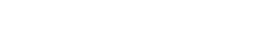

Vishnu K Gupta Executive Director Euro Safety Nonwovens & Euro Safety Equipments

Vishnu K Gupta Executive Director Euro Safety Nonwovens & Euro Safety Equipments

In a world that is constantly evolving, driven by

innovation, uncertainty, and bold ambition leadership has taken on a new meaning. It is no longer defined by titles or tradition but by the courage to lead with purpose, integrity, and vision. In this Insights Success edition of Leader of the Now: 2025’s Most Inspiring Minds, we proudly spotlight individuals who embody this new paradigm,andattheforefrontstandsVishnuKGupta

Vishnu’sjourneyisnotjustaprofessionalsuccessstory—itis a testament to resilience, ethical leadership, and a relentless commitmenttoshapingsystemsthatempowercommunities and industries alike. His work exemplifies what it means to lead now—to navigate complexity with clarity, to inspire change with humility, and to act not just for today, but with foresightforgenerationstocome.

As the world demands more mindful, inclusive, and valuedriven leadership,Vishnu’s impact resonates far beyond the boardroom.Hisabilitytomergestrategicinsightwithhumancentricvalueshaspositionedhimasnotonlyavisionarybut alsoabuilderofmeaningfullegacies.Incelebratinghim,we recognizeavoicethatchallengesconventionwhileuplifting othersthroughinnovation,mentorship,andservice.

This edition curates stories of individuals who are not just adapting to the present but actively shaping the future. We hope that these pages leave you inspired—not just by the accomplishments, but by the mindset that fuels them Because the “Leader of the Now” is not a status—it is a movement.

HappyReading!

Vishnu K Gupta

Leading with Purpose, Building with Integrity

Green Manufacturing as a Competitive Advantage

18

How Manufacturing Innovation Trends Are Redening Competitive Advantage?

Art

Business

Business

Digital

Co-designer

Marketing

Executive Director

N G

Fewexecutivescancombineoperationalexpertisewith

asteadfastcommitmenttoethicsinthequietbustleof industrial corridors and the intricate dynamics of contemporarybusiness.OnesuchuncommonnameisVishnu K Gupta, a leader whose path from the backbone of rural India to the forefront of multinational manufacturing and IT endeavors demonstrating perseverance, foresight, and people-firstleadership.

Hiscareerischaracterizedbythechangesheiscreating,not by the titles he has. His early innovation at Roger Industries Limited allowed him to transform a traditional HR position into a strategic force that transformed the business's operations and helped it obtain India's first SA8000 certification for exporting shoes. However, it was just the start. His impact grew as his responsibilities spanned operations,administration,andcompliance,finallylayingthe groundworkforhisdefininglegacy.

In charge of Euro Safety Group during the COVID-19 epidemic, one of the most unpredictable periods in world history, he is leading from the front, starting two production facilities from the ground up and helping to supply vital protectiveworkweartothenationalandinternationalmarket. Under his direction, Euro Safety Nonwovens is now a wellknownbrandinthemedicalandhygieneindustries.

As the Executive Director of Euro Safety Nonwovens & EuroSafetyEquipments,hisinventivenessandadaptability are evident in the tech industry His leadership aims to empower individuals, create trustworthy organizations, and promote intentional growth in addition to reaching milestones.VishnuKGuptaisaprimeexampleofhow,even in the most trying circumstances, true leadership combines integrityandresiliency

In2003,destinyknockedwhenGuptajoinedRogerIndustries LimitedasanHRManager.Whathappenednextreadslikea business school case study on transformation and vision. Within just one year of his arrival, he had implemented comprehensiveHRsystemsandhelpedthecompanyachieve SA8000certification—makingitthefirstfootwearexportunit inIndiatoearnthisprestigiousrecognition.

"That achievement planted a deeper seed in my mind. I realized that business excellence must be anchored in ethical practices and human welfare. It wasn't just about profits; it wasaboutcreatingimpact."Guptaexplains.

"I believe in the power of people. Whether it's organizing success

celebrations, conducting in-house training sessions, or offering simple words of appreciation,

I ensure the people around me feel inspired and empowered."

The success at Roger Industries opened doors to broader responsibilities Gupta's role expanded beyond HR to encompass administration, compliance, and operations. His abilitytoseamlesslytransitionbetweenfunctionsatraitthat wouldbecomehissignaturestrength—caughttheattentionof seniorleadership.

The real test of Gupta's leadership mettle came with his appointment as Executive Director of Euro Safety Equipments and Euro Safety Nonwovens The timing couldn't have been more challenging the COVID-19 pandemichadjustbegunreshapingglobalpriorities,andthere was an urgent need for high-quality personal protective equipment.

"While COVID-19 was a period of global uncertainty, for me it marked a pivotal moment of professional transformation. I was entrusted with starting two manufacturing units from the ground up during a pandemic. We weren't just building factories—wewerecontributingtopublichealthandnational resilience."herecalls.

Under his stewardship, Euro Safety Group expanded to include multiple manufacturing facilities in Bhiwadi and Mathura, specializing in technical safety workwear, disposable protective apparel, used in hygiene and medical products. The company now produces breathable and nonbreathablePEFilmandHotmeltlaminatefabrics.

"My vision is to position Euro Safety as one of India's leading manufacturers in the hygiene and medical sector We want to be among the top five companies in terms of quality, turnover, andcredibility."hestateswithcharacteristicconfidence.

What sets Gupta apart in the corporate landscape is his unwavering focus on human capital. Despite his evolution into operations, sales, and strategic planning, his HR roots remaindeeplyembeddedinhisleadershipstyle.

"I believe in the power of people. Whether it's organizing success celebrations, conducting in-house training sessions, or offering simple words of appreciation, I ensure the people aroundmefeelinspiredandempowered."heemphasizes

"That achievement planted a deeper seed in my mind. I realized that business excellence must be anchored in ethical practices and human welfare. It wasn't just about profits; it was about creating impact."

This people-first approach has earned him numerous accolades, including recognition as one of the "Most InfluentialHRLeadersinIndia"byTimesAscentin2017,and the"GoldenGlobeTigersAward"fromMalaysiain2019.His trophy cabinet includes honors like "100 HR Leaders Who MakeADifference,""101TopHRMinds,"andmostrecently, "BestBusinessLeaderofTheYear"in2025.

"Success is never it is always shared. When your team grows, yourbusinessgrows."hereflects.

Balancing Act: Professional Excellence and Personal Fulfillment

Managing multiple manufacturing units while maintaining work-life balance requires what Gupta calls "equal energy, presence,andrespecttowhatmattersmostineachmoment." His support system includes longtime friends Rajiv Gupta, Vivek Gupta, and Vinit Singh, who have been instrumental throughouthisjourney

"I've built strong, empowered teams who are capable of owningresponsibilities.Itrustthem.Thattrustnotonlykeeps operations smooth but also gives me space to manage my personaltime."heexplains.

His approach to leadership challenges extends to personal growth as well. "I can be hot-tempered in high-pressure situations.ButI'velearnedtochannelintensityintofocusand drive rather than frustration. I cool down quickly and never carryconflictforward."headmitswithrefreshinghonesty.

InnovationandGrowth:TheRoadAhead

Currently overseeing operations across Euro Safety EquipmentinBhiwadiandEuroSafetyNonwovensfacilities in both Bhiwadi and Mathura, Gupta's responsibilities span strategic planning, sales and marketing, operational leadership,andcompliancemanagement.Thecompany'sISO 9001, ISO 14001, and ISO 45001 certifications reflect his commitmenttoqualityandethicalbusinesspractices.

"We've achieved consistent exports and high-performance operations,butthisisjustthebeginning.Everytargetmetisa steppingstone,notafinishline."hesays

His business philosophy extends beyond manufacturing to encompass technological innovation. As co-founder and BoardDirectorofGFN-DselvaInfotechPvt.Ltd.,established in 2011, he has demonstrated his ability to identify and capitalizeonemergingopportunitiesacrossdiversesectors.

Drawing inspiration from mentors likeA.V.S. Yadav, under whom he worked for nine years, and the founders of Roger Industries Ltd, Kulbir Singh and Dalbir Kaur, Gupta now focusesonnurturingthenextgenerationofleaders.

"My advice to aspiring business leaders is simple but powerful. Never compromise on your values and never compromise on your work. Integrity is the foundation of sustainableleadership."heshares.

Hissuccessmantrarestsonfivepillars:believeinyourself,be honest with your work, stay open to learning, build a dependableteam,andwelcomechallengesasopportunities.

From a village cricket pitch to corporate boardrooms, from healthcareaspirationstomanufacturingexcellence,VishnuK Gupta's journey embodies the power of adaptability and perseverance. His story resonates particularly in today's rapidlychangingbusinessenvironment,wheresuccessoften depends on the ability to pivot, learn, and lead with authenticity.

"I'velearnedthatthebestwaytobalanceistobefullypresent. Whether I'm making a strategic decision in the boardroom or sharing a meal at home, presence creates balance." he concludes.

As Euro Safety Group continues its expansion trajectory under his leadership, Gupta remains focused on his goal: creating meaningful impact through quality products, empoweredteams,andethicalbusinesspractices.Hisjourney from village dreams to corporate leadership serves as a testamenttothefactthatsometimesthepathswedon'tchoose toendupchoosingus—andleadingustodestinationsbeyond ourwildestimagination.

Inanerawherecorporateleadershipisoftenscrutinizedforits values and impact, Vishnu K Gupta stands as a beacon of principledgrowth,provingthatsuccessandintegrityarenot justcompatible,they'reinseparable.

In a world ravaged by environmental concerns such as climate change, resource depletion, and pollution, corporations no longer have the luxury of ignoring the importanceofsustainability.Inamyriadofresponsestothis world cry, green manufacturing stands out as one potent answer providing not just a solution to minimize environmental footprints but also a competitive edge that determinesindustries'fates.

Whereas earlier, it was an expensive and utopian strategy, greenmanufacturingispresentlyshowingitselftobeawise, forward-thinking business strategy. Firms that incorporate environmentalstewardshipwiththeirproductionprocessare being rewarded with higher brand loyalty, cost savings in operations,marketgrowth,andheightenedinnovation.

Green manufacturing involves designing and bringing production processes into place that are more efficient, save energy and resources, and are less damaging to the environment It involves utilizing clean energy, green materials,effectiveequipment,aswellasgreenlogisticsand wastedisposalsystems.

Whatismostdistinctiveaboutgreenmanufacturingisitsendto-end approach. It is not so much about any single stage of manufacturing but reexamines the entire life cycle of a product—rawmaterialprocurementtodiscardorrecycle.Its goal is to see a closed-loop system wherein resources get continuously reused, emissions minimized to near zero, and efficiencyoptimized.

There'sbeenincreasedpressureforgreenproductionoverthe lasttenyears,andit'snothardtounderstandwhy Consumers now are far more mindful of the impact their products are havingontheenvironment.Notonlydoconsumerscareabout whataproductdoes,butalsoabouthowitwasmadeandwhat itstandsfor.Brandswhichcannotdemonstrateenvironmental responsibilitywillbeleftbehind.

Besides the customers, governments worldwide are also tightening up on environment regulation From carbon taxation to more stringent emission controls and green labeling, the rules are changing rapidly. The companies that become early adopters of green production practices are not onlyinabetterpositiontobecompliantbuttendtoenjoythe benefitsoftaxcreditsandsubsidies.

Investorsarealsoturningtheirattention.ESGconsiderations are becoming a central aspect of investment choices. Firms whichareperceivedtobesustainablefromanenvironmental perspective are being perceived as less risky and more sustainable in the longer term Therefore, green manufacturing is becoming core to how firms can access capitalandestablishmarketposition.

One of the strongest points in favor of adopting green manufacturingisitsclear-cutcompetitiveadvantageinmany respects.

It firstly reaffirms brand value. Today's consumers are more brand loyal to brands that are aligned with their values. A public pledge to being green adds trust and creates stronger emotional bonds with consumers. Patagonia, IKEA, and Unileverhaveallbeensuccessfulinachievingthisalignment ofgreenmanufacturingwiththeirbrands,whichhasservedto distinguishthemasleadersamongstotherchaoticmarkets.

Second, green manufacturing is an innovation stimulator Whenbusinessesturngreen,theyarecompelledtocreatenew technologies, enhance product design, and rethink supply chains. This emphasis on innovation can give way to streamlined processes, improved quality products, and new revenuestreamsingeneral.

Third, it enhances cost-effectiveness. While the technology costandtrainingexpensesmaybeincurredintheshortterm duringtheprocessofconvertingtogreenmanufacturing,the long-run yield is high. Reduced energy usage, waste minimization, and processes maximization lead to lower operational costs. Most businesses save a lot within three yearsofgreenprotocoladherence.

Furthermore, organizations that adopt green manufacturing havefreeraccesstonewmarkets.Governmentalagenciesand largecompaniesalsonowinsistthattheirsuppliersadhereto sustainabilityrequirements.Thatmeanscompanieswithsolid green credentials are more likely to secure contracts and partnerships.

Ultimately, green manufacturing can increase employees' satisfaction and retention Increasingly, employees, particularlymillennialsandGenZemployees,desiretowork for a firm that does some good. Doing something good generates a sense of pride and purpose that translates into greaterproductivityandreducedturnover

Greening is not a question of overnight revolution. It is a process that starts with a truthful accounting of how things stand.Firmsmustinventorytheirenergyconsumption,waste generation,rawmaterialsourcing,andshippingpractices.To pinpoint inefficiency and environmental hazards is the basis ofchange.

Having well-defined, measurable sustainability goals is essential These might be lowering energy use, using biodegradable packaging material, or using green certified suppliers for materials. Milestones must be measurable and disclosedopenlytostakeholders.

Technology is key to this transformation. High-tech productionsystems,high-efficiencyequipment,andanalytics enablefirmstomonitorandmaximizetheirprocessesinreal time.Technologyisnotsufficient,however Therealsomust beaculturalshift.Alllevelsofemployeesmustbemotivated, trained,andempoweredtoassistwithgreenefforts.

Supply chain cooperation is also a primary contributor Cooperation with suppliers and logistics suppliers that have sustainability-oriented philosophies helps strengthen the overallgreenmanufacturingmentality.

LookingAhead:AGreenerFutureIsaStrongerFuture

With the world's economy shifting towards greener production, green manufacturing has gone from being an optiontobecominganimperative.Itisnotsimplyareactionto climatechangeorcustomerpressure—itisadriverofgrowth, resilience,andinnovation.

Thosewhoinvestingreenmanufacturingnowarepositioning themselvesforlong-termsuccess.Theyarenotonlycreating moreproductiveandprofitablefactories,buttheyarecreating factoriesbettersuitedtomeetthechallengesofthefutureas well.Mostimportantofall,theyarecreatingabetterworld.

In the constantly changing world of industrial change,

waves of manufacturing innovation are now no longer niceties necessities for competitiveness. From intelligent factories and artificial intelligence-based quality controltosustainablematerialsandresponsivesupplychains, manufacturing is experiencing a renaissance today that is transforming how firms compete, expand, and thrive in the globaleconomy.

This article discusses how such innovation trends are remapping the manufacturing landscape and why companies mustkeeppaceorlag.

TheParadigmShiftfromEfficiencytoIntelligence

Manufacturers in the past were concerned with efficiency only—reducing wastage, reducing costs of production, and streamliningworkflows.Asmuchastheseremainimportant, manufacturing innovation trends have introduced a new era when intelligence, information, and flexibility come into prominence.

Smart manufacturing, powered by the Industrial Internet of Things(IIoT),usesnetworkedsensorsandreal-timeanalytics tomonitorandcontroleveryaspectofmanufacture.

With the capacity to predict failures, make adjustments automatically, and even communicate with each other, machines can maximize uptime and productivity levels beyondwhatwaseverthoughtpossiblejustadecadeago.

Thisshiftmakesproductionproactiveinsteadofreactive,and firms are competitive in anticipating market demand, minimizing downtime, and becoming operationally agile overall.

Not only is sustainability now a corporate obligation—it's a competitiveadvantage.Perhapsthemostsignificanttrendof manufacturinginnovationisembeddingsustainableapproach andcirculareconomylogicintomainstreambusiness.

Firmsthesedaysarealsodesigningtheirproductsfromcradle to grave—raw material extraction through the recycling of end-of-life products. For instance, the use of biodegradable plastic,recycledmetal,andenergy-efficientproductionhelps reducecarbonfootprintsoffirmswhileconcurrentlydrawing environmentallyconsciousconsumersandinvestors.

In addition, closed-loop production and zero-waste manufacturinglinesarealsogoingmainstream,showingthat green manufacturing not only pays, it's better for the environmenttoo.

The other manufacturing innovation trend is employing digital twins—computer models of physical systems that simulate, predict, and optimize performance in real-time. Digital twins allow manufacturers to test scenarios without interfering with live operations, without wasting time or money,usingthistechnology

For example, a firm can simulate the performance of a new assembly line under various loads, workloads, or product mixespriortoinstallation.Itisariskreductionandreturnon investment optimization. With AI and machine learning, digital twins allow continuous improvement through realtimefeedbackfromthefield.

Computersimulationisnotconfinedtohardware—itiseven done on products. Engineers are now able to simulate stress levels, material strength, and energy use, speeding up the productdevelopmentandprototypestagebyahugeamount.

Innovation is not just dependent on materials and machines; it's also severely affecting the workers. As the trends in manufacturinginnovationevolve,workerswithdigitalskills are more in demand. Human and machine cooperation has reached the forefront, with human tasks transforming from hands-ontoknowledge-basedanddecision-makingfocused.

Virtual reality (VR) and augmented reality (AR) are also being utilized to support jobs as well as training, and it is simpler to retrain workers at a faster pace. Collaborative robotsorcobotsassisthumansinperformingrepetitivetasks whilestaffmembersdohigher-valueworksuchasinnovation andqualitycheck.

Through the empowerment of employees with digital tools anddata-driveninsights,manufacturersarenotonlyboosting productivity but also supporting a culture of innovation that willfuellong-termsuccess.

Supply chain disruption on a global scale has proven that flexibilityandresilienceareessential.

In response, manufacturing innovation trends have moved towardsagileandtransparentsupplychainstrategies.

Advanced analytics, blockchain, and AI-based forecasting technology are employed to track vendor performance, anticipate shortfalls, and optimize logistics routes in realtime. It enables manufacturers to react more quickly to fluctuationsindemand,facilitateproactiveriskmanagement, andachievecontinuityamidstmarketturbulence.

Additionally, additive manufacturing (3D printing) is becoming feasible for localized and on-demand manufacturing, cutting the reliance on distant suppliers and enablingstunninglead-timereductions.

Today's customers expect products tailored to their specifications—andtheywantthemdeliveredquickly Mass customizationisperhapsthemostvibrantfactoryinnovation movement, growing with ease. Technologies such as AIbased design, digital manufacturing, and modular manufacturingsystemsenablethesmall-seriesproductionof personalizedproductsatmassproductionefficiency.

Whether it's customized footwear, modular furniture, or automobile features, firms that can deliver customized experiencesatthecostofsacrificeneitherintermsofcostnor velocitypossessasingularmarketadvantage.

Conclusion:InnovationastheNewBenchmark

The factory floor of today is revolutionizing dramatically. Trends in manufacturing innovation are helping companies break free from the old constraints and redefining what's possible From predictive maintenance with AI to environmentallyfriendlymaterials,tooptimizingthesupply chaininreal-time,thetrendsareraisingthebaronsuccess.

In a world where competition is tougher than ever and customer expectations are changing faster by the day, innovation is no longer an organizational function—but a mindset. Such firms that embed innovation into its very culture, stay ahead of trending dynamics, and bet on people andtechnologywillberunninginthepack.

The future of producing things is for those who don't just make things—but make them more intelligent, more rapid, cleaner,andmorehuman-friendlythaneverbefore.

For Subscrip�on: www.insightssuccessmagazine.com

www.x.com/insightssuccess