0 From prototyping to high-volume serial production

0 Upload a cad model, receive an instant quote

0 15+ processes, 130+ materials

0 10,000 vetted manufacturing suppliers

0 ISO 9001 :2015 certified

0 Parts in as fast as 3 days

03 Welcome

IMechE chief executive

Alice Bunn sets out the Institution’s goals for 2025

38 The big interview

Mohsin Nurbhai, head of engineering at AWE, on why the UK is having a nuclear renaissance

44 Averting disaster

Creative solutions to tackle the increase in extreme weather events, from wildfires to floods

52 Five materials that could transform net zero

Why cutting-edge materials could be our secret weapons against climate change

58 The hydrogen revolution

With alternative fuels in demand to reduce pollution, hydrogen could soon be having its moment

64 Weird engineering

Flying motorbikes might sound outlandish, but the SkyriderX1 is on its way

05 Opener

Quantum mechanics could advance the engineering industry in ways we are yet to fully understand

08 Breaking barriers

The Boom Supersonic aircraft broke the sound barrier in January

11 Five for the future

Meet the engineers and researchers who are coming up with groundbreaking innovations

13 Blueprint

IMechEoutlinesitsresponse to the UK government’s new Industrial Strategy

15 In the spotlight

Our series on IMechE members who are having a big impact profiles

DrAlexander Quayle

18 Competitions

We get the lowdown on this year’s UAS Challenge

21 Encouraging innovation

IMechE deputy president Clive Hickman on why the Institution is undergoing a transformative phase

24 Your voice

Readers have their say on key issues of the day

27 Heritage

The Thrust SSC supersonic car still holds the land speed record it broke in 1997

31 Diversity and inclusion

A recent IMechE event considered proactive ways to make the industry better reflect the diverse community it serves

35 Management

Why good managers need to consider both individual and team performance to get the best results

36 Hydropower

How improvements in technology are making turbines both more efficient and better for the environment

37 Electrifying rail travel

We have the ability to power trains by battery, so what are the current barriers to rolling out the technology more widely?

he Institution remains committed to improving the world through engineering. Demand for engineering skills has never been higher. In the UK alone, we need an extra 124,000 engineers and technicians a year to meet demand, according to EngineeringUK, with many companies struggling to recruit. To play ourvaluable role, we have translated our high-level mission into a clearly defined purpose to guide our activities and direction. Our purpose has four strands:

l Provide opportunities for the engineering community to develop skills, knowledge and professional practice.

l Maintain and enhance the professional status of mechanical engineers.

l Develop the pipeline of talent for the future of the engineering profession.

l Engage with society and governments to leverage innovation for sustainable economic development. These strands provide the detail beneath the two goals of our IMechE 2030 strategy – to support and develop our members and the wider community, and to maximise the positive impact of engineering on society. We aim to achieve these goals in manyways. IMechE courses provide life-long learning opportunities, notably to reskill to meet the fast-changing environment. Formula Student and our Challenges encourage the next generation, helping them to develop their skills and creativity in real-life settings.

Communication and collaboration

Communication and close collaboration are at the heart of everything we do; ‘one team’ is our mantra. Recognising our unique structure, we have established a new forum

PROFESSIONAL ENGINEERING

is published by Think on behalf of the Institution of Mechanical Engineers.

PE, 65 Riding House Street, London W1W 7EH 020 3771 7200

EDITORIAL profeng@thinkpublishing.co.uk

Editor: Amit Katwala

Deputy editor: Joseph Flaig

Sub-editor: Rebecca Dyer

Group art director: Jes Stanfield

Executive director: Jackie Scully

Client engagement director: Kieran Paul

ADVERTISING 020 3771 7232

to foster best practice sharing among chairs of operating boards and members of the executive, ensuring a more cohesive and efficient approach. Working together, we will have the most impact. Education and skills are a priority, with the policy team working with members to respond to the Industrial Strategy. This collaboration ensures that the engineering profession contributes to the debate. Matt Rooney, head of policy, shares further details on page 13.

Highlighting the work of our members is always a priority and we are making 2025 AYear of Rail. As the home of the railway engineering community, we are proud to mark the 200th anniversary of the world’s first passenger railway in 1825, pioneered by our first president, George Stephenson. Through events, training courses, and thought leadership, we’re championing the critical role of engineering in shaping the railways of tomorrow. We will also be delving into our archives, where my colleagues are digitising Stephenson’s letters, and can’t wait to see what they find.

Financial stability remains a priority. We are 178 years old, but more relevant now than ever before with the pace of technological change – we must thrive into the future. Engineering is at the heart of solutions to many global challenges and I am confident the Institution is well placed to encourage innovation and support ourmembers. Finally, I encourage all members to engage with the HQ Programme, instrumental in ensuring we are fit for the future. Your participation is crucial to determine the best path forward.

Commercial director: Michael Coulsey michael.coulsey@thinkpublishing.co.uk

Group commercial manager: Matt Hall matt.hall@thinkpublishing.co.uk

Senior commercial partnerships manager: Chris Barnard chris.barnard@thinkpublishing.co.uk

Commercial partnerships manager: Leanne Rowley leanne.rowley@thinkpublishing.co.uk

Copyright: Think Publishing 2025

SUBSCRIPTIONS

For address changes, phone 01952 214050 or email subscriptions@imeche.org

ABOUT IMECHE

The Institution of Mechanical Engineers is the professional body overseeing the qualification and development of mechanical engineers. It has 115,000 members in 140 countries.

Visit imeche.org for more information about membership and its benefits, or email membership@imeche.org.uk

@ProfEng tinyurl.com/PEmagazine

Views expressed in Professional Engineering are not necessarily those of the Institution or its publishers.

Chief executive: Dr Alice Bunn OBE FIMechE

President: Clive Hickman OBE FIMechE

IMechE is a registered charity in England and Wales number 206882

Innovate faster.

Test more design iterations before prototyping.

Innovate smarter.

Analyse virtual prototypes and develop a physical prototype only from the best design.

Innovate with multi physics simulation.

Baseyour design decisions on accurate results with software that lets you study unlimited multiple physical effects on one model.

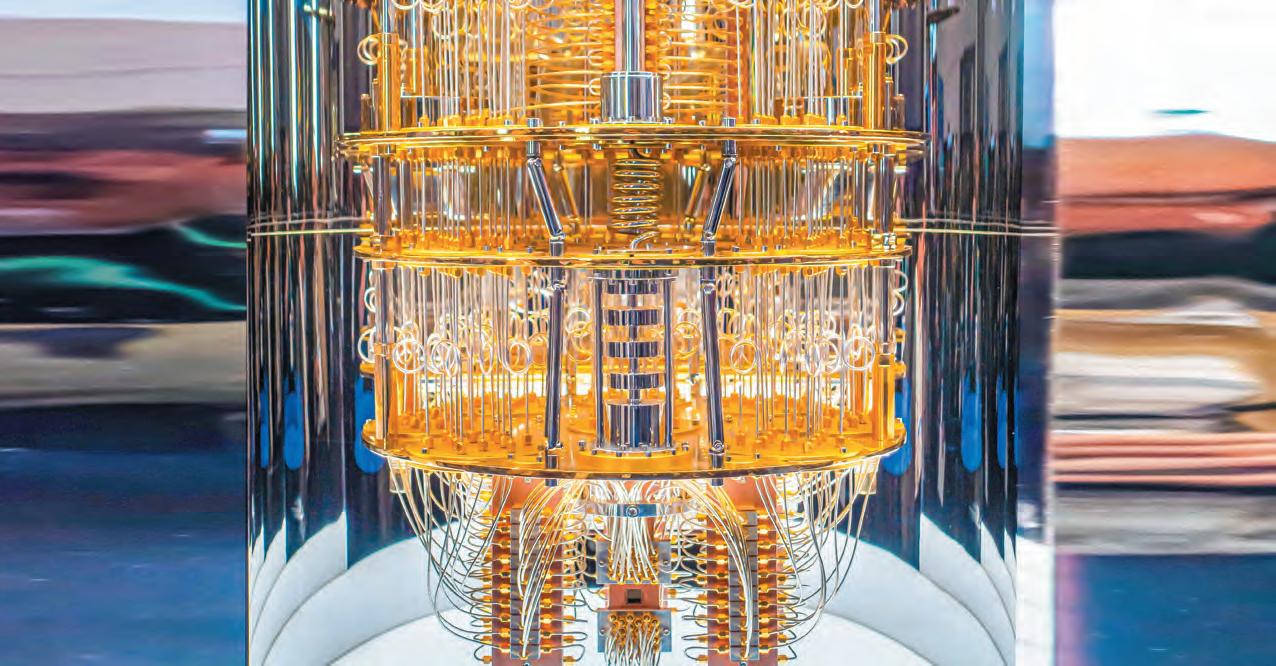

Greater understanding of the uncertainty behind quantum mechanics will change engineering – or will it?

The last two and a half years have been the start of the AI revolution, but the technology that looks likely to take us into the next decade and beyond is quantum. For the layperson, quantum can be inscrutable – a technology that exploits the laws of quantum mechanics to provide new opportunities in computing and other areas. But for those in the know, it’s a game-changing

technology for the world of engineering. Unesco has declared 2025 the International Year of Quantum Science and Technology.

“While the ‘why’ behind the theory of quantum mechanics has yet to be fully explained, the ‘how’ is very well understood,” says Matt Himsworth, chief scientific officer at Aquark Technologies and previously in charge of the Ministry of Defence’s quantum laboratory.

Put very simply, quantum mechanics is the study of matter on the atomic and subatomic scale. At that scale, particles behave in unexpected and seemingly paradoxical ways, with concepts including the uncertainty principle and quantum entanglement. Knowing only the ‘how’ and not the ‘why’ does not matter for engineering, Himsworth says. “We must think of quantum mechanics

as simply another tool in the engineer’s toolbox – it’s not going to be useful in all applications, but it provides new or alternative methods for attacking problems.”

Much of the attention has so far been paid to quantum computing – the idea of being able to do more powerful equations and calculations at a faster speed, enabling better, more accurate results.

Computational fluid dynamics (CFD) is one area where quantum can change engineering, says Chris Ballance, co-founder and CEO of quantum computing firm Oxford Ionics. “CFD relies on high-performance computers to perform large-scale and intensive computations, and quantum computing has the potential to improve the effectiveness of this process,” he says.

“Sophisticated quantum algorithms running on powerful quantum computers could improve overall accuracy for CFD and dramatically reduce the computation time and cost – empowering the aerodynamics sector to achieve unprecedented innovations.”

Endless possibilities

But quantum computing is just the beginning, says Himsworth. “There are applications in timing, magnetometry, electrometry, gravimetry and inertial sensing that are available already, and that can have a greater impact on engineering in the short to medium term, so long as we can unshackle them from the laboratory,” he says.

Cristian Bonato, an engineering and physical sciences professor at Heriot-Watt University, agrees.

“There are ways in which quantum can directly provide new tools for engineering, and then there are ways in which engineering needs to be taken into quantum to make the quantum devices work and accessible to users,” he says.

One of the areas Bonato and his university laboratory are working on is quantum sensors. “We use the spin of a single electron to detect magnetic fields and temperature with nanoscale spatial resolution,” he says. Such a new and precise way of benchmarking and characterising materials and their properties will be useful for engineers looking to create new devices from those materials, he explains. It’s also eminently possible that quantum computing could be used to discover new materials or to build better battery chemistries that could support future development of novel engineering areas.

Quantum dots, which produce different coloured lights depending on the size of the particle, enabling purer colours on televisions, are already in use in devices found in homes around the world and are just the beginning of the quantum revolution in engineering.

$55bn has been invested in quantum technologies by global powers, according to Forbes

“There are quite a few groups and companies also now using this nanoscience of quantum sensors to, for example… make a map of an electronic device and see what the flow is, and then you can detect if there are faults,” says Bonato.

Those current and potential future uses highlight the excitement of quantum – as debated in a recent episode of IMechE’s ‘Impulse to Innovation’ podcast. “Quantum 1.0 was lasers and things like that,” said Tobias Lindstrom, head of science for the department of quantum technology at the National Physical Laboratory. “Quantum 2.0 is applications that use entanglement and superposition.”

These new quantum applications can be used to more precisely measure how materials work – a core tenet of engineering. That can change the industry in new and exciting ways that we have not yet fully understood, says Himsworth.

“Most ‘classical’ technologies involve measuring the response of bulk materials to stimuli – for example, silicon photodetectors producing electricity when light falls on [them],” he says.

Those responses are reliable enough, but are always dependent on the quality of material and how well it has been manufactured. “In most quantum technologies, we’re interacting with single particles – atoms, ions, solid state defects – whose properties are defined by fundamental constants, meaning their response to stimuli is very predictable and identical from device to device.”

That reliability and predictability changes the equation – literally. It is the reason why many engineers are so excited about the potential of the technology.

Boom Supersonic is aiming to bring faster-than-sound passenger travel back to the skies for the first time since Concorde. In January, in tests over the Mojave Desert, the US company’s XB-1 demonstrator aircraft broke the sound barrier for the first time. It is the first independently developed jet to achieve that goal without the support of military or government backing. This is a major milestone as Boom tries to build Overture, a supersonic airliner that could fly from London to New York in three hours and 30 minutes. “XB-1’s supersonic flight demonstrates that the technology for passenger supersonic flight has arrived,” said Boom founder and CEO Blake Scholl. “A small band of talented and dedicated engineers has accomplished what previously took governments and billions of dollars. Next, we are scaling up the technology on XB-1 for the Overture supersonic airliner. Our ultimate goal is to bring the benefits of supersonic flight to everyone.”

Meet the scientists and researchers improving the world through engineering. For more, head to imeche.org/news

01

Your fridge could be getting a long overdue upgrade. Researchers in China have developed a new cooling technology based on thermogalvanic cells that produce a cooling effect using a reversible electrochemical reaction. It could be cheaper and more environmentally friendly than other cooling methods as it uses less energy.

Engineers have used silicone rubber enhanced with nanoparticles of zirconia to recreate the sticky, hydrophilic feet of the gecko. These sticky footpads allow the gecko to move over moist, slick surfaces, and the researchers hope their invention – which sticks to ice – could be incorporated into the soles of shoes to reduce injuries in humans. 02

04 03

At the CES trade show in January, Flint, a Singaporean start-up, unveiled batteries based on cellulose, a key ingredient in paper. The new products have a similar structure to lithium-ion batteries, with an anode, cathode and separator, but with proprietary chemistry aimed at cost-effective production, reduced environmental impact and high performance. The paper battery can bend and fold, which could make it ideal for wearables and medical sensors. It will also decompose naturally.

A new project called Pipeon, led by TalTech in Estonia, is developing robotic and AI-based technologies for mapping and monitoring Europe’s sewer networks. Engineers will build bots that can navigate in darkness, move through wastewater full of solids and fats, and survive for days on their own.

05

Caltech engineers are developing material for ‘lightsails’ that could help spacecraft reach other star systems. These ultra-thin sails will aim to capture solar radiation and use it for propulsion. Researchers are still trying to figure out how to build materials and test them, and have developed a system that fires a laser at a tiny patch of silicon nitride that vibrates like a trampoline. A long way to go.

The UK government is developing a new Industrial Strategy. Matt Rooney, IMechE head of policy, explains what it is and how the Institution is seeking to shape it

Last year, the new government came to power on a promise to boost the economy. Key to this is its new Industrial Strategy, which chancellor Rachel Reeves described as a “10-year plan to deliver the certainty and stability businesses need to invest in the high-growth sectors”. It identifies eight sectors with the potential to drive growth, including advanced manufacturing, clean energy and defence. When a government embarks on such a wide-ranging plan, the process involves broad stakeholder engagement. The first step was to publish a green paper, Invest 2035: The UK’s Modern Industrial Strategy, which sets out the plan in draft format and asks stakeholders 35 questions about the strategy. The IMechE’s policy team worked with our expert member committees across the Institution to draft a response. The five key messages we are making to the government are as follows:

01

Engineering as a foundational sector Engineering not only underpins each of the eight growth-driving sectors, but it is essential to their development. Technology development, investment and productivity improvements are engineeringrelated topics that will be important to ensure growth is achieved.

02

National engineering and technology workforce strategy

To address the demands of the Industrial Strategy, we advocate for a comprehensive national engineering and technology workforce strategy. This is vital to ensuring the UK has a robust pipeline of skilled engineers and technicians to lead progress in the sustainable development and innovation needed to deliver the government’s goals, including for growth-driving sectors and missions.

03

Systems thinking

Integrating systems thinking within the Industrial Strategy is essential for effective problem-solving and implementation. A systems approach would enable coordinated, scalable and sustainable solutions across industries, strengthening the UK’s global competitiveness.

04

Invest in infrastructure and clusters

scale-up. This proximity enables faster, more efficient development by bringing together all players in the value chain – an approach that we believe should be prioritised.

05

Commitment to a long-term strategic policy

Large-scale demonstration and test facilities have proven successful in advancing highintegrity engineering solutions, especially when co-located with industry clusters. These sites are places where innovative ideas and approaches can be introduced and showcased to validate and support

To ensure sustainable growth and productivity increases, the UK government must prioritise long-term strategic decisions and leverage tools to better align with the growth-driving sectors. By using policy levers such as government procurement, financing mechanisms, education and skills development, and regulatory frameworks, the government can create a supportive ecosystem that nurtures innovation and fosters investment. This is essential for providing stability and direction to industry sectors, enabling businesses to plan for the future and ensuring the UK is competitive on a global stage.

The IMechE response to the government consultation, Engineering the UK’s Future, is available in the Policy and Press section of our website.

Innovate faster.

Test more design iterations before prototyping.

Innovate smarter.

Analyse virtual prototypes and develop a physical prototype only from the best design.

Innovate with multi physics simulation.

Baseyour design decisions on accurate results with software that lets you study unlimited multiple physical effects on one model.

In our next article showing the tremendous impact made by IMechE members, we speak to Dr Alexander Quayle, whose engineering journey took him from his grandparents’ farm to developing a multibillion-pound offshore wind farm

Wind forecast: there’s a powerful gust of optimism blowing south from Edinburgh, expected to reach London in midMay. Alexander Quayle is a keynote speaker at the IMechE Wind Turbine User Group, and he’s travelling with a suitcase full of success stories about offshore wind projects.

Under his leadership, Flotation Energy recently secured a multibillion-pound, 15-year government contract for project Green Volt, putting it on track to become Europe’s largest floating wind farm by 2030. “With this success in hand, we’re really changing the landscape of the floating wind sector internationally,” says Quayle. “It’s creating a massive opportunity for the UK to lead the market globally as we look further offshore, into deeper waters.”

Believe in the fundamentals

At the event, starting on 14 May, Quayle will share his experience leading massive wind turbine projects such as Green Volt and Cenos, and discuss hurdles faced by the sector. He’ll reflect on the global mood around sustainable energy and deliver a key message: this moment, turbulent as it may be, offers an opportunity as much as a challenge.

“We’re going to see this transition [to clean, sustainable

energy] speed up and slow down. But, like a big freight train, it will move and it will pick up speed. And when it does, we want to be ready.”

What makes him so sure? “This is one of those moments where you have to take a longer-term view and believe in the fundamentals.”

By fundamentals, Quayle means the reality of global warming (scientists say the planet just had its warmest January on record), the fact that energy mixes must change, and the inevitable return of demand and investment.

Quayle talks a lot about the power of fundamental knowledge and skills. It’s a belief forged over

decades, starting with childhood days of “endless fascination” on his grandparents’ farm.

Growing up in West Yorkshire, on the outskirts of the Dales, Quayle helped out on the family farm. Those years, he says, had a major impact on his life.

“On a farm, there are always things to be done,” he explains. “You never run out of jobs, and you have to prioritise them. Many things can’t wait for tomorrow. So you develop an itch to always be doing something productive. You learn to make things happen.”

At the time, making things happen meant fixing a tractor’s starter motor at midnight, doing emergency fence repairs or fixing some trinket he and his grandfather bought at a local car boot sale. Later, it meant joining a school electronics club and winning awards for his inventions. Later still, it meant embarking on an engineering career that involved four of the world’s top universities and more than a decade working at energy giant BP.

There was a bit of magic along the way, too. When he was young, Quayle staged magic shows for his cousins. Even then, he knew success required preparation (if you’re making a bouquet of flowers appear, he says, you have to have them hidden away somewhere) and careful management of focus –especially that of the audience.

‘Many things can’t wait for tomorrow. So you develop an itch to always be doing something productive. You learn to make things happen’

After finishing school, Quayle, the oldest of three children, became the first in his family to head to university. His mother worked as an English teacher – she helped spark his love of literature – while his father balanced books as an accountant. Quayle wanted to be an engineer and managed to secure a spot at the University of Oxford. His Engineering Science degree was tough but multidisciplinary, which he loved.

He completed his final year on exchange at Princeton, and after that came a Mechanical and Aerospace Engineering PhD at Cambridge. His doctorate involved researching and designing an ultralow noise aircraft in collaboration

with the Massachusetts Institute of Technology.

“The equations you apply for a spring, or a viscous flow, are the same equations you apply to a circuit board, an inductor or a capacitor,” he says. “Getting handson experience of that has been really impactful. It allows you to work across many domains.”

Quayle’s first chance to apply himself was in a start-up, but it wasn’t long before he joined BP to work at In Salah Gas, then the world’s largest carbon sequestration project and a big focus for the energy giant at the time. Later, his role involved exploring the evolution of green energy technology and the decarbonisation of gas pipeline operations. Quayle also gathered valuable experience in managing large-scale infrastructure projects.

In 2021, he moved from one of the world’s biggest energy companies back to a start-up.

Joining Flotation Energy, a company of eight people at the time, was a chance to make things happen in the wind sector.

Quayle assumed the role of project director for the Green Volt and Cenos projects, securing seabed rights at auction and working with the board to launch them into a joint venture with Norwegian developer Vårgrønn. Investment during his tenure exceeded £100m. In September 2024, he led the Green Volt project through the CfD (Contract for Difference) auction process, securing a UK government contract to guarantee electricity sales for more than a decade.

Following this success, Quayle became technical director at Flotation Energy, extending his responsibilities across all projects. He has a passion for start-ups

l The Wind Turbine User Group offers attendees two days of technical content and knowledge sharing to support all engineers involved with wind turbine assets. Find out more and sign up at imeche.org/training-qualifications

and has co-founded a separate investment company, Apollo, with 15 investments so far. Married with two children, he’s also recently been building model aeroplanes with his son and teaching him a few magic tricks.

“In the real world,” Quayle muses, “saying abracadabra doesn’t produce the results you want.”

So, the bigger lessons will come later: use the technical fundamentals you learn, apply your focus where it’s needed most, plan carefully and make things happen.

To nominate an IMechE member making a difference, email profeng@ thinkpublishing.co.uk

This year’s UAS Challenge has an emphasis on design. By Joseph Flaig

Student teams are busy tweaking aircraft designs and fine-tuning performance ahead of this year’s Unmanned Aerial System (UAS) Challenge.

Following a record-breaking 10th year, in which more teams flew than ever before, the competition will return to BMFA Buckminster on the Leicestershire/Lincolnshire border from 30 June to 3 July.

We spoke to project manager Kristina Panikkar about what to expect from this year’s event, which could feature almost 40 teams.

What’s new for this year?

There’s a lot more emphasis on the design and testing, specifically the simulation elements. That’s what we focused on primarily this year – trying to fine-tune that, to give the students the right amount of time to do each of the stages in the design lifecycle.

We’re trying to educate more as well, with the webinars. We started doing them a couple of years ago, throughout the year of the competition, but we’ve put a lot more emphasis on them this year. We’ve got a couple more, and we’ll have sponsors and key personnel talking in those to try to aid the students in making design decisions and taking on board key elements from their industry experience.

More teams than ever flew at last year’s event – are you aiming to build on that?

The amount of teams getting to the event in a flyable condition and then doing successful flight tests is gaining traction year on year. I think that is largely to do with all these improvements and

the additional support we’ve put in place each year.

For the students, we have sponsorship opportunities and mentoring programmes. We also offer steering committee mentorship, where they can ask for clarity on rules or different aspects of the competition, and they take up more and more of those opportunities each year. We are seeing those have a positive impact on the challenge, by having more teams come in a state where they’re ready to fly very early on, rather than at the very end.

We haven’t changed a lot of the competition requirements because we really want to focus on finetuning that, the additional support at the competition, where they can get live feedback, live judging, and they can use that to improve very quickly. We’re hoping this year even more will be ready to fly.

How do you expect the event to evolve in future?

What we’re looking to do for next year already is adapt the mission requirements. What we’ve tried to do every year is change the mission requirements to actually reflect what’s happening in the world.

The competition is a simulated humanitarian aid mission. We changed the course a couple of years ago to reflect high-density populated areas. As well as obstacles such as trees, if you were trying to deliver humanitarian aid packages you would have

to accommodate that with the movability of your aircraft. Going forward, what we’re looking to do is develop new mission scenarios. We can give teams multiple options and then pick one at the event. They would need to be able to programme for that scenario. We will also be looking at the operational safety a bit more.

How does the competition help meet demands?

What industry wants to see is the innovation side – when students are given these new sets of requirements, how can they respond to those and what innovative ideas can they come up with? To do that, we have to

‘What industry wants to see is the innovation side – when students are given these new sets of requirements, how can they respond to those and what innovative ideas can they come up with?’

Above and right:

IMechE’s UAS Challenge had a record-breaking 10th year, with more teams flying than ever before

give them testing requirements and scenarios to encourage that. We’re always pushing the innovation; that’s what we want. That’s what these competitions are – they’re not only to teach you the design lifecycle of an aircraft, but also to inspire you to think a little bit outside the box: “How can we come up with solutions? How can we do this?”

If we keep the requirements fresh, we give more and more opportunity for the innovation and evolution of designs.

What does the competition offer students?

The lifecycle of an aircraft can go from 10 to 60 years, being designed ‘outside’ in the real world, and this gives them a condensed course in how to do all of those different processes. You wouldn’t necessarily get that perspective in university. You would be doing small parts of it at every stage, but getting to see how it impacts a programme of work and the key considerations you need to make is a really useful tool for students. Every competition we run, we have students saying how important it was for them in putting everything they’ve learned together. It also helps them when it comes to job applications and knowing what they want to do in future. There’s a wide world of aerospace engineering – this guides them into what they’re interested in and what they feel passionate about.

For more information, visit imeche.org/events/formulastudent and imeche.org/events/ challenges/aac-challenge

Railway Challenge

Open to spectators on 28-29 June, this competition sees students, apprentices and graduates design a miniature railway locomotive in accordance with a strict set of rules and a detailed specification. The Entry Level competition also returns this year.

26-29 June, Stapleford Miniature Railway

Race cars designed and built by student teams will roar onto the tarmac in July, but the Formula Student calendar is already well underway. The competition proposed a new concept class version of the autonomous FS-AI element in February, while over 60 teams have been taking part in the Sim Racing Series. 16-20 July, Silverstone

Apprentice Automation Challenge

Apprentice teams from companies including Leonardo, BAE Systems Submarines and 2024 winners Niftylift will design and manufacture devices to automate everyday products in this growing competition, returning for an 11th year.

25 September, Manufacturing Technology Centre

Student teams will design, build and test autonomous robotic charging devices for this year’s competition, with a key focus on automatic connection and disconnection. Regional finals are ongoing from March to May, ahead of the national final at IMechE headquarters later in the year.

10 October, One Birdcage Walk

Nylon

• SLA Stereolithography

• SLS SLS300. Sinterit

• MJP Pro jet 2500+ W IC

• DLP Figure 4

• CJP Pro jet 660 Pro

• BJP Concr3de

• FFF Omni. Fusion

• FFF-HT Funmat Pro 610 HT

For a quotationplease send your STLfile to: replik8@cdg.uk.com 01420556755

Pentagon delivers a full turnkey solution for plastic injection moulding from one site of UK Manufacture.

By Clive Hickman OBE, IMechE president

The Institution of Mechanical Engineers is undergoing a transformative phase, ensuring long-term financial stability and positioning itself for a future of innovation and excellence. In my year as president, we have focused on streamlining our operations, investing in digital advancements and making strategic decisions that will shape IMechE’s trajectory for years to come.

One of the key priorities for IMechE is securing financial sustainability. Significant steps have already been taken, including the sale of our two trading businesses, IMechE Argyll Ruane and Sonaspection, following a strategic review.

In line with these efforts, a thorough evaluation of operating costs is being conducted. By identifying areas for significant savings, the Institution aims to optimise resources while maintaining the high standards of service and support it provides to members.

I would like to thank all our members who attended the special meeting in January and took part in the vote about our headquarters building. With 83% of members who took part voting in favour of the resolution, we can now move

to the next phase. I would encourage all members to continue to engage with the HQ programme, which is instrumental in reaching a solution to ensure that our headquarters remain fit for the future.

Efficiency and strategic alignment remain at the heart of IMechE’s operations. A significant reshaping of the finance function is under way, with a focus on streamlining internal processes and improving operational effectiveness. The Institution is also exploring new ways of working to enhance productivity and deliver on its core purpose more effectively.

As part of its forward-thinking approach, IMechE continues to invest in digital transformation.

‘I was pleased to attend the Formula Student and Railway Challenges where it was inspiring to see the students’ enthusiasm and innovation’

This commitment includes a comprehensive review of its operating model to ensure that members benefit from cuttingedge tools, seamless services and improved accessibility to the Institution’s vast resources.

In a move toward greater transparency and improved reporting, IMechE has changed the date of the publication of this year's annual report to September. This is to accommodate the increasingly complex auditing process, which is faced by many organisations.

I have had some notable opportunities to engage with members during my presidency and know there are some exciting events in my diary for the remainder of my term.

I was pleased to attend the Formula Student and Railway Challenges where it was inspiring to see the students’ enthusiasm and innovation. Overall, it was a record year for participants at our Student Challenges.

I would like to express my gratitude for the encouragement and collaboration of members, and look forward to working together for the remainder of my term.

The path ahead is one of progress, resilience and innovation. With a clear vision and decisive action, IMechE is poised to build a stronger, more sustainable future – one that upholds the proud legacy of mechanical engineering while embracing the opportunities of tomorrow.

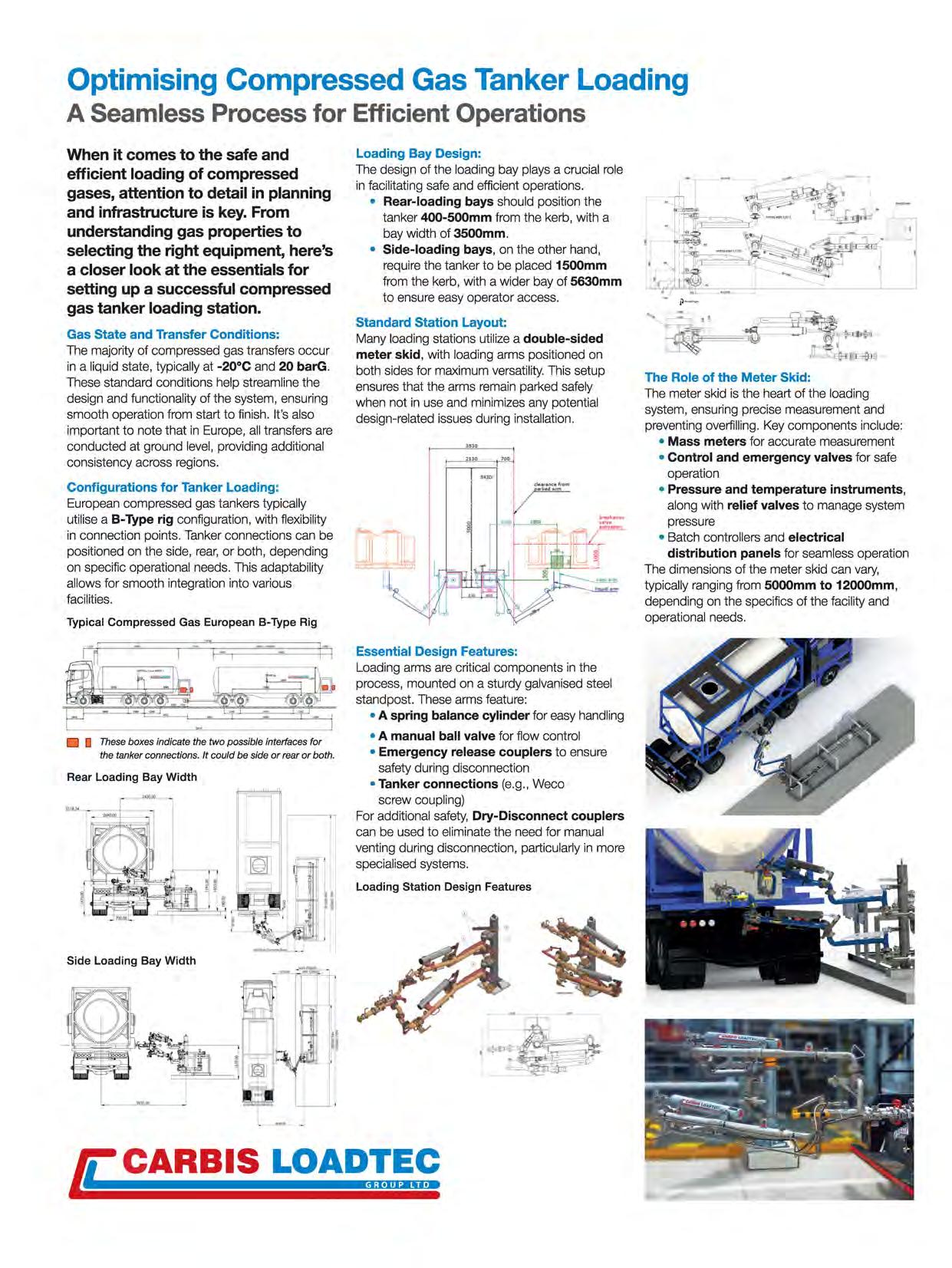

When it comes to the safe and efficient loading of compressed gases, attention to detail in planning and infrastructure is key. From understanding gas properties to selecting the right equipment, here's a closer look at the essentials for setting up a successful compressed gas tanker loading station.

Gas State and Transfer Conditions:

The majority of compressed gas transfers occur in a liquid state, typically at -20°C and 20 barG. These standard conditions help streamline the design and functionality of the system, ensuring smooth operation from start to finish. It's also important to note that in Europe, all transfers are conducted at ground level, providing additional consistency across regions.

Configurations for Tanker Loading:

European compressed gas tankers typically utilise a B-Type rig configuration, with flexibility in connection points. Tanker connections can be positioned on the side, rear, or both, depending on specific operational needs. This adaptability allows for smooth integration into various facilities.

Typical Compressed Gas European B-Type Rig

Loading Bay Design:

The design of the loading bay plays a crucial role in facilitating safe and efficient operations.

• Rear-loading bays should position the tanker 400-S00mm from the kerb, with a bay width of 3500mm.

• Side-loading bays, on the other hand, require the tanker to be placed 1500mm from the kerb, with a wider bay of 5630mm to ensure easy operator access.

Standard Station Layout:

Many loading stations utilize a double-sided meter skid, with loading arms positioned on both sides for maximum versatility. This setup ensures that the arms remain parked safely when not in use and minimizes any potential design-related issues during installation.

The meter skid is the heart of the loading system, ensuring precise measurement and preventing overfilling. Key components include:

• Mass meters for accurate measurement

• Control and emergency valves for safe operation

• Pressure and temperature instruments, along with relief valves to manage system pressure

• Batch controllers and electrical distribution panels for seamless operation

The dimensions of the meter skid can vary, typically ranging from 5000mm to 12000mm, depending on the specifics of the facility and operational needs.

Essential Design Features:

Loading arms are critical components in the process, mounted on a sturdy galvanised steel standpost. These arms feature:

• A spring balance cylinder for easy handling

• A manual ball valve for flow control

• Emergency release couplers to ensure safety during disconnection

• Tanker connections (e.g., Weco screw coupling)

For additional safety, Dry-Disconnect couplers can be used to eliminate the need for manual venting during disconnection, particularly in more specialised systems.

Loading Station Design Features

The transition to cleaner energy sources has driven a significant increase in the demand for Liquefied Natural Gas (LNG). As a result, the efficient and safe loading of LNG road tankers is a critical consideration for energy companies and logistics operators worldwide. This overview highlights the essential factors involved in setting up an LNG road tanker loading station, addressing key design and operational features that optimise efficiency and safety.

Optimising Space and Layout

One of the first considerations when planning an LNG road tanker loading station is the amount of space required. A typical articulated LNG road tanker is approximately 2.4 metres wide and 16 metres long, including the tractor cab. However, variations exist depending on the type of tank and the location of the loading connections, whether they are at the rear or the side.

Rear Loading Bay Width

For maximum space efficiency, rear connections allow for double-sided loading islands, reducing the overall footprint of the station. In contrast, side-loaded tankers typically require singlesided connections, potentially increasing space requirements. Additionally, an important factor in the layout is the handling of Boil-off Gas (B.O.G.). If the B.O.G. is to be recompressed and returned to storage or used for energy generation, metering skids must include an extra metre to track mass usage.

Key Features of a Loading Station

A modern LNG loading station is designed with both operational efficiencyand safety in mind. A standard station features loading arms mounted on a galvanisedsteel standpost with earthing provisions.

These arms facilitatethe seamless transfer of LNG and vapour return using specialised hardware, including:

• Spring balance cylinders for controlled movement

• Cold-resistant handles for safe operation in extreme conditions

• Swivel joints with nitrogen (N2) purge systems to prevent freezing and ensure operational integrity

• Breakaway couplers to prevent damage in case of accidental drive-away incidents

The nitrogen purge system plays a crucial role in maintaining the reliability of the loading arms. This system distributes N2 flow to each swivel joint and can be enhanced with monitoring sensors that detect inconsistencies, ensuring predictive maintenance.

Testing and Quality Assurance:

A robust Factory Acceptance Test (FAT)ensures the station meets performance expectations before deployment. The standard FAT includes an ambient pressure test, with the option to simulate real-world conditions using liquid nitrogen testing. This additional step provides an extra layer of assurance that the system will operate reliably in actual LNG loading scenarios

Metering and Flow Control:

Efficient LNG transfer depends on precise metering and flow control systems. Depending on the specific requirements of the facility, loading stations may include:

• Flow control skids, which integrate seamlessly with weighscale software to manage valve operations

• Meter skids, ranging in length from 5,000mm to 12,000mm, depending on the facility's needs

For stations where tankers are loaded on weighscales, a separate meter package may not be necessary. In such cases, the weighscale software communicates directly with the control skid to manage the loading process.

Got something to share with the IMechE community? Write to us at profeng@thinkpublishing.co.uk, using the subject line ‘Your Voice’

Step change

I have been taking Professional Engineering magazine for 60 years now and am pleased to say that the most recent issue was the best I have ever experienced for ease of reading, clarity of expression and general all-round coverage. What I see is a step change in the communication skills being demonstrated, and I wish to congratulate you and your staff for such a successful transformation of something that was often a trial to read into something I was unable to put down until I had finished it. Well done and thank you!

Barry

Woolley, CEng, FIMechE

The case for multiple baskets

Since the new government took office, there have been a series of announcements proclaiming the benefits of renewable power and its role in a net zero electricity network by 2030. Recent events should demonstrate the risks involved and our continued dependence on thermal generation. From late October into November, there was a three-week period of very low wind speeds and little sunshine. As of 17 November, the electricity production split for the previous 28 days was: natural gas 41%; offshore wind 9%; onshore wind 9%; solar 2% (from 10GW); nuclear 14% (from 6GW); and imports 14%. The thousands of wind machines therefore produced only 28% more electricity than the halfdozen subsea cable connections.

‘Simple, cheap methods of achieving the reduction of energy gain are readily available for immediate use’

The potential damage to everyday life when there is very low renewables generation because of the common mode failure during still, foggy weather is too real and terrifying to ignore.

A post-manufacturing economy needs electricity with a stable frequency 100% of the time. We must maintain adequate reserves of controllable power and not place all the eggs in the renewables basket.

Paul Spare

The geoengineered planet

sun moves around the sky, so the angle at which its rays are reflected would vary constantly. If retroreflective paint was used instead of a plane mirror, the radiant energy would be reflected back towards its source. No mechanism would be needed and the angle of the reflector would not be critical. Existing surfaces, such as roofs and walls, would all then be suitable platforms for treatment. Painting house walls and roofs with reflective paint would greatly increase the available treatable area and have the added benefit of keeping the property cool. Sheds and garages are easily treatable and the paint would help to protect them from the weather.

Referring to the article in Professional Engineering issue two of 2024, reflecting solar radiation back into space is one obvious way of reducing the gain of heat energy by the earth. Why are the methods of doing that, which are currently being discussed, so expensive and complicated? Simple, cheap methods of achieving the reduction of energy gain are readily available for immediate use. There are around 25 million households in the UK. If each one of them erected a 1m2 mirror in an exposed place, up to 25,000,000,000 watts (25 billion watts) could be reflected back into space whenever the sun shines.

The reflectors need not be optically perfect. A board covered in kitchen foil would suffice. The

Floating reflectors would keep the sea slightly cooler, assisting the North Atlantic meridional overturning current. Those could be tethered to – or close to – offshore wind farms so they would not present a great hazard to shipping.

I have bought a polished aluminium Venetian blind for a window at home. Hopefully that will keep one room cooler in summer and warmer in winter. Outside reflectors could be deployed to reflect the winter sun into a window to reduce the fuel requirement slightly. Cheap, simple solutions are often the best overall, and the more people who adopt them, the greater the overall benefit, even if the efficiency of each individual application is relatively low. They can certainly put a brake on a runaway situation until better methods can be deployed. They can continue to contribute beneficially thereafter.

Alan Winter

For most of us, it’s quite difficult to influence policy or be a worldleading expert consulting in a specific science or engineering discipline, but what we do all have are the foundations of science, technology, engineering and maths (STEM) under our belts to pass on to the younger generation. Sometimes a stage on which to inspire future engineers just needs to present itself.

The annual Royal International Air Tattoo (RIAT) attracts more than 150,000 people to RAF Fairford in Gloucestershire over three days in July. Some 30,000 children, young adults and students visit the show’s Techno Zone to explore, discover and be inspired by an incredible range of fascinating and fun activities and exhibits.

A small group of IMechE Aerospace Division volunteers joined the Foundations of Engineering section of the Techno Zone alongside the Institution of Engineering and Technology and other institutions. On the stand we ‘flew’ paper aeroplanes in a home-made wind tunnel, using kitchen scales to measure the ‘lift’ generated while demonstrating factors such as air velocity and wing area. Visitors were then challenged to make their own and earn a place on the ‘lift leaderboard’. This activity proved highly competitive, particularly among families. From paper aeroplanes to the real thing, we also displayed Hammerhead, the University of Nottingham’s entry in this year’s IMechE UAS Challenge. It proved an extremely popular exhibit and, fortunately, our volunteers included some of the third-year aerospace engineering students who had designed, built and flown the UAV, and were therefore well-placed to answer questions.

‘It was an enormous privilege to be a part of the show and a pleasure to work with our own young member volunteers’

The Techno Zone at RIAT is a vibrant hub, full of noise and enthusiastic young people experiencing and learning about STEM; hopefully, we have done our bit to inspire the next generation. It was an enormous privilege to be part of it and a pleasure to work with our own magnificent young member volunteers.

Volunteer quotes: “The experience was incredible this year and I enjoyed seeing sparks of inspiration appear in the people that approached the table. It was great fun engaging with both the visitors and the volunteers. It was a fantastic experience getting involved with the young ones and experiencing the rest of the air show – one that I will certainly be inspired by going forward.” Tony Harris, CEng, FIMechE

In Professor Kalghatgi’s letter in issue one of 2024, he makes several alarming mistakes, which lead him to an even more alarming conclusion. Firstly, he takes the primary energy provided to the UK from fossil fuels and assumes we need to replace 60% of it with nuclear or wind generation. This is known as the ‘primary energy fallacy’. It implies we need to replace most, if not all, of the fossil fuel demand in today’s economy with clean power. But because fossil fuels waste so much energy and heat, and direct electrification of processes, heat pumps, EVs, etc. are so much more efficient at converting energy inputs to useful energy, that 60% can be as low as a third (see Lawrence Livermore National Laboratory flowcharts for the US as an example).

He then asserts that, because humans have adapted to 1.2ºC of warming, that we will be OK if it continues to warm. I can only point readers to the Intergovernmental Panel on Climate Change’s 2022 impact report, which makes clear the hazards of unchecked warming, particularly on the most vulnerable, not to mention on nature itself.

I presume Professor Kalghatgi’s arguments are made in good faith, but as someone still in their 20s who will have to live through a warming world if emissions are not reduced, I cannot accept his conclusion that we have to give up on mitigation and just adapt. Quite aside from being built on poor analysis, defeatism like this shows a lack of faith in the ingenuity and determination of humanity, and cannot prevail if young people today are to have a chance at living on a thriving planet in the future.

Ed Wilson

In application areas as diverse as industrial, mobile, marine, machine tools, agricultural equipment and offshore installations, machinery that needs to generate high forces in a compact package will typically rely on hydraulic drive systems. At the heart of that power transmission system is the hydraulic pump, in turn driven by a prime mover which might be a motor, electric, hydraulic, pneumaticor an I.C.E.

Q: Why is coupling hydraulic pumps to prime movers critical for machinery performance?

A: Proper coupling ensures precise shaft alignment, improves efficiency, reduces wear, and prevents premature pump failure. It also minimizes maintenance costs and extends the system's lifespan by reducing unnecessary stress on components like seals and bearings.

Q: What role does a hydraulic pump play in machinery systems?

A: Hydraulic pumps are at the heart of power transmission systems in applications like industrial, mobile, marine, agricultural, and machine tools. They deliver high force in compact packages, powered by a prime mover, which can be electric, hydraulic, air motor, or internal combustion engine.

Q: What happens if hydraulic pumps are improperly installed?

A: Improper installation can lead to pump failure, increased maintenance costs, and reduced productivity. Additionally, misaligned pump shafts can cause excessive wear on seals and bearings, shortening the system's lifespan.

Q: What are torsional resonant frequencies, and why do they matter?

A: Torsional resonant frequencies are vibrations that can develop within the drivetrain. If unaddressed, they can damage components, reduce system life, and impact performance.

Q: How does jbj Techniques ensure proper coupling for hydraulic systems?

A: jbj Techniques designs, manufactures, and integrates customized components, including hydraulic pump adapters, bellhousings, and couplings. Their tailored solutions ensure precise coupling, optimized performance, and reduced wear for various machinery systems.

Q: What are jbj Techniques' hydraulic adapters, and how are they customized?

A: Hydraulic adapters consist of bellhousings and flexible drive couplings, fully machined to match driving and driven components. They can handle shaft-to-shaft, flange-to-shaft, or flange-to-flange connections and are tailored for specific system requirements.

Q: What electric motor sizes and configurations are supported by jbj bellhousings?

A: jbj bellhousings accommodate IEC frame sizes from D56 to D400 (0.06-750 kW) and are compatible with BS or B14 flange configurations. They also support NEMA and imperial frame motors with C-face or Dflange fitments.

Q: What materials are available for jbj bellhousings?

A: Standard options include aluminum and cast iron, with exotic materials available upon request. Aluminum bellhousings come in monoblock or composite formats for flexibility and rapid delivery-often same or next day.

Q: What coupling options does jbj offer?

A: jbj provides torsionally flexible or rigid couplings machined to meet DIN, SAE, ANSI, or ISO standards. Spider couplings are available in materials like aluminum, grey cast iron, nodular iron, steel, and stainless steel. Noise-sensitive applications can also benefit from anti-vibration and noise-reduction components.

Q: Are jbj hydraulic adapters suitable for hazardous areas?

A: Yes, jbj offers ATEX-compliant adapters for Zone 1 and Zone 2 hazardous areas. These include anti-static and flameproof drives. Wet mount bellhousings are also available to reduce seal temperatures and meetATEX standards for high-pressure applications.

Q: Can jbj adapters be used with petrol and diesel engines?

A: Yes, jbj provides hydraulic adapters for petrol and diesel engines. Their solutions support SAE dimensions from SAE 6 to SAE Oand offer custom bellhousings for engines that don't conform to SAE standards.

Q: What engines are compatible with jbj petrol engine adapters?

A: Adapters are available for popular brands like Honda, Briggs & Stratton, Kawasaki, Kubota, Hatz, and others. These adapters can be machined to fit a wide variety of hydraulic pumps and configurations.

Q: What makes jbj Techniques a reliable partner for hydraulic coupling solutions?

A: jbj's in-house design team and manufacturing capabilities provide tailored, competitively priced solutions with on-time delivery. Their extensive range of components, both off-the-shelf and custom-made, ensures optimal performance for any application.

For more detailed information, visit: www.jbj.co.uk/hydraulic-adaptors.html

Nearly three decades since it broke the sound barrier, the Thrust SSC still holds the land speed record

This iconic car became the first land vehicle to break the sound barrier, a feat accomplished in 1997 in the Black Rock Desert of Nevada. Driven by RAF squadron leader Andy Green, the 16.5m-long, 10.5-ton car broke the land speed record by hitting 763 miles per hour. The car was designed and built in Britain, by Richard Noble, Jeremy Bliss, Ron Ayres and Glynne Bowsher. It was powered by two Rolls-Royce Spey turbofan engines – the same ones used in F-4 Phantom II jet fighters. Those engines burned an incredible 18 litres of fuel per second to develop 223kN of thrust.

Incredibly, almost 30 years later, Thrust SSC’s record still stands. Its successor, Bloodhound LSR, has been in development since 2008 and is believed to be capable of up to 1,000 miles per hour, but has been beset by funding challenges. As of January 2025, the project is still alive and searching for more funding and a new driver, with Green stepping down in 2023. Get your applications in!

Find out more about the Institution’s history at imeche.org/engineering-heritage-awards

400+

Advanced Engineering UK is set to return to the NEC, Birmingham, on 29 and 30 October 2025, showcasing the latest innovations from the manufacturing and engineering sectors. With eight months remaining, the exhibition halls are filling up as companies across the supply chain secure their spots. Currently, 70 per cent of the space is already booked, so interested exhibitors should act promptly to reserve a place.

Following a record-breaking 2024 event that welcomed over 9,800 professionals, Advanced Engineering 2025 is gearing up for another big year. Providing a platform for engineering and manufacturing professionals to connect, the show organisers are planning for two action-packed days where attendees will gain access to cutting-edge technologies, expert-led conference sessions and networking opportunities.

For exhibitors, the event offers an opportunity to showcase the latest solutions in composites, automation, additive manufacturing, testing, green technologies and more. With access to over 9,000 industry leaders from Tier 1 suppliers and OEMs, businesses can position themselves at the forefront of industry transformation, helping manufacturers overcome critical challenges such as supply chain

resilience and the journey to net zero. Alongside the exhibition, attendees can expect over 200 expert speakers delivering insight across multiple forums, tackling key industry topics such as digitalisation, supply chain resilience and sustainability. Plus, in response to the ongoing skills shortage in the UK engineering and manufacturing sectors, Advanced Engineering is continuing its #MINDTHEskillsGAP initiative.

This campaign aims to address the critical skills gap by allowing collaboration between industry leaders, educational institutions and policymakers to develop effective training and recruitment strategies. By participating in the event, businesses can contribute to and benefit from efforts to build a skilled workforce for the future.

“Advanced Engineering is where the UK’s engineering and manufacturing community comes together to share ideas, do business and, ultimately, drive the industry forward,” explained Simon Farnfield, event director at Easyfairs, the organiser of Advanced Engineering.

Limited exhibition spaces available at the UK’s annual engineering and manufacturing event

“Every year, we see the latest innovations on the show floor and the energy from exhibitors and attendees proves just how important this event is. We can’t wait to be back in 2025 with even more opportunities for businesses to connect and make an impact.”

The show is again supported by a range of industry partners, including the Institution of Engineering and Technology (IET), Composites UK, Make UK, UKRI, UK Space Agency, the Institution of Mechanical Engineers, GAMBICA, BARA, the Department for Business and Trade, and ADS Group, who will be running the Meet the Buyer progamme again this year.

Such partnerships, along with many more, help the show to stay on top of the latest issues arising in the manufacturing and engineering industry, passing knowledge on these topics on to its visitors.

There is no place better to experience the innovation the UK’s engineering and manufacturing industry has to offer.

To book your stand, visit advancedengineeringuk.com and make an enquiry – but don’t hesitate as space is selling out fast.

Astheonlymanufacturer of everyretainingringstyle(circlips,snaprings& spiralrings),RotorClip ensuresyouhavethebestringsolutionforyourapplication.Standardorcustom,coiledorstamped, wearecommittedto producingthehighestqualityringswithunparalleledengineeringsupport.

A recent IMechE event highlighted the importance of diversity and inclusion in engineering

ngineering offers many ways to make the world a better place. But to truly meet society’s needs, industry must reflect it – and with persistently low levels of women engineers and low representation of minority groups, many hurdles still remain in the UK sector. Those barriers should be identified and removed through discussions between engineers and teachers, according to diversity and education expert Jeff Greenidge. “What hurdles did you overcome?” asked the Association of Colleges’ director for diversity and governance at an IMechE event in March. “We need

you to talk to us, and we will talk to you, and we will create something that is much more inclusive.”

The suggestion was made at Inclusivity by Design, the first event in the Institution’s new Engineering Needs Everyone series. Following on from the success of the Verena Holmes anniversary events in 2024, which celebrated the legacy of IMechE’s first female member, the evening set out to explore the steps organisations can and should take “to ensure all engineering spaces, both organisational and physical, are welcoming to all those with a contribution to make”.

Held on 13 March at the Institution’s headquarters in Westminster, London, the event came amid a global backlash against diversity, equity and inclusion (DEI) measures, spearheaded by the second Donald Trump administration. The US president has suggested diversity measures could have been to blame for the Washington DC plane crash, while his senior adviser Elon Musk has railed against what he calls the “woke mind virus”. Companies including Google and Meta have cancelled DEI programmes since the start of Trump’s presidency.

‘Why wouldn’t we want to make the most of those different thoughts, experiences and perspectives on life and on work?’

Speaking at the event, however, Greenidge said he was “happy to be woke” because it signals an inclusive approach to education and employment. The non-executive director at MTC Training stressed the importance of tackling internal biases during his presentation, which used the extended metaphor of building a concert hall with foundations, pillars, a stage and even mosaics with “jagged pieces”. Equity – giving people that need it assistance, rather than distributing resources equally regardless of need – is a “superpower” when it comes to creating spaces where everyone can thrive, Greenidge said.

He also stressed the importance of diversity to creating innovative and dynamic workspaces. “We’re all different, and so why wouldn’t we want to make the most of that difference in this room – all those different thoughts, all those different experiences, all those different perspectives on life and on work?” he asked.

“We can create a space where people fit in or we can create a place where people stand out. And I think we in engineering want to create that space where people stand out.”

Embedding inclusivity into the “DNA” of organisations means taking risks, he added. “We have to move beyond the compliance, which is comfortable, to a much more uncomfortable place where we’re talking about a cultural shift,” he said. “You are the ones who can help us do that, because that’s the way you think. You think about things right from the outset… as part of the overall picture.”

In education, Greenidge stressed the need for assessments and curricula that allow individuals to

show what they can do. Engineering success stories should also be “amplified” to encourage more young people into the industry, he continued.

“One of the outcomes of this session, I hope, is that you in the engineering arena will talk a lot more to us in the education and training sector, so we can make those links,” he said.

Inclusion by design is not just the right thing to do, according to the second set of presenters – it “makes great business sense”. The case study focused on the development of the Kent and Medway Engineering, Design, Growth and Enterprise (Edge) hub at Canterbury Christ Church University.

The formation of the school of engineering, technology and design, housed in the new £65m Verena Holmes building, set out to tackle local challenges including unemployment, low wages, a lack of STEM employer visibility and a reduction in school pupils taking science at A-level.

“It absolutely cried out to me that the region needed a university that was known for widening participation and responding to workforce challenges,” said former deputy vicechancellor of the university and chair of the IMechE Education and Skills Strategy Board Professor Helen James

OBE. “I was adamant I was not going to develop yet another ‘same old engineering department’: traditional curriculum, teaching, learning and assessment, masculine culture, staff and students, not industry-engaged… I was in a position of influence, and I was going to use that to the full.”

Also aimed at stemming the engineering ‘brain drain’ from the region, the new facility was based on “holistic, systems-based, integrated and inclusive” principles. This included removing maths and physics A-levels as entry requirements, both barriers that reduce the pool of people going to university.

Project leaders read the latest research literature on space layout, including measures to encourage inclusivity, such as collaborative learning spaces and maker spaces. They also made sure not to “clog up” the space with staff offices. “In essence, inclusion was and is the business case,” said James.

The school’s founding head, Professor Anne Nortcliffe, told Professional Engineering in 2022

‘It’s

not just the stereotypical grease and mechanics –it’s human factors, industrial design, biomedical stuff’

that 40% of the staff were female, providing a wealth of role models. The website even used “feminised” language, she said, and avoided the use of stereotypical imagery to encourage female applicants.

“Everybody brings that own minority characteristic. But you have to help people to… see from everybody’s perspective, to make sure they support the students appropriately, and nobody feels isolated,” she told the IMechE event. “DEI policy must exist, but it must be lived and breathed.”

Humanising engineering

The event concluded with a panel conversation featuring the presenters and other industry inclusivity experts. Facilitator Abbey Addison, an IMechE trustee board member, highlighted a recent BBC Bitesize survey that showed engineering was the secondmost popular future profession for 13- to 16-year-olds. This is at odds with the huge annual shortfall in the number of engineers and technicians joining the industry, however, with current projections showing a gap of 37,000 to 59,000.

Asked how the industry could maintain interest from young people

throughout their lives, Charlotte Briers from train manufacturer Alstom said it was important to “move away from stereotypes”. “It’s not just the stereotypical grease and mechanics – it’s human factors, it’s industrial design, it’s the biomedical stuff,” the rolling stock lead said. “It’s opening up everyone’s eyes to everything that engineering does. Engineering does touch everything in the world.”

Engineering broadcaster Dr Shini Somara, who is also board director of the Campaign for Science and Engineering and pro-chancellor at Brunel University of London, said it is important that engineers share personal experiences to “humanise” the profession.

Education should also nurture different ways of learning such as hands-on work, she said, to maximise everyone’s potential, including neurodiverse people. “Why are we not nurturing these different ways of learning? All these different strands of characters and talents and skills.”

Neurodiversity networks can help companies adapt and become more inclusive in their application processes, said Steven Murray, senior resourcing lead at Babcock International Group. “We used to ask: ‘Are you registered as disabled?’ We don’t do that any more, because a lot of neurodiverse people do not classify themselves as being disabled, but they still need reasonable adjustments. So our question, through discussion within the neurodiversity network, has become: ‘Do you require any reasonable adjustments to the application process? If you do, please let us know.’”

Other topics included the risk that some older engineers might see inclusivity initiatives as weakening the profession “by lowering standards and systems”. Reciprocal mentoring –also known as co-mentoring, in which junior and senior employees share their knowledge and experiences of work – can help turn that conversation around, Professor Nortcliffe said, changing older employees into advocates for DEI measures.

Inclusivity and diversity efforts should be seen from the perspective of the impact they make, Greenidge said. “It’s not a deficit. Part of this is about using people’s different talents and different skills.”

IMechE chief executive Dr Alice Bunn OBE highlighted the useful support on the Institution’s Culture and Inclusion webpage as she brought the event to a close.

“If we’ve got the right values in an organisation, that encourages the right behaviours,” she said. “If we have the right behaviours, that encourages inclusion. And if we get true inclusion, we get a diversity of thought.”

Engineering Needs Everyone: Inclusivity by Design is now available to watch online at youtube.com/@imecheuk

New 4-in-1 Large Volume 3D Scanner

• Wireless

• Markerless

• Video Photogrammetry

• Super Fast 3D Scanning

• Handheld or Tripod ounted

Objects up to 20 metres in size

E

very team is made up of individuals, but what works for one person might not translate to the wider group. A nuanced approach is needed to motivate and get the best from workers. An upcoming IMechE training course, Managing Team and Individual Performance, tackles both sides of the equation. Running in May, the course is aimed at leaders and managers who are responsible for the performance of others.

Leadership trainer and coach Andy Webber is one of its trainers. Here are his five tips to help you manage teams and individual performance.

As a leader, you need to adjust the way you delegate based on the individual and their experience. The first time you tackle a task together, you might show them how to do it. That should evolve the second time you do it, and the third, and so on.

Managers sometimes don’t want to let go of tasks. Trust your team members and their ability to do a good job.

Feedback is a really important tool to support development, both when something has gone wrong and when it’s gone really well. A leader and manager needs to have that information, and to share it with team members to help them make adjustments and develop in their roles.

It’s about flexibility –supporting development and recognising that needs evolve

01 02 03 04 05

One of the most important parts of the workshop is where we look at how people learn. Different people obviously need different things, and it’s your job as a manager to work it out and give people what they need. What’s slightly less obvious is that the same

person needs different things at different times. As a manager, you have to be quite directive with new tasks, telling team members what steps to take.

If you carry on with that approach, it quickly becomes micromanagement and they will get pretty annoyed. They will start to work it out for themselves, so what you need to do as a manager is back off and let them get on with it. It’s about flexibility – supporting development and recognising that needs evolve.

Treat the team like an organism

Leadership expert and author John Adair, famous for “actioncentred leadership”, recognises the importance of balancing the effective functioning of the team with the needs of the individuals within it. The team can be treated as if it’s a living, breathing organism in its own right – it is made up of individuals, but what the team needs might be quite different to what individuals within the team need at any one moment.

It’s about balancing those competing priorities, but also understanding what a team needs and how it evolves over time.

Similar to an individual learning something new, as a team gets more experienced and more knowledgeable, your job is to back off and let them get on with it, rather than micromanaging them.

If, as an individual, I have an objective and I don’t really understand how that connects to anything else, but I just come to work and do my stuff and then go home again, that’s not as motivating as a situation where I have my objectives but I am absolutely clear how they link to other people in the team.

When we put it together, it creates something bigger. It’s that sense of purpose that we are able to engender by connecting things.

IMechE's Managing Team and Individual Performance course runs in London from 27-28 May. Find out more and book at imeche.org/training-qualifications

A cornerstone of the renewables revolution is constantly improving thanks to engineering innovation, writes Chris Stokel-Walker

One energy source will play a vital role if the renewables revolution is to upend our energy mix for the better. Hydropower is the workhorse of the sector, generating more electricity worldwide than other renewables combined, according to the International Energy Agency (IEA).

While the combination of solar and wind was expected to overcome water power last year, hydro’s key role will continue for a decade or more, at least – but the 4,300TWh produced annually, says the IEA, can be supercharged by innovation.

Hydropower faces a conundrum: it’s widely recognised as a clean, reliable source, but there’s a belief that it has hit its peak from the design standards conceived of decades ago. The traditional system involves water being passed down a penstock so that gravity, combined with pressure, spins a wheel connected to a turbine to produce electricity, but other methods are now being deployed.

One of the most promising involves a vortex-based system that spins water into a whirlpool, developed in Australia, which can increase energy production by 10% or more. The method has been equated to a black hole by Marstecs, one of the companies behind the system. That 10% figure is based on retrofitting the new vortex system into pre-existing plants. Engineering advantages from a new plant could generate double or triple the amount of power compared with decades-old technology.

Beyond brute-force engineering,

‘Turbines that are better for fish survival need to function identically to a conventional turbine’

other decisions could eke out more efficiency from hydrogen. The AI revolution is sweeping all before it and the hydropower sector is no different, PV Magazine forecasts. It foresees a future where intelligent systems design enables turbines to be called on more accurately and quickly than the old way of working.

One of the biggest breakthroughs is in turbine reinvention. Conventional turbines were designed for efficiency, power output and longevity – but not ecological sustainability. New designs maintain and improve efficiency while reducing environmental footprint, particularly for fish populations.

“For turbines that are better for fish survival to be adopted, they need to function identically to a conventionally designed turbine,” says Abe Schneider, co-founder at Natel Energy. “Prior efforts resulted in turbines with really low power density.” Natel’s design includes sleek blades that are 10 times thicker than conventional ones, preventing fish from being sliced on impact by the peripheral speed of turbines ranging from 20 to 30 metres per second. Blade edges are also

angled to make it more likely that fish hit by them will survive.

Such innovations are enabled by advances in computational power. High-performance computers allow engineers to model every aspect and design custom solutions.

“Today it’s routine for us to take on a new project and create a completely new runner geometry for a specific hydropower station,” Schneider says.

“It is a generational opportunity to do the right thing, to modernise our hydropower fleets, to be a continued, efficient, reliable, lowor zero-carbon backbone of our clean energy economy, while at the same time making the right decision for the aquatic ecosystem.”

Hydropower Engineering 2025 will showcase the latest developments across the hydropower industry, covering regulatory updates, technical innovations, new opportunities and much more. Find out more and register at imeche.org/events

The technology to power rail travel by battery exists in theory – but putting it into practice is another challenge entirely, reports Chris Stokel-Walker

elays on the line are not news to passengers, but delays in batterypowered travel could be about to clear.

Japan Rail introduced the first battery trains between 2016 and 2019, converting 18 Dencha trains from diesel power. The model converts AC electricity from overhead lines to charge on-board batteries. Nearly a decade later, the UK has few options, but operators are considering batterypowered for the next generation.

Last year, Hitachi Rail replaced the diesel engine in one of its intercity Class 802 trains with a single 700kW battery. The trial included a 70km journey powered entirely by the battery. Following the test, Jim Brewin, chief director for the UK and Ireland at Hitachi Rail, said: “Everyone should be immensely proud of creating battery technology that had zero failures during the trial. The greenest mode of transport just got greener.” The next step for Hitachi Rail was a full intercity battery-powered train with a range of 100-150km.

Some experts are unsure if battery trains will become a frequent sight, however. “I’m slightly sceptical, but

people I talk to are very confident,” said transport commentator Christian Wolmar. He said the additional weight would scupper any chance of trains becoming economical. “It seems like a lot of weight for not much power. I can’t see it having widespread use… there might be places like branch lines where it could be useful, but I don’t think it’s a game-changer.”