DAMS & RESERVOIRS

Constructing the iconic Yusufeli Dam

WATER & WASTEWATER

The road to water digitisation

Sustainable and striking structures built to last in wire and stone

LEGAL EPC versus EPCM contracts

RENEWABLE ENERGY & ELECTRIFICATION

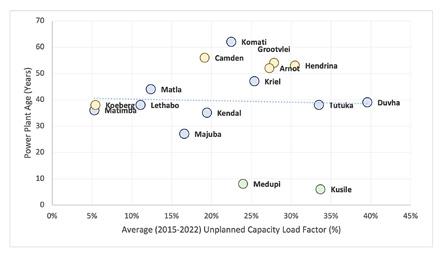

Loadshedding and recovery

OEM leaders in pump operations and maintenance

IMESA The official magazine of the Institute of Municipal Engineering of Southern Africa www .imesa.org.za INFRASTRUCTURE DEVELOPMENT • SERVICE DELIVERY • ROADS • BUILDING • MAINTENANCE • ENERGY ISSN 0257 1978 Volume 47 No. 01 • January 2022 • R55.00 (incl. VAT) ISSN 0257 1978 Volume 48 No. 08 • September 2023 • R55.00 (incl. VAT)

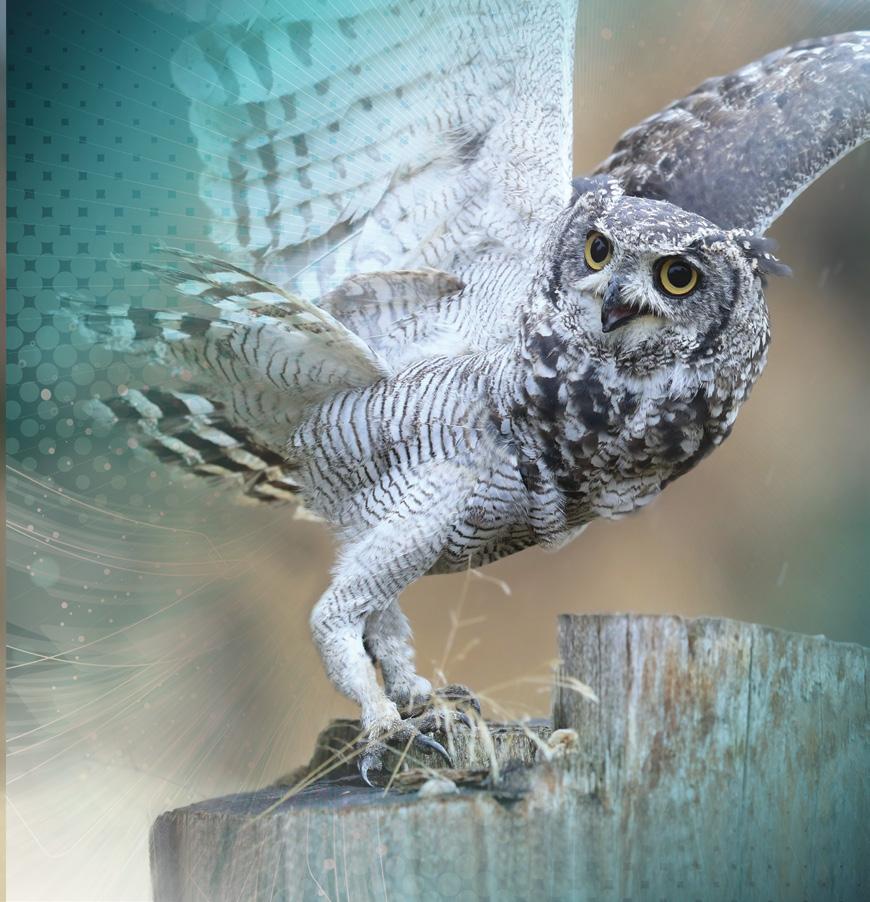

John Montgomery GM for APE Pumps and Mather+Platt

INDUSTRY INSIGHT

GABION

BASKETS

THE MOST EFFECTIVE SOLUTION

TOM® PVC-O PIPES

TOM® PVC-O pipes are a product developed exclusively with the Molecor innovative technology that provides the highest Molecular Orientation. The manufacturing process is continuous and completely automatic, which ensures the maximum product reliability and a quality control tube to tube for the 100% of the production.

Best Solution

TOM® is the best solution for the conveyance of water at medium and high pressure for irrigation systems, drinking water supply, reuse, industrial or fire protection lines, among other uses. The extraordinary technical advances of the manufacturing system of Molecor confer the TOM® Oriented PVC pipe significant improvements.

Main advantages

• Cost efficiency: Manual handling up to DN350 mm

• Natural resources Usage optimization: Optimization of the use of natural resources and 100% recyclable

• Energy efficiency: Lower energy consumption throughout the life cycle

Polyvinyl chloride (PVC) is essentially an amorphous polymer in which molecules are aligned at random. However, by stretching the material and under certain conditions of pressure, temperature and speed, the polymer molecules can be aligned in the same direction as it has been stretched.

www.sizabantu.com | proudly@sizabantu.com

A leader in its field, Gabion Baskets continues to push the boundaries of product innovation, backed by in-field experience and a unique ability to develop structures that set new industry benchmarks for form and function. P6

INDUSTRY INSIGHT

Two key issues are central to the turnaround of underperforming water and wastewater infrastructure within municipalities, namely proactive asset management, along with a well planned and executed operations and maintenance (O&M)

IMIESA speaks to John Montgomery, general manager for APE Pumps and sister entity Mather+Platt (the Group) about how their turnkey OEM solutions are making a difference.

Excellent progress reported on regional SANRAL projects 31 Water & Wastewater Where are you on the road to water digitisation? 32 Amphibious pumps for diverse applications 33 Recycle and reuse water to save the planet 34 Pipe Systems Nationwide campaign drives home the value of plastic pipe 35 South African Vinyls Association (SAVA) “Innovation in PVC” conference showcases local and global excellence 36 Renewable Energy & Electrification Establishing the Phezukomoya Wind Energy Facility 37 South Africa’s loadshedding woes and its path to recovery 38 Waste Management Office waste segregation qualifies for carbon offsets 41 Cement & Concrete Site visits help CCSA members maintain quality in construction 42 AfriSam lab passes SANAS recertification with flying colours 43 50 years of best practice in precast 44 Vehicles & Equipment Battery powered forklifts are the future 45 Gauteng sand operation ramps up production 47 Solar powered light tower provides sustainable solution 48

INSIDE OEM leaders in pump operations and maintenance John Montgomery INDUSTRY INSIGHT MESA IMESA The official magazine of the Institute of Southern Africa www.imesa.org.za RENEWABLE ENERGY & ELECTRIFICATION Loadshedding and recovery WATER & WASTEWATER The road to water digitisation LEGAL EPC versus EPCM contracts DAMS & RESERVOIRS Constructing the iconic Yusufeli Dam structures built to last in wire and stone GABION BASKETS ON THE COVER www.imesa.org.za Regulars Editor’s comment 3 President’s comment 5 Index to advertisers 48 Cover Story Sustainable and striking structures built to last in wire and stone 6 Legal Which is better for construction and mining projects – EPC or EPCM contracts? 10 Spatial Development & Planning Urban decay puts Joburg’s CBD in the spotlight 12 Industry Insight OEM leaders in pump operations and maintenance 14 Dams & Reservoirs Turkey’s Yusufeli Dam is one of history’s most iconic structures 16 Lesotho Highlands Phase II has a core focus on community and the environment 20 Precast Retaining Systems Mixed pattern wall design retains steeps slopes, with easy planting 24 IMESA Creating the future networks and connecting the dots 26 KwaZulu-Natal Golf Day 28 Women’s Day Celebrations 28 Training & Development Finance and oversight course empowers iLembe leaders 29 Roads & Bridges Cost effective dust suppression for unpaved routes 30 30 ROADS & BRIDGES PRECAST RETAINING SYSTEMS 24 21 VOLUME 48 NO. 08 SEPTEMBER 2023

P14

EARLY BIRD REGISTRATION

Register and pay BEFORE 31 July 2023

• Members: R6 700

• Non-members : R8 000

BOARDWALK HOTEL Gqeberha (Port Elizabeth)

STANDARD REGISTRATION

Register and pay AFTER 1 August 2023

• Members : R7 500

• Non-members : R8 900

HOTELS WITHIN CLOSE PROXIMITY OF THE BOARDWALK HOTEL (IMESA will provide a shuttle service to and from the hotels listed below)

t: +27 (031)266 3263

e: conference@imesa.org.za marketing@imesa.org.za

www.imesa.org.za

25-27 October 2023

IMESA ORGANISER THE INSTITUTE OF MUNICIPAL ENGINEERING OF SOUTHERN AFRICA (IMESA) CONFERENCE ENDORSED BY BOOK YOUR accommodation NOW

86 TH IMESA Conference

Road Lodge 100m from venue Town Lodge 430m from venue Beach Hotel 100m from venue Protea Marine Hotel 900m from venue Courtyard Hotel 100m from venue Chapman Hotel 1,1km from venue City Lodge 380m from venue Garden Court 1,3km from venue

EDITOR Alastair Currie

Email: alastair@infraprojects.co.za

DESIGNER Beren Bauermeister

CONTRIBUTORS Alex Goddard, Chetan Mistry, Sibusiso Mjwara, Bryan Perrie, Patrick Prestele, Natalie Reyneke

DISTRIBUTION MANAGER Nomsa Masina

DISTRIBUTION COORDINATOR Asha Pursotham

SUBSCRIPTIONS

Email: IMIESAdistribution@infraprojects.co.za

ADVERTISING SALES

KEY ACCOUNT MANAGER Joanne Lawrie

Tel: +27 (0)11 234 0825 / +27 (0)82 346 5338

Email: joanne@infraprojects.co.za

Every well executed infrastructure project makes the difference

Within the Southern Hemisphere, Phase I of the Lesotho Highlands Water Project (LHWP) – completed in 2003 and inaugurated in 2004 – was one of history’s landmark developments, only potentially to be eclipsed in Phase II by the works in progress for the construction of the Polihali Dam and transfer tunnel, plus associated works. We cover some of the findings on Phase I that influence Phase II in this issue.

PUBLISHER

IMESA (Pty) Ltd

P O Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Email: info@infraprojects.co.za

ANNUAL SUBSCRIPTION: R600.00 (INCL VAT)

ISSN 0257 1978 IMIESA, Inst.MUNIC. ENG. S. AFR.

© Copyright 2023. All rights reserved.

IMESA CONTACTS

HEAD OFFICE:

Manager: Ingrid Botton

P.O. Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Email: admin@imesa.org.za

Website: www.imesa.org.za

BORDER

Secretary: Celeste Vosloo

Tel: +27 (0)43 705 2433

Email: celestev@buffalocity.gov.za

EASTERN CAPE

Secretary: Susan Canestra

Tel: +27 (0)41 585 4142 ext. 7

Email: imesaec@imesa.org.za

KWAZULU-NATAL

Secretary: Narisha Sogan

Tel: +27 (0)31 266 3263

Email: imesakzn@imesa.org.za

NORTHERN PROVINCES

Secretary: Debbie Anderson

Tel: +27 (0)83 326 3050

Email: np@imesa.org.za

SOUTHERN CAPE KAROO

Secretary: Henrietta Olivier

Tel: +27 (0)79 390 7536

Email: imesasck@imesa.org.za

WESTERN CAPE

Secretary: Michelle Ackerman

Tel: +27 (0)21 444 7112

Email: imesawc@imesa.org.za

FREE STATE & NORTHERN CAPE

Secretary: Wilma Van Der Walt

Tel: +27 (0)83 457 4362

Email: imesafsnc@imesa.org.za

Another more recent and completed example that we also cover in this edition is the new Yusufeli Dam, now the highest in Turkey and the fifth highest double curvature arch structure of its kind in the world. The ARQ-Su Yapi team for the dam design was led by Dr Quentin Shaw of ARQ Consulting Engineers, based in Pretoria. It recently won the Best International Project category at the 2023 CESA Aon Engineering Excellence Awards.

Mega projects like the LHWP (Phase I and II) and the Yusufeli dam take years of planning and international funding preparation, and their establishment helps to provide longer-term water security for generations to come. However, the same is true for water and wastewater projects of all sizes – extending from new and replacement pipelines, to upgraded pump stations, and refurbished treatment works.

Every project in integrated

Even the smallest “non-mega” infrastructure upgrade makes a huge difference in the lives of communities when it comes to ensuring safe potable water and sanitation. And ultimately, all mega water projects ensure that every municipality and consumer have service delivery at the turn of a tap for drinking water, and sustained flushing when it comes to waterborne sanitation.

In South Africa those priorities keep growing –particularly on the sanitation side – underscored by the fact that only 23 out of close to 1 000 wastewater treatment plants across South Africa met the minimum 90 percent scoring requirement to qualify for Green Drop Certification.

Funding from the South African fiscus has been constrained for years, but despite this, the Department

of Water & Sanitation’s commitment to priority projects saw the allocation of around R40,3 billion for the 2023/24 financial year, and R43,9 billion and R48,4 billion for the 2024/25 and 2025/26 financial periods.

However, budgeted numbers have always been based on assumptions, like forecasted tax revenues collected, which strongly influence actual expenditure available. On 01 November 2023, the infrastructure sector in general will have a clearer understanding of what’s on the table over the next three years when South Africa’s Minister of Finance, Enoch Godongwana, delivers the Medium-Term Budget Policy Statement in parliament.

PPPs need guarantees

As we’ve seen from the Renewable Energy Independent Power Producer Procurement Programme, the local and international private sector does have the appetite to invest in bankable public private partnership (PPP) projects at mega scale. The key challenge at present is the length it takes to get approval. But perhaps even more importantly is the need for a government focus on PPPs at “micro scale” because this is one of the paramount priorities right now.

Either way, at local government level, the overriding mandate should be on ensuring that each municipality achieves its own financial independence through the effective delivery of the infrastructure services it sells to households and industry.

That requires strong leadership, expertise in engineering and finance, plus the integration of technologies that work. The latter include smart metering for water and electricity, Geographic Information Systems for real-time land and asset management, plus the latest in ICT.

Navigating the infrastructure landscape is a team effort that cannot isolate engineering from finance. Collectively, we need to plan the flight, and fly the plan together.

Cover opportunity

IMIESA September 2023 3

EDITOR’S COMMENT To our avid readers, check out what we are talking about on our website, Facebook page or follow us on Twitter and have your say.

Alastair

In each issue, IMIESA offers advertisers the opportunity to get to the front of the line by placing a company, product or service on the front cover of the journal. Buying this position will afford the advertiser the cover story and maximum exposure. For more information on cover bookings, contact Joanne Lawrie on +27 (0)82 346 5338. pump operations and maintenance John Montgomery INDUSTRY INSIGHT MESA IMESA of Municipal Engineering .imesa.org.za INFRASTRUCTURE DEVELOPMENT SERVICE DELIVERY ROADS BUILDING • MAINTENANCE • ENERGY RENEWABLE ENERGY & ELECTRIFICATION Loadshedding and recovery WATER & WASTEWATER The road to water digitisation LEGAL EPC versus EPCM contracts DAMS & RESERVOIRS Constructing the iconic Yusufeli Dam Sustainable and striking structures built to last in wire and stone GABION BASKETS The ABC logo is a valued stamp of measurement and trust. IMIESA is ABC audited and certified.

All material herein IMIESA is copyright protected and may not be reproduced without the prior written permission of the publisher. The views of the authors do not necessarily reflect those of the Institute of Municipal Engineering of Southern Africa or the publishers.

www.imesa.org.za

IMESA imesa_za imesa

SUPPORTING THE LIFECYCLE OF WATER

We enable our customers to drastically improve the way water and wastewater are managed, conserved, reused, and returned to nature.

Innovative, smart technology solutions for water and wastewater

Proven expertise across industries and the water cycle

Unmatched service and customer support

Find out how we can solve water together.

INFRASTRUCTURE INVESTMENTS AND ASSET MANAGEMENT

In August, I had the privilege of representing South Africa, and the associated Southern African countries that form part of the International Federation of Municipal Engineering (IFME) – namely Botswana, Namibia, and Zimbabwe – at IFME’s second of two board meeting for 2023.

Held on 29th August in San Diego, this meeting coincided with the 2023 Public Works Expo (PWX), which was organised and hosted by the American Public Works Association (APWA) and attracted some 6 000 delegates from across America and the globe.

PWX was a great gathering of some of the foremost thought leaders in municipal engineering and certainly an excellent networking experience. One thing is clear from the presentations: irrespective of our developed or developing nation status, every country – to a greater or lesser degree – faces common challenges such as climate change, burgeoning population growth, and a massive urbanisation shift.

For this reason, there’s a constant need to advance the infrastructure agenda as a core socioeconomic priority. To make that happen in practice requires constant lobbying at the highest political decision-making levels and not just in South Africa, as Scott Grayson, chief executive officer of the APWA and the Canadian Public Works Association (CPWA) pointed out at PWX, and last year during his presentation at IMESA’s 85th Annual Conference in Johannesburg.

Alignment and unification

Scott’s leadership via the APWA and CPWA has been instrumental in drawing attention to and prioritising infrastructure budget allocations from within the US Congress, Canadian parliament, and federal and provincial/state branches of government agencies in both countries. One of the key success factors has been effective alignment and unification, something we need to focus on more so that our various voluntary associations speak with one voice on pressing built environment issues.

IMESA is in a unique position to do so because it represents municipal engineers from across the civil, electrical, mechanical, and related disciplines at local government level. That’s great in terms of engineered outcomes, but we also appreciate that if councillors, financial officers, and municipal managers are not on the same page, we have a disconnect that can and does derail service delivery. Not just in terms of poor execution, but from a revenue perspective.

So IMESA is on a mission to increase its level of interaction with all public sector stakeholders –from National Treasury to the South African Local Government Association and the Department of Public Works and Infrastructure – to make sure our message is heard, understood, and actioned.

A stitch in time saves nine

Central to everything is asset management (AM), dovetailing with operations and maintenance (O&M). These were also key interrelated themes at PWX and mirrored at our own IMESA conferences.

As a general rule around 8% of budgeted infrastructure expenditure in any year should be allocated to AM. However, that isn’t happening in South Africa. And timing is another factor since

as maintenance backlogs grow and money becomes scarcer, it triggers a catalytic downward spiral of infrastructure decay that plays havoc on business and society. Loadshedding is a case in point.

As part of IFME’s Technical Committee, we had the opportunity to present and engage on wide ranging issues at PWX and it’s clear that each country has its own stages of maturity in applied AM. The consensus is that for AM to work optimally, the process must start at the design stage to optimise life cycle costing and the return on investment. However, the foremost priority is to maintain existing services effectively because we all know it costs far more to replace, say, a road or a wastewater pump installation.

Austerity measures

For this reason, we are concerned about the National Treasury’s recent proposal that a freeze be placed on new infrastructure procurement due to a contraction in tax revenues. That’s not where budgets should be cut, because it has a counterproductive effect on micro and macroeconomic performance.

It is a very tough global economic climate out there at present, and that’s reflected within our IFME community. However, as municipal engineers we know that without enabling infrastructure we don’t have an economy that works. Plus, flood damaged regions across the country, including eThekwini, still haven’t recovered and restored all their assets. And what about the recent damage caused by a gas pipeline explosion in Johannesburg’s CBD?

So, following the APWA example, IMESA’s mandate is to ensure that austerity measures don’t impede service delivery. Let’s rather focus on eradicating fruitless and wasteful expenditure.

IMIESA September 2023 5

PRESIDENT’S COMMENT IMESA

Sibusiso Mjwara, PrTechEng, MIMESA, MSAICE, MWISA, MIPET

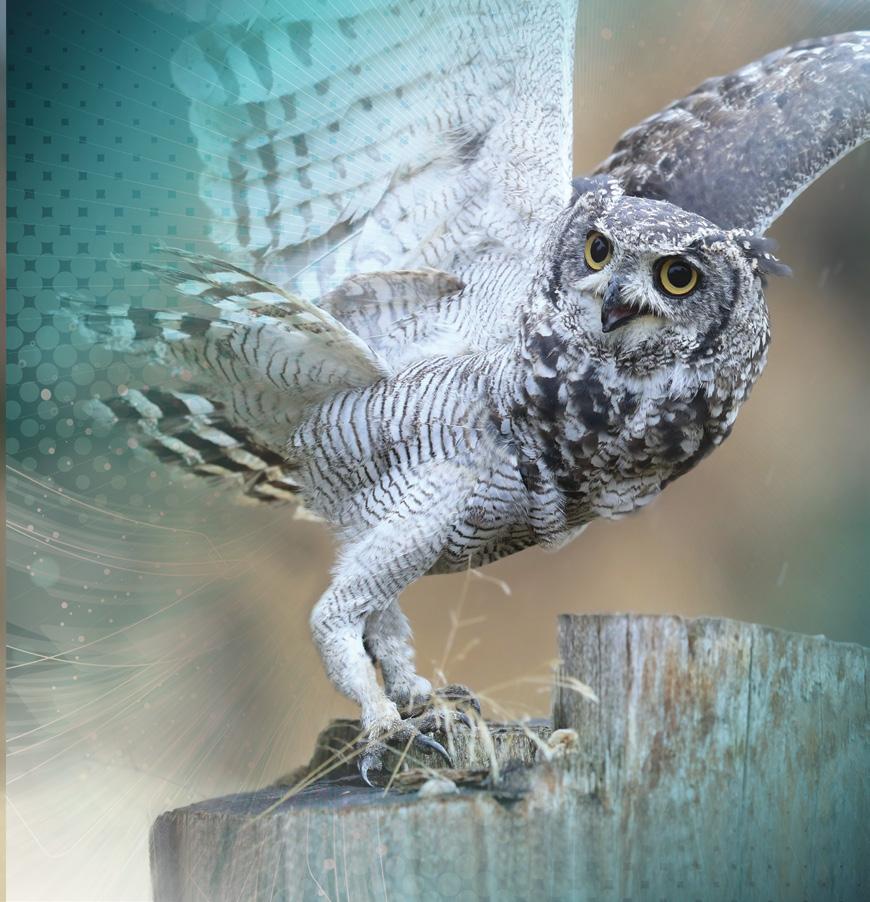

Sustainable and striking structures built to last in wire and stone

A leader in its field, Gabion Baskets continues to push the boundaries of product innovation, backed by in-field experience and a unique ability to develop structures that set new industry benchmarks for form and function.

The company was founded 17 years ago in 2006 as a specialist manufacturer in hexagonal double-twisted wire mesh systems, employed worldwide for well over 100 years to form gabion infrastructure predominately used for civil engineering

roles like mass gravity retaining walls, and river erosion works.

A more modern, and parallel development is the introduction of welded mesh products that can meet civils specifications but are predominately used for architectural applications that include interior and

exterior building cladding, reception desks, freestanding walls, landscaping, and allied designs that naturally enhance the aesthetic appeal of these rock-filled structures.

6 IMIESA September 2023 COVER

STORY

A virtual rendition of a gabion river wall retaining system

GABION ANIMATION

Gabions Baskets’ traditional 2D design services have evolved to encompass 3D animation, enabling clients, architects, engineers and contractors to obtain a virtual perspective and refine their requirements accordingly.

The latter include security and pedestrian barriers, and anything in between. A great example is Gabion Baskets’ launch of its Fire Pit range – essentially a welded mesh circular design that creates a unique entertainment feature for residential and allied commercial applications, such as guest lodges.

National manufacturing centres

Gabion Baskets’ main manufacturing centre is based in Johannesburg, supported by its satellite fabrication facilities in Durban and Cape Town. “In the past, all standard

Further down, an existing pedestrian bridge was rehabilitated by creating a new inlet and outlet culvert on either side. Lowering the height of the bridge and creating a concrete capping walkway allows the water to flow over the bridge if the existing pipes get blocked due to debris or extensive water volumes.

CASE STUDY: RIVER EROSION WORKS

and custom project-related orders were made in Johannesburg for on-site delivery, with Durban and Cape Town only receiving raw woven and welded mesh materials for onward sale to local assemblers,” explains Louis Cheyne, managing director, Gabion Baskets.

“We’re now closing that loop to ensure customers can order ‘ready to assemble’ kits from all three facilities, thanks to recent expansion activities that include a move to a new building for our Durban operation.

“Aside from shorter lead times – so critical for just-in-time construction delivery – the

Gabion Baskets’ Durban office recently provided a design recommendation and installation solution within the Mount Edgecombe Estate 2. The scope entailed the rehabilitation of a small river channel and associated low level road bridge crossing. Generally during normal light rain, stormwater flows are low. However, due to current road construction works on the neighbouring N2, this has increased significantly, overwhelming the capacity of the channel.

The solution entailed the installation of gabion mattresses – resting on a geotextile liner (an essential requirement) – to create a free-flowing channel. This measures 35 m in length and 2 to 3 m in width. A new gabion wing wall

was also constructed on the outlet side of the bridge to miminise the risk of downstream embankment erosion, especially during flood events.

The site did have existing 0,5 m high gabion retaining sections. However, without a foundational gabion mattress, they had been progressively undermined by scouring – a problem which was rectified by Gabion Baskets’ design recommendation and installation solution. For all project phases, the wire system used for the baskets and mattresses is Class A galvanised with a polymer coating for added durability against corrosion. In total, 96 tonnes of rock fill were supplied and packed by hand and the project duration was 19 days from start to finish.

IMIESA September 2023 7

COVER STORY

An artist’s impression of an attenuation pond incorporating gabion systems

The natural beauty of stone-filled gabion systems is now being explored for a range of architectural applications

BARRIER SYSTEMS

added benefit is that our locally based project managers and trainers are now much closer to their markets when it comes to design and installation advice for consulting engineers, contractors, and SMME sub-contractors. Plus, there’s an opportunity to stimulate regional growth in the gabion construction segment

FEATURE AND BOUNDARY WALLS

and create much needed jobs for private and public sector related works.”

Gabion Baskets’ Johannesburg facility has evolved significantly since 2006, shifting from a predominately manual fabrication process to a high degree of factory automation, in line with world class industrial engineering

practices. This has led to recent investments in machinery that enhance worker ergonomics and efficiencies, ensuring consistent throughput quality. A similar ongoing technical upgrade will follow for the company’s satellite centres.

Growth in South Africa and Africa

“In recent years, we’ve experienced an upsurge in demand from South African customers, alongside major export growth into Africa for countries that include Malawi, Mozambique, and Zambia. Further afield, we’re also increasingly supplying South African-based contractors working on projects throughput the African content, as well as governmental clients closer to home within the SADC region for a wide range of requirements. These range from African Union military missions to transportation engineering and mining developments,” Cheyne continues.

Boundary walls and cladding

One of Gabion Baskets’ fastest growing areas is the architectural market. “The number of enquiries continues to grow from architects, engineers, property developers and the general public and we’re responding with creative and ‘out of-the-box’ solutions,” Cheyne continues. “It’s an exciting new frontier with a high degree of interest shown during our recent stand exhibits at the Home and Garden expo, and the Decorex shows in Cape Town and Johannesburg.”

Recent project examples include perimeter walls for housing within the Eagle Canyon Golf and Lifestyle East. These are composed entirely of stacked welded mesh panels

8 IMIESA September 2023

COVER STORY

A river wall cross section indicating the key design elements

Examples of gabion wall systems constructed using welded mesh panels

A traffic barrier system designed and fabricated by Gabion Baskets for a commercial facility

Retaining walls are mass gravity structures that can be designed in a wide range of configurations to match ground contours. A case in point is an L-shaped structure where Gabion Baskets’ Durban office was requested to provide a design recommendation and build solution for a residential development. The design needed to provide an engineered solution that would also serve as an aesthetic feature wall.

founded on a concrete base and internally supported by interspersed rebar. Another recent project in Vanderbijlpark, entailed the design of a perimeter wall composed of brick columns interspersed with welded mesh sections. Clear fence walls supported by gabion columns are also proving popular as an added security feature, as are freestanding feature walls, as well as welded mesh cladding systems for buildings and landscaped wall features.

Welded mesh is ideally suited for these designs due to the flat finish and exact tolerances achieved, making it the definitive choice for architectural designs and building cladding. In theory, woven mesh could be used, but as Cheyne points out its core purpose is to perform in an engineering environment, like embankment stabilisation, in conjunction with geotextile systems designed to control permeability and soil retention.

Submerged in a riverine environment, a retaining wall constructed using welded mesh panels would break apart within a short space of time because it doesn’t have the purpose-designed flexible characteristics of woven mesh. However, for land-based structures, welded mesh can be used for retaining walls where the express purpose is to achieve an optimum aesthetic effect.

“Currently, our welded mesh systems

In addition to providing a retaining function, welded mesh gabion panels can serve a dual purpose as cladding to create a striking aesthetic effect

WALL CLADDING

come in a standard silver colour due to their Class A Galvanised finish. However, we’re now researching other colour options, either using a polymer or a powder coating, for architectural projects,” Cheyne continues.

“Colour is also an option for woven mesh, thanks to developments in polymer coatings. The latter provide the dual benefits of additional corrosion and scour protection. Plus, colours like tan or green enable engineered gabion structures to blend in with the environment, which may be a design requirement within urban areas,” he adds.

“Either way, the natural beauty of their

stone fill makes gabions a default choice for architectural, landscaping and engineering projects, and at times a combination of all three,” Cheyne concludes.

www.gabionbaskets.co.za

IMIESA September 2023 9 COVER STORY

L-SHAPED RETAINING WALL

The L-shaped wall measures 21 m and 16 m in length respectively, differing in height from 3 m to 1,5 m with a 6-degree batter against the embankment. At the client’s request, additional extensions were created at both ends of the wall.

WHICH IS BETTER FOR CONSTRUCTION AND MINING PROJECTSEPC OR EPCM CONTRACTS?

There is a swing away from the engineering, procurement, construction and management (EPCM) contracting model in the South African construction and mining sectors. Instead, engineering, procurement and construction (EPC) contracts are increasingly being used, according to construction law specialist, MDA

Attorneys.

By Natalie Reyneke, with Alex Goddard

There is a difference, and the consequences of choosing the wrong type of contract can be severe. While an EPC contract takes the form of a design and construction contract, the EPCM model can be regarded as a professional services contract. The EPCM contractor has a duty to ensure that the engineering and design of the project complies with the project’s technical and functional specifications.

In mining, as well as plant design and build or upgrade projects, EPC contracts are being used more frequently due to unprecedented risks and opportunities in the current economic climate –currently a very competitive market,

with a shortage of skills among clients (owners of the project). Cost and time overruns are common, so clients try to avoid assuming risk, especially when it is unlikely that project savings can be achieved. On the other hand, construction contractors are grateful for work secured and sometimes overlook the risks involved.

Cost difference

In an EPC contract, the contractor needs to price and schedule for the entire project (design, engineering, procurement, and construction services). The EPC contractor provides the tendered price and completion date, so clients are less likely to allow for any adjustments.

Clients expect their projects to be completed in the time and within the costs calculated and supplied by the contractor. The client does not expect to take much risk and does not expect to pay any more than what was budgeted.

In contrast, the EPCM contractor provides a cost estimate and estimated duration of the work, which are generally subject to contractual provisions, allowing for remeasurement and adjustment.

The client enters into multiple contracts on the advice of the EPCM contractor, so cost management is required on several contracts.

There are fundamental differences in terms of fixed price and remeasurable contracts, yet we are seeing EPC contracts

LEGAL

Alexander

being conflated by the insertion of “estimated” budgets in pricing documents, while the conditions of contract are essentially an EPC lump sum contract. The two simply don’t speak to each other.

The EPC contractor sees no harm in signing a remeasurable subcontract, believing that they can manage the budget. However, the EPC contract usually contains numerous restrictions on their ability to claim additional compensation or time. Adding to the risk, the EPC contractor must ensure that agreements with subcontractors follow suit, as any additional costs incurred by subcontractors cannot be claimed from clients.

What to look out for

Another anomaly that we often see is the insertion into the pricing schedule of a “contingency”. While it sounds like a good idea, the conditions of contract do not provide for such a concept. We also regularly come across the phrase “fixed and firm” when talking about pricing. This could mean either that there is no escalation on the prices making up the lump sum, or it’s intended to indicate the price of the project is a fixed lump sum and not subject to remeasurement.

Whose risk is it?

EPC contractors carry the risk of not completing the project on time and for the tendered price, whereas this risk is generally more evenly distributed between the client, the EPCM contractor and the appointed contractors or suppliers in an EPCM contract.

It stands to reason that the EPC contractor is bound by the price and timelines it has offered to the client. It is the contractor who designs and builds the works, so EPC contractors also assume the risk for performance. In addition, EPC contractors must manage the procurement and administration of supplies, professional services and subcontracts.

On the other hand, EPCM contractors do not contract with the construction contractors or suppliers – the client does – and EPCM contractors only take risks in relation to these contracts if problems have arisen due to a lack of skill and care.

Because EPC contractors include the assumed risk in their pricing, EPC contracts are more costly to execute. In addition, the EPC contractor very often stands to benefit from any cost savings occurring on the project. In this way a well negotiated, priced and executed EPC

contract can result in significant benefits to the EPC contractor.

Expertise requirements differ

Under the EPCM model, clients usually appoint both an EPCM contractor (who provides professional services) and a construction contractor. Under the EPC model, the appointed contractor provides design, engineering, procurement and construction services. In addition, the EPC contractor appoints subcontractors to implement and complete the project.

Due to the nature of EPC contracts and client expectations for contractors to provide turnkey services, there is little involvement from the client and the projects are largely managed by the EPC contractor, who contracts directly with the suppliers and other subcontractors. Cost risk and control are weighted towards the EPC contractor and away from the client.

Conclusions

With in-house skills in short supply currently, the use of an EPC contract allows the client to limit its involvement in the contract.

Furthermore, while there are several issues for contracting parties to consider when entering into and executing an EPC contract, alleviation of risks can be achieved with a clear understanding of what they are, a well negotiated contract, and a well-qualified tender submission.

LEGAL

Alex Goddard, candidate attorney

Goddard joined MDA Attorneys in 2022 having completed his BCom Law and LLB. Goddard has been involved in all the services offered by the firm including contract drafting, contracts management, contractual disputes and litigation.

Natalie Reyneke joined MDA Attorneys in 2012. Reyneke has extensive specialist contract skills in relation to the construction, mining, and technology industries. Advising all role players in the contractual hierarchy has provided deep knowledge of practicalities and nuances required to navigate legal issues.

Natalie Reyneke, director

IMIESA September 2023 11 www.mdalaw.co.za

In an EPC contract, the contractor needs to price and schedule for the entire project (design, engineering, procurement, and construction services).

URBAN DECAY PUTS JOBURG’S CBD IN THE SPOTLIGHT

the past two decades, TUHF has provided finance for affordable residential rental properties in all major metropolitan areas of South Africa, totalling over R7 billion and encompassing some 46 374 units

The recent spate of serious events in Johannesburg’s CBD – including the tragic fire in Marshalltown that claimed 77 lives, plus the devastating gas leaks in De Korte and Bree Streets – continue to raise concerns over poor urban management, lack of by-law enforcement and inadequate governance.

From the lack of service delivery, the increased scourge of hijacked buildings, damage to properties caused by the 2021 riots, xenophobic attacks and dangerously insufficient maintenance of infrastructure, we have relentlessly voiced our concerns and engaged with local government to find solutions,” says Paul Jackson, CEO of TUHF, which has been a key driver in Johannesburg’s inner city rejuvenation, with more than R5 billion invested there over the past 20 years.

“TUHF has empowered aspiring property entrepreneurs to create safe homes and jobs within the inner city and to make an impact on communities that live, work and play here. We remain committed to the property investors we support, and as such, we must call for urgent change in the way the Johannesburg CBD is being managed,” Jackson continues.

Systemic issues

TUHF is deeply saddened by the recent events in the Johannesburg CBD. Such incidents reflect a critical systemic issue which affects the capital markets, the insurance sector, rental housing suppliers and the tenants they serve.

However, TUHF believes in the business case for inner cities as an essential catalyst for inclusive and transformative economic growth. “Inner cities have the potential to

drive real growth at a local level, providing economic opportunities to SMMEs and low to moderate income households,” adds Lusanda Netshitenzhe, CEO of TUHF21, an allied group entity.

“Therefore, we are committed to collaborating with the city and other stakeholders to find sustainable solutions and believe that a united effort is essential to create a more prosperous city. This reality cannot be ignored any longer,” Netshitenzhe concludes.

12 IMIESA September 2023 SPATIAL DEVELOPMENT & PLANNING

A TUHF building in Johannesburg’s CBD. Over

Paul Jackson, CEO of TUHF

Lusanda Netshitenzhe, CEO of TUHF21

5 REASONS WHY A SAPPMA MEMBERSHIP MAKES SENSE

SAPPMA is an Association of leading companies in the plastics piping business, with the purpose of facilitating high standards of ethics, product quality and technical information. It is an open association, registered as a non-profit Section 21 Company and is well regulated by strong Articles of Association and Code of Conduct.

COLLECTIVE VOICE

TECHNICAL INFORMATION

SAPPMA members have access to objective, expert information on technical matters by way of personal consultations, technical publications, industry conferences and webinars and market survey results/reports.

PRODUCT STANDARDS

Members have free access to the latest product and SANS standards, quality systems and test procedures, test facilities, monitoring and quality control and have representation at SANS Technical committees and other certification authorities.

QUALITY

Members who are pipe producers and installers are set apart from other players in the market by passing the SAPPMA factory audits and adherence to the SAPPMA Code of Conduct.

MARKETING & COMMUNICATION

The SAPPMA mark on a product has become a sought-after quality guarantee that gives customers and end-users the peace of mind that their product meets local and international quality standards. Members are therefore supported by an established brand that is solely aimed at protecting the customer and the infrastructure of the country, as communicated through our marketing and advertising campaigns.

02 04

THE FOLLOWING BUSINESSES AND INDUSTRIES CAN QUALIFY FOR A SAPPMA MEMBERSHIP:

• Pipe & fittings manufacturers

• Raw material suppliers

• Consultants

• Construction companies

• Municipalities

• Water Boards

• Contractors & Installers

• Individuals

01 03 05 JOIN SAPPMA TODAY! www.sappma.co.za

SAPPMA represents more than 80 % of the plastic pipe market in Southern Africa and is the only representative plastic pipe forum in the country. Members have a collective voice at engineering associations, consulting engineering firms, municipalities, water authorities and contractors and are also afforded valuable networking opportunities, social interaction and enjoy a sense of community.

OEM LEADERS IN PUMP OPERATIONS AND MAINTENANCE

Two key issues are central to the turnaround of underperforming water and wastewater infrastructure within municipalities, namely proactive asset management, along with a well planned and executed operations and maintenance (O&M) regime. IMIESA speaks to John Montgomery, general manager for APE Pumps and sister entity Mather+Platt (the Group) about how their turnkey OEM solutions are making a difference.

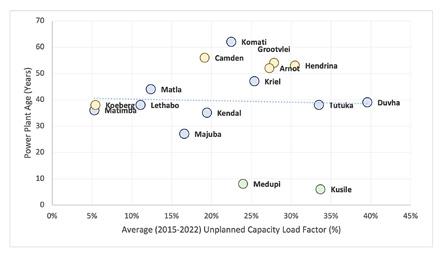

Asnapshot of the statistics published in the Department of Water & Sanitation’s 2022 Green Drop Report on the state of wastewater treatment plants shows that only a few municipalities were able to obtain Green Drop Certification during their 2021 assessment. The latter is a biennial incentive-based regulatory programme designed to set a benchmark for non-negotiable compliance in the interests of the environment, industry, and society.

The audit process covered 995 wastewater networks and treatment works. Only 23 attained Green Drop Certification, meeting the minimum 90 percent scoring requirement to qualify. The remainder were in a wide band, with 102 systems scoring below 31% and thus red flagged for intervention.

Proactive versus reactive

“The results do send a clear message that the need for proactive O&M has never been more critical,” says Montgomery. “While there are

exemplary treatment plants out there, the balance are in crisis mode due to various contributing factors that include a shortage of inhouse engineering capacity, inadequate skills, as well as reactive maintenance.”

Central to everything are the plant pump systems. “When these go down, the result is a breakdown in the process chain that results in pump stations and treatment works becoming overwhelmed by incoming effluent. Even the best pumps available worldwide – which we design and manufacture as a Proudly South African company – will fail if routine maintenance and scheduled upgrades are neglected,” Montgomery continues.

“This is not a lightly made observation, because we’ve been in the South African pump business since 1952, and a high percentage of the installed population across municipalities and utilities nationally are either APE Pumps and/ or Mather+Platt systems, and the same applies for private industry. Our asset management system shows that many are still functioning some 71 years later.”

“In fact, with effective maintenance they’re designed to work for many lifespans. However, along with expert system matching and utilisation, correct installation is essential to ensure pumps are rock-steady on their footings irrespective of their size. That’s a common cause of pump failures.”

Budget constraints present opportunities for O&M

At times, private sector investors have stepped in to help municipalities restore local water and wastewater treatment plants to bridge local government budget constraints and alleviate a crisis. Here APE Pumps and Mather+Platt have been contracted to repair existing pumps or replace them with Group products in various towns across South Africa.

It’s a short-term solution. However, as Montgomery points out, it could form the basis

14 IMIESA September 2023

John Montgomery, general manager for APE Pumps and sister entity Mather+Platt

Backed by its OEM solutions, APE Pumps is an 8ME (Mechanical and Electrical) contractor in terms of the Construction Industry Development Board grading system, enabling the Group to provide a full turnkey service

for an evolving public private partnership (PPP) model that would be a gamechanger for the future of the public sector water and wastewater landscape, where utilities can outsource to OEM contractors – and cap costs – but remain in full control of their operations. Allied to this, there are the associated benefits of OEM training and skills transfer for municipal personnel.

“In most instances, though, PPPs in this sector are going to be few and far between for municipal utilities where private investors don’t have a bankable guarantee. So, the best approach overall is to ensure that municipal plants have their own world class skills and support in place, together with a sustainable and financially sound service delivery model,” Montgomery continues.

The importance of SLAs

The Group’s response has been to offer service level agreements (SLAs) that enable private and public clients to outsource O&M on APE Pumps and Mather+Platt systems. Irrespective of their age and condition, most if not all Group pumps can be restored – not just to their original standard –but with incorporated technological upgrades.

ABOUT APE PUMPS AND MATHER+PLATT

Part of the WPIL Limited multinational group, APE Pumps designs, fabricates, installs, and commissions single and multistage pump solutions for most industry sectors in South Africa and Africa. These include municipal water and wastewater treatment works, complex and custom pump setups for leading water utilities, the power generation sector, agriculture, petroleum, and general industry. In parallel, Mather+Platt has its own purpose-designed pump systems in these and allied sectors, with a proud legacy that can be traced back to Britain’s First Industrial Revolution in the 19th Century.

Supporting these endeavours is an ongoing investment in new fabrication machinery and cutting-edge investments in 3D scanning technology. The latter provides unprecedented precision for the Group’s engineering and technical teams in determining exact tolerances for new pump designs and retrofits. In the latter respect, the Group has a blueprint of every pump it’s ever produced, so a 1952 product can easily be restored and upgraded to meet most modern requirements.

Design and engineering services

An allied investment in 3D design and simulation software further allows the Group’s engineers to walk through new and proposed refurbishment projects with clients and their professional consultants.

Recent contract examples include an extensive overhaul of Umgeni Water’s Verulam and La Mercy Pump Station – forming part of the Hazelmere Water Treatment Works (WTW) system – to cater for future network expansion. In addition to the refurbishment of the seven existing pumps, two additional APE vertical turbine centrifugal units were added. The scope of works also included electrical, mechanical and instrumentation repairs and upgrades, and the addition of a SCADA system.

“While we have a standard range, our true expertise is in designing, fabricating, and installing fit-for-purpose solutions that optimise fluid transfer in the most energy efficient manner – a pressing need now due to loadshedding and ensuing ‘water and wastewater shedding’, backed by our 8ME contractor registration with the Construction Industry Development Board,” adds Montgomery.

“Our ultimate goal is to revisit each of the hundreds of APE and Mather+Platt pumps installed across South Africa in the past seven decades and to assist private and public sector clients to bring them back to modern-day OEM specification. When the next Green Drop audit comes around, we want our clients to be ready,” Montgomery concludes.

www.apepumps.co.za

IMIESA September 2023 15

INDUSTRY INSIGHT

www.matherandplatt.com

APE Pumps’ and Mather+Platt’s core expertise is in the design, fabrication, and installation of fit-for-purpose solutions that optimise fluid transfer in the most energy efficient manner

A series of APE vertical turbine pumps installed for a pump station refurbishment and upgrade

The fifth highest double curvature arch dam in the world, and the ninth highest dam globally, Yusufeli Dam is a landmark engineering achievement and cost US$711 million to construct.

Turkey’s Yusufeli Dam is one of history’s most iconic structures

Situated on the Coruh River in the Artvin Province of the Black Sea region of Turkey, Yusufeli Dam is a 275 m high double-curvature concrete arch structure and has a developed crest length of 540 m and a section thickness of 8 m at the crest and 90 m at the base on the crown cantilever.

A view of the foundation excavation looking in the direction of stream flow. Various foundation stabilisation and reinforcement measures were required. The dam foundation excavation was completed in 2018, with a total of 3.9 million m3 of rock being removed

DAMS

& RESEVOIRS

16 IMIESA September 2023

The highest in Turkey, the dam was constructed with conventionally vibrated mass concrete and the structure contains 4 million m3 of concrete, impounding 2.1 billion m3 of water at full supply level.

Excavation for Yusufeli Dam commenced in 2014 and the final concrete lift in the dam body was placed in 2021. Impoundment was initiated at the beginning of 2023 and the water depth had reached 256 m by early September.

The dam has a controlled crest spillway, with three gates, which is supplemented by two controlled spillway tunnels on the right flank discharging into the river approximately 1 km downstream of the dam. The dam has a system of four mid-level outlets, which discharge into the spillway plunge pool immediately downstream.

The Yusufeli hydropower project includes an underground power station located beneath the right abutment immediately downstream of the dam, with an installed generation capacity of 558 MW and an average annual energy production of 1.8 billion kWh. It is predicted that the dam will contribute an annual amount of 1.65 billion Turkish Lira to the Turkish gross domestic product.

Owner and project team

The DSi (Turkish State Hydraulic Works) is the owner of the project, which was constructed by Limak Construction S.A. For the detailed and construction design, Limak appointed IC Consulenten of Austria for all geotechnical investigations and design, and a team comprising ARQ of South Africa and Su Yapi of Turkey for the

dam design. Su Yapi was also contracted for the power station design.

The ARQ-Su Yapi team for the dam design was led by Dr Quentin Shaw of ARQ. ARQ was responsible for all dam design, which included numerous complex and detailed studies to model all conditions and modes that could be experienced during construction and operation.

During investigation, design and construction of this super-project, many challenging geotechnical, topographical and logistical conditions were overcome through significant innovations and advances in engineering technology, and the project’s success was in a large part due to an effective cooperative relationship between owner, contractor and designer.

Typography and excavation

The Yusufeli Dam site is located in a remote mountainous area, with relatively extreme weather conditions and challenging site access. The local topography comprises a river with steep canyon slopes of complex rock mass formations showing signs of surface relaxation. The steep riverbank slopes create a topography suitable for an arch dam, while the igneous rock mass forming the V-shape valley demonstrated some challenges that required particular management. Excavation of the rock material was achieved by a combination of controlled blasting and mechanical excavation. As the excavation progressed downwards, the canyon cut slopes were stabilised with grout-injected post-tension prestress rock anchors. In general, 250 tonne, 80 m long anchors were used.

During excavation for the dam foundation, a cable crane and multiple batch plants were erected in preparation for casting of the concrete arch structure. The 3-line cable crane was

DAMS & RESEVOIRS

The completed structure, showing flow release through the dam’s outlet during reservoir impoundment

IMIESA September 2023 17

Construction of the final concrete lifts of the dam spillway

suspended from concrete platforms on the upper banks of the excavation and each crane had a 28 tonne capacity.

The primary concrete batch plant that fed the cable cranes was located on the upper left abutment and this was supported with one supplementary plant located on the downstream coffer dam and another located upstream of the dam, both feeding the placement by conveyor. The batch plants collectively had a concrete

The Yusufeli Dam project won the award for Best International Project at the CESA AON Engineering Excellence Awards held in Midrand, South Africa in August 2023. From left are David Leukes, CESA vice-president; Ryan Cassells, structural dams engineer, ARQ Consulting Engineers; Henry-John Wright, director, ARQ Consulting Engineers; and CESA board member, Jabulile Msiza

production capacity of 740 m3/hour and were operated 24 hours a day to meet the ambitious project production requirements.

The majority of the aggregate materials were sourced from site excavations, although it was necessary to open a supplementary quarry to complete the works. The aggregate crusher was located downstream of the dam site and indicated a capacity of 2 000 tonne/hour. Crushed aggregates were transported almost 2 km by conveyor, with a capacity of 200 m3/hour, to the batching plant at the dam site.

Concrete placement and cooling

The placing of concrete in the dam body commenced in late 2018 and continued without interruption for 30 months until mid-2021, during which time 4 million m3 of concrete were cast. Concrete was placed into forms by a combination of a 9 m3 bucket suspended from the cable crane, and temporary conveyor belts leading directly to the forms. Concrete was spread in the box by rubber-tracked bulldozers and compacted using gang-mounted immersion vibrators attached to an excavator with low-pressure tracks.

Extensive temperature control measures were implemented at Yusufeli Dam, both in terms of pre-cooling and post-cooling of the mass concrete. Pre-cooling was implemented using a cooling plant to chill the mixing water and more importantly the coarse aggregates prior to batching in order

to meet the maximum allowable placement temperature specification of 18 °C. Post-cooling was achieved by circulating chilled water through 32 mm cooling pipe loops (2.5 m c/c) installed in the bottom of each lift cast.

As the concrete construction progressed towards the dam crest, the thickness decreased and the crest length increased, meaning more monoliths were being cast concurrently. As is conventional practice for the construction of a conventionally vibrated concrete dam, a leaderfollower block approach was applied, whereby the monolith casting heights are staggered between neighbouring monoliths.

The final stages of concrete placement occurred in May and June of 2021, when the spillway peers and bridges were formed and cast. These components of the dam comprise reinforced concrete to account for concentrated loading of the structural steel spillway gates to be installed.

Filling the reservoir

Impoundment of the dam reservoir commenced in November 2022 and is currently still progressing. The rate of water reservoir rise during impoundment is controlled by release from the dam outlet works, as well as the release

18 IMIESA September 2023 DAMS & RESEVOIRS

Yusufeli Dam reservoir impoundment level 670 mASL (230 m above foundation)

The primary concrete batch plant and cooling plant located on the upper left abutment

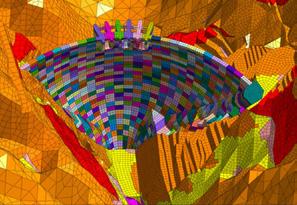

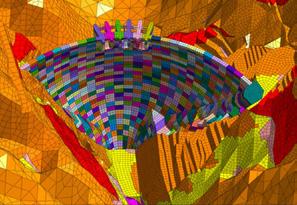

Finite element model of Yusufeli Dam and foundation

from upstream dams in the Coruh River Development Scheme.

The reservoir impoundment speed has been limited to a daily rate of rise not exceeding 1.5 m, pending the availability of sufficient river flow volume. At the current stage of impoundment, the reservoir elevation level has reached a height of 256 m above lowest foundation level.

Finite Element (FE) structural modelling

The unique engineering challenges addressed during the dam design included the development of systems to transfer load from high strength, high deformation modulus concrete into a rock mass with a lower and variable deformation modulus. Verification processes developed to ensure that the design foundation characteristics were achieved were complemented with real-time instrumentation monitoring. With impoundment completed in six stages, the structural behaviour measured on the prototype dam was verified against the respective predictions of the calibrated FE structural modelling at each stage.

FE modelling and analysis was used extensively throughout the design development and verification studies and the modelling capabilities of the latest versions of the MIDAS FEA NX software proved extremely valuable in enabling a very accurate representation of the actual dam and foundation rock mass characteristics. The capacities of MIDAS software were exploited to develop possibly the most complex foundation rock mass model yet for a dam design analysis.

The advanced design analyses undertaken by ARQ included linear elastic, thermal and seismic/dynamic analyses. Non-linearities were built into the FE model to accurately replicate the structural behaviour under both

static and thermal loads, while non-linear seismic time-history analyses and non-linear modelling, including some plasticity in the dam/foundation interface, were applied to replicate as accurately as possible the actual effects and conditions anticipated.

A structural calibration study of the dam FE model was conducted whereby the predicted behaviour of the dam, as output by the FE analysis, was validated against the observed instrumented behaviour of the dam during impoundment. The FE model proved to be marginally conservative, overpredicting displacements of the dam by 5-10 %.

While the average concrete placement rate of the order of 140 000 m3 per month achieved at Yusufeli Dam represents a world record for conventional mass concrete, as much of a challenge as the actual concrete placement was safe concrete post-cooling and joint grouting to provide lateral support to the cantilevers sufficiently rapidly so as not to slow concrete placement. The realisation of this requirement involved real-time instrument monitoring and a reactive management of postcooling processes.

Additional aspects for which ARQ was responsible included foundation rock mass stability analyses on both flanks, assistance and advice on concrete mixes, assistance with the spillway model tests and design, design of the plunge pool reinforced concrete lining, design of foundation stabilisation infills, design of the concrete post-cooling systems and stability design of the inlet for the twin tunnel spillways on the steep upper right abutment. In total ARQ provided more than 4 000 person-days, or 200 person-months of input on the project.

A celebration of excellence

As the central component of the Coruh River hydropower development, Yusufeli Dam is a landmark achievement for Turkey and a significant contributor in the country’s progress towards carbon-neutrality. From an engineering perspective, the project is significant in the increased accuracy of the FE modelling achieved with state-of-the-art software, allowing a substantially better representation of actual conditions, and the consequential development in the understanding of superhigh arch dam behaviour.

In recognition, the Yusufeli Dam project recently won the award for Best International Project at the CESA AON Engineering Excellence Awards held in Midrand, South Africa in August 2023. The dam is also currently the subject of an article published in the USA’s Engineering News-Record (ENR).

Aerial view of Yusufeli Dam reservoir impoundment

Aerial view of Yusufeli Dam reservoir impoundment

LESOTHO HIGHLANDS PHASE II has a core focus on community and the environment

After a long hiatus and planning preparation, construction on Phase II of the Lesotho Highlands Water Project (LHWP) is now well underway, central to which is the new Polihali Dam and transfer tunnel. IMIESA speaks to Tente Tente, Chief Executive of the Lesotho Highlands Development Authority (LHDA) – the LHWP’s implementing and management authority – about how experiences gained on Phase I have shaped the implementation of Phase II.

What were some of the key lessons learnt from Phase I?

TT Phase I, completed in 2003 and inaugurated in 2004, captured the attention of the world as one of the largest and most complex projects of its kind. It entailed the construction of major structures that include the Katse and Mohale Dams, as well as associated transfer and delivery tunnels that supply water to South Africa.

While Phase I was implemented with the required expertise and in line with internationally established standards, the realities of implementing a project of this magnitude and complexity for the first time brought many learnings. A prime example is that early and meaningful consultation with communities is crucial. Therefore, the groundwork for Phase II has been informed by Phase I and backed by extensive research. Baseline studies have included an assessment of the Instream Flow Requirements (IFR) encompassing water quality, flow and geomorphology aspects; the socio-economic conditions; fauna and flora; archaeology and public health. Environmental and Social Impact Assessments (ESIA) were also conducted, which were subjected to external independent review prior to the issue of environmental authorisations and records of decision by Lesotho’s Department of Environment.

Furthermore, the LHDA has established Area Liaison Committees (ALC) in all project-affected areas. They include representatives from the project, community leadership and community elected representatives. These structures serve to improve community participation in project activities and ensure an ongoing forum for issue identification and resolution.

The LHDA has introduced a robust project complaints management system, which integrates in-person and technological processes.

It closely monitors the management process to ensure that consultants and contractors effectively manage specific complaints relating to their work and people are given feedback. Every step is documented and recorded. Whilst these interventions have been effective to date, there will be a constant focus on improving partnerships with all communities during the life of the project.

How is compensation being managed for affected communities?

Under Phase II, consultations with affected households on compensation options have largely been completed, while registration of all assets that will be impacted has been finalised.

The LHDA has implemented alternative strategies to address compensation delays,

DAMS & RESEVOIRS

Tente Tente, Chief Executive of the Lesotho Highlands Development Authority (LHDA)

which were a pain point under Phase I. One of the strategies – over and above this early consultation and registration of assets –is a phased handover of the construction sites to contractors, where assets that are required by contractors for preliminary works are acquired first, and only handed over to contractors after the affected households have been paid.

It must be noted that in cases where the project needs to access people’s properties before payment has been issued, the LHDA consults the specific owners of the affected properties, and an agreement is reached with them allowing the LHDA access to the land while payment is being expedited.

LHDA is pleased with the significant progress made in compensation payments

for assets affected by the advance infrastructure projects under Phase II. Payments have also commenced for assets which will be affected by the Senqu Bridge, the Polihali Dam and Polihali Transfer Tunnel preliminary works. This is a major lesson learnt from Phase I that is directly being applied under Phase II and is showing benefit.

Does Phase II provide an opportunity to implement more sustainable land use?

Absolutely, and this is a crucial element since livelihood and land use activities in the LHWP catchments have a huge impact. For example, land degradation due to poor management of agricultural activities (crop farming and livestock grazing) affect the catchments and water sources that supply the reservoirs. Overgrazing on rangeland and wetlands and frequent soil disturbance due to poor cultivation methods lead to poor vegetation cover and increase the

DAMS & RESERVOIRS

Forming part of Phase I, the Katse Dam was constructed by the Highlands Water Venture (HWV), a consortium of seven international contractors. Construction began in February 1991 and was completed in May 1997

IMIESA September 2023 21

The diversion of the Senqu River via a pre-cofferdam, and the subsequent diversion of the river into and through a series of diversion tunnels from August 2023 onwards, marks the start of the construction of the main cofferdam upstream of where the Polihali Dam wall will be built

level of soil erosion and sedimentation in the reservoirs.

The LHWP Integrated Catchment Management (ICM) Implementation Plan was developed to address land degradation and livelihoods issues especially in Phase II of the project. The LHDA has intensified land rehabilitation and restoration activities to reduce soil erosion through improvement in vegetation cover and overall land management in the Polihali dam catchment.

The LHDA is concurrently studying the status of the wetlands in the Polihali catchment areas, especially those that are a priority for water delivery. The study will establish the rehabilitation needs of the wetlands and recommend appropriate rehabilitation measures that can be implemented even before impoundment of the Polihali Dam.

Phase I of the LHWP established protected areas at Bokong and Tšehlanyane. However, through biophysical studies of the Katse catchment, and during the development of the wetlands conservation strategy, it was realised that while Bokong and Tšehlanyane were important wetlands areas, they were not necessarily the priority wetlands for the Katse Dam. Hence, the wetlands studies of the LHDA have now focused on identifying wetlands that are a priority for water delivery for each of the reservoirs and on protected area establishment initiatives on such wetlands for Phases I and II.

What steps are being taken in terms of climate change?

The LHDA is currently implementing the contract to undertake the LHWP climate change vulnerability study and to develop the adaptation and mitigation plan.

The LHDA land rehabilitation and restoration activities implemented as part of the ICM implementation plan (e.g., brush control, reseeding, tree planting, establishment of protected areas, establishment of grazing associations, etc.) are meant to minimise the impacts of climate change on the catchments. Some of the main climate change elements are increased flooding (surface flow of water) and drought events.

The LHWP zones have a high concentration of peat wetlands. They are a specific type of wetland that play a particularly pivotal role in mitigating climate change. Peat wetlands hold some of the largest stores of carbon on the planet, and when disturbed or drained, they release the major heat trapping greenhouse gases, such as carbon dioxide (CO2) and methane (CH4).

Although peat wetlands make up only 3% of the planet’s land surface, they are said to absorb twice as much CO2 as all the world’s forests put together. Yet, despite their relevance for the global climate, wetlands are being destroyed faster than any other ecosystem. The LHWP’s

The impounding of the Polihali reservoir will submerge existing roads and tracks, affecting communities in the valleys and tributary catchments of the Senqu, Khubelu, Mokhotlong, Moremoholo and Sehonghong rivers. The three major new bridges being constructed – along with a network of feeder roads and the main access roads to the project area – all contribute towards minimising this disruption and helping to restore community access. Shown here is the Senqu Bridge site where excavations have started for the massive pier and abutment foundations necessary to support the new 825 m long and 90 m high bridge. This is the largest of the three in the LHWP Phase II programme

contribution to peat wetlands rehabilitation and restoration therefore contributes to climate change mitigation and to improving the resilience of the nation.

As testimony to this, the ESIA for Phase II of the LHWP received an award from the Environmental Assessment Practitioners Association of South Africa (EAPaSA) as the Best ESIA in the region. This demonstrates the LHDA’s commitment to environmental sustainability.

What are some of the key technologies and the construction method employed for the Polihali Dam?

Polihali Dam will be a 166 m concrete face rockfill dam (CFRD). The dam embankment will be constructed in compacted layers from free draining rockfill, sourced locally in the Lesotho Highlands, very close to the dam. The main dam embankment will

22 IMIESA September 2023 DAMS & RESEVOIRS

contain 15 million cubic metres of rockfill; and the 43 m saddle dam (also a CFRD) 1,25 million cubic metres of rockfill.

Due to the higher shear strength of rockfill compared to earthfill, side slopes can be steeper than earthfill embankments, resulting in less construction material and a shorter construction period. Using rockfill has a further advantage in that placement can continue during periods of heavy rainfall, frequent in Lesotho. That would not have been the case if the embankments were constructed from earthfill.

Polihali Dam was designed to be constructed in stages to allow overlapping of the major activities on the critical programme path, namely rockfill placement and concrete face slab construction. This method shortens the construction period and has a further advantage in that impoundment can be initiated during the construction period.

Are specialist concrete formulations required for the dam wall?

A number of site-specific factors have to be considered for concrete mix designs. The water at Polihali is “soft” making it moderately aggressive to concrete and this influences the required minimum binder content in mixes. Another important consideration is freeze/ thaw as temperatures at Polihali go down as low as minus 20 degrees Celsius during winter and during summer temperatures can rise to 35 degrees Celsius. Strict concrete specifications were therefore developed.

Concrete face slabs, considering the above factors, and because of low slump and good workability/durability requirements,

require very specialised mix designs. Face slab concrete will be placed directly from mixer trucks into chutes running down the dam face onto a conveyor belt that delivers concrete onto the face before vibration/ compaction and finishing off. It is therefore important for concrete not to segregate down the chutes and due to the freeze/ thaw aspect mentioned above, air has to be entrained into concrete.

Fine and coarse concrete aggregates will be crushed from good quality basalt rock in a dedicated quarry on site. Experience in Lesotho has shown over the years that laumontite and smectite minerals in some basalt types can badly affect concrete quality and basalt containing these minerals is therefore avoided.

What type of tunnel boring machines (TBMs) are being used to establish the Polihali tunnel?

The unit employed is a double-shield gripper TBM designed to install and grout precast concrete segmental linings as it advances. Being a double-shield machine, the unit is able to simultaneously excavate the rock and erect the segments, with the machine fully protected by the shield. The tunnellers are never exposed to unsupported ground, and in effect never see the rock, except for the spoil emerging from the cutter head.

What are some of the key challenges and the expected monthly tunnel advance rate?

Given the existing system of LHWP tunnels, the general ground conditions are well understood, but with almost 1 km of rock cover in places, the particular conditions at a given location are uncertain. Key risks are faulted ground and water ingress, both of which are addressed through the robust design of the TBM and its backup system.

The Polihali Transfer Tunnel is 38 km long and the logistics of the two long TBM drives will be challenging: getting personnel and materials to the face, removing spoil and water, ventilation, power supply, and communications all require a substantial system behind the actual TBM.

Going into Phase II, the LHDA developed the Maloti Minnow Conservation Action Plan that promotes protection of this species and its habitats. This is Lesotho’s only endemic freshwater fish. The LHDA has undertaken minnow assessments across the country, and in the Polihali catchment has identified natural waterfalls on the Senqu and Moremoholo Rivers that were assessed and found adequate to act as natural barriers for the migration of predatory fish into the uppermost minnow habitats

Depending on the rock class encountered, the advance rate will be 30 m/day on a good penetration rate and 7 m/d on the worst penetration rate.

And in closing?

Once completed, Polihali Dam will create a reservoir on the Senqu and Khubelu rivers with a surface area of 5 053 hectares, adding some 2 325 million m3 in storage capacity to the LHWP scheme. This is crucial for water security and future regional water demand management, particularly within South Africa’s Gauteng economic region.

Phase II is equally important for Lesotho in terms of its macro and micro economic objectives, a prime example being a ramp up in hydroelectricity as a sustainable and constant power supply. Another is a renewed focus on sustainable land use and agrobusiness enterprise development within the areas that remain after the Polihali Dam has been impounded.

IMIESA September 2023 23 DAMS & RESERVOIRS

The LHWP Integrated Catchment Management (ICM) Implementation Plan was developed to address land degradation and livelihoods issues in Phase II of the project

With slopes up to 12 m high, which included soft rock outcrops, creating a “soft” interface required the use of an undulating retaining system

MIXED PATTERN WALL DESIGN RETAINS STEEPS SLOPES, WITH EASY PLANTING

PROJECT TEAM

Client: Balwin Properties

Combining engineering with aesthetics, KCE Consulting Engineers created a Terraforce wall design to match the unique site characteristics of De Aanzicht – a new residential development constructed by Balwin Properties in Richwood, Cape Town.

Architect: DHK Cape Town

Engineers (civils & structural): KCE Consulting Engineers

Quantity surveyor: Balwin Properties

Main contractor: Balwin Properties

Sub-Contractor (civils & walling): PK Civils

Sub-Contractor (lateral support): Geociv Group

Terraforce installation: Decorton Retaining Systems

(Terraforce Recommended Contractor)

Terraforce block supplier: Klapmuts Concrete (Terraforce Licensed Manufacturer)

The design successfully interfaces with the environment by creating space for vegetation in the near vertical terraces and “shelves”, with plant pockets constructed by turning the round-faced side of selected Terraforce L12 blocks outwards at regular intervals. The system was installed by Terraforce Recommended Contractor, Decorton Retaining Systems.

Located in the north-eastern quadrant of the property development, the retaining wall acts as the buffer between the engineered platforms on the lower level and the protected nature conservation area to the east.

“The residential scheme nestles up against a large Rhenosterveld reserve. With slopes of up to 12 m high, which include soft rock outcrops, creating a ‘soft’ interface required the use of an undulating retaining system, combining access, planting, and stormwater management,” explains Nigel Barr at KCE Consulting Engineers.

This slope treatment is now gradually disappearing behind planting –hiding the “under the skin” engineering of soft soil anchors and tied back foundations, thanks to the clever use of the mixed pattern Terraforce block facings.

A two-part system

“In order to create the embankment required within the restricted footprint area, KCE designed and detailed a two-part system to adequately secure

PRECAST RETAINING SYSTEMS

24 IMIESA September 2023

Terraforce’s 4×4 Step Block™ system was employed to construct safe staircase access within the development

the embankment, while taking great care to avoid encroachment into the environmental buffers and restricted no-go zones around the conservation area,” Barr continues, elaborating on the design of the overall retaining system.

“A series of soil nailed terraces – the front faces stabilised with gunite shotcrete – were created as the initial lateral support system for the embankment, with a series of terraced Terraforce retaining structures constructed in front of the lateral support.”

As Barr explains, the Terraforce walls act as a cladding for the otherwise harsh and rustic finish of the lateral support system, while also providing planting pockets, accessible terraces and maintenance access routes throughout the embankment area.

When asked why Terraforce was chosen, Barr highlighted that, “Terraforce is the ‘go to’ block for almost all the gravity solutions throughout the region. The aesthetic appeal of the rockface finish blocks suited the overall environment and blends into the surrounding landscape with ease. The blocks are both familiar, proven and readily available, making it the obvious choice for this job. The design and engineered flexibility the Terraforce system provides was also a huge plus – to suit the intricate nature and shapes of the terraced embankment.”

A total of 1 620 m2 of Terraforce walling was installed, with planting of the wall completed early in 2023. The vegetation is now establishing well and already creating the effected envisaged in KCE Consulting Engineers’ initial design concept.

Plant pockets were constructed by turning the round-faced side of selected Terraforce L12 blocks outwards at regular intervals

A total of 1 620 m 2 of Terraforce walling was installed, with planting of the wall completed in early 2023

The Terraforce retaining wall acts as the buffer between the engineered platforms on the lower level and the protected nature conservation area to the east

Creating the future networks and connecting the dots

Hosted under the theme “Creating the future networks”, IMESA’s Northern Provinces Branch hosted a thought-provoking and engaging series of presentations at their annual seminar and AGM, held this year on 25th August at the Birchwood Hotel and Conference Centre in Boksburg, Gauteng.