INDUSTRY INSIGHT

Water & Wastewater

Building the case for reuse

Environmental Engineering

Water control with mattresses

Cement & Concrete

Mastering cold weather factors

IMESA The official magazine of the Institute of Municipal Engineering of Southern Africa www. infrastructurenews.co.za infrastructure development • m aintenance • service delivery

SPRAS: The new approach to wastewater

Siyabulela Fanie ceo, opecs

AfriSam

Concrete contribution to solar energy

ISSN 0257 1978 Volume 44 No. 5 • May 2019 • R50.00 (incl. VAT)

Use our rich media solution – video, animation and text – to reach and engage with your target market.

Media can be used in our: Digimags Newsletters Website

ADVERTISE Jenny Miller on +27 (0)11 467 6223 or jennymiller@lantic.net

SUBSCRIBE TO DIGIMAG +27 (0)11 233 2600 or subs@3smedia.co.za SIGN UP FOR NEWSLETTER www.infrastructurenews.co.za

Print and digital solutions for business communities www.3smedia.co.za Video ++= AnimationTextDynamicmessage

Rich

FOLLOW US infrastructurenews @infrastructure4

Grab your target market’s attention on

Complete water resource and wastewater management Water & Sanitation Africa ( + + (

T

www.infrastructurenews.co.za

OVER over 80 000 pageviews every month

INdustry IN s I ght

The rapid rate of urbanisation, combined with steady population growth, is placing pressure on existing wastewater treatment plants. Siyabulela Fanie, CEO at OPECS, discusses a revolutionary and field-proven alternative. P10

As of 30 January 2019, a new source of solar power is boosting Eskom’s national grid from the Northern Cape town of Kathu, where a R12 billion generation plant has achieved commercial operation, following two years of construction that saw almost 65 000 m3 of concrete poured. P6

volume 44 no. 5 may 2019 IMESA www. infrastructurene ws INFRASTRUCTURE DEVELOPMENT MAINTENANCE SERVICE DELIVERY SPRAS: The new approach to wastewater Siyabulela Fanie INDUSTRY INSIGHT AfriSam Concrete contribution to solar energy Environmental Engineering Water control with mattresses Water & Wastewater Building the case for reuse Cement & Concrete Mastering cold weather factors Regulars Editor’s comment 3 President’s comment 5 Africa round-up 8 Index to advertisers 52 Cover Story Concrete contribution to solar energy 6 Industry Insight SPRAS: The new approach to wastewater 10 Municipal Focus | Ekurhuleni Leading the way 12 Water Utilities Building the case for reuse 14 A blueprint for rural water supply 16 Panel Discussion Nyeleti Consulting 19 UltraTech SA 21 Environment Planning for climate change 23

14 INSIDE Water Utilities Building the case for reuse Meters, Pumps & Valves A potential shift to AMR 25 Environmental Engineering Water control with mattresses 28 Geotechnical Engineering Flexible drainage 31 Information Technology Embracing the revolution: can you afford not to? 32 Three decades of IT innovation 35 Geomatics Cadastral surveying: What is it and why do we need it? 36 Dams & Water Storage Resealing Von Bach Dam 38 Cement & Concrete Mastering cold weather concreting 41 Crash-tested 42 Connecting countries and economies 45 The perfect seal 46 Transport, Logistics, Vehicles & Equipment Leading in the 20 t class 48 Ultimate multitaskers 50

38 45 31 Dams & Water storage Resealing Von Bach Dam geotechnical engineering Flexible drainage cement & concrete Mastering cold weather concreting

Consistent quality requires consistent excellence ...

... in every area of wastewater management.

Serving both the public and private sectors, ERWAT promotes a healthy environment by providing cost-effective wastewater treatment solutions through innovative technologies. It specialises in sustainable, quality wastewater services, backed by focused technical, maintenance and engineering services. An ISO/IEC 17025 accredited laboratory renders a wide variety of specialised analyses, while industrial wastewater quality management assessments and advice are also offered.

East Rand Water Reg. No. 1992/005753/08

(Association incorporated in terms of section 21)

GPS Co-ordinates:

Address: Hartebeestfontein Office Park, R25, Bapsfontein/Bronkhorstspruit, Kempton Park.

Tel: +27 11 929 7000

E-mail: mail@erwat.co.za

www.erwat.co.za

ERWAT EXCELLENCE

IN WASTEWATER

S 26° 01’ 25.8”

E 28° 17’ 10.0”

and

uppe marketing A13900

MANAGING EDITOR Alastair Currie

SENIOR JOURNALIST Danielle Petterson

HEAD OF DESIGN Beren Bauermeister

CHIEF SUB-EDITOR Tristan Snijders

CONTRIBUTORS Randeer Kasserchun, Bryan Perrie, Altus Strydom

OPERATIONS & PRODUCTION MANAGER

Antois-Leigh Botma

PRODUCTION COORDINATOR Jacqueline Modise

FINANCIAL MANAGER Andrew Lobban

DISTRIBUTION MANAGER Nomsa Masina

DISTRIBUTION COORDINATOR Asha Pursotham

SUBSCRIPTIONS subs@3smedia.co.za

PRINTERS Paarl Media KZN +27 (0)31 714 4700

ADvERTISING SALES

Jenny Miller Tel: +27 (0)11 467 6223

Email: jennymiller@lantic.net

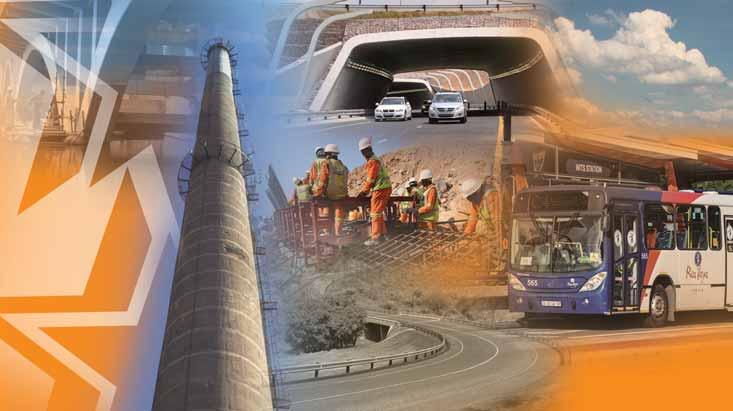

Working with BRICS

On 27 April 1994, South Africa held its first truly democratic election, where everyone had the right to vote. The results of the May 2019 General Election will herald in the sixth democratically elected Parliament, which will be responsible for steering the country as one of the key economic leaders in Africa and the only nation on the continent to hold a place at the G20.

Corporation to drive its Renewable Energy Sector Development Project; and $480 million (R6.9 billion) to finance Eskom’s environmental protection project at Medupi.

PUBLISHER Jacques Breytenbach

Novus Print (Pty) Ltd t/a 3S Media

46 Milkyway Avenue, Frankenwald, 2090

PO Box 92026, Norwood 2117

Tel: +27 (0)11 233 2600 Fax: +27 (0)11 234 7274/5 www.3smedia.co.za

ANNUAL SUBSCRIPTION: R600.00 (INCL vAT) ISSN 0257 1978 IMIESA, Inst.MUNIC. ENG. S. AFR.

© Copyright 2019. All rights reserved.

IMESA CONTACTS

HEAD OFFICE:

Manager: Ingrid Botton

P.O. Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Fax: +27 (0)31 266 5094

Email: admin@imesa.org.za

Website: www.imesa.org.za

BORDER

Secretary: Celeste vosloo

Tel: +27 (0)43 705 2433

Fax: +27 (0)43 743 5266

Email: celestev@buffalocity.gov.za

EASTERN CAPE

Secretary: Susan Canestra

Tel: +27 (0)41 585 4142 ext. 7

Fax: +27 (0)41 585 1066

Email: imesaec@imesa.org.za

KWAZULU-NATAL

Secretary: Ingrid Botton

Tel: +27 (0)31 266 3263

Fax:+27 (0)31 266 5094

Email: imesakzn@imesa.org.za

NORTHERN PROvINCES

Secretary: Rona Fourie

Tel: +27 (0)82 742 6364

Fax: +27 (0)86 634 5644

Email: np@imesa.org.za

SOUTHERN CAPE KAROO

Secretary: Henrietta Olivier

Tel: +27 (0)79 390 7536

Fax: +27 (0)86 629 7490

Email: imesasck@imesa.org.za

WESTERN CAPE

Secretary: Michelle Ackerman

Tel: +27 (0)21 444 7114

Email: imesawc@imesa.org.za

FREE STATE & NORTHERN CAPE

Secretary: Wilma van Der Walt

Tel: +27 (0)83 457 4362

Fax: +27 (0)86 628 0468

Email: imesafsnc@imesa.org.za

Collectively, the G20 country members, which include the BRICS group, alongside key players like Germany, Japan, the UK and USA, generate over 75% of global trade. They thus serve as an important economic hub when it comes to effecting positive change, particularly for developing regions. For this reason, adding additional African and Asian countries should be a priority to ensure meaningful representation. It’s also significant to note that within South America, only Argentina and Brazil are members.

On the African continent, a positive development in accelerating change is the appointment of South Africa’s president as the next chairperson of the African Union for 2020.

For South Africa, the BRICS relationship continues to open the door for greater intercountry investment and export opportunities, steered by the BRICS New Development Bank (NDB). At the fourth NDB annual meeting in Cape Town, held between 31 March and 2 April 2019, the stated plan was to “almost double its loan book to US$16 billion (R229 billion) this year and increase its impact, as the Bank seeks to broaden its global development partnerships and mobilise more institutional and private capital.”

Five new project loans amounting to around $1.2 billion (R17 billion) were approved at the end of March 2019, three of which are in South Africa. According to the NDB, these entail an approximately $220 million (R3.15 billion) loan to the TCTA to fund work on Phase II of the Lesotho Highlands Water Project; $80 million (R1.15 billion) to the Industrial Development

On 1 April, the NDB and the Development Bank of Southern Africa also concluded a new finance package. This entails a two-step loan, valued at up to $300 million (R4.3 billion), which will be channelled into funding local renewables ventures. These are likely to focus on biomass, wind and solar projects aimed at reducing the country’s carbon footprint.

Total NDB loans to South Africa now exceed $1.4 billion (R20 billion). The NDB says that there are plans to increase this to some $2.3 billion (R33 billion) by the end of 2019. That’s certainly exciting news for the local construction and allied industrial sectors.

Economic rebound

The South African economy is climbing back, following a particularly severe period of trading. According to Statistics SA, the formal business sector turned over some R2.57 trillion in Q4, up approximately 5.5% compared to Q3 2018. Manufacturing experienced the best improvement, recording a 7.1% gain between Q3 and Q4. Mining also experienced a 4.9% improvement, but construction is still in negative territory, recording a growth rate of -0.9%. The electricity, gas and water segment fell even lower at -17.1%.

Post elections, the expectation is that the construction sector will begin to see a surge in government funding inflows and an increased rate of tender awards.

Given our recent storm events across South Africa, there’s a substantial amount of maintenance and rebuilding required, which will dovetail with new infrastructure development.

Alastair

Cover opportunity

EDITOR’S COMMENT To our avid readers, check out what we are talking about on our website, Facebook page or follow us on Twitter and have your say.

In each issue, IMIESA offers advertisers the opportunity to get to the front of the line by placing a company, product or service on the front cover of the journal. Buying this position will afford the advertiser the cover story and maximum exposure. For more information on cover bookings, contact Jenny Miller on +27 (0)11 467 6223.

All material herein IMIESA is copyright protected and may not be reproduced either in whole or in part without the prior written permission of the publisher. The views of the authors do not necessarily reflect those of the Institute of Municipal Engineering of Southern Africa or the publishers. Infrastructure News @infrastructure4 IMESA official Institute Engineering Africa www.infrastructurene INFRASTRUCTURE DEVELOPMENT MAINTENANCE Thenew approach wastewater Siyabulela Fanie CEO, INDUSTRY INSIGHT AfriSam Concrete contribution to solar energy Environmental Engineering Water control with mattresses Water & Wastewater Building the case for reuse Cement & Concrete Mastering cold weather factors 1978 2019 R50.00 IMIESA May 2019 3

In memoria:

saying farewell to past presidents

Wesley Fourie , an esteemed member of iMesA and a Past President, passed away on 17 August 2018 in randburg. in his last position with the institute, he served as Honorary secretary – Treasurer.

Wesley was born in Hermanus in 1934. Following his matriculation from Paarl Gymnasium in 1951, he went on to study civil engineering at the stellenbosch university, graduating in 1956. He subsequently dedicated his working career to municipal engineering, starting as a junior engineer in Welkom, working in the roads and stormwater field. Wesley was then employed as senior engineer in Polokwane before moving to Vryburg in 1963 as town engineer.

During 1964, he was appointed as town engineer of ermelo. in 1970, he moved to randburg in the same capacity. on his retirement in 1994, he held the position of technical director for the city of randburg, and was responsible for all technical departments.

Wesley joined iMesA in 1964 and was appointed as a council member. He was elected as iMesA’s president in 1986. For 13 consecutive years, from 1982 through to 1994, he also served as iMesA’s secretary. His dedicated service to iMesA and municipal engineering was recognised by his election as an Honorary iMesA Fellow in 1988.

Tj AA r T VA n D er WA lT obtained a master’s degree and doctorate in Civil engineering Management at rAu (now uj). He delivered several papers on engineering management both nationally and internationally and was a recipient of the ‘Best Paper Award’ at the iMesA conference held in Durban in 2000.

He spent 20 years in private practice and 18 years in local government, and gained extensive experience in all facets of construction, municipal engineering and municipal administration. His first deployment in the municipal arena was as a civil engineering technician for roodepoort City Council in 1974.

During his 20 years in private practice, he was a partner, director and managing director of several companies, including construction, property and aircraft firms. He lectured part-time at uj for several years and moderated final-year engineering students. in his last public sector assignment, he was employed by the City of johannesburg in the Corporate Planning unit involved with research, strategic planning and performance management. He was a Past President and an Honorary Fellow of iMesA. Tjaart passed away on 4 April 2019.

IMESA Ob IT u ARIES

4 IMIESA May 2019

Flood control and countermeasures

As extreme weather becomes more severe, our municipal engineering interventions need to respond to cope with the erratic nature of climate change. There are some things outside our control, but it’s the way we anticipate and respond to them that counts.

During the recent spate of heavy rainfall across South Africa, many of our innercity roads were flooded as stormwater systems failed to cope with the deluge. In some cases, culverts and stormwater channels didn’t function optimally, either because they were blocked or simply overwhelmed in terms of their design capacity.

The broader KwaZulu-Natal region experienced particularly heavy rains and winds. Although Sanral reported that there was no structural damage on national provincial routes, some sections of the N2 and N3 were blocked due to landslides and flooding.

We also saw a spate of structural failures in buildings. A tragic example is the Pentecostal Church in Dlangubo, where a wall collapsed, killing a number of congregants. The cause has yet to be determined, but this reinforces the point that any structure, whether it’s a road, bridge or building, needs to be designed to withstand known, historic and projected storm conditions. Structures must be founded to specification and the correct drainage system installed to prevent undermining. In all instances, regular inspections must be part of the process.

Our informal settlements are especially exposed, particularly where homes have been built below flood lines or on hillsides.

Gabions as an intervention

In most cases, incorporating environmentally engineered solutions using gabions and river mattresses is a highly effective response to future flood events for rivers, channel

systems, roads and bridges, retaining slopes and embankments. This is especially the case where specific site locations experience extended dry periods and the ensuing erosion, an increasingly common scenario that exacerbates flood events.

Landslides and riverbank collapses can be prevented in the majority of instances if correctly engineered with gabions and/or mattresses, and at times combined with concrete retaining systems. A key factor is the control of drainage to prevent hydraulic pressure build-up. In this respect, gabions and mattresses are highly effective in slowing down water velocities while countering soil loss and erosion.

A further plus is that gabions are faster and cheaper to build than concrete structures. Environmental systems also predominately use labour-based construction techniques. For this reason, it’s an approved methodology in terms of the Expanded Public Works Programme and a great initiative to promote skills transfer and SMME development.

Gabions are, therefore, a perfect community initiative and will be a vital part of restoring infrastructure in the coming months, helping to stretch municipal budgets.

Water security

Managing water is a top-of-mind priority for municipal engineers, both in terms of disaster management and prevention, and storage. While most major dams across South Africa are now at 70% capacity or higher, there are still parts of the country experiencing drought conditions. For example, overall dam capacities for the Western Cape are at around 35.6%:

Cape Town’s overall storage was sitting at 47.3% towards the end of April.

Not surprisingly, most KwaZulu-Natal dam levels are on the rise. However, towns in northern Zululand, such as Nongoma and Ulundi, remain dry. A similar pattern exists in parts of the Eastern Cape and Free State. So it’s often a “feast or famine” approach. Our job as municipal engineers is to ensure sustainability of supply. Much of our stormwater is currently lost. This should be captured and reused, where practical. The balance can be safely channelled into our surrounding rivers and wetlands.

IMESA

P RESIDENT ’ S COMMENT IMIESA May 2019 5

Randeer Kasserchun, president, IMESA

Concrete contribution to solar energy

Based on concentrated solar power (CSP) technology, Kathu Solar Park is adding 100 MW to Eskom’s capacity – enough to supply 179 000 homes in the local community of John Taolo Gaetsewe District Municipality, Northern Cape, and South Africa as a whole, with clean and reliable energy. The project, developed by a consortium of local and international stakeholders, is part of the Renewable Energy Independent Power Producer Procurement Programme (REIPPPP) being implemented by the Department of Energy.

The CSP plant uses parabolic troughs, designed like curved mirrors, to direct and focus the sun’s energy on to an absorber pipe containing a heat-absorbing medium that carries the energy to the water in a

As of 30 January 2019, a new source of solar power is boosting Eskom’s national grid from the Northern Cape town of Kathu, where a R12 billion generation plant has achieved commercial operation, following two years of construction that saw almost 65 000 m3 of concrete poured.

boiler heat exchanger. Here, the heat is used to produce steam, which in turn drives turbines to generate electricity.

As one of the largest such plants in South Africa, it covers a footprint of 4.5 km², over which 384 000 mirrors have been installed. To make optimal use of the sun’s energy over the course of each day, a tracking system on each solar collector assembly makes sure that the sun’s rays are always focused on the absorber pipe. Using molten salt as a way of storing energy gives the system an extra 4.5 hours of thermal energy storage when the sun is not shining, so the plant can generate power for 16 to 18 hours a day.

EPC phases

The construction process began in May 2016, driven by a consortium formed by Acciona in partnership with Sener, which acted as the engineering, procurement and construction provider. Cement for the structures and foundations came from construction materials leader AfriSam, which supplied Kurumanbased contractor Agisane Civil Construction

with all readymix requirements. To meet the varying applications on the project, 19 different concrete mixes were used.

Much of the concrete was used for piling and the bases of the support structures for the thousands of parabolic reflectors, as well as for the foundations and supports for the large process elements in the project’s ‘power block’, at the centre of the solar field. These elements included bases for turbines, salt tanks, towers and storage vessels. For the reflector stands, about 40 000 reinforced piles were poured, with each stand foundation requiring four piles to a depth of 2 m to 8 m. Where soils were collapsible, making them unsuitable for piling, raft foundations were used.

The pit and towers for the storage area of the heat transfer fluid (HTF) system were another significant collection of concrete structures. Vessel tanks containing the HTF, which circulates through the solar fields to keep the salt molten, are held on concrete towers standing in a large concrete pit to contain any potential fluid spills. The HTF oil

C O v ER STOR y 6 IMIESA May 2019

Solar field with concrete bases

is heated to 400⁰C, so the columns holding the HTF storage vessels in the concrete pit were lined as a safety precaution. This lining included a special concrete mix using a lightweight expanded clay aggregate (LECA), which raises the concrete’s heat resistance to up to 1 000⁰C. This augmented a special treatment of the concrete floor of the pit, where three geolayers underlie the concrete pit base.

The large network of stormwater channels throughout the solar park, vital in providing adequate drainage and preventing erosion damage, also required considerable volumes of concrete. The area is generally dry, but rainfall can be intense and highly erosive.

Ambient temperature challenges

Among the most demanding pours for the large structures in the power block was for the turbine base, needing 2 000 m3

of concrete in five pours. In addition to the supply logistics to this fairly remote town, the high daytime temperatures created particular challenges for the concrete work. The turbine base pour, for instance, had to be conducted at night to make use of the coolest hours.

So hot were the ambient conditions that that the initial specification of a 30⁰C maximum limit for concrete had to be revised upwards to 35⁰C. The temperature of the fresh concrete was then measured continuously to ensure that it was within specification. Keeping within this limit meant applying several special precautions. For example, concrete was to be placed as quickly as possible, so trucks were not permitted to stand for more than half an hour before pouring; the temperature of each truck load was measured, both at the batch plant and the site of the pour.

The long pours, often at night, demanded a 24-hour cycle to be meticulously planned, so that schedules and resources could be closely managed. As the cement supplier, AfriSam sometimes had four or five bulk cement trucks from its Ulco plant near Kimberley waiting at the batch plant’s silos to replenish stock, as it was rapidly drawn out for the large pours. This was

to ensure that the silos could meet the overnight demand, and be topped up for the start of the day shift. Substantial stockpiles of aggregate would also be maintained at these times.

Other innovative techniques were adopted in the readymix process to deal with the intense heat. To adequately cool the concrete mix for the mass turbine base, ice was added to the 10 000 ℓ water tanks before the water was tapped into the mixer. Also, hessian was wrapped around the water tanks and kept wet, providing further cooling by evaporation.

Sustainable into the future

The environmental benefits of the project are mainly the saving of six million tonnes of CO2 emissions over its first 20 years of operation, but the social and economic benefits locally are also important. The site employed over 3 000 local workers and maintained nearly 42% of the staff from the local community. At its peak in September 2018, the project created 2 300 construction jobs. It is expected to continue promoting the local economy through various ventures such as a local community trust for the benefit of communities in John Taolo Gaetsewe District Municipality, as well as through the sourcing of services from local entrepreneurs.

www.afrisam.co.za

IMIESA May 2019 7

ABOVE Molten salt tank with concrete tower

ABOVE RIGHT Molten salt tank towers and pillars under construction

Concrete being pumped through the night in the turbine block

INFRASTRUCTURE NEWS FROM AROUND THE CONTINENT

sUb-saharan africa

funding renewable energy generation

The African Development Bank (AfDB) Group has agreed to invest up to $25 million in the ARCH Africa Renewable Power Fund (ARPF).

The $250 million private equity fund for renewable energy projects across subSaharan Africa is expected to reach first close in early 2019. The AfDB’s presence is expected to act as a catalyst for other investors to commit a further $60 million to $75 million equity from non-DFI sources.

ARPF will provide equity for the development and construction of 10 to 15 greenfield renewable energy projects in sub-Saharan Africa, adding approximately 533 MW of installed energy generation

capacity from renewable sources in the region.

ARPF projects will focus on mature technologies including wind, solar PV, small to medium hydro, geothermal and biomass. In addition to contribution to renewable energy, the project construction and operation will result in direct creation of at least 272 full-time jobs and 5 320 part-time jobs.

gambia linking nations

A newly opened bridge linking The Gambia to Senegal has improved goods transport and safety between the two nations.

The bridge is a safer and quicker alternative route to the risky ferry crossing or the long detour between the northern and southern parts of both nations.

The bridge, which spans the Gambia River, will enable free traffic flow between the northern and southern parts of both The Gambia and Senegal, and is expected to reduce travel time, boost trade and unite communities that were previously isolated. It will also facilitate and increase subregional trade and open up rural areas; while increasing the level and quality of service of the NouakchottDakar-Lagos road corridors

The 942 m long bridge, along with two border posts, completes the first phase of a

road project which has cost $93.68 million.

Kenya

major investment in housing Qatar is set to invest $3.5 billion in housing in Kenya. The funding is expected to aid in the development of 140 000 housing units in Kenya, as part of the government’s affordable housing strategy under the Big Four agenda.

Speaker of the National Assembly Justin Muturi lauded the investment, encouraging further partnerships to strengthen the bilateral relations between the two countries.

The Big Four agenda seeks to fast-track the construction of 500 000 low-cost houses, through the Kenya Mortgage Refinance Company. The National Assembly has also approved the establishment of the Kenya Housing Development Fund. Speaking on the subject, President

A new fund will finance greenfield renewable energy projects in sub-Saharan Africa

Uhuru Kenyatta noted that this is the first time that privatepublic partnerships will be instrumental in the provision of affordable homes.

mozambiqUe

enhancing water availability

With the help of the French government, Mozambique will undertake a project to harness ground water resources to enhance the availability of clean water in the Greater Maputo area.

The €6.2 million in French funding will allow for the establishment of 16 boreholes, a pumping station and pipes to carry water to the reservoirs. The aim is to make more than 40 000 m3 of water available to around 348 100 people in the southern Mozambican municipalities of Maputo, Matola and Boane by 2020.

The project will also include a programme to reduce water losses by the Maputo Regional Water Company.

The new 942 m long bridge between Gambia and Senegal will increase subregional trade

533 MW $3.5 billion

The ARPF will add 533 MW of renewable energy to subSaharan Africa

Qatar will invest US$3.5 billion for affordable housing in Kenya

Qatar will invest in the development of 140 000 affordable housing units in Kenya

8 IMIESA May 2019

SPRAS: The new approach to wastewater

The rapid rate of urbanisation, combined with steady population growth, is placing pressure on existing wastewater treatment plants, pushing up processing and maintenance costs, as older facilities struggle to keep pace with rising inflows. imiesa speaks to Siyabulela Fanie, CEO at OPECS, about a revolutionary and field-proven alternative.

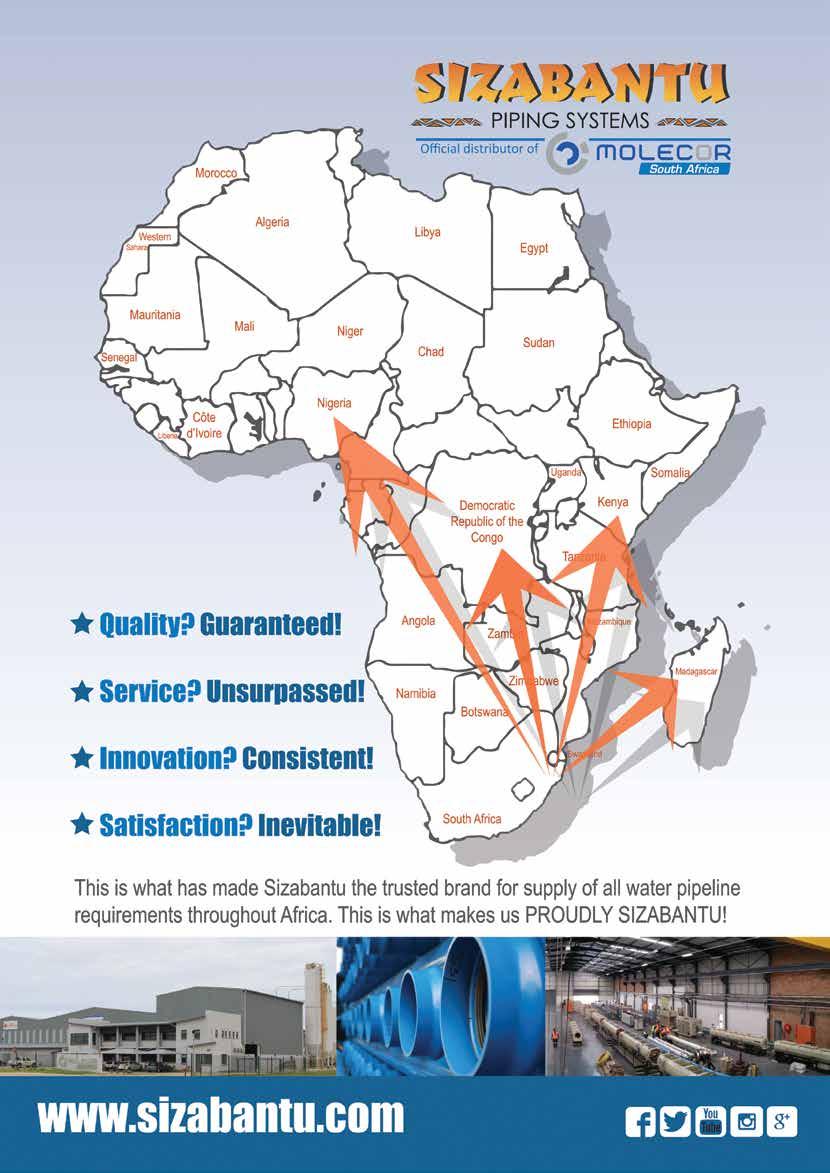

Operations and Enhancements Consulting Services (OPECS) entered the wastewater segment in 2015, following the conclusion of a partnership agreement with Chinese OEM Jinluo Water – a leader in water and wastewater solutions. Jinluo is ranked in the top 50 privately registered companies in China, a remarkable achievement given this highly competitive domestic market.

Within the wastewater sector, Jinluo’s proprietary SPRAS (Sludge Process Reduction Activated Sludge) technology challenges conventional treatment approaches. There are three key factors to note:

• No chemicals are required for the processing of domestic wastewater, while only a nominal portion is needed for industrial effluent.

• No downstream organic sludge is generated – it’s broken down and eliminated – so that rules out the issue of sludge discharge, which remains problematic and costly for conventional plants in terms of disposal and environmental compliance. Plus, the elimination of chemical dosing passes on major operational cost savings for utilities and municipalities.

• SPRAS is energy efficient, consuming as little as 0.5 kW per m3. Plants can run on a combination of mains, generator and solar power. But even without any power, the SPRAS treatment stream continues uninterrupted for up to eight hours, thanks to the inherent technology.

Our goal is to partner with national government, municipalities and consulting engineers to collaborate in accelerating water and sanitation delivery.”

Industry Ins I ght

It’s a unique anaerobic-anoxic-aerobic process, with the end stage entailing UV radiation to ensure the final disinfection of the treated water. During the processing stage, raw wastewater enters a holding or buffer tank, which regulates the flow at a constant rate before feeding through to the SPRAS treatment tank.

Plug and play

“The overriding benefit is that the wastewater treated in our package plants meets Department of Water and Sanitation and international quality standards, plus it’s a plug and play solution, which means it’s a site-specific response that’s not reliant on centralised conventional infrastructure layouts that include sewer lines running for kilometres,” Fanie explains.

The technology is also ideally suited to meet various reuse applications: some 90% of the treated water is reusable. That’s an important point to emphasise since South Africa is a water-scarce country that, along with many other nations worldwide, faces challenges when it comes to delivering clean potable water.

“Going forward, we have to rule out using potable water for non-human consumption

Benefits of sPRAs technology

needs and SPRAS fills this gap. Reuse must become the norm for non-potable requirements like crop irrigation, toilet flushing, construction, and general cleaning. In this respect, SPRAS is an ideal solution,” he continues. “It’s the answer when it comes to supplementing or supporting conventional wastewater treatment plants nationally, a number of which are not compliant and are discharging raw, untreated effluent into rivers.”

Pilot projects and commercialisation Since entering the market, OPECS has successfully completed two pilot projects that have proven the efficacy of the technology, then subsequently moving on to full-scale commercial operations. Plants can be supplied in a broad range of sizes, from as small as 70 m3 per day to 10 Mℓ facilities and higher. The technology also lends itself to BOOT (build, own, operate and transfer) opportunities.

The first pilot study was completed for the Sundays River Municipality in the Eastern Cape, where an existing treatment plant was not performing to standard. OPECS deployed two 150 m3/day package plants to increase the capacity of the existing facility. This had a direct benefit for the region’s citrus growing community, which was now able to comply with export standards thanks to the use of compliant irrigation water supplied via the OPECS plants.

The second pilot study was for Chris Hani Municipality in Cradock, Eastern Cape, where OPECS deployed a 300 m3/day plant, also as a backup to the in-situ treatment works. This was an urgent intervention, as the municipal plant was discharging raw sewage into the river.

Glen Agricultural College

second year. This plant, which is owned by the college, replaced an obsolete, existing plant.

Before the college went out on public tender, it analysed the costs of refurbishing the existing plant. OPECS’s package solution came in at around half that price. The savings are even greater when the cost of chemicals is subtracted from the college’s future operational expenditure budget.

OPECS has three units running at the college. Combined, they treat approximately 450 m3 daily, serving some 2 800 people. Like with all package plant installations, they are designed to work together or independently, so they can be scaled up or down depending on the load.

In terms of new projects, OPECS recently concluded a three-year agreement with the Free State Department of Basic Education to roll out package plants at designated schools across the province. This will be on an O&M basis.

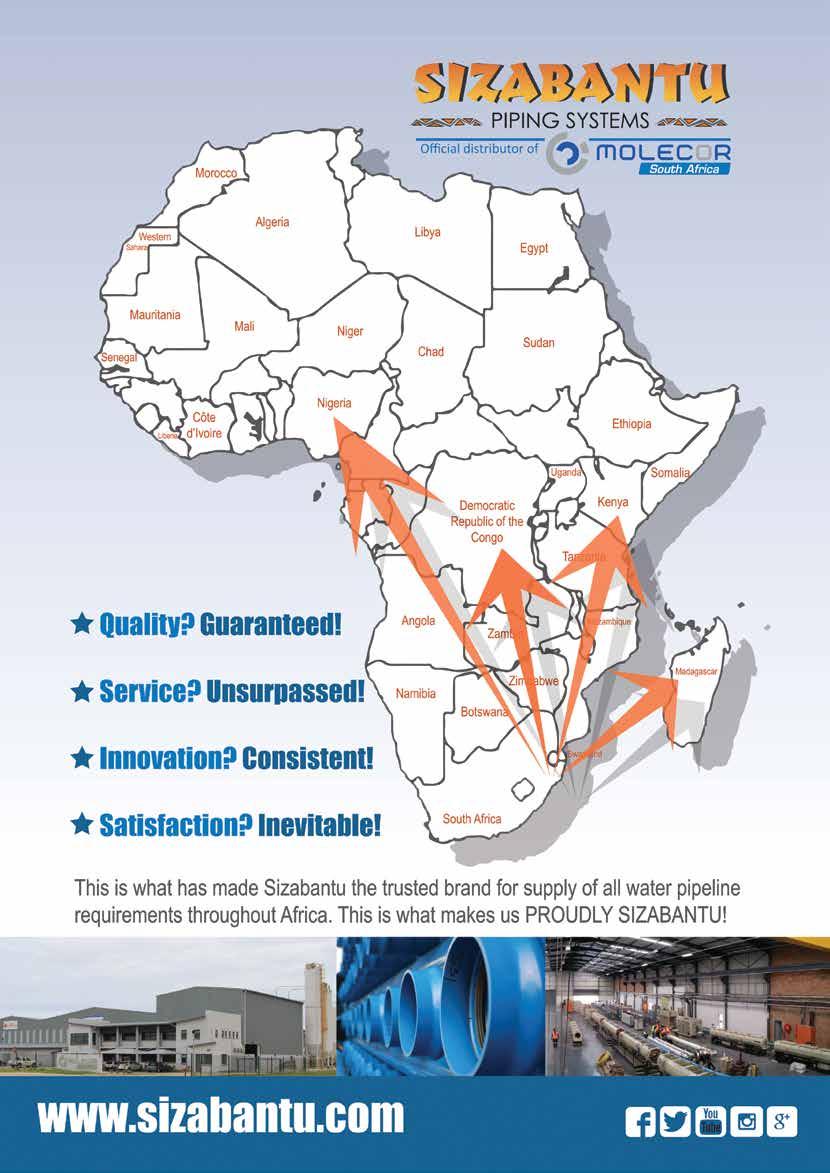

Growth in Africa

OPECS is also responding to recent enquiries from a number of African countries, which include Kenya, Nigeria and Rwanda, all of which have identified sanitation as a national priority. In the meantime, OPECS has secured a contract for a private residential developer in Kenya.

“Our goal is to partner with national government, municipalities and consulting engineers to collaborate in accelerating water and sanitation delivery,” says Fanie. “We believe SPRAS would be ideal for many new community developments that can now be developed with decentralised treatment facilities. SPRAS technology is compact and efficient, and odourless, plus its operation is silent, making it well suited to urban environments. Additionally, our plants can be installed alongside conventional works to supplement and increase capacity.

“In the meantime, we are expanding the business to meet current and future growth demands, focusing on recruiting and developing the best engineering and technical talent. That will be combined with ongoing organic growth through project excellence,” Fanie concludes.

OPECS’s first commercial project was for the Glen Agricultural College, an institution falling under the Free State Department of Agricultural and Rural Development. This OPECS operations and maintenance (O&M) project is now in its www.opecs.co.za

IMIESA May 2019 11

Industry Ins I ght - no organic sludge discharged during wastewater treatment - Water reuse - reduced footprint compared to conventional wastewater treatment plants - lower electricity consumption - Flexible construction (semiunderground or above ground) - no chemicals used to treat wastewater

easy maintenance, with built-in remote monitoring system

-

Leading the way

In his recent State of the City Address, Ekurhuleni Executive Mayor Mzwandile Masina made a bold claim: “Ekurhuleni is outperforming the other metros in the areas of delivering water services, sanitation services and renewable energy.”

When Ekurhuleni’s current dispensation took office in 2016, a programme of action was outlined to advance a pro-poor agenda focused on the roll-out of service delivery and economic development opportunities in a manner that uplifts the poorest sections of the city.

Under this action plan, a number of promises were made, to be delivered over the fiveyear term of office. These included:

• Electrifying all informal settlements

• Constructing 100 000 housing units

• Providing 59 000 service stands

• Making informal settlements more habitable by upscaling services

• Promoting preservation of water and continued investment in water infrastructure to ensure security of supply

• Building an Ekurhuleni Power Station

In his address, Masina stated that the city had come a long way in building a local economy that grows in the hands of the people.

“True to the success of our revenue collection and financial management systems, we have registered profound progress in the period under review. Our capital budget increased by an average of 10.5% per annum, from R2.3 billion to R6.5 billion. For the last financial year, the city funded its own capex – a testament to our financial health and credibility,” he said.

Electrifying informal settlements

Over the past 24 months, Ekurhuleni rolled out an informal settlement electrification programme leading to the installation of 33 236 PV lights. According to Masina, the city electrified 8 981 households, bringing the total number of connected households in informal settlements to 15 590. An additional 6 926 informal households are expected to be electrified by the end of June this year.

Investing in water and sanitation

Ekurhuleni has embarked on a programme to build 29 reservoirs from 2018/2019 to 2021 with a combined storage capacity of 550 Mℓ. To date, three reservoirs with a combined capacity of 55 Mℓ have been constructed, and work on a further nine reservoirs will commence before June 2019 to add a further 140 Mℓ of storage capacity. As a result of unmatched growth demand, the existing reserve capacities in some areas of the city can only supply between 2 to 10 hours in the event of water interruption. The construction of new reservoirs will ensure security of water supply and inter-link the water supply from one zone to another.

Mun I c I pal Ins I ght | Eku R hul ENI 12 IMIESA May 2019

Executive Mayor Mzwandile Masina, Ekurhuleni Metro

The municipality has also added 11 323 new connections for water and sewer to formal dwellings, along with the installation of 23 483 new water meters. This investment helped to reduce water losses from 34.3% to 30.85% over the past 12 months. Another 12 537 water service points were installed in informal settlements to improve access points and reduce distance travelled to collect water.

As part of the integration of informal settlements, the household ratio of chemical

toilets has been reduced from 1:10 to 1:5. These chemical toilets are regularly serviced, and Masina says the city is looking at ways to improve the efficiency of this service at a contained cost. The city will also be investing in an alternative sanitation programme.

Building houses

Masina reports that the city has completed 26 000 low-cost houses over the past 24 months and is in the process of constructing three housing mega projects, namely John Dube, Daggafontein and Leeuwpoort, with a combined total yield of 50 571 units.

Ekurhuleni’s approach to human settlements is to deliver a combination of subsidised, low-cost and rental stock to advance the life chances of the city’s residents. “We provide them with free housing when their economic means are dire; we offer them rental stock when they have slightly improved and will also

26 Nagington Road, Wadeville, Germiston 1400, South Africa

Tel +27 11 824 4810 / Fax +27 11 824 2770

E-mail info@apepumps.co.za / info@matherandplatt.com Website www.apepumps.co.za / www.matherandplatt.com

Split Case Pump

• Sugar and Paper

Refineries

encourage them to graduate into bonded houses in an area of their choice when their economic fortunes have increased,” said Masina.

The city has also been embarking on the regularisation of townships since 2016 to assist with the conversion of leasehold erven to freehold erven, providing residents with title deeds.

Leading the metros

“Overall, we are doing better than almost all municipalities in Gauteng. More instructive is the fact that we are a leader of our peer group of metros. We have performed better than all the other metros in terms of the level of citizen satisfaction in the Quality of Life assessment,” said Masina.

“In light of the fact that we are the youngest city and have a much more pronounced spatial legacy of apartheid, we should all be proud that we are now ranked as the city affording its citizens with the highest quality of life in comparison to other metros in the province.”

Mun I c I pal Ins I ght | Eku R hul ENI

Chemical Horizontal Multistage Pump Power Generation Plants Cooling and Heating Systems Mining Applications Vertical Turbine Cooling Water Circulation Irrigation Locally Manufactured

Mills •

• Petro

Building the case for reuse

As a water-scarce country, South Africa needs to diversify its water mix, moving away from a complete dependence on surface water resources. But are we doing enough? b y Danielle Petterson

Globally, two-thirds of the population live in areas experiencing water scarcity, and water demand is beginning to exceed supply in many regions.

In South Africa, 98% of available water resources have been allocated, with 77% of this comprising surface water.

In the face of growing and competing demands, water reclamation and reuse is gaining momentum as a reliable way of augmenting supply. However, Jeremiah Mutamba, manager: Water-Centred Knowledge, Trans-Caledon Tunnel Authority, questions whether South Africa is doing enough to manage the potential water deficit it faces.

He points out that although South Africa has plans and strategies in place that

feature reuse, little has been done to move from studying and planning to implementation.

Global successes

Water reuse has been practised for around 5 000 years. Today, the water reuse trend has been increasingly supported by improving technology, treatment costs and a growing supply/demand gap, with countries such as France, Israel, Portugal, Singapore and the USA leading the way.

Mutamba points to China as a prime example of how reuse can be embraced during tough times. The country, which is increasingly facing freshwater supply challenges, is among the 13 countries with the lowest water availability per capita. As a result, China has made water reuse a key component of its national water strategy.

In 2016, China reported that 21% of its 2 billion m3/year of treated wastewater was being reused. Similarly, Australia reuses 21% of its treated wastewater. Closer to home, Namibia has been a pioneer, driving reuse since the 1960s.

However, Mutamba notes that countries like Australia have clear targets that push them to move from planning to implementation. South Africa, on the other hand, does not have a dedicated institution driving reuse.

“We do not have national commitment to incorporate reclaimed water into the water mix. Other countries drive this with rigour and set targets,” he says. Beyond the national reuse strategy and reconciliation recommendations, there is no tangible, nationally driven reuse agenda.

Water u t I l I t I es

Johan Lubbe, product development specialist, Development Bank of Southern Africa, explains that although there are some notable examples of reuse in South Africa, we have not yet seen the adoption of largescale projects and programmes.

“The reuse agenda in South Africa is very ad hoc and fragmented. There is a need for integration, boldness and bravery. It is not a sprint – it is a marathon,” adds Mutamba.

The perception challenge

Mutamba argues that reused wastewater has the potential to meet 15% of our national demand; however, there are some critical challenges that must be overcome if it is to be fully embraced.

The biggest challenge is public perception. Despite the advancements in technology, there is still resistance when it comes to water reuse for drinking purposes.

Public perception, social, cultural and religious beliefs often prevent direct potable reuse options from being considered, despite the fact that the technology exists to treat wastewater to the required potable standard. “We need a national education programme

or campaign to start changing people’s mindsets around reuse. Without this, no project will be successful,” says Lubbe. Similarly, Mutamba stresses that despite scientific excellence and technological advancements, a reuse project can fail if people do not trust the product. “It is essential that the public and other stakeholders accept the product.”

Mutamba believes the future success and trajectory of reuse in South Africa very much depend on navigating what he calls the trust dividend. This requires political buy-in, acceptance from all stakeholders, knowledge, and improved stewardship.

There is also a negative perception around the perceived complexity and costliness of reuse, although it offers a cheaper alternative to desalination. However, Lubbe stresses the need for cost-effective tariffs, arguing that South Africa’s low tariffs for what is fast becoming a scarce resource often result in people not valuing water.

Reuse infrastructure as an asset class

In addition to adopting a programmatic approach to reuse in South Africa, funding options are needed to make the application more viable.

Lubbe called to the establishment of a national reuse programme that will support the preparation, financing, and implementation of municipal water-reuse projects. This kind of programmatic approach offers many benefits, including the establishment of best practices and technologies, cost optimisation, and the standardisation of contracting documents and procurement.

The aim is to create a new asset class by using credit enhancement to crowd in private sector funding and use debt capital market instruments to focus and define the asset class.

The idea is to have an asset class of largerscale water reuse infrastructure assets that offers acceptable financial returns but is in line with ESG impacts and helps to meet the Sustainable Development Goals.

Lubbe argues the project bonds are likely the best instrument to achieve this, because they are designed to fund largescale infrastructure projects. Furthermore, the regulatory environment and listing requirements for project binds are already in place on the JSE.

The biggest problem at the moment is bankable projects. Encouragingly, some municipalities have begun to explore reuse infrastructure at scale, but the bankable feasibility studies must still be undertaken, and financing methods established.

Lubbe goes on to propose three possible funding solutions:

1. Convention (municipal balance sheet)

2. PPP/concession (design, build finance, O&M)

3. Hybrid (PPP without finance)

These, he says, offer the ability to respond to and finance projects at scale.

“The time has come for us to extract maximum value from our water resources by using water more than once. For most of us, load-shedding is probably an inconvenience, but water-shedding will be a different story. We have no option but to look to water reuse as one of our water supply options, and this has to be done quickly and at scale.”

IMIESA May 2019 15

A blueprint for rural water supply

A unique community-based water supply scheme developed by JG Afrika has made a lasting difference for a remote rural community in north-west Botswana.

The Botswana Ministry of Land Management, Water and Sanitation Services hosted an event on 20 March 2019 to celebrate the formal handover of the Habu Community Water Supply infrastructure. The scheme has been successfully managed by the community for two years.

Bogadi Mathangwane, director of Botswana’s Department of Water Affairs, said the stellar performance of the scheme since its completion in 2016 has provided ample evidence that they now have a potential blueprint for similar communitymanaged initiatives nationwide.

Held at a kgotla in Habu village, the event was also attended by Dr Obolokile Obakeng, Deputy Permanent Secretary of the Ministry of Land Management, Water and Sanitation Services; and representatives of the Water Utilities Corporation (WUC).

Ruth Stewart, managing director of Initiatives; Robyn Tompkins, an executive associate at JG Afrika Botswana; and Attie Jonker, managing director of Franklin Electric, as well as executive director of the Franklin Wells for the World Foundation, were also in attendance.

Tompkins, a water, sanitation and health (WASH) development expert, led the JG Afrika team appointed by Initiatives to assist in the design and development of this first-of-its-kind water supply project. This was commissioned on behalf of the Paul G Allen Family Foundation’s Philanthropy programme.

Franklin Electric was contracted by JG Afrika to install the borehole pumps. Franklin Wells for the World Foundation also donated borehole infrastructure, alongside that supplied by the Paul G Allen Family Foundation. This allowed the project team to install two boreholes. Together, they are more than sufficient to supply the needs of this large community of around 1 500. Prior to the completion of the scheme, members of the Habu community were without a reliable water supply for up to three years.

Before JG Afrika completed the water scheme, members of the Habu community did not have a reliable supply of water for up to three years

“When Robyn initially presented this concept to me in 2015, I wondered if it could be done, because we had tried this model in other communities and it hadn’t worked,” says Mathangwane. “However, she presented a clear roadmap of how they could work; today, I see it has.”

Overall, the major success factor was the attention given to the social aspects from the onset, which ensured the necessary community buy-in.

Essential toolkit

JG Afrika developed a robust governance framework for the scheme and a toolkit to train representatives of the dedicated wateruser committee, comprising two caretakers and five water monitors. These community members also underwent technical training in basic infrastructure maintenance to cover most repair or servicing scenarios.

Community members pay for their consumption by registering with a water association. They present a stamped token to the monitors, who open the taps at 09:00 and lock them at 18:00.

The set-up consists of five tanks on stands that supply taps located at a central point for each of Habu’s five wards. Pumps are powered by solar energy and governed by manual switches. A manual system ensures that community caretakers are in constant contact with the system.

The Integrated Water Resources Management & Water Efficiency Plan was developed by the Botswana Government in 2013. “The country’s authorities are in the

Water u t I l I t I es 16 IMIESA May 2019

Attie Jonker, MD of Franklin Electric (left), presents Dr Obolokile Obakeng of the Botswanan Ministry of Land Management, Water and Sanitation Services, with a copy of the SAICE Outstanding Engineering in a Community-Based Project award

process of developing a water-catchment model in which water-user associations and committees are an important subcomponent of the management of the country’s water resources,” says Tompkins.

In 2017, the World Bank approved a US$145.5 million loan to improve water

availability in Botswana’s drought-prone areas. This includes the augmentation or rehabilitation of existing water schemes, which is expected to benefit over 450 000 people.

Tompkins is now planning to host a workshop for representatives of the

JG Afrika developed a robust governance framework for the scheme and a toolkit to train representatives of the dedicated water-user committee, comprising two caretakers and five water monitors

WUC and the Department of Water and Sanitation, the latter now being the owner of the Habu scheme, to fine-tune the service delivery model. She sees immense potential to incorporate information and communications technologies used successfully in other African countries and elsewhere in the world to bolster monitoring and evaluation of these watersupply projects.

In recognition of the collective achievements at Habu, JG Afrika received the award for Outstanding Engineering in a Community-Based Project at the South African Institution of Civil Engineering annual awards in 2018.

Proudly independent, proudly South African and proud to service Africa, JG Afrika has built a strong reputation for offering innovative and sustainable engineering and environmental consulting services of the highest quality. A Proud Past. A Bright Future. Great reputations are built over time. www.jgafrika.com Level 1 B-BBEE Water u t I l I t I es

The official opening of the scheme, which consists of five tanks on stands that supply taps located at a central point for each of Habu’s five wards

NYELETI CONSULTING

What are some of the biggest challenges you see at water and wastewater utilities?

at & ss We often see technical capacity challenges and budgetary constraints that prevent utilities from offering world-class services.

Unfortunately, a lack of investment in infrastructure, particularly due to the absence of planning and preparation of bankable projects, is often coupled with a reluctance to embrace private sector funding and support through risk-sharing mechanisms like privatepublic partnerships or even privatisation. What we are left with is ageing infrastructure that is often not sufficiently maintained, and therefore susceptible to regular breakdowns. In the case of wastewater infrastructure, this results in the overflow of sewage into natural watercourses, causing damages to the environment and living species, and posing health risks to human beings and livestock. In the case of water infrastructure, millions of litres of scarce water resources are wasted.

How can Nyeleti assist utilities with the operations and maintenance of their water infrastructure?

Sustainable operations and maintenance of any infrastructure is dependent on several factors, key ones being capacity development and training of operations and maintenance staff. The others are materials, machines, methods and funding. Capacity development and skills training is therefore critical for the successful

operations and maintenance of water infrastructure, with capable management ensuring that maintenance is budgeted for, appropriate maintenance tools are used, materials and parts are in stock and correct operations and maintenance methods are followed.

At Nyeleti, we have the skills and experience to support municipal and water utilities with operations and maintenance of infrastructure, which includes capacity development, diagnostic review of existing operations and maintenance activities (including composition of teams, training needs, etc.), re-engineering of operations and maintenance teams and processes.

What about new infrastructure projects?

Nyeleti has the skills to support municipal and water utilities with planning, preparation of bankable projects, design, operation and maintenance of infrastructure. We are involved with our clients’ operations and maintenance personnel during all stages of project development to ensure that they understand the design rationale so as to better operate and maintain the infrastructure.

What are some of the most important things to keep in mind when

designing modern water and wastewater infrastructure?

It is important that South Africa stays abreast of the latest international trends, technology and design techniques. However, an appreciation of the existing skills and knowledge of plant operators is important when developing infrastructure to ensure that the appropriate technology is implemented. When used correctly, technology can reduce risks and provide high levels of assurance as well as a method to record large quantities of quality data. However, one must always consider the operating environment, budgets and, therefore, appropriateness of such technologies.

Involving the client’s operations and maintenance personnel in all stages of the project development, and training them on correct operation and maintenance methods, is particularly helpful when implementing new technology. Design software has evolved, allowing for improved visualisation and project development timeframes, which can greatly assist in this process.

Director

Director

How is Nyeleti embracing modern technology and Industry 4.0?

Modern technology brings with it the ability to optimise infrastructure, thereby reducing costs both in terms of design and construction.

Nyeleti has invested in modern design software, such as 3D designs and BIM, and our software capabilities allow us to use tools such as virtual reality to provide clients with improved perspective of the project. By applying appropriate technology on projects, we are helping our clients to ensure long-term sustainability by improving infrastructure and operations. We know that technology is the future and we are focused on developing young talent in order to maximise the use of current and future technology, thereby enhancing the power of human creativity.

PANE l D ISC u SSION | Water u t I l I t I es

Abe Thela | Director

IMIESA May 2019 19

Stuart Seath | Technical

WITH 3 GROUNDBREAKING PRODUCTS

Wastewater and sewage are pumped underground to the lifting station where it is chemically treated and sent for separation. By dosing our Ultra S3® (RSS) at the lifting station, it eliminates H2S within 3 minutes of contact time - completely removing the smell and associated occupational hazards associated with H2S. By eliminating H2S with Ultra S3® (RSS) at this point it also removes sulphuric acid - one of the major contributor to infrastructure corrosion.

Our broad spectrum Ultra-Archaea® microbes are dosed into these primary settling basins targeting organic waste and hydrocarbons present in wastewater. Ultra-Archaea® metabolises Ammonia, Nitrate, Nitrite, Phosphate, E-Coli, Faecal Coliforms, Petroleum contaminants (incl. PAHs2) and odours in a very short space of time, reducing the chemical oxygen demand (COD and BOD). By replacing or running the Ekosource Magnetic Ballast Clarifier (MBC) in parallel with the primary settling basin, the MBC can increase the treatment capacity by 2 to 3 times. It reduces the solids loading on the clarifier, increases the settling ability of the clarifier, and increasing the biological treatment capacity of the system.

Effluent is then pumped to the aeration tank where Ultra-Archaea® is introduced in order to accelerate and oxygenate active sludge systems to further breakdown harmful bacteria.

By replacing chlorine with Ultra S3® (RSS) solution in the disinfection station, it will destroy common non-pathogenic bacterium and also pharmaceutical contaminants thereby eliminating the reliance on expensive, dangerous and corrosive chlorine gas.

Secondary clarifiers gravity feed the water through and continues to clean the water to a potable level. An Ekosource MBC can be installed after or in parallel with the secondary clarifier to remove phosphates that are precipitated by the addition of an aluminium or iron salt.

WWW.ULTRATECHAFRICA.COM SOUTH AFRICAN BASED +27 81 264 5104 | info@ultratechafrica.com Let’s change the way we think about the performance of water treatment in Africa! ADVANCED WASTEWATER TECHNOLOGY

WASTEWATER

TREATED

U LTRAT EC h SA

Shaun Blackmore-Reed | Director

What are some of the biggest challenges in the wastewater treatment space?

sb The Department of Water and Sanitation reports that around 56% of wastewater treatment works (WWTWs) are in poor or critical condition – the Vaal crisis is a prime example of this dire situation. Unfortunately, these problems would cost trillions to fix, using traditional methods.

Maintenance is often not prioritised, and the harsh nature of WWTWs means they are frequently exposed to high levels of hydrogen sulfide (H2S), which causes significant corrosion damage and is also the leading cause of gas inhalation deaths in the industry.

How do you combat the threat of H2S?

By eliminating H2S, you not only drastically reduce corrosion and odours – which translates into savings on maintenance, repairs and downtime – but you also create a safer work environment. While H2S simply results in an unpleasant rotten egg smell in lower quantities, in higher amounts it signals your diaphragm to shut down, posing a serious safety concern.

Our Ultra-S3® product is an effective oxidising system suitable for WWTWs and a number of other related applications like abattoirs. Up to 3.5 times faster and 241% more effective than hydrogen peroxide (H2O2) alone, Ultra-S3 eliminates H2S quickly and efficiently. However, the two can be combined to form our Rapid Sanitizing System (RSS), which is

three times more powerful than chlorine, making it ideal for WWTWs.

The RSS gets injected into the water stream to produce a compound that separates H2S into water and elemental sulfur so quickly that they cannot recombine, effectively eliminating H2S within three minutes.

What makes RSS so ideal for South Africa is that it can be introduced without making any changes to existing infrastructure, and the entire process is monitored by sensors, eliminating opportunities for error. Furthermore, utilities can save up to 50% on their monthly chemical bill by eliminating chlorine and other associated chemicals.

What are the other applications for Ultra-S3?

Ultra-S3 is also a powerful sanitiser and has been shown to eliminate many common bacteria, including Pseudomonas aeruginosa and Corynebacterium aquaticum, both of which present serious health threats. Ultra-S3 and RSS have also been shown to remove emerging pollutants like pharmaceuticals, which our current WWTWs are simply not designed to treat.

For a more holistic sanitising solution, S3 can be combined with our Ultra-Archaea® product.

Tell us more about Ultra-Archaea.

Ultra-Archaea was first developed to eliminate the toxic conditions associated with oil spills, and proved its effectiveness in

cleaning up the Deepwater Horizon spill in the Gulf of Mexico in 2008. However, the product also offers an excellent solution for wastewater treatment due to its affinity for organic waste matter.

Ultra-Archaea is a range of natural microorganisms that speed up the rate of natural degradation and help the bioremediation process occur in days and weeks rather than months or years. The microorganisms have a lifespan of around 12 weeks and will remain active as long as there is a food source, digesting hydrocarbon molecules and breaking them down into harmless by-products of water, carbon dioxide and lipids.

Ultra-Archaea is a completely natural solution and has been shown to be highly effective. In a controlled study with samples from the Deepwater Horizon spill, Ultra-Archaea was found to perform better than three other leading products. Most notably, it removed 98.5% of PAHs (polycyclic aromatic hydrocarbons).

Are these products safe for the environment?

Absolutely. Ultra-S3 has passed all three of the CSIR’s toxicity tests with a Class I result and has been classified as nonhazardous under the USA’s Toxic Substance Control Act of 1976. It is chemically engineered to target problem compounds without destroying environmentally beneficial microbes, and actually supports good biology by oxygenating water. There is also no threat to overdosing. In fact, the opportunity exists to purposefully overdose with S3 and Ultra-Archaea to help remediate catchment areas where sewage spills have occurred.

Ultra-Archaea is also completely safe because the microbes are 100% natural and not genetically engineered or modified. They are non-toxic and non-pathogenic.

Together, the products offer simple, fast and cost-effective solutions that have been successfully used in the US for decades.

IMIESA May 2019 21

PANE l D ISC u SSION | Water u t I l I t I es

t +27 (031)266 3263 e conference@imesa.org.za conference.imesa.org.za Book online now REGISTRATION Register and pay BEFORE 28 June 2019

Members: R6 100 • Non-members: R7 300 IMESA ORGANISER THE INSTITUTE OF MUNICIPAL ENGINEERING OF SOUTHERN AFRICA (IMESA) TEL: 031 266 3263 DEBBIE OR MELANIE Earn 2.5 CPD opened has DURBAN INTERNATIONAL CONVENTION CENTRE 83RD IMESA CONFERENCE 02-04 October 2019 STANDARD REGISTRATION Register and pay AFTER 28 June 2019 • Member: R6 900 • Non Member: R8 100 CONFERENCE ENDORSED BY GOLF COMPANION TOUR R520, excl. Golf cart and caddy R1 100 per person

•

Planning for climate change

The CSIR’s Green Book is a novel and unique attempt at interdisciplinary, applied sciences that combines the expertise of researchers across a broad spectrum. These include climatology, demography, disaster risk sciences, environmental sciences, geography, informatics, urban planning, economics, ecology, architecture, anthropology, hydrology and statistics.

The Green Book forecasts to the year 2050 by projecting human settlement growth combined with quantitative, scientific evidence of the likely impacts that climate change will have on towns and cities. Every settlement risk profile proposes customisable adaptation actions, to be considered for integration into local plans and strategies.

There are three main components. The first is a series of interactive national story maps. The user is able to browse through them to learn more about the research methodology, findings and recommendations, as well as to access the technical reports and interactive datasets.

The second component is the municipal Risk Profile Tool. This provides dynamic risk profiles for each municipality and its associated human settlements in South Africa. They provide information on vulnerabilities, population projections, exposure to climate hazards, and the impacts of climate change on key municipal resources.

The third component is the municipal Adaptation Actions Tool, which offers a range

The Green Book, its resources and tools can be accessed online at www.greenbook.co.za

of planning and design actions for municipalities.

The Green Book also provides information on adaptation planning at a local government level. This includes information on why it is important to plan for climate change, how to deal with uncertainty, and the mechanisms that support climate change adaptation. The latter include disaster risk reduction, funding mechanisms, capacity building and awareness raising, and as well as monitoring and evaluation.

Known as the Green Book, the CSIR has launched a state-ofthe-art online climate risk profiling and adaptation tool to assist municipalities with their spatial planning.

The development of the Green Book was funded by the International Development Research Centre in Canada and the CSIR, and partnered by the National Disaster Management Centre. The Department of Environmental Affairs, the National Disaster Management Centre and Santam are committed to partnering with the CSIR on Phase II of the Green Book.

”This phase will focus on rolling out the Green Book for implementation in municipalities

most at risk, identifying gaps in research and development of this kind, and building the capacity of officials and departments to deal with climate change adaptation,” comments Willemien van Niekerk, senior researcher and project lead, CSIR.

“Given the risks, there is a great need for proactive investment in disaster risk reduction in South African urban settlements in order to cope with increasing extreme events in future,” Van Niekerk concludes.

IMIESA May 2019 23 E N v IRONMENT

HOW DOES UNRELIABLE WATER SUPPLY IMPACT

INCREASE RELIABILITY WITH GRUNDFOS SOLAR SQFLEX PUMPS

POWER FROM ANY SOURCE

A built-in frequency converter ensures that the motor runs on both AC and DC from power sources such as solar panels and wind turbines.

GRUNDFOS SUBMERSIBLE SOLUTIONS SOLAR PUMPING SOLUTIONS MADE EASY

Grundfos offers a range of solar pumping solutions that can be tailored to suit almost any application or local conditions: for remote off-grid areas, Grundfos solar pumping solutions offer many benefits over traditional grid-based or diesel powered pumping systems including

• Easy installation

• Low maintenance

• Low operating costs

For more information or to find your nearest Grundfos Distributor, visit za.grundfos.com/campaigns/submersible-solutions

Trademarks displayed in this material, including but not limited to Grundfos, the Grundfos logo and “be think innovate” are registered trademarks owned by The Grundfos Group. All rights reserved. © 2019 Grundfos Holding A/S, all rights reserved.

YOUR PEACE OF MIND?

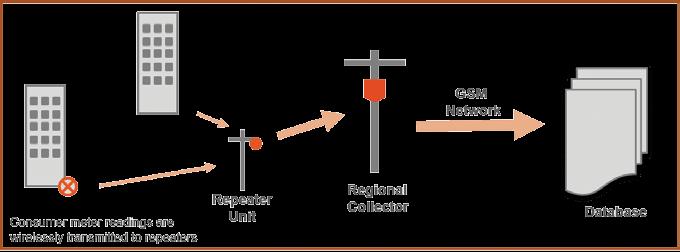

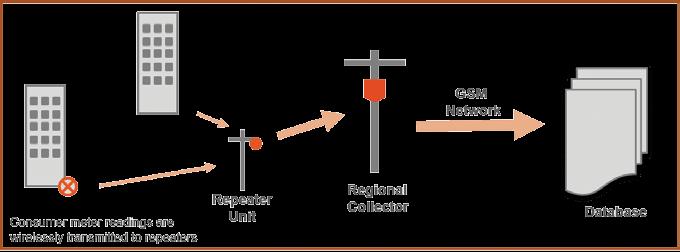

A potential shift to AMR

For individual and business consumers, bulk water consumption is determined by meter readings. This practice hasn’t changed over the years, but now there’s a more intelligent approach, according to Meghan Brinkley of SMEC South Africa. by alastair currie

Modern-day mechanical meters are AMR, or automated meter reading, compatible. When linked to GSM wireless-based systems, they are interconnected and then provide accurate readings of bulk water consumption and their ensuing billing reports.

In this sense, AMRs are defined as ‘smart’ in terms of their remote reading access and provide ease of reporting via routers to a central source. They provide one-way communication from the meter to the data collection and billing centre, so

physical inspections are no longer required.

Innovations include GSM drive-by or walk-by apps for water meter readers.

By comparison, smart meters, by definition, are more advanced and intelligent, providing one-way, real-time communication between the on-site device and the base station. However, smart meters are still in their early stages of application worldwide. Their main advantage is that they continually inform users on consumption patterns and potential water losses, enabling them to regulate usage accordingly. However, they rely on battery packs to function and require specialists to interpret and respond meaningfully to the large volumes of data being transmitted. If accurate billing is the key requirement, AMRs can assist in performing this task.

“SMEC has investigated solutions for both AMR and smart meters,” explains Brinkley.

“At this stage, I believe the first step is the understanding and control of the mass

data that will now be available with the use of smart metering solutions. As smart metering is still in its infancy, pilot projects should be considered. That will enable all practical implications to be evaluated, including battery maintenance, frequency of data being received and its handling, plus the management and storage of the data. For businesses, going the smart route could make more sense.”

Client focus

SMEC predominantly works with public clients that include Johannesburg Water, the City of Ekurhuleni, Midvaal Local District Municipality, Mangaung Metropolitan Municipality and Sekhukhune District Municipality on meter management projects, some of which include the development of the most effective billing approach, which is interdependent on accurate meter audits.

As the transaction advisor, SMEC is currently involved in rolling out a publicprivate partnership (PPP) for Sekhukhune. This PPP is currently at the RFP stage and will see the deployment of AMR technology within

IMIESA May 2019 25 M ETERS , Pu MPS & vA lv ES

Meghan Brinkley, section manager: Management Services, SMEC South Africa

The site supervision team

INSURANCE THAT SPECIALISES IN YOUR CONSTRUCTION PROJECTS

Every project you undertake requires your full attention. At Old Mutual Insure, we understand your needs; that’s why we have the right cover for you. It’s simple. It’s convenient. It’s efficient. With our experience and specialist expertise, you’ll know that you can count on us.

The great things you do tomorrow start with the small steps you take today. Take that step with Old Mutual Insure. The time is now.

Speak to your broker or visit ominsure.co.za to take that first step.

All products are underwritten by Old Mutual Insure, an Authorised Financial Services Provider (FSP 12) DO GREAT THINGS EVERY DAY INSURE 119263L/E

the municipality. The end goal is twofold: to enable more accurate measurement of technical water losses, and to ensure improved revenue collection via the correct tariff structures.

SMEC has a long track record of successful interventions, which includes a large-scale project on behalf of Johannesburg Water between 2013 and 2015. Approximately 30 000 defective water meters were replaced, which underscores the importance of audits.

In terms of present day examples, SMEC is currently conducting a study for Mangaung where the top 100 consumers in the metro are being assessed. SMEC will determine if they are being billed correctly and registered on the correct meter. SMEC is also conducting an audit on the metro’s bulk network meters. As with all SMEC projects, audit data is captured on tablets by the field teams, so it’s a paperless process.

SMEC is one of five consultants presently working with the City of Ekurhuleni. Each consulting firm has been allocated a specific region. SMEC’s scope entails responding to customer complaints and authorising appointed contractors to carry out required maintenance. Examples include water interruptions, leaks and defective meters. The City of Ekurhuleni is currently in the process of replacing

all meters that are 15 years and older; unmetered areas have also been identified and are being transferred to the metro’s billing system.

Field audits

“A key service we offer is the physical auditing of meter performance. As meters have a finite life, this is an essential process,” Brinkley explains. “We also check for illegal connections and situations where the land use has changed but has not been reported – for example, a property that has been subdivided or where the original meter no longer exists.

“With regard to bulk reservoir meters, in all cases, we inspect the bulk and reservoir supply flows to confirm that

these are accurately metered. It’s equally important that telemetry systems are in place to ensure precise monitoring. Once all systems have been accurately determined, this will ensure that utilities and municipalities can balance their water network via check meters,” she continues.

“In many instances, we’ve been able to detect and help remedy major leakages.

“Going forward, AMR can potentially be considered as an alternative approach to ensure equitable water use and fair billing, provided the data management aspect is taken into consideration. Accurate metering is also an environmental imperative in ensuring longer-term water management and security,” she concludes.

M ETERS , Pu MPS & vA lv ES IMIESA May 2019 27

Consumer meter readings are wirelessly transmitted to repeaters Repeater unit Regional collector Database GSM Network

The AMR process

A new smart meter

Adesigning and constructing with gabions and river mattresses

is a highly specialised civil engineering field, which requires a sound understanding of geotechnics, hydraulic flows and soil mechanics, among other disciplines. Once mastered, the benefits of these erosion control systems as cost-effective and sustainable solutions become clearly evident. With no design limits, they are ideally suited to labour-intensive construction methods under professional project management guidance.

“This is as close as one can get to an ecologically balanced intervention. That’s because gabion and river mattresses are permeable, flexible and designed to coexist with the environment, unlike rigid structures like concrete,” explains Louis Cheyne, managing director, Gabion Baskets.

“This makes them ideal when it comes to the promotion of vegetation, while, in rivers, their free-flow design helps to ensure the sustainability of microorganisms and fish. Even

Water control with mattresses

Flash floods and heavy rainfall are often unpredictable, and sometimes devastating, but there are engineering countermeasures. These include gabions, and more specifically river mattresses, for a diverse range of applications encompassing river systems in general, culverts, channel lining structures, ford crossings, and slope and embankment protection measures. by alastair currie

if erosion occurs at the toe of a mattress lining, given design flaws or extreme environmental conditions, it will still settle into the ensuing scour hole and continue providing protection. That wouldn’t happen with a concrete structure, like a retaining wall, which would be progressively undermined.”

River mattresses are configured using hexagonal woven mesh, and the same technique applies in the manufacture of gabion baskets; however, the mesh size differs. For gabion baskets, it’s typically 80 mm x 100 mm; for mattresses, a 60 mm x 80 mm aperture is specified. Mattress wire diameters are also smaller, at around 2.2 mm, compared to 2.7 mm for gabions. There’s a reason for this: a smaller mesh size enables contractors to install at least two layers of rock within the mattress. This is the minimum recommended to ensure an optimal mechanical interlock.

A mesh size of 60 mm x 80 mm also makes provision for a smaller rock size – an essential consideration. However, as Cheyne points out, this also has a major influence on installation practices, since the loss of rock due to hydraulic action must be prevented to ensure the mattresses’ integrity. No rock movement is allowed, and no stone can be allowed to escape. For this reason, an 80 mm minimum size rock is recommended, as opposed to 100 mm for gabions.