Manifold Solutions for Streamlined Rail Applications

Breakthrough engineering for a better world

Breakthrough engineering for a better world

We create solutions for our customers which enable smarter, safer, more productive and sustainable factories, production lines and warehouse operations. Our pneumatic and electric motion systems help machine builders and end users around the world automate and optimise manufacturing and warehousing processes.

We have partnered with customers in industrial automation for over a century, applying our experience and innovation to create lasting value for their businesses. Our solutions support critical industries such as automotive, food and beverage, pharmaceuticals and even the space industry. We support the automation of precision manufacturing, product assembly, testing and packaging.

We use the latest digital technologies in our automation products and constantly innovate in close partnership with our customers. By applying our deep expertise, we can solve their toughest automation challenges, today and tomorrow. Through increased productivity, efficiency and safety, our customers can serve their own customers better, creating sustainable competitive advantage and delivering growth.

Our world-class product portfolio includes IMI Norgren, IMI Bimba, IMI Bahr and IMI Buschjost.

Breakthrough engineering you can count on.

NOTE:

our

we

Enhance reliability, simplify installation, and optimise space in rail systems with manifold assemblies. Backed by 70+ years of IMI expertise.

Reliable pneumatic control is critical to rail safety and performance. Pneumatic and electrical components need to work flawlessly in all conditions while enduring constant vibration and potentially millions of operational cycles over decades of service life.

For engineers designing these systems, integrating valves and control components has always presented challenges. How do you fit multiple components into tight spaces without adding complexity and accessibility issues? Is it possible to prevent leaks or simplify installation with well-designed systems?

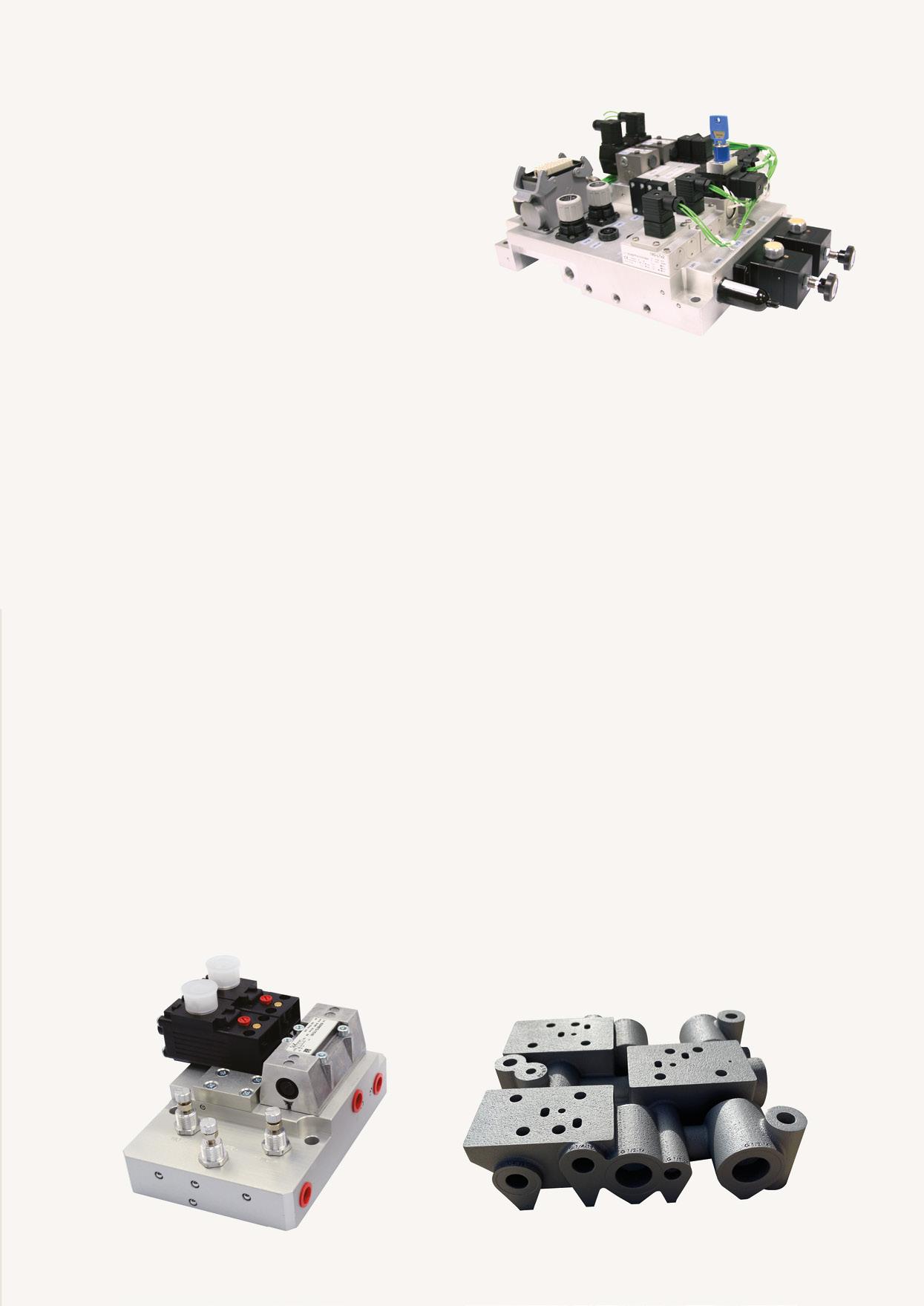

This is where manifolds come in, providing an engineered platform that combines solenoid valves, pressure switches, check valves, regulators, and other components into a unified assembly.

Assembling valves and other components on manifolds enables train OEMs to design and build more compact, reliable equipment, often reducing both cost and time.

This whitepaper delves into the engineering principles that make manifold integration indispensable in rail applications, discussing the design and manufacturing processes behind these components.

We’ll also share real-world examples showing how wellengineered manifold solutions boost performance, enhance reliability, and simplify maintenance.

Manifolds offer several key advantages: reliability, ease of assembly, smaller footprints, and costeffectiveness.

A manifold combines multiple pneumatic and electrical control components into one engineered assembly.

Instead of mounting solenoid valves, pressure switches, check valves, regulators, and gauges separately – each with their own connections – everything integrates into a single unit.

We can break down the benefits of manifolds for rail system design into four key areas:

Pneumatic rail system failures can cause serious safety issues or halt operations, impacting thousands of passengers.

Leaks tend to be one of the primary sources of pneumatic reliability issues. Consolidating components into a single manifold assembly reduces potential leak points by eliminating excess tubing and fittings, directly addressing a frequent source of system failure.

Here’s what that means in practice:

• Every connection eliminated is one less potential point of failure.

• When issues do arise, troubleshooting is straightforward and systematic.

• Maintenance crews spend less time addressing individual component issues.

Traditional fluid control installations comprise multiple components with multiple mounting points and connections.

Manifolds are much simpler, offering pre-mounted assemblies that integrate into the train system with just a few connections. The benefits extend throughout the entire installation process:

• Manifolds reduce installation time compared to mounting individual components.

• Fewer connections enables faster, error-free assembly and lower labour costs.

• Streamlined designs simplify documentation and maintenance tasks.

Manifolds enable system designers to increase the density of components while eliminating tubing and mounting brackets that consume space.

The resulting compact footprint offers rail engineers greater design flexibility – particularly valuable in crowded undercarriage or ceiling installations. The space-saving benefits offered by manifolds include:

• Higher component density without sacrificing accessibility

• Greater design flexibility for challenging installation locations

• More efficient use of limited undercarriage or ceiling space

Manifold assemblies enable rail OEMs to lower acquisition costs, while helping end users reduce operational expenses.

Sourcing a manifold and its components from a single supplier eliminates the hassle of coordinating multiple vendors for product selection, specification, and qualification.

Partnering with a supplier like IMI, who assembles and tests the entire system, delivers even greater time and cost efficiencies across the project lifecycle. For rail OEMs and operators, the economic benefits stack up impressively:

• Single-source procurement cuts down on vendor management time and costs.

• Reduced installation labour translates to immediate savings.

• Component standardisation reduces spare parts inventory.

Let’s now take a closer look at how manifolds are built and why quality matters. Every aspect of their design and manufacture plays a role in determining performance, durability, and resilience. By examining the processes behind manifold construction, we can uncover the key factors that distinguish reliable, high-performing systems from those more likely to fail.

Manifolds route multiple flow paths through a single block, replacing external connections with internal channels. This is achieved through cross-drilling – creating precisely positioned holes that intersect within the manifold block. Multiple flow paths are routed through these intersecting channels, converging at a single opening.

The challenge lies in the drilling process itself. When a drill bit breaks through into an existing channel, it can create debris or burrs in the intersection. Even microscopic debris can eventually loosen and damage valve mechanisms, compromising the entire system.

This is why precision manufacturing is critical. Every intersection must be flawlessly clean and machined to exact specifications to ensure the highest levels of performance and durability.

Choosing a supplier with the right technical expertise and experience is vital for achieving top-tier manifold performance and reliability.

With over 70 years of fluid and motion control expertise, we combine advanced technical knowledge with a deep understanding of real-world challenges, delivering manifold solutions that meet the highest standards of reliability and performance.

While simple manifold assemblies essentially function as valve islands, more sophisticated systems can incorporate dozens of components performing multiple tasks.

A more complex, comprehensive manifold might include:

• Solenoid valves and regulators for precise control

• Pressure relief and flow control valves for system protection

• Check valves and non-return valves to manage flow direction

• Manual on/off valves for isolation and maintenance

• Filters and other accessories for system protection

Manifold-mounted components deliver clear benefits for installation and maintenance compared to stand-alone alternatives.

Fluid connections are centralised on one side, and plug-in subbase valves allow for quick and easy replacements in the field. Integrated tube connections extend directly from the manifold block, removing the need for additional fittings and reducing potential leak points.

The resulting modular design ensures that individual components can be replaced without disrupting the rest of the system, streamlining maintenance and minimising downtime.

For optimal results, OEMs should work with suppliers experienced in both manifold design and seamless component integration.

With over 70 years of expertise in pneumatics, we provide preassembled, rail-validated units that simplify installation, enhance reliability, and help OEMs focus on delivering high-performing rail systems.

While engineers can source and integrate components individually, partnering with a supplier who offers both manifold expertise and a complete component range delivers significant system performance and reliability advantages.

At IMI, we offer several distinct types of manifolds – from solid machined blocks to the latest 3D additive manufacturing. Each brings strengths and advantages to rail pneumatic control.

These manifolds are machined from solid blocks of metal – aluminium, stainless steel or brass. We precisely drill the network of internal channels and connections, ensuring every intersection is completely burr-free.

Precision machined manifolds can be fitted with different connection types - NPT, straight thread, or flat bottom ports –offering flexibility in integrating them into your systems.

Using advanced 3D metal and polymer printing technology enables the creation of intricate shapes and optimised flow paths that were previously difficult or impossible to achieve. Additionally, this approach addresses challenges like obsolescence and long lead times, delivering faster and more adaptable solutions to meet evolving needs.

Either type of manifold - machined or 3D printed- can form the foundation of a complete, custom manifold system. We integrate all necessary valves, regulators, and other control components directly onto the manifold.

Every custom manifold system undergoes thorough testing before delivery to ensure reliable performance.

Manifold solutions solve diverse rail challenges where reliability and long-term durability are mandatory.

Here are a couple examples that showcase how thoughtfully engineered manifold assemblies solve challenges in rail system design:

Space is incredibly tight when designing for nose cone control, while system reliability is non-negotiable.

Challenge

The challenge here was twofold: eliminate potential leakage points while fitting everything into an extremely confined space.

Solution

Our integrated solution combined solenoid valves, mechanical valves, and a pressure regulator in a weight-optimised package. We also incorporated integral manual valves into the design to ensure nose cone operation even during complete electrical failure.

Sanding systems are critical for safe operation, improving both traction and braking performance during bad weather (snow, ice) and on challenging gradients.

These systems work by delivering a controlled amount of sand to the rail surface, increasing friction between the wheels and the track to prevent slipping.

Challenge

This application required a solution that was modular, lightweight, and fully compliant with strict rail certification standards.

Solution

Our engineering team developed a modular, lightweight solution that offers flexibility and ease of maintenance. Each component was carefully chosen for rail certification to ensure reliable performance in demanding environments.

The final system was not only easy to maintain but also allowed for quick component swaps when different functions were required, all while meeting the rigorous standards for use in harsh rail conditions.

Manifold reduces complexity and size, and meets low temperature requirements

Manifold helps to improve traction during bad weather conditions over long steep gradients.

Manifolds can deliver tangible improvements in system reliability, installation simplicity, and space efficiency – all critical for rail applications where every millimetre counts and failure is not an option.

Achieving these advantages relies on selecting precision-manufactured manifolds.

Cross-drilling internal channels demands absolute accuracy to prevent debris and leaks, while thoughtful component integration ensures the manifold design operates at peak efficiency.

A poorly designed or manufactured manifold can create more issues than it promises to resolve.

That’s why partnering with an experienced manifold manufacturer and supplier like IMI is so valuable. We combine deep rail industry expertise with comprehensive manufacturing capabilities to deliver first-class solutions.

Drawing on over 70 years of fluid and motion control expertise, we support rail engineers with ultra-high-quality manifolds that deliver on every key benefit, allowing them to focus on their design and operational priorities. Contact us today to discuss how our manifold solutions can support your rail systems.

Our Industrial Automation sector operates four global centres of technical excellence and a sales and service network in 50 countries, as well as manufacturing capability in Europe, Americas and Asia Pacific.

Supported by distributors worldwide.

For further information, scan this QR code or visit www.imiplc.com/industrial-automation

The information in this brochure is provided for informational and promotional purposes only and is provided “as is” and without warranties of any kind, whether express or implied, including but not limited to implied warranties of satisfactory quality, fitness for a particular purpose and/ or correctness.

Any specifications, features, pricing, or availability contained in this brochure are subject to change without prior notice. IMI plc does not represent or warrant that the information and/or specification in this brochure are accurate, complete, or current and therefore make no warranties or representation regarding the use of the content. IMI plc or one of its subsidiaries own all images, logos, product brands, and trademarks mentioned in this brochure. Unauthorised use, reproductions, or modification of this content is prohibited.

© Copyright IMI plc. All rights reserved. z10357WP en/03/25

Selected Images used under license from Shutterstock.com