FILTERING NATURAL RESOURCES

AN ABUNDANCE OF WILDFIRES, DROUGHTS & ENERGY SHORTAGES

HIGHLIGHT OPPORTUNITIES FOR FILTRATION INNOVATION

AIR FILTRATION

Dualing Hazards to Health from Wildfire Smoke

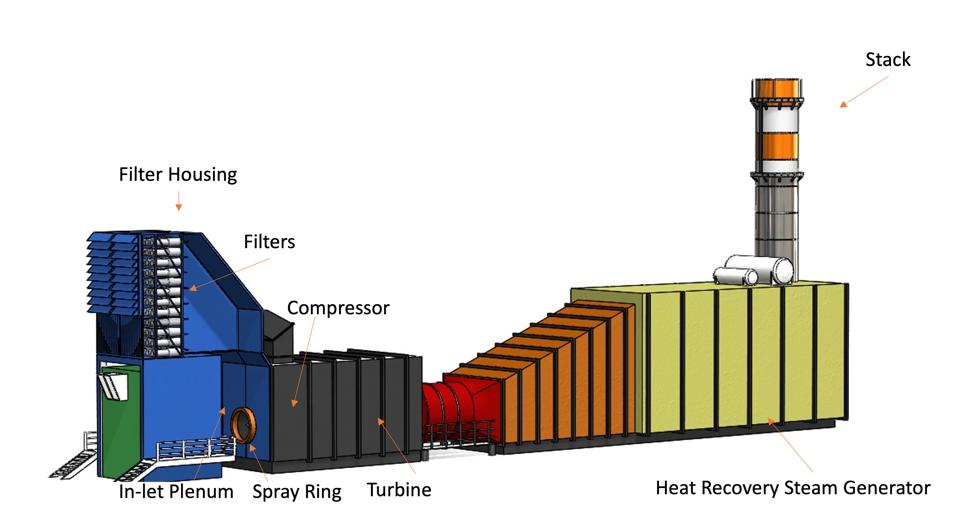

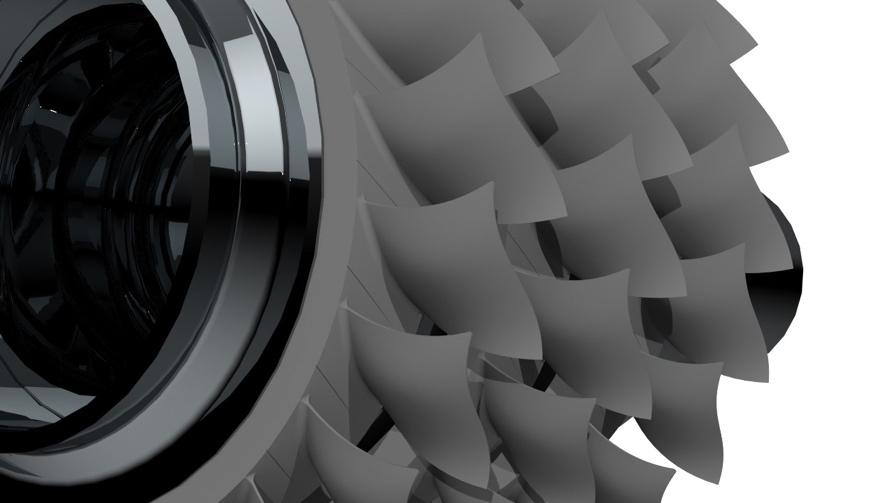

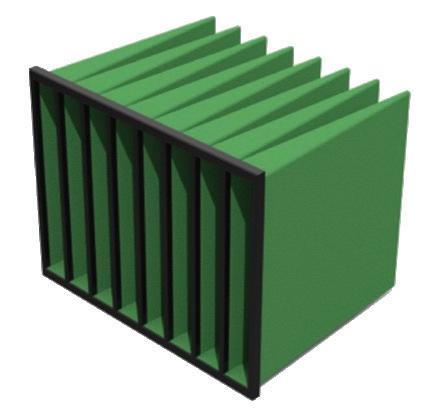

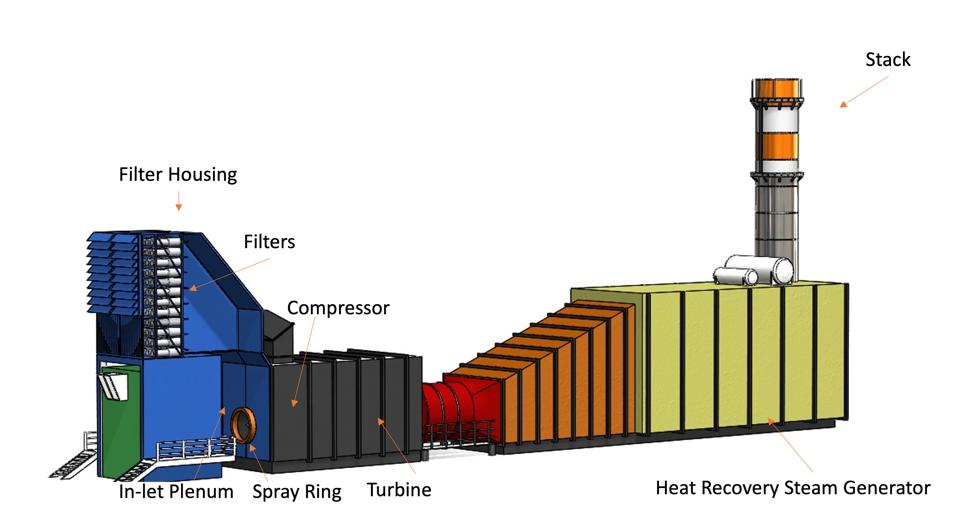

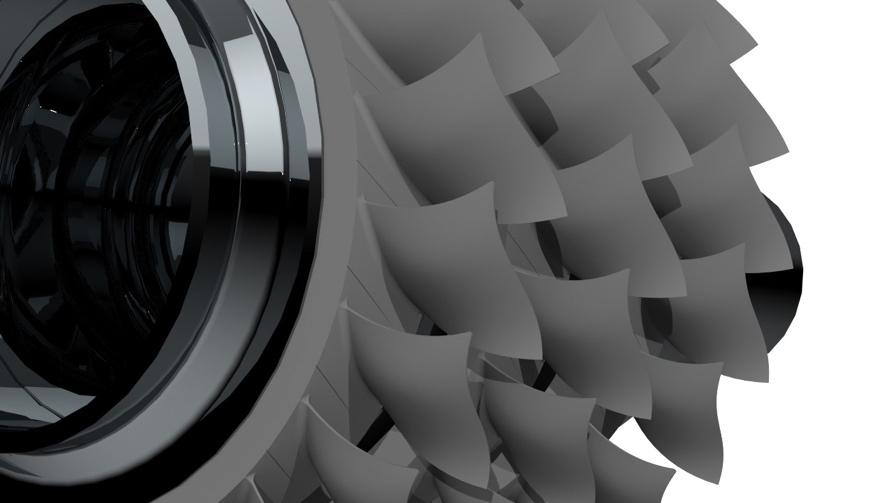

GAS TURBINE PERFORMANCE

Why Filters Cannot Fail

WATER MANAGEMENT

Extreme Decentralization Is a Viable Option

filtnews.com Issue 5 | 2023

2023

PREVIEW

FILTXPO

SHOW

TM

Creating a cleaner world.

At H&V, the sky ’s the limit for cleaner air, water and energy.

OUR FILTRATION BRANDS

NanoWave®

Technostat®

NanoWeb™

Trupor™

AlphaPerm™

OUR TECHNOLOGIES

Molecular

Cellulose

Composites

Microfiber Glass

Nanotechnology

Meltblown

Electret

Membrane

OUR INDUSTRIES

Appliance Filtration

Cleanroom

Mobility

Indoor Air Quality

Industrial Filtration

Process Liquids

Mechanical Power

Respiratory & Medical

H&V is a global leader in filtration and energy storage solutions. Our advanced materials are used in nearly every industry and touch every aspect of modern life – helping to make air healthier, water cleaner and energy greener.

For more than 200 years, H&V has been known for continuously innovating to meet the world’s needs. Today, with more than 100 scientists and 13 R&D and manufacturing facilities throughout the Americas, Europe and Asia, we’re able to serve the unique requirements of our customers efficiently, accurately and cost effectively – wherever they are.

See for yourself what makes H&V a valuable partner and a true worldwide leader at booth #401 and at hollingsworth-vose.com.

™ Visit us at FiltXPO 2023, Booth #401

hollingsworth-vose.com

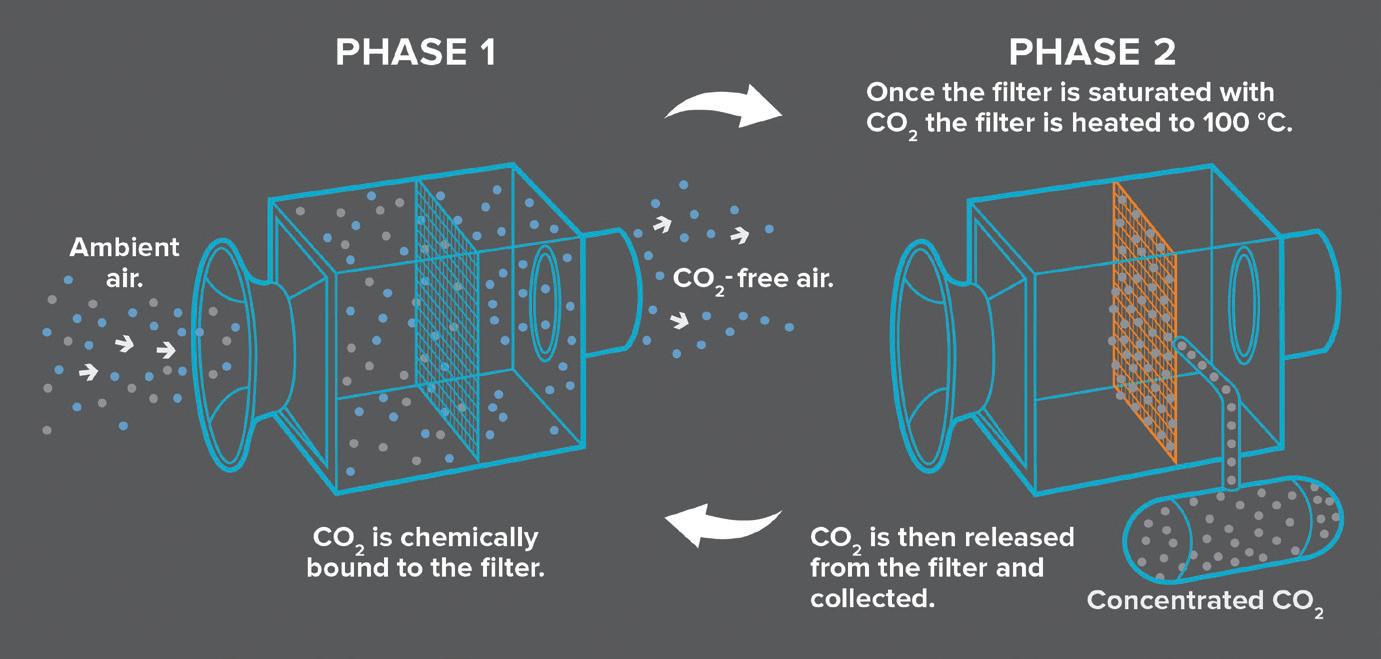

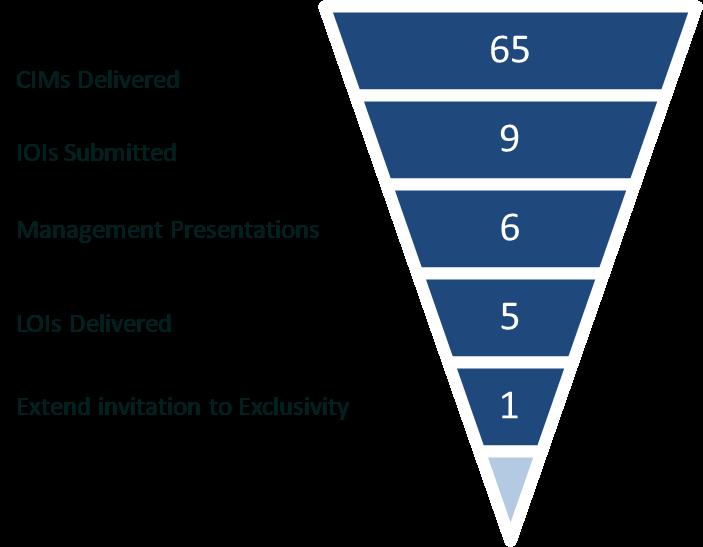

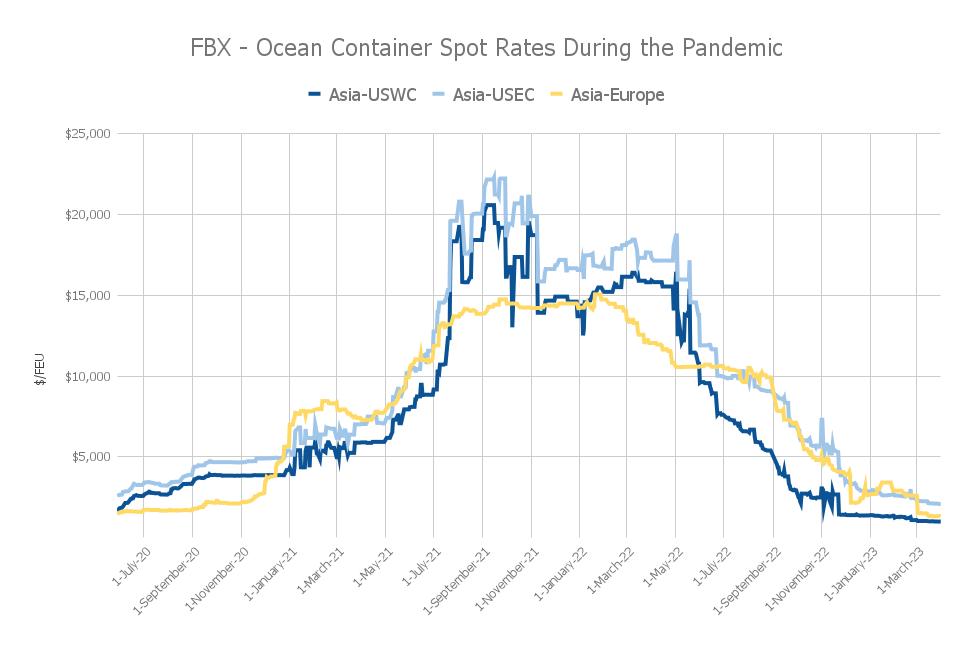

2 IFN ISSUE 5 2023 CONTENTS Corporate Profile A2Z Filtration Specialties Solution Center Showcasing Solutions for Success Berry Global Showfloor Showcase: FiltXPO™ 2023 Showcasing Solutions for Success Beverlin Specialty Tube Chase Machine & Engineering Inc. Hollingsworth & Vose JCEM Engineering Manufacturing PSE – Pleating Systems & Equipment Dualing Hazards to Your Health from Wildfire Smoke By Mark Davidson Extreme Decentralization By Will Sarni Gas Turbine Performance: Why Filters Cannot Fail By Dr. Iyad Al-Attar Biden Administration Bets the House on Direct Air Capture By Adrian Wilson, International Correspondent, IFN Show Preview: FiltXPO™ 13 12 2023 | VOL 42 | ISSUE 05 30 Viewpoint When Clean [insert resource here] Is Gone By Caryn Smith, Chief Content Officer & Publisher Tech Spotlight Parker Hannifin Starts Operating New Test Rig Tech Notes New Technology Briefs Tech Talk Back to School By Matt O’Sickey, Director of Education & Technical Affairs, INDA True Cost Expanded Program to Reduce Filtration True Costs While Increasing Supplier EBITDA By Bob McIlvaine, President, The McIlvaine Company M&A Insights Competitive M&A Sell-Side Process Generally Leads to Outlier Results for the Owner By Len LaPorta, Managing Director, Wiley Bros.-Aintree Capital, LLC Movers & Shakers Industry News & Notes 26 FEATURES 14 20 30 26 34 38 6 42 8 44 46 40 10 COLUMNS & DEPARTMENTS

iStock/Benny

34 40

Cover:

Marty/TWildlife

INDA mosickey@inda.org

+1 919.459.3748

Jennifer

Molecular Filtration Segment Manager, Western U.S./Mexico Camfil USA, Inc.

Water Foundry will@waterfoundry.com +1 720.341.7272

Custom Converting and Automation Equipment for the Filtration Industry

EQUIPMENT:

• Pleat Welding

• Ring Welding

• Laminators (Ultrasonic/ Thermal/ Adhesive)

• Slitters (Ultrasonic/ Laser/ Mechanical)

• Traverse/ Spiral winders

• Hollow fiber/ Memb rane Lines (Lab/ Pilot Scale)

• Custom Mac hines

TECHNOLOGY:

• Ultrasonics

• CO2 Lasers

• RF Welding

• Hot Air/ Wedge

• Band Sealing

• Adhesive Dispensing

• Impulse Welding

Visiting Academic Fellow School of Aerospace, Transport, and Manufacturing Cranfield University Iyad.Al-Attar@cranfield.ac.uk

CALL FOR CONTRIBUTORS

International Filtration News is actively seeking contributed technical articles from qualified industry professionals and those allied to the filtration industry. If you would like to pitch an article for publication in IFN, contact Caryn Smith at csmith@inda.org or +1 239.225.6137.

We employ our 68 years of web handling experience to benefit our customers. Contact Chase Machine today for your equipment needs!

4 IFN ISSUE 5 2023 CONTRIBUTORS | ISSUE 5 2023

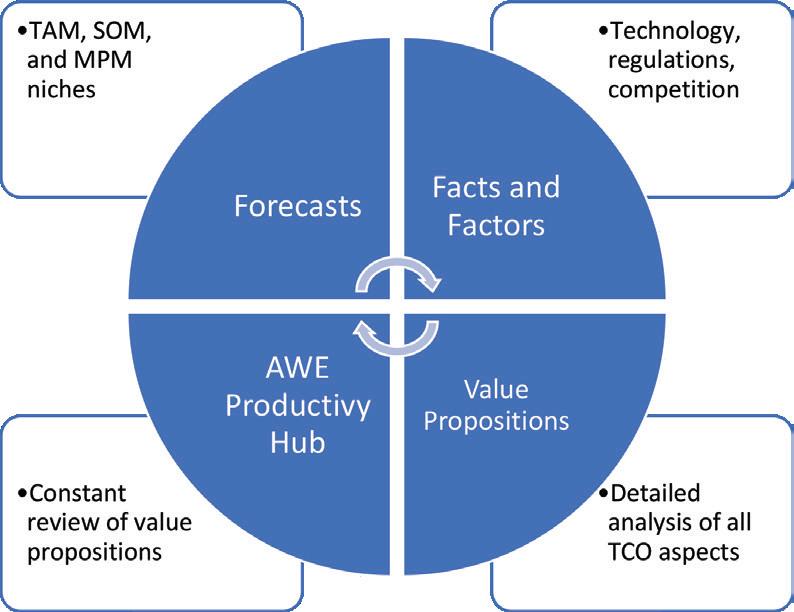

Bob McIlvaine President, The McIlvaine Company +1 847.784.0013 rmcilvaine@mcilvainecompany.com

Caryn Smith Chief Content Officer & Publisher, INDA Media csmith@inda.org

Len LaPorta Managing Director Wiley Bros.-Aintree Capital, LLC llaporta@wileybros.com

ULTRASONIC LAMINATORS HOT MELT LAMINATORS

ULTRASONIC RING WELDERS

� se\<"µ,essed\ iitJICl.�E MA CHINE & ENGINEERING, INC. ._...__. 324 Washington Street, West Warwick, RI (401} 821-8879 • www.chasemachine.com

Matt O’Sickey Director of Education & Technical Affairs,

Dr. Iyad Al-Attar

Will Sarni Founder and CEO of

Webb

Mark Davidson Marketing and Technical Materials Manager Camfil USA, Inc. mark.davidson@camfil.com

Adrian Wilson International Correspondent, IFN +44 7897.913134 adawilson@gmail.com

CSMITH@INDA.ORG +1 239.225.6137

When Clean [insert resource here] Is Gone

Do not, my friends, become addicted to water. It will take hold of you, and you will resent its absence!

—Immortan Jo, Mad Max: Fury Road

Well, that may be an outlandish headline, but it probably got your attention. The quote, though, it might have some truth in it. I love a good sci-fi movie, like Mad Max (1980) and Mad Max: Fury Road (2015). These cult classic films explored scarcity of resources we take for granted. At the time, these films were outlandish fiction. Now, they might have some resonating undertones.

Headlines surrounding the Colorado River’s historically low water supply, tell the story: “The water wars of the future are here today – Seven thirsty states, including California, are fighting over the dwindling waters of the Colorado River,” says the University of Southern California News. The article says, “The fate of the Colorado now depends on the states’ [Arizona, California, Colorado, New Mexico, Nevada, Utah and Wyoming] ability — and willingness — to agree on a plan to slash water consumption and equitably distribute what’s left.”

The amount of water on the earth is the same as it always has been, experts say. What has changed is the number of people requiring access to the resources. There is a correlation.

The top fastest growing states in 2023 according to the U.S. Census Bureau – measuring growth from 2010 to 2023 in percentages – are Utah (#1 by 23.88%), Nevada (#5 by 19.45%), Colorado (#6 by 19.25%), and Arizona (#9 by 15.45%) [Source: worldpopulationreview.com]. California is losing residents,

yes, but is still the most populated state in the U.S.

“Extreme Decentralization” (page 26) explores water scarcity looking at the American West’s water problem in a piece by Will Sarni. He is the founder/CEO of water strategy consultancy, Water Foundry, and the CEO of the Colorado River Basin Fund, the first placed-based water-focused investment fund in the U.S. that invests in exponential technology solutions to address water scarcity, quality and equitable access.

My thoughts go to filtration. While nearly 70 percent of the world is covered by water, only 2.5 percent of it is fresh. The rest is saline and ocean-based. Even then, just 1 percent of our freshwater is easily accessible. Desalination looks attractive as a filtration solution, but isn’t without its own consequences.

Filtration experts – you are smarter than me; feel free to chime in. Email your thoughts on water to csmith@inda.org! Your letter may run in our new “Letters to the Editor.”

Also in this issue is an interesting article on air filtration (page 20) by Mark Davidson on filtering contamination of wildfires. And, on page 30, Dr. Iyad Al-Attar explores “Gas Turbine Performance: Why Filters Cannot Fail.” I hope you enjoy the read!

Caryn Smith

Chief Content Officer & Publisher, INDA Media, IFN

International Filtration News Editorial Advisory Board

R. Vijayakumar, Ph.D., Chair

AERFIL

Tel: +1 315-506-6883

Email: vijay@aerfil.com

Rahul Bharadwaj, Ph.D.

Lydall Performance Materials

Tel: +1 603-953-6318

Email: rbharadwaj@lydall.com

Tom Justice, CAFS, NCT

ZENE, LLC Filtration

Tel: 757-378-3857

Email: justfilter@yahoo.com

James J. Joseph

Joseph Marketing

Tel/Fax: +1 757-565-1549

Emai: josephmarketing120@gmail.com

Wenping Li, Ph.D.

Agriltech Research Company

Tel: +1 337-421-6345

Email: wenpingl@agrilectric.com

Ernest Mayer, Ph.D.

E. Mayer Filtration Consulting, LLC

Tel: +1 302-981-8060

Email: ernestmayer6@gmail.com

Robert W. McIlvaine

The McIlvaine Company

Tel: +1 847-784-0013

Email: rmcilvaine@mcilvainecompany.com

Thad Ptak, Ph.D.

TJ Ptak & Associates

Tel: +1 414-514-8937

Email: thadptak@hotmail.com

INDA, Association of the Nonwoven Fabrics Industry. +1 919.459.3700 info@filtnews.com | www.filtnews.com News & Press Releases to IFNNews@inda.media

International Filtration News covers the topics and technologies that will shape the future of filtration and separation. Using subject matter experts from all parts of the industry, IFN is the leading source for the dialogues, debates and innovations across the full spectrum of filtration and separation applications and processes.

If you would like to utilize your expertise to help shape the content in the IFN , consider applying for the IFN Editorial Advisory Board. We welcome participation through input on trends and innovations, new story ideas and overall thought leadership. This is a collaborative board that meets quarterly to discuss the state of the industry. Send an email to Caryn Smith at csmith@inda.org for consideration.

6 IFN ISSUE 5 2023

VIEWPOINT CONTENT | EDITORIAL CHIEF CONTENT OFFICER Caryn Smith Driven By Design LLC csmith@inda.org | +1 239.225.6137 EDITORIAL & PRODUCTION MANAGER Ken Norberg ken@filtnews.com | +1 202.681.2022 ART DIRECTOR Julie Flynn INTERNATIONAL CORRESPONDENT Adrian Wilson ADVERTISING | SALES PUBLISHER Driven By Design LLC advertising@inda.media | +1 239.225.6137 ADVERTISING COORDINATOR Vickie Smead vsmead@inda.org +1 919 459 3700 x 3720 AUDIENCE | CIRCULATION CIRCULATION MANAGER inda@stamats.com | +1 800.553.8878 INTERNATIONAL FILTRATION NEWS (ISSN: 1078-4136x), is published bi-monthly by INDA, Association of the Nonwoven Fabrics Industry, +1 919.459.3700. Subscription price is $125 per year for non-U.S. subscribers. Periodicals postage paid at Novi, MI, and additional mailing offices. POSTMASTER: Please send address changes to International Filtration News, PO Box 158 Cedar Rapids IA 52406-0158 USA. International Filtration News is published by INDA Media, the B2B publishing arm of

MISSION

TM

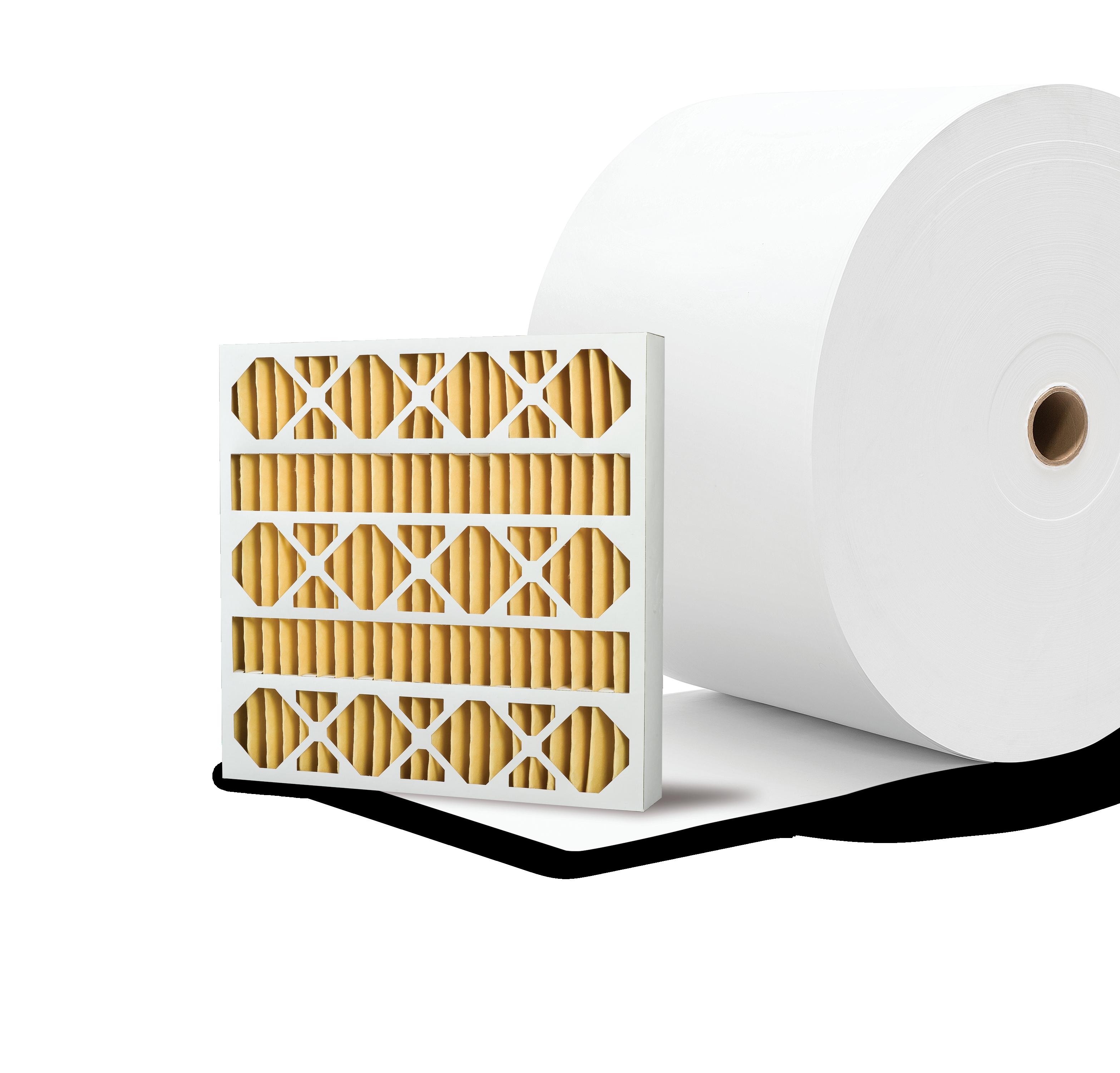

GESSNER PROVIDES FILTRATION SOLUTIONS FOR THE MOST COMPLEX CUSTOMER CHALLENGES AND TAKES PRIDE IN ITS MISSION TO PROTECT PEOPLE, MACHINERIES, AND THE ENVIRONMENT

Leveraging the combined knowhow and expertise of former SWM & Neenah after the merger, we now present a broader portfolio of filtration solutions for diverse applications under the GESSNER brand.

Our highly engineered papers, films, nets, nonwovens, cores, tubes, and machined parts are designed and manufactured for a variety of industries, such as Transportation Filtration, Water Filtration, Air Filtration, Industrial Processes, and Life Science.

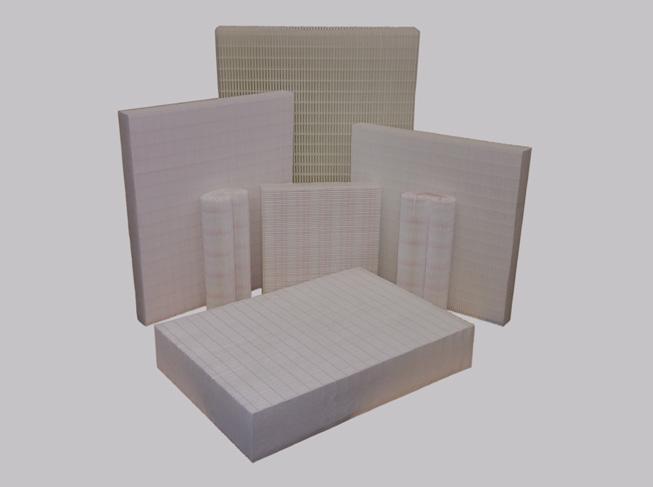

FILTER MEDIA

PLEAT SUPPORT

FEED SPACER

October 10th - 12th, 2023

www.gessner-filtration.com

gessner@mativ.com

CORES, TUBES & SLEEVES

• Delpore™, NeenahPure®, NeenahGuard® , & NeenahSilence® Meltblown Nonwoven

• Delpore™ Thermobond Nonwoven

• Alphastar™ Triboelectric Nonwoven

• Cranemat® Synthetic Wetlaid Nonwoven

• Craneglas® Glass Wetlaid Nonwoven

• GESSNER® Cellulose Wetlaid & Nonwoven Composites

• Naltex™ Extruded Diamond Nettings

• Conwed™ Extruded Square Nettings

• Delnet™ Apertured Films

• Naltex™ Extruded Diamond Nettings

• Conwed™ Rigid Tubes & Cages

• Naltex™ Extruded Sleeves

• Coretec™ Tubing

• Coretec™ Machined Parts

our team at FiltXPO in Chicago, IL

Meet

Booth #208

Parker Hannifin Starts Operating New Test Rig

A Major Milestone for Fuel Cell Technology

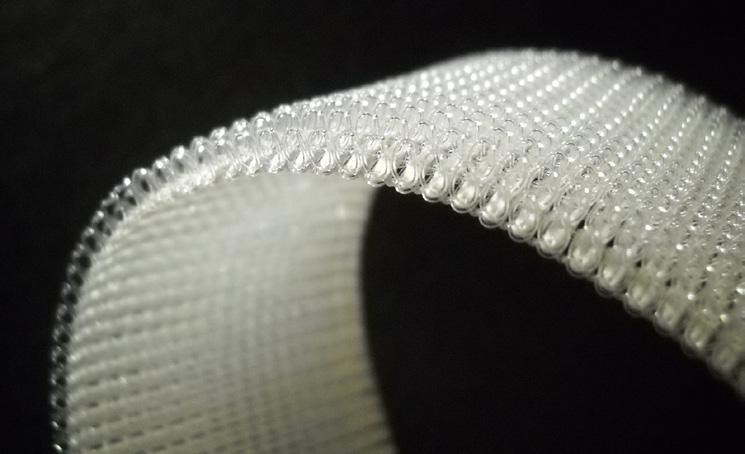

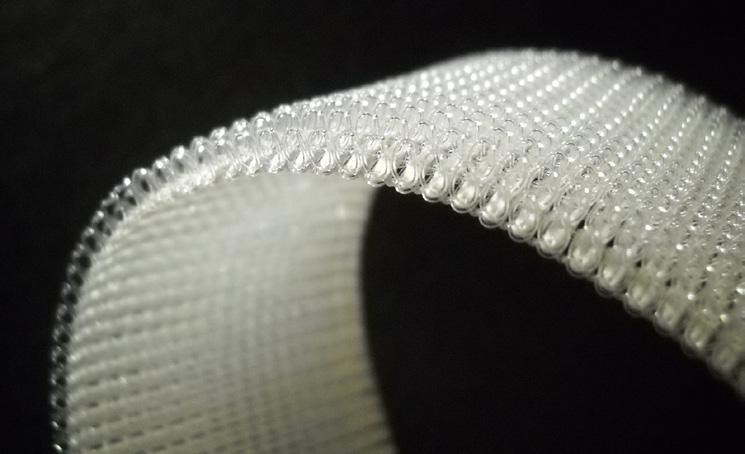

Parker Hannifin’s filtration business has reached a major milestone on the journey towards mass production of hollow fiber membrane technology for fuel cell humidification applications, a vital step towards reducing carbon emissions. By enabling optimal moisture levels, hollow fiber membrane technology allows fuel cells to last longer and to perform more efficiently and reliably. It supports the transition from fossil fuels, accelerating the shift to fuel cell electrical vehicles in the next five years.

Burkhard Hartmann, R&D Officer at Parker’s Engine Mobile Filtration Europe (EMFE) Division, said: “The results speak for themselves: This has been an outstanding collaboration with the Fraunhofer Institute. It moves us all towards better, more efficient, more reliable fuel cell electrical vehicles, a vital step towards a cleaner, better tomorrow.”

Dr. Gunther Kolb, representative from the Fraunhofer Institute for Microengineering and Microsystems, said: “Fuel cell technology is key to reduce emissions worldwide. The

Dr.

Dr.

for fuel cell humidification applications. The partnership was expected to run for up to two years and cover efficiency evaluations of existing Parker-designed fuel cell humidifiers; development and use of a specialized test rig; and performance simulations to identify the effects of fiber length, diameter and permeability on the humidifiers.

Parker first introduced membrane fibers for gas separation in the 1980s and is now using this knowledge to develop the next generation of fuel cell humidifiers.

Parker Hannifin is a Fortune 250 global leader in motion and control technologies. For more than a century, the company has been enabling engineering breakthroughs that lead to a better tomorrow. Learn more at www. parker.com.

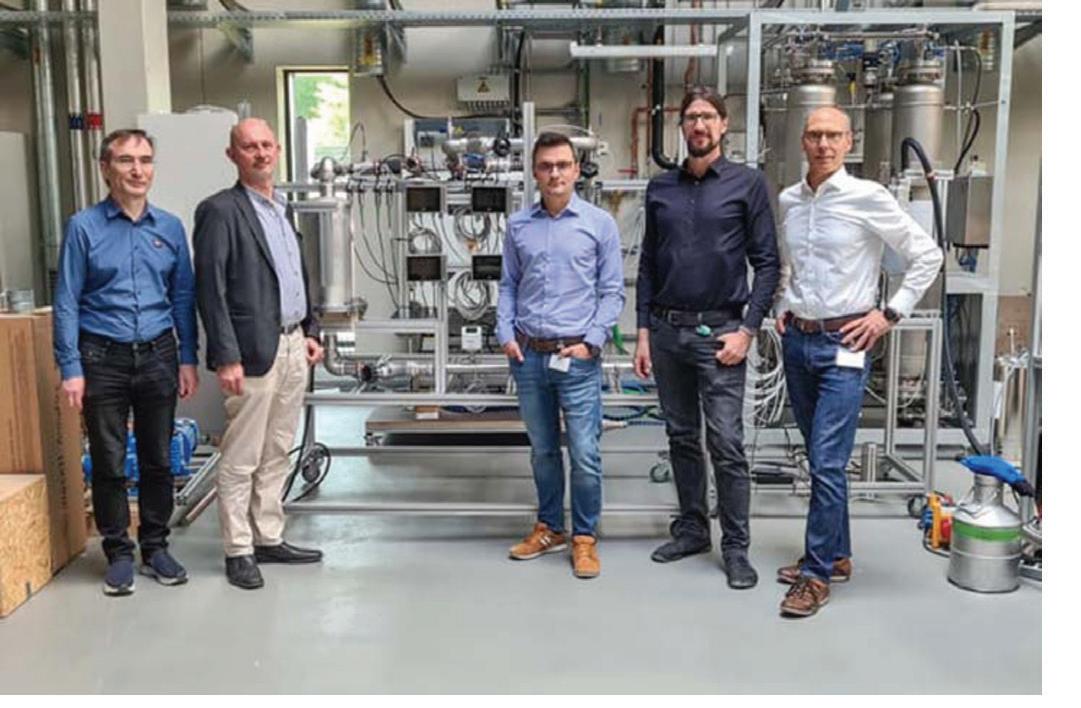

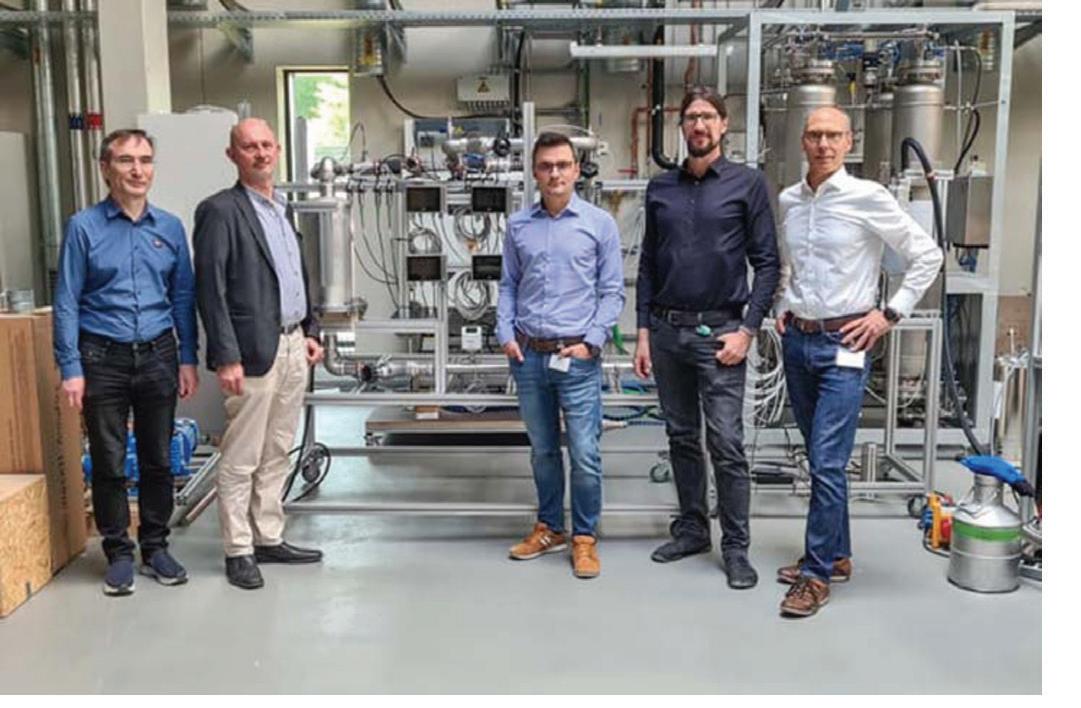

Parker announced the successful completion of the specialized test rig which is to validate products by Parker OEM (Original Equipment Manufacturer) customers. This new technology enables Parker to test the membrane technology in ways that are much more advanced and aids in developing robust system solutions for fuel cells. It was produced in partnership with the Fraunhofer Institute for Microengineering and Microsystems (IMM), a Germany-based non-profit for scientific research.

partners are confident that the hollow fiber membrane technology will be further improved, the service life of the fuel cell humidifiers will be extended, and their efficiency will be increased for the customers.”

It was last year that Parker Hannifin’s Engine Mobile Filtration EMEA Division (EMFE) announced they were partnering with Germany’s Fraunhofer Institute for Microengineering and Microsystems (IMM) to further develop and test new proprietary hollow fiber membrane technology designed

The Fraunhofer Gesellschaft, based in Germany, is the world’s leading applied research organization. Prioritizing key future-relevant technologies and commercializing its findings in business and industry, it plays a major role in the innovation process. A trailblazer and trendsetter in innovative developments and research excellence, it is helping shape our society and our future. Founded in 1949, it currently operates 76 institutes and research units throughout Germany. Over 30,000 employees, predominantly scientists and engineers, work with an annual research budget of €2.9 billion. Fraunhofer generates €2.5 billion of this from contract research.

parker.com

www.fraunhofer.de/en

For details on how to submit your company’s technology for consideration as a “Technology Spotlight” in IFN , contact Ken Norberg at ken@filtnews.com or +1 202.681.2022.

8 IFN ISSUE 5 202 3

SPOTLIGHT TECH

t Parker Hannifin’s test rig and the development team, left to right:

Valerii Danilov, Fraunhofer Institute, Simulations;

Gunther Kolb, Fraunhofer Institute, Head of Business Division Energy; Robert Jozsa, Parker EMFE, Product Manager Alternative Technology; Dr. Jonas Schramm, Fraunhofer, Hydrogen Technology Group; and Burkhard Hartmann, Parker EMFE R&D Stuttgart Officer. Parker Hannifin

Put your trust in us Filtration Products Increased demand for better indoor air quality requires highly efficient solutions. For unmatched quality and expertise, choose the leader in nonwoven technology–Kimberly-Clark Professional™ Find out more at KCProfessional.com ®/™ Trademarks of Kimberly-Clark Worldwide, Inc. or its affiliates. Marques de commerce de Kimberly-Clark Worldwide, Inc. ou de ses sociétés affiliées. © KCWW. T23T88 5/23 Visit us at the You can sample our filter media material at Booth 220.

NOTES TECH

Aquaporin and Singapore’s PUB Work on Biomimetic Low-Energy RO Membrane Demo

Danish company Aquaporin A/S, an innovative water technology company dedicated to rethinking water filtration with biotechnology, announced that Aquaporin and PUB, Singapore’s National Water Agency, are partnering to develop the world’s first lowenergy Aquaporin Inside ® membrane demonstration for NEWater.

A total of 504 CLEAR Brackish Water Reverse Osmosis (BWRO) modules from Aquaporin will be implemented at one of PUB’s NEWater production facilities, with a capacity of 1.7 million imperial gallons per day. This will demonstrate the Aquaporin Inside® technology’s ability to save energy and validate the technology for implementation in PUB’s future membrane replacement projects.

The Aquaporin Inside® CLEAR products feature the world’s first and only biomimetic BWRO membranes. The Aquaporin Inside® technology inspires itself from nature’s way of filtering water by incorporating biotech-based protein water channels into a filtration membrane. www.aquaporin.com

New Melt-Blown Polyester Depth Filter Cartridges from Eaton

Eaton’s LOFTOP™ and LOFTREX M™ depth filter cartridges ensure the safe and efficient filtration of demanding media such as process chemicals, fine chemicals, acids, alkalis and solvents, as well as paints, lacquers and resins. The filtration division of the energy management company Eaton is now expanding its range to include filter cartridges that use polyester as the filter material for particularly high chemical resistance. The new melt-blown polyester depth filter cartridges are not only suitable for a variety of aggressive media, but also provide an alternative to filter cartridges that are bonded with phenolic resin. The entire LOFTOP and LOFTREX M filter cartridge range is now available with polypropylene (PP), polyamide 6.6 (PA) or polyester (PES) filter material.

NUS Scientists Develop a New Class of Artificial Water Channels for More Efficient Industrial Water Purification

A team led by scientists from the National University of Singapore’s (NUS) Department of Biological Sciences in collaboration with the French Centre for Scientific Research (CNRS) has successfully synthesized a special protein-mimic that can self-assemble into a pore structure. When incorporated into a lipid membrane, the pores permit selective transport of water across the membrane while rejecting salt (ions). These proteinmimics, known as “oligourea foldamers,” represent an entirely new class of artificial water channels (AWC) that can be used to improve the energyefficiency of current methods of industrial water purification.

Current methods of water purification involve the use of reverse osmosis and membrane distillation technologies. Reverse osmosis, however, is a highly energy-intensive process as high pressures are needed to pass seawater or wastewater through a series of semi-permeable membranes to remove salts and other pollutants. In light of climate change and the growing demand for fresh water, there is an impetus to develop more energy-efficient, water-selective membranes for large-scale desalination purposes. This invention represents an excellent contribution to these efforts. The relatively high water permeability of the pores formed by these oligourea foldamers suggests that overall energy requirement for water purification can potentially be reduced. www.nus.edu.sg

The filter cartridges are available in different lengths and with all common adapter configurations and sealing materials so that they can be used safely in a wide range of applications and filter housings. LOFTOP depth filter cartridges offer absolute retention rates from 0.50 to 120 μm with a retention efficiency of 99.98%. LOFTREX M depth filter cartridges offer nominal retention rates from 1 to 150 μm with a retention efficiency of 95%. www.eaton.com/filtration

10 IFN ISSUE 5 202 3

p A team of scientists from NUS comprising (left to right) Prof. Prakash Kumar, Prof. Manjunatha Kini, Dr. Li Jianwei and Dr. Pannaga Krishnamurthy, has developed a new class of artificial water channels for more efficient industrial water purification. NUSNews

Aquaporin membrane

FreshAir Announces Smart Sensors That Detect Mold Conditions in Military Barracks

FreshAir, an industry leader in the development of sensors to detect and alert for hazardous chemicals, announced new Smart Sensors that can track conditions that allow mold to grow, as well as monitor for and detect tobacco and marijuana smoking. The system provides real-time alerts to building and operations managers, enabling corrective action before mold growth, significantly improving living conditions in military barracks and housing. Using FreshAir’s devices will result in cleaner and safer military barracks and housing, as well as reduce long-term smoking-related medical costs.

FreshAir’s Wi-Fi devices provide real-time monitoring and send alerts of mold conditions and smoking incidents to clients with scientific proof, including detailed, time-stamped charts. The devices detect specific components of tobacco and marijuana smoke with patented, polymer sensor technology (PolySens™), the only technology that can monitor for and specifically detect tobacco smoke and marijuana smoke. FreshAir devices are used at hundreds of locations across the United States, including apartments, hotels, housing authorities, schools and other multi-unit, professionally managed properties. The new patented mold sensor provides an effective way for proactively monitoring

spaces, enabling building operators to address conditions before mold growth can occur.

FreshAir’s detection devices are easy to install; they plug into outlets and are secured with tamper-proof screws. The WiFi-enabled detection devices connect to building networks to communicate 24/7 with FreshAir’s monitoring platform. Each device can monitor up to 500 square feet of open space.

When potential mold conditions or smoking is detected in a monitored space, FreshAir sends users an immediate alert via email, computer desktop, and/or mobile phone push notification. Smoking alerts come with timestamped reports of the incident in the monitored space, providing the scientific proof needed to enforce no-smoking policies. FreshAir’s Mobile App and online portal allow facilities teams to access alert history, stay updated on device information, and log additional evidence of smoking to be archived in the account’s alert history. www.freshairsensor.com

ISSUE 5 2023 FILTNEWS.COM 11

AVAILABLE NOW! High-performing filtration solutions made in the U.S. specialties@berryglobal.com | 1.877.662.3779 | berryglobal.com Contact your Berry sales rep or scan the code for product details, specs, and samples. WWW.EXPAC.COM (909) 481-8800 Developers of X-Mesh® for filters. U.S. Patent 8,696,781 MicroForm® micromesh for specialized applications. Three strategically located U.S.-based plants: California, Georgia, Texas. State-of-the-art tooling facilities with an onsite Engineering & Design Team. Customized specifications for your needs. YOUR PARTNER FOR HEALTHY AIR QUALITY Employee-owned and North America’s largest manufacturer of light gauge expanded metals for air filters. BOOTH #309 WALLNER EXPAC ENGINEERS INNOVATORS MANUFACTURERS C M Y CM MY CY CMY K ai169273452523_2023 Filtration News- QTR PG Vertical Ad-SEP-OCT APPROVED.pdf 1 8/22/2023 1:02:06 PM

and Housing

p FreshAir smart sensors that detect mold conditions.

The Largest Range of End Caps & Components

A2Z Filtration Specialities manufactures a large variety of end caps, components and parts to suit the assembly of all types of filters. A2Z supplies products in sheet metal duly stamped, machined, cast as well as injection molded parts. With a range of over 6500-part numbers, we offer the broadest range of end caps on earth. Only the latest version of SolidWorks is used to design all tooling. The ability to manufacture our own tooling with HAAS CNC machines allows us to quickly turn around parts from concept to finished product in less than three weeks.

A2Z Supplies

• End caps – stamped, spun and fabricated.

• Expanded metal is available as cut-tosize sheets as per the specification of the customers or in coils in galvanized steel, stainless steel and aluminum.

• Injection molded parts can be supplied in nylon (any grade), ABS, polypropylene silicon, polyester and polycarbonate materials. The above components can be supplied in various grades including FDA-approved.

• Machined parts in materials such as steel, stainless steel, aluminum, Brass and nylon.

• Synthetic rubber grommets, gaskets, sponge rubber air filter molded sealing rings (endless/jointless). Available in EPDM, natural rubber, and silicone among other materials as per requirement.

• Weld mesh cages of any size or configuration.

• Deep drawn housings and threaded top cover plates for spin-on filters.

• Perforated sheets (tin, mild steel, zinc plated or paper board)

• Springs

The picture top right showcases over 50,000 square feet of area used for storage of over 6,500 tools and dies.

Infrastructure for Quick Turnaround of Your Needs

1. Over 11 solid workstations for design

2. A tool room is spread over 75,000 square feet and consists of seven Haas CNC machines, over 14 mechanical lathes, surface grinders, milling machines. At any given time A2Z carries over 500 tons of various grades and thicknesses of stainless steel and steel materials.

3. We have spot welding, projection welding, MIG welding, TIG welding,

capacitor discharge projection welding and stud welding machines.

4. We have over 60 pneumatic power presses, hydraulic presses, double action presses with the range from 10 tons to 250 tons spread over 100,000 square feet. We can offer a quick turnaround of your orders.

5. We also have a turret punch press and CNC hydraulic press brake machines to manufacture a large range of frames and punched parts.

6. Four dedicated high-speed automated expanded metal lines to produce expanded metal.

7. State-of-the-art inspection system such as Carl Zeiss – CMM – Mitutoyo Contracer and various measuring instruments from Mitutoyo.

A2Z is the go-to supplier for all your component needs. A2Z also has the ability to provide supplies through thirdparty warehouses in North America.

For further information, please visit our website – www.a2zfiltration.com or contact us at info@a2zfiltration.com

12 IFN ISSUE 5 202 3

ADVERTORIAL | CORPORATE PROFILE

p HAAS CNC Machines for tooling.

p Over 50,000 square feet of area used for storage of over 6,500 tools and dies.

q With a range of over 6,500 part numbers.

Innovation for the World. Solutions for You.

At Berry, we leverage our unmatched global capabilities, sustainability leadership, and deep innovation expertise to serve customers of all sizes around the world. Harnessing the strength in our diversity and industry leading talent of 47,000+ global employees across more than 300+ locations, we partner with customers to develop, design, and manufacture innovative products with an eye toward the circular economy. The challenges we solve and the innovations we pioneer benefit our customers at every stage of their journey.

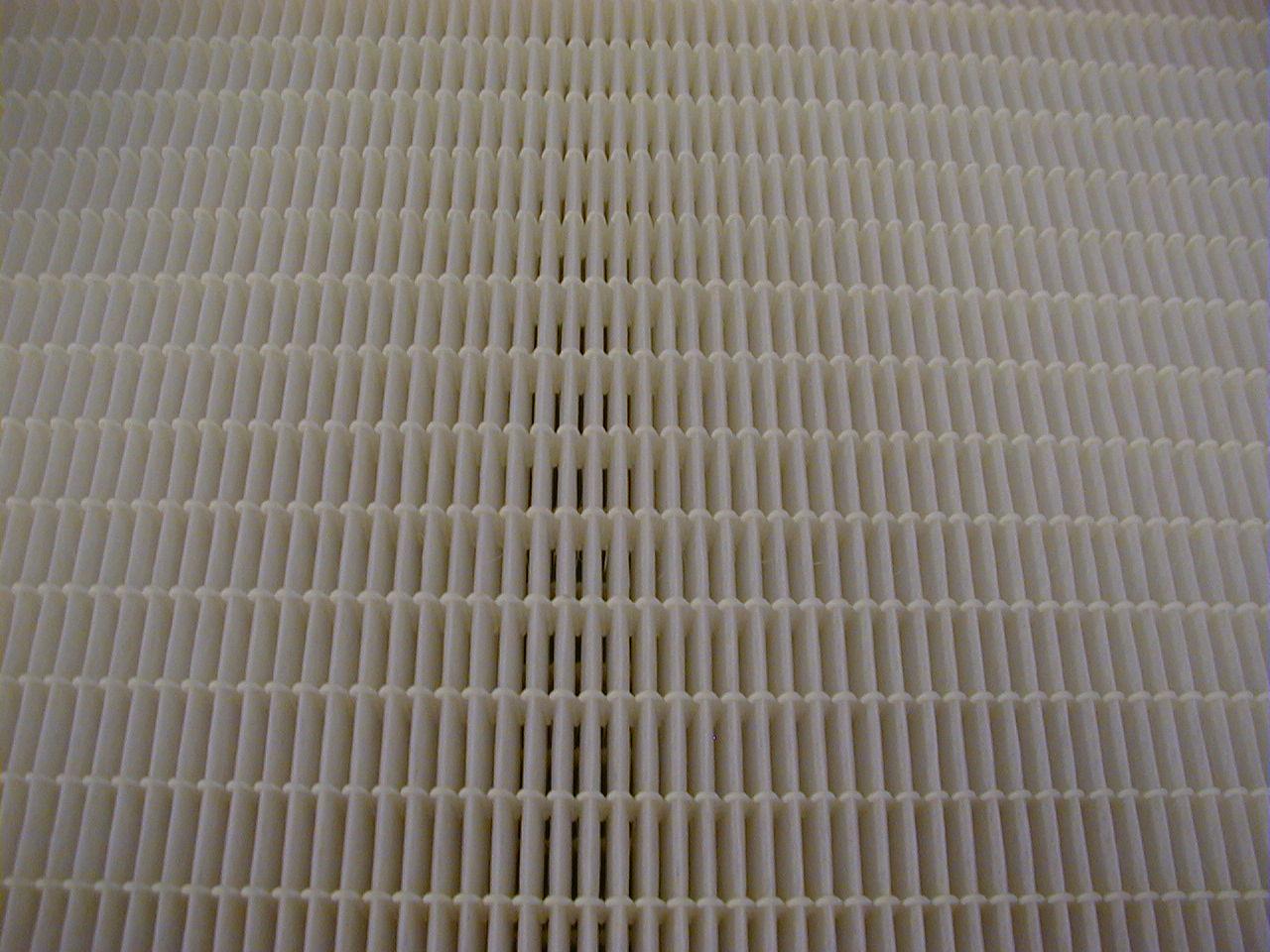

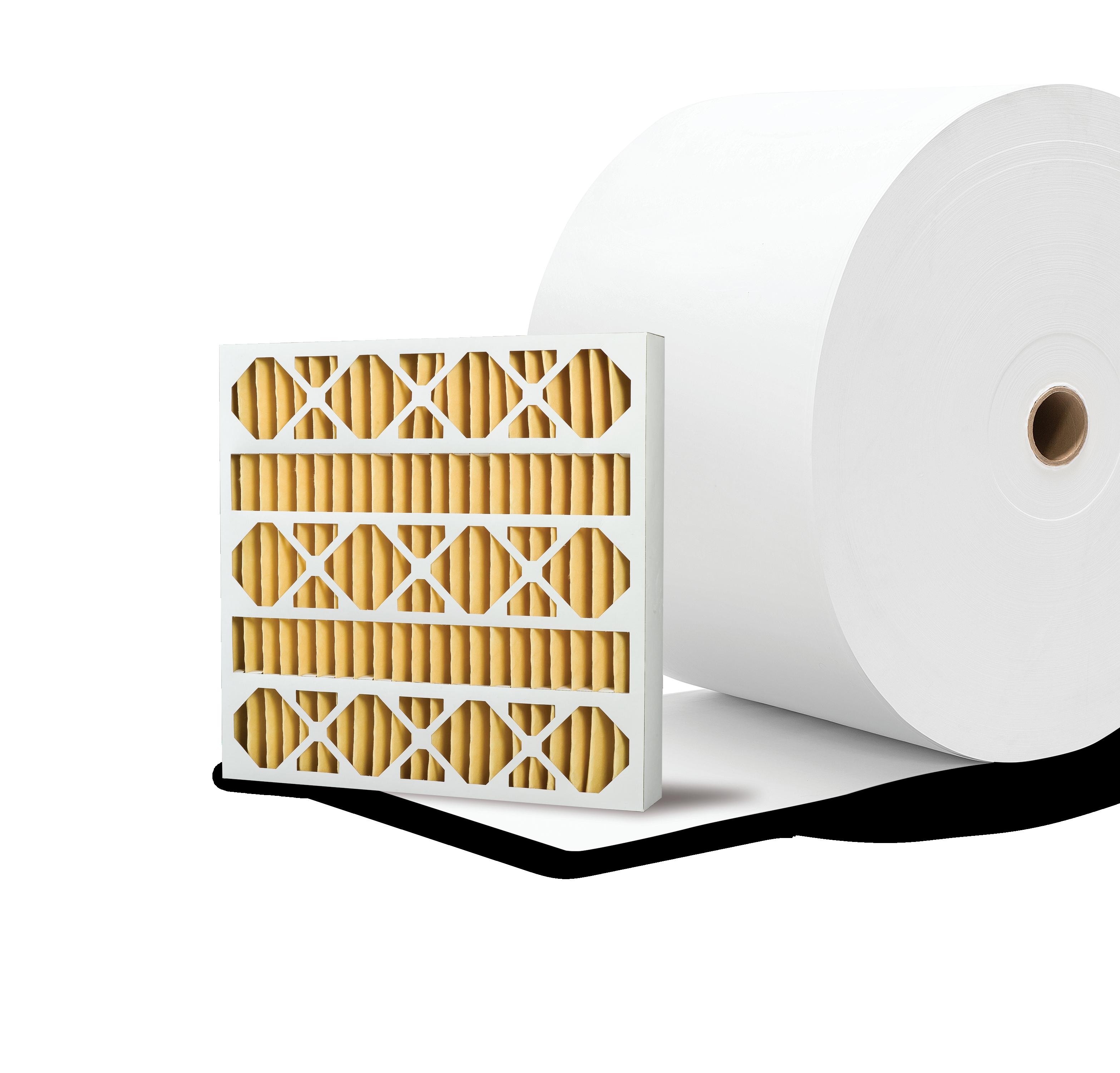

With over 35 years of experience manufacturing filtration media, Berry Global’s products have become the industry standard in the pleat support and filter layers for air, liquid, and gas applications. Berry Global’s proprietary technologies deliver unique material solutions for challenging customer needs. Whether using our unique REEMAY® spunbond PET technology in vaccine manufacturing, or TYPAR® spunbond PP nonwovens in water filtration to create safe drinking conditions, customers trust our proven filtration solutions.

Our filtration capabilities encompass a wide range of specialty materials, process technologies, and state-of-the-art innovation centers.

• Reemay®

• Meltex™

• Typar®

• Superpleat

• Air Filtration

• Industrial Filtration

• Water Filtration

• Automotive Filtration

• Food & Beverage Filtration

specialties@berryglobal.com

ISSUE 5 202 3 FILTNEWS.COM 13

ADVERTORIAL | SOLUTION CENTER: WWW.BERRYGLOBAL.COM

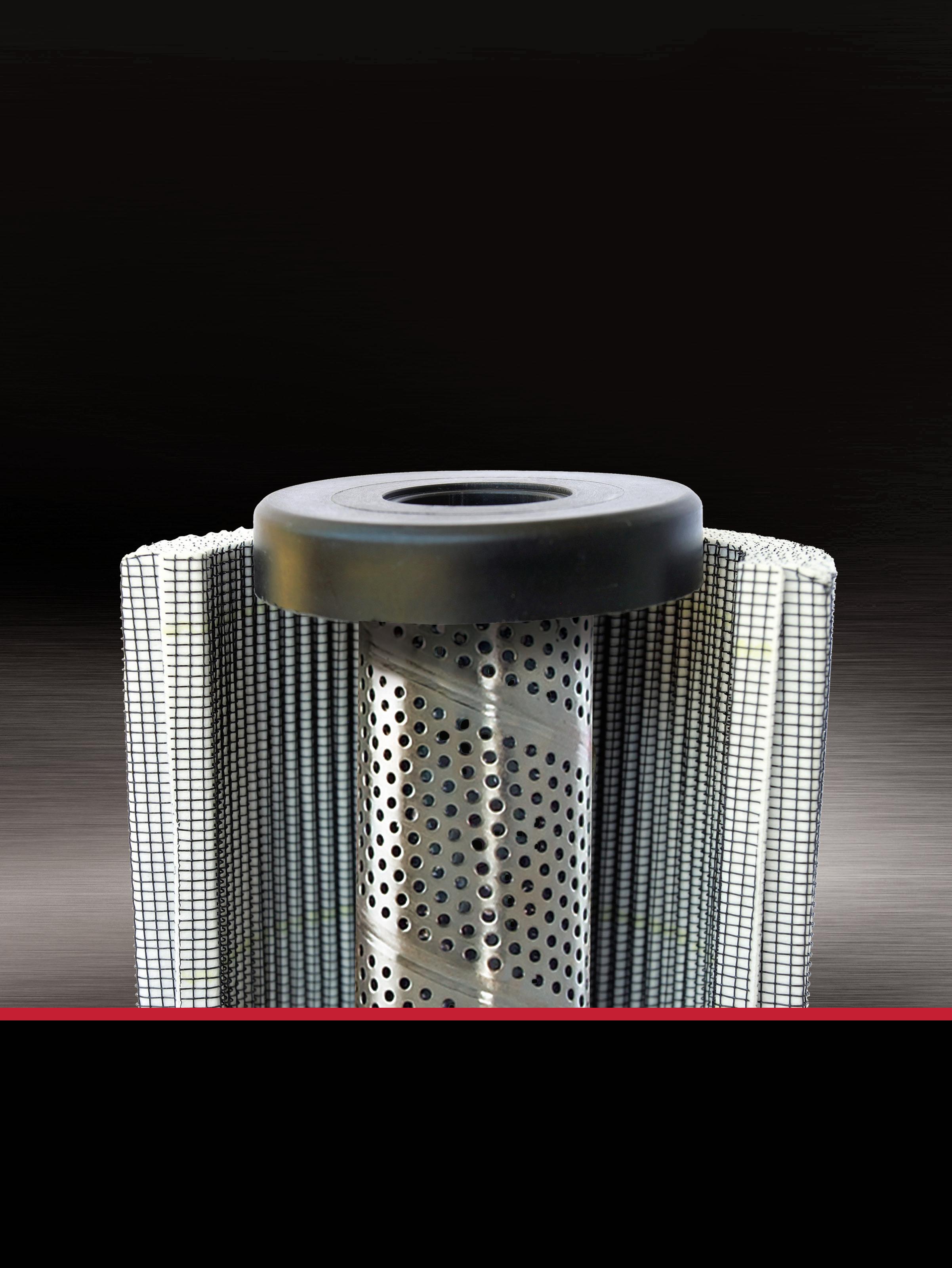

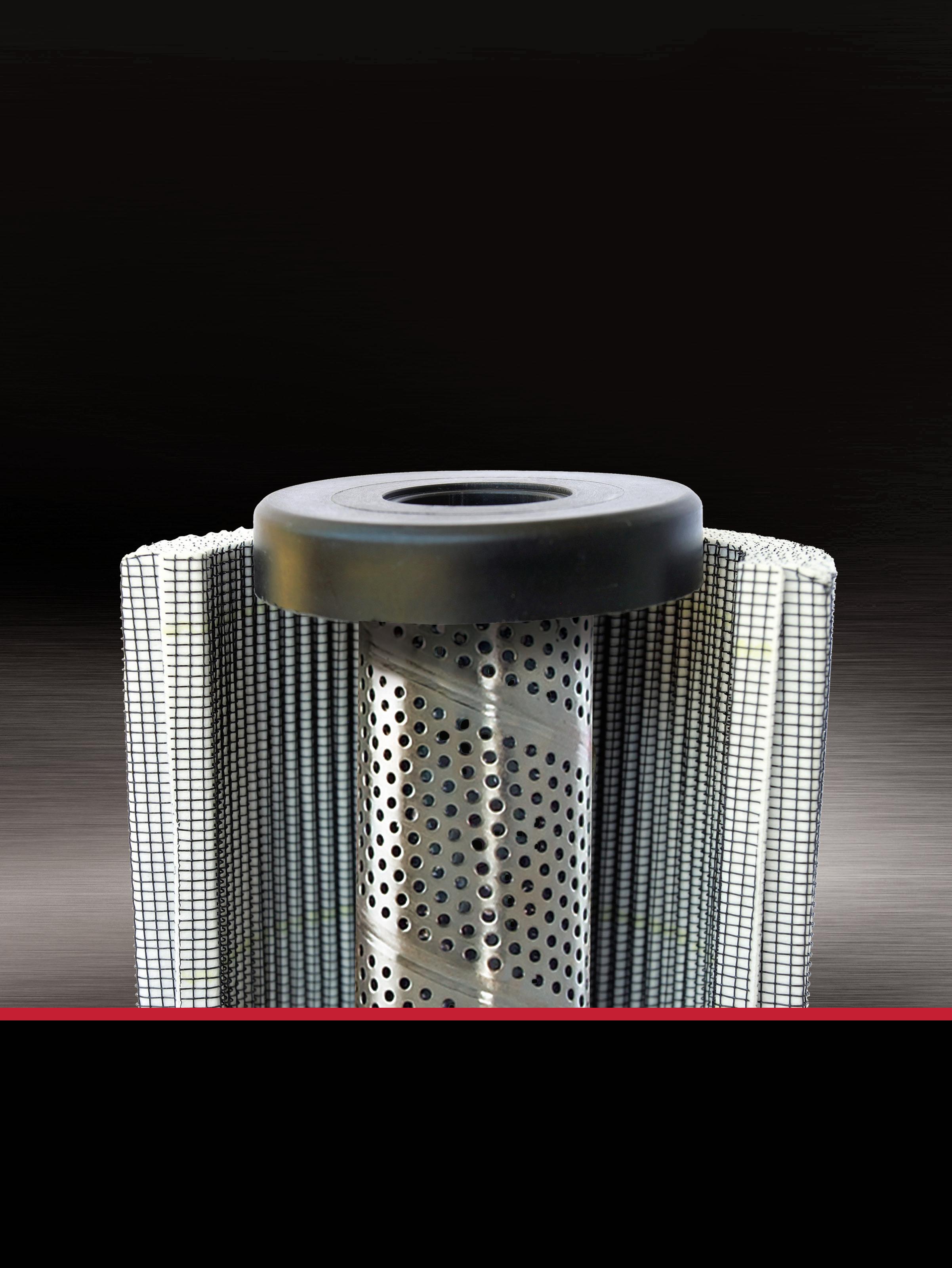

Beverlin’s Custom Core Solutions

Beverlin’s focus is producing welded perforated cores and welded assemblies for filter manufactures. We are the recognized leader and have been since 1976.

We have a global reach and provide many industries including Aerospace, Oil & Gas, Industrial, Power & Energy, Nuclear, Defense, Medical and Food & Beverage for the most demanding and critical applications. We take great pride in being the core that our customers build upon.

Benefits of a Welded Core

• The most obvious advantage is strength, a welded core is stronger for demanding high pressure applications. We would argue that if it is a critical or demanding application where failure is truly NOT an option – a welded core is the best solution.

• Ability to use thicker material for demanding applications up to 1/8’’ thick and even .157’’ in some cases.

• Welded cores are not made from pre-plated materials like other cores.

With pre-plated materials the holes, seam and edges are not plated.

• Welded cores are “flush” so there are no raised areas, or raised seams. The flush seam allows the filter media to reach its peak potential.

• DESIGN FREEDOM – Not only are welded cores stronger and able to be thicker – there are many other advantages that most people have not considered.

> You can have any diameter, any length, any material type (steel, stainless, exotic alloys, aluminum or Titanium).

> You can pick any perforated pattern and add feature holes.

> You can have the seam style you want (straight or spiral).

> You can incorporate end margins (non-perforated areas).

> You can incorporate a counterbore.

> With a welded core you can use any surface treatment you desire vs. preplating of coil.

> With a welded core, we can produce any shape you need (round, triangle, rectangle, oval, etc.).

> Welded cores provide more design freedom so you can provide a more reliable and better performing core to better serve your customers and provide better solutions.

> With the design freedom of a welded core it can be made “unique” or custom making it difficult for someone else to recreate it. Your design could even be patented. That way the OEM can lock in their hard work and retain the ongoing sales for the long haul. That is huge!

* Remember ‘’if your part looks the same as everyone else’s, you will be competing with everyone else.’’

Showcase for FiltXPO

Aside from our extensive standard offerings we will also be showcasing four categories.

• Our large diameter core offerings – more and more we are seeing the need for larger diameter cores that are 10’’, 12’’ and 14’’ and more.

• Examples of welded assemblies – we have been providing our customers with 100% complete welded assemblies including the core, CNC components, sleeves, posts, flanges and more which allows them to focus on a clean room type assembly.

• A new patented “seamless” technology with exceptionally tight tolerances that outperforms stainless steels in its mechanical properties and in corrosion while also providing holes as small as 80 microns – it will be a game changer for some applications.

• Offerings that include perforated cores and assemblies that are made from exotic super austenitic alloys like Hastelloy, Duplex, Super Duplex, Nickel 625, Nickel 825 and Titanium.

www.beverlin.com

14 IFN ISSUE 5 202 3

ADVERTORIAL | SHOWFLOOR SHOWCASE: FILTXPO 2023

Visit us at FiltXPO: Booth #301

Chase Machine and Engineering Designs and Builds Custom Converting and Automation Equipment for Your Application

For over 68 years, Chase Machine and Engineering has been designing and building a variety of standard and custom converting machinery for woven-nonwoven fabrics, films and foils. From integrating independent modules to supplying Full-Scale Production Lines, we offer a comprehensive range of machinery that play an essential role in the success of well-known brands and products worldwide.

As one of the premier design and manufacturing companies for custom web handling machinery, Chase serves a wide range of customers in the textile, medical, nonwoven, converting, geotextile, extrusion, filtration, and packaging industries. We partner with leading manufacturers to produce application-specific equipment ranging from festooners, accumulators, inspection machines, unwinds/rewinds and traverse winders, to ultrasonic slitters, laminators, and cut-to-length machines.

Chase specializes in the integration of technologies such as Ultrasonics, Impulse Welding, RF Welding, Band Sealing, Hot Air Welding, Glue Dispensing, Hot Knives and Conventional Blade Slitters as well as Vision and Marking Systems.

Chase is a vertically integrated company, utilizing state-of-the-art 3D solid modeling software for our machine designs. Within our 28,000 sq. foot facility, located in West Warwick RI, we program our PLC’s and HMI’s, build our electrical control panels and machine, weld/fabricate, paint and assembly our equipment while maintaining tight control of quality and delivery.

We place a high priority on customer and product confidentiality, and

Chase specializes in the integration of technologies such as ultrasonics, impulse welding, RF welding, band sealing, hot air welding and glue dispensing, and more.

constantly seek to improve our quality and process controls as we help our customers improve their products and processes. Working together with our customers, Chase will deliver equipment that is newer, faster, more efficient, and more reliable for a timely return on your investment.

For those interested in product development, the Chase Materials Application Lab exists to help your team take their ideas to the next level. Whether creating new products or improving existing ones, Chase can determine the optimum method for manufacturing. Lab capabilities include web handling systems with ultrasonic technology for laminating, embossing, welding, slitting as well as impulse welding machines.

ISSUE 5 202 3 FILTNEWS.COM 15

Visit us at www.chasemachine.com and learn why Chase Machine and Engineering has adopted the tagline “EXPECT TO BE IMPRESSED.” www.chasemachine.com

Ultrasonic Ring Welder.

ADVERTORIAL | SHOWFLOOR SHOWCASE: FILTXPO 2023 Visit us at FiltXPO: Booth #804

q Chase Ultrasonic Laminators.

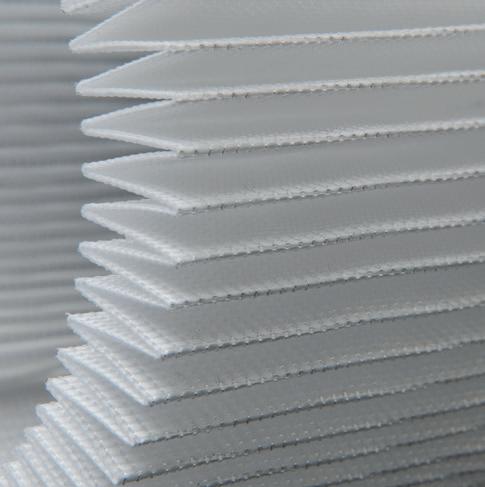

H&V Brings Innovation, Commercial Solutions to FiltXPO

Hollingsworth & Vose (H&V) is a global leader in filtration and energy storage solutions. The company’s advanced materials are used in nearly every industry and touch every aspect of modern life. Wherever you work, live or travel, chances are an H&V solution is close by, contributing to a cleaner, healthier, more sustainable world.

In the world of filtration, H&V’s innovative materials and solutions – including synthetic filter media, microfiltration membranes, microfiber glass, nanofibers and more – meet and exceed the exacting demands of customers.

H&V helps clean and filter everything from air and water to fuel and industrial liquids across a wide range of industries and applications, including appliances, cleanrooms, process liquids, healthcare, heavy industry and mechanical power.

At FiltXPO, H&V will be spotlighting all of its filtration solutions. Its team of skilled experts, who understand the complex applications and process needs of the industries they serve, will be on hand to match FiltXPO attendees with the H&V solution that is right for them. Fred Lybrand, H&V’s Senior Director of Membrane Microfiltration, will lead

a presentation about “Accelerating Membrane Adoption with ROI.”

Among the H&V brands being highlighted at this year’s FiltXPO:

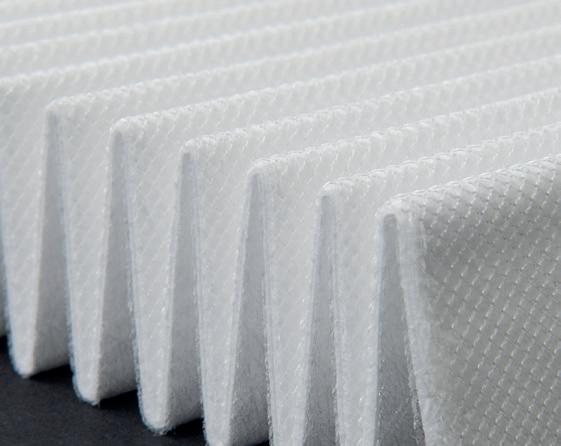

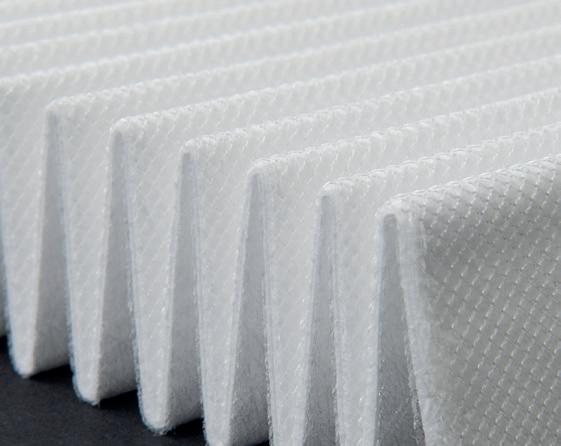

• HV Technostat® – Technostat® is the leading electret filter media traditionally used in critical applications such as medical ventilators, spirometry, CPAP and respirators. Technostat® also offers higher efficiency for capturing small particles, low pressure drop, a long shelf life and exceptional performance in highly regulated applications.

• HV TRUPOR® – Trupor® leverages two centuries of H&V innovation in fibrous porous materials. It is H&V’s first product for buyers of micro-

filtration membranes, targeting food, beverage and bioprocessing applications. Trupor brings membrane reliability and maximum performance with the thinnest possible efficiency layer, which is made possible by superior pore size uniformity. Its composite design delivers long life and stable performance.

• HV NanoWave® NanoWave® is a patented extended surface area synthetic filter media that works against hazardous air pollution by providing clean air while significantly lowering energy consumption in commercial, residential and industrial buildings. It provides extraordinarily low pressure drop and superior dust-holding capacity, and it improves air quality by enabling higher levels of filtration without reducing HVAC system airflow. The result: better filtration with lower energy usage.

www.hollingsworth-vose.com

16 IFN ISSUE 5 202 3

ADVERTORIAL | SHOWFLOOR SHOWCASE: FILTXPO 2023

Visit us at FiltXPO: Booth #401

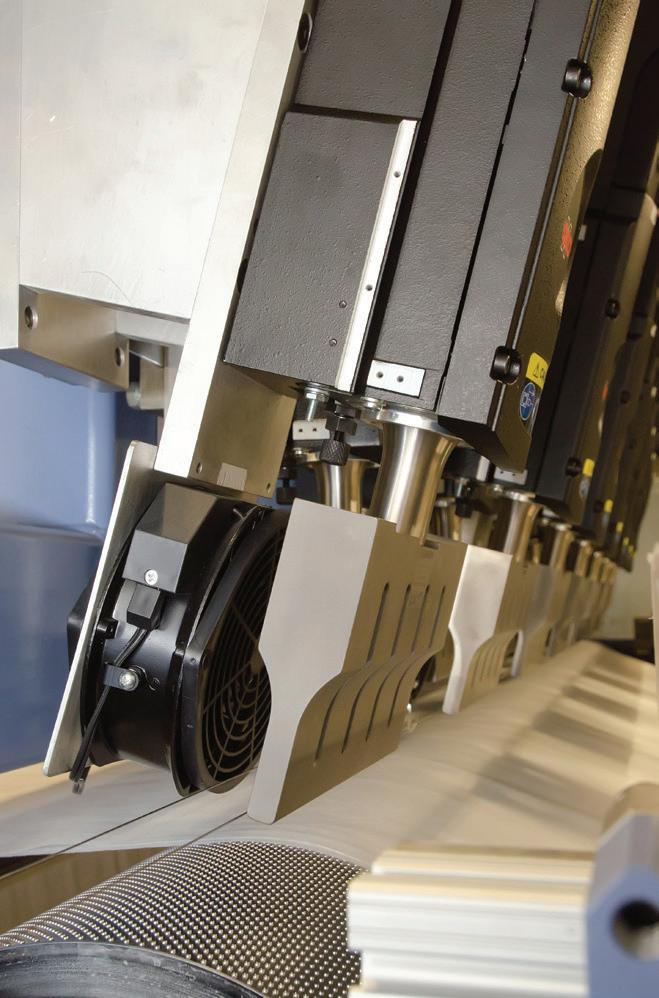

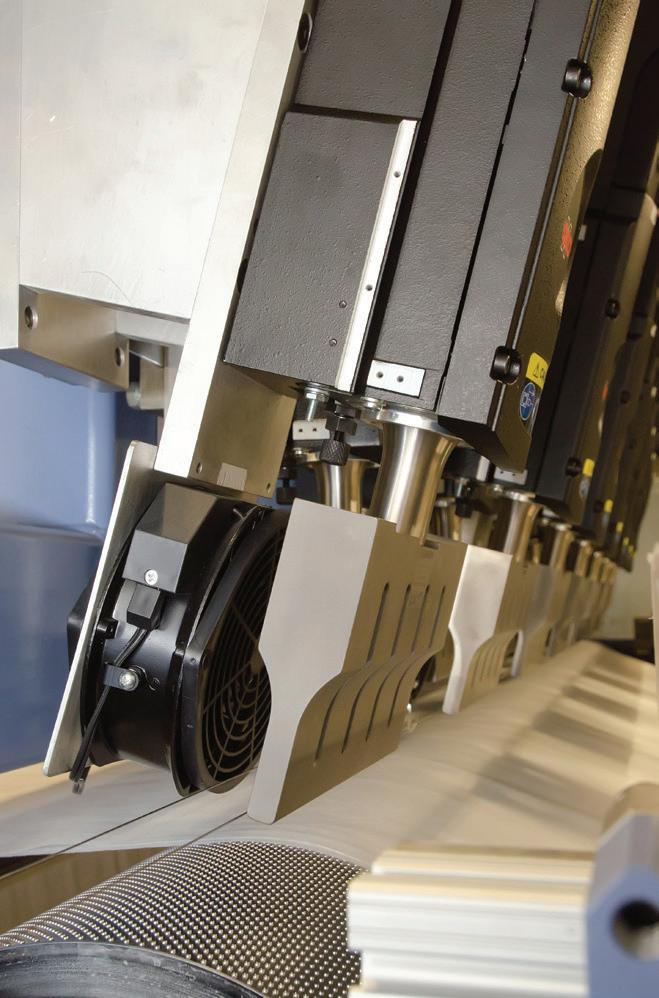

JCEM Group Announces All-New, High Performance, High-Speed Combi-Line Pleating System

In 2017, JCEM introduced its P7 HighSpeed Blade Pleating machine, the world’s fastest blade pleating machine to date, with speeds of up to 350 pleats/ minute. And now, in 2023, JCEM releases its latest high-speed pleating machine, the all-new P8 with speeds of up to 500 pleats/minute!

The new P8 uses the latest Bosch Rexroth magnetic levitation technology that allows for record-breaking speeds previously thought to never be achieved in a blade pleating application. The P8 design has tremendously reduced the number of mechanical/moving parts that eliminate the need for greasing or cleaning, while still offering very good strength characteristics. The result is world-record pleating speeds with excellent pleat height tolerance and quality.

Simultaneously, TAG, part of the JCEM Group, has also just released its latest Mini-Pleating machine with completely new Beckhoff controls and Bosch Rexroth motors and drives. For customers, the new platform offers many updates,

such as higher pleating speeds (up to 30 meters/minute), improved web tension control, a new Servo Unwinder, full synchronization between Mini-Pleater and Blade Pleater, and much simpler integration of additional accessories or features in the future.

Another big advantage is the ability to change pleat heights completely onthe-fly without stopping the machine, which is quite revolutionary as this is a huge time saver, as well as a tremendous reduction in scrap. This allows the user to load an entirely new recipe with a different pleat height, glue pattern, pleat spacing, and pleat count without

having to stop the machine to “reload.” Customers can also opt for an automated slitting system that adjusts slitting knives to desired slit-width positions with no operator involvement at all.

Together, the new P8 and updated TAG machine create an extremely highperformance Combi-Line Pleating system for applications requiring synthetic media with glue-bead separators. This was part of the overall strategy when JCEM acquired TAG GmbH, to create software, programming, and component commonality between all machinery for a more streamlined customer experience and offering the evermore popular Industrie 4.0 compatibility.

JCEM Group, including JCEM GmbH (Switzerland), TAG (Germany), and JCEM Inc. (USA), is the global leader for all types of pleating equipment, offering the world’s most innovative, efficient, and robust pleating systems available.

www.jcem.group

ISSUE 5 202 3 FILTNEWS.COM 17

The P8 design has tremendously reduced the number of mechanical/moving parts that eliminate the need for greasing or cleaning, while still offering very good strength characteristics.

ADVERTORIAL | SHOWFLOOR SHOWCASE: FILTXPO 2023

Visit us at FiltXPO: Booth #313

The JCEM P8 pleating machine with speeds up tp 500 pleats per minute.

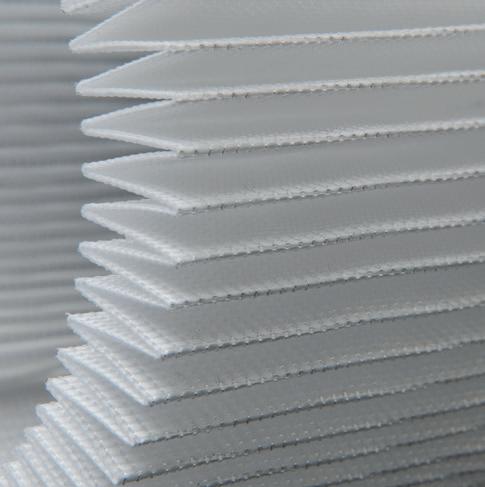

Flexibile and Proven Pleating Solutions for Filter Production

Pleating Systems & Equipment – a leading supplier of high-quality manufacturing equipment and contract pleating services – specializes in helping filter manufacturers to select the right type of equipment and solutions to fit their filter production needs.

The principals of “PSE” have owned and operated the largest privately owned filter manufacturing facility in the United States from 1996, while simultaneously owning the most successful pleating machine distributorship for 20 years. We are experts in filter manufacturing, pleating machinery and accessories and understand the challenges manufacturers face. At PSE, we are third-generation filtration family and continue to provide outstanding solutions for our customers.

Our Capabilities

The brands we represent offer best-in-class solutions for all filter manufacturers from start-ups to the largest in the industry. The advances in technology have changed everything from media and adhesives used in the filters, to the equipment used in their manufacture. Outdated equipment in the industry is being replaced by our newer, quieter and more simplistic operating designs without compromising robust performance, faster speeds and higher precision. Being a leader in the filter manufacturing equipment industry allows us to offer a wide range of manufacturing solutions and a faster return on investment than ever before, including:

High Speed CNC Blade Pleaters

Integrated Mini-Pleat Systems

Servo Rotary Pleaters

USED Equipment

Contract Pleating

OEM Parts & Service

Our Brands

currently assisting with the COVID-19 demand for pleat packs for respirator filters. Our production lines feature our new CroyBilt Integrated Mini Pleat Systems and the latest High-Speed CNC ROTH Blade Pleaters. Capabilities include 4-300mm pleat heights including glue bead application.

Used Equipment and Trade-In Program

CroyBilt is our flagship brand of highquality mini-pleating machines, rotary pleating machines, and many other types of filter manufacturing equipment.

Used pleating equipment can be a great way to get started or expand your growing filtration business. PSE regularly acquires used pleating equipment, often via our trade-in program. Customers can frequently check our website to see what treasures we have in our warehouse.

Additionally, not only do we provide highquality pleating equipment, but also a wide selection of ancillary equipment options:

Roth Industries, which recently partnered with Pleating Systems & Equipment, was founded in 1947, is supported by over 1,000 employees globally, and has long been respected as an innovator in the areas building & industrial equipment solutions.

Contract Pleating

PSE continuously runs multiple contract pleating lines to accommodate customer’s overflow pleating requirements, interim machine sale pleating, and is

Perforators

Robotic Automation

Edge Banding

Filter Banding

Potting Stations

Unwind Systems

Core Machines

Pre/Post Cutting

Inline Slitters

Gluing Systems

18 IFN ISSUE 5 2023

pseusa.com

Visit us at FiltXPO: Booth #513 ADVERTORIAL | SHOWFLOOR SHOWCASE: FILTXPO 2023

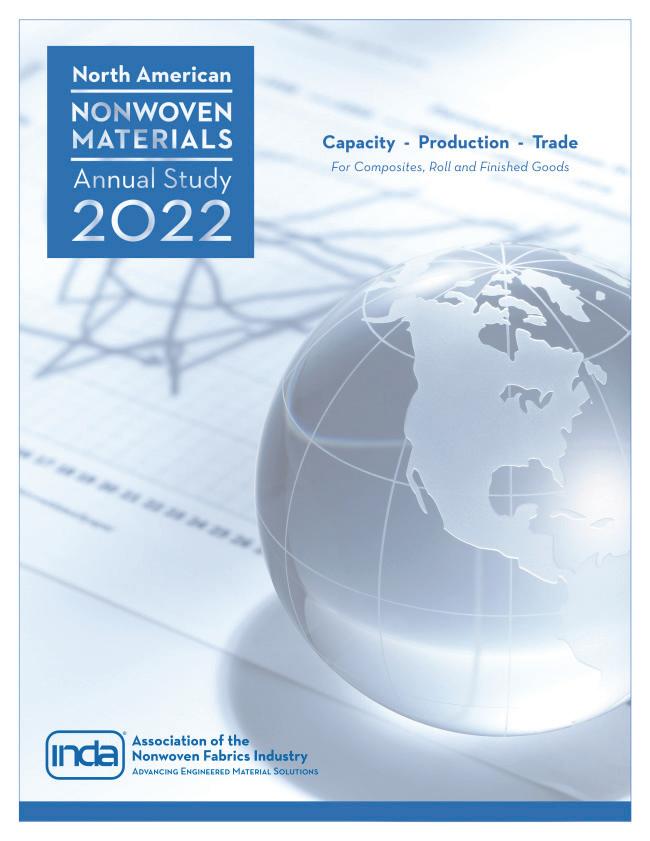

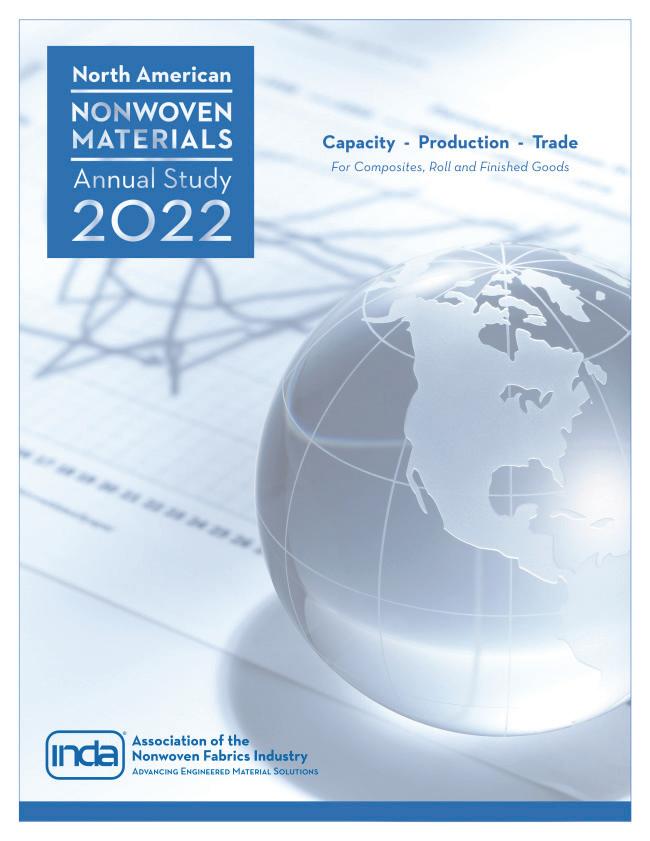

NORTH AMERICAN NONWOVEN MATERIALS ANNUAL STUDY 2022

A COMPREHENSIVE SURVEY AND OUTLOOK

This new report details the 2022 key metrics for capacity, production, and operating rates for the overall nonwoven material industry.

• North American capacity continues to increase with investments being made across all the processes and for a variety of end-uses.

• In 2022, capacity of nonwovens in North America reached 5.565 million tonnes, an increase from the previous year of 2 4% (net growth of 128,700 tonnes).

• North American imports, in tonnage, decreased 24. 3% in 2022 and exports decreased 16. 3%.

The geographic scope for this study is Canada, Mexico, and the United States. This study presents the detailed capacity and production for the North American nonwovens industry in 2022 based on actual surveys and interviews with nonwoven producers. It also compares 2022 data to prior data points from previous INDA surveys and INDA publications.

Create better investment and planning strategies with actionable, relevant, and accurate data.

To purchase this report, visit: https://bit.ly/INDApubs

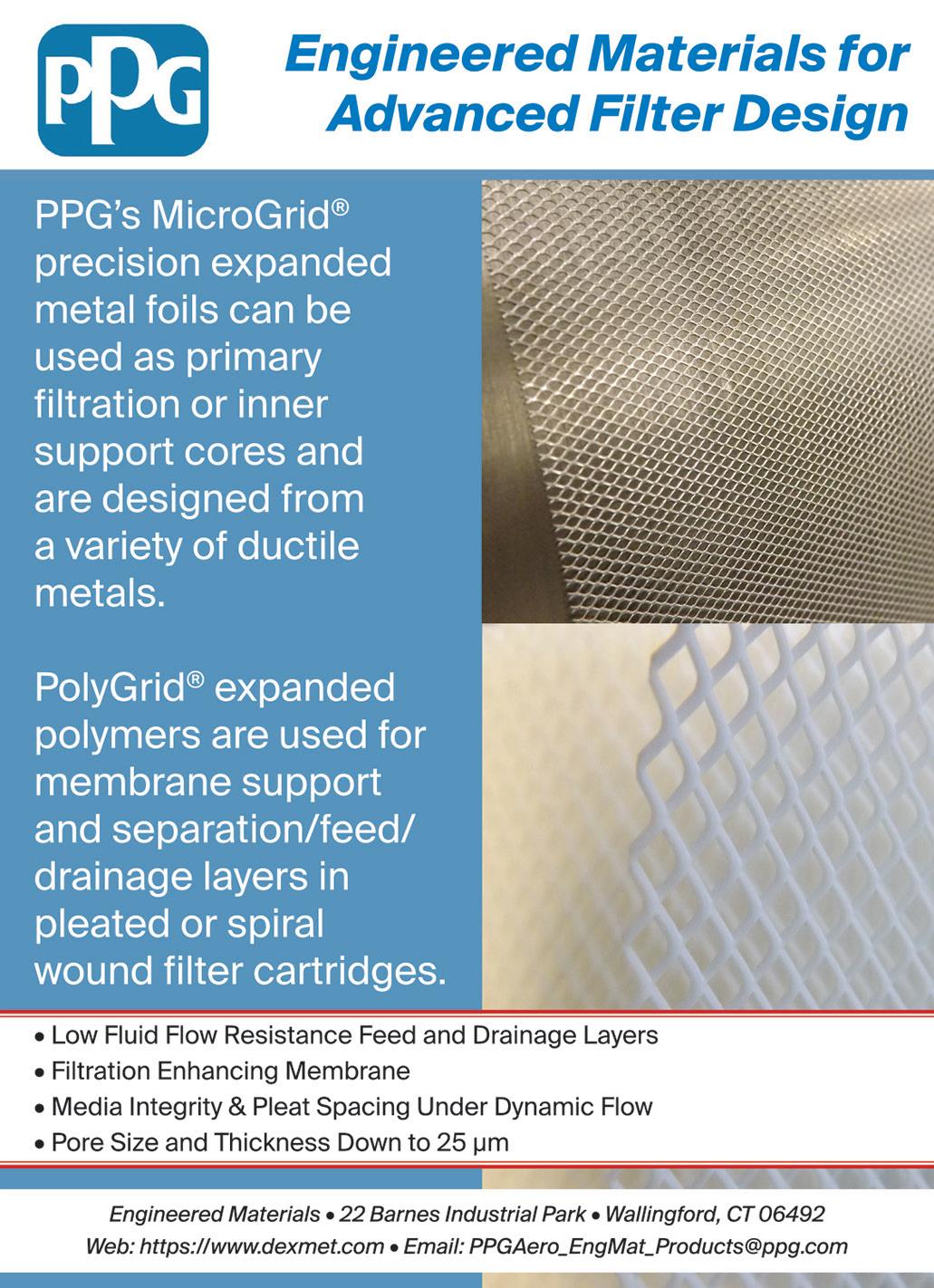

Advancing Engineered Material Solutions

1100 Crescent Green, Suite 115, Cary, NC 27518 P: 919 459 3700, F: 919 459 3701 inda.org For ordering questions, contact Cindy Garcia, publications@inda.org, T: +1 919 459 3711 © INDA 2023. INDA is a registered trademark of INDA

DUALING Hazards to Your Health from Wildfire Smoke

By Mark Davidson

By Mark Davidson

There are occasions when the knowledge and experience a person has developed over their professional career intersects with their personal life. Such is the case for many in the air filtration industry who are unfortunate enough to find themselves in areas where air quality is jeopardized by wildfire smoke. While generally considered to be an issue that those living in the Western half of the United States deal with every year, vast portions of the Northeast and Upper Midwest experienced weeks of air quality alerts in the summer of 2023 due to wildfires in Central and Eastern Canada.

In 1999, the Environmental Protection Agency (EPA) created a measure for the quality of the air known as the Air Quality Index (AQI), which is easily accessed through the website AirNow.gov. A network of sensors around the nation reports the current air quality for five pollutants; ground-level ozone, fine particle pollu-

tion, carbon monoxide, sulfur dioxide, and nitrogen dioxide. Alerts are announced when the AQI Index for a given area is deemed to be unhealthy. There is a specific area of AirNow dedicated to conditions created by wildfire smoke.

Air filtration professionals, accustomed to troubleshooting and recommending solutions for a wide range of industrial and commercial applications, now use these skills in their homes and those of their family and friends when the AQI Index climbs due to wildfire smoke. The same steps used when troubleshooting on a job are followed and one of the first steps to improving air quality is to identify the particles of concern and determine how best to remove those from the indoor environment.

Two Hazardous Components of Wildfire Smoke

Wildfire smoke is comprised of particulate matter and various gaseous substances.

Particulate matter generated by burning matter become suspended in the air and carried vast distances. While the smoke odor is a nuisance, the fine particles are harmful to human health.

Gaseous substances are released by the process of combustion. These include nitrogen dioxide, various volatile organic chemicals (VOC), and ozone. Due to the presence of other powerful odors, ozone is sometimes not immediately detected by our sense of smell. The damage ozone can

AIR POLLUTION

20 IFN ISSUE 5 202 3

do is sometimes described as a sunburn on your lungs.

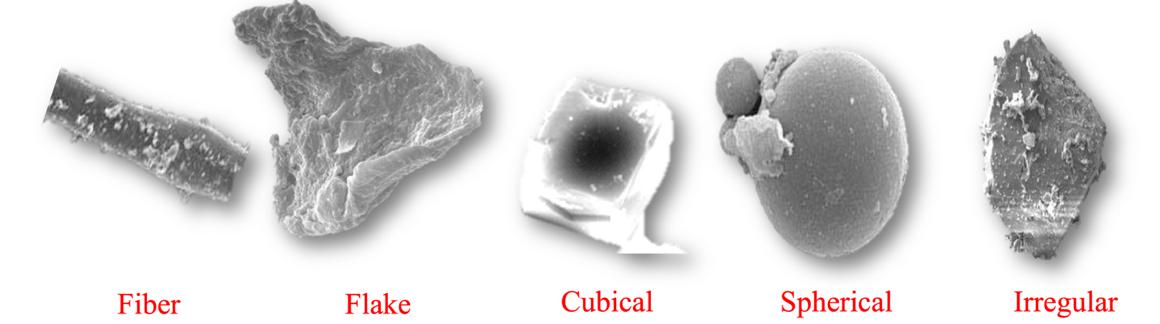

The exact mixture of wildfire smoke for both particulate matter and gases depends on what’s burning, what stage the fire is in, and how hot the fire is. An intense fire with visible flames can produce one mixture while a smoldering fire produces another. And as the distance increases from the source of the fire, the dynamics of the smoke can change as larger particles settle and gases disperse. As such, knowing exactly what type and size of particulate matter and gaseous substances are in the smoke is often difficult to predict.

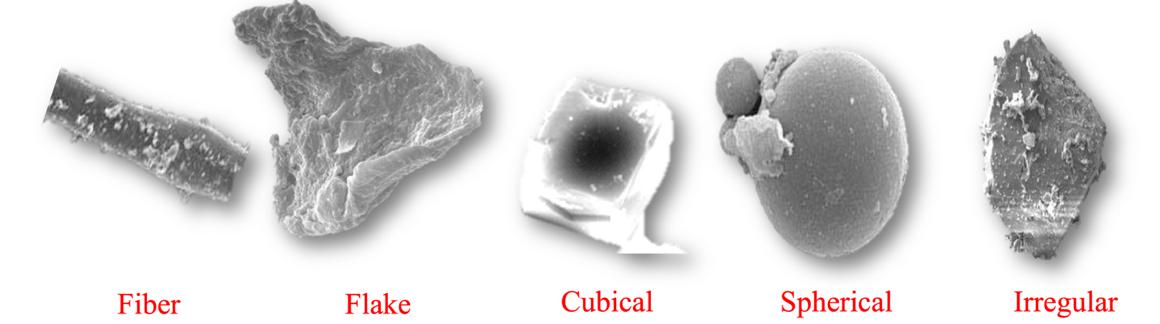

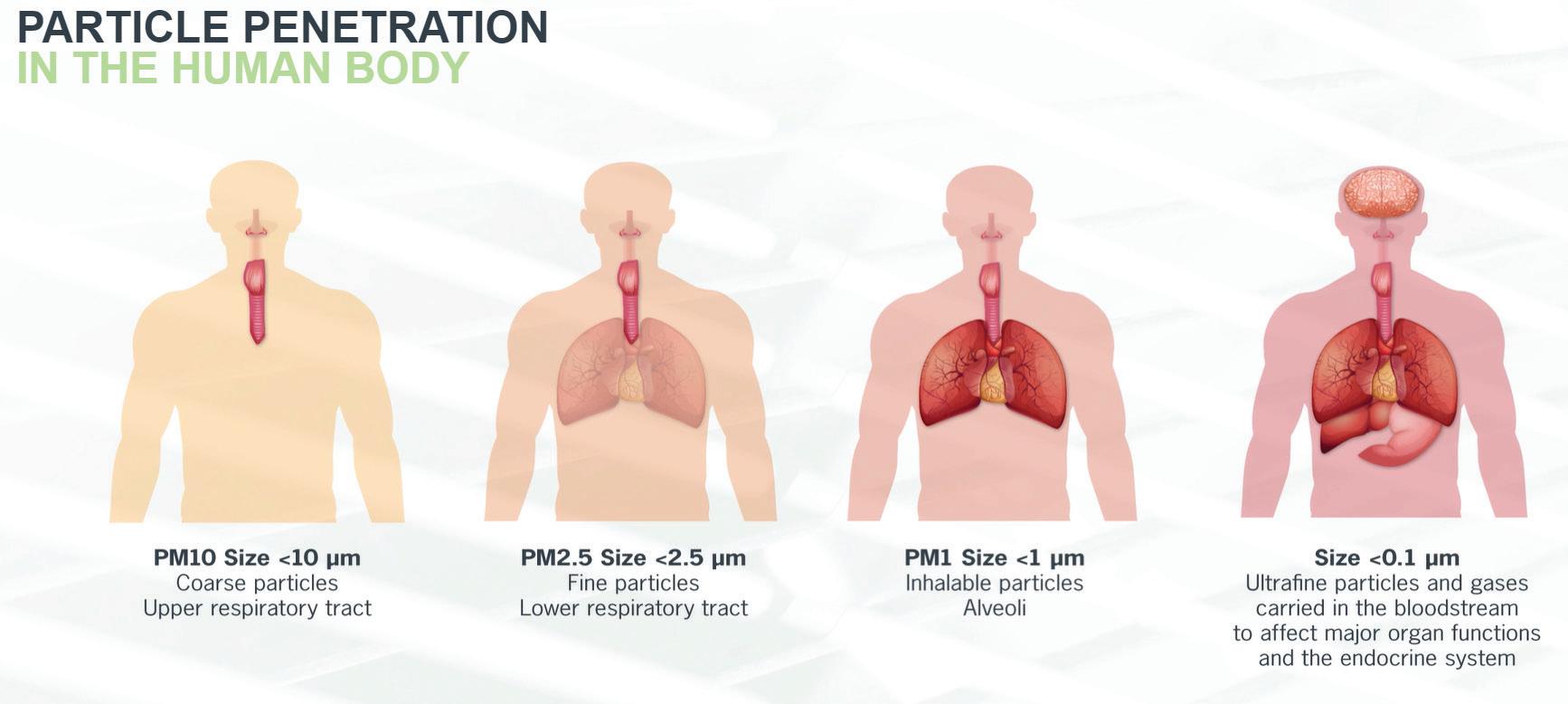

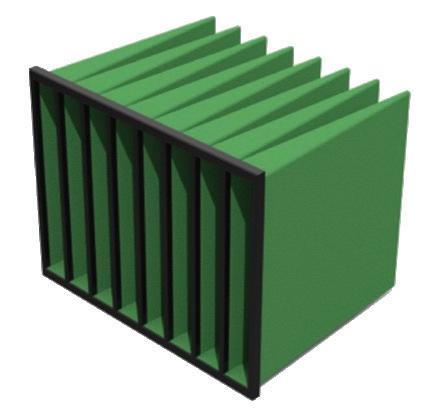

Particulate Filtration

From an air filtration point of view, controlling particulate matter from a wildfire requires a different approach than controlling the gaseous substances released during that same fire.

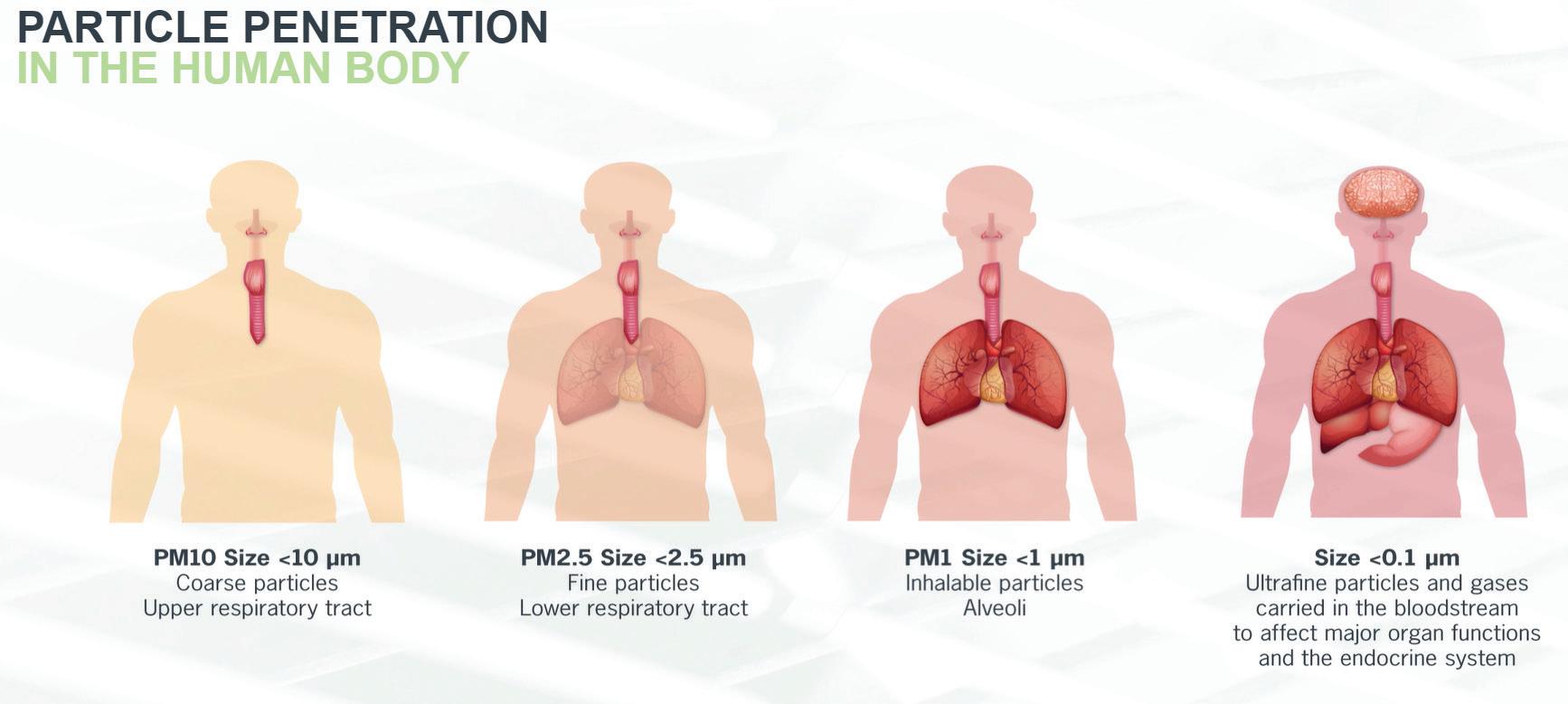

Particulate matter is broken down into one of three categories based on size: PM10, PM2.5, and PM1. The size of a particle dictates how far into the human body it could penetrate. PM10 particles are coarse particles 10 microns and

smaller, PM2.5 particles are 2.5 microns and smaller and PM1 are 1 micron and smaller. Particles with a diameter of less than one micron are sometimes referred to as ultrafine particles. The AQI Index for particle pollution is calculated based on the level of only PM2.5 and PM10 particles, not PM1 or ultrafine particles.

For particulate filtration, general ventilation air filters are tested and classified by their particle capture efficiency and assigned a performance value according to test procedures outlined in ASHRAE Standard 52.2 or ISO Standard 16890. Standard 52.2 test filters against particle sizes ranging from 0.3 to 10 microns while ISO16890 classifies performance based on PM10, PM2.5, and PM1 particle capture. While wildfire smoke varies according to the fire and what’s being burned, 90% of the particulate mass in wildfire smoke is comprised of PM2.5 particles.

When testing an air filter to assign a MERV value according to 52.2 or ePM percentage according to 16890, calibrated test dust whose particle composition is well-defined, is fed into a test duct with a new filter installed. Based on how well a filter captures particles in each various size ranges, 52.2 assigns a MERV value between 1 and 16 while ISO assigns a ePM average. It’s important to note that the ISO16890 test includes a procedure

to account for efficiency drop-off due to electrostatic degradation while a similar procedure in 52.2 is an optional appendix. Note: after 1/1/25, the new ASHRAE Standard 241 requires filters tested under 52.2 to include the optional test, known as Appendix J, and designate the results as the filter’s MERV-A value.

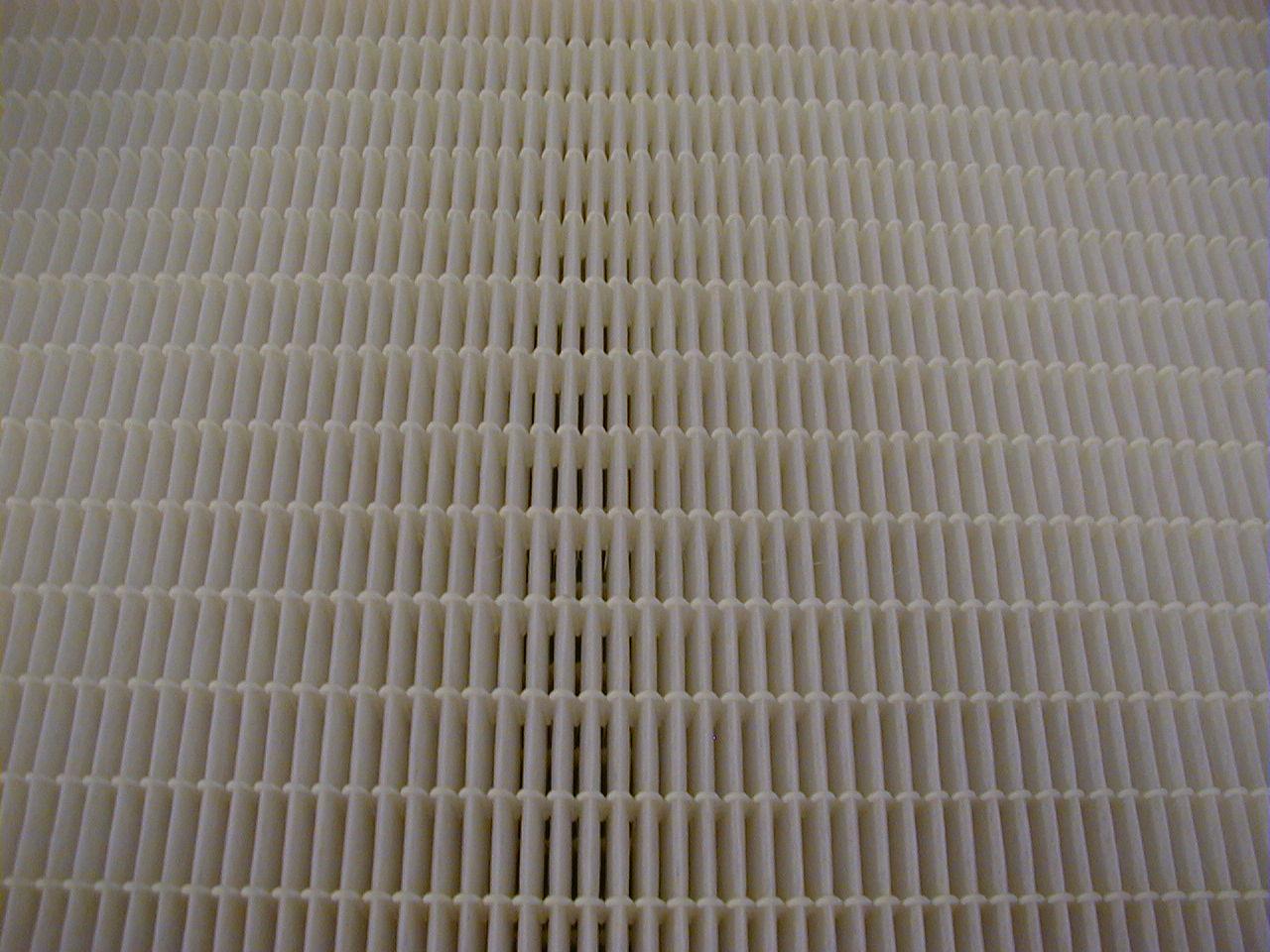

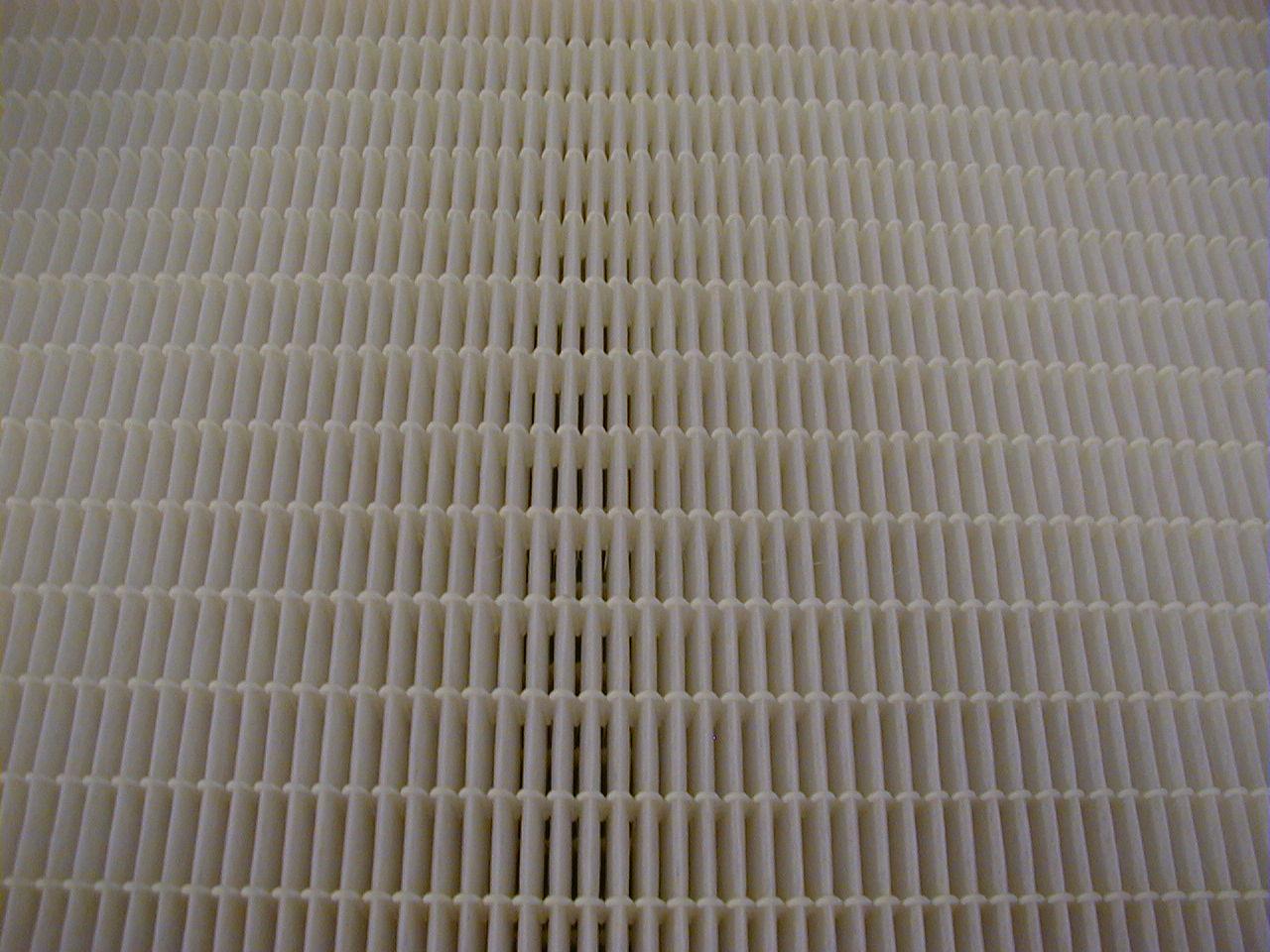

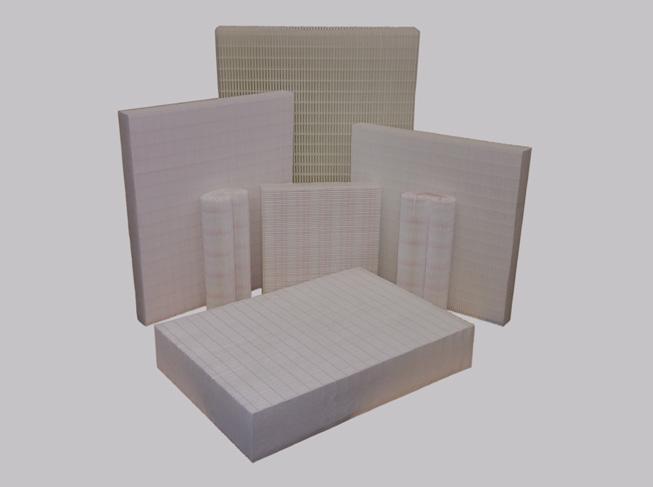

Earlier it was stated that 90% of wildfire smoke is estimated to be comprised of PM2.5 particles and high-quality, non-degrading general ventilation air filters can achieve 90-95% particle capture efficiency on particles of this size. However, in a large fire or multiple fires where smoke merges and travels hundreds of miles, the number of ultrafine particles that penetrate high-efficiency filters is significant and represents a serious health hazard, particularly when the smoke event lasts for days. This is where HEPA filtration plays a role.

The common definition of a HEPA in the U.S. following IEST-RP-CC001, is one tested to a minimum efficiency of 99.97% on 0.3-micron particles. HEPA filters with higher efficiencies can be produced as well. Other HEPA test standards, EN1822 or ISO29463, classify efficiency performance on most penetrating particle size (MPPS) which is generally between 0.1 and 0.2 microns. The minimum efficiency considered to be a HEPA filter according to those standards is 99.95% on MPPS.

ISSUE 5 202 3 FILTNEWS.COM 21

Camfil

t The Triborough Bridge along the East River in New York City with massive air pollution from wildfires. iStock/James Andrews

IEST-RP-CC001

EN1822 CLASSIFICATION

ISO 29463 CLASSIFICATIONS

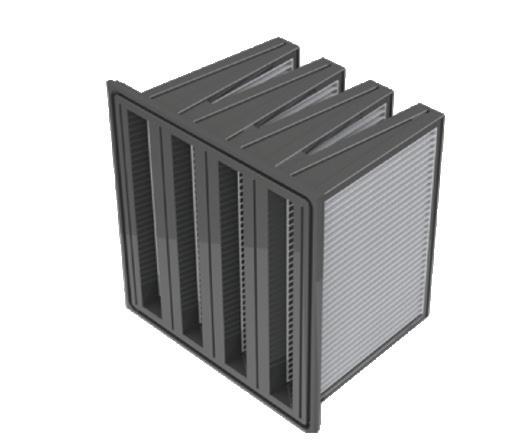

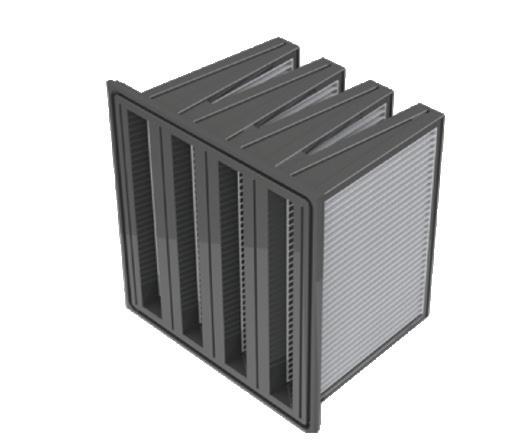

While air handling units serving industrial and commercial spaces are typically capable of holding high MERV-rated air filters, HEPA filters require special frames and stronger fans to overcome their higher resistance. For a residence, it's unlikely MERV 14 or MERV 16 air filters (or ISO16890 equivalent) are an option unless the unit has been reconfigured to hold a larger, six or 12-inch deep filter which would lower the resistance to suitable levels. The resistance (aka pressure drop) on a thinner, 2- or 4-inch panel-type filter rated a MERV 14 or 16 would likely be far too high for a residential unit, especially if the filter is a legitimate MERV 14A or 16A. In those cases, a stand-alone air purifier with HEPA filtration to supplement the HVAC system could be considered. It operates independently of the HVAC system. The majority of air purifiers are portable and can be moved to areas impacted by wildfire smoke that caused clean air alerts.

Gas-Phase Filtration

Controlling the gaseous pollutants produced in a wildfire can be more challenging. Jennifer Webb is the Molecular Segment Manager for Camfil USA covering the Western portion of the U.S. which includes Northern California where she lives. Having lived near prime wildfire country most of her life, smoke-filled skies are almost a seasonal occurrence with some years being worse than others. As her career in the air filtration industry took shape, she was able to use the knowledge gained in molecular filtration to better protect her family and friends during particularly bad air quality alert days.

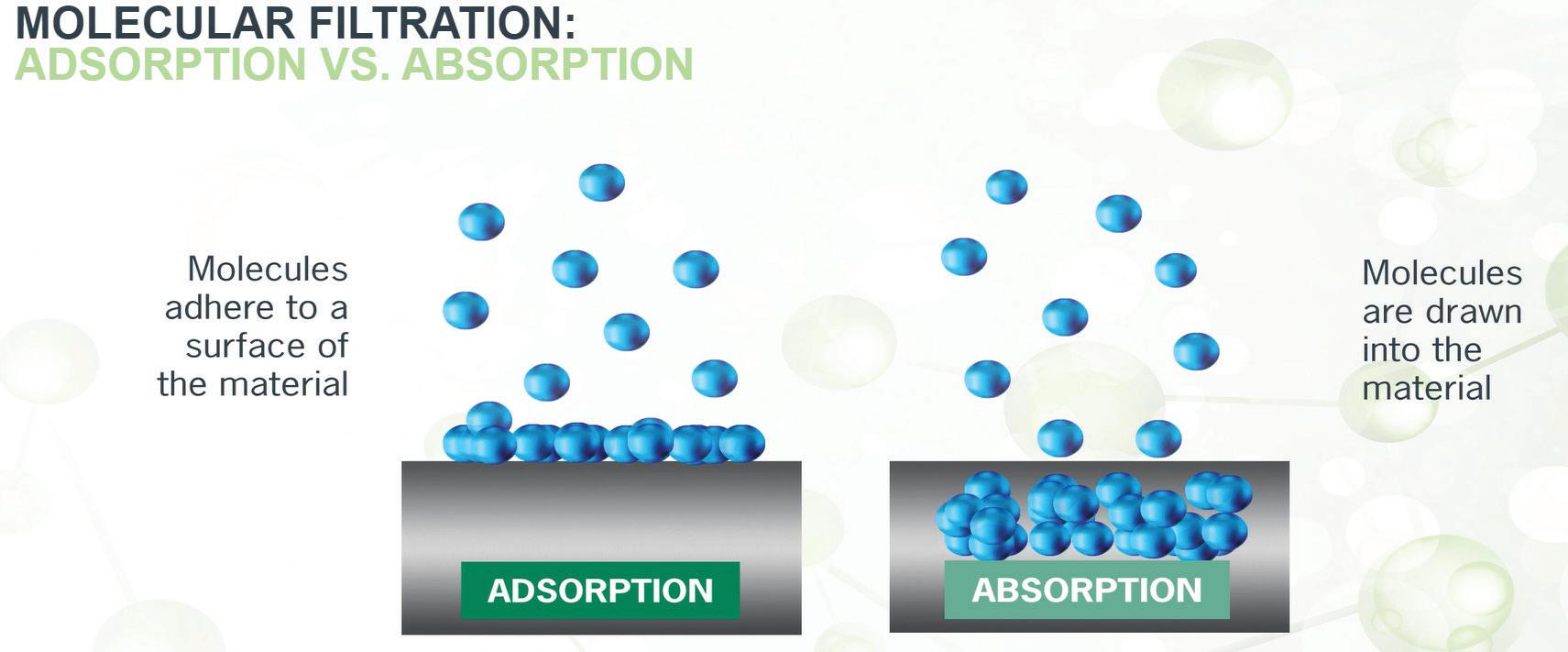

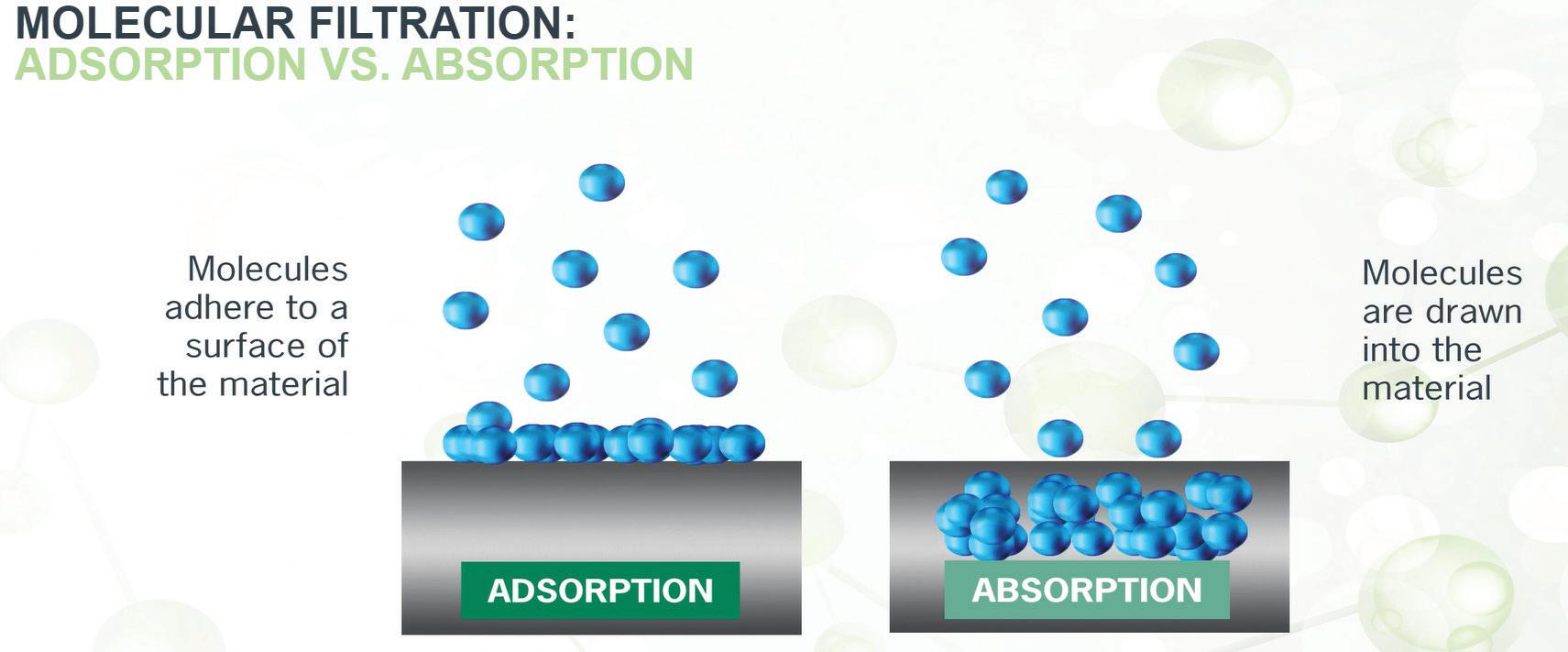

Jennifer explains molecular filtration. “Molecular filtration involves a technique known as adsorption to capture particles at their molecular level, thousands of times smaller than what the best HEPA filters can capture. Adsorption, with a “d,” is different from the more common word, absorption, with a “b.” In absorption, the molecules are drawn into the material and cannot easily be separated again such as milk added to coffee. In adsorption, molecules adhere only to the surface of the material and remain separate, such as a sponge adsorbing water.”

22 IFN ISSUE 5 202 3

Filter Class Particle Size for Testing Global Values Local Leak Values Collection Efficiency (%) Penetration (%) Collection Efficiency (%) Penetration (%) Multiple of Global Efficiency (%) E10 ≥ 85 ≤ 15 E11 ≥ 95 ≤ 5 E12 ≥ 99.5 ≤ 0.5 H13 MPPSa ≥ 99.95 ≤ 0.05 ≥ 99.75 ≤ 0.25 5 H14 MPPSa ≥ 99.995 ≤ 0.005 ≥ 99.975 ≤ 0.025 5 U15 MPPSa ≥ 99.9995 ≤ 0.0005 ≥ 99.9975 ≤ 0.0025 5 U16 MPPSa ≥ 99.99995 ≤ 0.00005 ≥ 99.99975 ≤ 0.00025 5 U17 MPPSa ≥ 99.999995 ≤ 0.000005 ≥ 99.9999 ≤ 0.0001 20 a MPPS - Most Penetrating Particle Size

Filter Type Particle Size for Testing Global Values Local Leak Values Collection Efficiency (%) Penetration (%) Collection Efficiency (%) Penetration (%) Multiple of Global Efficiency (%) A 0.3a ≥ 99.97 ≤ 0.03 B 0.3a ≥ 99.97 ≤ 0.03 Two-Flow Leak Test E 0.3a ≥ 99.97 ≤ 0.03 Two-Flow Leak Test H 0.1-0.2 or 0.2-0.3b ≥ 99.97 ≤ 0.03 I 0.1-0.2 or 0.2-0.3b ≥ 99.97 ≤ 0.03 Two-Flow Leak Test C 0.3a ≥ 99.99 ≤ 0.01 ≥ 99.99 ≤ 0.01 1 J 0.1-0.2 or 0.2-0.3b ≥ 99.99 ≤ 0.01 ≥ 99.99 ≤ 0.01 1 K 0.1-0.2 or 0.2-0.3b ≥ 99.995 ≤ 0.005 ≥ 99.992 ≤ 0.008 1.6 D 0.3a ≥ 99.999 ≤ 0.001 ≥ 99.99 ≤ 0.005 5 F 0.1-0.2 or 0.2-0.3b ≥ 99.9995 ≤ 0.0005 ≥ 99.995 ≤ 0.0025 5 G 0.1-0.2 ≥ 99.9999 ≤ 0.0001 ≥ 99.999 ≤ 0.001 10 a Mass median diameter particles (or with a count median diameter typically smaller than 0.2 µm as noted above). b Use the particle size range that yields the lowest efficiency.

Filter Class (Group) Particle Size for Testing Global Values Local/Leak Values Collection Efficiency (%) Penetration (%) Collection Efficiency (%) Penetration (%) Multiple of Global Efficiency (%) ISO 15 E MPPS ≥95 ≤5 - -ISO 20 E MPPS ≥99 ≤1 - -ISO 25 E MPPS ≥99.5 ≤0.5 - -ISO 30 E MPPS ≥99.9 ≤0.1 - -ISO 35 E MPPS ≥99.95 ≤0.05 ≥99.75 ≤0.25 5 ISO 40 E MPPS ≥99.99 ≤0.01 ≥99.5 ≤0.5 5 ISO 45 E MPPS ≥99.995 ≤0.005 ≥99.975 ≤0.025 5 ISO 50 E MPPS ≥99.999 ≤0.001 ≥99.995 ≤0.005 5 ISO 55 E MPPS ≥99.9995 ≤0.0005 ≥99.9975 ≤0.0025 5 ISO 60 E MPPS ≥99.9999 ≤0.0001 ≥99.9995 ≤0.0005 5 ISO 65 E MPPS ≥99.99995 ≤0.00005 ≥99.99975 ≤0.00025 5 ISO 70 E MPPS ≥99.99999 ≤0.00001 ≥99.9999 ≤0.0001 10 ISO 75 E MPPS ≥≤99.999995 ≤0.000005 ≥99.9999 ≤0.0001 20

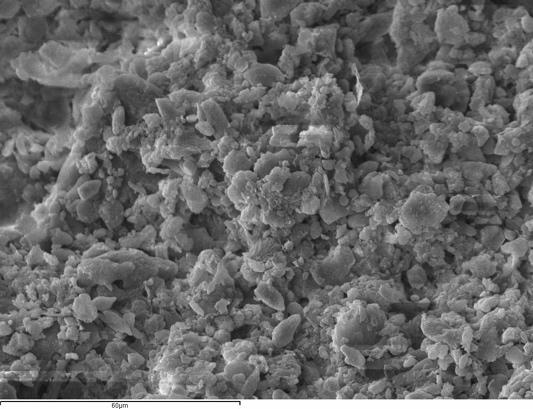

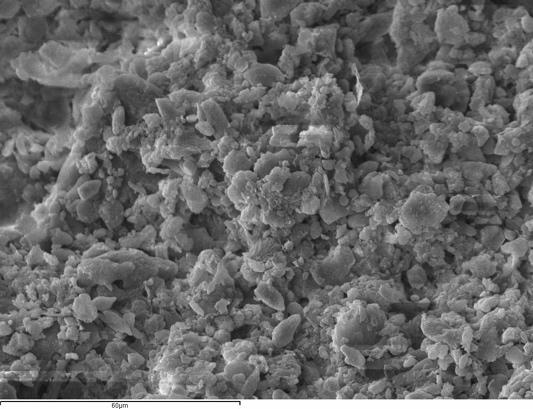

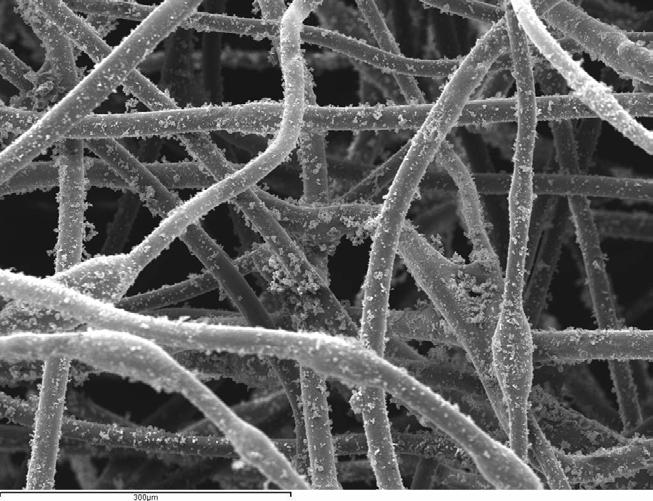

“Unlike air filters that use a fibrous media, molecular filtration relies on a porous media like activated carbon, commonly made from carbonized coconut shells. If you were to view a piece of activated carbon under strong magnification, you would see the surface fractured with deep canyons and cavelike structures. This greatly increases the surface area of the material to such an extent that if a spoonful of activated

carbon were spread flat, it would cover an entire football field.”

“When the various gases created in a wildfire encounter an activated carbon filter, the molecules making up the gas are physically attracted to the surface of the media by weak intermolecular forces. This attraction holds the molecule in place and removes it from the airstream.”

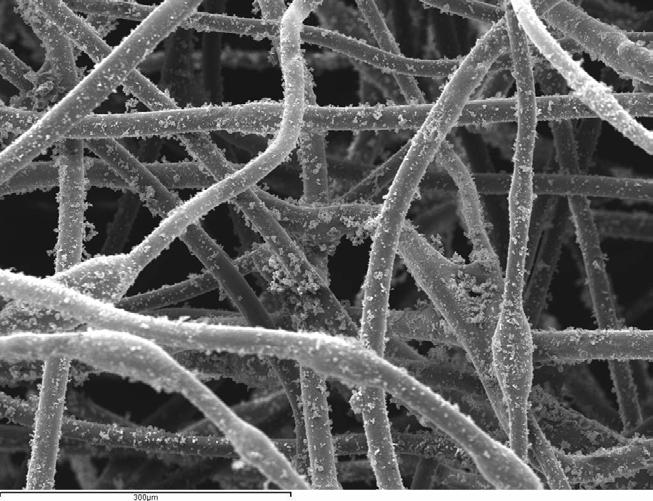

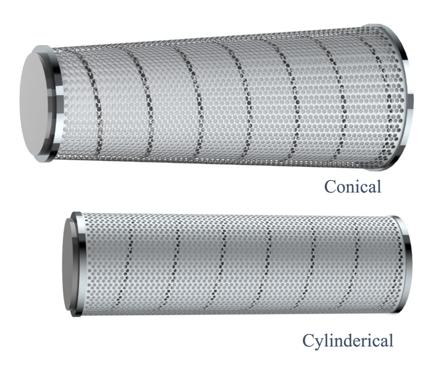

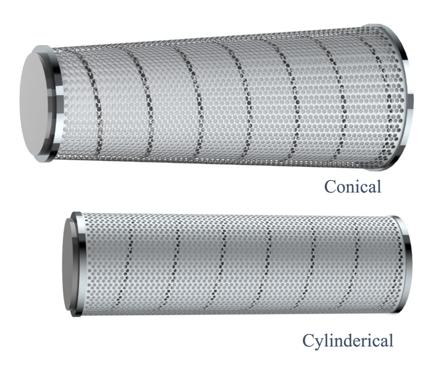

Molecular air filters can look similar to general ventilation filters, but with

activated carbon included in the design, or they can look dramatically different and require specialized housings to hold the cylinders or modules.

Strategies To Keep Smoke Out

In the U.S., there’s an average of almost 70,000 individual wildfires per year(1) and the number of acres burned recently has been as high as ten million. Strategies to prevent wildfire smoke from entering a facility depend on the design of the building and its HVAC equipment. Commercial, retail, or industrial buildings for example generally have more complex HVAC systems than smaller stand-alone buildings and residences. Commercial spaces often have minimum requirements for how much outside air must be brought into the building based on size, intended use, or occupancy. But the buildings may also have requirements to exhaust air from certain spaces such as kitchens or restrooms.

ISSUE 5 202 3 FILTNEWS.COM 23

DESIGNED, ENGINEERED, BUILT, ASSEMBLED AND SERVICED IN THE U.S.A Elsnereng.com | eew@elsnereng.com | 1.717.637.5991 Elsner's automated filter manufacturing machinery helps you save time and money. From unwinding and folding to cutting and gluing to pack building and robotic glue applications, we make every step of the way easy to boost your productivity. 2023 Elsner Engineering Works, Inc Save Labor, Boost Throughput & Improve Quality!

Camfil

When wildfire smoke surrounds a building, positive air pressure inside creates a barrier that helps keep smoke from entering through open doors, windows, and unseen cracks. If the air pressure inside a building, or a separate space within the building, is lower than the surrounding area, a pressure differential exists and air will naturally flow from higher to lower. Exhausting air can create a low-pressure zone and a pathway for smoke to enter. For commercial, retail, and industrial facilities, this can be difficult to manage since employees, customers, shipping, and deliveries can continue during business hours. This is a little easier to manage in smaller facilities or residences, but there are surprising day-to-day activities such as running a dryer or range hoods that need to be monitored. Exhausting that air could be enough to tip the scales from positive to negative.

Ultimately, outside air polluted with wildfire smoke will get into a facility. It could be unintentional when pressure slips or it could be because the HVAC equipment must run to bring in warmed or cooled air. When this happens, air filters in the HVAC system or in stand-alone air purifiers can be used to remove the PM and gaseous pollutants within the smoke.

Most commercial HVAC equipment has the capability to adjust the amount of outside air brought inside. Setting the system to recirculate as much air as possible gives the air filters multiple opportunities to filter the same unit of air. As mentioned before, high-efficiency air filters capture a high percentage of PM2.5 in a single pass, and multiple passes through an air filter with a lesser efficiency can also be effective. However, there’s still the issue of ultrafine particles below the capability of high-

efficiency air filters especially during times of extreme wildfire events. Stand-alone individual room air purifiers with HEPA filters are useful in this situation. There may be certain areas of a facility where managing smoke is more difficult than others, such as in shipping and receiving. In those situations, areas of the facility with greater occupancy such as office or shopping spaces, can be isolated with both physical barriers and barriers created by air pressure. Within these areas, air can continually be recirculated through the air purifiers. This is true for homes as well. Many air purifiers also contain molecular filters that target the gaseous pollution from wildfire smoke.

Jennifer Webb was in this situation and was able to use her experience in both particulate and gaseous filtration. “Since the highest my house’s HVAC system could accept is a MERV11 filter and while I could set the fan to recirculate the air continuously, I wanted to find a separate recirculating system that would capture the smaller particles more efficiently. I also wanted it to capture any ozone gas that might be present. And finally, back to the very beginning of our conversation, I wanted something to remove the nuisance odors. So not only did I need something with a higher MERV value, but I also needed a molecular- or carbon-filter to capture the odors and gases.”

Wildfire smoke contains both particulate matter and gaseous pollutants. Each requires a specific type of air filter to manage the contaminant levels. While there are strategies to limit smoke from entering buildings, it's likely smoke will find a way inside. Relying on what air filtration professionals have learned is a good starting point to protect human health.

Mark is the Manager of Technical Marketing which includes responsibility for writing and editing articles for Camfil’s popular Clean Air Blog and participating in ASHRAE committees including 170 for healthcare facilities. Prior to that role, Mark was the Food and Beverage Segment Manager for Camfil USA with overall responsibility for growing market share in food or beverage production facilities located throughout the United States.

His 25-year background in industrial food processing and healthcare facilities gives him the understanding required to select the air filtration solution that provides the appropriate level of indoor air quality while tackling the high cost of energy, fewer maintenance staff, and a growing shortage of landfill space.

After completing her BS in Mechanical Engineering from the University of Delaware, Jennifer Webb worked in various product, process and sales engineering roles in the aerospace and semiconductor manufacturing industries.

She joined Camfil in 2019 as the Molecular Filtration Segment Manager for the western United States and Mexico. She is responsible for technical sales, marketing and business development of molecular (aka-”carbon“ or “gasphase”) filtration solutions for a wide range of industries and applications, including airports, hospitals, cannabis, cultural heritage preservation, petrochemical, wastewater, pulp and paper, industrial exhaust and biogas.

24 IFN ISSUE 5 202 3

1Wildfires and Acres | National Interagency Fire Center (nifc.gov)

Housing with carbon modules.

Carbon pleat. Carbon filled cylinder. Camfil

Welcome to the future of liquid filtration technology. Single Bag Housings Multi-Bag Housings Polypropylene Housings Indicating Filter Centrifugal Separators Backwashing Systems Coolant Filter Systems High Capacity Elements Filter Bags Contact us today for more information. 800.821.5373 RosedaleProducts.com Rosedale Products Inc. 3730 W. Liberty Rd. Ann Arbor, MI 48103 Email: Filters@RosedaleProducts.com Phone: 734.665.8201 • Fax: 734.665.2214 ©2023 Rosedale Products Inc.

EXTREME Decentralization

What It Means for Technology Innovation and Investing

By Will Sarni

Global Water Technology Innovation

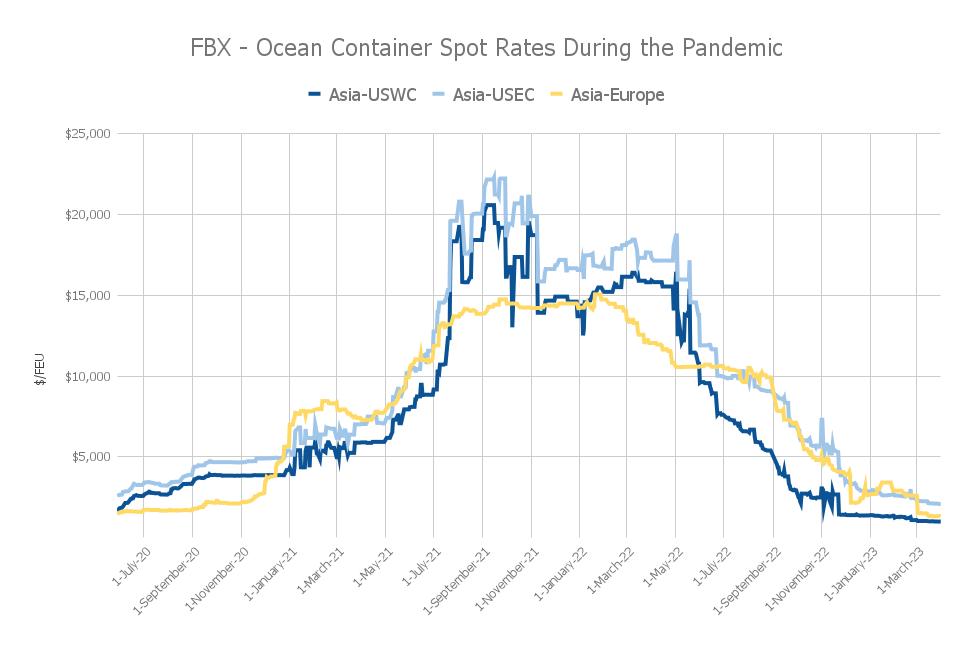

The onslaught of news on droughts, mega-droughts (aridification), and the impacts of climate change in the U.S. and globally has reached a new high. Water scarcity and poor quality are taking their toll on local communities, regions, and countries along with impacts to business continuity and growth. The American West, Latin America, Europe, and the Middle East are dealing with less water for utilities, agriculture, cities, and ecosystems.

The reality of rapidly declining water security has resulted in a robust renewal of investing in innovative water technologies and business models to solve “super wicked water problems.” Examples of the opportunities in investing in water technologies have been recently chronicled in numerous articles such as “Investment in European Water Tech Startups,” “3 Ways to Invest in America’s Crumbling Water Infrastructure,” and “Amid VC’s Downturn, Some Corporate Titans Are Doubling Down on Startups.”

In my view, the key trends in investment in innovative water technologies are digital technologies (AI, remote sensing, sensors), advanced treatment membranes (graphene and 3-D printing), smart water homes (water efficiency, leak detection, and water reuse), alternative sources of water (air moisture capture and reuse), industrial (AI for monitoring asset performance and water use) and agricultural technologies (precision gravity irrigation).

For me, one of the more significant trends and compelling investment opportunities is in residential and commercial water treatment technologies. For this article, I will focus on the trend of “extreme decentralization” in residential and commercial buildings as I believe it is one of the most significant opportunities for technology innovation and investment.

The Case for Extreme Decentralization

Residential and commercial water treatment technologies can be categorized as decentralized (local or neighborhood

scale) or extreme decentralized (the individual home or commercial building) water treatment systems. An excellent overview of extreme decentralization is captured in the article, “The Third Route: Using Extreme Decentralization to Create Resilient Urban Water Systems.”

They advocate for household-based personalized water systems, first targeted at the affluent who expect more functionality and sustainability from water systems, with the funds to invest in systems tailored to their personal water preferences. The result, they say, will allow for tremendous creativity-base of individual users and entrepreneurs, facilitating the type of co-creation that accelerated the rapid development of consumer electronics.

The authors make the case that the water sector can learn from other sectors on infrastructure transition. Specifically, the transition in the power sector from centralized systems to localized (residential and commercial) systems most closely resembles the water sector.

26 IFN ISSUE 5 2023

THOUGHT LEADERSHIP

q Drought conditions causing low levels in the Colorado River which supplies water to western USA and Mexico. iStock/adogslifephoto

The learnings from the power sector infrastructure transition include the significant decline in costs for residential solar and the appeal of renewable energy by early adopters. The appeal by early adopters included the reliability of being “off-grid” and the contribution to reducing greenhouse gas emissions. The rapid growth of household and commercial solar systems accelerated advances in technology innovation and the development of an “innovation ecosystem.” This innovation ecosystem included home-based power storage systems and integration with electric vehicles. The authors conclude that the “opportunity to create sustainable electric power at the individual household level became the key driver for a rapidly innovating sector, in time surpassing the conventional sector from an economic standpoint and bringing along secondary applications.”

The major conclusion of the authors is that, when considering the developments of distributed power generation as a model, “centralized urban water systems will coexist with decentralized systems during a transition phase. Eventually, centralized systems will lose their viability in some areas with low population densities and be replaced by fully household or building-scale systems in locations where decentralized systems offer substantial advantages.”

Moreover, radical innovation was possible in the power sector through the emergence and mass production of personalized, small-scale systems. The authors maintain that the same is possible in the water sector, if we are willing to consider alternatives to the existing centralized, large-scale infrastructure with piped and trucked water. Their research concludes that in many cases houses and buildings can become waterindependent or can deliver water with occasional supplementation.

What does this mean for the water sector?

The water sector is very different from power generation. However, we are seeing a move to decentralized and extreme decentralized water treatment systems

in residential and commercial buildings in response to water scarcity and the challenges facing traditional water utilities (e.g., aging and underinvested infrastructure). Moreover, in many parts of the world communities can no longer solely rely upon traditional sources of water (surface water and groundwater), and water reuse is gaining acceptance.

While decentralized and extreme decentralized water treatment systems may not completely replace more traditional water treatment infrastructure in the near future, we will likely see greater adoption and the birth of hybrid systems (centralized and decentralized/ extreme decentralized systems). Also, the technology opportunities for the adoption of water treatment technologies in the “built environment” are being accompanied by other water technologies in the areas of water efficiency and leak detection (e.g., flume, conservation labs, etc.). It is important to keep in mind that this trend of smart water homes mirrors the development of residential and commercial power generation (residential solar) and energy-efficiency appliances and metering which we now take for granted.

An Example: The American West

The need for innovative water reuse technologies at the residential and commercial scales is strikingly apparent in the American West and in particular, the Colorado River Basin (CRB) and Arizona.

The CRB is one of the most productive and influential, economically and environmentally, yet conflicted regions of the United States. The Basin spans seven states, with its northernmost borders stretching into Wyoming, across Colorado and Utah, and down into Nevada, southern California, Arizona, and New Mexico. From there, the basin expands into northern Mexico where the Colorado River reaches toward the Gulf of California.

In addition to its environmental role, the economic importance of the CRB cannot be overstated: the Colorado River supports $1.4 trillion in annual economic activity and 16 million jobs – the equivalent to about 1/12 of the total gross domestic product in the U.S. It is estimated that if 10 percent of the river's water were unavailable (a decline quite possible under projected climate change scenarios of 10 to 30 percent flow reductions by 2050), there would be a loss of $143 billion in economic activity and 1.6 million jobs, in just one year.

The CRB is experiencing severe water scarcity due to the aridification (extreme prolonged drought) from climate change. This aridification has led to intervention by the U.S. Federal government, which ultimately forced key states to craft an agreement to use less water. Arizona, California, and Nevada agreed to take less water from the CRB – a breakthrough agreement that, for now, keeps the river from falling so low that it would jeopardize water supplies for major Western cities like Phoenix and Los Angeles as

ISSUE 5 2023 FILTNEWS.COM 27

U.S. Bureau of Reclamation

p The Basin spans seven states, with its northernmost borders stretching into Wyoming, across Colorado and Utah, and down into Nevada, southern California, Arizona, and New Mexico. From there, the basin expands into northern Mexico where the Colorado River reaches toward the Gulf of California.

well as for some of America’s most productive farmland.

What this translates to is a negative impact on economic development, which is being covered in recent media coverage. In particular, this coverage has focused on the impact of water scarcity on residential development highlighting the severity of aridification (not a drought but a long-term shift in the climate to an arid environment) on the region and the opportunity to accelerate the scaling of water reuse at utility scale and, in my view, residential and commercial scales (“Arizona Limits Construction Around Phoenix As Its Water Supply Dwindles” and “Phoenix Hopes To Turn Wastewater Into Drinking Water by 2030.”) Alternative sources of water, such as reuse, are needed as the Colorado River can no longer be the sole source of reliable water for the region.

What is happening in Arizona is part of a broader trend in the American West. Many western states are expanding water reuse with California, Arizona, and Texas have seen the fastest growth recently due to supportive policies, growing populations, and recurring drought issues. Water reuse adoption is growing fastest in a few key states:

California – California has emerged as a leader in water reuse. The state has set goals to increase recycled water use by two million acre-feet per year by 2030. Major reuse projects exist in Southern California, the San Francisco Bay Area, and the Central Valley.

Texas – Recycled water use has expanded rapidly in cities including, El Paso, San Antonio, and Dallas-Fort Worth. Agriculture and landscape irrigation are major uses. Texas also has the largest direct potable reuse project in the country.

Nevada – Las Vegas recycles nearly all water used indoors for uses like

irrigating golf courses and parks. Nevada requires the evaluation of reuse potential for new developments.

Colorado – Reuse in Colorado is focused on non-potable uses such as irrigation, but direct potable reuse is being explored in response to shortages in the CRB.

New Mexico – Albuquerque and other New Mexico cities have significant recycled water programs, mainly for landscape irrigation and industrial uses. More projects are in development.

manufactures decentralized, consumerfriendly, IoT-connected, compact and scalable graywater recycling products for residential and commercial properties, reducing water consumption by up to 45 percent. Hydraloop has a global partner network of more than 120 partners in more than 50 countries. Headquartered in the Netherlands, Hydraloop has offices in the United States and the Middle East, as well as representatives in Canada and Australia.

Innovative Technologies and Companies

Examples of companies focused on extreme decentralized that I find interesting are Hydraloop (we are an investor), Greyter, Epic Cleantech, and Rainstick.

Hydraloop – A Dutch company that makes a compact unit that recycles shower and sink water for reuse in toilets, washing machines, and irrigation. Their units can recycle over 85% of household water. Hydraloop is a multi-awardwinning company that designs and

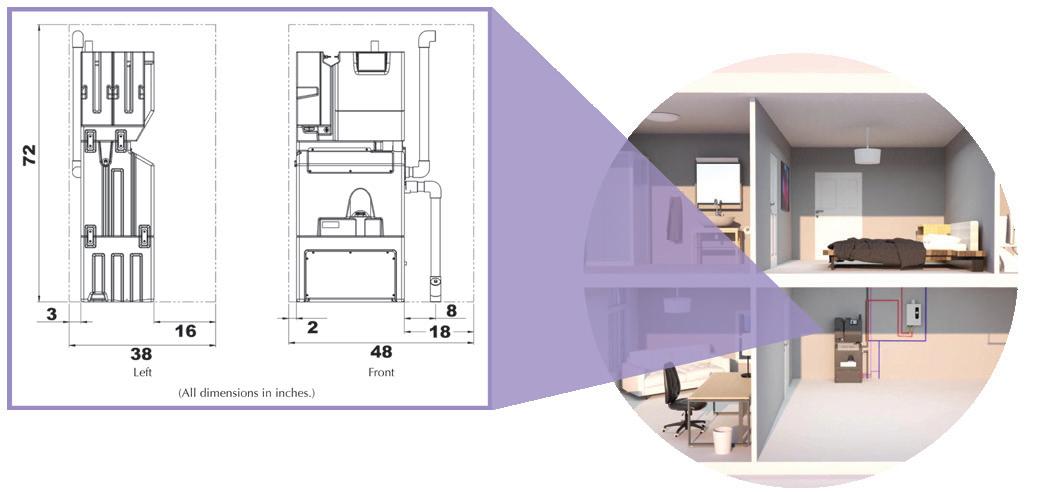

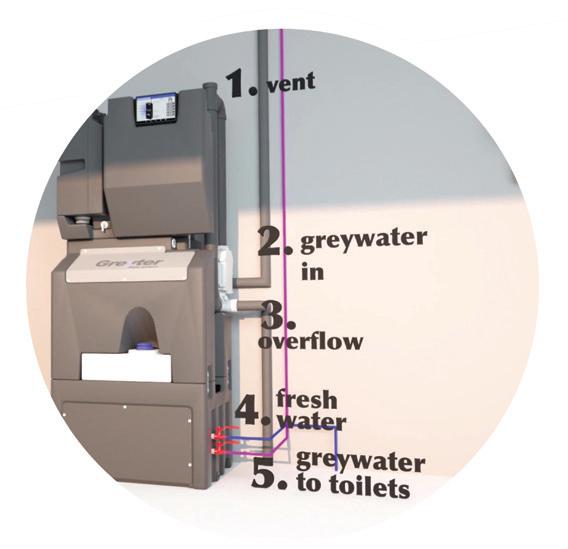

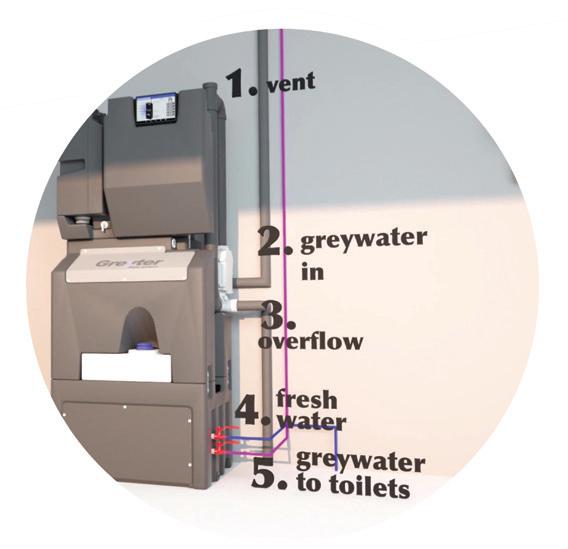

Greyter – A U.S.-based company focused on simple, compact greywater recycling systems for the home. Their systems filter and disinfect greywater for non-potable residential residential use. The system captures greywater from bathroom sinks, showers, tubs and washing machines. The greywater passes through a hair and lint filter first to remove large particles and then goes through a two-stage filtration system: a sediment pre-filter followed by a cotton filter. After filtration, the water passes through a UV disinfection system to kill bacteria and viruses. Finally, the treated greywater is stored in a 30-gallon tank and can be reused for non-potable purposes like irrigation

The entire system fits under the sink or in a basement/garage for easy retrofits and can recycle over 22,000 gallons per year, reducing household water use.

Epic Cleantec – A U.S.-based company that Epic Cleantec (Epic) specializes in innovative, energy-efficient decentralized wastewater recycling suitable for sites not connected to sewer systems. Epic opened its U.S. headquarters and first American demonstration facility in San Francisco in 2018 when it retrofitted

28 IFN ISSUE 5 2023

p Hydraloop designs and manufactures decentralized water recycling products for new builds and retrofits. We offer a wide range of innovative, sustainable, and IoT-connected water recycling devices for residential and commercial real estate. Hydraloop

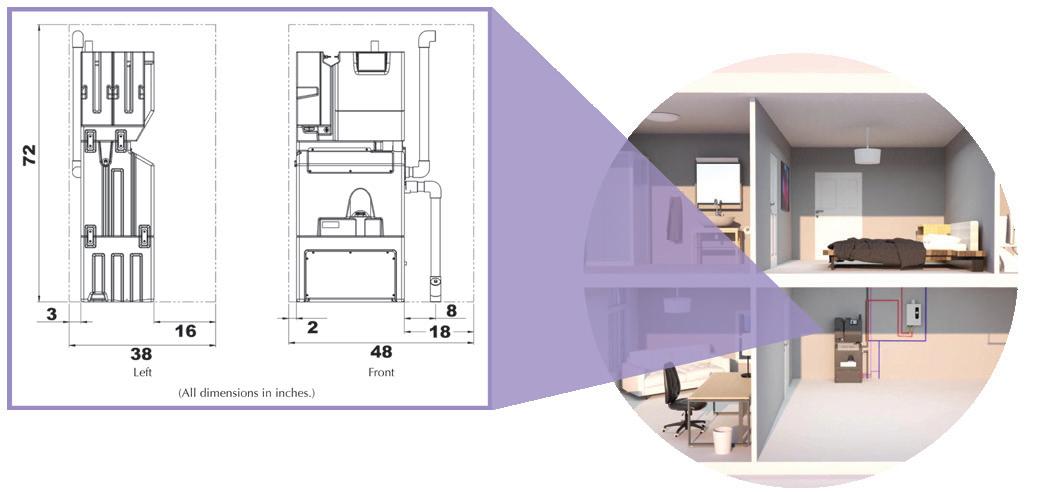

With only five standard plumbing connections, the compact, energy-efficient Greyter HOME™ Water Recycling System is designed for quick and easy installation into new residential developments. This simple process enables professional plumbers to install several systems per day, helping to dramatically reduce the cost of equipping growing communities with advanced water recycling appliances.

Greyter

p The compact Greyter HOME is easily installed in a garage or basement, ensuring no impact to living space and eliminating the time and cost of building an enclosure to conceal the unit. Greyter