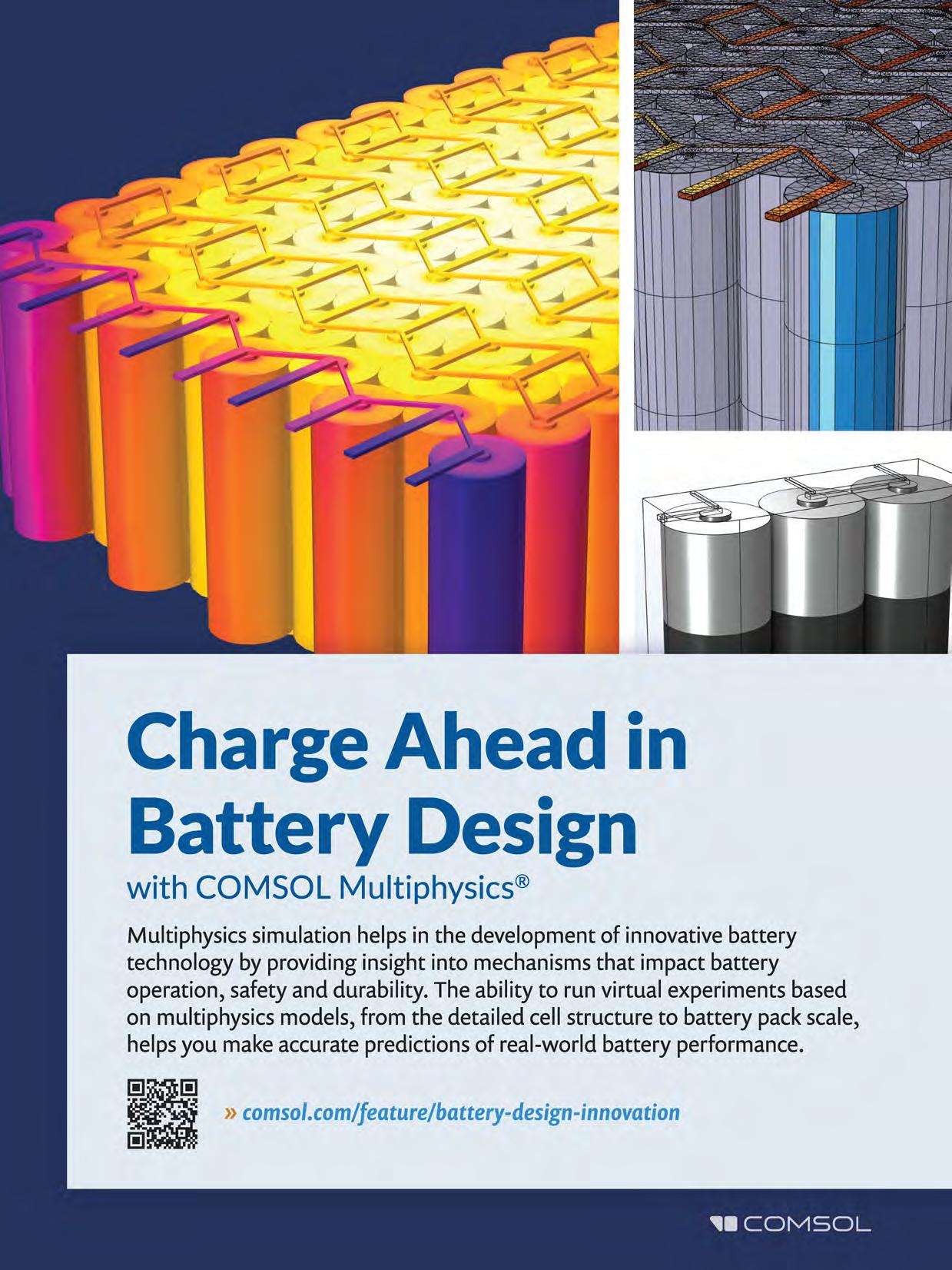

Multiphysics simulation helps in the development of innovative battery technology by providing insight into mechanisms that impact battery operation, safety and durability. The ability to run virtual experiments based on multiphysics models, from the detailed cell structure to battery pack scale, helps you make accurate predictions of real-world battery performance.

» comsol.com/feature/battery-design-innovation

03 Welcome

Chief executive Alice Bunn sets out IMechE’s response to the Industrial Strategy

40 The big interview

IMechE president Matt Garside wants to put trust front and centre during his one-year term

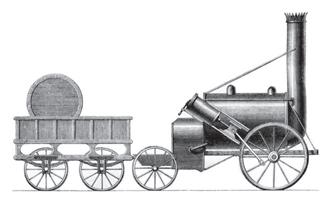

44 Next stop: the future

Rail travel has come a long way since Stephenson’s 1825 locomotive. What will the next 200 years bring?

50 Ready for launch

All things aviation were celebrated at the Paris Air Show. Here are five of this year’s stand-out projects

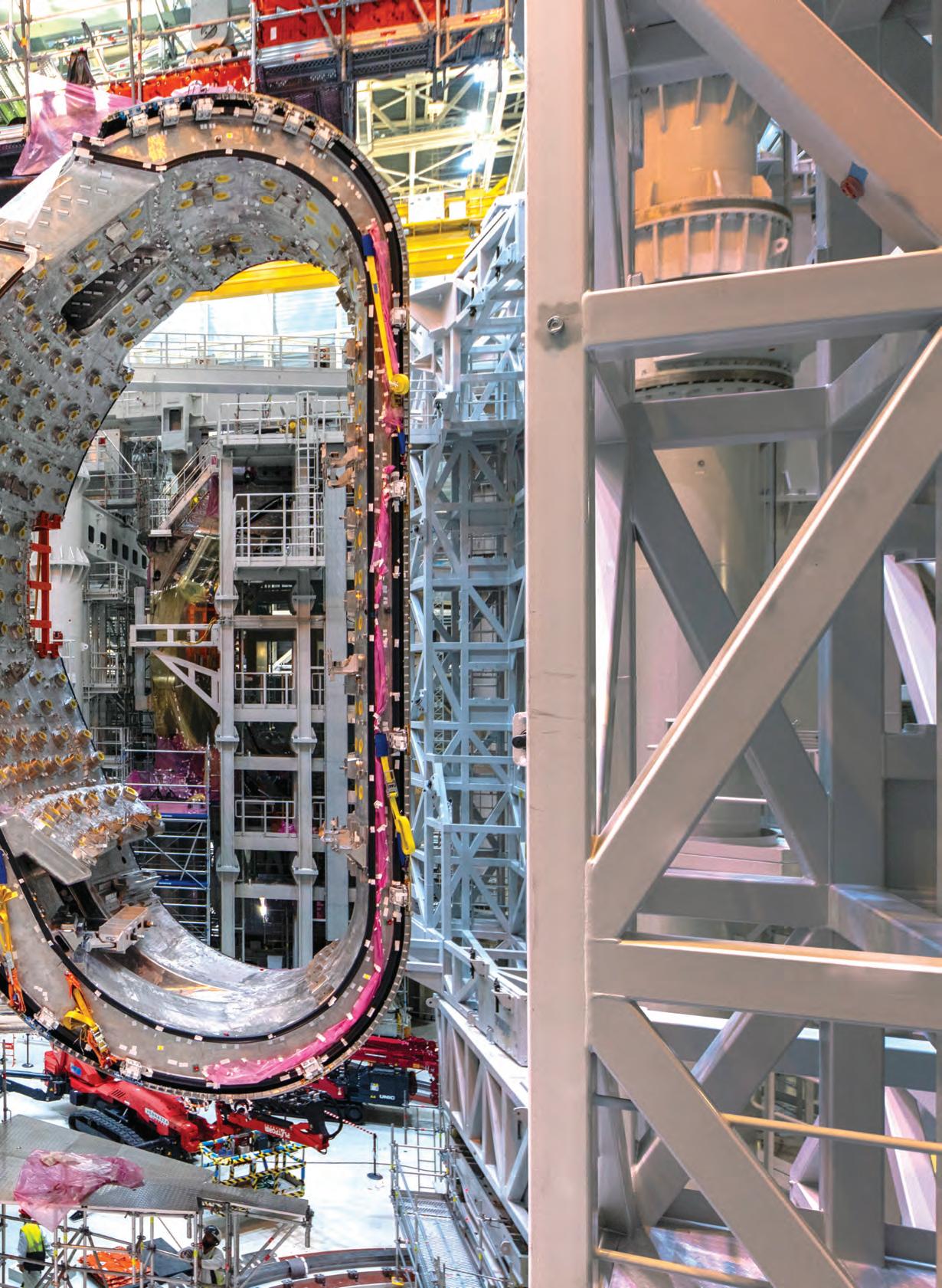

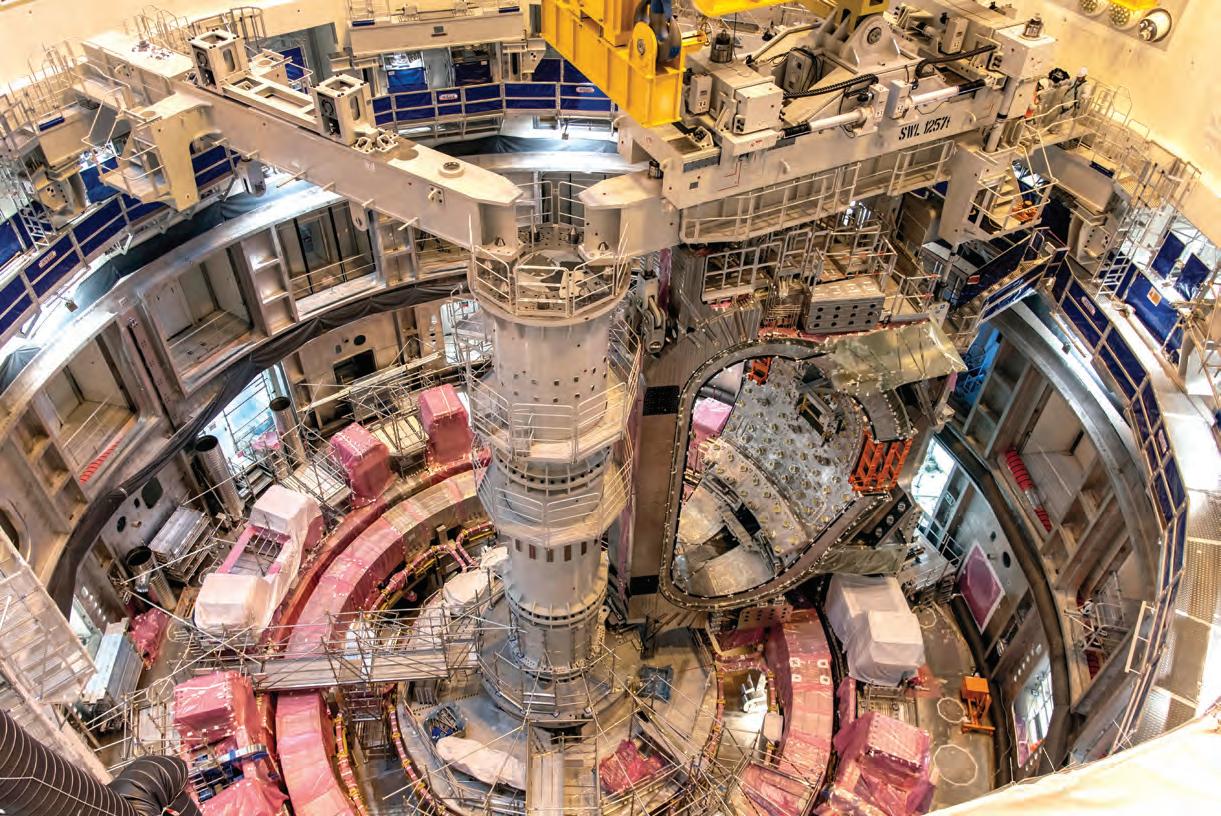

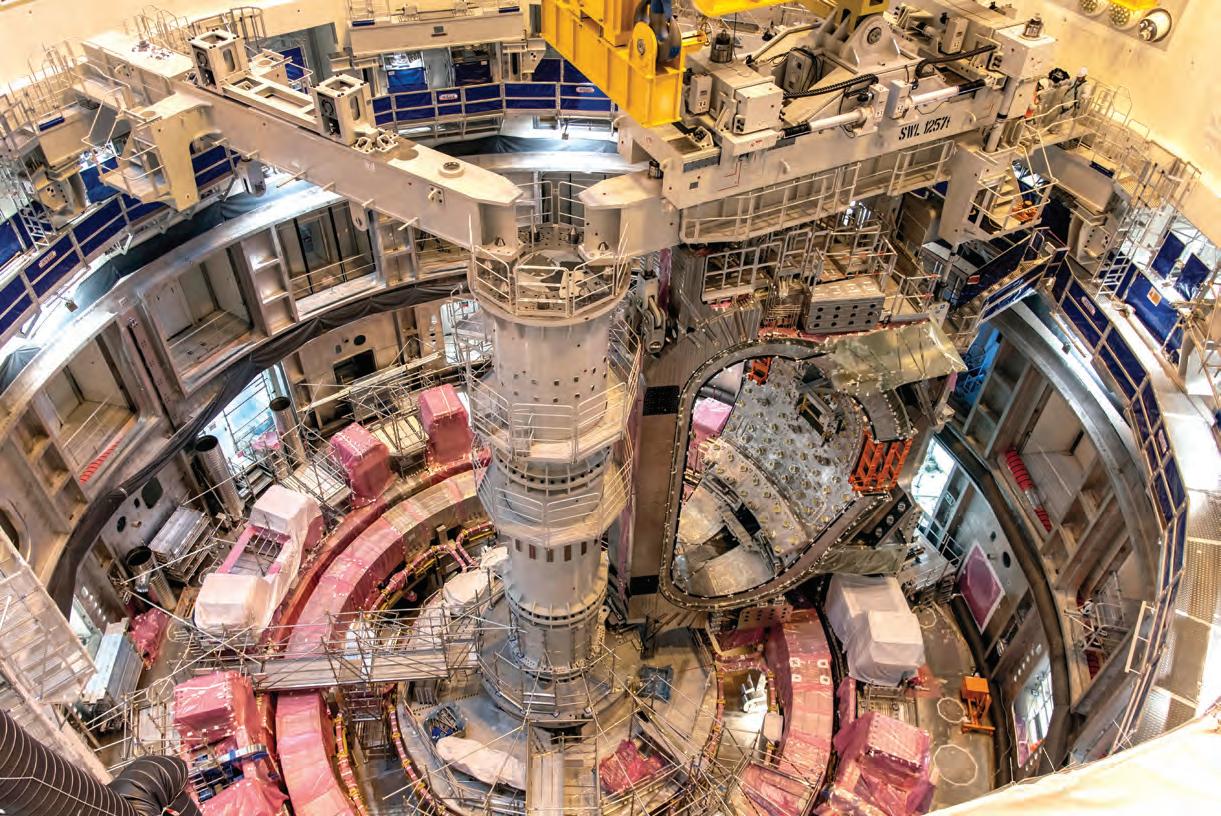

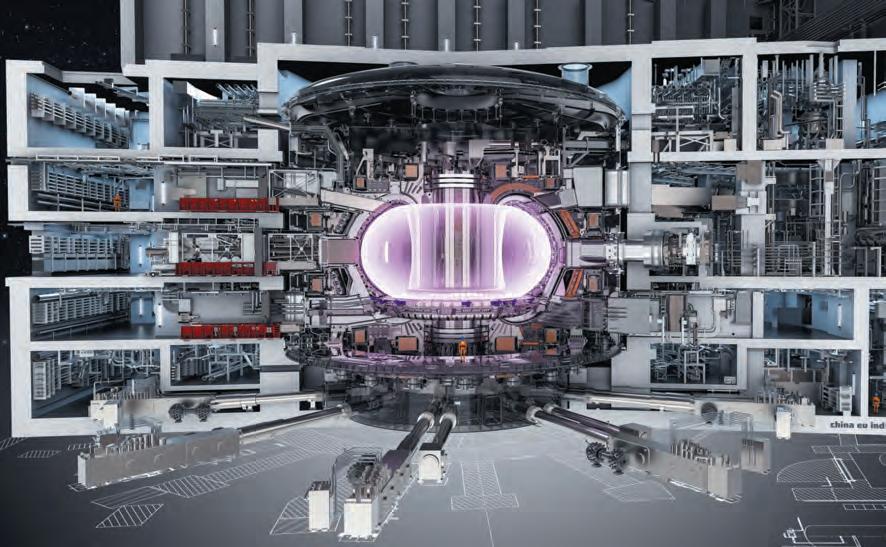

56 How to build a sun

We visited Iter in southern France to find out why the science of metrology is so crucial to nuclear fusion

64 Weird engineering

Can a car ever drive upside down? Yes, if

05 Opener

Why the slowdown of a key global ocean current could have huge repercussions for Europe’s climate

08 Buckle up

The first multi-adaptive seatbelt uses sensors to make car travel safer than ever

11 Five for the future

Meet the engineers and researchers who are coming up with groundbreaking innovations

13 Blueprint

Ahead of an upcoming IMechE report,we look atwhat engineers can do to improve accessibility on public transport

17 In the spotlight

Our series on IMechE members who are having a big impact profiles

Steve Fletcher

20 Ticket to ride IMechE’s Railway Challenge welcomed young engineers to tackle some of the rail industry’s toughest problems

23 Your voice

Readers have their say on key issues of the day

33 Transport automation

What challenges are raised by the increasing use of automation in transport?

Plus, an update on the IMechE headquarters

37 Driverless vehicles

The rise of autonomous cars could have a big impact on the powertrains of tomorrow

38 Artificial intelligence

NewAI-based simulation and modelling techniques are proving transformative

39 Communication

Why perfecting your interpersonal skills is important forworking in every industry

"We want to understand our products, understand our customers and focus on them. We don't really want to deal with the minutiae of servers and keeping the lights on, keeping the technology going."

Richard Hughes, Ecommerce & Marketing Mgr, Industrial Tool Company

Simplify with a single front and back end experience for retail and wholesale. Automate customer group management, and customise prices and discounts down to the unique SKU level.

Manufacturing buyers are different from other consumers, but they still expect modern buying experiences. Deliver an engaging and frictionless journey to gain a competitive advantage.

he UKgovernment’s publication of the Modern Industrial Strategymarks a commitment to shaping the nation’s economic future through innovation, resilience and inclusive growth. At the centre of thisvision is engineering as a driving force behind the success of keysectors from energyand infrastructure to advanced manufacturing and mobility. The challenges this strategyseeks to address are not unique to the UK. Howdowe equip peoplewith the right skills forthe future? Howdowe adopt newtechnologies at scale? Howdowe align growthwith environmental and social priorities?These are global conversations,within which engineering is a common thread.With eight highgrowth sectors identified – each demanding technical talent and agile, future-focused capabilities – engineering has neverbeen more relevant, essential orvalued.This new strategyrepresents a pivotal moment forthe profession and a recognition that engineering is the backbone of a prosperous, secure and sustainable society.

IMechE policy recommendations

Ourrecommendations are reflected across the strategy, including commitments to long-term and stable R&D funding and embedding systems thinking in innovation policy.The government’s pledge of £100m across three years forengineering skills in England is significant, and wewelcome the regional approach to skills andworkforce development. Equallyimportant is the emphasis on sector workforce strategies, simplifying the skills system and encouraging collaboration between industryand academia. As an Institution,we are calling fora National Engineering

is published by Think on behalf of the Institution of Mechanical Engineers.

PE, 65 Riding House Street, London W1W 7EH 020 3771 7200

EDITORIAL profeng@thinkpublishing.co.uk

Editor: Amit Katwala

Deputy editor: Joseph Flaig

Sub-editor: Rebecca Dyer

Group art director: Jes Stanfield

Executive director: Jackie Scully

Client engagement director: Kieran Paul

andTechnologyWorkforce Strategyto address theworker shortage and plan forfuture demand. Skills passports, increased support fortechnologyadoption and reforms tovisa pathways are also encouraging. Ourpresident, Matt Garside, points out that these measures must be met with close collaboration between government, employers and professional institutions like IMechE.

As an Institution,we areworking to realise this future. Our Learning and Development programme continues to evolve, designed to help engineers upskill and adapt.Thisyear alone,we’ve launched 14 newcourses,with a strong focus on the energytransition and heating and cooling systems. Our FocusWeeks, introduced in June, have brought engineers togetherthrough themedwebinarseries on critical areas of engineering practice.These free, accessible sessions provide opportunities formembers at everystage to learn from experts and peers.Two moreweeks are scheduled thisyear. We also continue to support early-careerengineers through ourstudent competitions, attracting teams from around the world, andyoung memberengagement initiatives.

Looking ahead,we’re excited about ourAdvancing Automotive Engineering Conference this October, a flagship event to explore trends and technologies spanning propulsion systems, emissions reduction, thermal management andvehicle dynamics. Ultimately, this is a moment forengineering to lead –with confidence, creativity and impact.The Modern Industrial Strategyprovides the opportunity. It’s up to all of us – engineers, educators, employers and institutions – to help build the future.

ADVERTISING 020 3771 7232

Commercial director: Michael Coulsey michael.coulsey@thinkpublishing.co.uk

Group commercial manager: Matt Hall matt.hall@thinkpublishing.co.uk

Senior commercial partnerships manager: Chris Barnard chris.barnard@thinkpublishing.co.uk

Commercial partnerships manager: Leanne Rowley leanne.rowley@thinkpublishing.co.uk

Copyright: Think Publishing 2025

SUBSCRIPTIONS

For address changes, phone 01952 214050 or email subscriptions@imeche.org

ABOUT IMECHE

The Institution of Mechanical Engineers is the professional body overseeing the qualification and development of mechanical engineers. It has 115,000 members in 140 countries.

Visit imeche.org for more information about membership and its benefits, or email membership@imeche.org.uk

@ProfEng tinyurl.com/PEmagazine

Views expressed in Professional Engineering are not necessarily those of the Institution or its publishers.

Chief executive: Dr Alice Bunn OBE FIMechE

President: Matt Garside CEng FIMechE MIET

IMechE is a registered charity in England and Wales number 206882

400+

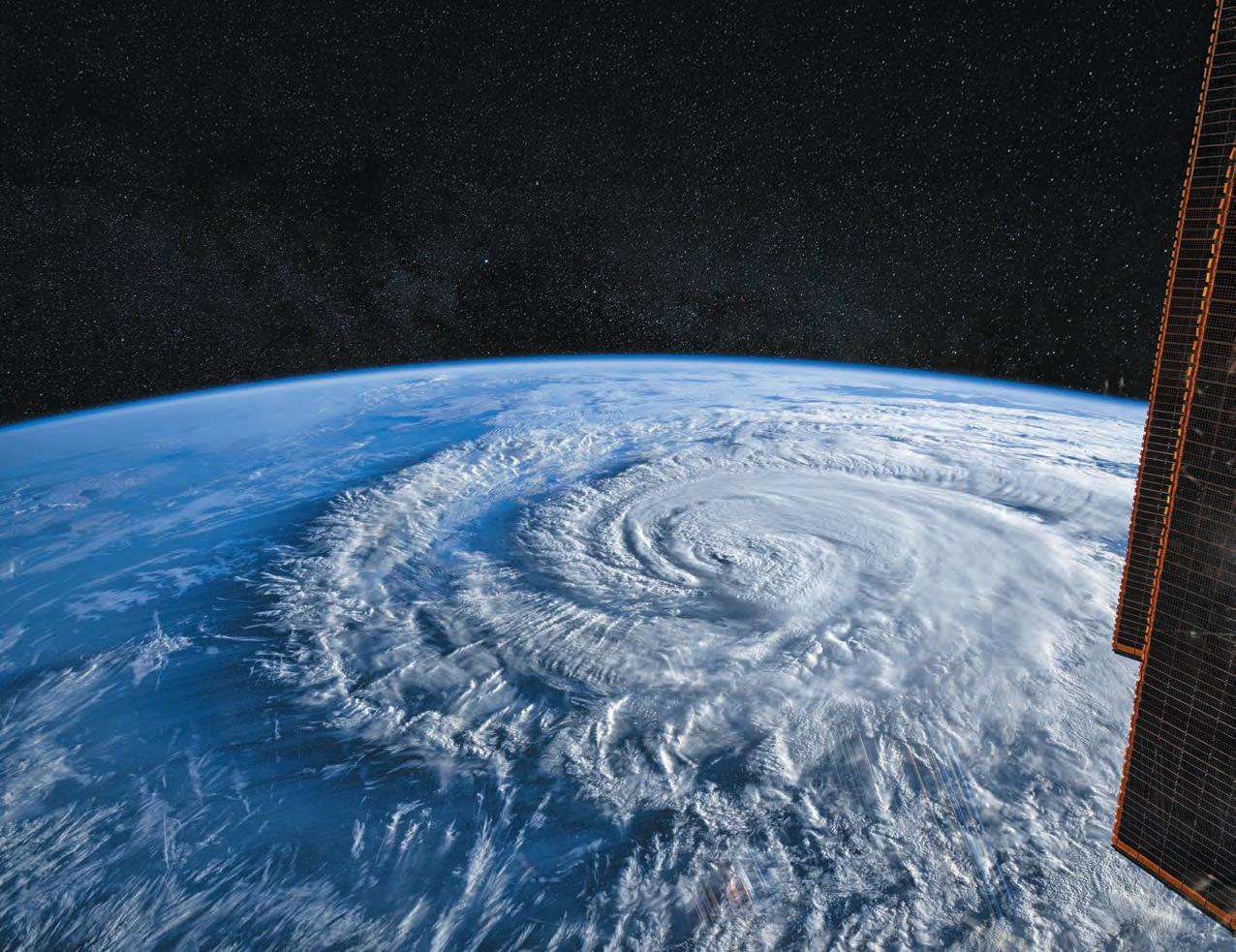

A crucial global ocean current could soon stop, throwing the world into climate chaos. Can engineers adapt in time?

The picture for climate change is clear, set out in thousands of papers: temperatures will continue to rise for the next few decades; heatwaves, droughts and wildfires will be harsher and more frequent; rising seas will lap ever higher; and millions will be forced from their homes as crops fail and water runs out. At the regional level, however, the picture is fuzzier. Significant uncertainties remain around how certain meteorological systems will change – and what happens will shape the lives of billions.

The slowdown of ocean currents associated with the Atlantic Meridional Overturning Circulation (Amoc) is one such scenario, with significant repercussions for the UK, as well as elsewhere in Europe,

Africa and North America. The conveyor belt-like system of ocean currents carries warm water from the tropics northwards, causing milder winters for the UK compared with other countries at that latitude. Input of cold water from melting ice plays a key role – but as that melt increases, it is expected to weaken the system, and some researchers fear it could stop entirely.

The risk of such a change is still being studied. A Naturepaper by scientists from the Met Office and the University of Exeter found that the Amoc is unlikely to collapse over the next 75 years but “very likely” to weaken. A reduction might offset some greenhouse gases for Western Europe, but a shutdown would have extreme consequences.

75

years is the time period in which the Atlantic Meridional Overturning

Circulation is ‘very likely’ to weaken -

Changes to Amoc currents would have “profound implications for the outcome of our current adaptation and resilience-building strategies”, according to organisers at a recent IMechE event. Focusing on the Amoc slowdown, the 20 May webinar gathered experts to look

Electric vehicle batteries running too hot?

jbj Techniques have the answer. We can take your EV battery cooling requirement and turn it into a reality. Complete autonomous systems that can be used in conjunction with the vehicle air conditioning circuit. Power saving fan drives to reduce the draw on the EV battery pack. We can take your cooling requirements from concept through to the finished package.

Hydraulic system running too hot?

jbj Techniques have the answer. In line coolers or offline coolers available from our extensive range.

Need to cool your diesel or petrol engine, intercooler or gearbox oil?

jbj Techniques have the answer. For machine manufacturers requiring improved performance or combined cooling of multiple media in a compact design or different cooler area footprint.

Have a hydraulically driven cooling fan requirement?

jbj Techniques have the answer. Proportional fan drive systems having CAN Bus compatibility.

ATEX certified coolers - stainless steel coolers - coolers to CSM protection?

Yes, we have the answer.

Contact jbj Techniques Limited for carefully considered, excellently designed, cooling requirements.

jbj Techniques Ltd in partnership with IRA Engineering are pleased to announce an exciting new addition to their product portfolio. This new addition being the IRA Engineering, Italian manufactured, range of air blast coolers.

The range of air blast coolers is extensive, consisting of the RAL, aluminium, series of inline coolers, having a heat dissipation range of 1.6 kW to 200 kW (based on a aT of 40°C) and an oil flow capacity of 5 to 800 1pm.

at potential changes and assess physical impacts to the built environment. As with other aspects of adaptation, there will be a big role for engineers – and preparation needs to start as soon as possible.

Conventional scenarios assume a gradual increase in greenhouse gas concentrations and a gradual response from the climate system, according to Professor Nigel Arnell, climate science specialist at the University of Reading. But, he asked, “What if something weird happens?”

‘Weird’ changes

One of those “weird” changes could be an Amoc slowdown – and the effects could lead to a “step change”, Arnell said. He set out a scenario for South East England if the circulation switched off in 2030, based on experiments by the University of Exeter and Met Office.

“By 2050, temperatures are about six degrees cooler than they would have been otherwise, and then gradually increasing again, slowly, as the greenhouse effect continues to kick in. That’s quite a substantial change; we’re looking at temperatures three to four degrees below what we’re currently experiencing,” he said. “That will be well outside the range of human experience, and this is on average –around that we would get extremes and some ‘mild’ winters. But a mild winter would be really cold. We would likely see slightly less rainfall in winter and a lot less in summer… and we would expect a higher sea level as the Amoc switches off.”

Changes could be compounded by the collapse of the ‘subpolar gyre’, he warned, another ocean circulation that could, if switched off, lower temperatures by about 2ºC.

However, we do not know how close we are to the threshold for Amoc collapse, Arnell said, so the warning time could vary massively. “It’s not going to happen overnight, so we don’t need to worry about a TheDayAfterTomorrowscenario – we may get 25 years warning, it may be 10 years, it may be 40.”

Such uncertainty only increases the tension between preparing for different scenarios. “That’s an awful lot of challenging changes to deal with,” said Dr Tim Fox, chair of IMechE’s working group on climate change adaptation. “The built environment, physical infrastructure and other engineered systems will be subjected to environmental conditions for which they have not been designed – or indeed adapted.”

Engineers in Northern Europe should focus on developing “no-regrets” technologies, he told ProfessionalEngineering, which work in extreme heat and cold, and during both flooding and drought. “We must also concentrate on developing innovative solutions that futureproof infrastructure at the point of construction by enabling cost-effective changes.”

Engineering standards also play an important role in adaptation but

2050 could see temperatures in South East England six degrees cooler, according to one study

2ºC is the amount that temperatures could decrease by if the subpolar gyre collapses

so far have not considered potential “tipping points”, said Professor John Dora, director at consultancy Climate Sense. That is beginning to change, with standards including the adaptation framework of ISO 14090 being revised. ‘Adaptation pathways’ can provide flexibility for dealing with uncertainties, Fox added. The BS 8631:2021 standard, for example, provides “a full description together with the methodology,” he said.

However, with net zero efforts threatened by populist politics, how can we ensure adaptation is taken seriously? One of the best ways is highlighting the risks to clients’ business operations – and profits and shareholder value, said Fox. “It is crucial that we communicate with clients in a language they can relate to, focusing on value propositions, benefits to be accrued, co-benefits to be exploited, timescales for action and likely costs of inaction.

“Through taking this opportunity, our profession can help to ensure that adaptation is not abandoned in the decades to come.”

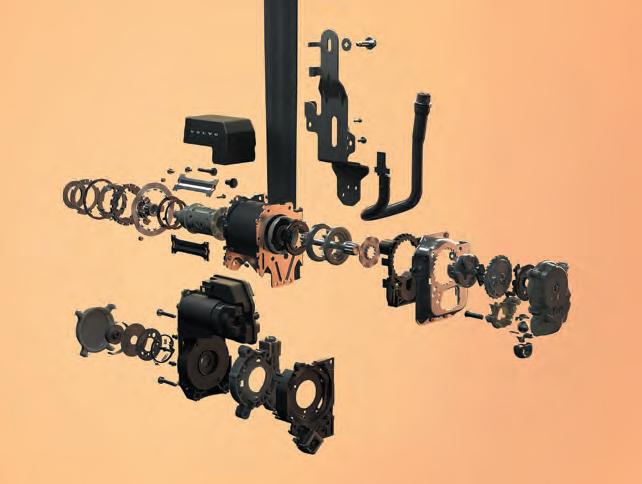

Above and left: The multi-adaptive safety belt can utilise data from different sensors positioned around a vehicle

The humble seatbelt just got an upgrade. This is the world’s first multiadaptive safety belt, designed to adapt to both traffic variations and the person wearing it in real time. It draws on a suite of sensors around the car to adjust the tension in the belt and reduce the risk of serious injury. For example, larger occupants in high-speed crashes might get a higher belt load to reduce the risk of head injuries, while smaller people in milder crashes might get a lower one to reduce the chance of rib fractures. The belt will debut in the electric Volvo EX60 in 2026. Here you can see an exploded view of the various components of the system, which was fine-tuned by Volvo engineers using a database of more than 80,000 real-life accidents.

CEJN eSafe 320 couplings offer high flow with a low-pressure drop, enhancing tool performance for increased productivity. Their innovative patented design vents downstream pressure before disconnection, effectively eliminating hose whip and reducing noise.

They also require low connection force and have a compact, easy-grip design that can be operated with one hand, making them quick and easy to use.

CEJN eSafe is the ultimate high-performance safety coupling with unparalleled durability for long-term use.

ventedsafety- onehandoperation - stainlesssteel- ISO4414

FIVE FOR THE FUTURE

Meet the scientists and researchers improving the world through engineering. For more, head to imeche.org/news

MIT engineers have developed an atmospheric water harvester that can pull moisture from even the driest air without the need for power. The device is a black, window-sized panel made from a water-absorbent hydrogel coating in a cooling layer. The researchers say the technology could be used to passively supply a house with drinking water.

can control live beetles with video game controllers thanks to a removable backpack that steers them in the desired direction. They hope the technology could be used for search and rescue.

OVERGROUND

UNDERGROUND

01 05

Researchers at the University of Southern California have created miniature flexible electrical stimulators that can be secured to the spine and triggered with ultrasound to reduce the symptoms of chronic pain without the need for a bulky battery.

04 03

Engineers have designed ‘living tattoos’ for buildings that could monitor pollution and reduce heat stress. The Remedy project, a collaboration between several European research institutes, is developing ink that contains microorganisms with various properties that can be applied to buildings with an inkjet printer.

Tube trains in London will run on solar power as part of a deal between EDF and Transport for London. One fifth of the operator’s output will come from a new solar farm in Essex as it strives to use 100% renewable energy by 2030.

Discover how Advanced Engineering 2025 is celebrating the Year of Rail, spotlighting innovation, hydrogen and cross-sector collaboration

Q: Why has Advanced Engineering chosen to spotlight rail for 2025?

A: Rail is at a pivotal moment. As the sector faces rising pressures – from climate resilience and decarbonisation to ageing infrastructure and digital transformation – it’s clear that the future of rail depends on fresh thinking.

Advanced Engineering is positioned to support that shift. By bringing together innovation from aerospace, automotive, energy and more, the show provides a space where the rail industry can discover new materials, smarter systems and proven technologies that can be adapted to meet its own challenges.

Q: What can visitors expect from the rail presence at future shows?

A: Advanced Engineering will continue to show how the rail industry is breaking out of silos and embracing cross-sector innovation. Visitors can expect a focus on emerging technologies, from composites and lightweight materials to AI, intelligent monitoring and climate-adaptive design, all aimed at building a safer, more efficient and sustainable rail network.

There’ll also be growing attention on the need to rethink long-standing standards that can slow innovation. As the sector looks to adopt solutions already proven in aerospace, automotive and energy, the conversation is shifting from “can we?” to “how soon?”

Q: How is the rail industry collaborating with other sectors at the show?

A: Today’s rail operators and suppliers are working closely with composites manufacturers to reduce carriage weight, consulting with aerospace engineers on systems design and looking to the energy sector for hydrogen storage and transport solutions.

For instance, rail engineers also collaborate daily with civil, electrical and mechanical engineers to ensure the smooth, safe and sustainable operation of railway systems. The rail content at the show has very much been designed with these overlaps in mind –to help spark collaboration and get all these people in one room together for meaningful communication.

Q: Hydrogen is a hot topic. How is it relevant to rail at the show?

A: At this year’s show, you’ll find exhibitors and speakers tackling these issues from a rail perspective, covering everything from modular storage and pressure vessels to safety standards and

system integration. It’s a great chance to see how hydrogen tech developed for automotive and aerospace is now being adapted for rail, helping to drive the sector towards a cleaner future.

Q: Any final thoughts for rail professionals considering attending?

A: Absolutely – if you work in rail or want to get into the sector, you can’t miss this year’s event. Whether you’re an engineer, buyer, policymaker or innovator, Advanced Engineering 2025 is a chance to step outside your usual silo and connect with adjacent sectors doing incredible things in materials, systems and sustainability.

We’re putting rail front and centre – not just the big-picture challenges like decarbonisation and modernising infrastructure, but also the real technical advances driving progress. Think highspeed rolling stock, smarter signalling, predictive maintenance using AI and breakthroughs in power and propulsion. You’ll leave with practical insights and new contacts to keep momentum going. LEARN MORE

Ahead of a new IMechE report due later this year, we look at some of the challenges faced by engineers in trying to make mass transit more accessible

Anyone who’s tried to cross a city in a wheelchair or while pushing a pram will be painfully aware of the shortfalls of the UK’s public transport system when it comes to inclusivity. Research from the National Centre for Accessible Transport found that 79% of disabled people travel less often and 84% experience longer journey times due to barriers like cluttered pavements, a lack of step-free access and poor staff assistance. Outside of London, a lack of connectivity between transport modes means many journeys are impossible to complete on public transport – even for non-disabled people.

Isolation and exclusion

This has a huge impact on the wellbeing of disabled people, reducing access to work, health and leisure opportunities. Studies have found that the difficulty of accessing transport contributes to the fact disabled people have lower employment rates – 53.1% in the second quarter of 2024, compared with 81.6% for nondisabled people, according to official figures. Lack of available transport worsens social isolation, stress and anxiety, and creates a cycle of exclusion and inequality. But fixing these challenges isn’t easy. The UK’s transport network is a complex web of different operators: a single city may have

multiple bus companies and train or tram networks, governed by different regulations. Infrastructure upgrades provide opportunities to improve accessibility from the design stage, when it is easier and cheaper than retrofitting old kit and crumbling stations.

In Belfast, the £340m Grand Central Station project includes accessible features such as ticket machines with height-adjustable screens, help in sign language and a sensory nook respite area for neurodivergent people.

In England, Merseyrail’s new fleet of trains have been praised for their automatic sliding step that opens to meet the platform edge for unaided level boarding, as well as wider aisles and a continuous carriage, making it easier to move around.

to improve railway accessibility, but it only applies to specific changes to create accessible routes to or between train platforms. It doesn’t ensure level boarding when a train has pulled into the station.

Competing goals

Tension also arises with net zero goals, for example a move towards the use of e-bikes and e-scooters has stirred controversy due to them blocking pavements.

79% of disabled people travel less often because of public transport barriers

For engineers, though, improving the status quo requires a number of considerations. The first is the need to interface with existing infrastructure – our 200-yearold rail network is not easy to make quick changes to, and any significant work might require closing stations temporarily, thereby reducing accessibility in that area in the short term. Funding is also limited: the government’s Access for All scheme has been running since 2006 to try

However, engineers have a key role to play in helping people travel comfortably and navigate our multimodal network. Plenty can be done to harness this expertise, and the Institution’s policy team is working with expert members from the Automobile, Railway and Manufacturing Industries Divisions to find solutions. An IMechE report on inclusive transport, to be published in autumn, will also make a number of recommendations for improving accessibility on public transport.

Head to imeche.org/policy-andpress/reports to read the latest policy reports from IMechE, including the upcoming report on inclusive transport

IMechE member Steve Fletcher is exploring ways to keep the magic of iconic cars alive in the electric, selfdriving era. By Alex

Eliseev

The day Lotus launched its “intoxicating” Emira sports car – a “track beast” with a price tag north of £80,000 – few people were thinking about its windscreen wipers. But Steve Fletcher was. He was thinking about them a lot.

The engineer joined Lotus when the Emira was nothing more than an idea, waiting to become a design. With his team, Fletcher worked on the car during the Covid years, emerging with the “world’s fastest four-cylinder sports car”, which screams around corners, leaving echoes of Lotus lore in its wake.

Fletcher was there on launch day, in the summer of 2021. He, and everyone else at Lotus, had hoped for clear skies and sunshine. Instead, they got rain. Bucketloads.

“There was a torrential thunderstorm in Norfolk. It was chucking it down,” he remembers. “The car was still a prototype. It hadn’t done many development miles. It had never really been out in the rain. It came out, with (Lotus’) Gav Kershaw driving it, windscreen wipers at full pelt, working properly. I was like ‘Yes!’”

To understand his excitement, one has to travel to the streets of Coventry, where he grew up “in

the shadow of” Jaguar’s factory, and back to the 1980s and 90s, when Ferrari F40 and Porsche 959 posters adorned his bedroom walls.

Always having a go

One of four children, Fletcher grew up in a busy home near the Browns Lane plant (which Jaguar no longer uses). His mother worked as a nurse and his dad as a tradesman.

Helping his dad fix cars, Fletcher adopted an “I’ll have a go” attitude, which spilled over into dismantling stopwatches, clocks and televisions – with mixed success.

“Everyone I knew, their dads worked at the Jag factory or some other car plant,” Fletcher explains. “I was super-inquisitive about anything mechanical. For a while, I broke everything. Then, as I grew

The ELESA standard in your favorite COLOUR

The

up, I started to break fewer and fewer things.”

With guidance from a physics teacher he remembers fondly, he decided to study mechanical engineering at the University of Leeds. He loved physics, with its balance of logical mathematics and abstract weirdness (like quantum mechanics) – but was steered towards mechanical engineering as ‘applied physics’. He was also a keen musician, playing bass guitar for a covers band that was filling out some big venues and had a residency at a local bar.

From musician to conductor

With his engineering degree, Fletcher landed a spot on Jaguar’s graduate programme. He’d done a lot of FEA (finite element analysis) simulation during his studies, which came in handy at Jaguar.

He worked on projects like the XF model, analysing side and rear crash simulation models and feeding them into the design.

“This was absolutely foundational. I worked on some amazing projects,” Fletcher says. “Our analysis drove a lot of the design.”

After about six years, Fletcher joined Tata Motors, which coincidentally landed up buying Jaguar. He started travelling to India, to train and develop teams. He also helped draw up a roadmap for the company to break into global markets.

In the years that followed, Fletcher worked at a consulting firm, popped back to spend another year at Tata, jumped in for a thrilling ride at Lotus and tried out a few start-ups. He grew from an engineer solving problems into a business leader, managing teams and designing organisational structures.

Fletcher studied further and was exposed to global client work and business development. Or, as he likes to frame it, he went from

being a musician in the orchestra to a conductor, who had learned to be comfortable with the fact that he can’t play every instrument.

Earlier this year, Fletcher, an IMechE member, joined DRVN Automotive Group as technical director. It was another job that “scared the hell out of my wife”, he jokes. That’s because it was an adventure with a young company out to capture the illusive magic of “peak analogue” – restoring or replicating classic cars from bygone eras.

DRVN is a low-volume business, associated with a handful of big motoring brands, from Ferrari to Ford. The company is designing its own “reimagined” classics

‘The hardest decision I ever made was to leave Jaguar. But I didn’t want to be the guy riding it out until my pension’

– which are top secret at the moment – but most of its efforts go into modifying or recreating heritage cars (like the Ford Escort RS Mk1), driving them into the 21st century. This includes using new, lightweight composite materials or boosting the performance of a powertrain. There’s also a big focus on optimising parts and improving the driver’s experience.

While DRVN is exploring alternate fuel technologies to lower emissions, it’s not turning internal

combustion cars into electric vehicles. Fletcher says their clients are after that “visceral sensation” that came before today’s “iPhone type of vehicles”.

He is enjoying the new challenge and loves finding simple ways to understand incredibly complex engineering problems – like how to improve a set of windscreen wipers from the 1960s.

Don’t be a passenger

Fletcher still plays bass, although not as much nowadays, and has two children. He also likes to run and conquered the London marathon a couple of years ago.

To engineers just setting out on their journeys, his message is all about remaining firmly in the driver’s seat.

“Own your career,” he says. “The hardest decision I ever made was to leave Jaguar. But I didn’t want to be the guy riding it out until my pension.

“A lot of graduate engineers are looking for a business to help them. Flip this around. Make your own decisions. And ask questions. Even the dumb ones. You’ll usually find there are five other people in the room who don’t know the answer.”

To nominate an IMechE member making a difference, email profeng@ thinkpublishing.co.uk

Young engineers got the full rail industry experience at IMechE’s Railway Challenge. By Joseph

Flaig

Teams of aspiring engineers tackled some of the rail industry’s most pressing challenges in June, demonstrating new ways to optimise passenger comfort, regenerative braking and auto-coupling with bespoke locomotives. Designed to show the interesting and rewarding careers available in the sector, the IMechE Railway Division’s annual Railway Challenge returned to the Stapleford Miniature Railway, near Melton Mowbray in Leicestershire, from 26-29 June.

The event’s 14th year featured 12 full teams, including university students as well as apprentices and graduates already working in industry. Eight groups brought locomotives to the competition, which featured both static and dynamic challenges.

The joint team from Network Rail and Colas Rail came out on top overall, with victories in the energy storage, auto-coupler and business case challenges. Two of the three

international groups made up the rest of the podium, with Germany’s Team Eagle from the Nürnberg Institute of Technology in second and FH Aachen’s FH2Rail in third.

Among the new additions to the competition was the ride-on challenge, meaning teams could design their locomotives to accommodate drivers for the first time, instead of requiring them to sit on the first passenger carriage. Four took the opportunity, with Poznan University of Technology winning that component.

Smaller,

Set in gentle rural surroundings, the 10¼ inch (260mm) gauge railway at Stapleford Park informed some of the challenges.

The markers for the energy storage challenge, for example, were on a flat stretch of track next to the lake, which buzzed with dragonflies and butterflies in the hot June sun. A sloping section was used for the traction challenge,

where the teams’ locomotives had to accelerate while pulling two coaches.

“They learn then that it’s not just about having a lot of power, because the wheels could slip,” explained Simon Iwnicki, chair of the challenge’s organising committee.

Other track events included the passenger comfort challenge, which measured acceleration, and the auto-coupler challenge, automation of which is a focus for the industry. In the maintainability challenge, teams had to remove a powered wheelset from the locomotive as quickly as possible, then put them back and start moving again.

“We’re throwing them real-life problems… to see what sort of novel ideas they can come up with,” said Andrew Skinner, immediate past-chair of the division. “There’s a lot of established solutions, but are there smaller, lighter ones for the same problem?… Weight is a key thing for us.”

The track also featured a new turntable, which helped prevent delays and should enable the competition to more than double capacity in future.

Taking part in the competition gives aspiring engineers solid technical experience, said Alice Callaghan, a competitor in Ricardo Rail’s winning 2018 team and now a challenge judge. “It might be their first proper experience of the railway – you might not know what a bogie is before you do this, but you’ll definitely know by the end of it,” she said.

‘Hands-on experience’

She continued: “It’s understanding the set-up, understanding signalling, understanding how it’s happening, for a full appreciation of the railway. That’s really important – a lot of the time you don’t get the opportunity to be really hands on, and having that hands-on experience is just brilliant.”

The industry as a whole benefits from the challenge, she added –a previous Birmingham team had a hydrogen locomotive, for example, which fed into work on the Hydroflex mainline locomotive with Porterbrook.

“They’re all quite sophisticated machines,” said Iwnicki. “We provide a specification and a set of rules; they’re not very detailed documents. We want them to be

as free as they want to be in the way they design them, obviously within limits: they have to run on our track and fit through the tunnel, and be safe to operate.

“But they can choose any form of motor power, any form of control… We try to mimic the challenges that are real in the railway industry.”

The event also offers great opportunities for networking and discussions with senior employees from major rail and transport organisations, the organisers said, such as chief judge Bill Reeve, director of rail for Transport Scotland. Lots of the students that have taken part are now in senior positions in railway companies, Iwnicki added.

Aspiring engineers at the event learn from each other as well as senior colleagues, said Callaghan. Locomotives are inspected for potential upgrades for next year, and teams get bonuses for going out of their way to be helpful.

“A team might lend a piece of equipment, or they might have a spare part that they can share with others,” Callaghan said. “It’s just

‘You might not know what a bogie is

before you do this challenge, but you’ll definitely know by the end of

it’

really friendly; you go around and you see what everyone else is doing and you learn. That’s the way it works – and that’s the way the railway is as well.”

As well as 12 full teams, five entry-level teams were also present, benefiting from the open sharing of knowledge. One group of students from Monash University in Melbourne, Australia, attended, bringing a virtual design with the intention of returning in 2026.

“The teams are really nice and they were very willing to answer our questions. So, just by being here, we already have a much better idea of how we should redesign our locomotive,” said Patrick McCarthy, chief technology officer of the Monash Railway Express team at the university. “We’re looking to get a minimal viable product – and we have to make it quickly, because it’ll take three months to ship overseas to the UK.”

Travelling all that way – and planning to transport a locomotive the same long distance – reveals how valuable the event is. “Australia has a really big industry in rail, and currently there’s pretty much only a few courses,” McCarthy said.

“The only way that people learn is by getting a job in a rail company and learning from there. So what we’re trying to provide for Australians is that stepping stone into the rail industry, which currently just doesn’t really exist.”

For more information on how to enter IMechE competitions and challenges, visit imeche.org/ events/challenges

Got something to share with the IMechE community? Write to us at profeng@thinkpublishing.co.uk, using the subject line ‘Your Voice’

In his article ‘Could better batteries electrify rail travel?’ (issue one of 2025), Chris Stokel-Walker repeats the much-quoted figure of only 38% of our rail network being electrified. But this is measuring in route-miles, not by usage. Given the high capital cost of electrification, it is inevitable that the busiest lines are electrified first. If measured in passenger-miles (i.e. usage), that figure jumps to nearer 70%. Similarly, our motorways are a modest percentage of the road network in length, but carry a much larger share of total traffic.

The Merseyrail extension cited, using batteries, was absurd: just one mile of relatively cheap third rail (not overhead) electrification

was avoided, at the Office of Road and Rail’s insistence, for unnecessary complexity and cost on the trains that are proving troublesome. Where our rail network desperately needs electrification is in in-fill schemes, notably for long-distance freight traffic, e.g. the short branch lines to the ports at Felixstowe and London Gateway, but also for passenger services such as to Uckfield in Sussex – currently diesel in otherwise electric

I have been a membership adviser for a number of years, focusing on member to fellow upgrades. My role is to review applications against the defined competencies and make a recommendation to the Professional Review Committee as to whether the applicant should be upgraded to FIMechE. It’s been a fascinating, enjoyable and rewarding experience learning how others are progressing their professional careers in the wonderful and diverse world of engineering.

However, assessors return a significant number of applications as the information and evidence provided is incomplete. A reasonable conclusion is that the sponsors have not carried out a critical review of the application and worked with the applicant to ensure it meets the criteria. At least one sponsor should be a fellow of IMechE or another professional institution registered with the Engineering Council, so should be familiar with the process and its requirements. The guidance notes state: “You should discuss your application in detail with your sponsors to ensure they agree with the information you have provided. They are signing the form to indicate that they believe you are suitable for consideration as a fellow of the Institution of Mechanical Engineers.” Applicants, pick your sponsor with care and use them as your mentor to help you present an application that will be successful. Sponsors, it’s a privilege and a responsibility to be asked to sponsor an application, so do take time to review the application and advise as necessary.

Applicants, pick your sponsor with care and use them as your mentor to help you present an application that will be successful

Wishing future applicants at any grade every success with their applications. Bob Hayes

territory. Scotland has led the way with a rolling programme of electrification, which keeps construction teams together and progressively reduces both capital and operating costs. David Odling

The International Energy Agency’s inability to accurately predict deployment of global renewables (‘The hydrogen revolution’ in issue

one of 2025) is quite well known. It is also known for a bias towards traditional energy generation methods. For the sake of balance, could ProfessionalEngineering compare its predictions for hydrogen’s annual demand in 2050 to another source?

The brilliant Auke Hoekstra of Eindhoven University has compared predicted solar deployment against actual for several IEA annual growth reports.

Joshua Knight

Patron: His Majesty King Charles III

Supporting members and STEM projects worldwide

DIVERSE people need diverse support. That's why, at Support Network, we tailor our responses to meet individual circumstances.

We're the personal, practical, and emotional support organisation for IMechE members and their families worldwide. All our support is free and confidential.

We know that no two situations are the same. Life brings various challenges: health issues, financial

difficulties, or unexpected changes like unemployment or bereavement. We assist in all these areas and more. Our small paid team works alongside volunteers drawn from the IMechE membership, who help with visits and initial assessments, and also contribute strategically as Trustees.

Over the last five years, our Foundation Funding work has given support to STEM projects in the overlapping areas of international development. education and engineering innovation. We can reach many more people in this way.

In this Annual Review, you'll find examples of our foundation work

plus comments from members we've helped. It presents performance statistics and a financial breakdown, including member donations, which are gratefully received. Finally, you'll read the perspectives of some of our Trustees.

In 2025-2026, we'll conduct a member survey and focus groups seeking your feedback and suggestions for further development. In the meantime, we hope you enjoy reading about our work and what Support Network provides for the wider IMechE community.

ANNI BROADHEAD, Chief Executive Officer, Support Network

1111

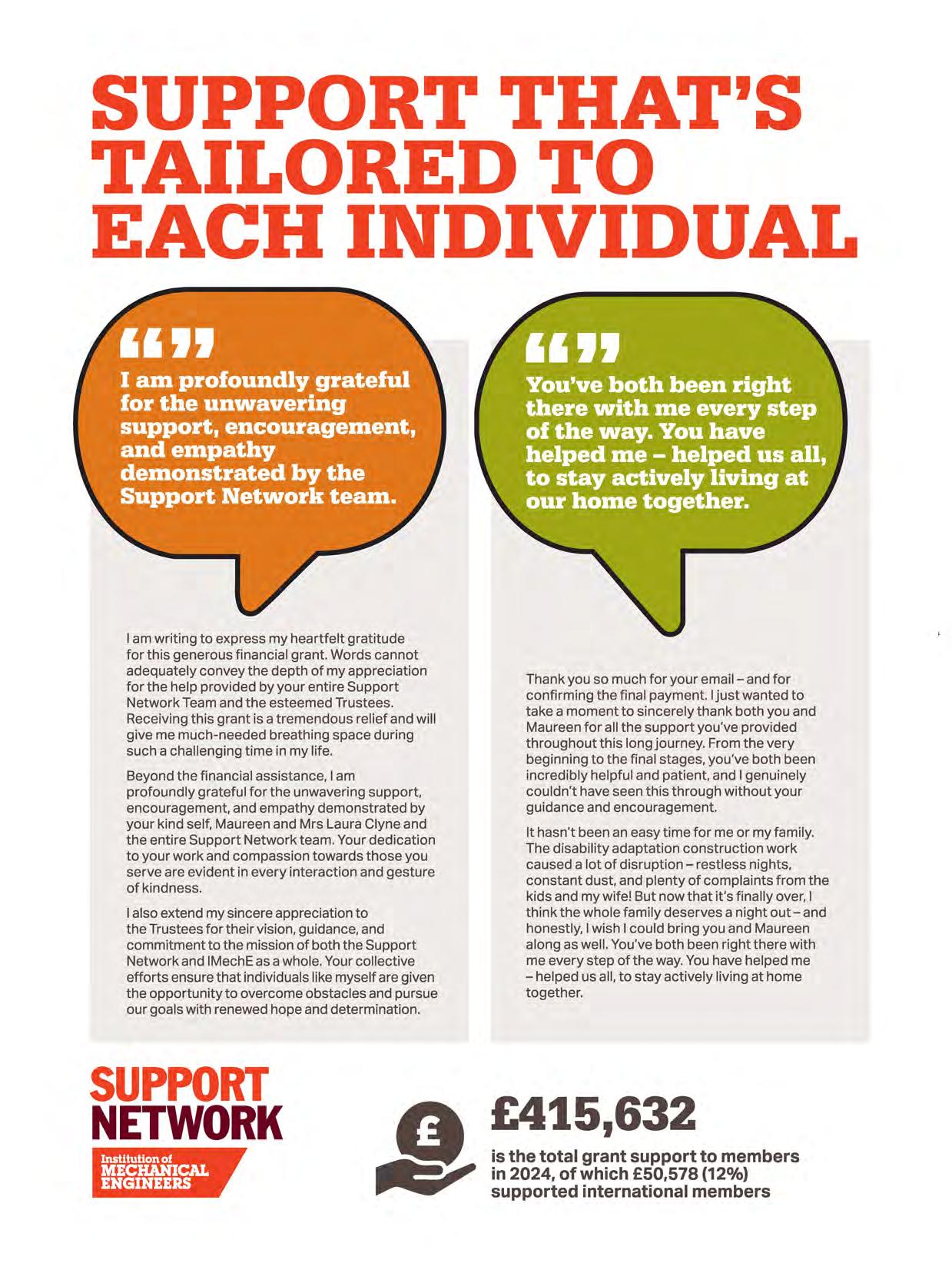

I am profoundly grateful for the unwavering support, encouragement, and empathy demonstrated by the Support Network team.

I am writing to express my heartfelt gratitude for this generous financial grant. Words cannot adequately convey the depth of my appreciation for the help provided by your entire Support Network Team and the esteemed Trustees. Receiving this grant is a tremendous relief and will give me much-needed breathing space during such a challenging time in my life.

Beyond the financial assistance, I am profoundly grateful for the unwavering support. encouragement. and empathy demonstrated by your kind self, Maureen and Mrs Laura Clyne and the entire Support Network team. Your dedication to your work and compassion towards those you serve are evident in every interaction and gesture of kindness.

I also extend my sincere appreciation to the Trustees for their vision, guidance, and commitment to the mission of both the Support Network and IMechE as a whole. Your collective efforts ensure that individuals like myself are given the opportunity to overcome obstacles and pursue our goals with renewed hope and determination.

Thank you so much for your email -and for confirming the final payment. Ijust wanted to take a moment to sincerely thank both you and Maureen for all the support you've provided throughout this long journey. From the very beginning to the final stages, you've both been incredibly helpful and patient. and I genuinely couldn't have seen this through without your guidance and encouragement.

It hasn't been an easy time for me or my family. The disability adaptation construction work caused a lot of disruption -restless nights, constant dust. and plenty of complaints from the kids and my wife! But now that it's finally over, I think the whole family deserves a night out-and honestly, I wish I could bring you and Maureen along as well. You've both been right there with me every step of the way. You have helped me -helped us all, to stay actively living at home together.

£415,632

is the total grant support to members in 2024, of which £50,578 {12%) supported international members

I hope to one day be in a position to give back and support your organisation in achieving its goals.

Thank you very much for following up with us. My son had his test on Monday and the initial feedback from the assessor confirms our thoughts that he does indeed have a level of dyslexia. This now provides the tangible evidence for his EHC (Education, Health and Care) plan application to hopefully enable future Special Educational Needs support for him. We now have everything in place for the EHC plan application.

I can't emphasise how grateful my wife and I are for the IMechE support and your specific help with this; it has now given us the best chance of getting support in good time before secondary school transition. I'll check the payment arrives OK, but thanks to you and your team once again for some fantastic support.

I am writing to express my sincere gratitude for the Christmas hamper I received yesterday evening from Support Network. It was such a wonderful surprise and I am so grateful to be remembered at this time of year. Losing my partner so suddenly was difficult. Support Network has been invaluable to me, and I am truly thankful for all the help and support I have received.

Now that I have started my pension and am working on my projects, I hope to one day be in a position to give back and support your organisation in achieving its goals. Thank you again for your kindness and generosity. I wish you and everyone at Support Network aver happy festive period.

It has been a privilege and pleasure to work alongside the Sky is the Limit team and Support Network in Uganda, as together we are helping some of the most needy children and young people in Fort Portal via the school and linked farm project.

It was great to see the new farmhouse completed, irrigation system installed, and new crops developed to supply the school children with additional nutrition and regular meals. We look forward to the establishment of the new poultry shed and three-year development plan for the school, which will be transformational.

All of this has been made possible by the kind and generous donation of resources by Support Network and IMechE members, and we look forward to continuing the journey together over the coming years Thank you!

MATTHEW BAND

CEO Mondo Foundation

In countries outside of the UK where there is high demand, we now work directly with partner universities to support final-year mechanical engineering students in financial difficulty.

The universities help us to focus our support on those students who need it most. In 2024, we worked with seven universities in Nigeria and Malaysia, supporting 92 students. In 2025-26, we will expand this programme further, initially reaching out to all universities and countries where the IMechE has a student chapter. In 2025, we aim to work with universities in Angola, Ghana, India, Palestine, Pakistan, Papua New Guinea, and the West Indies.

LAURA CLYNE

Operations and Services Director, Support Network

Our Foundation Funding work enables Support Network to reach much further. We support STEMrelated projects on a global basis in education, international development and engineering innovation. This is a valuable extension of our core work. We now contribute to 14 of the 17 United Nations Sustainable Development Goals.

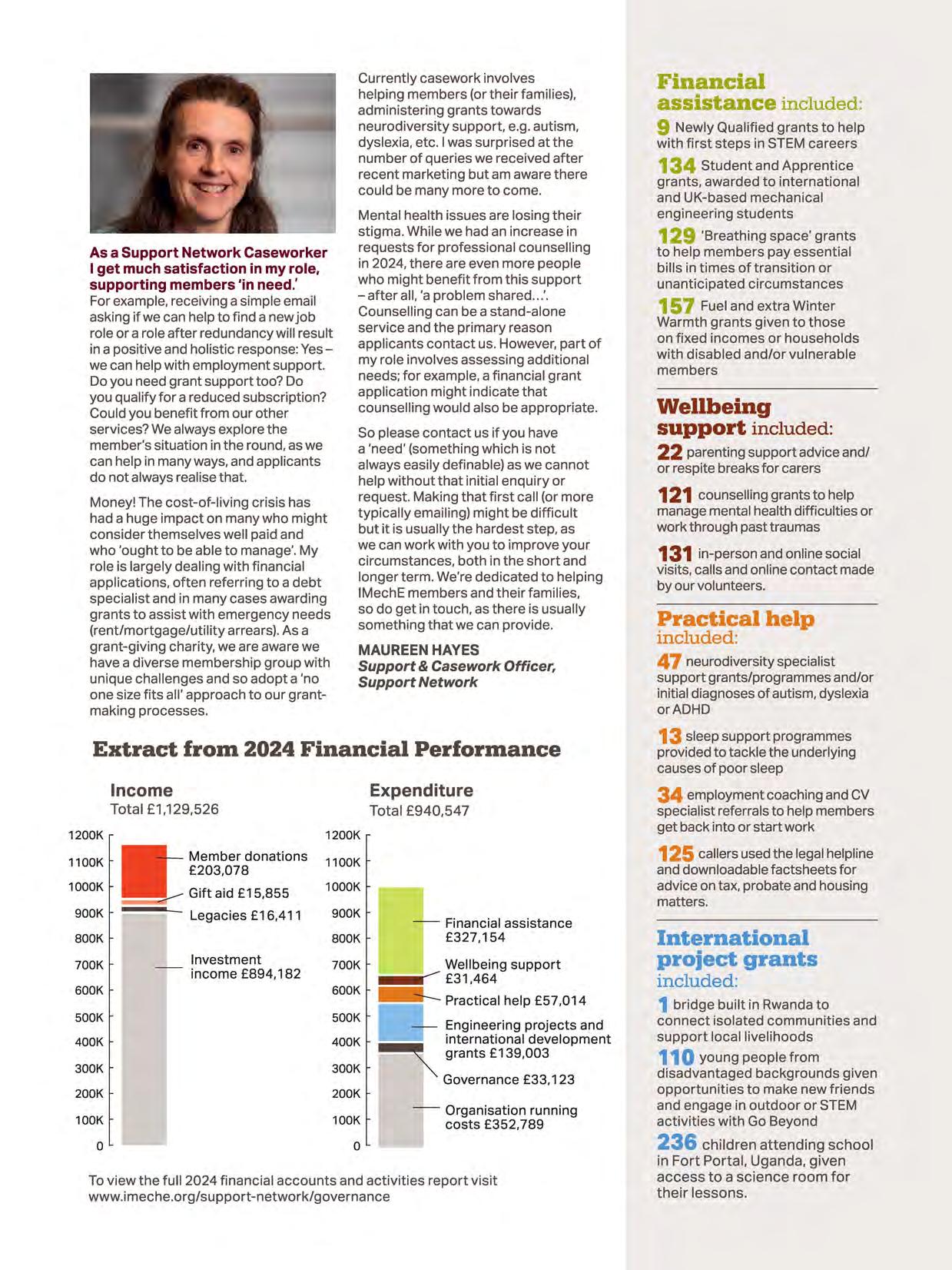

As a Support Network Caseworker I get much satisfaction in my role, supporting members 'in need.'

For example, receiving a simple email asking if we can help to find a new job role or a role after redundancy will result in a positive and holistic response: Yeswe can help with employment support. Do you need grant support too? Do

Currently casework involves helping members (or their families), administering grants towards neurodiversity support. e.g. autism, dyslexia, etc. I was surprised at the number of queries we received after recent marketing but am aware there could be many more to come.

Mental health issues are losing their stigma. While we had an increase in requests for professional counselling in 2024, there are even more people who might benefit from this support

-after all, 'a problem shared .. .'. Counselling can be a stand-alone service and the primary reason applicants contact us. However, part of my role involves assessing additional needs; for example, a financial grant application might indicate that counselling would also be appropriate. you qualify for a reduced subscription? Could you benefit from our other services? We always explore the member's situation in the round, as we can help in many ways, and applicants do not always realise that.

Money! The cost-of-living crisis has had a huge impact on many who might consider themselves well paid and who 'ought to be able to manage'. My role is largely dealing with financial applications, often referring to a debt specialist and in many cases awarding grants to assist with emergency needs (rent/mortgage/utility arrears). As a grant-giving charity, we are aware we have a diverse membership group with unique challenges and so adopt a 'no one size fits all' approach to our grantmaking processes.

So please contact us if you have a 'need' (something which is not always easily definable) as we cannot help without that initial enquiry or request. Making that first call (or more typically emailing) might be difficult but it is usually the hardest step, as we can work with you to improve your circumstances, both in the short and longer term. We're dedicated to helping IMechE members and their families, so do get in touch, as there is usually something that we can provide.

MAUREEN HAYES

Support & Casework Officer, Support Network

assistance included:

9 Newly Qualified grants to help with first steps in STEM careers

134 Student and Apprentice grants, awarded to international and UK-based mechanical engineering students

129 'Breathing space' grants to help members pay essential bills in times of transition or unanticipated circumstances

157 Fuel and extra Winter Warmth grants given to those on fixed incomes or households with disabled and/or vulnerable members

support included:

22 parenting support advice and/ or respite breaks for carers

121 counselling grants to help manage mental health difficulties or work through past traumas

131 in-person and online social visits, calls and on line contact made by our volunteers.

help included:

47 neurodiversity specialist support grants/programmes and/or initial diagnoses of autism, dyslexia orADHD

13 sleep support programmes provided to tackle the underlying causes of poor sleep

34 employment coaching and CV specialist referrals to help members get back into or start work

125 callers used the legal helpline and downloadable factsheets for advice on tax, probate and housing matters.

International project grants included:

1 bridge built in Rwanda to connect isolated communities and support local livelihoods

110 young people from disadvantaged backgrounds given opportunities to make new friends and engage in outdoor or STEM activities with Go Beyond

236 children attending school in Fort Portal, Uganda, given access to a science room for their lessons.

MARTIN BURROWS F/MechE

Career in pressure vessel design, manufacturing, oil and gas sector. IMechE Fellow since 2011.

WENDY GARNER Chartered Engineer

Former manufacturing engineer for Rolls-Royce and academic at Coventry University.

Having recently retired, I am keen to continue my links with engineering and especially to help the young engineers of the future. Working as a Trustee for the IMechE Support Network gives me the opportunity to use my engineering and academic experience to do this. I very much look forward to the year ahead and being part of the good work that the Support Network team delivers.

I enjoy volunteering as a Support Network Visitor because I find it interesting to listen to other engineers talk about their careers and have the opportunity to offer support when it is needed. I became a Trustee to help me understand how the Support Network operates and help where possible to contribute to its ongoing success.

MAJULA RAJAPPA Young Member Trustee

University can be a rough path to tread alone. Many of us have had to juggle financial worries, family obligations, and sometimes even the responsibility of caring for a loved one. As such, it can be lifechanging to receive support from any available channel. Support Network is one such source. Not only has Support Network helped me as a student and Newly Qualified beneficiary, but it also provided me with an amazing opportunity to give back.

When I started as a Young Member Trustee, I was the first Trustee to still be studying. I was therefore able to bring a unique perspective, drawing from my lived experience of being a student. I was able to speak about being part of an applicant group. My years on the Trustee board have been enlightening, as I have encountered diverse situations and perspectives. Engineers have challenges too!

I highly recommend young engineers to consider engaging with Support Network for an enriching experienceeither as a contributor or as a recipient.

or engineers with a passion for solving complex challenges and working on mission-critical technology, there’s never been a better time to take your career to new heights. At BAE Systems we’re recruiting to support cutting-edge radar products, and we want to hear from talented individuals at every stage of their professional journey.

BAE Systems provides some of the world’s most advanced, technologyled defence, aerospace and security solutions, helping customers stay ahead of evolving threats across land, sea, air, cyber and space. Cowes on the Isle of Wight acts as the central hub for radar innovation and collaboration, a unique site with industry-leading facilities. Our team and opportunities are also based in Portsmouth and Chelmsford.

We’re revolutionising radar capability and embarking on a once-in-a-generation portfolio refresh where we demonstrate and leverage innovative technology into a new product offering, supporting the UK’s campaign for Future Air Dominance and establishing leading capability with our customers across the globe.

ENGINEERING ROLES ACROSS DISCIPLINES

Our radar sector demands the expertise of engineers in disciplines including: l Mechanical Engineering – design and develop the physical structures and thermal systems that house and

protect advanced radar equipment.

l Systems Engineering – integrate complex subsystems into cohesive, high-performing solutions that meet the requirements of our clients.

l Electronic and Electrical Engineering – drive the development of signal processing, power systems and critical control electronics.

l Software Engineering – develop and optimise the real-time code that powers radar systems, from algorithm design to UI development.

l Integrated Logistics Support – ensure long-term maintainability and reliability of systems during their lifecycle.

l Systems Design Authorities – provide strategic oversight and technical leadership on all programmes.

l Project and Engineering Management – lead the delivery of exciting and complex projects and drive people development and career progression. No matter your speciality, you’ll work with multidisciplinary teams, leveraging stateof-the-art facilities and collaborating with the brightest minds in the industry.

CULTURE OF INCLUSION AND EXCELLENCE

Innovation thrives on diversity, and we are committed to building an inclusive workforce. We strongly encourage applications from individuals who are under-represented in engineering and technology, including women, people

Ready to dive into a new challenge? BAE Systems is hiring talented engineers across various disciplines

from ethnic minority backgrounds, individuals with disabilities and LGBTQ+ professionals. We also support veterans and reservists, recognising the unique skills and perspectives they bring.

MODERN WAYS OF WORKING

We understand that applicants want a healthy work-life balance and an environment that supports wellbeing. That’s why we embrace modern working practices that prioritise flexibility and autonomy without compromising on collaboration or performance.

Many radar roles are based on the Isle of Wight, home to our flagship radar site and a growing community of engineers and technologists. It’s an exciting place to live and work, with scenery and lifestyle to suit all. We offer competitive relocation packages and preferential rates on connections to the mainland.

READY TO TAKE THE NEXT STEP?

If you’re ready to make a real impact in radar technology and join a forwardthinking team that values innovation, inclusion and excellence, visit our careers page and join our Talent Community for opportunities, company news and invites to events and webinars.

IMechE is working to make sure AI is safely incorporated into autonomous systems, writes Robin Sarfas, the Institution’s engineering community impact manager

Automation is increasingly used in every mode of transport. Beyond vehicle control, AI is being applied to assist or replace human task elements in system design, maintenance and operation, and these challenges are fundamental to most human-centered systems being disrupted in this way.

IMechE is driving forward a programme, motivated by its 132nd president Carolyn Griffiths and co-sponsored by the Royal Academy of Engineering and the Parliamentary Advisory Council for Transport Safety, to establish better practices to safely integrate autonomous systems. During her time as chief

of the Rail Accident Investigation Branch, Griffiths saw her fair share of accidents caused by inadequate understanding and anticipation of human performance. She said: “We must step up our understanding of the range of human performance, how it can change over time or due to other factors, in an automated environment. We are overdue a systematic framework of protocols and principles that ensure we engage new understanding. Engineers must recognise that complex systems require people and technologies to work together, contributing to the performance of the systems

themselves, as well as the impact of system design on behaviour.”

To this end, Griffiths organised the 2024 Thomas Hawksley Lecture by Professor Sarah Sharples, chief scientific adviser at the Department for Transport. The feedback from this event confirmed that this is an area in need of more concerted attention from the engineering community, so Griffiths and Sharples convened a roundtable of 20 of the UK’s top experts to discuss these challenges, focused in four areas. What follows is a summary of each of these challenges and a high-level overview of the key takeaways.

‘AI is often intended to improve over time, so how do we regulate a technology that evolves after its efficacy has been assessed?’

1 How should the engineering design process change with the adoption of AI in transport?

The behaviour of autonomous and AI-enabled systems poses challenges due to the complexity of the systems themselves and their ability to evolve and learn, as well as their operation within a complex and highly variable system of systems. Operator performance will also fluctuate due to natural factors such as health, ageing and ambient conditions. Interactions between the driver, other vehicles, the environment and remote decisionmakers produce an effectively infinite set of circumstances for autonomous systems to process and react to. Iterative design is key to building up the capabilities of the systems to manage this complexity, with initially unforeseen interactions and circumstances emerging in testing. This more agile design process is not yet prevalent, but would provide designers with a wealth of additional data to be the basis of assurance of the system, which includes elements of AI.

A threshold must be agreed upon to define what is “safe enough”. That threshold will be different for different modes: there is a variation in degrees of freedom across transport modes.

Professor Roderick Muttram, who chaired the discussion, noted: “The improvements made in UK mainline rail mean that the last driver errorcaused fatality was at Ladbroke Grove in 1999, over 25 years ago. Any system for controlling trains must achieve a similar level of integrity.”

Realistically, an adoption of a threshold is likely to mean regulation will exclude some technology capabilities where there is less data for assurance from deployment, but this compromise is imperative to help build trust. Moreover, these considerations should feature in design and validation processes, defined as part of the regulated approvals process.

2 How do we develop a means of safety assurance for transport systems that incorporate AI?

Many AI technologies are intended to change and improve over time, learning through exposure to different experiences and circumstances. This presents a challenge for assurance and regulation: how do we regulate a technology that evolves after its efficacy has been assessed?

Machine learning and AI-enabled systems can self-learn from data

collected in operations, but this self-learning should be done in a controlled environment away from production, so it can be validated and verified before being deployed on vehicles in live environments. This need to conduct assurance will limit the rate of change for systems evolving and constrains some of the benefits of ‘continuously deployed AI’, but it is a necessary trade-off to make systems safer. There is also the question of transparency into both the algorithms at the heart of these systems and the performance of AI models within strict intellectual property frameworks. Safety can currently only be assured through an understanding of what is going on in the decisionmaking process. Yet the use of opaque technologies, which even their designers cannot understand, results in the so-called ‘fallacy of explainability’ i.e. the belief that humans can explain their decisions and therefore that it is possible for AI-based systems to produce equally compelling explanations.

A culture where manufacturers work with regulators, extending what is required by the legislation that established air, rail and marine investigation branches, will allow accidents and aberrant performance to be investigated without threatening intellectual property. This open collaboration is essential for safety.

3 How should training evolve to enable engineering and human factors professions to work effectively with AI?

As the technology underpinning safety-critical and safety-related systems evolves, so must the competencies of designers, operators and, to some extent, the public when it comes to products on the market. The obvious answer to this issue is that existing further and higher education courses must evolve with contemporary challenges in mind. There is agreement that teaching young engineers concepts of systems thinking, and generally making courses more interdisciplinary, is to

‘Our experience is that CPD must be grounded in practical issues that are relevant to the domain. We see real willingness to engage at the engineering level’

be desired. However, there is already great pressure on syllabi; there comes a point at which adding more content to undergraduate courses means dispensing with other material. It may take time to incorporate these principles into education, and the skills gap risks widening further, but there is an imperative for change to reflect the technology at large.

Much of the emphasis, at least in the short to medium term, must be placed on engineers’ continuing professional development (CPD) to upskill experienced engineers and meet the requirements for earlycareer professionals taking their first steps in industry. CPD cannot replace education as the process for embedding core competencies in engineers, but it can bridge a gap in workforce capability while technology becomes more widely prevalent, and ensures professionals can remain competent as technology evolves.

Professor John McDermid, director of the Centre for Assuring Autonomy at the University of York, had this to say: “Our experience is that CPD must be grounded in practical issues that are relevant to the domain, e.g. rail or maritime. We see real willingness to engage at the engineering level, but it is also important to provide CPD to policy and decision-makers.”

In the UK, a clear case must be made for regulators, the Engineering Council and professional engineering institutions to embed human factors into both education and CPD, and likewise human factors professionals must be equipped with a robust understanding of the design process.

4 What is needed to support multidisciplinary teams to maximise the impact of AI on transport safety, effectiveness and resilience?

The emphasis on interdisciplinary thinking must go beyond traditional branches of engineering to include

human factors. Incorporating human factors comprehension should be mandated and not ‘left to chance’. Professionals at the interface between engineering and human factors should have both specific understanding of how to identify and mitigate the risks, and how to capitalise on the opportunities of interaction and integration of human performance, automation and AI.

Frequently, human factors concerns are thought to be taken care of simply by the presence of a specialist, rather than being considered at each stage of the design process. There is a risk that businesses only see the true value of human factors when damage is done, either to their bottom line or after a serious accident. Instead, engineers must take responsibility for considering the principles of human factors throughout the design process –embracing human factors expertise rather than seeing it as a box to tick.

Emphasis must be placed on shared experiences and a common language within multidisciplinary teams to change the culture and enable the development of hybrid skillsets. Engineers throughout the value chain must buy into a set of principles underpinned by an all-encompassing appreciation of the relation between engineering, human factors and safety.

Work continues within this programme to define the problems described above and how they can be resolved. This roadmap will build on many sources of research and opinion that already exist and the expertise of those engaged in this workstream. What is clear already is that these challenges will not be overcome individually, in one mode of transport or in one discipline of engineering. Problems emerging for the deployment of new technology in a system of systems require the input of experts drawn from throughout those systems.

he Headquarters Programme aims to address the key challenges facing the Institution’s London HQ and ensure it continues to meet the needs of members, while supporting the Institution’s long-term purpose and strategy.

The programme is entering its next phase as the Trustee Board reviews a shortlist of options – a decision that will help shape the Institution’s future. A preferred option is expected to be selected in the coming weeks. This will be presented to members for approval via a two-week ballot, which will be launched following a hybrid special meeting. All members are encouraged to attend, and eligible members are urged to cast their vote and help shape the Institution’s future. The future of our headquarters is an important and complex decision. We are committed to a thorough, transparent process, and to making a choice that best serves the long-term interests of the Institution and our members. I would like to thank the Headquarters Sponsor Board, and IMechE colleagues and volunteers, past and present, whose commitment and expertise have been vital to getting us to this point. As we move forward, I encourage all members to stay engaged and play their part in shaping the future of our Institution.

Matt Garside, 140th IMechE President

For more information on the progress of the HQ Programme, visit imeche. org/hqprogramme/login

The increasing prevalence of autonomous vehicles will unlock efficiencies in some areas and throw up engineering headaches in others, writes Chris Stokel-Walker

Fleets of self-driving vehicles are coming to the world’s roads. Whether it’s in Phoenix, Arizona, where electric taxis glide to and from their Waymo depot to recharge, or on the streets of the UK following a government decision to bring forward trials, the future is now inevitable.

Waymo provides a vision of what could be around the corner. The firm says its US-based fleet provided 4 million driverless rides last year, cutting 6 million kilograms of carbon dioxide from the air. It was able to achieve this by working its vehicles at a rate humans could never match.

The company’s vehicles spend up to 20 hours a day in service – a rate unimaginable for privately owned cars, not least because human drivers would fatigue long before that. The workload rewards the simplicity and low maintenance of electric drivetrains, but it also requires redefining what a powertrain is when a car never sleeps.

Electric revolution

“The advent of autonomous vehicles marks a significant shift in the automotive industry, promising to revolutionise how we perceive and interact with transportation,” says Otmar Scharrer, senior vice president for R&D e-mobility at ZF Group, a German company that develops vehicle systems. But the always-on nature of how those vehicles work puts pressure on powertrains, he says.

“Autonomous vehicles, designed to operate continuously, demand highly reliable and efficient powertrains,” he says. That means they are likely to run out of steam quicker and be prone to earlier faults than those in traditional vehicles, which are used less frequently and for shorter periods.

“These vehicles will likely require advanced driveline technologies that

integrate seamlessly with braking and motion control systems to ensure optimal performance and safety,” Scharrer says. “The need for continuous operation will drive the development of powertrains that can withstand prolonged use without compromising efficiency.”

Drivetrain durability is one problem. Another is keeping vehicles charged on the road. Slow charging is topped

‘The advent of autonomous vehicles marks a significant shift in the automotive industry’

up with fast charging, but that pace abuses cells so developers are programming vehicles to preheat on the way back to base, pushing cell temperatures upwards so they last longer, extending life by 15% in early trials. The alternative is to simply swap batteries. California start-up Ample robot-swaps a depleted pack for a fresh one in five minutes.

It’s not just vehicles ferrying humans that could benefit from these redesigned, always-on powertrains. Amazon (and subsidiary arm Zoox), FedEx, UPS, DHL and Walmart are

Autonomous electric vehicles like the fifth-generation Waymo Driver on the Jaguar I-Pace are a common sight in Phoenix

all big logistics firms investing in autonomous delivery and trucking.

The problem with driverless vehicles is that you have no human available to understand or fix faults. To solve that problem, Volvo Autonomous Solutions operates duplicated steering actuators, power supplies and sensor fusion computers so the truck can continue or reach a safe stopping spot after a fault.

Beyond catastrophic failure, there is also an engineering quandary in that parts wear out quicker – including the batteries powering the next generation of electric cars. Tesla’s own data shows a noticeable capacity loss after 200,000 miles in their vehicles.

Potential solutions to those issues include predictive maintenance, such as vehicles leaving the depot through a scanner that can flag issues, which early research suggests could improve vehicle availability by around 20%.

The Powertrain Systems for a Sustainable Future Conference 2025 will take place at the British Motor Museum near Warwick from 21-22 October. Find out more and sign up at imeche.org/events

The rise of new technology is transforming engineering and reducing the risk of costly mistakes, writes Chris Stokel-Walker

The old mantra ‘check twice, cut once’ is a vital reminder when making anything – and engineers know more than most about the risks of costly mistakes. While physical prototypes are always useful, the rise of technology enables engineers to simulate and model ideas before putting hard cash into building things.

AI is poised to play a “huge role” in the future of simulation platforms, particularly in creating high-fidelity digital twins that mirror the real world, says Saber Fallah, professor of safe AI and autonomy at the University of Surrey. These digital twins – physical infrastructure or products recreated in silico, where they can be tested with a number of variables – can help optimise and validate assumptions, improving designs in the long run.

“The value of these AI systems is the generation of high-fidelity simulation platforms,” says Fallah. “These models have access to the different types of data – for example, images, LiDAR, canvases, all these things – so they can produce more realistic environments based on data and generate different sorts of environments.”

It’s not just in the ability to produce these simulations that AI has proven transformational. It also makes it easier to spin up simulations without coding expertise. Traditionally, harnessing the power of those data streams and producing high-fidelity simulations would require high-level knowledge of how to develop such models and code them by hand.

With “classical models or physicsbased models, it was really hard to generate a multi-purpose or generalpurpose simulation platform,” says

Fallah. However, large language model-based platforms can turn plain text queries into complicated simulations in an instant – and troubleshoot any errors that arise.

Digital twins have become a buzzphrase within engineering, perceived as a solution to many issues faced by a sector with high overheads and constrained investment. A 2024 survey of industry found that around two-thirds of businesses say the main reason for using digital twins is to optimise processes to be more efficient, while six in 10 say they help support decision making.

One area for more growth is in design and development, with only 40% of respondents saying they

Two-thirds of businesses that use digital twins do so to optimise processes to be more efficient

use twins for that. The team behind the survey, representing several universities worldwide, say digital twins “are gaining popularity in both academic and industrial contexts”.

Beyond catalysing new ideas, the supercharging of simulation also reinforces the ability to fine-tune preexisting designs. Take the design and testing of vehicle safety features, such as crumple zones, roll bars or other areas. “Using reinforcement learning, we can train simulations or agents of

the simulation to create cases that rarely happen in the real world,” says Fallah. That allows manufacturers to test the impact of one-off crashes in silico, rather than in real life.

It’s a principle Fallah and his lab tested themselves with Jaguar Land Rover, designing specific agents using reinforcement learning to maximise the chance of accidents with autonomous vehicles to check the safety of the technology.

But it’s not just worst-case scenarios modelling benefits. For transport infrastructure on roads, rail and in the air, simulation can understand population-level flows. “We can use AI-based simulations to optimise traffic for managing fleets,” he says. “We can also look at public transport network systems and logistics, ondemand and mobility models.”

Fallah can envisage a future where governments and testing bodies could adopt simulation and modelling tech to develop policy and approve infrastructure – though issues inherent within AI will have to be ironed out before that occurs, particularly in sensitive areas such as healthcare. “I believe AI and large language models will play a significant role in the next generation of simulation platforms, which maximise their productivity in the real world,” he says, “and provide near-real world performance.”

Simulation and Modelling 2025 will take place in Birmingham from 30 September to 1 October, covering the latest applications of simulation technologies, AI and machine learning, digital twins, multiphysics modelling and much more. Register at imeche.org/events

ll relationships are based on communication – and the more effective that communication is, the more successful you can be in both your professional and personal lives. If you want to improve your communication skills and get better at influencing people, an upcoming IMechE training course could be for you. Communication and Influencing Skills uses well-established models and theories to highlight the skills, knowledge and behaviours you need, using them as the foundation for an interactive and engaging workshop. Phill Slater is one of the course trainers. Here he gives five useful tips to start communicating with and influencing people effectively.

Understand the power of effective communication