• At RYER, all our feedstocks are manufactured to the highest level of quality, with excellent batch-to-batch repeatability.

• RYER is the ONLY commercially available feedstock manufacturer to offer all five debind methods.

• RYER offers the largest material selections of any commercially available feedstock manufacturer.

• RYER offers technical support for feedstock selection, injection molding, debinding and sintering.

• A direct replacement for all current commercially available catalytic debind feedstocks

• Improved flow

• Stronger green and brown parts

• More materials available and better surface finish

• Custom scale-up factors available

• Faster cycle times

• 65°C / 150°F mold temperature

• Water Debind

• Custom scale-up factors available

• Large selection of available materials

• Solvent, Super Critical Fluid Extraction (SFE) or Thermal Debind methods

• Hundreds of materials available

• Custom scale-up factors available

Publisher & Editorial Offices

Inovar Communications Ltd

11 Park Plaza

Battlefield Enterprise Park

Shrewsbury SY1 3AF

United Kingdom

Tel: +44 (0)1743 469909 www.pim-international.com

Managing Director & Editor

Nick Williams, nick@inovar-communications.com

Group News Editor & Director

Paul Whittaker, paul@inovar-communications.com

Advertising Sales Director

Jon Craxford

Tel: +44 (0)207 1939 749 jon@inovar-communications.com

Assistant Editors

Amelia Gregory, amelia@inovar-communications.com Emma Lawn, emma@inovar-communications.com

Assistant News Editor

Charlie Hopson-VandenBos charlie@inovar-communications.com

Marketing Lead

Mulltisa Moung, mulltisa@inovar-communications.com

Production Manager

Hugo Ribeiro, hugo@inovar-communications.com

Operations & Partnerships Manager

Merryl Le Roux, merryl@inovar-communications.com

Office & Accounts Manager

Jo Sheffield, jo@inovar-communications.com

Technical Consultant

Dr Martin McMahon

Consulting Editors

Prof Randall M German

Former Professor of Mechanical Engineering, San Diego State University, USA

Dr Yoshiyuki Kato

Kato Professional Engineer Office, Yokohama, Japan

Professor Dr Frank Petzoldt Ingenieurbüro Dr. Petzoldt, Geestland, Germany

Dr David Whittaker

DWA Consulting, Wolverhampton, UK

Bernard Williams Consultant, Shrewsbury, UK

Subscriptions

PIM International is published on a quarterly basis as either a free digital publication or via a paid print subscription. The annual print subscription charge for four issues is £150 including shipping.

Accuracy of contents

Whilst every effort has been made to ensure the accuracy of the information in this publication, the publisher accepts no responsibility for errors or omissions or for any consequences arising there from. Inovar Communications Ltd cannot be held responsible for views or claims expressed by contributors or advertisers, which are not necessarily those of the publisher.

Advertisements

Although all advertising material is expected to conform to ethical standards, inclusion in this publication does not constitute a guarantee or endorsement of the quality or value of such product or of the claims made by its manufacturer.

Reproduction, storage and usage

Single photocopies of articles may be made for personal use in accordance with national copyright laws. All rights reserved. Except as outlined above, no part of this publication may be reproduced or transmitted in any form or by any means, electronic, photocopying or otherwise, without prior permission of the publisher and copyright owner.

Design and production

Inovar Communications Ltd.

ISSN: 1753-1497 (PRINT)

ISSN: 2055-6667 (ONLINE) © 2025 Inovar Communications Ltd.

A lot can change in a year, and this year has been no exception – especially in Binder Jetting. The technology has ridden a wave of hype for more than a decade, but, over the past twelve months, there was a real risk that its reputation would be tarnished by the highly publicised legal dramas surrounding Desktop Metal, its collapse into administration and subsequent scaled-back reorientation.

Nevertheless, it is impossible to ignore the fact that many of the world’s leading MIM producers recognised Binder Jetting’s potential early on and still believe in it. From GKN Powder Metallurgy and Indo-MIM to Parmatech and Zoltrix, Binder Jetting gives MIM firms a route to MIM-like prototypes, low-volume ‘pre-tool’ production runs, components that cannot be moulded, and improved mould inserts for the MIM process itself.

Now, other Binder Jetting machine makers are capitalising on the void that has been left by Desktop Metal and, to a lesser extent, Markforged (now part of Nano Dimension, and owner of Digital Metal’s BJT technology), which is currently maintaining a far lower profile.

One of the most prominent players is HP Additive Manufacturing, whose machines are appearing with increasing regularity at both industrial firms and research centres. Our report on Fraunhofer IFAM’s sinter-based AM workshop reveals much of that momentum. At the same time, the work of companies such as Rolls-Royce on the Binder Jetting of superalloys for aerospace components stands out as an encouraging signal for the technology’s future.

Nick Williams Managing Editor

Cover image

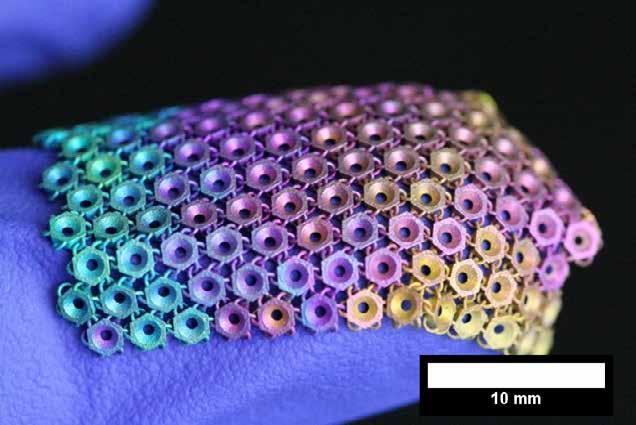

Colour-anodised MIM titanium components (Courtesy Element 22)

MATERIALS DEVELOPMENT SINTERING OPTIMISATION

DIVERSE AM TECHNIQUES

Want to learn more about Ceramic AM at Lucideon?

Take a look at our dedicated AM brochure that describes our offering: from materials development and the various AM techniques we can support, to sintering parameter optimisation

ANALYSIS AND EVALUATION

COMPUTATIONAL TECHNIQUES

Ceramic AM is an emerging technology area with applications across sectors including healthcare (orthopaedic and dental), aerospace, and energy. Novel materials and printing technologies are under development, and Lucideon can provide scale-up support and validation to help progress towards full commercialisation.

www.lucideon.com/brochure

query@lucideon.com

www.linkedin.com/company/lucideon

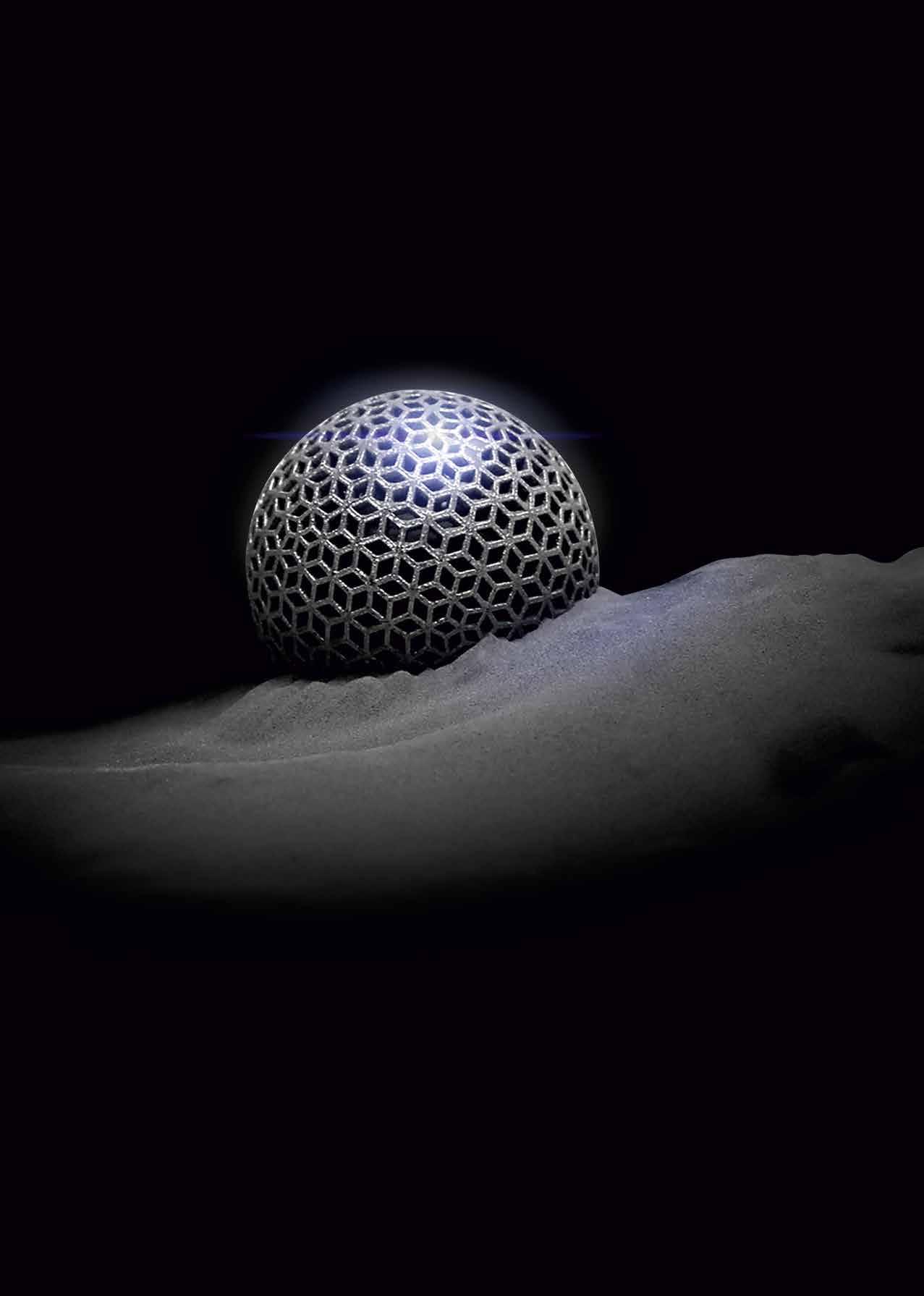

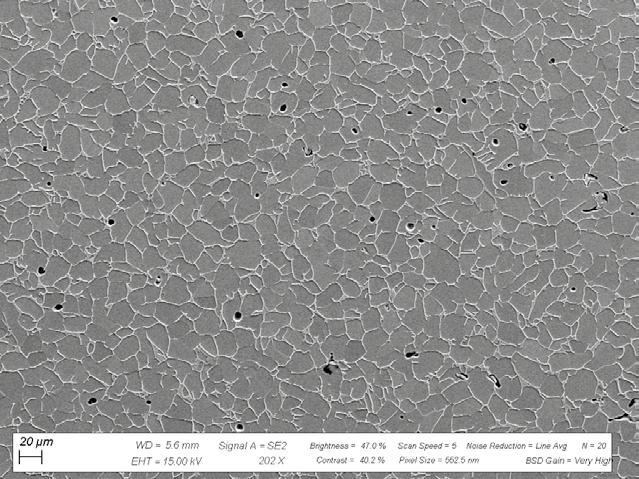

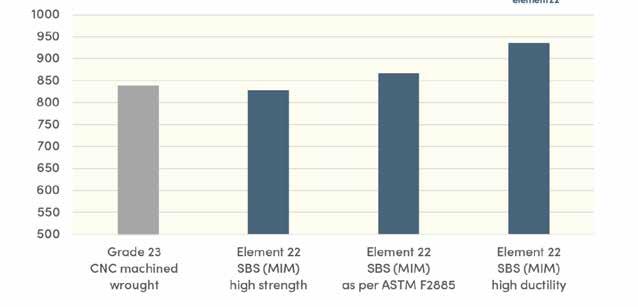

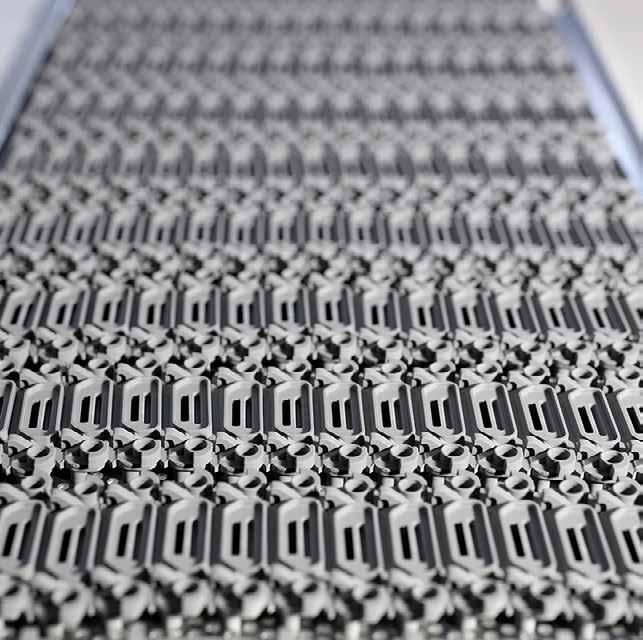

53 Element 22: Mastering titanium component production with Metal Injection Moulding and Additive Manufacturing

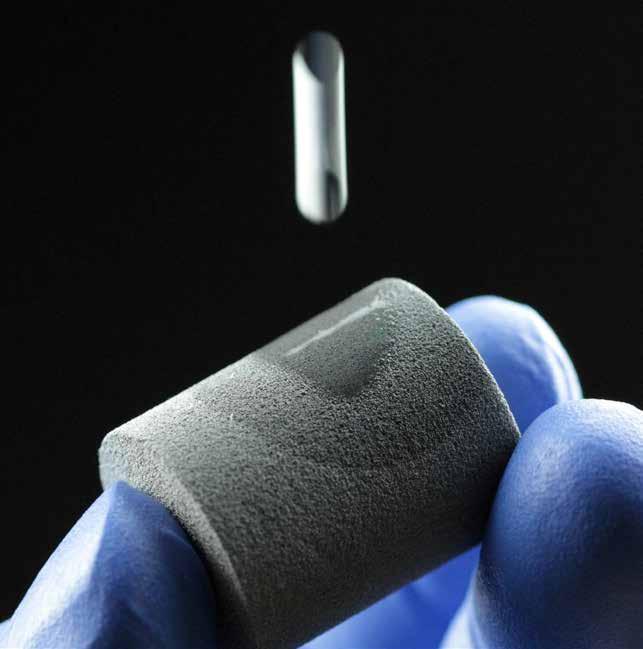

Element 22 GmbH has built its reputation on developing efficient ways to manufacture complex titanium components for demanding applications in medicine, aerospace, luxury goods and emerging hydrogen technologies. By leveraging Metal Injection Moulding, sinterbased Additive Manufacturing and carefully controlled finishing processes, the company demonstrates how titanium parts can be produced reliably and at scale.

The information in this document is proprietary and confidential to Rolls-Royce and is available to authorised recipients only – copying and onward distribution is prohibited other than for the purpose for which it was made available.

Dr Georg Schlieper recently visited the company for PIM International to explore its processes and ongoing developments. >>>

67

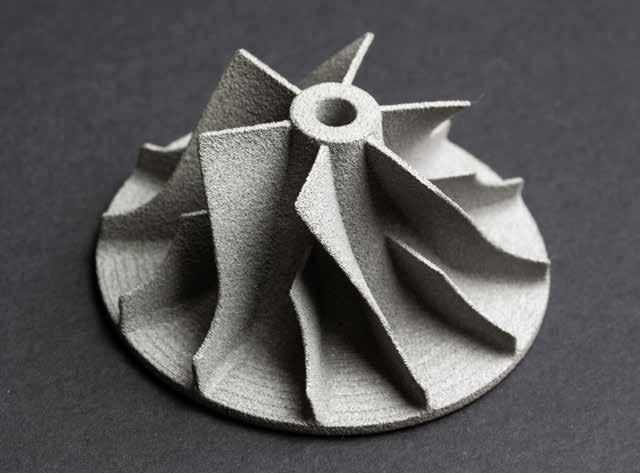

Advancing industrialisation:

Binder Jetting at the forefront of a maturing sinter-based AM landscape

Binder Jetting’s accelerating progress toward industrial production set the tone at Fraunhofer IFAM’s 6 th Workshop on Sinter-based Additive Manufacturing, held on October 8-9, 2025, in Bremen, Germany. Alongside Binder Jetting, the programme highlighted advances across the wider family of sinter-based AM processes, with industry and research speakers presenting new applications, cleaner and more stable workflows, and expanding material options.

This report, by Fraunhofer IFAM’s Lea Reineke and Michael Norda, reviews the event’s key findings. >>>

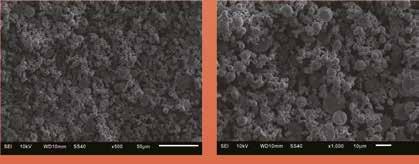

81 Tailored feedstocks for MIM, CIM and sinter-based AM: How Blesol Tech is responding to market requirements

Blesol Tech is emerging as a notable European supplier of metal and ceramic feedstocks for Metal Injection Moulding, Ceramic Injection Moulding, and sinterbased Additive Manufacturing. Based in Castilla-La Mancha, Spain, and led by Dr Gemma Herranz and Dr Cristina Berges, the company brings together academic expertise and industrial-scale production.

As this article outlines, its close collaboration with MIM and CIM producers offers clear insight into shifting market requirements, informing the development of tailored materials and adaptable feedstock solutions. >>>

The PIM International newsletter is sent to several thousand industry professionals worldwide. Register today to ensure you benefit from reading the latest industry news and advances in Metal Injection Moulding, Ceramic Injection Moulding and sinter-based AM technologies. TO OUR NEWSLETTER

www.pim-international.com/e-newsletter

Discover our latest and highly versatile tool steel powder Osprey® MAR 55. This new alloy bridges the gap between maraging steels and tool steels. With Osprey® MAR 55 you no longer have to choose between good weldability of carbon-free maraging steels and the strength and high wear resistance of carbon bearing steels. Also, Osprey® MAR 55 gives you good mechanical properties and wear resistance already in the as-built condition.

Learn more and explore how Osprey® MAR 55 creates opportunities for your business.

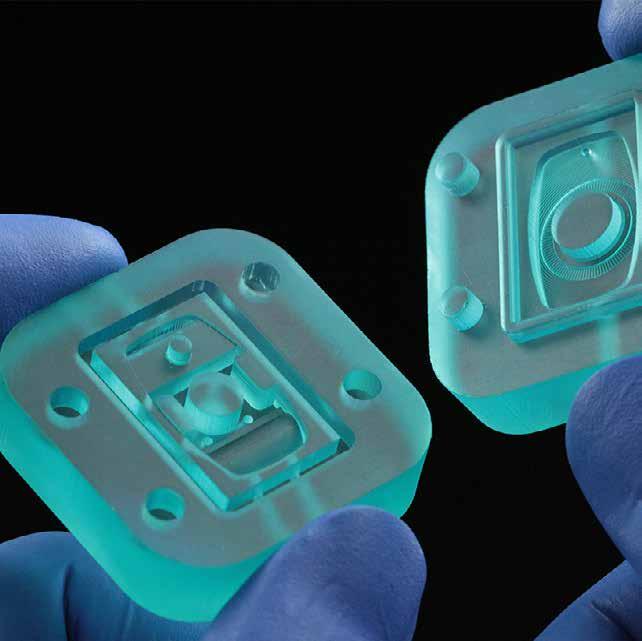

91 Cleaner semiconductor etching: Bosch Advanced Ceramics’ two-part AM injector produced with Lithoz technology

Semiconductor manufacturers increasingly rely on components that can withstand extreme plasma environments while delivering tighter process control and near-zero contamination.

To meet these demands, Bosch Advanced Ceramics and Lithoz have transformed a previously two-part injector design into a fully integrated single ceramic component using ceramic Additive Manufacturing.

By pairing high-purity alumina with precision AM technology, complex internal geometries could be unlocked, enhancing reliability and performance for advanced wafer production. >>>

Discover the leading suppliers of materials and equipment for MIM, CIM and sinterbased AM, as well as part manufacturing and

View a list of upcoming events for the MIM, CIM & sinter-based AM industries. >>>

> nick@inovar-communications.com

• Be visible: Ask about advertising opportunities

> jon@inovar-communications.com

• Stay connected: Follow us on LinkedIn

> www.linkedin.com/company/ piminternationalmagazine

To submit news for inclusion in PIM International contact Paul Whittaker: paul@inovar-communications.com

Bosch Advanced Ceramics, based in Immenstadt, Germany, has announced that it has entered into an acquisition agreement with Sintokogio Group, Nagoya City, Japan. From January 2026, the company will rebrand and operate under the name Sinto Advanced Ceramics Europe GmbH, part of the Sintokogio Group.

Since 2016, Bosch Advanced Ceramics has been funded by Bosch Business Innovations GmbH, the corporate venture builder of Bosch. Since its establishment, Bosch Advanced Ceramics has become an established global contract manufacturer of additively manufactured technical ceramics from its production base in Immenstadt, Germany.

Synergies strengthen market position

For customers and partners, all manufacturing processes and materials, services are expected to remain unchanged. The core focus will continue to be the contract Additive Manufacturing of technical ceramics.

By joining the Sintokogio Group, the newly named Sinto Advanced Ceramics is expected to gain access to additional resources, investments in technology and capacity, and a global network. This support is designed to create a strong foundation for the continued development and expansion of existing business activities.

Under the new company structure, Nikolai Sauer, the current CTO of Bosch Advanced Ceramics, will become the Managing Director of Sinto Advanced Ceramics Europe GmbH. Sophie Berninger, the current CEO of Bosch Advanced Ceramics, will take on a new position within the Bosch Group.

“I look back with pride on the development of Bosch Advanced Ceramics under Bosch Business Innovations GmbH and would like to thank all partners and customers for their longstanding support,” stated Berninger.

Sauer added, “Becoming part of the Sintokogio Group opens up new perspectives and strengthens our position in a dynamically growing market. Together, we will continue to drive the advancement of Additive Manufacturing of technical ceramics

and deliver the highest levels of quality and reliability to our customers.”

At the end of the third quarter of 2025, Bosch Advanced Ceramics reported 115% year-over-year revenue growth, a clear indicator of rising demand for additively manufactured technical ceramics and the company’s strong market position.

“We are very pleased to welcome Bosch Advanced Ceramics to the Sintokogio Group,” said Atsushi Nagai, president of Sintokogio. “Their expertise and market position are an ideal fit for our portfolio and open new opportunities in innovative industries. This integration marks an important step in expanding our global expertise in high-performance ceramics and 3D printing.”

www.bosch-advanced-ceramics.com www.sinto.co.jp

Sintokogio Group is set to acquire Bosch Advanced Ceramics, renaming the company Sinto Advanced Ceramics (Courtesy Bosch Advanced Ceramics)

INDO-MIM Ltd, headquartered in Bengaluru, India, is reported to have filed for an initial public offering (IPO) of shares to raise up to Rs 1,000 crore (approx $113 million) via fresh issue.

As part of the offer for sale, Green Meadows Investments Ltd, Anuradha Koduri, John Anthony Dexheimer and the Indian Institute of Technology Madras will offload shares.

One of the world’s largest Metal Injection Moulding operations, INDO-MIM was founded in 1996.

Today, the company operates globally, with facilities in India, the United States, the United Kingdom and Mexico. Its main facility in Bangalore houses what is said to be the world’s largest installed capacity for MIM and employs over 2,500 skilled workers.

INDO-MIM’s annual report states that total Income for the year ended March 2025 was INR 28,338.46 million (approx $319 million), up from INR 24,383.81 million (approx $275 million) in FY 2024.

www.indo-mim.com

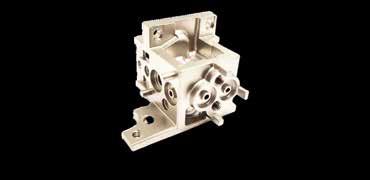

Nichols Portland Inc (NPI), Portland, Maine, USA, has reported that it is investing $4.7 million to expand its operations in St Marys, Pennsylvania. This underscores the region’s role in the company’s advanced manufacturing strategy.

The company has moved from its MIM – Ridgway location into a larger technology hub and business showcase in the St Marys Industrial Airport Park on a ten-year lease. The facility also functions as NPI’s corporate headquarters, supporting six manufacturing locations and a

global customer base. The expansion is expected to add forty-two new jobs.

NPI received a funding proposal from the Pennsylvania Department of Community and Economic Development (DCED), including a $300,000 Pennsylvania First grant and a $76,000 WEDnetPA grant to train its workers. The City of St Marys also received a $614,000 grant through the Pennsylvania Strategic Investments to Enhance Sites Program (PA SITES) to support this project. These funds

INDO-MIM is reported to have filed for an initial public offering of shares to raise up to approximately $113 million (Courtesy INDO-MIM)

are intended to increase gas pressure and expand electric supply.

“We are excited to expand in Elk County, leveraging the expertise and solid workforce that has been the foundation of growth across the entire powder metal industry,” said Thomas Houck, President and CEO of Nichols Portland, Inc.

“With a focus on innovation and technology, we look forward to building NPI’s future in Pennsylvania and beyond to support our global customer base. I would like to recognise our tremendous local partners and contractors who have completed the necessary infrastructure improvements to bring our vision and strategy to a reality.”

“We thank Governor [Shapiro] and his administration for their support in NPI and our community. This is proof that targeted partnerships between the public and private sectors can create real, sustainable opportunities, especially in manufacturing-driven regions like Elk County,” the company stated on LinkedIn.

Nichols Portland offers advanced manufacturing solutions, including PM and MIM. The company is a specialist supplier of pump and precision valve solutions.

www.nicholsportland.com

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

Eco-wise Powder For F uture-wise Mak ers.

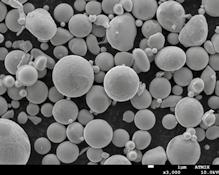

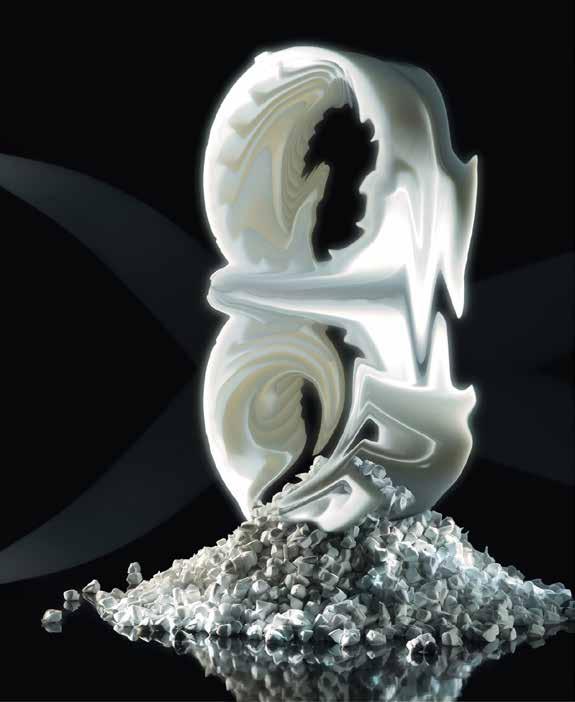

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Mitsubishi Steel's fine powder for achieving superior MIM products.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

Proposal for Special Alloy Powders tailored to customer specifications.

contact_sales_w.powder@mitsubishisteel.co.jp

contact_sales_w.powder@mitsubishisteel.co.jp

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

Proposal for Special Alloy Powders tailored to customer specifications. contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

Tel:+81 3-3536-3122

3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

contact_sales_w.powder@mitsubishisteel.co.jp Tel:+81 3-3536-3122

3-3536-3122

The UK Manufacturing Technology Centre’s (MTC) National Centre for Additive Manufacturing (NCAM), located in Coventry, UK, has acquired a new HP Metal Jet S100 Binder Jetting (BJT) Additive Manufacturing machine. In a separate announcement, it was also reported that HP Inc has become a Tier 2 member of the MTC, with the partnership focusing on advancing Additive Manufacturing technologies in the UK.

Reported to be the first HP Metal Jet installed in the UK, the machine is expected to allow MTC to develop capabilities for Additive Manufacturing hard-to-process and crack-prone materials.

“We’re delighted to announce HP as new members to MTC. This partnership aims to unlock further collaboration and innovation in the Additive Manufacturing space, positively impacting MTC’s members and wider industry,” stated Ajdin Foric, Business Development Manager – MTC.

Dr Hoda Amel, Technology Manager, Additive Manufacturing –MTC, added, “Our partnership with HP supports NCAM’s mission to accelerate the uptake of Additive Manufacturing in the UK by helping industry de-risk emerging technologies like metal Binder Jetting. Together, we’re taking a step towards scalable, cost-effective AM solutions that are ready for realworld production.”

The MTC houses a wide range of Additive Manufacturing machines and equipment, used to process metal, polymer and ceramic materials.

“MTC has a strong history of driving new and innovative manufacturing technologies, and together we want to create an open-door policy for metal Binder Jetting collaboration,” said Micheal Goodwin, Commercial Account Manager, UK/I & Nordics, Metal 3D Printing Solutions – HP Inc. “The value of metal Binder Jetting

INDO-MIM, headquartered in Bengaluru, India, has qualified OptiPowder Ni718 from Continuum Powders, based in Houston, Texas, USA, using its HP Metal Jet S100 Binder Jetting (BJT) Additive Manufacturing machines.

In extensive evaluations, INDO-MIM reported achieving sintered parts with density levels exceeding 98% of theoretical, with consistent hardness values (74–79 HR15N) and tightly controlled carbon content (0.013–0.014%) across multiple sinter runs.

“Qualifying Ni718 on the HP Metal Jet S100 is a major step forward for binder jet adoption in high-performance industries,” said Jag Holla, Sr VP Marketing, INDO-MIM Additive Technologies. “This milestone demonstrates INDO-MIM’s commitment to

advancing Binder Jetting into production and enabling our customers to benefit from scalable, cost-effective solutions for superalloy components.”

According to INDO-MIM, metallographic analysis confirmed OptiPowder Ni718 exhibited the powder quality required for denser parts in BJT Additive Manufacturing, enabling the expected gamma phase microstructure critical to Ni718’s high-temperature strength and oxidation resistance.

Because of its ability to withstand extreme environments, Ni718 is one of the most widely used superalloys in aerospace, defence, and energy applications. According to Continuum, the successful qualification of OptiPowder Ni718 on a Binder Jetting Additive Manufacturing machine

Dr Hoda Amel, Technology Manager Additive Manufacturing – MTC, with the new HP Metal Jet S100 Binder Jetting machine (Courtesy MTC)

as a scalable, cost-effective, and production-ready technology is clear, and establishing a collaborative centre in the UK will give industry and academia the opportunity to explore, develop, and scale this innovation into real production. Creating this shared space ensures that the benefits of the technology are accessible to all, accelerating adoption and strengthening the UK’s position in advanced manufacturing.”

www.the-mtc.org www.hp.com

may enable scaled production of high-performance components while leveraging BJT’s speed and cost advantages.

“This qualification is an important milestone not just for INDO-MIM, but for the wider adoption of Binder Jetting,” stated Dr Mukund Nagaraj, Senior Manager – Additive Manufacturing Operations, INDO-MIM.

“By combining our production expertise with Continuum’s US-based environmentally friendly powders, we’re demonstrating that binder jet can deliver complex, high-value components with the consistency and performance our customers demand.”

“Achieving this milestone with INDO-MIM on an HP Metal Jet S100 system represents a breakthrough for binder jet adoption in aerospace, defence, and energy,” added Rob Higby, CEO of Continuum Powders. www.continuumpowders.com www.indo-mim.com

Sintek Powder Metallurgy Inc, Çayırova, Türkiye, has expanded its production capacity by adding Metal Injection Moulding to its Powder Metallurgy technology portfolio through the addition of an Allrounder 270C from Arburg, based in Lossburg, Germany.

Building on over sixty years of experience in the Powder Metallurgy industry, producing small, complex and tight-tolerance parts, the company added Metal Injection Moulding to meet growing demand for critical components. The company anticipates that MIM, in particular, will make a major contribution to local manufacturing capacity in defence, medical, and electronic industries.

The company’s new MIM line reportedly offers an annual production capacity of up to two million

Sintek Powder Metallurgy has added MIM to its portfolio with the addition of an Arburg Allrounder 270C (Courtesy Sintek Powder Metallurgy)

parts, depending on part size and geometry. The line is also designed for environmentally friendly production, offering a low carbon footprint and lowered environmental impact. Operating from its new 2,000 m 2 facility, Sintek Powder Metallurgy serves both domestic and international markets.

www.sintek.com.tr

Gevorkyan a.s., headquartered in Vlkanová, Slovakia, has established Gevorkyan Force Defense (G-FD), a subsidiary focusing exclusively on the arms industry. The subsidiary is under full management of the parent company. Gevorkyan manufactures parts by conventional Powder Metallurgy routes, Metal Injection Moulding, and metal Additive Manufacturing.

Gevorkyan has begun implementing the AS9100 standard for aerospace and defence, as well as ISO 27001 and TISAX cybersecurity standards. G-FD will also implement Allied Quality Assurance Publications (AQAP) 2110 certification. AQAP is a NATO-developed framework for quality assurance systems. AQAP 2110 is a prerequisite for supplying arms to NATO members.

Small-calibre ammunition project in

Building on its experience in the arms industry, Gevorkyan has signed an NDA and is beginning a project with a Western European manufacturer that has been in operation for over a century. Gevorkyan will contribute to the development and production of special components for high-quality ammunition.

www.gevorkyan.sk

Inland Atomize Metal Powder LLP (IAMP), based in Vadodara, Gujarat, India, has begun production of metal powders at its new manufacturing facility. Once fully operational, IAMP expects to produce up to 700 metric tonnes of metal powder annually.

The company will use Vacuum Induction Gas Atomisation (VIGA) and a hydrometallurgy process to produce a wide range of metal powders. Its powder is reported to be suitable for Additive Manufacturing, Powder Metallurgy, Metal Injection Moulding, Hot Isostatic Pressing (HIP) and other advanced powderbased technologies. Its VIGA process enables precise control over particle morphology, size distribution,

and chemical composition. It is used to produce IAMP’s stainless steel, nickel, tool steel, tin, pre-alloyed and copper alloy powders. Hydrometallurgy is also used to process nickel, cobalt and tungsten.

IAMP’s equipment includes the VIGA 200, a hydrogen reduction furnace, nitrogen system, vibrating screen (sieving machine), blending machine, attritor, and pulveriser machine. Quality control is undertaken via atomic absorption spectrophotometer, particle size distribution by laser diffraction, and Fisher sub-size sieve analysis.

“At Inland Atomize Metal Powder LLP, our mission is to combine metallurgical expertise with cutting-edge atomisation to

Inland Atomize Metal Powder has begun powder production at its new facility (Courtesy Inland Atomize Metal Powder)

deliver powders that exceed expectations – ensuring quality assurance, sustainable practices, and unwavering customer trust,“ the company stated. www.inlandatomizemetalpowder.com

These two binder systems have excellent characteristics during the production process and combine attractive prices with worldwide availability

High performance as well for the 3D-Printing process based on the water soluble binder system

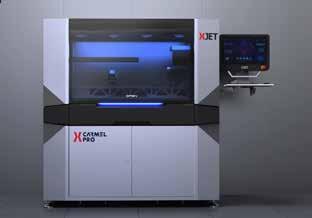

XJet, Rehovot, Israel, has announced the Carmel Pro, a metal and ceramic Additive Manufacturing machine based on the company’s NanoParticle Jetting (NPJ) technology. The compact machine represents a 60-70% reduction in initial investment compared to XJet’s existing Carmel machines, making it accessible to small-to-medium enterprises, research centres and premium jewellery manufacturers.

“The Carmel Pro represents a significant milestone in democratising access to industrial, powderless and safe metal and ceramic Additive Manufacturing,” stated Guy Zimmerman, CEO of XJet. “By delivering the same precision and material capabilities of our larger systems in a compact, costefficient format, we’re enabling a new generation of manufacturers, designers, and researchers to leverage the unique advantages of NanoParticle Jetting technology.”

The Carmel Pro features multimaterial Additive Manufacturing capability with four material chan -

nels and is fully compatible with XJet’s complete portfolio of metal and ceramic inks, including the company’s precious metals capabilities. XJet intends to further expand the machine’s capabilities into highvalue materials and specialised applications.

The machine introduces smart automation features designed for ease of use and minimal operator intervention. Single-button job starts with automated pre-checks, guided setup wizards, and self-monitoring systems make the platform wellsuited for non-expert users and shift operators. It also requires less than a twenty-minute turnaround between jobs, with rapid cleaning and setup processes intended to minimise downtime.

The launch of Carmel Pro is expected to expand the company’s market beyond large-scale industrial manufacturing players to serve small-to-medium-sized enterprises, startups, and research institutes and universities that focus on product and technology development. XJet’s existing product portfolio, featuring

Ecrimesa Group, headquartered in Santander, Spain, reports that Mimecrisa has launched a new Research and Development and Innovation (R&D&I) project in collaboration with the University of Castilla-La Mancha (UCLM), Ciudad Real, Spain, with the support of the Centre for the Development of Industrial Technology (CDTI), Madrid, Spain.

The project, titled “High-nickel enhanced blends for applications with high mechanical requirements at elevated temperatures” (CDTI IDI-20250150), focuses on the

design and validation of new catalytic feedstocks suitable for both Metal Injection Moulding (MIM) and material extrusion-based Additive Manufacturing (AM). These developments target critical sectors such as aerospace, energy, chemical, and high-temperature industrial applications.

The project is organised around five key technical objectives:

• Converting injection scrap into usable AM filaments

• Inconel 718 feedstock for components exposed to high temperatures

the Carmel 5000X, 1400C and 1400M, was developed to deliver serial production at an industrial level.

“We’ve seen incredible innovation happening in smaller organisations – startups developing breakthrough medical devices, university labs pushing the boundaries of materials science, and independent jewellery designers creating extraordinary pieces,” Zimmerman continued.

“These innovators have been locked out of advanced metal and ceramic 3D printing because of cost and complexity barriers. The Carmel Pro changes that equation entirely. We’re not just selling a machine; we’re enabling the next generation of manufacturing innovators to bring their ideas to life.”

The Carmel Pro is expected to be commercially available in Q2 2026.

www.xjet3d.com

XJet’s Carmel Pro is scheduled to be commercially available in Q2 2026 (Courtesy XJet)

Hastelloy C22 formulation, offering exceptional corrosion resistance

• 420 MA stainless steel feedstock, designed for enhanced mechanical properties and industrial reintroduction

• AM filaments for prototyping and short-run manufacturing. By the end of the project, Mimecrisa expects to have: three validated feedstocks ready for production; a new high-performance filament line for FFF manufacturing; a functional in-house recycling system for injection scrap; and opportunities for patent protection and participation in EU innovation programmes. www.ecrimesagroup.com

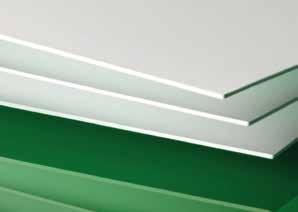

• high purity ceramics (Al2O3, ZrO2)

• fine pores

• anti-adhesion properties in high-temperature sintering applications up to 1500°C

• tailor-made surface properties

• optionally with (micro-) structured surface

• high thermal shock resistance

Tel.:

www.kerafol.com cts@kerafol.com

Professor José Manuel Torralba, Senior Researcher and former Director of the IMDEA Materials Institute and Professor at the Carlos III University of Madrid (UC3M), has been formally inducted as a full member of the Royal Academy of Engineering (RAI).

During the swearing-in ceremony, held at the RAI headquarters in Madrid on September 30, Professor Torralba was accompanied by a large representation from the IMDEA Materials Institute and UC3M, as well as family, friends, and former doctoral students.

“My personal experience at the inauguration ceremony was very gratifying,” said Professor Torralba after the ceremony. “I was fortunate and honoured to have a significant part of my family, colleagues from both IMDEA Materials and the University, collaborators, friends, and especially former PhD students and doctors who have worked with me over the years.”

“The academy also fully participated in organising the event, which made it unforgettable for me. I don’t think you could have a better start for an institution. I’m entering the academy with great enthusiasm and a huge desire to work,” he added.

In a statement, IMDEA Materials stated, “We […] are very proud to have been present on such a special day, with the assistance of our director, Jon Molina; our deputy director, Damien Tourret; our manager, Covadonga Rosado; as well as several group leaders, current and former researchers, and members of our administration. We would like to congratulate Professor Torralba again for this well-deserved recognition.”

www.materials.imdea.org www.raing.es

Professor José Manuel Torralba has been sworn in as a full member of Spain’s Royal Academy of Engineering (Courtesy IMDEA Materials Institute)

Sentes-BIR, headquartered in Kemalpaşa, Türkiye, has announced that its quality control laboratory has achieved ISO 17025 accreditation for the characterisation and testing of metal powders. The standard is important for calibration and testing laboratories globally, demonstrating technical competence and the ability to produce precise and accurate data.

For Sentes-BIR, this accreditation underscores its commitment to the

highest quality standards, a critical factor for partners in the aerospace sector where material integrity is paramount. The company already holds AS9100 certification for its powder production.

This new certification is expected to enhance confidence in SentesBIR’s extensive range of metal powders, which includes nickel, cobalt, iron, copper, and aluminiumbased alloys.

www.sentes-bir.com

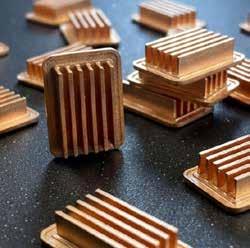

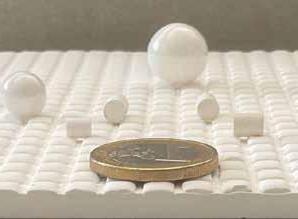

Porite Taiwan, based in Zhunan, Taiwan, has reported that it has successfully produced a number of sample pure copper parts via Metal Injection Moulding. The parts featured a density of 8.77 g/ cm³ and are said to have achieved both excellent structural integrity and superior thermal conductivity.

These attributes make them well-suited to thermal management applications such as electronic heat dissipation, power device cooling and precision thermal modules.

Porite Taiwan was also keen to highlight that the MIM parts are more cost-effective than conventional machining of copper.

Porite Taiwan has over thirty years of experience using Metal Injection Moulding technology, working in a range of sectors including automotive, aerospace, toolings and power tools, 3C, medical and general mechanical parts. The company also has extensive press and sinter

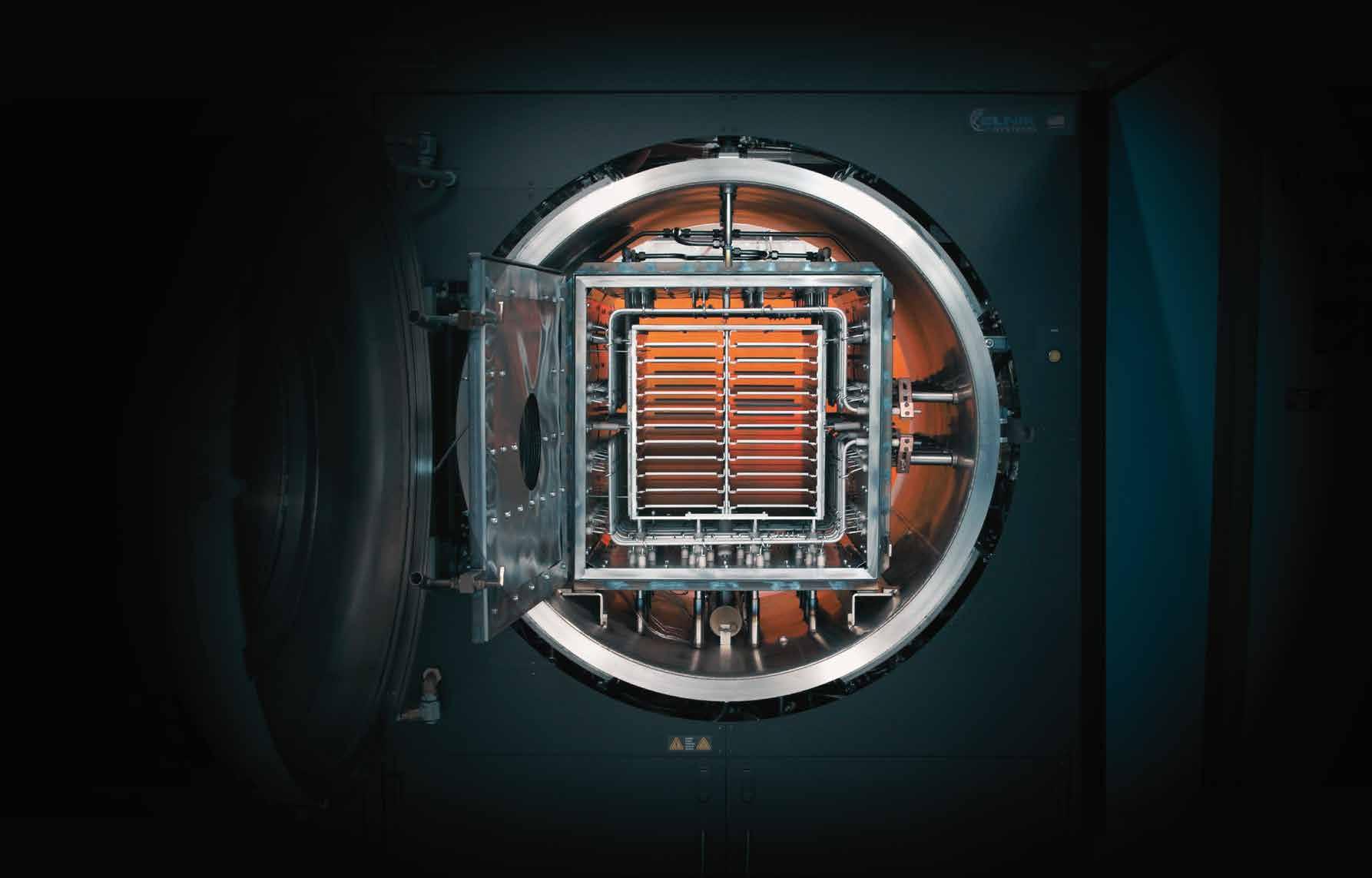

• Combination of different heat treatments in one furnace (Debinding+Sintering)

• High-purity atmosphere over a long operating time

• Same furnace for several materials

• Various size in combination with a very compact design (foot print 1 m x 1.6 m)

• Low installation and unit costs

Powder Metallurgy capabilities, as well as numerous post-processing operations.

Porite added that it is continuing to conduct performance testing and exploring new applications for its copper MIM. tw.porite.com

Lithoz, based in Vienna, Austria, has announced the installation of three CeraFab S65 Additive Manufacturing machines at Safran Aircraft Engines Gennevilliers, France. This investment is expected to enable the French engine manufacturer build up the serial production of complex casting cores, meeting the high cooling demands of next-generation aircraft engine turbine blades. Increasing high-pressure turbine inlet temperatures is key for future engine generations, so turbine components must be able to withstand these temperatures. This can

be achieved by implementing more complex cooling channels during the casting process used to manufacture the turbine blades. Lithoz stated that its LCM technology has reached a level of complexity for casting cores that wasn’t achievable via traditional ceramic manufacturing processes.

Safran stated that the CeraFab S65 was chosen for its performance and short production time. The ergonomics and software functions are adapted to production and meet aeronautical traceability requirements. The company also noted the technical skills and quick response capabili - ties of Lithoz teams, which were said to have been major assets during the initial target planning and in reaching the success of this project.

Jet Ventures, based in Brno, Czech Republic, is leading a €1.8 million funding round in Headmade Materials GmbH, headquartered in Wuerzburg, Germany, following its €1 million investment. The remaining €0.8 million was contributed by Matterwave, AM Ventures, and the European Innovation Council (EIC).

Headmade’s Cold Metal Fusion (CMF) technology is a sinter-based Additive Manufacturing process that enables the cost-efficient production of metal parts in large batches. The company plans to use

the investment to expand the range of materials for CMF technology and develop new applications in cooperation with customers in Europe and the USA.

“Headmade Materials is an attractive firm for its combination of technological innovation and a business model that enables faster scaling and recurring revenue,” stated Roger Dorsch, Director of Jet Ventures, Jet Investment’s venture capital team. ”CMF technology has the potential to fundamentally transform the production of metal components by making serial 3D

“The installation of these three CeraFab S65 printers is a true milestone for both Lithoz and the aerospace industry,” added Johannes Homa, Lithoz CEO. “As Safran Aircraft Engines moves forward to further develop their serial Additive Manufacturing process for ceramic casting cores, Lithoz remains strongly committed to providing our constant support in this important project.”

www.lithoz.com

www.safran-group.com

printing available to a wider range of industrial companies. We believe that Headmade Materials has the potential to become a major player in the global market and, at the same time, suitably complements the portfolio of our Jet Venture 1 fund.”

“Our latest investment round is a signal of confidence in our technology, strategy and team,” stated Christian Staudigel, CEO and co-founder of Headmade Materials. “The funds raised represent a milestone for us on the path to further growth and expansion of applications that will accelerate the adoption of Cold Metal Fusion technology in the market.”

www.jetinvestment.eu

www.headmade-materials.de

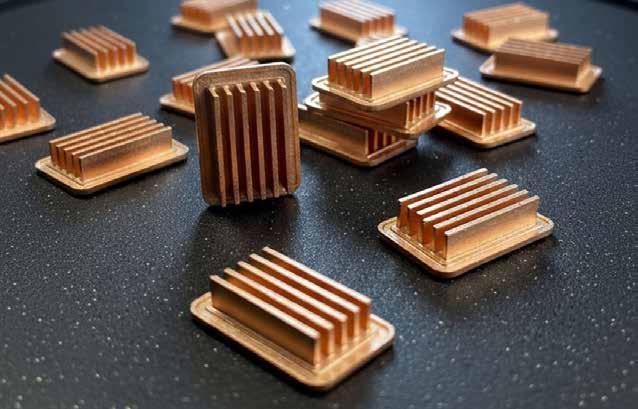

Schunk Sintermetalltechnik GmbH

Discover the future of power electronics with our cutting-edge heat sinks, crafted using advanced Metal Injection Moulding (MIM) technology. These innovative heat sinks offer unparalleled thermal management, ensuring optimal performance and longevity for your electronic devices.

MIM allows for complex geometries and superior material properties, resulting in highly efficient heat dissipation. Perfect for high-power applications, our MIM heat sinks are lightweight, durable, and cost-effective. Upgrade your power electronics with our state-of-the-art MIM heat sinks and experience the difference in performance and reliability. Embrace the next generation of thermal solutions today!

� Roßtrappenstraße 62 06502 Thale, Germany

� +49 3947 7 1560 At thorsten.klein@schunk-group.com � schunk-mobility.com

Arburg, headquartered in Lossburg, Germany, premiered its updated Allrounder Trend line of injection moulding machines at K 2025. The new machines are intended to be quick to set up, easy to operate and maintain, energy-efficient, and offer reliable parts production.

“We have completely redeveloped the Allrounder Trend – from the all-electric drive train, energy-efficient clamping and highperformance injection unit to the dynamic electric ejector and the new Gestica lite control variant. This ensures repeatable and reliable part production,” stated Guido Frohnhaus, Managing Director Technology & Engineering. “The machine technology is very easy to master, even without specialist personnel, and enables quick and easy entry into injection moulding of standard components.”

The Allrounder Trend line is aimed at a range of industries, including technical injection moulding and electronics. With performance optimised for standard applications, Trend machines are

intended to offer low investment and operating costs, in terms of both returns on investment (ROI) and total cost of ownership (TCO).

At market launch, there are four sizes in the clamping force ranging from 500-2,000 kN and with electric injection units in sizes 100-800. The injection speed is between 200-500 millimetres per second.

Tobias Baur, Managing Director Sales and After Sales, added, “Our new Trend performance level offers high cost-efficiency coupled with proven Arburg quality and globally standardised service. We wish to reach existing customers worldwide as well as completely new target groups who do not yet have an Allrounder in their injection moulding production facilities.”

The naming style has also been updated: in the new system, the clamping force follows the product name Allrounder. The Allrounder 1000 e Trend, for example, has a clamping force of 1,000 kN; the ‘e’ stands for electric and ‘Trend’ for the performance level in the standard machine segment.

The easily accessible large mould installation space and interfaces for electronics, pneumatics and cooling water close to the mould enable convenient setup and start-up. Peripheral devices can be connected using ‘Plug & Work’, and the cylinder module can also be replaced quickly when needed.

Arburg has also placed emphasis on ease of maintenance and low maintenance requirements. For better accessibility and simpler setup, the safety gate has been significantly enlarged, and the sliding guard on the injection unit can be opened wide in two stages. The maintenance points on the injection and clamping unit, e.g., for grease lubrication, are easy to access without the need for special tools.

The new electric Trend machines will be available worldwide from spring 2026.

Arburg France celebrates 40 th anniversary

It was also announced that Arburg SAS, based in Tremblay-en-France, celebrated its fortieth anniversary in early November. The team marked the occasion at the Arburg Technology Centre, where around 100 participants were joined by Juliane Hehl, Managing Partner, and Tobias Baur, as well as Steffen Eppler, Vice President Sales Europe.

“Our aim of establishing a global presence with our own organisations was and still remains to provide our customers with first-class and comprehensive on-site support. We are deeply impressed by what our French team has achieved over the past four decades,” Hehl said on the occasion. “Even back then, it was very important to my father Eugen Hehl to convey the image of our company worldwide through uniform appearance of the ARBURG buildings at home and abroad – and of course our technology and expertise.”

Arburg SAS was company’s first foreign subsidiary. Hehl went on to thank customers for their trust in Arburg over the years, and the French Arburg team for their successful work.

www.arburg.com

Continuum Powders, based in Houston, Texas, USA, and HP

Additive Manufacturing Solutions have entered into an agreement to accelerate the development of high-performance alloys using HP’s Metal Jet S100 Binder Jetting (BJT)

Additive Manufacturing machine.

“This collaboration underscores the future of Additive Manufacturing, where best-inclass printing platforms meet sustainable, high-quality powders,” stated Don Magnuson, Senior Vice President of Continuum Powders.

“Working alongside HP, we are not just qualifying materials –we are enabling Binder Jetting of superalloys once considered out of reach. This means higherperformance parts, reduced supply

chain risk, and faster pathways to production.”

The first alloy in development is OptiPowder M247LC. This is a lowcarbon, nickel-based superalloy engineered for high-temperature strength and corrosion resistance in aerospace and energy applications. The companies’ multi-phase development programme includes:

• Powder characterisation

Using Continuum’s Melt-toPowder process to achieve control over chemistry, particle size distribution (PSD) and morphology to meet BJT requirements.

• Build parameter development HP AM’s Barcelona, Spain, R&D team will work to optimise

Gevorkyan a.s., headquartered in Vlkanová, Slovakia, has announced selected financial and operating results for the six months ending June 30, 2025, as well as providing updated full-year 2025 and five-year outlooks.

The company reported first-half 2025 revenues were up 11% year-onyear at €42.2 million, with EBITDA at

€13.8 million, a 15% year-on-year growth. The EBITDA margin was 32.7%, a 1.2% increase over the same period in 2024.

The company also reported operating EBIT of €4.6 million in H1 2025, an increase of 12% compared to the same period last year, and profit after tax (PAT) at nearly €3.0 million, representing a 17.9%

process settings to achieve part densities exceeding 98% of theoretical, with repeatable green strength and sintering response.

• Mechanical & metallurgical properties

The programme will evaluate hardness, microstructure ( γ / γ′ phase distribution), and mechanical properties to confirm aerospace-grade performance.

“Binder Jetting is delivering industrial-scale production today and extending such production to high performing alloys requires a rigorous materials development programme,” added Brett Harris, Global HP Metal Jet Product Manager, HP Additive Manufacturing Solutions. “With Continuum, we are demonstrating the robustness of the Metal Jet S100 system across demanding alloys like OptiPowder M247LC, ensuring our customers can move from pilot runs to full-scale production with confidence.”

The Continuum–HP collaboration is designed as a scalable framework: once M247LC is qualified, additional high-value alloys – including other nickel superalloys and future titanium grades – can be advanced through the same methodology. The development of this framework is intended to better-position Binder Jetting Additive Manufacturing as a production-ready solution for aerospace, defence, and energy applications.

www.continuumpowders.com www.hp.com

increase compared to the same period in 2024.

Building on its 2025 H1 results, confirmed orders, and expected tailwinds, Gevorkyan projects revenue growth of 11–18% and EBITDA up 15–23% at EBITDA margins around 36%. In the five-year term, the company expects revenue CAGR of 10–16% and EBITDA CAGR of 10–18%, underpinned by its backlog and new contracts in aerospace and defence and other strategic sectors.

www.gevorkyan.sk

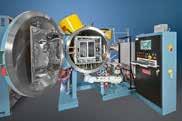

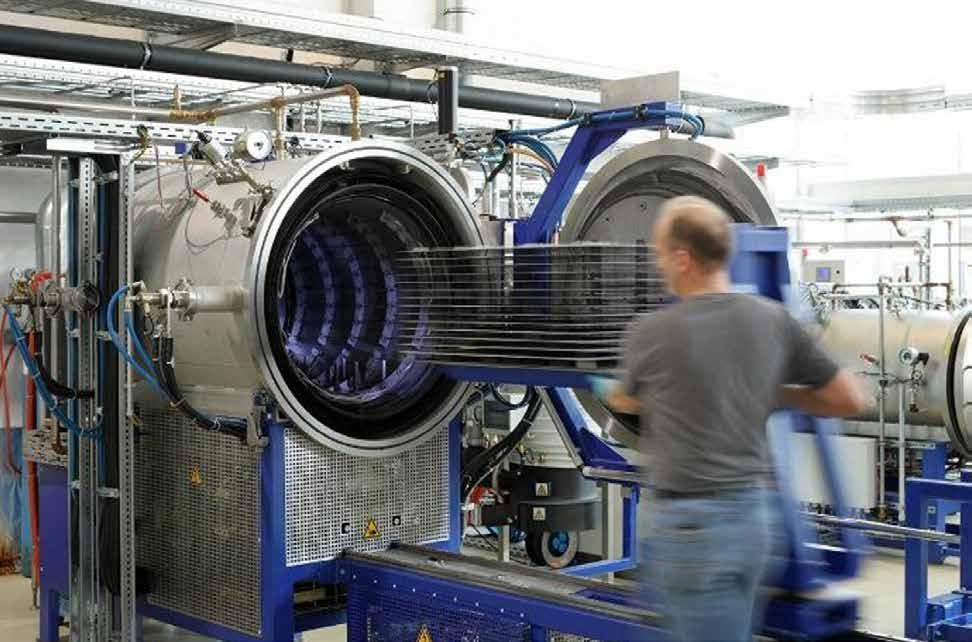

Reliable Vacuum Furnaces for better end-to-end production. From prototyping to high-volume production, Ipsen offers vacuum furnaces in a variety of sizes that accommodate common heat-treatment processes used for AM, such as debinding, sintering, stress relieving and annealing.

Amazemet, based in Warsaw, Poland, has announced the integration of an advanced artificial intelligence model to fully automate its rePOWDER ultrasonic atomisation machine. The move is intended to address the need for constant, manual supervision of metallurgical processes, often required in industrial and academic R&D. In particular, the company noted the suitability of this upgraded machine for use in high-throughput materials testing facilities.

“In most institutions, it is far easier to buy new equipment than to hire new technical staff,” stated Dr Łukasz Żrodowski, CEO of Amazemet, Adjunct Professor at Carnegie Mellon University. “Amazemet focused its efforts on limiting the time users must commit to atomising novel alloys. Our new AI process control delivers much

more autonomy, allowing researchers to focus on discovery or supervise more devices and processes at the same time.”

The AI model utilises machine vision, processing a live video feed from a welding camera to analyse melt pool characteristics in real-time. It autonomously determines and adjusts torch position, power, and material feeding every 120 milliseconds. According to Amazemet, this continuous optimisation ensures high wettability of the atomised material on the sonotrode, a key element for an efficient process, resulting in the highest possible yield in the desired Particle Size Distribution (PSD).

The AI also controls the ultrasonics, overspray removal, atomisation atmosphere and gas flow.

(Courtesy Amazemet)

Matsuura Machinery Ltd, based in Coalville, UK, has been named as the exclusive United Kingdom reseller of HP’s Metal Jetting Additive Manufacturing machines. The high-volume, sinter-based Metal Jet machines are intended for sectors such as automotive, industrial, medical and consumer products.

“Our appointment as the exclusive UK stockist for the HP Metal Jet represents a natural evolution of our partnership with HP,” stated David Chapman, Managing Director, Matsuura Machinery. “We have been supporting UK manufacturers with HP’s polymer 3D printing technology for years, and our customers can now benefit from the same

The integration of AI required a comprehensive machine overhaul, centred around a new Advanced Control Cabinet featuring an industrial-grade GPU and highspeed, industrial PLC. Its integration with industrial networks via API enables remote process control and monitoring.

The rePOWDER machine features a new, specially designed and optimised plasma source and connected feedstock feeders to track the quantity of processed material. The machine also features integrated gas recirculation with a passivation system for increased safety.

The AI-integrated rePOWDER was benchmarked using Ti-6Al-4V (Titanium Grade 5) wire, reportedly achieving production rates of up to 0.5 kg/h and a minimum of four hours of unattended processing. Amazemet aims to extend this autonomous operation to eight hours in the next year.

While Ti-6Al-4V is the benchmark, the company stated that it is already developing autonomous processes for other high-value materials, including NiTi for shape-memory applications and the C-103 (Nb) alloy for hightemperature applications.

Amazemet is also developing new feeder systems for bar/ rod, machining chips, and powder feedstocks, further expanding the machine’s autonomy and material flexibility.

www.amazemet.com

world-class service, training, and applications expertise for metal Additive Manufacturing. Our decades of experience with our own AM/CNC hybrid LUMEX platform gives us a deep understanding of metal 3D printing.”

Matsuura’s AM Centre in Leicestershire will serve as the hub for Metal Jet demonstrations, applications development, training, and long-term customer support.

www.matsuura.co.uk

www.hp.com

Regardless of the complexity of your custom application and formulation, it remains standard for us with our quality systems, technical support, and two proprietary binding systems.

We ensure 100% batch-to-batch consistency, a wide range of alloys, and 36 years of supplying MIM feedstocks for mission-critical parts.

Advanced Metalworking Practices (AMP) manufactures and supplies a wide range of both standard and custom-configured MIM feedstocks for your application. Contact Chris Chapman at cchapman@ampmim.com or 724-396-3663.

Scan the QR code or click here to view our current list of alloys www.ampmim.com/resources

Lithoz, headquartered in Vienna, Austria, showcased real-world examples of additively manufactured ceramic parts produced by its proprietary Lithography-based Ceramic Manufacturing (LCM) technology at this year’s Formnext. Ceramic cores, used for building single crystal turbine blades for next-generation aircraft engines,

were reported to be a highlight of the booth. These demonstrators were representative of those produced by Safran Aircraft Engines, which recently installed three CeraFab System S65 Additive Manufacturing machines at its facility near Paris. The blades feature delicately branched cooling channels, enabling improved temperature management.

Over 6,500 production and laboratory furnaces manufactured since 1954

• Metal or graphite hot zones

• Processes all binders and feedstocks

• Sizes from 8.5 to 340 liters (0.3–12 cu ft.)

• Pressures from 10-6 torr to 750 torr

• Vacuum, Ar, N2 and H2

• Max possible temperature 3,500°C (6,332°F)

• Worldwide field service, rebuilds and parts for all makes

Also on show was a complex alumina atomic layer deposition ring, designed by Plasway and serially produced by Alumina Systems. Using LCM Additive Manufacturing, the 380 mm diameter, lightweight ring features very thin walls and optimised flow channels. As a critical wear part in the semiconductor industry, the ring reportedly offers verifiably extended uptime of one to nine months, while trebling production output.

Lithoz also premiered a monoblock turntable cartridge with moving coil technology. The Thales VORO cartridge for analogue turntables from HiFiction AG is encapsulated in an additively manufactured zirconia housing built as a single piece without support structures. Its shape is inspired by naturally occurring Voronoi skeleton structures. Developed and scaled to production by Steinbach AG, the functional part‘s capsule is characterised not only by its geometry but, thanks to the use of high-strength zirconia, also by its resonance behaviour at the lowest possible weight. The integration of engineering design and advanced manufacturing saw the technology secure the Thales VORO the iF Design Award 2025.

Lithoz also showcased another highly intricate customer component serially produced for the semiconductor industry. The gas injector for etching processes on

Ceramic cores used for building single crystal turbine blades for next-gen aircraft engines (Courtesy Lithoz)

show was manufactured by Bosch Advanced Ceramics.

Also included in the company’s semiconductor display were ultra-precise aluminium nitride (AIN) cooling plates with intricate, three-dimensional internal lattice and gyroid structures that enable efficient heat transfer, compact form factors and targeted thermal regulation.

Lithoz showcased the highly complex 380 mm alumina atomic layer deposition ring (Courtesy Lithoz)

The medical and dental section of the Lithoz booth premiered patient-specific ceramic earmoulds for hearing aids, designed and marketed by Swiss company OC GmbH and mass-customised by CADdent.

“With this focus on real series applications from various industries, we are not only sending a clear signal about the growing rele -

vance and adoption pace of ceramic Additive Manufacturing for OEMs in these turbulent times,” stated Johannes Homa, Lithoz CEO. “This concerted focus on premiering realworld components successfully scaled to industrial level on Lithoz CeraFab printers is our manifesto for serial production in ceramic 3D printing.” www.lithoz.com

FEATURES

• Metal or Graphite Hot Zones

• Metal and Graphite Retorts

• Debinding & Sintering

APPLICATIONS

• Additive Manufacturing

• Metal Injection Moulding

• Ceramic Injection Moulding

• Powder Metallurgy

• Trapping Systems to Suit The Best Thermal Processing Solution for the Powder Industry Our experienced team is ready to solve your toughest thermal processing challenges and will design, manufacture, install and maintain the

Furnace you’ll ever own.

NSL Analytical Services, Inc, based in Cleveland, Ohio, has shared a case study by Dr Ross Cunningham, Director of Science and Technology at NSL Analytical Services, Inc, exploring how Inductively Coupled Plasma (ICP) analysis and LECO (which includes Combustion Analysis and Inert Gas Fusion) testing deliver complete material analysis. ICP and LECO testing are two industry-leading methods for testing elemental composition of a wide variety of materials, ranging from enhanced metal alloys and ceramics on aircraft to pharmaceuticals and cosmetics.

Each method brings a unique capability to accurately generate compositional information on most material systems. ICP is capable of detecting bulk and trace elements across the majority of the periodic table, while LECO is used to detect light elements, like oxygen and nitrogen, that ICP is unable to measure. When used together, they provide nearly the whole spectrum of elements from bulk to trace levels, ensuring a high confidence of material quality and regulatory compliance.

These techniques are believed to be essential tools for engineers and manufacturers, offering fast, accurate and repeatable results, and require only a small amount of test material. As a result, they enable enhanced quality control and assurance at every stage of the production cycle, from raw materials to end products.

What are the methods and principles behind ICP testing?

Depending on the required detection range (the percentage of an element of interest, from bulk to ultra-trace), ICP testing utilises one or both of two techniques to precisely detect and measure elements in a wide range of materials. If the sample is initially solid, it is first dissolved in an acid to form a liquid solution. Each technique involves vaporising, atomising and ionising the liquid sample by injecting it into an argon plasma formed by a radio frequency generator, known as an Inductively Coupled Plasma, or ‘ICP’.

Optical Emission Spectroscopy (ICP-OES), otherwise known as Atomic Emission Spectroscopy (ICPAES), operates on the principle that excited atoms emit light at specific

characteristic wavelengths. In this technique, the liquid sample is injected as an aerosol into the plasma, where the intense heat vaporises the sample and ionises the atoms therein. When the ions return to their ground state, they release the energy as photons of light, whose intensity is measured with photomultiplier tubes (PMTs) or charge-coupled devices (CCDs). The wavelength of an emitted photon is characteristic of the specific element, while the intensity is proportional to its concentration. This allows for accurate, quantitative analysis of a wide spectrum of elements simultaneously.

Mass Spectrometry (ICP-MS) combines the high-temperature ionisation capabilities of ICP with mass spectrometer detection. It is similar to ICP-OES in that the sample is introduced into an argon plasma to be atomised and ionised but is unique in that this method directly measures the ions the plasma produces.

The charged ions are then extracted through an interface (typically a pair of water-cooled cones) and directed through ion optics (electrostatic lenses) that guide the ions into a mass analyser where the ions are separated and measured based on their massto-charge ratio, or m/z value. The signal generated is directly proportional to the relative concentration of the element in the sample, which is converted to a concentration by comparing it to a calibration standard of a known value.

While powerful in its breadth of elements and range of detection limits, ICP is not capable of detecting all elements. This is where LECO testing comes in, which is the common brand name of equipment for methods that utilise Combustion Analysis or Inert Gas Fusion to identify specific light elements in a sample that are generally not measurable with ICP, namely for C, S, O, N and H.

Combustion analysis heats a small sample to a high temperature in an oxygen-rich environment, converting carbon and sulphur into their gaseous oxides, like CO 2, which are measured using an infrared absorption detector.

Inert gas fusion heats the sample in an inert atmosphere, such as helium or argon, to release nitrogen, oxygen, and hydrogen. These elements are then processed through a series of catalysts, detectors, and scrubbers to independently analyse the constituent elements.

Why are ICP and LECO testing valuable to manufacturers?

These testing methods ensure that the raw materials and finished products meet precise specs for elemental composition. This is a key consideration for performancecritical industries like aerospace and defence, automotive, and medical devices, because users are now demanding more from materials, and even the smallest out-of-spec variations in trace elements like carbon or sulphur content can impact the material’s properties and fitnessfor-use, ultimately undermining the safety or performance of the product.

ICP testing is a method for testing the elemental composition of a material utilising ICP Mass Spectrometry and/or ICP Optical Emission Spectrometry to precisely detect and measure elements in a wide range of materials, including advanced metal alloys and ceramics (Courtesy NSL Analytical Services)

Accurate and repeatable elemental analysis allows manufacturers to meet strict compliance and specification targets through each stage of the product lifecycle, whether it’s R&D, quality assurance or failure analysis. While invaluable in making sure elements are present in the

appropriate concentrations in alloys and materials, they are equally useful in ensuring contaminants like oxygen or sulphur in alloys or dangerous elements, like lead or mercury, are absent or below acceptable limits for medical or consumer-facing products. www.nslanalytical.com

NEW MACHINE GENERATION

Catalytic Debinding Furnace

Continuum Powders, based in Houston, Texas, USA, has announced the commercial availability of its OptiPowder CoCr F75 alloy powder. Known for its strength, corrosion resistance, biocompatibility, and thermal stability, CoCr F75 is a critical material for demanding applications across aerospace, industrial, and medical sectors.

OptiPowder CoCr F75 is produced through the company’s proprietary Melt-to-Powder (M2P) gas atomisation process, which delivers highly spherical particles, low oxygen levels, and flowability for consistent part quality. Continuum’s CoCr powder can be tailored with regard to particle size distributions and powder characteristics to align with the requirements of each modality and OEM platform, enabling it to meet customer specifications across platforms and technologies such as Laser and Electron Beam Powder Bed Fusion (PBF-LB or PBF-EB, respectively), Binder Jetting (BJT), and Directed Energy Deposition (DED) Additive Manufacturing processes and Metal Injection Moulding.

Target applications for F75 include engine turbine components such as nozzles and valves, industrial wear parts, and medical implants such as dental prosthetics and joint replacements.

“CoCr F75 has long been a go-to alloy for critical applications in aerospace and medical industries, but its adoption in Additive Manufacturing has been limited by quality and supply challenges,” said Rizk Ghafari, Chief Operations Officer at Continuum Powders. “By offering a reliable, high-performance F75 powder produced through our sustainable M2P process, we’re helping manufacturers expand design freedom, improve part performance, and build more resilient supply chains.”

Sunil Badwe, VP, Research & Development at Continuum, “The quality of powder defines the performance of the part. At Continuum, we engineer powders with purpose, tailoring their behaviour to specific applications. Our CoCr F75 powder sets the standard for aerospace and medical use, delivering consistency and reliability where it matters most.”

Continuum Powders’ OptiPowder CoCr F75 is part of the company’s broader portfolio of advanced alloy powders designed to deliver technical excellence with a circular advantage. By transforming reclaimed metal feedstock into high-quality powder, Continuum aims to reduce reliance on virgin raw materials while maintaining high performance standards and cost flexibility.

www.continuumpowders.com

The EROWA PM Tooling System is the standard interface of the press tools between the toolshop and the powder press machine. Its unrivalled resetting time also enables you to produce small series profitably.

www.erowa.com

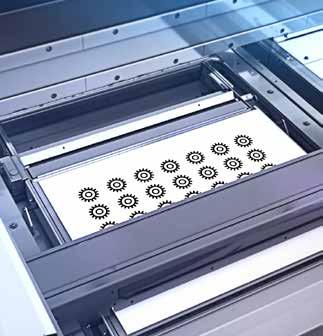

Partner with the leader in industrial DLP Sub-Systems

The UV imaging copilot for your next breakthrough

Co-engineering from day one

Support from prototype to industrial-scale systems

Custom, tailor-made optics with own production

From small-batch to mass production - high repeatability

Casio has announced a new goldcoloured version of its metal injection moulded ring watch. Following the success of last year’s model, designed to commemorate the company’s 50 th anniversary, the new CRW-001G-9 has the same physical dimensions as the previous model.

The fully functional miniature watch is around 10x smaller than a normal watch. Metal Injection Moulding is used to produce the stainless steel case, case back and ring in a single piece. The watch is then finished with gold-coloured ion-plating.

The ring watch has an inner diameter of 20 mm and a circumference of 62.8 mm, with the company providing spacers to make it fit different-sized fingers. The six-digit LCD displays the time down to the second, and features a calendar, dual time and a 1/100-second stopwatch, all controllable through three buttons.

Metal Injection Moulding is an established, cost-efficient manufacturing process for the production of watch designs. These can range from

Casio has announced a new goldcoloured version of its popular MIM ring watch (Courtesy Casio)

everyday stainless steel watches to luxury, diamond-clad timepieces. Ceramic Injection Moulding (CIM) is also used, with many high-value designer watchmakers adopting the technology.

In addition to the previous ring model, Casio has used MIM before in the production of its watch cases. A recent highlight was its use in the G-Shock Mudmaster watch. Here, a complex button guard MIM component was produced in stainless steel. www.casio.com

creating images – together

visitech.com

The CRW-001G-9 features a stainless steel MIM case, case back and ring produced in a single piece (Courtesy Casio)

Fomas Group, headquartered in Osnago, Italy, has announced the appointment of Giancarlo Scianatico as Managing Director of Mimete, the group’s metal powder business.

With over fifteen years of experience in the industrial sector, Scianatico brings a foundation in mechanical engineering as well as sales and human resources management. His international career spans France, Germany, and Italy, where he has worked with leading industrial companies, gaining deep insights into global operations and multicultural business environments.

“I am proud to join Fomas Group, a prestigious multinational company and global leader in the science and technology of metals,”

stated Scianatico. “I am honoured to contribute to the success of Mimete in advancing the metal powder business, where we already hold a leading position in key industries such as power generation and aerospace.”

“Giancarlo’s arrival strengthens our commitment to the metal powders business, a key pillar in Fomas Group’s technological evolution,” added Jacopo Guzzoni, president & CEO of the Fomas Group. “His expertise will help us expand our presence in this highly specialised market and deliver advanced solutions that meet the growing demands of global industries.”

The Fomas Group has been working in the metals industry

Giancarlo Scianatico, Mimete Managing Director (Courtesy Fomas Group)

since 1956, from forging to metal powders and rolled rings. The group offers iron, nickel, and cobaltbased powders under the Mimete brand, designed for applications in Additive Manufacturing, thermal spray coating, and across industries such as power generation, oil & gas, industrial, biomedical, and aerospace. www.mimete.com www.fomasgroup.com

Incus GmbH, based in Vienna, Austria, launched the Hammer Pro25 sinter-based metal Additive Manufacturing machine at this year’s Formnext 2025 exhibition. Using a Vat Photopolymerisation (VPP) process, the Hammer Pro25 is designed to combine industrial-scale metal AM with high precision, automation, and throughput.

Incus states that the machine can produce MIM-like quality, while allowing every part to be fully customised.

The Hammer Pro25 offers continuous, automated production metal parts with material throughput of up to a reported 980 cm 3/h, with automated material refill and removal of finished parts. Engineered for 24/7 production, the machine supports lights-out manufacturing and is capable of producing large, heavy-duty parts as well as small, intricate geometries.

The Hammer Pro25 offers high resolution, with a lateral resolution of 25 μm, powered by dual scrolling projectors, enabling simultaneous manufacturing on two platforms. The machine has a build volume of 200 × 205 × 140 mm and flexible layer thicknesses between 10 - 100 μm.

Additionally, the Hammer Pro25 reportedly offers high surface quality after sintering (Ra approx. 2 μm), often eliminating the need for postprocessing. The machine design is intended to enable the highest productivity, and, together with the Evo series, provide a solution for the workflow from R&D and small-series production to mass manufacturing.

“With the Hammer Pro25, we are empowering manufacturers to scale up Additive Manufacturing with unprecedented reliability and

Incus unveiled the Hammer Pro25 at Formnext 2025 (Courtesy Incus GmbH)

efficiency,” stated Gerald Mitteramskogler, CEO at Incus. “The system’s combination of precision and automation provides true industrial capability, while its surface finish drastically reduces the need for costly post-processing.” www.incus3d.com

Our high-performance VIGA systems deliver high-quality metal powders, engineered for novel and complex alloy compositions

Plastometrex, a developer of mechanical testing solutions based in Cambridge, UK, announced that its ASTM E3499-25 for Profilometry-based Indentation Plastometry (PIP) standard has been approved. The approval follows a thorough, multi-year process, including collaborative validation work with NPL, Airbus, Nikon, and Renishaw, as well as reviews and balloting through ASTM’s committee system, a process that reflects the consensus of experts across the global materials community.

The standard is intended to give engineers and researchers a globally recognised route to faster, easier, and more cost-effective mechanical testing, whilst providing users with audit-ready data, consistent results across laboratories and supply chains and a clear route to adoption in regulated sectors such as aerospace and energy.

Complex/miniature medical device components

High temperature stainless steel/superalloy automotive parts

Advanced ceramics with high density, high wear and tear resistance, and high precision.

Micro MIM/CIM

Materials customization and RnD.

ASTM E3499-25 – Standard Test Method for Indentation Plastometry of Metallic Materials is also expected to reduce barriers to internal approval, make audit readiness straightforward, and ensure results are comparable across organisations. Because ASTM standards are internationally recognised, this development may also provide a foundation for global comparability and regulatory alignment, bolstering the use of PIP overall.

The path to standardisation

The standardisation effort was initiated and led by Plastometrex CTO Dr Jimmy Campbell, who originally coined the term ‘Indentation Plastometry’ in a 2019 peer-reviewed paper, and has since guided its technical development.

“From the outset, our goal with Indentation Plastometry was to create a method that gave engineers the same fundamental mechanical properties as conventional tensile testing, but with far greater efficiency and versatility,” stated Dr Campbell. “Securing an ASTM standard is a major step in that journey. It validates the rigour of the science, recognises the work of the experts involved, and gives industry the confidence to enjoy the benefits that PIP offers.”

“For me,” he continued, “it’s rewarding to see a concept we’ve been developing since the early 2000s now established as an international test method standard that will help accelerate innovation and raise the bar for mechanical testing worldwide.”

Profilometry-based Indentation Plastometry is a physics-based approach that extracts stress-strain curves from indentation data using an inverse finite element method. This technology is used in all of Plastometrex products: PLX-Benchtop, PLX-HotStage and PLX-Portable, each of which will be covered by the new standard.

PIP testing is valued for delivering stress-strain curves quickly, using minimal material, and without the complexity of conventional tensile testing. It is also suitable in scenarios where tensile testing is not feasible, such as with small or thin specimens, or in-service assets, broadening the scope of mechanical testing beyond what has been possible before.

www.plastometrex.com | www.astm.org

At Formnext 2025, Nanoe, headquartered in Ballainvilliers, France, debuted an ultra-high-temperature ceramic (UHTC) composite, consisting of zirconium diboride (ZrB 2) and silicon carbide (SiC). The material is available in powder form for pressing and Ceramic Injection