta (based in Thailand)

Tel: +66 (0) 8 1801 7464

E-mail: chanitprapa@vnuasiapacific.com

BOOK YOUR STAND BEFORE APRIL 1, 2025 AND TAKE ADVANTAGE OF THE EARLY BIRD SALES DISCOUNT . CONNECTING ALL AMERICAN CONTINENTS BRAZIL São Paulo JOIN US in 2025 FEED INGREDIENTS LATIN AMERICA 2025 FEED INGREDIENTS LATIN AMERICA 2025 SEPTEMBER 16-18, 2025 EXPO CENTER NORTE, WHITE PAVILION, SÃO PAULO, BRAZIL victamlatam.com 190 x 132 Perendale.indd 1 16-05-2024 14:54 International Trade Show from Feed to Food NANJING, CHINA 5- 7 Septermber Hot Sale, Welcome to Join us ! For Booth Equiry www.VIVchina.nl Hatching & Breeding Slaughtering & Processing Feed & Equipment Waste Treatment Animal Health Smart Farming

50,000m2 Exhibition Area 500+ Exhibitors 30000+ Visitors International Petfood - June 2024 | 35 E

addition in pet food processing’. Jonathan brought attention to potential problems in high meat production, such as moisture content in raw meat materials, and how Zhengchang Research & Development and testing overcame this issue, producing great results in high meat addition.

Bringing the conference to the half-way mark is Neal Cass from Hydronix discussing automation, ‘The importance of moisture control and measurement throughout the feed milling process’. Neal answered questions regarding why you need to measure moisture, where, and how you control, as well as methods and benefits to moisture control.

Kicking off the second hour was Roger Ubags from Van Aarsen on heat treatment and pelleting, informing everyone on ‘Safe feed forms, the basis for safe food’. Roger briefed the audience on Van Aarsen’s innovations, and how they successfully work at improving the pelleting process.

After Ubags was Claus Braunbeck from FrigorTec on cooling with ‘Grain management for reliable feed milling’. Claus discussed the importance of maintain quality and quantity of stored commodities with grain cooling as a total solution.

BMFM then had two separate presentations on bulk handling, the first being from Justin van den Heuvel from Muller Beltex with his presentation ‘Improve your bucket elevators in view of the total cost of ownership’. This was followed by Nicoleta Axenti from Metalmont with her presentation ‘Automated and safe bunker storage of raw products and pellets’.

To continue with bulk territory, Sven Konings from TSC Silos touches on storage and bulk outloading with his presentation ‘From process design to a building design: How structural thinking saves time, space and errors’. Sven talked about the importance of integrating constructive thinking early in the design process, and how it can yield significant benefits such as saving time and space, reducing errors, and enhancing efficiency.

To end the day was a fascinating joint presentation from Andritz by Marco Bauman and Dr Sohail Nazari covering future feed milling. They discussed Andritz’s innovative technology, and how to ‘Build your plant with operational readiness using digital twin technology’.

The conference was ended with a group Q&A and discussion, allowing the audience an opportunity to question and collectively discuss and debate the topics that were brought forward during the previous two hours. An educational and thoughtprovoking moment this was that encouraged everyone in the room to participate.

36 | June 2024 - International Petfood E

MORE INFORMATION nickmouthaan@victam.com +31 6 2126 4398 victaminternational.com PRE BOOKING RATE : until October 31st, 2024 * EARLY BIRD RATE : until October 31st, 2025 * SEE YOU IN 2026 * Sales starts in March 2024 and as the event takes place in different halls, the stand allocation is done on a first come first serve basis JUNE 2-4, 2026 JAARBEURS, UTRECHT, THE NETHERLANDS JOIN OUR 60TH ANNIVERSARY 190 x 132 Perendale Int2026.indd 1 25-03-2024 10:48 Organized by MOST COMPLETE TRADE SHOW FOR LIVESTOCK PROFESSIONALS IN SUB SAHARAN AFRICA VIV AFRICA 2024 KIGALI, RWANDA 2-3 OCTOBER WWW.VIVAFRICA.NL

PAVILION FEATURING International Petfood - June 2024 | 37 E

PAVILION DAIRY

The Market Place lists leading manufacturers of equipment used for the production of petfood. To be included in the Market Place please contact Tuti Tan at tutit@perendale.co.uk.

Bagging systems

FAWEMA

+49 2263 716-0 mypetfood.info/zsJa

PAYPER

+34 973 21 60 40 mypetfood.info/payper2

Bulk storage

Symaga +34 926640475 mypetfood.info/HUNG

Van Aarsen International +31 475 579 444 mypetfood.info/Rkxo

Computer software

KSE

+31 (0)497383818 mypetfood.info/ERrL

Van Aarsen International +31 475 579 444 mypetfood.info/Rkxo

Coolers & driers

Dosing

Extru-Tech +785 284 2153 mypetfood.info/fViL

FrigorTec GmbH +49 7520 91482-0 mypetfood.info/Ucfl

FAMSUN +86 85828888 mypetfood.info/UXax

Van Aarsen International +31 475 579 444 mypetfood.info/Rkxo

KSE +31 (0)497383818 mypetfood.info/ERrL

PAYPER

+34 973 21 60 40 mypetfood.info/payper2

Van Aarsen International +31 475 579 444 mypetfood.info/Rkxo

Elevator buckets

4B Braime +44 113 246 1800 mypetfood.info/Rjhf

Tapco Inc

+1 314 739 9191 mypetfood.info/ucab

Elevator & conveyor components

Equipment

Extruders

4B Braime +44 113 246 1800 mypetfood.info/Rjhf

Tapco Inc