and a giant leap for infrastructure

Sizabantu Piping Systems launches Africa’s first locally manufactured pipes, with capability from 710mm to 1200mm, now in full production.

In a landmark moment for local manufacturing, Sizabantu Piping Systems and Molecor have successfully produced large-diameter PVC-O pipes, with future capability of up to 1200mm.

Celebrating their 74th anniversary in 2026, APE Pumps and Mather+Platt continue to gain ground in the South African and broader African market, backed by their turnkey solutions approach. In addition to OEM pump and component fabrication, this incorporates in-house engineering design, plus mechanical and electrical contracting services. P6

Cover

Collaboration

IMESA elects new Fellows and Honorary

Bitumen

Transportation

Beyond the Grid: Why Johannesburg’s energy crisis demands a decentralised revolution 26

Sustainability

Smart gardens reuse greywater. Simple steps to extra cash in your pocket

Legal PPPs that saved SA’s energy sector can

In today’s demanding industrial and municipal environments, you need more than a product; you need a complete, integrated solution. Xylem’s Water Solutions and Services (WSS) division is your single, expert partner, offering an unparalleled portfolio to tackle your most complex water and wastewater challenges head-on.

We combine decades of experience with a deep understanding of your operational needs, ensuring seamless project execution, from initial assessment to long-term management. Trust us to provide the strategic oversight that turns complex problems into efficient, reliable outcomes.

From critical Drainage and Dewatering to processing the most abrasive Sludge and Slurry, we provide the world’s leading technology. Our fleet features the legendary reliability of Flygt submersible pumps and the powerful performance of Godwin pumps, ensuring you have the right equipment for any job, no matter how tough. This is more than just hardware; it’s a guarantee of performance, backed by comprehensive support, delivering total peace of mind and operational excellence.

Don’t let water challenges slow you down. Contact our experts today to design your complete solution.

EDITOR Alastair Currie

Email: alastair@infraprojects.co.za

DESIGNER Beren Bauermeister

CONTRIBUTORS Carine Heyns, Devesh Mothilall, Geoff Tooley, Ian Venter, Michelle Kerr, Miyelani Holeni

DISTRIBUTION MANAGER Nomsa Masina

DISTRIBUTION COORDINATOR Asha Pursotham

SUBSCRIPTIONS

Email: distribution@infraprojects.co.za

ADVERTISING SALES

KEY ACCOUNT MANAGER Joanne Lawrie

Tel: +27 (0)82 346 5338

Email: joanne@infraprojects.co.za

PUBLISHER

IMESA (Pty) Ltd

P O Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Email: info@infraprojects.co.za

ANNUAL SUBSCRIPTION: R805.00 (INCL VAT)

ISSN 0257 1978 IMIESA, Inst.MUNIC. ENG. S. AFR.

© Copyright 2025. All rights reserved.

IMESA CONTACTS

HEAD OFFICE:

Manager: Ingrid Botton

P.O. Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Email: admin@imesa.org.za

Website: www.imesa.org.za

BORDER

Secretary: Celeste Vosloo

Tel: +27 (0)43 705 2433

Email: celestev@buffalocity.gov.za

EASTERN CAPE

Secretary: Susan Canestra

Tel: +27 (0)41 585 4142 ext. 7

Email: imesaec@imesa.org.za

KWAZULU-NATAL

Secretary: Narisha Sogan

Tel: +27 (0)31 266 3263

Email: imesakzn@imesa.org.za

NORTHERN PROVINCES

Secretary: Lethale Magagane

Tel: +27 (0)72 059 7444

Email: np@imesa.org.za

SOUTHERN CAPE KAROO

Secretary: Henrietta Oliver

Tel: +27 (0)79 390 7536

Email: imesasck@imesa.org.za

WESTERN CAPE

Secretary: Michelle Ackerman

Tel: +27 (0)21 444 7112

Email: imesawc@imesa.org.za

FREE STATE & NORTHERN CAPE

Secretary: Wilma Van Der Walt

Tel: +27 (0)83 457 4362

Email: imesafsnc@imesa.org.za

All material herein IMIESA is copyright protected and may not be reproduced without the prior written permission of the publisher. The views of the authors do not necessarily reflect those of the Institute of Municipal Engineering of Southern Africa or the publishers.

Next year marks the 32nd anniversary of South Africa’s 1994 transition to a new democratic dispensation. This remains an evolving process that has matured over time but needs a restart in places to ensure that we truly bridge the inequality gaps.

The only way to achieve this is by ensuring that South Africa’s political leadership are unified and in partnership with the private sector as the micro and macroeconomic drivers. Community participation also needs to be far more inclusive in effecting transformative infrastructure implementation.

One of the major burning issues is the unfolding water crisis, and here there are a combination of factors at play. Foremost is the population growth rate. When the first post-1994 census was completed in 1996, South Africa’s population was estimated at 40,5 million. Fast forward to the last census in 2022 and the figure had climbed to around 62 million, placing increasing pressure on existing infrastructure, and compounded by a steady rural migration to urban centres.

When you factor in asset management failures at local government level – highlighted by past Green Drop and Blue Drop Reports – it’s now reached a point where a hard restart is urgently required in terms of maintenance and new construction. This is reinforced by recent government statistics. These indicate that national reliability has dropped to around 68%, and the quality of water in 60% of water supply systems is deteriorating.

Addressing the rising threat is government’s Water Task Team, which is now engaging actively with the private sector to explore joint venture opportunities, in conjunction with key stakeholders that include Infrastructure South Africa.

Sustained industrial supply is essential in key sectors like agriculture, manufacturing, and mining – where there’s arguably more appetite for 50/50 public-private partnership (PPP) ventures. Then there’s the need to create new bulk water supply provision for municipalities, which is equally crucial. That’s a major motivator for new PPP mega treatment works but depends on local governmental capabilities to effectively manage the financial and engineering interface.

Either way, while private sector investment is an essential enabler, the public sector remains central to an effective and efficiency infrastructure network. Every taxed rand spent well makes the difference and there are many positive examples.

A case in point is a snapshot from Statistics South Africa’s recent Capital expenditure by the public sector survey. This confirms that public sector spending on infrastructure and other fixed assets rose from R234 billion in 2023 to R276 billion in 2024. A major portion was expended by Eskom during 2024 – amounting to some R49,5 billion – on capacity expansion and allied programmes, up from R39,3 billion in 2023. That ticks all the right boxes.

Allied strategic investments in 2024 included R21,8 billion expended by Passenger Rail Agency of South Africa for the restoration of urban commuter rail services. Transnet also invested around R18,3 billion to maintain capacity on port, pipeline, and rail infrastructure. In turn, SANRAL spent approximately R13,3 billion on South Africa’s strategic road network.

Then at the local level around 25,9% of the R276 billion spent in 2024 was invested by municipalities. The standout leaders were the City of Cape Town, the City of Johannesburg, and eThekwini Metropolitan Municipality.

So, there’s major work in progress, but still with many gaps to fill going into 2026. In some cases, like water and sanitation, it requires a quantum leap to get ahead of the curve. Plus, we need to provide sustainable assurances to investors.

The upside is that all indications flowing from the highly successful 2025 G20 Summit in Johannesburg support the view that its alliance partners are committed to helping build a stronger South Africa within the Global South context. That includes infrastructure renewal.

In addition to home benefits, this directly and indirectly contributes to broader African macroeconomic objectives that foster equitable trade and counter climate change threats that affect the entire globe.

To our avid readers, check out what we are talking about on our website, Facebook page or follow us on Twitter and have your say.

In each issue, IMIESA offers advertisers the opportunity to get to the front of the line by placing a company, product or service on the front cover of the journal. Buying this position will afford the advertiser the cover story and maximum exposure. For more information on cover bookings, contact Joanne Lawrie on +27 (0)82 346 5338.

At the culmination of our 88 th IMESA Annual Conference in October 2025, the unified feedback from delegates is that municipal engineers must regain their place as joint decision-makers in infrastructure processes.

In the past, this has often been a onesided viewpoint that has not been commonly shared by municipal officials and politicians. The result has been a growing disconnect between engineering and political objectives, which has led to widespread service delivery shortfalls and growing community unrest.

Revisions to the current 1998 Local Government White Paper will go a long way in correcting this gap, with our conference panel debate on the topic exposing the pain points and highlighting some of the solutions.

The original White Paper was meant to be transformative in a post-apartheid South Africa. Key goals included the establishment of a new system of strong, accountable local government focused on socio-economic development. Citizens were also recognised as having the democratic right to truly participate in joint decision-making on matters effecting their lives and livelihoods.

Nothing changes here in terms of the original objectives. However, the stark reality is that the initial goals didn’t materialise as planned. So, that’s the key difference in the new White Paper revisions. They set out to tackle the systemic failures and performance challenges since 1994 that have intermittently derailed the intended outcomes of the first White Paper.

Based on the timeline, the nominated revision research groups had a deadline for respective report completion by the end of November 2025. A collated draft of all the findings will then be produced by designated writing teams for final public comment. After that, in March 2026 the ultimate document will be submitted to the Minister of Cooperative Governance and Traditional Affairs (CoGTA), as the custodian of the process, for actioning.

How inclusive and participative is the process?

As IMESA we’ve provided our comprehensive input. However, one of the key questions

we’ve raised concerns the composition of these writing teams, and more specifically the number of municipal engineers involved. To date, we haven’t received a response. That’s concerning because it would be pointless for engineering bodies to submit proposed action items and not have engineers represented in interpreting and compiling the final White Paper revision objectives.

The potential risk, if that is the case, is that the document could become more weighted in terms of legal and financial elements and not deal effectively with the engineering aspects that are fundamental to the local government turnaround strategy. Our appeal as IMESA is that we don’t miss this vital last step, because without sustained and equal engineering participation the objective of universal municipal performance will not be possible.

Why information sharing is key

Often the facts are hidden in plain sight, and siloed thinking can be eradicated through information sharing. Our national rollout of IMESA’s training module on “Design Flood Estimation in Municipal Areas in South Africa” is a good example.

This course was aimed at engineers and allied built environment professionals. However, fully understanding that nothing works in isolation, we’ve now incorporated a parallel layman’s programme entitled “Understanding Flood Risk”. This is aimed at councillors and top management municipal decision-makers who frequently influence or approve spatial development plans. The course highlights key flood risk factors, as well as the legal responsibilities of municipalities to plan appropriately for a safe environment. We’ve had unanimously positive responses from those attending, who’ve stated that

this high-level training better equips them to make the right decisions in support of their municipal engineers. It’s a positive work in progress.

Another interesting possibility that’s food for thought is the creation of a platform that enables retired engineers to stand for election as councillors. There are existing isolated examples. However, replicating the model across the municipal spectrum would certainly add major value in terms of top down and bottom-up infrastructure implementation, especially in terms of funding provision for asset management. That’s the Achilles Heel of effective service delivery.

Time for the holidays

In the meantime, I’d like to thank all our members, readers and advertisers for their fantastic support during 2025. Your commitment and passion for our industry as change agents is part of the “Build Back Better” strategy that can only be achieved through concerted public and private sector collaboration.

Next year’s local government election will be a key milestone in terms of South Africa’s evolving infrastructure roadmap. The successful implementation of the revised White Paper will also be an instrumental factor in subsequent national elections. However, for now it’s time for a well-deserved break. On that note, I would like to wish you and your families a happy and fulfilling festive season. I look forward to engaging with you all again in the New Year.

Celebrating their 74th anniversary in 2026, APE Pumps and Mather+Platt continue to gain ground in the South African and broader African market, backed by their turnkey solutions approach. In addition to OEM pump and component fabrication, this incorporates in-house engineering design, plus mechanical and electrical contracting services.

Over the past three years, we’ve invested extensively in new digital technologies and fabrication machinery upgrades to ensure that we have a full in-house capability, as well as the latest cutting-edge techniques,” explains John Montgomery, General Manager at APE Pumps and Mather+Platt, which forms part of multinational OEM leader, WPIL Limited.

“As a WPIL entity, we have an acquisition mandate to actively identify potential local pump OEMs and construction contracting specialists that align with our culture. The objective is to ensure that we have the capacity and skills to support South African new mega infrastructure projects in our fields of expertise,” Montgomery continues.

APE Pumps and Mather+Platt have also embarked on an integrated initiative to streamline their production throughput, supply chain and project implementation efficiencies in line with their ISO 9001 certified quality management system. A core focus is on digitising all operational and financial processes – including transitioning all

the group’s design blueprints since its formation in 1952 onto their cloud-based platform.

ERP integration: Faster, more efficient and transparent

Once finalised, APE Pumps and Mather+Platt’s Enterprise Resource Planning (ERP) system will seamlessly communicate in real-time with every departmental function. That includes key

CAD engineering design and Autodesk Fusion Operations software interfaces, with the capability for full automation of machining processes.

“The end goal for us is to eliminate paper processes wherever practical and to embrace the full advantages of the industry 4.0 and 5.0 environment. We recognise the value and future of Artificial Intelligence as a competitive tool, while ensuring that our personnel remain central and relevant,” explains Thorne Zurfluh, APE Pumps and Mather+Platt’s Engineering Manager leading the digitalisation project.

“In addition to helping lower APE Pumps and Mather+Platt’s carbon footprint in terms of waste reduction, this digitalisation process has direct benefits for our customers. These include faster fabrication and refurbishment turnaround times with no compromise on quality (thanks to real-time NCR reporting) – especially critical in the energy and water sectors,” Zurfluh explains.

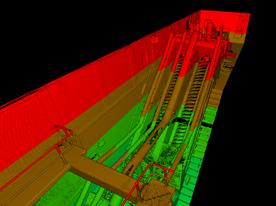

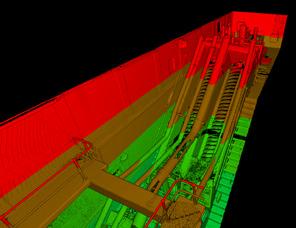

In addition to tracking, it provides full transparency on refurbishment estimations. An example is a pending power station project, where APE Pumps and Mather+Platt personnel have employed 3D scanning on the client’s Archimedes screw pump installations to accurately price the job based on a detailed method statement.

APE Pumps and Mather+Platt’s investment in 3D laser scanning enables personnel to precisely capture all elements to create a digital twin model

“Beyond our internal IT networks, there’s also an evolving need to embrace emerging external platforms like Building Information Modelling (BIM) as a multi-disciplinary project management and asset management interface,” says Zurfluh. “BIM is now a requirement on specified public sector infrastructure projects in countries like the UK, and South Africa is going the same route, spurred on by accelerated private sector adoption.”

APE Pumps and Mather+Platt’s work for Rand Water at the Lethabo raw water abstraction pump station serves as a prime example of digital twinning at work.

Originally installed in the 1980s, the four 650 Mℓ/d Mather+Platt pumps in service have performed optimally but reached the point where a comprehensive phased overhaul is required.

The first unit was extracted and shipped to APE Pumps and Mather+Platt’s Wadeville facility for refurbishment in Q4 2024 following a comprehensive 3D scan of the pump and facility. Completed within 12 weeks, the overhauled pump was subsequently reinstalled and commissioned in Q1 2025 during a scheduled Rand Water shutdown.

What makes this project especially significant is that all phases were completed by APE Pumps and Mather+Platt in-house in collaboration with Rand Water’s engineers.

“It also provided an opportunity to refine the investments we’ve made in our ERP and digital process enhancements to perfect digital twin layouts,” Zurfluh explains. “The ability to capture and import all surveyed data enables unprecedented engineering precision, which we interrogate during the design and preplanned reinstallation stages via simulation modelling. For the Lethabo project every last detail was incorporated down to the pipe support stands and fed into our approved production drawings.”

“Having all surveyed data captured in real-time is also a major time saver, especially since in the past this required manual measurement. This ensured that we were equipped to complete the works within the scheduled three-month timeframe. In addition to this, the refurbished pump is now performing at a higher output than the original with lower energy costs.”

Building on the lessons learnt, the second pump identified for refurbishment was completed within a much shorter timeframe of under two months during Q3 2025. The unit has been reinstalled and is pending commissioning.

“To reinforce the point in terms of turnaround efficiencies, a general estimated timeline in industry for a pump of this size would typically be around six months,” says Zurfluh.

Based on the envisaged programme, APE Pumps and Mather+Platt will refurbish the remaining two Rand Water units during 2026.

Meanwhile other recent projects completed include work for the Blantyre Water Board (BWB) in Malawi during Q4 2025, where new APE Pumps and Mather+Platt units have been installed in place of another OEM’s pump systems.

In the past, APE Pumps and Mather+Platt were appointed in 2013 to carry out two major turnkey refurbishment projects for BWB, which encompassed mechanical, electrical and civil phases at the Chileka pump station, and the Walker's Ferry raw water and high-lift pumping stations. Existing Mather+Platt pumps installed at these facilities during the 1960s were overhauled and brought back into optimum service, while latest generation group OEM pumps were added to meet increased water supply demand.

Wastewater opportunities

Alongside water and energy is the crucial importance of wastewater treatment. In the potable space APE Pumps and Mather+Platt work with all of South Africa’s Water Boards as well as leading Water Boards in Africa. The same applies in the industrial sector in terms of specialist pumps for raw water and downstream effluent treatment in key segments like the sugar cane industry.

However, as has widely been reported, South Africa (and many parts of Africa) face serious challenges in effecting compliant wastewater provision at municipal level. Here there are concerning gaps in funding provision, process control efficiencies and skills that negatively impact the water cycle.

“As a pump OEM, we are well-equipped to bring water or wastewater treatment plants back to specification. However, that won’t guarantee longerterm sustainability unless there’s a proactive shift

to public-private partnership (PPP) models that can co-finance and co-manage these plants efficiently and profitably,” says Montgomery.

“We continue to study the PPP possibilities, but the deciding factor is always going to be upfront financial guarantees in terms of operations and maintenance (O&M). That in turn will be strongly influenced by the greater or lesser extent of environmental pollution –often an unknow variable that significantly impacts on O&M treatment costs,” he continues.

Either way, Montgomery emphasises that specialist OEMs are the best qualified in terms of optimising their purpose-designed mechanically engineered systems. A good example is the selection of the right electric motor, e.g. air or water cooled, to ensure that OEM pumps run optimally. “Every component interacting with our pumps forms part of a holistic system, and one incorrect element can impact fluid transfer performance and unnecessarily increase running costs. It’s also vital that pumps selected match the duty requirements,” Montgomery explains.

In the end, it comes down to skills, experience and commitment. “As an employer we recruit and retain the best, and most of those who join stay for the remainder of their careers. They are proud to serve, and we are proud to celebrate their long service,” adds Montgomery.

“At the foundation level, we have a fresh batch of N6 qualified fitter and turner apprentices on the factory floor. We are also expanding our pool of engineers to ensure we can take on projects of increasing scale and complexity. Across the board we continue to lead, and our digital transition will set a new benchmark for industry performance,” Montgomery concludes.

www.apepumps.co.za www.matherandplatt.com

Hosted every two years, the IMESA/CESA Excellence Awards provides a platform to celebrate and elevate the role of municipal engineers and their built environment partners in designing and executing sustainable infrastructure that empowers communities.

CATEGORY 1: WINNER Community Upliftment and Job Creation

As change agents, IMESA’s objective is to ensure that municipal engineers are recognised as innovators and leaders in a highly specialised field. In addition to celebrating excellence, the awards programme therefore serves as an opportunity to reinforce the importance of joint decision-making between municipal engineering leaders and public officials in the planning, design, maintenance and building of resilient towns and cities,” says IMESA President, Geoff Tooley, speaking at the awards ceremony on 28 th October 2025 the day before the IMESA 88th Annual Conference held in East London.

Comments Consulting Engineers South Africa (CESA) President, David Leukes, who co-presented at the awards ceremony:

“The Awards are a reminder of the power of collaboration in advancing sustainable development for all South Africans. In this respect, the 2025 IMESA/CESA Excellence Awards are a symbol of innovation, integrity and meaningful impact in our sector.”

“At CESA we see engineering as more than structures and systems. It is a tool to shape a sustainable and inclusive future. Municipalities are on the frontline of service delivery. This is where the partnership between IMESA, CESA and all other industry associations and stakeholders provides a powerful platform to advocate for professional solidarity as the foundation for good governance and outstanding engineering execution,” Leukes continues.

“Every successfully completed project embodies hope and progress. However, infrastructure is not an end in itself; it’s a catalyst for dignity, safety and opportunity. Yet we know that we face challenges, like constrained budgets, procurement bottlenecks, skills shortages, and the growing impact of climate change. Irrespective, every infrastructure investment must create enduring value for generations to come, and sustainability must be embedded at every stage of development.

“The projects recognised for an award at this event demonstrate that South African engineers are not only keeping pace with global best practice but are leading innovation, tailored to local contexts. To work in practice, the complexity of today’s infrastructure challenges demands collaboration across all spheres of government, the private sector and communities. When we work together, we can create systems that are not only functional but transformative. Let us continue to collaborate for the future we want.”

This year there were 21 entries, competing for an award in one of three categories, and the finalists are as follows:

Community Upliftment and Job Creation Winner

Project: Construction of four 25 m span reinforced concrete pedestrian bridges in Amaoti

Municipality: eThekwini Municipality

Main Consultant: eThekwini Municipality – Engineering Unit – Roads Provision Department

Category 1: Winning project description

The Amaoti community has faced repeated devastation from flooding, with the April 2022 events significantly worsening conditions due to climate change. These floods caused the Ohlanga River to widen and destroyed the existing 12 m steel pedestrian bridges, leaving residents vulnerable and disconnected.

In response, the eThekwini Municipality’s Engineering Unit – Roads Provision Department launched a strategic intervention to improve resilience through the construction of four new pedestrian bridges. Funded by the National Disaster Management Centre (NDMC) as part of the Disaster Recovery, Reconstruction and Rehabilitation Programme, this initiative embodies the core principles of “Building Back Better”.

These new 25 m long single-span, U-shaped conventional reinforced concrete pedestrian bridges within a 1.7 km radius are designed to withstand future extreme weather events and provide safe, permanent access for the community.

A total of 40 people were employed, including 26 local residents and five emerging subcontractors. The project

also served as a training ground for young professionals through a graduate employment programme, helping close the engineering skills gap.

Importantly, all phases from conceptual design to construction supervision were executed entirely by in-house structural engineers from eThekwini Municipality, showcasing the city’s technical competence and commitment to sustainable, communityfocused infrastructure.

Project: Naledi Clinic

Municipality: City of Johannesburg

Main Consultant: DELTA Consulting Engineers & Project Managers

Project: Vlakfontein Public Transport Facility

Municipality: City of Johannesburg

Main Consultant: Mashigo/Timmas Holding Group JV

Environment and Climate Change

Winner

Project: Climate resilient sanitation demonstration project in the informal settlements of the City of Cape Town and eThekwini

Municipality: City of Cape Town and eThekwini

Municipality

Main Consultants: Delta Built Environment Consultants; Khanyisa Projects Submission: Water Research Commission

The stark reality of informal settlements in South Africa serves as daily evidence of the persistent inequalities that scar our nation. Since 1994, the South African government has prioritised service delivery, striving to rectify historical inequalities and expand access to essential services.

While progress has been made, the application of conventional service delivery models has often fallen short, particularly in reaching and effectively serving marginalised and indigent communities in informal settlements. The topography and density of settlements in these communities also makes it difficult to deploy traditional service delivery approaches, which are further challenged by climate change impacts.

With funding support from the Gates Foundation and the Department of Science, Technology and Innovation (DSTI), the Water Research Commission in collaboration with the City of Cape Town and eThekwini Municipality are demonstrating how innovative water efficient sanitation systems (WESS)/ Non-Sewered Sanitation (NSS) technologies can effectively provide dignified and climate resilient solutions through pilot projects. These include the Masincedane informal settlement in the City of Cape Town and the Pholani informal settlement in eThekwini.

WESS/NSS are full water recycling systems, which are adaptable, scalable, reduce the risk of environmental contamination, and can

be implemented with minimal disruption to existing infrastructure. Furthermore, they offer the potential for resource recovery (water, energy, and nutrients). Their proven application provides a sustainable framework that can be adopted by other municipalities in South Africa facing similar challenges.

CATEGORY 2: WINNER

Environment and Climate Change

From left are Geoff Tooley, IMESA President; Phillip Majeke, Commercialisation Manager for the South African Sanitation Technology Enterprise Programme (SASTEP) at the Water Research Commission; Ednah Mamakoa, Technical Officer for the SASTEP Programme; Bhavna Soni, Deputy Head: eThekwini Water and Sanitation Unit; Denvor Cloete, Senior Professional Officer, Directorate: Water and Sanitation, City of Cape Town; and David Leukes, CESA President

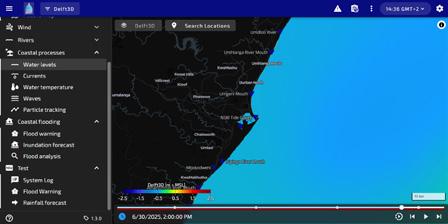

Project: eThekwini's Coastal Modelling and Forecasting

Municipality: eThekwini Municipality

Main Consultant: Deltares

Project: The rehabilitation and upgrade of the eastern stormwater channel in Orange Grove Municipality: City of Johannesburg

Main Consultant: Ndodana Consulting Engineers

CATEGORY 3

Engineering Excellence in Structures and Civils Winner

Project: Shallcross/Blundell Road and Bridge Construction

Municipality: eThekwini Municipality

Main Consultant: eThekwini Municipality –Engineering Unit – Roads Provision Department

The upgrade of the

eThekwini Municipality’s sophisticated Forecast Early Warning System (FEWS) is primarily focused on predicting stormwater-related floods

and adjoining

in

The Blundell “Smart Bridge” has a variety of different electronic sensors embedded throughout the structure that provide detailed information about exactly what is happening inside the concrete, which is a first for eThekwini Municipality

The project entails a new road alignment which has increased the minimum curve radii to 65 m, from less than 25 m before, which has in turn doubled the road design speed, while enhancing vehicle stability and comfort. A wider road cross section was designed to accommodate larger vehicles, particularly heavy trucks and buses, which frequently use the road. Pedestrian safety was a key consideration, with two sidewalks incorporated, one on each side along the entire route.

The old bridge was 32 m long and 6 m wide, and was severely undersized for both road traffic, pedestrian traffic and hydraulic

CATEGORY 3: 2ND PLACE

purposes. The new bridge is 90 m long, 14.5 m wide, and has a deck and abutments that sit completely outside the existing flood limits. It is also the first fully integral bridge in Africa to include a partially curved layout. The unusual structural arrangement is being monitored with a suite of built-in, web-linked instruments that will gather data to inform future designs for these kinds of tough, floodproof structures.

The works included demolishing the existing structure and using the demolished material within platforms and embankment protection. Other work included various service relocations, a new stormwater facility, river rehabilitation and the establishment of a picnic area.

This project demonstrates how conventional limits on the use of fully integral concrete bridges can and should be pushed by designers in South Africa. The project is deliberately intended to encourage the use of integral concrete bridges in a wider range

The Green Point Dome is a firstof-its-kind timber structure in South Africa, showcasing engineering ingenuity, sustainable design, and technical excellence

The Hunslet Road Bridge replaces three separate, old and deteriorated cellular bridges that were placed in a roadway fill embankment crossing the Piesang River floodplain

CATEGORY 3: 3RD PLACE

of circumstances than has previously been considered by designers. These types of bridges are an important form of resilient infrastructure that can handle the unpredictable demands of future climate change.

Planning, design, and contract management were performed in-house by municipal staff immediately after the flood event and all project stages were successfully fast-tracked due to the urgency. The project aims to serve as a motivation and strengthen the technical abilities within eThekwini Municipality by this novel structure, as well as promote and inspire other government authorities to follow.

The project balanced the economic needs of the local community, the larger community of ratepayers, and the environment to create innovatively sustainable, maintenance-free, elegant infrastructure which blends into nature visually and practically.

2nd

Project: Hunslet Road Bridge over the Piesang River

Municipality: eThekwini Municipality

Main Consultant: eThekwini Municipality –Engineering Unit – Roads Provision Department

Project: General building works of new education dome and experiential education garden: Green Point Park

Municipality: City of Cape Town

Professional Team: DK Architects, HHO Consulting Engineers, Senekal Allen & Partners (Quantity Surveyors), Entsha Construction

Conclusion

“Each project entered tells a story of creative responses that epitomise South African municipal engineering in practice. We congratulate the first, second and third place category winners on their exceptional achievements, and salute all our project entries for their outstanding work in positively changing the municipal landscape for a better South Africa,” Tooley concludes.

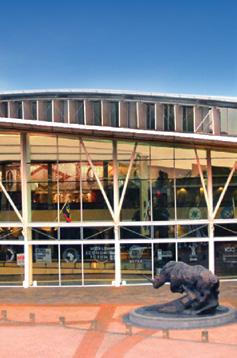

The integral role that municipal engineers play in enabling socio-economic development was a central focus at the 88th IMESA Annual Conference. Held between 29th and 31st October 2025 at the East London International Convention Centre, more than 650 delegates from across the public and private sector came together to listen and interact with a top range of speakers under the conference theme, “Sustainable Engineering Solutions”.

The conference’s keynote speaker, Lizelle Maurice, Executive Director at the Border-Kei Chamber of Business (BKCOB), stressed the crucial role of municipal engineers in enabling socio-economic sustainability through efficient, well-run towns and cities

Speaking at the opening session, IMESA President, Geoff Tooley, highlighted the challenges and opportunities to address gaps in infrastructure performance, both at local government level as well as across the public sector in general. “Finding solutions requires our combined experience, ingenuity and resourcefulness for service delivery and the fact that our 88th conference was sold out in record time illustrates the passion and commitment of those attending,” he states.

“Hosting this year’s conference in East London – a strategic port, agricultural and automotive hub – also underscores the importance of giving equal focus to every South African town and city as part of a unified approach to tackling infrastructure backlogs,” he continues.

“Throughout South Africa, there are municipal pockets of excellence that set the benchmark for others to follow. This conference serves as an

important platform to rally the industry behind IMESA’s mandate to promote and foster worldclass municipal engineering through knowledge transfer and capacity building, leading to professional registration with the Engineering Council of South Africa (ECSA).

“In parallel, South Africa’s consulting engineers and specialist OEMs play a vital role in design innovation and fit-for-purpose technology adoption. For municipal engineers, making informed decisions requires an expert understanding of the solutions available. Even more significantly, those solutions must be structured around the needs of business and communities.”

Keynote address: Everything rises and falls on municipal engineering

This latter viewpoint was reinforced by the conference’s keynote speaker, Lizelle Maurice, Executive Director at the Border-Kei Chamber of Business (BKCOB), who stressed the crucial role of municipal engineers in enabling businesses and communities to flourish.

“There’s a real need for municipalities to reinvest the tariff revenue earned in the upkeep of infrastructure services. We also understand that organisations like BKCOB have a direct and indirect contribution to make,” says Maurice.

Founded in 1877 and headquartered in East London, BKCOB’s primary mandate as the “Voice of Business” includes crowding in investment, facilitating commercial growth, NGO and community participation, plus ensuring that the

Paper 11: “Transforming Waste: Sustainable Sewage Sludge Management in George Municipality”

Author and presenter Melanie Geyer, Manager of Infrastructure Planning at George Municipality, together with IMESA President Geoff Tooley

Paper 4: “Transforming Conventional Wastewater Treatment into Multifunctional Water Reuse Facilities: The Ecreuse Approach in Buffalo City” Presenter and co-author Dr-Ing Manuel Krauss, Head of Resource Efficiency and International Cooperation at the Research Institute for Water Management and Climate Future at RWTH Aachen University is congratulated by IMESA President, Geoff Tooley

necessary services are in place, spearheaded by BKCOB’s Infrastructure Committee. Working closely with municipal representatives in conjunction with its members, the Infrastructure Committee’s mandate is to ensure that the enabling services – from electrification, water and sanitation to road and rail networks –function optimally, keeping pace with demand. An especially critical intervention has been the need to manage the economic cost of Eskom loadshedding. As a countermeasure, BKCOB facilitated a workable curtailment agreement solution, working with its municipal electrical engineering counterparts and Eskom, and dividing its manufacturing member entities into various blocks. During Stages 1 to 4, they could continue production without interruptions. Then from Stage 5 and above, members could choose one day of voluntary loadshedding in exchange

for uninterrupted supply for the next four days of production.

“Keeping the lights on is obviously crucial, but from BKCOB’s perspective, diversification is the key for our future success. While the automotive sector has historically been a major contributor to our regional economy, and hopefully will continue to do so, an overreliance carries a degree of risk in an evolving market. We have therefore identified the need to facilitate growth in other key segments like agriculture, agro-processing, general manufacturing, and tourism. In term of the latter, we have so much untapped potential,” Maurice explains.

“Naturally, that hinges on ensuring that East London and our surrounding towns are safe and welcoming places for visitors. First impressions are lasting impressions. We’ve compared ourselves against benchmarked cities like Cape Town and taken note of their successes, including their highly acclaimed central business district – a clean, vibrant hub for ongoing residential, commercial and hospitality development,” she continues.

“Our goal is to replicate this model by making East London the cleanest, safest, most beautiful city by the end of 2026. In addition to pristine infrastructure, that requires adopting a circular economy approach. We must divert more waste from landfills, in turn creating SMME and community employment opportunities.

“This initiative is particularly important within our informal settlements, which currently contribute to widespread litter pollution, impacting the environment, with downstream adverse effects on water quality, river, lagoon and ocean health.”

Through BKCOB’s Waste and Environmental Management Committee, eight recycling buyback centres have been rolled out to date, in partnership with PRO entities. An allied partnership was concluded in May 2022 following the signing of an MoU between BKCOB, the Buffalo City Metropolitan Development Agency and Buffalo City Metropolitan Municipality as part of their Clean and Green City programme.

“Within the mix, sport is a big stimulator of an economy, a prime example being the 2024 Summer Olympics in Paris. Everything had to work perfectly – and not just the event itself, but the engineered city services. Like the Olympics – or any other significant local or international sporting event – towns and cities must compete for the

about progress through partnerships, innovation and a shared duty for the industry to engineer with purpose.

capabilities – step by step with industry needs, deepening the disciplines that deliver reliability,” she continues.

“Let’s be very frank about the municipal reality. Our systems are under pressure, but they are not beyond repair. Non-revenue water losses are a pressing concern, finances are constrained, and aspects like floods, droughts and power disruptions are pushing fragile systems to the breaking point.

“But rather than asking what went wrong, we need to ask what we need to do collectively that works. Sustainable solutions aren’t just timely, they are urgent. Municipalities don’t need more plans that gather dust, they need partners than can deliver real-time outcomes driven by technology enabled solutions.

right to host the event. Those with inadequate infrastructure will not make the cut. The same applies to attracting and retaining investors in general,” Maurice stresses.

In terms of sporting events, East London’s hosting of the annual National Water Polo Currie Cup is a prime example. The tournament has been successfully held in East London every year since 2022 – thanks to a BKCOB intervention that restored the dysfunctional state of the existing public swimming pool over a period of six weeks.

However, the same success story has not applied to the annual Iron Man 70.3 competition series, which used to include East London as one of its host cities. East London lost out to Mossel Bay in 2021 due to deteriorated structural issues at the Orient Beach Complex, which is owned by the Buffalo City Municipality. It will cost millions to restore. “This event used to contribute more than R30 million over a weekend to East London’s local economy. This reinforces the point that timely infrastructure maintenance is a key factor in winning or losing commercial opportunities,” Maurice explains.

“Ultimately, the way forward is through public and private sector cooperation. For an equal partnership to work, however, we must ensure that our municipalities are fully equipped with the skills and personnel needed to connect the dots. Everything rises and falls on municipal engineering,” Maurice concludes.

Diamond Sponsor address: The transformative power of infrastructure Zimile, the conference’s Diamond sponsor, concurs. Addressing the delegates, Marisa Naidoo, Business Unit Head: Innovation and New Technologies at Zimile says it’s fundamentally

“Since our founding in 2009, Zimile has been driven by the principle that engineering needs to uplift communities. Infrastructure is not just about steel and concrete: it’s about community dignity and reliability, as well as opportunities for the next generation,” says Naidoo.

“In this respect, technology is reshaping the way we plan, design, build and maintain – and people expect more – not just new assets, but assets that work sustainably within the climate change context. That’s why we refreshed our identity in 2025 with the tagline‘Zimile –Unbounded Engineering’. This means we refuse to be limited by past practices. Our engineering is open, data driven, collaborative and future focused.

“In response, we established our Innovation Unit – our engine for digital transformation, analytics and technology partnerships. This is only the start. We will keep growing our

“We translate emerging technologies into tools that operators can use practically. For the roads segment, we translate digital data into prioritised rehabilitation plans that optimise expenditure and extend pavement life. In wastewater, decanter dewatering improvements focus on stabilising operations while trimming down on opex and energy costs. For above and below ground assets, we’re looking at structured digital condition assessments that move teams from clipboards and reactive fixes to dashboards and predictive action. These are not theoretical pilots, they are live, field tested and designed to interlock with systems that municipalities already run.

“The IMESA 88th conference challenges us to make sustainability more than just a goal – it should be an engineering standard. Our work changes lives. Let’s move from innovation on paper to transformation on the ground. Let’s engineer without limits for our people, our progress and for South Africa and Africa.”

The panel for the “Quo Vadis? Updating the 1998 Local Government White Paper” interactive discussion. From left: Geoff Tooley, IMESA President; Johan Basson, IMESA EXCO Technical Director; Nick Graham from Nick Graham & Associates; Sandile Booi, Head of Directorate: Spatial Planning and Development at Buffalo City Metropolitan Municipality; and Luntu Ndalasi, Chief Director: Infrastructure Planning, Delivery and Maintenance at MISA

That future focus depends on a sustained pipeline of engineering graduates who are equipped to embrace an increasingly complex world. This was the motivation for the establishment of IMESA’s Young Professionals Portfolio (IMESA YP 2), founded within the IMESA KwaZulu-Natal branch in 2023 and now expanding nationally via IMESA’s branch network, recruiting members in the private and public domain.

Headed at IMESA EXCO level by Bhavna Soni, the current branch leadership comprises Dhiveshni Naidu (IMESA KwaZulu-Natal branch), Shravan Hanuman (IMESA Northern Provinces branch), and Lloyd Govender (IMESA Western Cape branch).

Co-presenting at the conference, Hanuman says the purpose of IMESA YP2 is to ensure that young engineers have a voice and access to opportunities. “We’ve achieved major successes to date through events, training and CPD accredited workshops, plus engagement with universities and students to ensure continuous connection through tertiary, graduate and professional levels.”

“We are now calling on passionate young engineers to come onboard and to help establish YP2 Chapters where these currently don’t exist at our other branches,” explains Hanuman. “These roles include event management, innovation, technical development, mentorship and outreach initiatives. If there’s one thing engineers love more than problem solving, it’s finding a smarter way to do it.”

Adds Naidu: “Our vision is simple but powerful. To create meaningful impact by promoting excellence, developing motivated mindsets, leadership, and enhancing both professional and personal growth.”

Programmes delivered to date include a speed mentorship event interacting with seasoned professional engineers, and an IMESA YP2 rendition of the Amazing Race in 2023, coined the Engineers’ Edition. “In partnership with our OEM sponsors, participating teams had to solve clues and complete staged engineering challenges – like assembling a water storage tank – in a race against time to win,” says Naidoo.

Programmes for 2026 include an IMESA Fun Run, the return of the leadership and mentorship workshop, and the Amazing Race Engineers’ Edition. IMESA YP2 will also be launching two fresh events in 2026, a mini conference to prepare young engineers for bigger stages like the IMESA Annual Conference; and a take on the old TV show “Who wants to be a millionaire” with the IMESA YP2 version, “Who wants to be an engineer”. Adds Hanuman: “Essentially, the future of engineering begins with us. It’s not something

that we wait for, it’s something that we build right now.”

Quo Vadis? Updating the 1998 Local Government White Paper

Effective infrastructure delivery is of course dependent on clear and practical implementation. The conference’s Panel Discussion entitled “Quo Vadis? Updating the 1998 Local Government White Paper” drilled down into this revision initiative being led by the Department of Cooperative Governance and Traditional Affairs (CoGTA). A core element is the need to address burning issues impacting on coherent service delivery. A key paper to read is Dr Kevin Wall’s conference presentation, entitled “How sound are the municipal foundations laid in 1998, and why is this important to local service delivery?”

Priorities outlined in the updated White Paper include improving cooperative governance between national, provincial, and local levels, depoliticising municipal governance, and promoting community-led development. The review process – with a final version planned for submission to CoGTA’s Minister in March 2026 – also endeavours to make municipalities more capable and financially viable.

The debate included the potential to consolidate smaller municipalities and tribal authorities, and to shift metros from an overreliance on national subsidies, together with a more workable execution of infrastructure development plans.

Delegate responses from the floor were revealing, particularly in ensuring that communities share a common goal with municipal engineers to promote, protect and preserve new and existing infrastructure. The common observation is that unemployment and disaffected communities remain a key

IMESA President, Geoff Tooley together with the IMESA Head Office Team. From left are Debbie Anderson, conference organiser; Melanie Stemmer, marketing and communications; Narisha Sogan, finance, CPD and bursaries; Dashree Reddy, delegate registration and technical divisions; Adel Naidu, membership and website administrator; and Ingrid Botton, institute secretary and head office manager

factor in infrastructure vandalism, plus illegal connections.

A number of delegates also emphasised the need for a clear separation between political influence – within a five-year administrative term – and medium and long-term infrastructure engineering led execution. The general view was that once the plan is approved and in place, it must be an exclusive engineering responsibility.

“The 17 papers presented were of the highest standard and will remain important references for future feasibility and design studies. Paper topics extended from non-revenue water management to wastewater reuse, strategic optimisation of Municipal Infrastructure Grant funding, flood line management, the implications of the Public Procurement Act, and waste management,” he continues.

Municipal finance departments must also ensure a fair allocation of revenue collection for infrastructure service provision in terms of maintenance and construction. In the past, the city engineer made the decisions, and the town clerk made sure the money was made available, following council approval.

The digital version of the 88 th IMESA Annual Conference Proceedings is available online, plus all the papers. Visit www.imesa.org.za to view and download

“The lessons learnt and the knowledge shared at our IMESA 88th Annual Conference are an inspiration for all engineers and public officials driving the change we need to see on the ground. A special thanks to Lizelle for reaffirming our value as municipal engineers,” says Tooley.

“The remaining papers covered water and sanitation strategies, biodiversity impacts, stormwater management and municipal road maintenance. Congratulations to all our presenters – they were selected from over 80 abstract submissions – and have made this year’s conference a major success,” adds Tooley.

“On a final note, we’d like to thank all our delegates, sponsors and exhibitors for their unwavering support. We look forward to welcoming you at our 89th IMESA Annual Conference at the Durban International Convention Centre, being held between 28th and 30th October 2026. In the meantime, let’s collectively move the infrastructure agenda forward,” Tooley concludes.

At the 88th IMESA Annual Conference in October 2025, special recognition was conferred on members of the Institute of Municipal Engineering of Southern Africa (IMESA) – either as Fellows or Honorary Fellows – for their dedication and commitment.

In terms of the criteria, elected Fellows must be corporate members of the Institute who are professionally registered with the Engineering Council of South Africa and actively in service. They also

need to have been an IMESA member for at least five years and either hold or have held a senior executive or senior professional position in the field of infrastructure engineering and added value.

At the highest level, those achieving Honorary Fellowship status have distinguished themselves through their exceptional contribution to the advancement of infrastructure engineering.

During the 88th IMESA Conference, the following members were recognised by IMESA’s EXCO and Council:

Elected as Fellows

• Albertus Bezuidenhout

• Kubendran Govender

• Louis Havenga

• Johannes Karemaker

• Simon Knutton

• Mpoti Machaba

• Mark Marais

• Molahlehi Marate

• Moeketsi Mohlabi

• Ben Molleman

• Philippus Nice

• Hilna Viljoen

• Kwena Maphoto

Elected as Honorary Fellows

• Thabo Hlabela

• Allyson Lawless

“Being elected as either a Fellow or Honorary Fellow is a major career milestone, and our 2025 recipients are well deserving of this recognition,” says IMESA President, Geoff Tooley.

CONFERENCE OF THE

INSTITUTE OF MUNICIPAL ENGINEERING OF SOUTHERN AFRICA

DIAMOND SPONSOR

GOLD SPONSOR

SIVER SPONSOR

BRONZE SPONSORS

MEDIA PARTNER

South Africa’s municipalities are caught in a cycle of service delivery protests, audit failures and declining public trust. Yet a tool designed to help break this cycle is often sidelined as a compliance burden. That tool is the Municipal Standard Chart of Accounts (mSCOA).

It is a system developed by National Treasury to create a standard way for all municipalities to record, classify and report their financial information. Its purpose is to improve the quality, consistency and comparability of financial data across municipalities.

At its core, mSCOA ensures that everything from budgeting to financial reporting is done in the same structured way, making municipal finances transparent and easier to manage.

Miyelani Holeni, Group Chief Advisor at Ntiyiso Consulting Group

By Miyelani Holeni

Too often, mSCOA has been dismissed as a finance department concern. But it was never meant to be just about compliance. It is a strategic tool that, if embraced properly, can transform how municipalities plan, deliver services and build public trust.

National Treasury’s current work to regulate 14 core municipal business processes (including budgeting, supply chain management and asset management) represents the next step in mSCOA’s evolution: from a financial reporting exercise to a central engine for effective local governance. This is a clarion call for mayors, municipal managers and all directors to finally see mSCOA for what it is: a shared opportunity to build trust and accelerate delivery.

The evidence of its transformative power is no longer theoretical. mSCOA’s segments provide a multi-dimensional language that speaks to every part of the organisation. The project segment speaks directly to engineers and asset managers, allowing for precise tracking of infrastructure projects. The region segment empowers councillors and communities by providing a clear view of expenditure and outcomes

in every single ward. The funding segment offers the entire executive team a clear-eyed view of fiscal viability, moving us from asking “Did we comply?” to “Are we effective?”

This shift is profound. The regulation of these business processes will force the integration of strategy (the Integrated Development Plan, or IDP), budgeting and performance management (the Service Delivery and Budget Implementation Plan, or SDBIP) into a single, coherent cycle.

This integration kills two birds with one stone: it creates the elusive “one version of the truth”, and it eliminates the debilitating reporting fatigue that plagues our municipal officials. Imagine a real-time dashboard reflecting the true health of the municipality, replacing stacks of contradictory spreadsheets. This is within reach.

However, as a recent webinar poll starkly highlighted, the biggest barriers to this bright future are not technical, but human. Resistance to change and lack of staff capacity were identified as the primary obstacles. This confirms a universal truth: you can have the most compliant software system money can buy, but without the right people and processes, it is a sports car parked in the driveway.

The move to regulate business processes is a golden opportunity to address this exact failure. It forces us to look up from our spreadsheets and look at our organisations.

The prescription for success is clear and draws from the practical lessons of those leading the charge:

• Leadership ownership: the municipal manager and mayor must be the chief advocates, not

passive observers. mSCOA cannot be a finance project; it is an organisation-wide transformation that demands political will and cover. This regulation makes mSCOA undeniable, providing a mandate and a clear plan that leaders can rally behind.

• Breaking silos: this means reconstituting dormant mSCOA steering committees to include not just finance, but also IT, performance management, asset management, and operational departments such as procurement and HR. The Eastern Cape Provincial Treasury has provided a masterclass in this coordinated approach, employing dedicated champions in each district and fostering relentless coordination. Success is a function of breaking down internal walls.

• Investing in capacity: the wealth of materials provided by National Treasury, including detailed process manuals and system specifications, are themselves training tools. As Silma Koekemoer, Doctor of Philosophy from Nelson Mandela University has emphasised, these are designed for both financial and non-financial staff.

Continuous training is the antidote to the capacity constraint. Furthermore, the regulatory clarity justifies critical investment in modernising fragmented IT systems and integrating data platforms, providing a clear benchmark against which to measure current capabilities.

• Using the data: too often, mSCOA data is used only to prepare reports for National Treasury. This is like using a smartphone only to make phone calls. Its true value lies in tracking monthly performance, adjusting budgets mid-year and informing council decisions. This enables municipalities to track spending down to a specific project in a specific ward – making “ghost projects” a thing of the past.

For municipalities that have struggled to keep up with mSCOA implementation, this regulatory shift is not a threat, it is a definitive blueprint and a chance to reset. It provides the clarity and uniformity we have lacked, moving the conversation from “How do we interpret

the requirement?” to “How do we master the process?”

It also arms municipal officials with a clear set of requirements for their software vendors and consultants, allowing them to be held accountable for delivering systems that enable these critical processes, not just technically comply with them.

The path to victory, from vision to tangible service delivery, is paved with credible data. The regulation of these 14 processes provides the essential guardrails on that path. The challenges of change management remain very real, but they are now challenges we face with a clear map and a common goal.

This is our shared opportunity. It is a chance to move beyond compliance and use data to tell a new story about local government – a story of transparency, accountability and tangible progress.

The framework is no longer a constraint: it is the powerful enabling tool it was always meant to be. It is now up to local government to depress the accelerator and use mSCOA to drive the change our citizens so desperately need. Let’s not waste this roadmap.

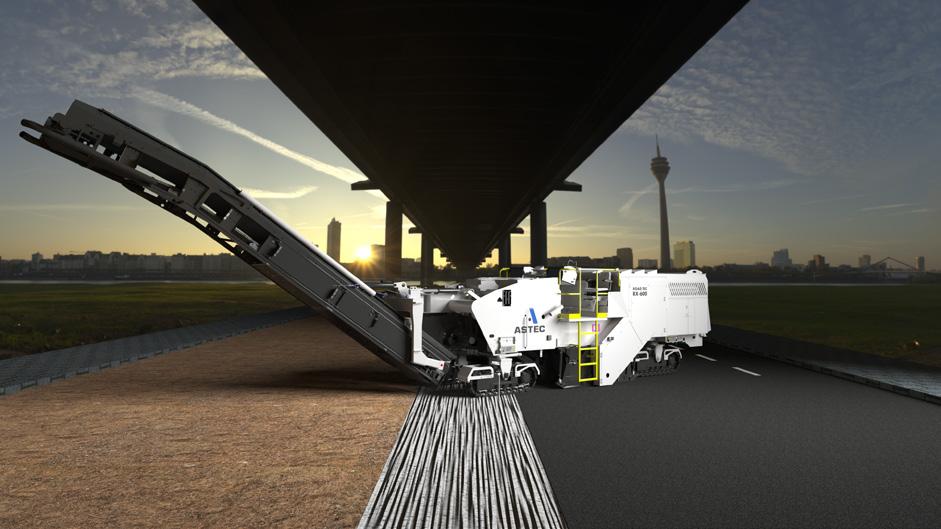

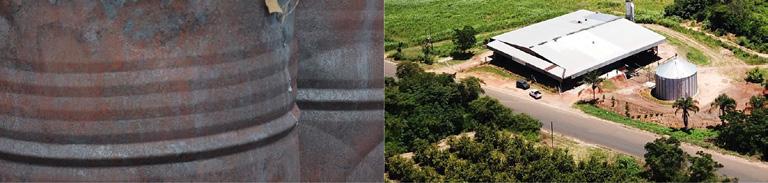

“In the evolving landscape of road construction and safety, the success stories lie right beneath our feet – quite literally,” says Michelle Lewis, KwaZulu-Natal Regional Technical Manager at Much Asphalt.

One of the most promising developments in modern pavement technology is Bitumen Rubber Asphalt Open Grade (BRAOG), a material that blends engineering innovation with environmental awareness. “Being part of the first BRAOG project in KZN is an honour and a privilege,” Lewis adds.

BRAOG is a stone skeleton and essentially an open-graded asphalt mix with an interlocking matrix of the coarse aggregate modified with bitumen

rubber. The binder is produced by blending base bitumen with finely ground crumb rubber obtained from the buffing of recycled pneumatic vehicle tyres. It is a non-homogeneous binder as the rubber crumb and bitumen remain as distinct detectable phases with their own localised properties.

Once the rubber crumb particles are added to the superheated bitumen they start to react with the aromatic components in the bitumen. This reaction process may be aided by the addition of a small quantity of aromatic oil to act as an “extender” to assist with the digestion of the rubber crumbs. Such oils, frequently termed “extender oils”, allow

the rubber particles to swell without removing the binder aromatics required for product lifespan and aid particle dispersion in the binder.

“The result is a flexible, durable and environmentally friendly surfacing material that offers a unique combination of performance and sustainability,” says Lewis.

BRAOG is a functional layer, used for improved surface texture, surface drainage and noise abatement, and is upheld by a support layer or membrane to ensure longevity of the pavement structure.

Unlike dense-graded mixes, the open structure of BRAOG allows water to drain through the surface, reducing splash and spray during wet conditions and improving driver visibility and safety. This characteristic makes it especially effective for high rainfall regions and high-speed roadways.

“At the heart of BRAOG’s appeal is its recycled rubber component,” Lewis explains. “By repurposing end-of-life tyres, BRAOG directly contributes to waste reduction and circular economy goals – a major win for both engineers and environmental stewards.”

From a technical standpoint, the bitumen rubber blend enhances the binder’s elasticity and resistance to cracking and oxidative aging. The viscosity of the binder also supports the addition of more binder by mass into the mix compared to conventional binders. The result is a road surface that remains flexible under stress, minimising reflective cracking and extending pavement lifespan.

BRAOG’s high permeability aids in surface drainage while the rubberised binder provides superior noise reduction, a feature increasingly valued by road users, urban planners, and communities.

Where science, sustainability, and vision meet on the open road

Motorists experience quieter, smoother rides and road maintenance agencies benefit from longer maintenance cycles and reduced lifecycle costs. However, Lewis warns that successful implementation requires careful attention to the mix design, suitable drainage systems, handling of the binder, as well as placement and compaction techniques. “The viscosity and curing behaviour of bitumen rubber differ significantly from conventional binders, making quality control and expertise crucial to its performance and outcomes.”

A step forward for South Africa

Bitumen Rubber Asphalt (BRA) has been used successfully in South Africa since its introduction in the early 1980s.

“However, the application of BRAOG has not been nearly as widespread as its continuously graded or gap graded bitumen rubber asphalt counterparts. As far as we are aware BRAOG has not been used in KwaZulu-Natal to date and its performance in local conditions remains unverified,” says Lewis.

“Much Asphalt is performing comprehensive trials as a prelude to its planned use for SANRAL’s Upgrade to National Route 3

Section 3 between Ashburton Interchange (km 0.8) and Murray Road (km 5.9).

“These early trials and pilot projects are opening doors to evaluate the local performance of BRAOG under varying climatic and traffic conditions.”

Lewis, together with Joanne Muller, Gauteng Inner Regional Technical Manager at Much Asphalt, designed the BRAOG14 specifically for this application. “It uses a single size 14 mm and 10 mm stone combination to achieve the desired gap in the 14 mm nominal maximum particle size mix. We aim for 20% target voids in the mix to allow free draining of water that could otherwise cause adverse safety conditions.”

Paving trials using BRAOG14 at Ashburton on the N3 freeway

A close-up view of the functional 14 mm NMAS BRAOG layer

The mix has been successfully tested at the Much Asphalt Pietermaritzburg plant and paving trials are in progress on the southbound lanes of the N3 at Ashburton. The trial sections will be trafficked for eight to twelve months before the whole project gets a BRAOG14 final wearing course, should it perform as expected. The binder is being supplied by Colas, the consultant on the project is Naidu Consulting, the main contractor is Base Major Construction/CSCEC JV, and Ten Civils Construction is the sub-contractor for the paving works.

“As infrastructure agencies continue to balance cost, durability, and environmental stewardship, BRAOG stands out as a forward-looking solution –leveraging waste for improved performance, while delivering safer, smoother, longer-lasting roads,” Lewis concludes.

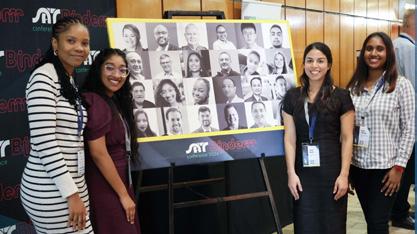

In nine short months, on 2nd and 3rd September 2026, the Society for Asphalt Technology (SAT) will host its fourth SATBinderrr conference. SATBinderrr 2026 will showcase talent and innovation and encourage discussion, with an overarching focus on sustainable quality across all aspects of asphalt and bitumen.

Named not only for its correlation to asphalt, but also for its role as the conference that binds the industry, SATBinderrr has enjoyed great success since its first iteration in 2021. It was held again in 2022 and is now a

biennial event that leapfrogs CAPSA conferences and in so doing supports the industry without competing with CAPSA.

SAT has close to 800 members, from students to globally recognised asphalt leaders. Their common goal is to promote excellence in the

asphalt industry. From within this pool comes the combination of proven wisdom and fresh ideas upon which we build SATBinderrr. SAT is known to offer the best value for money in the industry in its quest to provide quality professional development through learning and networking. SATBinderrr is the pinnacle of this offering.

We’re on the move

While retaining focus on what is important for the industry, the next SATBinderrr has some differences. Most importantly, the 2026 event is moving from its traditional home at the CSIR in Pretoria to The Capital Zimbali on the Dolphin Coast, north of Durban in KwaZulu-Natal. 3 4 1 2

1 At SATBinderrr 2024 (from left): Sthabile Sibiya, Chemistry Focus Area Chair; Tarlia Gerald, Construction Focus Area presenter; Nishaat Mowzer, Seals Focus Area Chair; and Nikisha Sewpersad, Seals Focus Area presenter

2 Chemistry Focus Area speakers at SATBinderrr 2024 (from left): Tladi Mofokeng; Sinethemba Mkhize; Sthabile Sibiya, Focus Area Chair; Georges Mturi, Focus Area Mentor; Jianmin Ma, international guest speaker; and Nteseng Ramoraswi

3 SATBinderrr 2024 Construction & Manufacturing Focus Area presenters (from left): Gary Wright, Focus Area Joint Chair; Eben van Zyl, Focus Area Mentor; Tarlia Gerald, presenter; Craig Naicker, Focus Area Joint Chair; and Randhir Haripersad, presenter

4 “Get to Know Shony” interview at the SATBinderrr 2024 cocktail evening. Tumelo Thothela, Asphalt Focus Area Mentor, is pictured on stage with Fulufhelo Shony Mathagu, Director: Roads Transport – Research, Policy and Guidelines at the National Department of Transport. This robust and entertaining interview and Q&A session with the audience was a highlight of SATBinderrr 2024, inspirational for the youth in the audience while answering important questions about the future of the industry

5 A full house at SATBinderrr 2024

6 SATBinderrr 2024 Seals Focus Area session and panel discussion

Nik Berning, who has bravely taken on the role of heading up the organising committee for the second time, says the decision to move away from Gauteng for this round was not taken lightly. “KwaZulu-Natal is undergoing tremendous infrastructure development and the freeway system around the eThekwini Metro and across the province is in the midst of unprecedented upgrades,” says Berning.

“We think this is a very exciting time and place to be hosting a conference that speaks to the critical topic of our road networks.”

He adds that The Capital Zimbali is a superb venue in a beautiful setting that will contribute to this conference as an experience not to be missed on the 2026 calendar. “There will be more space for the delegates and more branding opportunities to add value for our sponsors.”

Berning praised the SAT Eastern Region for its outstanding support and dedication to ensuring the success of this conference on home soil in KwaZulu-Natal. “We have the right people on the ground and I’m very happy about that.”

A call for abstracts, details of the focus areas, sponsorship opportunities, and the identity of the keynote speaker will follow soon.

On the issue of networking, the major motivation behind the founding of SATBinderrr www.socsat.co.za

in 2021, Berning says a golf day at the Ernie Els-designed Zimbali Lakes Signature Course has been secured for just this purpose. This event, preceding the conference on 1st September, is expected to draw a strong field and there will be a “get-to-know” golf session for anyone who wants to hit a little ball with a stick but does not yet have the skills.

Thinking back to when I was a green youngster in our sector, I was borderline terrified of speaking in front of an inperson SAT or RPF event, let alone a conference, be it CAPSA or otherwise. My first exposure to conference speaking came like a freight train, to an audience in Istanbul where my nerves got the better of me and I spoke so fast the translators struggled to keep up. It was nerve wracking, to say the least.

SATBinderrr, for me, is geared to giving the young practitioners an opportunity to hone the skills needed to stand on those stages. Having mentors through the conference process to assess and advise is a huge opportunity for the participants to learn and grow, to understand what is expected and what is acceptable. While they may not be seasoned presenters, these professionals are the future of our industry and are more than qualified to ensure that SATBinderrr upholds the technical excellence for which it is known.

This is a place where likeminded people from all walks of life and subsectors of the roads industry meet to collaborate, share their experiences and knowledge, and create connections that stand the test of time.

where talent, innovation & quality meet

It's often not what you know, but who you know to call for advice that makes the difference. SATBinderrr is the perfect coalescence of SAT’s objectives, providing the platform to share knowledge and technological improvements while bringing practitioners together to create connections and stimulate discussion and debate.

Joanne Muller

The journey towards the George Integrated Public Transport Network (GIPTN) began in 2005, following the redevelopment of the George Thembalethu taxi terminus and upgrading of the Sandkraal Road between the N2 and Industrial Road. One of the key outcomes of the study was a recommendation to develop George’s public transport system, as the existing services were failing residents.

By Carine Heyns

Routes were limited, services unsafe and unreliable, infrastructure inadequate, and taxi drivers faced precarious working conditions. These findings laid the groundwork for the George Mobility Strategy, which envisioned to provide a safe, affordable, accessible, reliable, dignified and convenient scheduled public transport system.

GO GEORGE was launched in December 2014 with an “infrastructure light” approach. This approach was adopted due to uncertainties relating to passenger demand and take-up, and thus the risk of investing in infrastructure that might be unused should the operation not materialise.

Phase by phase, the system grew, connecting more suburbs, and expanding on the initial infrastructure, with the most recent addition in October 2024 extending services between Thembalethu and the George industrial area.

Today, the network has 33 routes, 565 universally accessible stops, and 40 transfer locations that act as vital nodes, linking routes, and enhancing passenger comfort, safety, and wayfinding.

Since its introduction, the GO GEORGE service has had a significant socio-economic impact. In terms of improved accessibility and mobility, it operates 16 hours a day, seven days a week, linking previously underserved communities to healthcare, recreation, education, government services, and employment opportunities, with 70% of passengers using the service to travel to work.

By offering subsidised fares, the system significantly improves mobility for low-income households, making transport more affordable for the poorest of the poor, with 89% of passengers paying less for transport than they did before its introduction. GO GEORGE also provides enhanced accessibility for passengers with special needs, such as pregnant women, the elderly and children, and passengers with disabilities through universal design features, such as wheelchair ramps and level boarding, ensuring that the service is inclusive and equitable.

GO GEORGE has also generated a wide range of employment opportunities, creating jobs for bus drivers, technical staff, call centre agents, a vehicle operating company (VOC), construction firms, and local vendors. At the same time, it has contributed to the formalisation of the taxi industry by compensating or incorporating local minibus taxi operators into the system as VOC shareholders.

Through this process, 139 shareholders have been given the opportunity to participate in a formal business environment in a relatively lowrisk manner, fostering economic empowerment and long-term stability within the local transport sector.

In terms of urban development and investment, the introduction of GO GEORGE has catalysed significant urban improvements, triggering upgrades to roads, sidewalks, transfer locations, and areas around bus stops, thereby enhancing both the safety and attractiveness of key corridors and neighbourhoods. The GIPTN network has also shaped spatial planning, informing land use intensification corridors in the MSDF 2023. These interventions have contributed to rising property values and increased commercial activity along main routes, particularly within the CBD and other high-density areas, with most passengers recognising the system’s positive contribution to their neighbourhoods.

Since its inception, GO GEORGE has attracted over R741 million in infrastructure investment, of which about R568 million originated from outside of George, with further allocations still to be spent, demonstrating the system’s ongoing role as a driver of economic development and urban renewal.

Furthermore, the GO GEORGE fleet exceeds legislative minimum emission standards, operating 35 minibuses at Euro 4 level and 98 large buses at Euro 5 level, reinforcing its role in promoting cleaner, safer, and more efficient urban mobility.

The positive impact of GO GEORGE continues to unfold, with several routes in Phase 4A still under way and future phases (5, 6 and 7) planned. The evidence is clear that scheduled, safe, and reliable public transport is not a luxury but an essential investment in community upliftment, economic growth, and sustainable urban development.

This December, celebrate the holiday season with Ammann Kenzam’s exclusive Christmas Specials! Up to 20% discount on a wide range of our premium products, including laboratories, bitumen tanks, spare parts, drill core trailers, valves, burners, and mobile pressure washers. Our Christmas Specials are designed to help you enhance your operations while spreading holiday cheer. From December through January 2026, take advantage of this limited-time opportunity to invest in quality equipment that guarantees performance and reliability. Let us help you unlock excellence in asphalt technology this festive season.