Water & Wastewater

Achieving financial sustainability

Roads & Bridges

Bridging the gap in steel

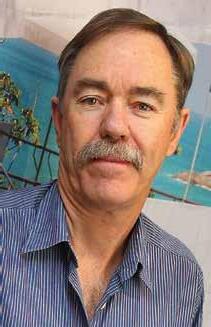

IN THE HOT SEAT

“Our strategy has always been to focus on larger-scale projects that put our skills to the test; however, no project has ever been too small for Nyeleti, and we will continue to take up each and every challenge that comes our way.”

IMESA The official magazine of the Institute of Municipal Engineering of Southern Africa www. infrastructurenews.co.za infrastructure development • m aintenance • service delivery

Pine Pienaar executive director, nyeleti consulting ISSN 0257 1978 Volume 44 No. 6 • June 2019 • R50.00 (incl. VAT)

ORSCO GPR

at Middle

survey

Lake Dam

Consistent quality requires consistent excellence ...

... in every area of wastewater management.

Serving both the public and private sectors, ERWAT promotes a healthy environment by providing cost-effective wastewater treatment solutions through innovative technologies. It specialises in sustainable, quality wastewater services, backed by focused technical, maintenance and engineering services. An ISO/IEC 17025 accredited laboratory renders a wide variety of specialised analyses, while industrial wastewater quality management assessments and advice are also offered.

East Rand Water Reg. No. 1992/005753/08

(Association incorporated in terms of section 21)

GPS Co-ordinates:

Address: Hartebeestfontein Office Park, R25, Bapsfontein/Bronkhorstspruit, Kempton Park.

Tel: +27 11 929 7000

E-mail: mail@erwat.co.za

www.erwat.co.za

ERWAT EXCELLENCE

WASTEWATER

IN

S 26° 01’ 25.8”

E 28° 17’ 10.0”

and

uppe marketing A13900

IN THE HOT SEAT

reported from a ground-penetrating radar survey will help to pinpoint anomalies in the concrete spillway structure at Middle Lake Dam in Benoni, which recently suffered significant erosion damage. This emergency situation required urgent action to reduce the risk of potential failure of the

volume 44 no. 6 June 2019 IMESA of Municipal Engineering of Southern Africa infrastructurenews.co.za IN THE HOT SEAT “Our strategy has always been to focus on larger-scale projects that put our skills to to take up each and every challenge that comes our way.” Pine Pienaar ExecutiveDirector,NyeletiConsulting Water & Wastewater Achieving financial sustainability Roads & Bridges Bridging the gap in steel ORSCO GPR survey at Middle Lake Dam Regulars Editor’s comment 3 President’s comment 5 Africa round-up 9 Index to advertisers 56 Cover Story Remediating Middle Lake Dam 6 Hot Seat Two decades of excellence 10 Sustainability Smart cities are green cities 12 Clay pavers promote mobility 15 Driving building sustainability 17 Roads & Bridges Bridging the gap in steel 18 Bridging rural routes 22 Reinstating a vital port connection 23 Public Lighting Lighting the way 24 The data

P6 15 INSIDE SuStainability Clay pavers promote mobility A visionary leader in its field, Nyeleti Consulting celebrates its 20th birthday in 2019. IMIESA speaks to executive director Pine Pienaar about the company’s successes and its future ambitions. P10 26 39 18 MeterS, PiPeS, PuMPS & ValVeS Spiral welded pipes ideal for municipal works roadS & bridgeS Bridging the gap in steel daMS & Water Storage Tunnel designers prep for Phase II

spillway.

Meters, Pipes, Pumps & Valves Spiral welded pipes ideal for municipal works 26 Genuine parts deliver 28 PVC-O advances 29 Exploring the future of plastic pipes 31 Key benefits of prepaid water 32 Water & Wastewater Capacity boost for Zuikerbosch 33 Creating a financially sustainable sector 34 Conflicting data impacts RO deliver 36 Dams & Water Storage Tunnel designers prep for Phase II 39 SASTT Trenchless News Key considerations for trenchless projects 40 Cement & Concrete Moving mountains for sport 43 The potential and challenges of RCC 44 Slagment is green 47 Insurance Engineering and construction insurance in a challenging market 49 Transport, Logistics, Vehicles & Equipment Screencore launches in SA 51 Custom-built plant boosts capacity 53 Stronger and faster 54

LEADERS IN SMART WATER MANAGEMENT www.utility-systems.co.za +27 (0) 31 700 4143 enquiries@utility-systems.co.za Providing smart solutions for the responsible management of the world’s most valuable resource… water

MANAGING EDITOR Alastair Currie

SENIOR JOURNALIST Danielle Petterson

JOURNALIST Nombulelo Manyana

HEAD OF DESIGN Beren Bauermeister

CHIEF SUB-EDITOR Tristan Snijders

CONTRIBUTORS Alaster Goyns, Nico-Ben Janse van Rensburg, Randeer Kasserchun, Keitumetse Moumakoe, Bryan Perrie, Marcus Thulsidas

OPERATIONS & PRODUCTION MANAGER

Antois-Leigh Botma

PRODUCTION COORDINATOR Jacqueline Modise

FINANCIAL MANAGER Andrew Lobban

BOOKKEEPER Tonya Hebenton

DISTRIBUTION MANAGER Nomsa Masina

DISTRIBUTION COORDINATOR Asha Pursotham

SUBSCRIPTIONS subs@3smedia.co.za

PRINTERS Paarl Media KZN +27 (0)31 714 4700

ADvERTISING SALES

Jenny Miller Tel: +27 (0)11 467 6223

Email: jennymiller@lantic.net

PUBLISHER Jacques Breytenbach

Novus Print (Pty) Ltd t/a 3S Media

46 Milkyway Avenue, Frankenwald, 2090

PO Box 92026, Norwood 2117

Tel: +27 (0)11 233 2600 Fax: +27 (0)11 234 7274/5

www.3smedia.co.za

ANNUAL SUBSCRIPTION: R600.00 (INCL vAT)

ISSN 0257 1978 IMIESA, Inst.MUNIC. ENG. S. AFR.

© Copyright 2019. All rights reserved.

IMESA CONTACTS

HEAD OFFICE:

Manager: Ingrid Botton

P.O. Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Fax: +27 (0)31 266 5094

Email: admin@imesa.org.za

Website: www.imesa.org.za

BORDER

Secretary: Celeste vosloo

Tel: +27 (0)43 705 2433

Fax: +27 (0)43 743 5266

Email: celestev@buffalocity.gov.za

EASTERN CAPE

Secretary: Susan Canestra

Tel: +27 (0)41 585 4142 ext. 7

Fax: +27 (0)41 585 1066

Email: imesaec@imesa.org.za

KWAZULU-NATAL

Secretary: Ingrid Botton

Tel: +27 (0)31 266 3263

Fax:+27 (0)31 266 5094

Email: imesakzn@imesa.org.za

NORTHERN PROvINCES

Secretary: Rona Fourie

Tel: +27 (0)82 742 6364

Fax: +27 (0)86 634 5644

Email: np@imesa.org.za

SOUTHERN CAPE KAROO

Secretary: Henrietta Olivier

Tel: +27 (0)79 390 7536

Fax: +27 (0)86 629 7490

Email: imesasck@imesa.org.za

WESTERN CAPE

Secretary: Michelle Ackerman

Tel: +27 (0)21 444 7114

Email: imesawc@imesa.org.za

FREE STATE & NORTHERN CAPE

Secretary: Wilma van Der Walt

Tel: +27 (0)83 457 4362

Fax: +27 (0)86 628 0468

Email: imesafsnc@imesa.org.za

A greener powered solution

Historically, our electricity has been derived exclusively from coal-fired power stations, with the exception of Koeberg in Cape Town, which remains Africa’s sole nuclear producer, predominantly serving the Western Cape region.

Although the renewables market is a definite step in the right direction, over the medium term, the bulk of national energy demand will continue to be powered by coal, which remains a cheap energy source. South Africa has abundant coal resources, with untapped reserves projected to last well beyond 100 years. Across the border, Botswana has massive untapped reserves that will last much longer. That’s good news for our mining sector, and South Africa’s macro economy in terms of the export market to key buyers, which include India, via the Richards Bay Coal Terminal. Coal can be green, when power plants are designed using the latest lower-emission clean coal technologies. Plus, as the World Coal Association states, “38% of the world’s electricity and 71% of the world’s steel is (still) produced using coal.” Coal also has other downstream benefits that are used to formulate products like petroleum, polymers, solvents and bitumen.

Maintaining the power balance is not just about the continuation or discontinuation of coal. Overall, it’s about the best power delivery options and affordability. This is top of mind for every consumer, and especially local and international investors planning expansions or greenfield projects. Financial markets have responded positively to the proposed unbundling of Eskom into niche-focused entities. Hopefully, a firm decision in this respect will be announced shortly following the establishment of the new cabinet. In the meantime, electrical distribution infrastructure needs to be modernised and maintained.

Tariff increases and the Carbon Tax

For all consumers, the new electricity tariff increases are a concern, since further price adjustments could still be passed on by municipalities during the balance of 2019. That will definitely motivate consumers to look for ways to cut down further on consumption costs.

Now, the introduction of South Africa’s new Carbon Tax Act (No. 15 of 2019) since 1 June 2019 adds a further incentive; although its primary goal is the reduction of greenhouse gas emissions, based on the polluter-pays principle.

The intention is to motivate users, particularly industrial ones, to adopt cleaner technologies. During Phase I (running until 31 December 2022), tax-free emissions allowances will range from 60% to 95% and apply exclusively to what are defined as Scope 1 emitters. The second phase runs from 2023 to 2030.

From 5 June, everyone owning a vehicle is immediately affected by the Carbon Tax, following an additional fuel price levy of R0.09 and R0.10 for petrol and diesel, respectively. Taxation collected during Phase I will generate billions in revenue for the state.

Hopefully, a balance of the taxation monies raised will be used to fund renewables projects. That would also speed up the approval of independent power purchase agreements, accelerating the large-scale growth of a new and sustainable green industry. Over time, it could eventually replace fossil fuels in the energy mix, but coal still has its place for the foreseeable future.

Alastair

Cover opportunity

EDITOR’S COMMENT To our avid readers, check out what we are talking about on our website, Facebook page or follow us on Twitter and have your say.

In each issue, IMIESA offers advertisers the opportunity to get to the front of the line by placing a company, product or service on the front cover of the journal. Buying this position will afford the advertiser the cover story and maximum exposure. For more information on cover bookings, contact Jenny Miller on +27 (0)11 467 6223.

All material herein IMIESA is copyright protected and may not be reproduced either in whole or in part without the prior written permission of the publisher. The views of the authors do not necessarily reflect those of the Institute of Municipal Engineering of Southern Africa or the publishers. Infrastructure News @infrastructure4 IMESA official Institute Engineering Africa www.infrastructurenews.co.za INFRASTRUCTURE DEVELOPMENT MAINTENANCE IN THE HOT SEAT strategy has always been focus on larger-scale projects put our to test; however, project ever been small for Nyeleti, and we continue up each every challenge that comes way.” Pine Pienaar Director, Consulting 1978 R50.00 Water & Wastewater Achieving financial sustainability Roads & Bridges Bridging the gap in steel ORSCO GPR survey at Middle Lake Dam IMIESA June 2019 3

HOW DOES UNRELIABLE WATER SUPPLY IMPACT YOUR PEACE OF MIND?

INCREASE RELIABILITY WITH GRUNDFOS SOLAR SQFLEX PUMPS

POWER FROM ANY SOURCE

A built-in frequency converter ensures that the motor runs on both AC and DC from power sources such as solar panels and wind turbines.

GRUNDFOS SUBMERSIBLE SOLUTIONS SOLAR PUMPING SOLUTIONS MADE EASY

Grundfos offers a range of solar pumping solutions that can be tailored to suit almost any application or local conditions: for remote off-grid areas, Grundfos solar pumping solutions offer many benefits over traditional grid-based or diesel powered pumping systems including

• Easy installation

• Low maintenance

• Low operating costs

For more information or to find your nearest Grundfos Distributor, visit za.grundfos.com/campaigns/submersible-solutions

Trademarks displayed in this material, including but not limited to Grundfos, the Grundfos logo and “be think innovate” are registered trademarks owned by The Grundfos Group. All rights reserved. © 2019 Grundfos Holding A/S, all rights reserved.

Work stoppages and unemployment

Now that the General Election has passed, the hard work of implementing government’s multifaceted action plan begins again in earnest. It’s another exciting stage in South Africa’s democracy and the construction sector will be watching closely to gauge the pace of infrastructure delivery.

The scarcity of work in our sector has resulted in intensified competition; however, there has also been another unexpected consequence in the form of work stoppages on projects. Community members, local business forums, the unemployed, as well as unsuccessful bidders are increasingly disrupting awarded projects in progress, demanding a share of the work – frequently around 30% of the contract value. Some of these disruptions have turned violent, threatening the safety of construction workers and sometimes resulting in the destruction of valuable equipment and plant. On top of that is the delay in implementing affected projects, which has a downstream financial impact on contractors, municipalities

and the economy. The situation also negatively hampers investor confidence in our country, at this critical time.

IMESA and other associations forming part of the South African Forum for Engineering are now rallying together to more effectively lobby government and find a solution to this impasse. That includes working closely with key stakeholders like Sanral and the Department of Public Works to nip this issue in the bud. Projects awarded by both these entities have experienced an especially sharp increase in construction ‘mafia-type’ behaviour.

Butcher Matutle, registrar, South African Council for the Project and Construction Management Professions, recently stated that “such tactics cannot be condoned, and can only be classified as acts of criminality. Greater dialogue should go a long way in addressing the problems that are plaguing the construction industry.”

Building capacity

Fixing the problem won’t happen overnight given the high rate of unemployment in South Africa and the present macro- and micro-economic environment. According to Statistics South Africa’s Q1 2019 Quarterly Labour Force Survey (QLFS), around 27.6% of the country’s population is out of work. Compounding this scenario is the constant increase in the working-age population entering the market within a trading environment where employment opportunities are declining across most industries. Leading the sectors in this regard is construction, which shed 142 000 people in Q1 2019.

The QLFS report presents an especially alarming stat when it comes to the youth. It

states, “Of the 20.3 million young people aged 15 to 34 years, 40.7% were not in employment, education or training.” Clearly that’s a serious concern and a renewed focus on infrastructure roll-outs is part of the solution in building the capacity needed to create new job opportunities.

As municipal managers and engineers, we have a direct and indirect role in revitalising construction and infrastructure activities, ensuring that we create the right framework for local and foreign direct investment within our increasingly urbanised landscape. That includes the development of public-private partnerships that stimulate development in key sectors like ICT, manufacturing and tourism. A number of metros are also investigating the implementation of integrated public land development programmes for mixed-use projects. The growth in the renewable energy sector also holds the promise of new work.

South Africa invested around R3 trillion over the past two decades on public infrastructure. More recently, though, there has been a contraction brought about by budget cuts; however, as the Auditor General confirms, a number of municipalities are still underspending on their infrastructure budgets. The end goal should be to improve efficiencies in the tender process to increase the flow of project awards that are budgeted for. Hopefully, that will alleviate the present work stoppage situation.

Our commitment as IMESA is to proactively engage within the three spheres of government to deliver the best value as municipal engineers.

IMESA

P RESIDENT ’ S COMMENT IMIESA June 2019 5

Randeer Kasserchun, president, IMESA

Remediating Middle Lake Dam

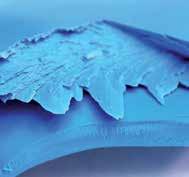

The data reported from a ground-penetrating radar survey will help to pinpoint anomalies in the concrete spillway structure at Middle Lake, which recently suffered significant erosion damage. This emergency situation required urgent action to reduce the risk of potential failure of the spillway to acceptable levels.

Benoni’s 4.22 km long Middle Lake forms part of a series of four interconnecting dams, the oldest of which is known as Homestead Lake. Their establishment dates to around 1896, when they were progressively built to support the region’s booming gold mining industry.

Bordering the N12 national route, they currently mostly serve as flood control facilities for Ekurhuleni residents living in the area, in addition to sustaining the surrounding wetlands for which this region is well known.

These Category 2 earth-fill dams are all registered with the Dam Safety Office, under the Department of Water and Sanitation. In terms of the dam safety regulations, Category 2 structures need to be inspected every five years by an approved professional person

(APP), which has been the case for Middle Lake and its sister dams. (The interval period may be extended by the Director-General of the DWS, depending on the status of the dam.)

An APP is normally a registered professional person, such as a civil engineer, with advanced specialisation in dam engineering and dam safety, and approved by the Engineering Council of South Africa for this task.

The last major maintenance intervention at Middle Lake took place during 2004, which entailed repairs to the dam’s concrete spillway. Cracks and joints were sealed, and cavities grouted. To prevent seepage, a vertical cutoff concrete beam was also installed at full supply level.

On 23 December 2018, a concrete slab section on Middle Lake’s spillway suddenly

caved in during a period of particularly heavy rainfall. The collapse of the concrete slab was unexpected and needed an urgent intervention to prevent further weakening of the overall spillway structure and its potential collapse.

Full credit is due to a number of officials of the Ekurhuleni Roads and Stormwater Department, such as Alice Chauque and Philip Nice, supported by Ekurhuleni Disaster and Emergency Management Services, for their quick reaction and the ensuing mobilisation of a joint operations committee (JOC) to coordinate and oversee the action plan to deal with the emergency. Ekurhuleni Municipality was strongly supported by officials and experts from the DWS, DWS Gauteng Region, DWS Construction, the Gauteng Department of Agriculture and Rural Development, and Rand Water, to name a few.

Cover story

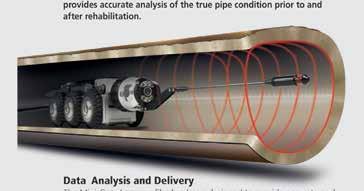

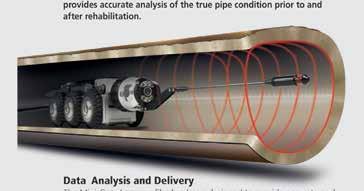

ORSCO deployed the LMX 200 Sensors & Software radar for the GPR survey Radar is very accurate and an excellent way to ‘X-ray’ structures Non-destructive pipe scanning Leak detection CCTV crawler (non-destructive)

Key ServiceS

ORSCO provides numerous key services, which include:

• Live, under-pressure condition assessment of water and effluent pipes (pressurised and gravity fed). These include trunk mains, distribution networks and reticulation

• GPR surveying of utility location and mapping of all underground infrastructure

• Scanning of concrete structures

• Mapping of shallow bedrock, locating voids, etc.

• CCTV/robotic crawler inspection of all type of pipelines

• Leak detection on municipal, industrial, commercial and residential networks

• Training on and hiring of scanning equipment

Sandbags were immediately installed to divert and channel the force of the water around the damaged area on the spillway. Siphon suction pumps were then installed to reduce the dam level and keep the spillway clear for damage assessment and the ensuing remedial interventions. In Phase I, the exposed gap was repaired as part of the emergency repair. The Phase I work to the spillway was completed in February 2019 to the satisfaction of all authorities concerned.

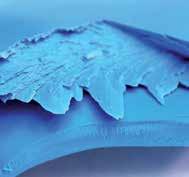

Ground-penetrating radar investigation

Henriette Anderson, as a team member of consulting engineering firm Delta Built Environment Consultants, was appointed as the APP to carry out the condition assessment and optimum repair methodology forming the second and final phase of the works. To ensure a high degree of accuracy, Benoni-based specialist subcontractor ORSCO was appointed to complete a full survey investigation of the spillway and stilling basin using GPR (ground-penetrating radar) technology

Ultrasonic flow logger measuring syphonic flow draining the dam

to map potential shallow voids underneath the concrete slabs covering the earth-fill spillway and flaws in the concrete slabs covering the spillway and stilling basin.

“Radar is very accurate and an excellent way to ‘X-ray’ structures, as well as to detect underground services such as water and sewer pipelines,” explains Darek Leskiewicz, senior consultant: GPR at ORSCO, a 6 CE CIDB contractor. “As a non-destructive methodology, it minimises the need for open-cut or core drilling during investigation and facility condition assessments, which also lowers overall project costs.”

The basic principle of GPR is the transmission of a short electromagnetic pulse, with a specified frequency, into the ground and the recording of reflected energy as a function of time, amplitude and phase. The reflected energy is recorded as a pattern on radar grams displayed in real time.

The recorded data can then be processed and analysed off-site using specialised software to produce 3D subsurface maps.

A series of GPR grids and depth slices were collected during the survey, which were divided into three sections, namely the top of the spillway, the slope of the spillway, and the stilling basin. These slices were captured at progressive depths of up to 5 m. The results from each stage were combined to create one super grid for easier data processing and interpretation.

The client will be able to use this data to pinpoint where further testing is required. This might include selective core drilling to confirm the extent of identified anomalies. That will then confirm the extent and cost of the engineering interventions required.

“The primary concern is to ensure the safety and structural integrity of the dam and the safety of those downstream,” explains Anderson.

Ground-penetrating radar used for utility location to update as-built drawings

Thanks to GPR, Ekurhuleni Municipality will have a high degree of certainly about the repairs needed in Phase II, which should significantly shorten the construction time to fully repair the erosion damage to the Middle Dam spillway. It will also enable a more costeffective approach for extending the life of this structure, rather than demolishing it completely and reconstructing.

“Worldwide, GPR has certainly revolutionised the way municipal engineers inspect and maintain a wide range of infrastructure services. As in Middle Dam’s case, it has certainly proved to be an invaluable tool,” adds Leskiewicz.

The Middle Lake Dam emergency situation and the repairs that had to be undertaken taught the Ekurhuleni Roads and Stormwater Department officials invaluable lessons (both on a technical and corporate governance level), which would not have been possible had it not been for the assistance of professionals and officials from other departments within the city, as well as departments from other spheres of government. The Roads and Stormwater Department wishes to acknowledge each and every person that contributed (whether minorly or majorly) to finding solutions to fixing the Middle Lake Dam wall and to everyone who put their trust in the department to deal with the matter.

087 160 0310 im@orsco.co.za www.orsco.co.za

C over story

IMIESA June 2019 7

INFRASTRUCTURE NEWS FROM AROUND THE CONTINENT

ethioPia

building an iPP framework

In an effort to support the roll-out of a sustainable procurement framework for independent power producers (IPPs) in Ethiopia, the Sustainable Energy Fund for Africa (SEFA) has approved a US$995 000 (R14.44 million) grant.

Ethiopia has vast but untapped renewable energy potential. The SEFA grant will be used to strengthen the government’s capacity to undertake bankability and technical analyses, including feasibility assessments of projects in the hydro priority pipeline. It also provides for environmental and social impact assessments, resettlement action plans, and preparation of bidding documents for hydro projects.

The Kenya Affordable Housing Finance Project (KAHFP) has acquired the loan to support the establishment and operationalisation of the Kenya Mortgage Refinance Corporation (KMRC).

The KMRC is a largely privatesector-owned and non-deposittaking financial institution under the supervision of the Central Bank of Kenya. Its goal is to drive affordability of mortgages by providing more long-term funding to financial institutions.

According to Felipe Jaramillo, country director: Kenya, World Bank, urban housing currently remains unaffordable for most Kenyans due to the cost of financing, the short loan tenures, and the high cost of properties.

Ethiopia is seeking private investment into hydropower projects

within the mortgage gap and low-cost categories, and represent 95% of the formally employed population.

Investment into affordable housing will also have a strong economic multiplier effect and could facilitate 132 000 new jobs, in addition to supporting improved health and education outcomes.

leSotho

improving water supply

US$78 million (R1.13 billion) in financing from the International Development Association is set to benefit up to 115 000 Basotho and businesses in the Lesotho Lowlands, under the Lesotho Lowlands Water Development Project – Phase II.

The project aims to finance activities to improve access to reliable domestic and industrial water supply services in the towns of Maputsoe and Hlotse, as well as settlements and villages along the transmission pipeline route.

the delivery of measurable operational improvements facilitated by change management support. These improvements include: improving the quality of its technical and financial data to facilitate decisionmaking and delivering on technical and financial performance against annual targets set by the Lesotho Electricity and Water Authority.

MozaMbique

expanding sanitation services

Roughly 200 000 Mozambicans will benefit from increased access to sanitation services thanks to a US$115 million (R1.67 billion) grant from the World Bank.

The funding will be used to provide infrastructure expansion, support institutional and capacity developments, and offer technical assistance to the cities of Maputo, Beira, Nampula, Tete and Quelimane.

This is expected to encourage private investments into hydropower projects through Ethiopia’s Renewable Energy Programme.

Kenya

Making housing affordable

The World Bank recently approved a US$250 million (R3.6 billion) International Bank for Reconstruction and Development loan to enhance access to affordable housing finance for Kenyans who are unable to access long-term housing finance.

The KAHFP support will target households that are classified by the Kenyan government to fall

The monies will also assist in improving the technical and financial performance of Lesotho’s Water and Sewage Company, for better sanitation infrastructure and services. This will be achieved by incentivising

Projects include the rehabilitation end expansion of the Infulene Wastewater Treatment Plant in Maputo, as well as on-site sanitation facilities for the peri-urban residents of Quelimane and Tete. In Quelimane and Tete, sewer networks will be rehabilitated and expanded, new wastewater treatment plants constructed, and stormwater drains installed.

Currently, only 1 in 10 households has access to sanitation services, and one in three to safe water in Mozambique. These projects are expected to help alleviate pressure on already precarious sanitation infrastructure and services.

Mozambique is embarking on projects to expand its sanitation infrastructure

IMIESA June 2019 9

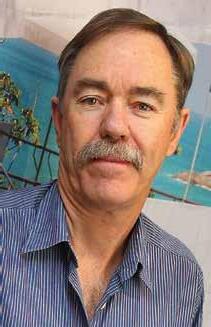

Two decades of excellence

A visionary leader in its field, Nyeleti Consulting celebrates its 20th birthday in 2019. iMieSa speaks to executive director Pine Pienaar about the company’s successes and future ambitions.

What sets Nyeleti apart from the competition?

PP Nyeleti is a black-owned consulting engineering firm with expertise in most civil engineering fields, specifically structural, water and transportation engineering.

Over the past 20 years, we’ve had the privilege to be involved in a number of flagship projects within South Africa, which have greatly refined our capabilities.

These include involvement in the design and construction of stadiums for the 2010 FIFA World Cup, the Gauteng Freeway Improvement Project, Gautrain, balance-of-plant and auxiliary buildings for Eskom’s Medupi and Kusile power stations, and the design of elements of the well-known Msikaba and Mtentu N2 Wild Coast bridges. We are grateful to clients and lead consultants who afforded us these opportunities.

We have also had the opportunity to design and supervise numerous projects

within the urban and rural infrastructure sphere.

These projects include road infrastructure development, the implementation of local public transport systems, and the development of water reticulation and sewerage systems.

World-class project execution is at the core of our business – and this all depends on people. Skills development, mentorship, the allocation of project responsibility, company ownership and management, succession planning, staff retention and wellness are all internal priorities. This investment in human resources has made us the success we are today.

Our slogan is ‘Engineered to excel’ and our name, Nyeleti, means ‘star’. This symbol reflects our commitment to excellence.

What does the future hold for the consulting profession?

The challenges currently being experienced within this sector are well known. Poor GDP growth, an increase in public sector debt, and increased social needs have resulted in a drastic decrease in the funding available for infrastructure development. However, over the longer term, we know that infrastructure provision and operation are essential for the economic wellbeing of the country and the development of its people. The consulting engineering profession has a huge role to play, so we’re optimistic about the future of the profession.

How have past milestone projects shaped the company?

We consider milestone projects to be important for a number of reasons. These projects are generally technically challenging, which hones the abilities of our

designers and, in some cases, construction supervisors.

Milestone projects also contribute to the company’s wellbeing, in that engineering staff generally like to be associated with these projects. In this way, these projects contribute towards staff motivation and retention. Perhaps most important is the marketing value of these projects, assisting the company with being more visible within the industry and demonstrating its capabilities.

Which projects are you currently working on?

We are pleased and grateful to have a healthy order book in this tough economic climate. An exciting project we were recently appointed for, in joint venture with Bigen African and GIBB, is the design and supervision of the Mokolo Crocodile Water Augmentation Project, Phase 2, also referred to as

Hot s eat 10 IMIESA June 2019

Pine Pienaar, executive director, Nyeleti Consulting

Nyeleti management team

of water to the Lephalale region in Limpopo.

The project is being implemented in support of one of the strategic integration projects (SIPs) forming part of government’s National Infrastructure Plan, namely SIP 1. SIP 1 aims to unlock the economic potential of the northern mineral belt located in the Waterberg area.

Another interesting project in the water field is the Hammanskraal bulk and distribution network in Tshwane, currently in the construction phase. The project includes a bulk supply steel pipeline, 800 mm in diameter and 5.2 km long, serving Hammanskraal Ext 1, Temba and adjacent townships. The project also includes an outfall sewer, consisting of a 3.4 km long, 600 mm diameter concrete pipe. Water and sewer services are being provided to 2 770 stands, as well as toilet top structures. In the roads field, Nyeleti is responsible for the design and construction supervision of various national road projects for Sanral, including portions of the N2 and N3 in KwaZulu-Natal and the N8 ring road in Bloemfontein.

The upgrading of the Watt Interchange in Johannesburg for the JDA is a prominent project with interesting challenges, while our order book also includes a number of provincial-level road rehabilitation projects.

A first for Nyeleti is the appointment as independent engineer on the Bakwena N1-N4 Toll concession project. Here, we are working in joint venture with a newly established black-female-owned company, Merchelle’s Collective.

Traffic engineering and impact studies also form part of our bread-and-butter work. Although we do not currently have an active public transport project, we have been intimately involved in this field over the years. We treasure this involvement, understanding the importance of public transport in addressing the mobility needs of our population.

The work of our Forensic Investigation Unit typically consists of shorter-duration investigations into the condition of concrete infrastructure such as chimneys and silos, and the determination of structural characteristics, such as the level of provision of rebar, slab thickness or concrete properties.

Does the future plan include BOOT projects?

South Africa and the SADC region are seeing collaboration between public and private entities in the delivery of infrastructure. We are also seeing more country-tocountry project funding initiatives in countries such as Mozambique and Zambia. Continental funding institutes are coming on board to assist in delivering energy, roads and water infrastructure.

Going forward, Nyeleti would like to become more involved in BOOT or PPP projects. Our focus is to familiarise ourselves with the typical requirements and align ourselves with strategic partners active in the field.

How is technology changing engineering?

We have a history of embracing technology and our vision is to continue to do so.

New technologies becoming essential to the profession include the exponential growth in the computational strength of computers, digitisation, geolocation, tracking and spatial technology, building information modelling, 5D design (where time and cost parameters are integrated into the 3D design model), AI, virtual reality, realtime monitoring of variables, 3D printing, drone technology, and many others.

Is the cross-border market still attractive?

Working in the SADC region is very much part of our growth strategy. Nyeleti’s approach is to focus on two or three countries. Our primary focus is Mozambique, where we have a local presence and have been successful in winning work. Nyeleti is currently busy with a 50 km water supply pipeline to Pemba, a coastal city with 200 000 inhabitants. The capital of Cabo Delgado Province, Pemba is experiencing high growth due to the development of offshore gas fields in the region.

How critical is SA’s infrastructure maintenance backlog?

In our view, the infrastructure maintenance backlog is a huge threat to efficient service delivery. As engineers, we are very aware of the effects of inadequate maintenance. Be it roads or bridges, water networks or structures, inadequate maintenance leads to a loss of functionality, a reduction in lifespan, and poses safety risks to users and communities. As a

country, we still have a long way to go to realise and understand the importance of maintenance, the implications of neglecting maintenance, and what needs to be done to address it.

What’s the vision for the next 20 years?

Nyeleti’s vision for the next two decades is built around our people and our values. We will continue to attract and retain the best talent available, ensuring that succession planning is in place for our future leaders. We have an excellent team of young engineers, both male and female. Our strategy has always been to focus on larger-scale projects that put our skills to the test; however, no project has ever been too small for Nyeleti, and we will continue to take up each and every challenge that comes our way.

In order to survive into the future, we know that we need to be at the forefront of technological developments, while identifying new fields of expertise and services that we can offer our clients. Forensic engineering investigations are a prime example – a business that we believe will grow from strength to strength over the next decade. We operate in a free market environment, so we need to offer the best service at a competitive price.

www.nyeleti.co.za

IMIESA June 2019 11 Hot s eat

Smart cities are green cities

The definition of a smart city differs across sources; however, one thing is clear: all smart city initiatives should add up to a sustainable, resilient environment.

Cities are facing an increasing number of challenges, ranging from population growth and urbanisation, to declining natural resources, pollution and climate change. The world’s urban environments are becoming increasingly vulnerable and at risk, as a result.

According to Arup’s Cities Alive: rethinking green infrastructure report, a fundamental shift is needed in the design approach for urban environments, in which nature becomes a key driver. Rather than being an optional add-on, ‘greening’ must become a fundamental part of the solution.

Promoting green infrastructure

Green infrastructure is considered among the most effective tools in managing environmental risks and climate change. According to the report, green

Environmental

Improved visual amenity

Enhanced urban microclimate

Improved air quality

Reduced flood risk

Better water quality

Improved biodiversity

Reduced ambient noise

Reduced atmospheric CO2

infrastructure comprises a number of components within city environments, including open spaces, natural areas, urban woodland and parks, green streets, squares and public realm, sustainable drainage systems, rivers and waterways, cycleways and pedestrian routes, and smaller-scale interventions such as green roofs, walls and facades.

By adopting a green infrastructure approach, cities can not only become healthier and more attractive but, over time, develop into a resilient ecosystem capable of generating a substantial range of social, environmental and economic benefits, while also protecting against climate change.

“A green-infrastructure-led design approach has the potential to unlock complex interactions between, say, development, housing, flood management, food production and

biodiversity. By adopting a multifunctional design approach, more dynamic, integrated and forward-thinking solutions can be realised, which can also generate multiple secondary benefits,” states the report.

The benefits can be seen across all sectors of society, ranging from local authorities, to residents, developers, business, retailers and tourists (see Table 1).

Down to practicalities

To see a real difference, green infrastructure should be considered from the outset of any urban project or strategy. Rather than attracting piecemeal investment, it should not be seen as an independent driver for development, but as a solution to a range of issues.

To more consistently deliver this, Cities Alive identifies the following key aspects:

Economic benefits

Increased property prices

Increased land values

Faster property sales

Inward investment encouraged

Reduced energy costs via microclimate

Regulation

Improved chances of gaining planning permission

Lower healthcare costs

Social benefits

Physical activity encouraged

Improved childhood development

Improved mental health

Faster hospital recovery rates

Improved mental health

Improved workplace productivity

Increased social cohesion

Reduction in crime

s ustainability | S M a RT CITIES

Table 1 Benefits of green infrastructure (Source: Cities Alive: rethinking green infrastructure, Arup)

benefits

1

Vision – all delivery should be underpinned by and contribute to a large-scale strategic vision that identifies the assets, opportunities, risks and vulnerabilities.

2

Collaboration – green infrastructure is increasingly being seen as a concept that unites a range of disciplines and interests, and facilitates collaborative working. In the context of green infrastructure, competing priorities can often complement each other.

3

evidence – preparation of a green infrastructure framework should be underpinned by evidence to ensure that interventions are appropriate to their context. Evidence is particularly important

to understand the value of a city’s natural resources to enable future planning for enhancement potential.

4

tools – planning plays a vital role in the delivery of projects, and will be triggered in many interventions involving new and existing development.

5

Management – management and maintenance of green infrastructure should always be a key consideration from the outset of a project. This ensures longevity and secures the full potential of interventions.

6

Funding – traditionally, local authorities provided funding for the delivery, management and coordination of green infrastructure. Increasingly, this type

of funding is more difficult to secure, leading to new, creative and innovative ways for funding and the use of available resources. Considering funding for maintenance and management from the outset will help deliver long-term benefits. Cost reduction and the recognition of the value of existing assets are also important. Most importantly, political champions are needed to promote a vision in which green infrastructure adds to the quality of a city and differentiates its offer by attracting investment. Green infrastructure and its subsequent maintenance must become integral to individual projects, and must always be linked into the wider vision and framework of the city.

IMIESA June 2019 13

IMIESA June 2019 13

PERFECT PAVING FOR GOOD

Clay pavers o er a stylish, timeless appeal with impressive sustainability credentials. And they aren’t just good looking and good for the environment - they are also low maintenance and tough enough to cope with high levels of loading for life.

Ceramic clay pavers won’t fade in corrosive industrial or coastal environments and the textured nish remains safely slip-resistant in wet or frosty conditions.

Go to www.claybrick.org to learn more about this sustainable construction material

CLAYBRICK.ORG FOECIOVEHT T H E CLAYBRICKINDUSTRY STYLE SUSTAIN SAVE SECURE environment-friendly This Switch Africa Green Project is co-funded by the European Union This project is co-funded by the European Union Promoting Inclusive Sustainable Practices in the South African Clay Brick Sector

Photograph courtesy of Corobrik

Clay pavers promote mobility

Clay pavers have been used in streets, sidewalks, paths and plazas for hundreds of years due to their durability, long-lasting colour, small scale, and ability to blend in. They also create smooth riding surfaces for wheeled users.

Accessibility is particularly important for people with limited mobility, whether they are in wheelchairs or using crutches or walking aids, as well as those with poor vision. It is also important that municipal infrastructure makes provision for the free movement of people in general, e.g. mothers pushing prams, workers handling trolleys, and cyclists and runners making use of designated paths. Clay segmental pavers excel in all these areas while also providing major aesthetic appeal.

“Pavements using clay segmental pavers behave differently from monolithic concrete slabs,” explains Mariana Lamont, executive director, Clay Brick Association of South Africa (CBA). “It is often assumed that large slabs are superior to clay segmental pavements because they have fewer joints.

“However, vibration measurements conclude that the narrow joints in clay segmental pavements result in less severe vibrations than control joints in concrete slabs. More joints mean smaller incremental changes between pavers. Segmental pavers are also easier to repair than poured concrete, resulting in simpler and less costly maintenance,” adds Lamont. Many clay pavers have chamfers (bevels) on their top edges. Some clay pavers also have lugs (spacers) on their sides to create uniform joint widths. The main purpose of chamfers is to reduce chipping on pavers and avoid direct contact between the top edges of adjacent pavers. Chamfers also create an interesting visual pattern and may help channel surface water run-off.

It is important to select pavers that have top surfaces and edges that are planar. Pavers with

RIGHT A section of the Green Point precinct in Cape Town surfaced with clay pavers. The design makes provision for two mature trees abOVe A roadway section along Durban’s beachfront promenade, designed using a classic herringbone pattern abOVe leFT A walkway in uMhlanga, KwaZulu-Natal, demonstrates the aesthetic appeal of clay segmental pavers

chamfers less than 6 mm wide allow the front wheel of a wheelchair (126 mm in diameter or larger) to span the distance between the top surfaces of the pavers without creating undue stress on the user. Pavers with larger chamfers may cause discomfort.

Where applied, a 90-degree herringbone pattern is preferred over a 45-degree pattern. This is because this 90-degree pattern will maintain safe levels of vibration, even with 6 mm chamfered pavers.

A running bond pattern is recommended where the longitudinal joints are aligned with the direction of travel.

Slip resistance

Clay pavers commonly have slightly roughened surfaces, which provide slip resistance without detrimentally affecting accessibility. Pavers that are heavily textured may not be suitable due to the increase in vibration for wheeled users.

Surfaces with higher coefficients of friction and slip resistance are desirable – static slip resistance values of 0.6 on horizontal surfaces and 0.8 on ramps are recommended.

Maintenance

Paving constructed with a sand bed layer is easier and cheaper to maintain. Assemblies with mortar joints will require more maintenance

due to the mortar having a shorter lifespan than the pavers. Since the base affects the stability of the pavement, it must be strong enough to resist occasional overloading and saturation. Differences in elevation of the top surfaces of adjacent pavers should be kept to a minimum through careful design and installation, and should be maintained as part of a regular maintenance programme. Changes in level can result from heaving or settling of the pavement base and more frequently occur at features that penetrate the paver layer, such as metal manhole covers. Trees roots are a common problem, so root barriers are recommended: these force the roots to grow down rather than spreading underneath the pavement. They also strengthen the tree by causing the roots to extend deeper into the soil. It is essential to inspect and maintain paving on a regular basis. This includes, when necessary, refilling sand in the joints in sand-set brick paving assemblies. Surfaces should be regularly cleared of loose sand and stone chips. Removing mould, moss and algae, which might make the surface slippery, is also a routine maintenance requirement. In all other respects, if correctly installed and maintained, a clay segmental paving system will remain in place for decades without any movement.

For further information and technical tips, download a free copy of the CBA’s Clay Paving Guide: www.claybrick.org/paving-guide

IMIESA June 2019 15 s ustainability | Bu I l DIN g Sy STEMS

(Photographs: Corobrik)

Secure your stand now and have the opportunity to:

• present your company, products and services to a target audience

• gain industry insight and meet potential partners, suppliers and clients

• interact with key decision-makers and industry peers

Sponsor a unique aspect of the conference and enjoy great benefits such as:

• free exhibition stands

• complimentary delegate registrations

• brand representation at the event, promotion of your company in the conference proceedings magazine and online

• free entry for guests at the social evening and much more.

EXHIBITORS BOOK your stand NOW

IMESA ORGANISER THE INSTITUTE OF MUNICIPAL ENGINEERING OF SOUTHERN AFRICA (IMESA) TEL: 031 266 3263 DEBBIE OR MELANIE CONFERENCE ENDORSED BY DURBAN INTERNATIONAL CONVENTION CENTRE 83RD IMESA CONFERENCE 02-04 October 2019 SIGN UP FOR A SPONSORSHIP NOW t +27 (031)266 3263 e conference@imesa.org.za conference.imesa.org.za Book online now

Driving building sustainability

In a first for South Africa, a new ecobrick has been manufactured mostly from previously unrecyclable material, and could enable zero waste in the luxury vinyl tile flooring space.

Evalution Flooring has embarked on the first phase of a sustainability project that will slash its carbon footprint by recycling luxury vinyl tile (LVT) offcuts and pull-ups into ecobricks, pavers and potentially other reusable products.

Until now, there had not been a way to recycle LVT due to the many layers that make up the product; however, as an LVT supplier, Evalution Flooring sought a way to recycle the products it sells and has teamed up with Recycle 4 Africa Waste Management (R4AWM) to recycle LVT offcuts and pull-ups.

“The first brick has been made completely out of recycled waste, including plastic that can’t currently be recycled and would have landed up in landfill,” says Eva Kaiser, founder, Evalution Flooring.

“Unlike other ecobricks, no sand or cement has been added. The brick has been tested and was found to have no leaching and no emissions. It also has a compressive strength of 15 MPa – higher than the average 5.2 MPa of concrete bricks. Plus, it is resistant to fire and rodent activity. The product will soon be tested officially by the National Home Builders Registration Council to obtain certification for use in the building industry,” she continues.

Sustainable building materials

This latest move by Evalution Flooring builds on its existing efforts to ensure sustainability. “Our Amtico Spacia, Amtico Spacia Acoustic and Amtico First received GreenTag Certification in

April 2018, followed by the mFlor range, which was certified in February 2019,” says Kaiser.

GreenTag Certification involves the entire supply chain – from the ingredients to the final product – including all sustainable practices throughout the production process.

“We only import from the Amtico and mFlor LVT factories, who are constantly making efforts to improve sustainability in their production processes. The GreenTag Certification shows that they are already well in line with what is achievable, and we will continue to work to ensure that our offcuts and pull-ups do not end up at landfill,” says Kaiser.

“Over the past 11 years, Green Building Council South Africa has been on a sustainability journey to advance the transformation of the South African built environment and construction sectors, and it is encouraging to mark this Green Star rating for internal finishes with Evalution Flooring,” says Grahame Cruickshanks, managing executive: Market Engagement, Green Building Council South Africa.

Creating a market for LVT recycling

Evalution Flooring is currently in the process of costing the establishment of a recycling facility and is working with contractors to ensure that all LVT pull-ups and offcuts are kept and returned for recycling.

“There’s plenty of LVT all around South Africa and we are currently working on how to logistically get all this material to a central point without adding to the carbon footprint. We are also exploring how to finance this massive project. While we might not be able to supply the market with ecoblocks just yet, the most important thing is that there is now a solution for directing LVT away from landfill,” explains Kaiser.

She believes that if this kind of recycling can be achieved on a national basis, the potential to produce ecobricks is huge. Although the cost per brick is still being calculated, Kaiser says it will likely be around the same price as cement building bricks.

“It is important to look after our planet in every possible way. All sectors of the building industry, including architects and clients, should be a part of ensuring that waste is minimised on a site. If everyone starts playing their role, I truly think that our ecobricks will become a reality much sooner and less waste will end up at landfill.”

s ustainability | Bu I l DIN g Sy STEMS

This new ecobrick is manufactured entirely from previously unrecyclable luxury vinyl tile

The only GreenTag Certified vinyl in South Africa. Amtico & mFlor Wood, Stone and Abstract Look LVT in stock Tel: 021 557 0599 Email: vinyl@evalution.co.za www.evalution.co.za

IMIESA June 2019 17

Bridging the gap in steel

A number of factors need to be considered when deciding on whether to build a bridge from steel or concrete. Project costs and maintenance are two key elements.

Steel offers numerous advantages, including quick construction in the field, the ability to prefabricate sections, predictable material properties, the lower weight of steel compared to that of concrete, and the fact that any structural damage is readily accessible for inspection.

“Contemporary bridge designers have the choice of steel or concrete for their construction material. However, these days, bridges are often not constructed exclusively of concrete or exclusively of steel, an example being the steel-beam and concrete-deck bridges we see today,” explains Amanuel Gebremeskel, technical director, Southern African Institute of Steel Construction (SAISC).

“The design of a bridge greatly affects its initial cost; the more efficient the design, the lower the cost. A further design consideration is the bridge’s purpose – that is, whether it will be carrying pedestrians, motor vehicles or railway rolling stock,” Gebremeskel explains.

The advantage of steel’s lower weight translates into lower erection costs, since the bridge sections can be handled using lighter construction equipment. If designed soundly, the lighter weight of the steel bridge will also allow for lighter foundations. Generally, it is easier to make spans continuous for both live and dead loads, and to develop composite action with steel designs rather than with concrete ones.

“However, the major advantage in the construction of steel bridges is that they are considerably faster to complete, with fewer logistical challenges. Where a bridge is being constructed over a busy highway, for example, disruption to traffic is far less. With steel construction, the need for time-consuming and elaborate formwork is also eliminated. If necessary, steel sections can be prefabricated off-site and then bolted and welded together to complete the final structure,” he comments.

Steel used in the construction of the Thelle Mogoerane Hospital bridge allows for an aesthetically pleasing structure

In terms of maintenance, decks are historically the most vulnerable part of the bridge. To replace a concrete bridge deck requires the removal of the entire section at one time, whereas steel bridge decks can be replaced one lane at a time, allowing for uninterrupted – albeit reduced – traffic flow.

Where bridges cross other infrastructure or geographical features such as a deep ravine or river (particularly in Africa with the often rugged terrain), steel has the advantage that the section of the completed bridge can be shallower than its concrete counterpart.

Environmental factors

“Over and above these considerations –not just locally, but globally – environmental

18 IMIESA June 2019

r oads & b ridges

considerations are also an important factor in the use of steel,” he adds.

In this respect, the raw material used to construct bridges today is often scrap steel. In a white paper, the American National Steel Bridge Alliance states that new steel bridge construction in the US consumes about 350 000 t of scrap metal annually. And, when a steel bridge has reached its allotted lifespan, the raw material can be recycled.

When bridges have to be constructed in environmentally sensitive areas, the fact that steel spans can be longer than their concrete counterparts minimises the environmental impact, as fewer piers are needed to support the bridge.

In addition, high-performance ‘weathering’ steels offer greater weather resistance and feature toughness and weldability at affordable prices. “This technology is readily available in South Africa,” Gebremeskel points out.

Advances in fabrication

forms, both internationally and locally. For example, tubular steel is now widely used and known for its aesthetic appeal, light weight and superior strength.

Furthermore, with the advent of laser fabrication, steel tubing can be processed very quickly into interlocking bridge components, thereby improving the strength, speed and efficiency of welding –resulting in stronger and more aesthetically appealing structures,” he says.

The choice of whether to build a steel or concrete bridge is also dictated to some extent by which region of the world the

economic benefits, the use of steel as a construction medium for bridges also offers the more lasting appeal of design excellence,” he continues.

“If one thinks of the internationally renowned San Francisco Golden Gate Bridge, Millennium Bridge in London or the Sydney Harbour Bridge, one has excellent examples of structures that are of immense practical use and yet at the same time are highly visually pleasing examples of superb engineering design.

“As with many other bridges around the world, the element that made these enduring and iconic structures possible was the versatility and excellence of steel,” Gebremeskel concludes.

r oads & b ridges

The Markgraaff pedestrian bridge in Bloemfontein is visible confirmation that steel can be used to create a unique and innovative structure

The Nelson Mandela Bridge in Johannesburg is a tribute in steel to our iconic leader

This elegant sky bridge is one of the entrants in this year’s SAISC Steel Awards

Enabling safer, faster, more efficient rural access in South Africa To see how we can enhance your project, please contact: Tel: +27 (0) 12 329 4116 Fax: +27 (0) 12 329 4120 Email: sales@ecmtech.co.za 18 Eighteenth Street, Hazelwood, Pretoria, Gauteng, South Africa www.ecmtech.co.za www.mabeybridge.com

Modular to enable rapid installation and minimise on-site works

Pre-engineered to shorten project delivery

Full-scale tested to ensure product safety and durability

Hot-dip galvanised to minimise through-life maintenance Cost-effective vs traditional concrete to ensure investment payback

Simple to transport and store for future use

Sustainable to protect the environment

Easily configurable for heavy vehicle access in partnership with Permanent and temporary steel bridging solutions for vehicle and pedestrian applications

Helping municipalities to do more with less

Local municipalities in South Africa are operating under extreme pressure. Resources are limited and there is a drive to achieve greater efficiencies –to do more with less. The result is that municipalities are forced to focus on localised projects, around the immediate towns, which they can manage, monitor, resource and maintain most efficiently at a minimum cost.

Rural projects are less tangible; they are difficult to manage and carry high risk, dependent not only on the reliability of contractors and the availability of skilled labour, but also on changeable weather conditions and challenging remote terrain. For people living in rural areas, the resulting lack of investment in rural infrastructure compromises access to hospitals, schools and basic amenities, impedes social mobility and constrains economic growth.

The good news is that help is at hand; We have been working closely with local communities for over 50 years, and have seen, first-hand, the societal and economic benefits delivered by the installation of critical infrastructure in rural locations. We know what resources municipalities have available, we understand their challenges, and so, by default, we are well-placed to be able to provide them with the tools to deliver rural infrastructure quickly, safely and efficiently… helping them to do more with less.

One such project was a recent bridging project in Ngqakaqheni village, in the Eastern Cape of South Africa. Situated at the foothill of a large mountain range with a river surrounding it, a single access road was the only access route in and out of the village. Local economic activities relied heavily on road transport and during rainy season the village could be cut off for up to two weeks at a time. To overcome this, the local municipality, Mhlontlo, looked to construct a bridge crossing the river to enable safe access throughout the year. The village’s remote location

meant that it would be very difficult to use a concrete bridging solution, which would require the use of heavy-duty construction equipment, which adds logistical challenge and time-dependent mixing and curing requirements on site. Mhlontlo Municipality turned to Mabey Bridge and South Africa representatives, ECM Technologies, for an alternative solution.

A Compact 200™, Mabey Bridge’s most popular modular steel bridging solution, was chosen as the ideal solution for the project. The core focus of Mabey Bridge’s C200 design is to simplify construction methods and construction costs on site, by minimizing the requirement for heavy and costly plant and equipment, making it possible to use unskilled labour effectively and sustainably. The C200 can service both pedestrian as well as vehicular traffic and can span clear gaps of up to 60 metres without the need for any intermediate supports. Designed with safety at the forefront, the C200 can also safely carry, in standard configuration, loads of 41 tons over the 60 metre gap, enabling access for heavier delivery vehicles to service start-up businesses and small enterprises in rural communities. Furthermore, Mabey Bridge’s steel structures are all hot-dip galvanised to ensure a long and low maintenance service life.

On the Mhlonto project, the single lane 40 metre long Compact 200™ was constructed in 7 days by a local contractor with a local work force, overseen by a Mabey Bridge Site Advisor, and delivered in partnership with ECM Technologies. Now providing reliable, safe, access all year round for the rural community of Mhlonto, the project illustrates how simple, modular, off-the-shelf bridging solutions can offer significant savings in design, transport, resource, logistics and construction and also demonstrates how ease of construction and the use of unskilled labour, and minimum plant and equipment, can reduce on-site costs and minimise risk.

If you have a project like this, please get in touch. It would be our pleasure to help deliver peace of mind on each and every project you work on. Let us help you do more, with less.

IMESA 2019

We’re extremely proud of our work in South Africa. We have reduced the cost of rural bridges – so it’s possible for a higher number to be supplied and maintained – and we have reduced construction times so the benefits can be felt more quickly.

To celebrate this ongoing mission to develop critical infrastructure and connect rural communities across the region, we will be working with our South African partners, ECM Technologies, to demonstrate our expertise at this year’s IMESA event.

Visit Mabey Bridge and ECM at Stand 38 & 51 at IMESA to find out more.

Ngqakaqheni village bridging project

Bridging rural routes

The new bridge over the Mankgatle River is one of two large structures along the route

The flexibility

of

precast is well demonstrated on a modified bridge design that ties into a new road layout in Limpopo.

The Roads Agency Limpopo (RAL) is forging ahead with the construction of a new road that will connect three villages in the mainly rural Sekhukhune District Municipality to two provincial routes. Lonerock Construction is the main contractor, with works scheduled for completion in September 2019.

Since the original engineering design was completed more than eight years ago, it needed to be updated to suit current conditions.

“Road construction was delayed by RAL due to limited financing and other pressing responsibilities,” explains Joseph Myoya,

Ubona Engineers’ resident engineer on-site. “The villages have since expanded, with many properties now located within the originally planned route. The road, therefore, had to be extensively realigned to avoid having to relocate more than 200 affected properties. Our approach resulted in significant cost savings.”

The original design of the Mankgatle River Bridge was modified to meet the new and higher road realignment. This meant that substantially more reinforcing steel was required for the taller concrete abutments.

Additional precast concrete elements were also needed to build the larger 20 m long and 11.5 m wide superstructure,

Eight precast concrete beams and 126 precast concrete deck planks were manufactured and installed by CoreCivils

which stands at a height of 6 m above the riverbed.

Alternative foundation approach

The redesign of the bridge foundations also had to accommodate the terrain, which is overlain by rocks and large boulders. A decision was taken to anchor the foundations of the bases of the abutments into the large boulders, as opposed to removing them by drilling and blasting.

“Mass concrete was cast over the boulders and we then drilled through them to insert the dowels. This approach provided some cost savings for our client, considering that up to 45 000 m³ of rock had to be removed by drilling and blasting during the earthworks stages of road construction,” says Myoya.

The eight precast concrete beams and 126 deck planks were manufactured and installed by CoreCivils, the precast concrete bridge beam and parapet arm of CoreSlab.

r oads & b ridges

Reinstating a vital port connection

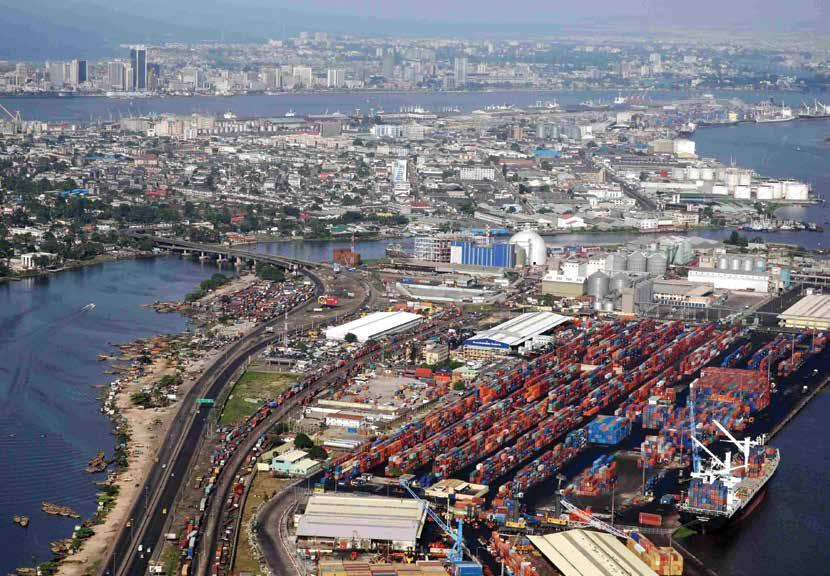

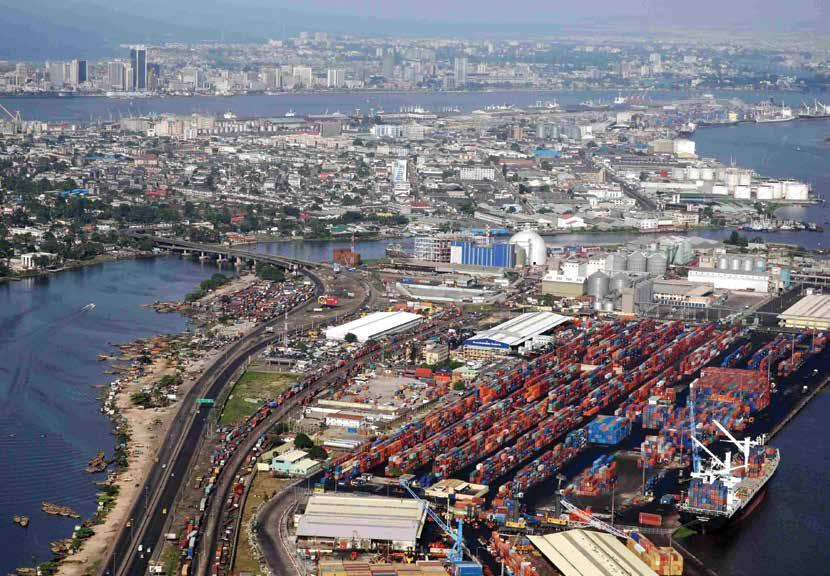

Studies recently completed by JG Afrika, a leading South African firm of consulting engineers, have informed the design of the rehabilitation of a strategic road that connects Tin Can Island Port to major commercial centres in Lagos State, Nigeria.

The existing access road from Tin Can Island and the sixlane expressway that connects Apapa Wharf to Oworonshoki was built as early as the 1970s, and has since fallen into a serious state of disrepair.

In addition to causing severe congestion and unsafe travel conditions, this has negatively impacted efficiencies at the port and had a knock-on effect on businesses in the area.

The rehabilitation of the road network, as part of a public-private partnership, was first mooted by AG Dangote Construction, a subsidiary of local cement entity Dangote Industries, and the proposal was favourably received by the Federal Ministry of Power Works and Housing.

JG Afrika proposed a continuously reinforced concrete pavement (CRCP) design to better cope with the growing number of heavy commercial vehicles travelling along the route. The design is similar to the technology deployed in the construction of South Africa’s Ben Schoeman Highway linking Johannesburg and Pretoria.

This design replaced the initial suggestion of using a conventional jointed concrete pavement. This would ultimately have developed slab tilting and stepping on the extremely soft subgrade material

encountered along sections of the existing road from Apapa to Oworonshoki.

In-depth pavement evaluation

Led by Dr Emile Horak, a foremost pavement specialist, JG Afrika was appointed to undertake the pavement evaluation in 2018. These critical insights have been incorporated into the final rehabilitation design by Yolas Consulting, a Nigerian engineering consultancy working on behalf of AG Dangote Construction.

A detailed assessment of the condition of the road pavements and a geotechnical investigation of the material used in the existing road were undertaken as part of the project. In addition, JG Afrika undertook an extensive investigation of all available construction materials to build the road and structures.

The studies identified high deflection on the road as a result of a very weak pavement structure, while very poor materials were also used in the construction of the existing road, especially for the foundation layers.

Testing undertaken on asphaltic concrete samples showed that all of the properties met the specification requirements and that the grading of the aggregates was within the specification envelope for wearing course. However, unsuitable material was identified

Catastrophic pavement failure due to unacceptable moisture conditions, combined with overloading

(Photograph: Looking for good in Lagos, 2011)

in the sub-base and sub-grade layers from samples that were collected at various locations along the road.

According to the study, it will be possible to source sufficient filling material from all of the borrow pit areas that were investigated, while suitable crushed rock aggregate for the base course can be obtained from the rock outcrops observed along LagosIbadan road.

The engineers also found the available aggregate, water and river sand to be of a suitable quality for the construction works. Should there be insufficient river sand, they have recommended supplementing supply with quarry dust.

JG Afrika also noted that adequate provision be made in the detail design report for drainage and sub-drainage improvement, especially in swampy areas, in addition to the need to reinstate the shoulder of the entire road.

Horak says the concrete pavement design expertise of Ane Cromhout, pavement engineer with the JG Afrika team, formed the basis of the recommendations to use CRCP. These recommendations made by JG Afrika were well received by the contractor and work is expected to commence imminently on the rehabilitation of this critical road infrastructure.

r oads & b ridges

Port of Lagos, Apapa: the largest container terminal in Nigeria

IMIESA June 2019 23

(Photo credit: Global Construction Review, 2017)

Within South Africa, close to 90% of the population has access to electricity; while in North Africa, Algeria, Egypt and Libya have virtually 100% coverage, according to World Bank data.

In-between, the percentages steadily drop. Within SADC, for example, Zambia and Zimbabwe are at around 28% and 32%, respectively, and Mozambique at approximately 21%. Botswana is the next highest after South Africa, with some 56% receiving electrical power.

Across the continent, there are a number of initiatives in progress to effect positive change. A recent example is the approval of the Regional Off-Grid Electrification Project for West Africa. This includes US$150 million (R2.2 billion) in the form of credit and grants from the International Development Association and a $74.7 million

Lighting the way

(R1.09 billion) contingent recovery grant from the Clean Technology Fund. This will help the West African Development Bank and the Ecowas Centre for Renewable Energy and Energy Efficiency expand off-grid access to electricity for populations in 19 countries. These countries include Burkina Faso, Cameroon, Ghana, Nigeria and Sierra Leone.

The project is expected to benefit about 1.7 million people currently living without an electricity connection or with unreliable supply, as well as businesses and public institutions that will use modern standalone solar systems to improve their living standards and economic activities.

EEDSM initiative

In South Africa, a key initiative aimed at promoting sustainability is the Energy Efficiency Demand Side Management (EEDSM) programme managed by the Department of Energy (DoE). The end goal is to help qualifying municipalities lower their energy footprints. They need to submit a proposal to have their business case approved for funding.

EEDSM grants support the planning and adoption of energyefficient technologies ranging from traffic and street lighting to HVAC and lighting in buildings, and interventions at purification plants. The estimated electricity saving potential for traffic lights is up to 80%; for street lighting, between 40% to 70%; for office buildings, 20% to 30%; and 15% to 25% for pumps used for water provision and treatment.

Municipalities interested in the EEDSM programme have to respond to the requests for proposal issued by the DoE at the beginning of October each year. The DoE evaluates these proposals based on their energy savings potential, cost and payback period.

EEDSM best practice lighting examples include traffic light installations for Swartland Municipality in the Western Cape, resulting in a forecasted saving of approximately 29 MWh annually over a 6.5-year payback period. In place of 50 W lightbulbs, 9 kW LED lightbulbs were installed at 50 robots.

Another example saw Nelson Mandela Bay Metropolitan Municipality install 400 W LED lightbulbs on 360 high masts in place of conventional lightbulbs, at a cost of around R8.8 million. The projected savings on installation were 1 050 MWh annually, over a payback period of 6.9 years.

Nationally, public lighting, alongside electrification, remains a top priority for municipalities, particularly in informal areas. Going forward, and alongside LED technologies, the installation of solar systems will be part of the mix in providing immediate solutions that don’t place further demands on the grid.

24 IMIESA June 2019 STRUCTA TECHNOLOGY is part of the STRUCTA GROUP of Companies T: 0861 STRUCT (787828) F: 016 362 3608 E: masts@structatech.co.za Meyerton, Gauteng www.structatech.co.za Specialists in the design, supply and installation of lighting support structures Full mast kits, “ready to erect” including mast, electricals, lights and pre-cast foundations can be supplied LEADERS IN LIGHTING MAST TECHNOLOGY Street light poles Midbow lighting masts Abamax hydraulically liftable masts Standard high masts Stadium masts Street light poles Midbow lighting masts Standard high masts Stadium masts Hydromax hydraulically liftable masts Structa Technology is a Level 1 BBBEE Contributor Public lighting

Steel Pipe for Water, Petrochemicals, Gas, Construction and Mining

Hall Longmore ranks amongst the most reputable pipe manufacturers in the world. The company’s world-class manufacturing facilities produce large-bore welded steel pipes for a variety of applications.

+27 11 874 7300 info@hall-longmore.co.za www.hall-longmore.co.za Established in 1924 Electric Resistance Welded Steel Pipe Oil Country Tubular Goods Helical Submerged Arc Welded Pipe International Specification Coatings and Linings International Quality Standards

Spiral welded pipes ideal for municipal works

For many decades, the most critical water projects in South Africa have either used spiral welded steel pipes or have had steel pipe as a construction option, all locally manufactured and purpose-designed for each application. by Keitumetse Moumakoe*

TThe roll-out of water and sanitation civil infrastructure is a key step towards the realisation of ensuring water security and availability in our communities

he issue of water security for South Africa not only circumscribes the entire water sector, but also has far-reaching consequences across the entire economy of South Africa. In the context of the Department of Water and Sanitation’s master plan, water security touches on many facets, including identifying future water sources for our growing population, the operation and maintenance of water and sanitation infrastructure, and the proper management of our water quality. It affects the growth and development of all sectors of our economy.

The roll-out of water and sanitation civil infrastructure is a key step towards the realisation of ensuring water security and

availability in our communities. It also has a plethora of value-added opportunities addressing employment, industrialisation, manufacturing localisation and designation of materials.

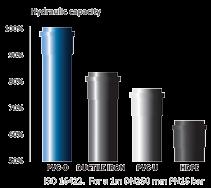

Spiral welded pipe is a 100% designated product as per Treasury Designated Sector Circular No.4 of 2017/2018 and a product that is suitably applicable in municipal piping applications for the conveyance of water. It has been used extensively by many municipalities and metros in their water infrastructure projects with great success, sustainability and suitability.

Locally, we have three proudly South African companies manufacturing spirally welded, large-bore steel pipes, ranging from

Meters, Pi P es, Pu MP s & valves

26 IMIESA June 2019