Industrial Ethernet Book

The only publication worldwide dedicated to Industrial Ethernet Networking and the IIoT. Visit iebmedia.com for latest updates.

New website offers deepest, richest archive of Industrial Ethernet and IIoT content on the web.

View and/or download latest issue of Industrial Ethernet Book and past issues.

Search our database for in-depth technical articles on industrial networking.

Learn what's trending from 5G and TSN, to Single Pair Ethernet and more.

Keep up-to-date with new product introductions and industry news.

GET CONNECTED…

Industrial Ethernet in AI World

Ninety-five percent of manufacturers are investing in AI to navigate uncertainty and accelerate smart manufacturing, according to a new report from Rockwell Automation.

Rockwell announced the results in its 10th annual “State of Smart Manufacturing Report.” The global study surveyed more than 1,500 manufacturers across 17 of the leading manufacturing countries.

As manufacturers continue to face uncertainty driven by economic shifts, the report highlights how companies are turning to smart manufacturing technologies to manage risks, improve performance, and support their workforce. It also examines adoption of emerging technology, including artificial intelligence (AI), machine learning (ML), and cloud-based systems.

Key global findings include:

81% of manufacturers say external and internal pressures are accelerating digital transformation, with cloud/SaaS, AI, cybersecurity, and quality management ranking as the top areas of smart manufacturing technology investments.

95% of manufacturers have invested in, or plan to invest in, AI/ML over the next five years.

Organizations investing in generative and causal AI increased 12% year-over-year, signaling a maturing approach to advanced technologies beyond experimentation.

Cybersecurity ranks as the second biggest external risk, with 49% of manufacturers planning to use AI for cybersecurity in 2025 – up from 40% in 2024.

48% of manufacturers plan to repurpose or hire additional workers due to smart manufacturing investments. Additionally, 41% are using AI and automation to help close the skills gap and address labor shortages.

Quality control remains the top AI use case for the second year in a row, with 50% planning to apply AI/ML to support product quality in 2025.

Beyond these data points, the report reflects broader movement towards more efficient and adaptive operations. Manufacturers are using smart technologies to strengthen supply chains, accelerate sustainability initiatives and make faster, more informed decisions. There has also been a 5% rise in the importance of analytical and AI skills for leaders, showing that talent development and technical innovation must go hand in hand. Still, many manufacturers face challenges when implementing AI. Nearly half of respondents say the ability to apply AI is now an extremely important skill – up from just 10% last year.

Al Presher

Industrial Ethernet Book

Editor: Al Presher, editor@iebmedia.com

Advertising: info@iebmedia.com

Tel.: +1 585-598-6627

Free Subscription: iebmedia.com/subscribe

Published by IEB Media Corp., 1247 Anthony Beach Rd., Penn Yan, NY, 14527 USA ISSN 1470-5745

Single Pair Ethernet: 28 New Products: 45

Unified locating key to Physical AI plus APL over Profinet testing

News releases emphasize the importance of unified locating as a key to physical AI, and new certified PROFINET over APL products now in field tests with end users.

Unified locating as a key to Physical AI

A collaboration between AIM-D, omlox / PI, and the OPC Foundation brings together the disciplines of identification, locating, and communication in a common spatial context.

Industrial automation is facing a paradigm shift: machines, robots, and mobile systems are learning to “understand” space. With the new OPC UA Companion Specification for Identification and Locating, AIM-D e.V., PROFIBUS & PROFINET International (PI) with the open locating standard omlox, and the OPC Foundation are establishing the foundation for a common language of “spatial intelligence.”

Physical AI, or AI that actively perceives physical space and acts contextually, requires a unified understanding of positions, movements, and identities in space. This is precisely where the new Companion Specification comes in: it harmonizes the spatial data model for absolute positions within the OPC Foundation and allows for a unified global positioning of assets in the physical and digital world.

This enables a seamless integration of spatial data into industrial IT and OT systems, a prerequisite for autonomous mobile robots, intelligent assistance systems, and selforganizing production environments.

The new specification is now freely available on the OPC Foundation’s website and is considered a milestone for the next evolutionary stage of industrial intelligence.

“Machines need a unified understanding of their position in space for coordinated interaction between stationary equipment and mobile robots in the flexible production of tomorrow,” explains Dr. Matthias Jöst, Committee Leader omlox at PI. “With the now available OPC UA Companion Spec, OPC Foundation, AIM-D, and PI jointly create the basis for a new generation of spatially networked and AI-enabled systems.”

“AIM particularly benefits from the connection between AutoID and locating technologies,” adds Peter Altes, Managing Director of AIM-D e.V. “The unified data model strengthens interoperability – a decisive prerequisite for digitally connected logistics and industry.”

Stefan Hoppe, President and Executive Director of the OPC Foundation, emphasizes: “OPC UA connects worlds – from identification

SOURCE: PI INTERNATIONAL

several pilot plants in the chemical industry. The basis for a high degree of interoperability is a certification test for all product types, including controllers, sensors, actuators, and switches. Tests for actuators have been added to the latest version of the PROFINET Test Bundle. The first products have already successfully passed the certification tests. For example, Samson has received the first certificates for its positioners.

"In addition to developing user-friendly technology and establishing targeted measures for product quality assurance, we believe that working with users is an important step in establishing the technology in plants and promoting its acceptance. For years, we have been working closely with users throughout the entire life cycle of technology. This begins with the creation of requirements and extends to the evaluation of prototypical or real products in pilot or demo systems. The experience gained in this process is incorporated into the maintenance and further development of our technologies," says PI Chairman Xaver Schmidt.

to locating to control. This new specification demonstrates how open standards together create true interoperability – making the industrial Internet of Things scalable and future-proof.”

The collaboration between AIM-D, omlox / PI, and the OPC Foundation brings together the disciplines of identification, locating, and communication in a common spatial context. This creates a decisive foundation to equip robots, vehicles, and machines with a shared spatial understanding – the key to Physical AI, resilient supply chains, and autonomous industrial ecosystems.

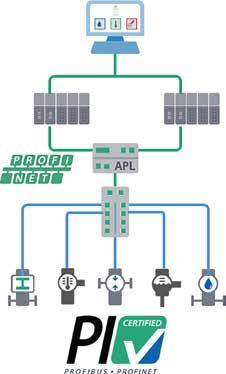

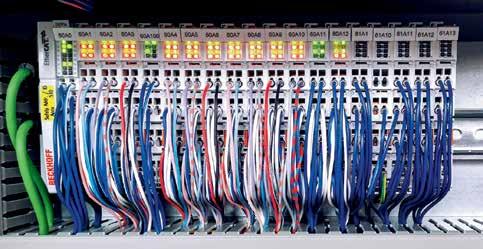

Certified PROFINET over APL products in field tests with users

The functionality of PROFINET for explosion-proof applications in process automation is available in its complete scope. In joint working groups, experts from PROFIBUS & PROFINET International (PI) are currently working closely with end-users to intensively evaluate the potential for use and interoperability of PROFINET over APL products from different manufacturers in

In addition to physical layer tests to verify suitability for intrinsically safe applications, the scope of certification testing for PROFINET over APL products includes additional APL-specific test cases for verifying PROFINET communication, the execution of an APL-specific test setup for interoperability scenarios, and tests for the Profile for PA Devices. With the availability of certification for actuators, the PI experts for PROFINET over APL have completed another step toward deployment in process automation.

In the meantime, end-users have positively evaluated the suitability of PROFINET over APL with certified products in several test lab installations. PI has initiated activities involving PI experts and users from the process industry to define further field tests. These will also be extended to the topic of security, considering the underlying non-Ethernet communication systems.

In addition, the topics of functional safety with PROFIsafe and the certification of switches are on PI's agenda, which are also being developed in close cooperation with end-users from the process industry.

Certification is now available for all device types with PROFINET over APL.

Machine learning for all automation sectors

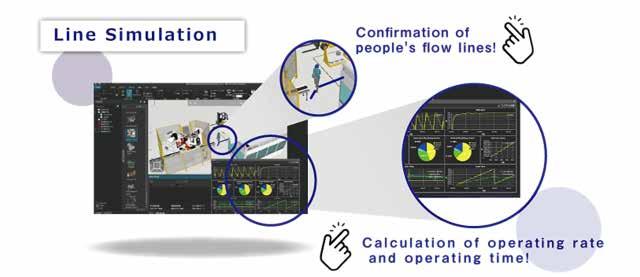

TwinCAT Machine Learning: AI is simply integrated into the control level

AI models as a function block in the PLC: AI as a component of the control code

real-time execution on the standard control IPC: in sync with motion, sequential logic, vision, and much more acceleration of complex AI models: Beckhoff IPC with NVIDIA GPU and interface from the PLC

automated training of AI models: AI model creation that doesn't require AI expertise

open interface for trained AI models (ONNX): trained AI with interoperability

AI model lifecycle management: model updates without compilation, stop, and restart

Industrial wireless technology solutions update

Industrial wireless technology trends include the continuing expansion of 5G, the integration of AI and machine learning into networks, the growth of Wi-Fi 6/6E/7 solutions and advancements in edge computing. AI is being used to automate network operations, enhance security and drive intelligence at the network edge.

FOR OUR UPDATE ON INDUSTRIAL WIRELESS solutions, the Industrial Ethernet Book reached out to industry experts to get their perspective on the trends driving new technology. Not surprisingly, adoption of 5G is leading the way along with the emergence of Wi-Fi 6/6E and new developments with Wi-Fi 7. Add in AI, advancements in Time-Sensitive Networking (TSN) over wireless media and new 6GHz spectrum -- and the scope and evolution of the technology is apparent.

As Alice Masini of Cisco concluded, "the outlook for industrial wireless is marked by rapid growth, deeper integration, and expanding capabilities. As organizations increasingly value flexible, scalable, and reliable wireless connectivity, adoption of advanced solutions will continue to rise—extending well beyond traditional Wi-Fi or 5G alone."

Wi-Fi 6/6E and 5G solutions

NearFi technology offers very low latency, contactless energy and data transmission.

Phoenix Contact sees several key technologies enabling new Industrial Wireless solutions. Wi-Fi 6/6E brings higher capacity, deterministic communication and improved security with OFDMA, MU-MIMO and WPA3. The use of the 6 GHz band reduces interference and supports applications such as driverless transportation systems and moving machines.

“5G, especially in the form of campus networks, opens up a largely wireless factory infrastructure. It combines high reliability, low latency and real-time capability for industrial processes,” Jörg Brasas, Strategic Product Marketing, Business Unit Automation Infrastructure for PHOENIX CONTACT GmbH

told IEB. “NearFi technology also offers very low latency, contactless energy and data transmission via air gaps or non-conductive materials, ideal for wear-critical or moving components.”

Another trend is consistent security by design in accordance with IEC 62443: wireless solutions are embedded in holistic security concepts to ensure data integrity and network protection. With these technologies, Phoenix Contact creates scalable, robust and real-time capable wireless solutions "from the sensor to the network" and lays a foundation for flexible, secure and future-proof industrial applications.

Industrial 5G in smart factory operations

“Industrial 5G acts as a lever for more flexibility, real-time capability and efficiency

“5G, especially in the form of campus networks, opens up a largely wireless factory infrastructure. It combines high reliability, low latency and realtime capability for industrial processes,” Jörg Brasas, Strategic Product Marketing, Business Unit - Automation Infrastructure for PHOENIX CONTACT.

in the smart factory,” Brasas said. “From Phoenix Contact's point of view, 5G, together with Wi-Fi 6/6E, will make standardized real-time communication and high reliability widely available on an industrial scale for the first time. As a result, production systems can be networked largely wirelessly, which reduces wiring, speeds up conversions and seamlessly integrates mobile assets such as AGV/AMR.”

At the same time, the network capacity for sensor technology, condition monitoring and data-driven services increases. In practice, 5G enables deterministic communication in control processes, extends coverage over large plant areas and supports scalable fleets of autonomous systems.

Where rotating or moving applications have additional requirements, Phoenix Contact technologies such as NearFi (contactless energy and real-time Ethernet transmission) and Industrial WLAN/Wi-Fi 6 complement the 5G infrastructure - always thinking "from the sensor to the network". Security by design is also an integral component: Industrial Wireless solutions are embedded in IEC 62443-compliant concepts to ensure that the connectivity provided by 5G remains secure.

New industrial wireless technologies

New Industrial Wireless products from Phoenix Contact combine state-of-the-art wireless technologies with consistent cybersecurity. Wi-Fi 6/6E offers OFDMA, MU-MIMO and WPA3 for high data rates, low latency and reliable communication, while the 6 GHz band reduces interference. Series such as WLAN 1020/1120 combine client and soft access point functionality for mobile applications such as AGVs. In addition, NearFi enables contactless energy and real-time Ethernet transmission via air gaps - a unique selling point compared to previous solutions.

“In the 4G/5G sector, we are focusing on the simplest connection of devices and networks with END-to-END encryption with the new Celllulink devices,” Brasas said.

He added that “a key differentiating feature is the security-by-design strategy; all products meet the requirements of IEC 62443-4-1 (secure development process) and IEC 62443-4-2 (secure components). This includes features such as secure boot processes, cryptographic key management, role-based access control and encrypted communication.”

This ensures the integrity of the data and the resilience of the network - even in highly networked smart factory environments. This creates scalable, robust and future-proof wireless networks "from the sensor to the network".

Application areas

The latest industrial wireless solutions from Phoenix Contact are addressing central application areas of the smart factory. The

Two drivers are shaping the outlook for Industrial Wireless: Artificial Intelligence (AI) and virtual solutions. AI-supported analytics optimizes radio planning, roaming parameters and anomaly detection, while virtual radio evaluation/simulation and remote services accelerate commissioning and check changes in advance with low risk.

focus is on mobile transportation systems such as AGVs and AMRs, which require reliable wireless communication for navigation and fleet management. Wi-Fi 6/6E enables stable, low-latency networking in environments with a high density of devices - ideal for flexible material flows and intralogistics.

Another area is flexible machine integration: wireless solutions enable location-independent operation, set-up and maintenance of production systems via tablets or smartphones. For moving or rotating machine parts, Phoenix Contact offers NearFi, a contactless energy and real-time Ethernet transmission system that replaces wear-prone plug connections and reduces downtime costs.

It also addresses applications in the automotive industry, machine building and logistics, where robust communication under harsh conditions and high safety requirements are crucial. All solutions are developed according to IEC 62443 standards and offer security-by-design for the protection of critical data and processes. Phoenix Contact thus creates wireless networks that combine mobility, flexibility and security - from the sensor to the network.

Engineering challenges

Automation engineers face challenges such as high cabling costs, limited flexibility during conversions and the integration of mobile systems into existing networks. Phoenix Contact addresses these problems with advanced Industrial Wireless technologies.

“Wi-Fi 6/6E and 5G make wireless communication available for the first time with high reliability and low latency, so that mobile robots, AGVs and sensors can be integrated without complex cable infrastructure. This reduces installation costs and speeds up production adaptations,” Brasas said.

He added that another obstacle is communication in moving or rotating

applications, where cable wear leads to failures. With NearFi, Phoenix Contact offers contactless energy and real-time data transmission via air gaps - a solution that drastically reduces maintenance costs and downtimes.

“There is also growing pressure to ensure IT security in networked factories. Phoenix Contact integrates security-by-design in accordance with IEC 62443-4-1 and -4-2, minimizing risks such as tampering or data loss.” Brasas said. “The result: Advanced wireless solutions eliminate cabling constraints, increase flexibility and secure the smart factory against cyber threats.”

Looking to the future

From Phoenix Contact's perspective, Industrial Wireless will become a standard component of the Smart Factory in the coming years. Wi-Fi 6/6E and 5G will become widely available and carry real-time radio into control processes; additional 6 GHz channels and higher packet rates will allow larger, more densely occupied networks for mobile robotics, intralogistics and flexible machine islands.

NearFi expands the spectrum to include contactless energy and real-time Ethernet transmission for moving/wear-critical areas. At the same time, security-by-design in accordance with IEC 62443-4-1/-4-2 is becoming a basic requirement: future wireless products and solutions will have integrated, certifiable safety functions and thus accelerate the scaling of wireless networks.

Brasas said that two drivers in particular are shaping the outlook: AI and virtual solutions. AI-supported analytics optimizes radio planning, roaming parameters and anomaly detection (e.g. for condition-based maintenance), while virtual radio evaluation/ simulation and remote services accelerate commissioning and check changes in advance with low risk.

“Key technological trends driving new industrial wireless solutions include the introduction of Industrial 5G, advancements in Time-Sensitive Networking (TSN) over wireless media, and the adoption of the latest Wi-Fi standards with new 6GHz spectrum in several countries.” -- Daniel Mai, Director Industrial Wireless Connectivity Siemens AG.

Industrial 5G and Wireless TSN

Along with the adoption of the latest Wi-Fi standards with new 6GHz spectrum.

According to Daniel Mai, Director Industrial Wireless Connectivity at Siemens AG, “key technological trends driving new industrial wireless solutions include the introduction of Industrial 5G, advancements in Time-Sensitive Networking (TSN) over wireless media, and the adoption of the latest Wi-Fi standards with new 6GHz spectrum in several countries.”

Mai said that these technologies offer higher data rates, lower latency, and improved reliability, which are essential for modern industrial applications that need more and more connectivity. As a result, there is a growing acceptance and adoption of these wireless solutions across various industries, enabling more efficient and flexible operations.

“With growth of an ecosystem of end devices supporting these new technologies the adoption will be accelerated,” Mai said.

Industrial 5G impact

“Industrial 5G is significantly impacting smart factory operations by providing deterministic and highest reliability in wireless communications. This enables reliable real-time control of machines and processes, which was sometimes challenging with other wireless technologies. The enhanced

connectivity supports the deployment of autonomous vehicles and collaborative robots, improving the flexibility and efficiency of production lines,” Mai said.

Industrial 5G also facilitates seamless communication between a vast number of devices, contributing to more integrated and intelligent manufacturing environments. Additionally, the possibility to set up tailored private 5G networks utilizing private spectrum will enable secure and interference-free wireless connectivity on industrial campuses.

Unique capabilities

Mai added that the new products offer improved performance, higher data throughput, and support for deterministic wireless communication, enabling the wireless control of mission-critical applications. They meet the need for increasing connectivity, edge computing and higher data traffic in smart factories to collect and transfer data and thus enable data driven decisions and e.g. AI applications.

Compared to previous solutions, they also provide advanced cybersecurity measures and seamless integration with existing industrial protocols, enhancing both security and ease of deployment and creating a reliable OT-backbone.

The latest industrial wireless solutions are targeting business-critical applications that

require high bandwidth, deterministic, and reliable connectivity. This includes mobile robotics, remote monitoring and maintenance, augmented reality for training and complex assembly tasks, autonomous inspections, and process automation.

“The use of wireless for industrial control is becoming more prevalent, as modern wireless technologies have addressed many of the reliability and latency concerns that previously hindered their adoption. Industries are increasingly confident in deploying wireless solutions for a broader range of control applications,” Mai said. “A big game changer will be the introduction of AI to the industrial space. AI applications need data. Implementing a reliable wireless communication infrastructure will facilitate the easy deployment of additional sensors and edge devices in existing factories to feed AI and enable data driven decision making.”

Addressing challenges

Mai said that automation engineers often face challenges such as the inflexibility of wired networks and high installation costs, especially in existing installations. Advances in industrial wireless technology are helping to overcome these issues by providing increased mobility, flexibility, and real-time communication capabilities. This allows for easier reconfiguration of production

layouts and more scalable operations, also in brownfield environments.

“Looking to the future, the outlook for industrial wireless is promising, with expected continued innovations in areas like Industrial 5G, Wi-Fi technologies, and edge computing,” Mai concluded. “These advancements are likely to lead to fully connected and highly adaptable industrial environments, driving efficiency and productivity to new levels addressing the emerging economic challenges driven by global competition and upcoming retirement waves with the associated workforce shortage.”

Industrial Wireless Evolution

Driven by the rise of automation and rapid adoption of AI.

“The industrial wireless landscape is rapidly evolving, fueled by the rise of automation and the rapid adoption of AI. A new generation of wirelessly connected assets, including AI-driven robots, autonomous and automated vehicles, and data-rich endpoints such as cameras, demands networks that deliver ultra-low latency, high reliability, and seamless handoffs,” Alice Masini, Product Manager, Industrial Wireless at Cisco told the Industrial Ethernet Book recently.

Masini said that Wi-Fi 6E and Wi-Fi 7

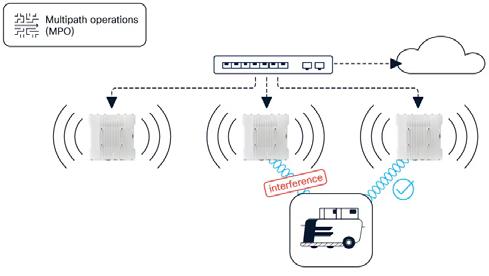

have significantly increased bandwidth and device capacity, enabling high-performance connectivity in demanding industrial environments. While 5G continues to attract attention, it remains complex and costly for many organizations. Cisco Ultra-Reliable Wireless Backhaul (URWB), an extension of Wi-Fi, is specifically designed for critical applications that require more reliability than Wi-Fi alone can provide—applications that cannot tolerate communication loss and must remain connected even while roaming amid obstacles and RF interference.

Now, Wi-Fi and URWB are integrated within the same access points, greatly simplifying network operations, reducing costs, and giving industrial organizations the flexibility to choose the optimal wireless technology for each use case.

Impact of Industrial 5G

“Industrial 5G introduces valuable capabilities such as high capacity, low latency, and reliable connectivity for a wide range of smart factory applications. However, real-world experience shows that 5G is just one component in a broader connectivity strategy,” said Masini. Technologies like Wi-Fi and URWB also play vital roles in supporting robotics, automated guided vehicles (AGVs), real-time analytics, and remote operations. The greatest impact

comes when organizations evaluate their environments and use cases and deploy the optimal combination of technologies to meet their needs. While 5G can be complex and costly for some organizations, URWB provides private 5G-like performance without the need for licensed spectrum or the associated management overhead.

Wi-Fi and URWB can be operated simultaneously in a single access point, enabling manufacturers to manage both technologies through a single interface, reducing silos between IT and OT teams, and eliminating the need for duplicate infrastructure.

Ultimately, the transformative impact in smart factories lies in adopting a mix of wireless technologies that enable more adaptive, efficient, and secure operations—a holistic approach essential for modern industrial environments.

Technology innovation

Masini said that new industrial wireless solutions deliver greater flexibility, reliability, and operational simplicity. Cisco’s access points support both Wi-Fi and URWB on a unified hardware platform, allowing organizations to use high-bandwidth Wi-Fi for general connectivity and URWB for ultrareliable, low-latency applications—all with

Remote Machine Diagnostics and Commissioning

the same device.

“URWB’s “make-before-break” approach ensures uninterrupted connectivity for applications that cannot tolerate loss during roaming. Its Multipath Operations (MPO) technology duplicates critical traffic across multiple, uncorrelated frequencies to several access points, minimizing latency and maximizing reliability,” Masini said.

The capability to enable and configure URWB and Wi-Fi in the field help extend the lifespan of devices and protects investments. Additionally, the refreshed portfolio features compact, industrial-grade form factors for easy deployment in challenging environments. These innovations enable a seamless path to digitalization, supporting advanced automation and mobility while reducing complexity and total cost of ownership compared to previous generations of industrial wireless solutions.

New Industrial Wireless solutions

Masini added that the latest industrial wireless solutions are tailored for a broad spectrum of demanding applications, such as mobile automation, autonomous vehicles, robotics, real-time monitoring, and remote control across manufacturing, logistics, and warehouses. They address the connectivity requirements of AGVs, collaborative robots, and remote machinery, where constant, reliable communication is essential.

URWB provide seamless handoffs and uninterrupted service for fast-moving or mission-critical assets. Beyond mobile

applications, URWB’s near-zero latency increasingly supports data-driven use cases, including predictive maintenance, process optimization, and AI-powered analytics, all of which drive productivity and safety improvements.

“The flexibility of Wi-Fi and URWB integration enables precise adaptation to specific needs, from fixed sensors along production lines to mobile assets operating in expansive outdoor environments. As automation and digital transformation continue to accelerate, advanced wireless connectivity is pivotal for unlocking new efficiencies and operational insights,” Masini said.

Challenges

“Automation engineers must ensure reliable, always-on connectivity in dynamic and often harsh industrial settings, support seamless mobility for autonomous assets, and scale or reconfigure networks quickly as needs change. Advances in industrial wireless—especially the convergence of Wi-Fi and URWB—are addressing these challenges with robust, high-reliability connections and simplified management. Wi-Fi supports high-bandwidth needs while URWB supports high-reliability requirements,” Masini added.

Unified hardware platforms reduce network complexity and make it easier to upgrade or transition between wireless technologies as requirements evolve. Enhanced security features guard against growing cyber threats, while improved scalability allows for the rapid addition of new devices without major

infrastructure overhauls. These innovations empower automation engineers to deploy and operate advanced automation systems with increased confidence, agility, and efficiency for safer workplaces and more resilient industrial operations.

Industrial wireless outlook

“The outlook for industrial wireless is marked by rapid growth, deeper integration, and expanding capabilities. As organizations increasingly value flexible, scalable, and reliable wireless connectivity, adoption of advanced solutions will continue to rise— extending well beyond traditional Wi-Fi or 5G alone,” Masini said.

She added that integrating technologies such as Wi-Fi 6E, Wi-Fi 7, and URWB on unified platforms will further streamline operations, reduce costs, and support even the most demanding automation, AI-driven analytics, and autonomous system requirements. Ongoing innovations in reliability, security, and ease of deployment will position wireless connectivity as the foundation of industrial digital transformation.

“Looking forward, industrial wireless will enable new applications, drive higher operational efficiency, and support the shift toward more autonomous, data-driven, and adaptive industrial environments— empowering organizations to fully realize the benefits of Industry 4.0 and beyond,” Masini concluded.

Al Presher, Editor, Industrial Ethernet Book

"The industrial wireless landscape is rapidly evolving, fueled by the rise of automation and the rapid adoption of AI. A new generation of wirelessly connected assets, including AI-driven robots, autonomous and automated vehicles, and data-rich endpoints such as cameras, demands networks that deliver ultra-low latency, high reliability, and seamless handoffs,” -- Alice Masini, Product Manager, Industrial Wireless, Cisco.

Wi-Fi 7 trials demonstrate enterprise performance gains

Recent testing shows that Wi-Fi 7 delivers increased throughput, lower latency and enhanced efficiency for high-demand, real-world enterprise environments, setting a new standard for enterprise connectivity, according to recent research released by the Wireless Broadband Alliance (WBA).

WIRELESS BROADBAND ALLIANCE WI-FI 7 trials data released in 2025 demonstrate significant performance gains in real-world enterprise environments.

The Wireless Broadband Alliance, dedicated to driving the seamless and interoperable service experience of Wi-Fi across the global wireless ecosystem, announced the results of its Wi-Fi 7 industry trials in Enterprise Scenarios, conducted in collaboration with AT&T, CommScope (RUCKUS Networks), and Intel.

The trials, designed to evaluate Wi-Fi 7’s real-world performance, demonstrated significant improvements in throughput, efficiency and latency, highlighting Wi-Fi 7’s ability to support mission-critical enterprise applications such as XR, AI, cloud computing, and industrial IoT.

The WBA Wi-Fi 7 trials focused on assessing rate vs. range performance in enterprise settings, comparing Wi-Fi 7

with Wi-Fi 6E across the 5 GHz and 6 GHz bands. The tests which were conducted in live enterprise environments, revealed that Wi-Fi 7 delivers:

• Nearly double the throughput of Wi-Fi 6E at 5 GHz using 40 MHz channels

• Sustained 1 Gbps+ throughput up to 40 feet away from the access point (AP) in the 6 GHz band with 160 MHz channels

• Lower latency and improved efficiency, supporting next-gen applications such as AR/VR, video conferencing, and automation

• Greater network reliability, helping enterprises manage high-density environments with thousands of connected devices

• Downlink of 2 Gbps and reduced congestion with MLO

The trials assessed Wi-Fi 7’s capabilities in both controlled and real-world enterprise

environments, focusing on throughput, latency, and signal range across different frequencies and channel widths. A t 6 GHz with 160 MHz channels, Wi-Fi 7 achieved nearly 2 Gbps downlink throughput at close range, maintaining over 1 Gbps up to 40 feet away. In highdensity enterprise settings, where APs must support thousands of simultaneous connections, Wi-Fi 7’s enhanced spectral efficiency and Multi-Link Operation (MLO) provided more stable, reliable connectivity, mitigating network congestion even in heavily loaded conditions.

Addressing enterprise connectivity challenges for new and legacy devices

Findings demonstrate Wi-Fi 7’s ability to address key connectivity challenges in smart offices, manufacturing, healthcare, and immersive digital environments.

The WBA Wi-Fi 7 trials focused on assessing rate vs. range performance in enterprise settings, comparing Wi-Fi 7 with Wi-Fi 6E across the 5 GHz and 6 GHz bands. The tests which were conducted in live enterprise environments.

Commercial AFC Service, Enabling Standard Power Wi-Fi in 6 GHz Band Leveraging Critical Spectrum

Wireless Broadband Alliance Services (WBA Services), a subsidiary of the Wireless Broadband Alliance, has announced the commercial launch of WBA Services AFC, its Automated Frequency Coordination (AFC) service. The cloud-based platform is fully certified by the U.S. Federal Communications Commission (FCC) and enables the deployment of standard power Wi-Fi devices in the 6 GHz band (5.925–7.125 GHz) while ensuring they do not cause interference to existing incumbents, such as fixed microwave and radio astronomy links.

The launch of WBA Services AFC reflects the organization’s goal to advance global Wi-Fi innovation, delivering faster, more reliable, and more secure wireless connectivity. By enabling standard power devices in the 6 GHz band, WBA Services is unlocking a critical new spectrum resource for high-performance use cases such as enterprise networking, smart city infrastructure, industrial IoT, and immersive experiences like AR/VR. AFC enables more efficient use of the spectrum, benefiting not only infrastructure providers and service providers, but the millions of end users and businesses that rely on seamless, wireless broadband and low-latency access in homes, offices, stadiums, and public spaces.

The WBA Services AFC is based on the OpenAFC open-source specification and provides infrastructure manufacturers, service providers, and enterprises with dynamic frequency and power management based on device location and local spectrum conditions. This ensures compliance with regulatory requirements while maximizing spectrum availability and performance.

Tiago Rodrigues, CEO of Wireless Broadband Alliance Services, said: “As the demand for high-speed, low-latency wireless connectivity grows, the 6 GHz band represents a critical resource. Our AFC service empowers the ecosystem to harness this band responsibly and effectively. This is another great example of how WBA members’ work on AFC and across our working groups is leading the industry, driving new innovations and business opportunities for Wi-Fi technologies including Wi-Fi 6E and Wi-Fi 7 in a wide range of industrial, commercial and consumer use cases.”

AFC at the core of the 6 GHz opportunity

The AFC framework is vital for enabling standard power and outdoor Wi-Fi operations in the 6 GHz band. Devices query the WBA Services AFC to determine which frequencies and power levels are permitted at their location. This enables real-time, interferencefree spectrum use for high-performance deployments in enterprise campuses, public venues, and dense urban environments, without the need for additional spectrum licenses.

Enterprises that rely on real-time collaboration, video conferencing, AI-driven automation, and AR/VR applications will benefit from Wi-Fi 7’s lower latency and higher throughput, ensuring seamless user experiences without performance bottlenecks. The trials also confirmed that Wi-Fi 7 delivers significant improvements in 5 GHz networks, where many legacy devices still operate, ensuring backward compatibility and an easier transition for enterprises upgrading their infrastructure.

While This trial focused on 160 MHz channels in the 6 GHz band which would be typical for high-density commercial Wi-Fi 7 network deployments requiring many access points. However, most of today’s Wi-Fi 7 devices also support 320 MHz channels which would be more common for smaller networks, and enable even higher levels of performance for hybrid work and consumer experiences as documented in the recent WBA Wi-Fi 7 Trial report for residential settings.

Here is what industry experts had to say about the future of Wi-Fi 7.

Tiago Rodrigues, President and CEO of the Wireless Broadband Alliance

"Wi-Fi 7 is not just an evolution, it’s a game changer for enterprise connectivity. These trials prove that Wi-Fi 7 offers real-world improvements in speed, reliability, and

efficiency that businesses need to support the next generation of applications. As adoption accelerates, enterprises will see tangible benefits in everything from hybrid work and immersive experiences to AI-driven automation. The WBA is committed to ensuring the industry has the data and insights needed to maximize Wi-Fi 7’s potential."

JR Wilson, VP, Tower Strategy & Roaming at AT&T

"Enterprises are demanding more from their Wi-Fi networks than ever before. These trials confirm that Wi-Fi 7 can deliver the high-performance, low-latency connectivity required for modern digital environments. At AT&T, we see Wi-Fi 7 as a key enabler for businesses looking to optimize their operations and embrace the future of connectivity."

Mittal Parekh, Senior Director, Business Development RUCKUS Networks at CommScope

"Wi-Fi 7 introduces groundbreaking features like Multi-Link Operation (MLO) and 4K QAM, which significantly enhance network efficiency and throughput. Our participation in these trials has demonstrated how enterprises can leverage these advancements to enable the most demanding applications in the most challenging environment in a variety of industry verticals.”

Eric A. McLaughlin, VP & GM Connectivity Solutions Group, Intel Corporation

"6 GHz Wi-Fi 7 marks a major leap forward in wireless technology, and the results of our collaboration in these trials reinforce its real-world benefits. Business PC users can enjoy enhanced productivity and collaboration experiences in the office or in hybrid work scenarios as 160 MHz channel use scales broadly across corporate networks and 320 MHz channels become mainstream at home. With improved spectrum utilization and dramatic performance improvements, the findings of the trial help underscore Wi-Fi 7’s ability to meet the needs of next-gen applications in enterprise, industrial, and residential settings."

Driving Wi-Fi 7 adoption

Following these successful trials, the WBA will continue to collaborate with industry leaders to accelerate Wi-Fi 7 adoption, refine implementation strategies, and support enterprises in leveraging Wi-Fi 7’s full potential.

To learn more about the WBA’s Wi-Fi 7 initiatives and trial findings, visit The Road to Wi-Fi 7 link below.

Technology article by the Wireless Broadband Alliance (WBA).

Learn More

Meeting the demands of evolving industrial wireless connectivity

By leveraging Wi-Fi and URWB, industrial enterprises can unlock the full potential of agile, resilient and intelligent wireless networks—empowering them to lead the way in deploying next-generation, AI-powered solutions across even the most challenging environments.

INDUSTRIAL ORGANIZATIONS ARE AT A pivotal moment. As digital transformation accelerates, the demand for robust, agile, and secure wireless networks is skyrocketing. The rise of automation, artificial intelligence (AI), and mobility is fundamentally changing how industrial environments operate.

Today’s wireless networks are now expected to support not just more devices and applications, but also to underpin mission-critical operations where reliability is non-negotiable.

The growing complexity of industrial wireless

Modern industrial wireless networks face a unique and complex set of technical challenges:

Device density: The sheer volume of connected sensors, cameras, and mobile assets can lead to congestion and interference.

Diversity of devices and applications: Networks must support everything from legacy sensors to bandwidth-hungry 4K cameras and real-time AI applications— each with distinct performance needs.

Demand for high speeds: Applications like high-definition video, AR/VR, and AI-powered vision systems require higher data rates than traditional wireless can always provide.

Ultra-Low latency needs: Real-time control and analytics depend on minimal lag for safety, efficiency, and fast decisionmaking.

Security and reliability: As more businesscritical processes move to wireless, the network must be both highly reliable and highly secure, ensuring uninterrupted operations.

Operationally, network managers are also navigating increased complexity:

Agility and scalability: Wireless networks are expanding rapidly, often beyond traditional office spaces, even as IT budgets and resources remain constrained.

Consistent performance: Delivering seamless coverage and a consistent user experience, even in high-density or interference-prone areas, remains a constant challenge.

Security and compliance: Protecting the

network from unauthorized access and cyber threats, while ensuring regulatory and corporate compliance, is more crucial than ever.

The good news is that wireless technologies are evolving rapidly to meet these demands. Let’s look at three key advances shaping the future of industrial connectivity:

Wi-Fi 7: Raising the Bar for Wireless Performance

Wi-Fi 7 is the latest evolution in wireless networking, offering significant improvements in speed, capacity, and efficiency. With support for higher throughput, lower latency, and advanced management of dense device environments, Wi-Fi 7 is well suited for many industrial

applications—from high-definition video streaming and AR/VR to large-scale IoT deployments. Its improved spectrum utilization and multi-link operation help organizations overcome many traditional bottlenecks, setting a new benchmark for enterprise wireless.

Private 5G: powerful, but not without hurdles

Private 5G networks are generating excitement for their potential to deliver ultra-low latency, strong security, and robust support for a diverse range of industrial use cases. However, deploying Private 5G can be complex. It often requires dedicated spectrum licenses, specialized expertise, and a significant upfront investment in infrastructure. For

URWB has been used across different industrial settings to support mission-critical applications that require near-zero latency and uninterrupted hand-offs.

many organizations, these factors make widespread adoption a longer-term goal rather than an immediate solution.

URWB: purpose-built for industrial reliability

Ultra-reliable Wireless Backhaul (URWB) addresses the specific needs of missioncritical applications that are very sensitive to latency or require uninterrupted roaming.

URWB delivers the ultra-low latency, seamless mobility and consistent reliability that traditional wireless technologies may struggle to guarantee in harsh, dynamic, or mobile industrial environments.

URWB is built on 802.11, and like Wi-Fi, it operates in unlicensed spectrum which simplifies deployment and reduces costs. URWB delivers near-zero latency (<10ms) and seamless handoffs —enabled by key technical innovations:

• An end-to-end overlay technology emulates a virtual switch over 802.11 wireless links to deliver ultra-low latency (<10ms).

• Ultra-fast failover in less than 500ms delivering carrier-grade availability.

• “Make-before-break” handoffs ensures moving assets establish a reliable connection with a new access point before dropping connectivity from the previous access point.

• Multipath Operations (MPO) technology replicates high-priority packets via up to 8 different paths on uncorrelated frequencies at the same time to multiple access points, exploiting time, spatial, and frequency diversity.

This functionality, combined with cutting edge hardware capability, can further reduce latency and improve reliability, addressing both interference and hardware failures.

With these capabilities, URWB is able to bridge the gap between the promise of next-generation wireless and the realities of industrial operations— enabling organizations to confidently connect autonomous vehicles, robotics, remote sensors, and more, even in the most demanding settings. URWB has been successfully used across diverse industrial settings:

In factories, warehouses and healthcare facilities, it keeps hundreds of automated guided vehicles continuously connected, boosting uptime and workplace safety.

In mines, it enables critical remote control of unmanned vehicles in treacherous terrain, ensuring instant response for improved precision and safety.

In ports, it connects cranes, machinery, and automated vehicles, feeding real-time data to Terminal Operating Systems to maximize port capacity, throughput, and efficiency.

Multipath Operations (MPO) technology replicates high-priority packets via up to 8 different paths on uncorrelated frequencies at the same time to multiple access points.

And on the rails, it ensures continuous telecommunications for traffic management, delivering safer, more efficient, and highercapacity rail operations.

URWB has been used across different industrial settings to support missioncritical applications that require near-zero latency and uninterrupted hand-offs.

Tackling operational complexity with unified wireless integration

Together, Wi-Fi and URWB offer an unparalleled wireless solution, with Wi-Fi supporting high-speed, low-latency requirements and URWB ensuring reliable communication for applications that require ultra-low latency and seamless roaming.

That is why we integrated URWB and Wi-Fi technologies in a wide selection of our Wi-Fi 7, 6E and 6 access points enabling organizations to unlock new use cases and capabilities without overhauling their existing network.

URWB and Wi-Fi technologies are now integrated in a wide selection of Cisco Wi-Fi access points enabling organizations to support a wider range of devices and applications while streamlining deployments, simplifying management, and reducing costs.

This unified approach offers several advantages:

Streamline deployment and save costs: Both Wi-Fi and URWB operate simultaneously on the same hardware platform, so there is no need to duplicate the infrastructure.

Simplified operations: Administrators can manage URWB and Wi-Fi from a single pane of glass using Wireless LAN Controllers (WLC) or Cisco Catalyst Center. This greatly simplifies network operations and lifecycle management.

Increased security: Security policies can

be pushed across Wi-Fi and URWB networks.

End-to-end solution: Wi-Fi with URWB access points come in a variety of form factors supporting indoor, outdoor and industrial use cases eliminating complexities, and the additional cycles of dealing with point solutions and multiple vendors.

By bringing together the strengths of high-speed Wi-Fi and ultra-reliable URWB, Cisco delivers a comprehensive wireless solution that supports a wide range of industrial use cases—without the need for costly network overhauls or complex, siloed systems.

The future of industrial wireless

As industrial organizations accelerate their digital transformation, driven by the adoption of AI and automation, the need for reliable, high-performance wireless connectivity will only grow.

Cisco’s integrated approach—combining the robust capabilities of URWB with the operational flexibility and performance of our Wi-Fi access points—empowers organizations to power complex, innovative use cases, such as autonomous systems, predictive analytics, and real-time monitoring, all of which require seamless, always-on connectivity.

By leveraging Wi-Fi and URWB, industrial enterprises can unlock the full potential of agile, resilient, and intelligent wireless networks—empowering them to lead the way in deploying next-generation, AI-powered solutions across even the most challenging environments.

Patricia Costa, Sr. Marketing Manager, Industrial Wireless, Cisco.

Learn More

IEB Special Report: Industrial Ethernet in an AI World

As AI makes an impact, smart manufacturing is looking for solutions that combine automation, AI and secure architectures from edge-to-cloud to optimize operations and reduce exposure to cyber, compliance and operational risks. The immediate goals: cybersecurity, quality control, logistics and process optimization.

The Impact of AI in Smart Manufacturing

Smart manufacturing is expected to be profoundly changed with the infusion of a wide array of AI technologies, and anticipated advances in cybersecurity, machine learning, use of Big Data and cloud computing architectures. The future of Industrial Ethernet networks will be fundamentally shaped by advances in artificial intelligence (AI) and virtual technologies.

THE IMPACT OF AI ON INDUSTRIAL ETHERNET is expected to result in profound changes to the fundamental landscape of industrial networks according to industry experts that the IEB interviewed for this special report. Here are a few of the findings:

AI technology is poised to profoundly influence automation and control networking by requiring networks to become faster, more reliable, and more secure while also driving the adoption of smarter, more flexible architectures. Industrial Ethernet networks will be fundamentally shaped by advances in artificial intelligence (AI) and virtual technologies. AI will be used to create more adaptive, secure, and self-optimizing Industrial Ethernet networks.

Read on to learn details on how Industrial Ethernet will evolve and adapt in an AI world.

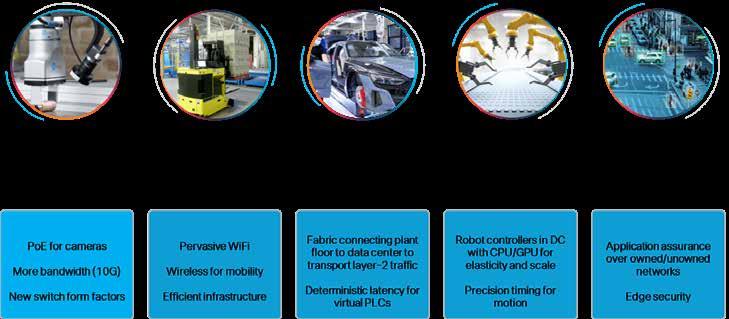

Speed, reliability and security

Industrial networks using AI must be scalable, flexible, and high bandwidth.

“AI technology is poised to profoundly influence automation and control networking by requiring networks to become faster, more reliable, and more secure while also driving the adoption of smarter, more flexible architectures,” Vivek Bhargava, Product Marketing Manager at Cisco told the Industrial Ethernet Book recently.

Bhargava said that, because AI is limited by the quality of its input data, industrial networks must gear up to deliver pristine, comprehensive data to AI applications. This data needs to be gathered from as many sources as possible to include all causalities, must be transmitted without hiccups so as

not to lose any important packets, must be secured and protected, and delivered in near real-time to avoid delays.

“AI's demands directly translate into specific network requirements. To gather the maximum data from all available sources, the network must be scalable, flexible, and high bandwidth. To maintain an uninterrupted data stream, it needs to be resilient, recovering from failures quickly without dropping packets. Furthermore, the network must offer robust security to protect sensitive data and guarantee low-latency, low-jitter data transmission for time-sensitive AI applications,” Bhargava said.

Technology megatrends

“Newer industrial switches offer key hardware features to meet modern network demands.

in the data center

Nervous system is the network

Physical components in the field

Network

They provide multiple high-speed 10 Gbps uplinks. high-density, high-wattage Power over Ethernet (PoE) to simplify deployment, and flexible connectivity options with both copper and fiber ports,” Bhargava said.

“Designed for harsh environments, they feature compact form factors and IP67 ratings for use in confined or moisture-prone areas.”

Similarly, Industrial wireless is evolving to support industrial AI by delivering highly reliable, near-zero latency, seamless handoffs even at high speeds, and uninterrupted secure connectivity tailored for industrial applications.

He added that, from a software perspective, a number of features are critical for industrial

AI. Software-defined networking enables scaling the network and making it flexible to adapt to changes quickly. Built-in visibility for connected devices and traffic, segmentation based on access policies and zero-trust principles, and secure remote access is critical for keeping out malware, protecting data, and easy access to configuring and monitoring devices.

Finally, comprehensive visibility across both owned and unowned networks is vital for proactively identifying and resolving potential issues.

From a connectivity perspective, it is important that the industrial networks seamlessly and securely connect to the

enterprise network to reach to datacenters and cloud, enabling data-driven decision making, remote monitoring and control, and for regulatory compliance.

Key application areas

“Industrial Ethernet enables a broad and diverse set of AI and automation use cases. Some of the key ones that are gaining rapid popularity include machine vision systems, adaptive robotics, software-defined automation, and sustainability,” Bhargava said.

Machine vision systems, used for product quality assessment, barcode scanning, and robotic coordination, require industrial

The industrial network connects assets to intelligence.

Industrial AI’s reliance on high-performance networking.

"AI

switches for high-wattage PoE and high-speed ports to connect cameras to continuously learning and inferencing AI applications in co-located servers.

AI-driven adaptive robotics for tasks such as tactile insertion and valve manipulation use a variety of sensors that need highbandwidth, low-latency, and resilient connectivity to function effectively.

Software-defined automation technology used to virtualize industrial PCs (IPC) and programmable logic controllers (PLCs) also depend on low-latency low-jitter networks with a scalable fabric to tunnel Layer-2 control messages between machines and their controllers.

“By collecting vast data through their networks, manufacturers use AI to simulate scenarios that directly improve industrial efficiency, product quality, and reduce energy consumption, thereby increasing sustainability,” Bhargava added.

Looking into the future Bhargava said that the challenges facing automation engineers in the future are largely driven by the demands of Industry 4.0 and the increasing complexity of OT networks due to the necessity of connecting an unprecedented number of sensors, actuators,

and devices.

“Modern Industrial Ethernet switches are empowering automation engineers to upgrade operations and accelerate innovation. These switches with their high-speed ports, highwattage PoE, low-latency switching, built-in security, and resiliency, enable a shift toward flexible software-based solutions and ensure engineers have the timely data needed for superior decision-making,” Bhargava said.

Modern switches also significantly benefit OT teams and automation engineers by enabling faster troubleshooting to minimize unplanned downtime, maintaining operational agility, and optimizing PoE power usage. Moreover, modern switches facilitate a necessary partnership between IT and OT. By standardizing the OT network to be compatible with IT infrastructure, organizations can leverage the same management tools, apply consistent security policies enterprise-wide, and utilize existing IT expertise within the operational domain.

Paradigm shift for industrial networks

Industrial Ethernet networks will be fundamentally shaped by advances in artificial intelligence (AI) and virtual technologies.

“The future of Industrial Ethernet networks will be fundamentally shaped by advances in artificial intelligence (AI) and virtual technologies. Phoenix Contact views AI as a key driver in optimizing network management, fault diagnosis and predictive maintenance,” said Julia Reker, Director Network Technology, Industry Management and Automation for PHOENIX CONTACT GmbH. “AI-based systems analyze network data in real time, detect anomalies at an early stage, and enable automated responses-a crucial step towards self-healing networks.”

Reker said that virtual solutions such as digital twins, complement this development by creating virtual replicas of physical networks. These enable simulation-based planning, commissioning and optimization of communication structures-particularly in complex automation environments.

Combined with Industrial Ethernet and wireless technologies such as Wi-Fi 6 or 5G, highly available, adaptive networks are emerging that meet the growing demands for flexibility, security and data availability.

Phoenix Contact positions itself as a solution provider that integrates and further develops both traditional Ethernet infrastructures and AI-based, softwaredefined network concepts.

technology is poised to profoundly influence automation and control networking by requiring networks to become faster, more reliable, and more secure while also driving the adoption of smarter, more flexible architectures. Because AI is limited by the quality of its input data, industrial networks must gear up to deliver pristine, comprehensive data to AI applications," -- Vivek Bhargava, Product Marketing Manager, Cisco Industrial IoT.

Key technology trends

According to Reker, industrial communication is on the brink of a paradigm shift. Phoenix Contact sees the combination of highperformance hardware, AI-driven software and flexible connectivity solutions as the key to the future of industrial Ethernet networks. Technologies such as Time-Sensitive Networking (TSN) enable the deterministic convergence of IT and OT worlds, while wireless real-time communication via 5G and Wi-Fi 6 creates new levels of freedom in automation.

“Virtual solutions such as digital twins and AI-based network diagnostics are transforming planning, commissioning and maintenance-shifting from reactive to predictive processes. REST APIs in communication modules open new avenues for automated machine integration. At the same time, cybersecurity is moving into focus, with IEC 62443-compliant solutions ensuring networks are resilient and futureproof,” said Reker.

Phoenix Contact is pursuing a holistic approach where Industrial Ethernet is becoming not only faster and more flexible, but also smarter serving as the backbone for tomorrow’s intelligent, connected production.

Industrial Ethernet solutions

“Industrial Ethernet is a key enabler for digital transformation in machine and

process automation,” Reker said. “Phoenix Contact sees its role not only in technological advancement, but also as an active architect of the All Electric Society-a vision of the future where energy from renewable sources is used efficiently, intelligently and entirely electrically.”

In this context, she added that Industrial Ethernet enables seamless networking of machines, sensors and controllers, both wired and wireless via 5G and Wi-Fi 6. This is essential for mobile applications such as AGVs or modular production lines.

Virtual solutions such as digital twins and AI-based diagnostic systems support predictive maintenance and optimize energy flows in real time. In this way, Industrial Ethernet becomes the infrastructure for a connected, energy-efficient and CO2-neutral production environment-in line with the All Electric Society.

Automation engineering challenges

Reker said that automation engineers are facing increasing complexity: rising volumes of data, shorter innovation cycles and more stringent cybersecurity requirements. Phoenix Contact addresses these challenges with a future-oriented Industrial Ethernet portfolio that combines openness, scalability and intelligence. A central focus is the convergence of both IT

and OT technologies.

“Technologies such as Time-Sensitive Networking (TSN) enable deterministic communication over a shared network-the foundation for virtualized control systems and software-defined architectures. This is complemented by wireless real-time communication via 5G and Wi-Fi 6, which supports mobile applications such as AGVs or modular machine concepts,” Reker said.

“Virtual solutions such as digital twins and AI-supported diagnostic systems help to manage complexity and automate maintenance processes. At the same time, Single Pair Ethernet (SPE) creates new opportunities for seamless communication right down to the field level," she added.

Adaptive, secure, selfoptimizing networks

AI can assist with intelligent network configuration for optimal performance and redundancy.

According to Pooyan Dehghani, Product Marketing Manager at Moxa Europe GmbH, “AI will be used to create more adaptive, secure, and self-optimizing Industrial Ethernet networks. It can assist with intelligent network configuration for optimal performance and redundancy. Beyond

“The future of Industrial Ethernet networks will be fundamentally shaped by advances in artificial intelligence (AI) and virtual technologies. Phoenix Contact views AI as a key driver in optimizing network management, fault diagnosis and predictive maintenance,” -- Julia Reker, Director Network Technology, Industry Management and Automation for PHOENIX CONTACT GmbH.

“AI will be used to create more adaptive, secure, and self-optimizing Industrial Ethernet networks. It can assist with intelligent network configuration for optimal performance and redundancy. Beyond setup, AI can monitor performance and automatically reroute traffic, adjust priorities, or reconfigure topology based on production needs or failures,” -- Pooyan Dehghani, Product Marketing Manager at Moxa Europe GmbH.

setup, AI can monitor performance and automatically reroute traffic, adjust priorities, or reconfigure topology based on production needs or failures.”

Dehghani added that machine learning trained on network traffic can recognize unusual activity and detect attacks.

“AI and ML support predictive maintenance by identifying potential issues before they become visible. In time-sensitive environments, integrating AI with TSN enables dynamic bandwidth allocation, lower latency, and adaptive responses to real-time traffic,” Dehghani said. “Pairing AI with digital twins allows 'what-if' modeling to predict bottlenecks and test configurations before deployment.”

The future of Industrial Ethernet

Dehghani said that high-performance switches and routers are required to support TSN and deterministic Ethernet, plus robust edge devices that can help move processing closer to the factory floor.

A key development is AI-powered switches that embed AI or ML into network hardware. These switches enable autonomous optimization, predictive diagnostics, and enhanced cybersecurity by analyzing traffic in real time to improve reliability and reduce latency.

“AI-powered platforms are being

integrated into network design, monitoring, and optimization. Advanced management solutions use AI and ML to detect abnormalities, optimize traffic, and simplify troubleshooting and device configuration,” Dehghani said. “The same analytics can strengthen cybersecurity by detecting unusual behaviors and threats.”

Key application areas

Dehghani added that both process and discrete manufacturing are under pressure to become more data-driven, adaptable, and efficient, while meeting rising cybersecurity and performance demands. In discrete industries such as electronics, packaging, and automotive, Industrial Ethernet connects machines, robots, and enterprise systems in real time.

This enables instant data sharing for quality control, production tracking, and order visibility, which supports more adaptable and resilient operations. In process industries such as energy, food and beverage, and pharmaceuticals, Ethernet-based networks help ensure continuous and safe operation while improving sustainability.

Real-time optimization across remote plants, predictive maintenance, and tighter process control are all supported. Combined with edge computing and AI, Industrial Ethernet provides a fast, predictable,

and secure backbone for fully connected, intelligent manufacturing. Standardized Ethernet communication lets data flow from the shop floor to enterprise and supply chain systems for better visibility and decisionmaking.

“Automation engineers still face complex troubleshooting, manual device setup, and rising cybersecurity threats. Configuring each device from discovery to deployment is timeconsuming and error-prone,” Dehghani said. “Finding the root cause of network issues can be difficult and costly, and keeping every device updated and secure is a constant task.”

He added that new Industrial Ethernet solutions with AI capabilities are starting to help. Intelligent tools can monitor performance, automate configuration, and assist with troubleshooting.

“AI and ML can sift large volumes of network data to detect early warning signs, forecast failures, and suggest maintenance before disruptions occur,” Dehghani said. “They can also enhance defenses by detecting anomalous activity. AI is not a magic fix, so human oversight remains essential. In industrial networks, where reliability is critical, engineers interpret, validate, and refine AI’s suggestions.”

Al Presher, Editor, Industrial Ethernet Book

Advancing Physical AI safety systems in manufacturing

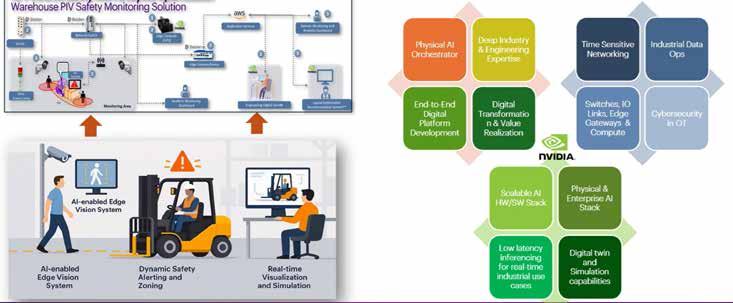

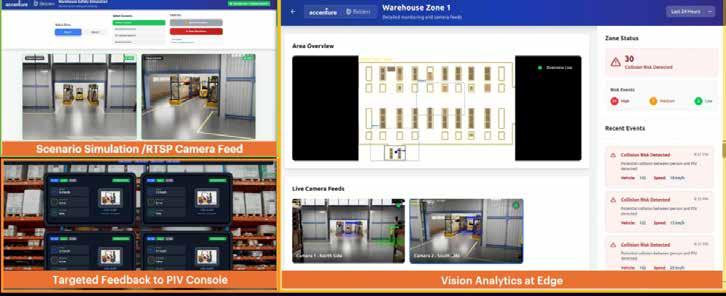

New virtual safety fence and real-time quality inspection systems use industrial-grade network infrastructure. Accenture, NVIDIA, and Belden are creating safer, smarter, and more connected industrial operations where the physical and digital worlds converge.

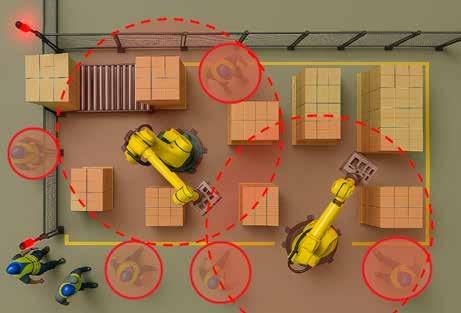

BELDEN. HAS COLLABORATED WITH ACCENTURE to help develop and deploy physical AI systems for worker safety in factories and warehouses. The systems demonstrate how time-sensitive network infrastructure enables advanced AI applications that enhance worker safety, improve quality control and modernize existing factory operations as modern manufacturing increasingly integrates autonomous systems alongside human operators.

"By providing the full stack of technology from sensor to edge, we're enabling manufacturers to implement advanced AI safety systems using existing factory infrastructure."

Belden’s virtual safety fence solution was developed with Accenture’s “Physical AI Orchestrator,” which uses NVIDIA Omniverse, NVIDIA Metropolis libraries for digital twins and agentic AI from Accenture. It applies computer vision and closed-loop control to

monitor worker movements and automatically pause robotic operations when humans enter hazardous zones.

Following the pilot project completed in September, the virtual safety fence solution is now expected to be commercially deployed at an automotive manufacturer for pedestrian safety in warehouse environments later this year. "The physical AI safety systems we are building represent our evolution from

Accenture's Physical AI Orchestrator, powered by NVIDIA Omniverse and NVIDIA Metropolis libraries and integrated with Belden's Time-Sensitive Network, enables real-time monitoring and orchestration.

Accenture, NVIDIA, and Belden are creating safer, smarter, and more connected industrial operations where the physical and digital worlds converge.

Making Safer Spaces: NVIDIA and Partners Bring Physical AI to Industrial Infrastructure

Advanced blueprints, vision language models and synthetic data generation extensions accelerated by NVIDIA RTX PRO 6000 Blackwell GPUs enhance productivity and improve safety across environments.

Physical AI is becoming the foundation of smart cities, facilities and industrial processes across the globe. NVIDIA is working with companies including Accenture, Avathon, Belden, DeepHow, Milestone Systems and Telit Cinterion to enhance operations across the globe with physical AI-based perception and reasoning.

The continuous loop of simulating, training and deploying physical AI offers sophisticated industrial automation capabilities, making cities and infrastructure safer, smarter and more efficient. For example, physical AI applications can automate potentially dangerous tasks for workers, such as working with heavy machinery. Physical AI can also improve transportation services and public safety, detect defective products in factories and more.

Advancing Physical AI

Accenture is collaborating with Belden, a leading provider of complete connection solutions, to enhance worker safety by creating smart virtual fences that factories can place around large robots to prevent accidents with human operators.

The smart virtual fence is a physical AI safety system that uses an OpenUSD-based digital twin and physics-grounded simulation to model complex industrial environments. Using computer vision-based mapping and 3D spatial intelligence, the system is adaptive to increased variability in the dynamic human-robot interactions that occur in a modern shopfloor environment.

Accenture taps into the NVIDIA Omniverse platform and Metropolis to build and simulate these smart fences. With Omniverse, Accenture created a digital twin of a robot arm and workers moving in a space. And with Metropolis, the company trained its AI models and deployed them at the edge with video ingestion and the NVIDIA DeepStream software development kit (SDK)’s real-time inference capabilities.

connectivity products to comprehensive industrial solutions," said German Fernandez, VP of Ecosystem Partner Programs at Belden. "By providing the full stack of technology from sensor to edge, we're enabling manufacturers to implement advanced AI safety systems using existing factory infrastructure."

Enabling synchronized precision for safety-critical applications

The technical breakthrough centers on Belden's Time Sensitive Networking (TSN) capabilities, which enable microsecondprecise synchronization of video streams from multiple cameras across factory floors. This synchronization is essential for accurate tracking of people and equipment movement in real-time safety applications.

"The physical AI systems we help Belden build on Accenture’s Physical AI Orchestrator platform address the critical need to protect workers while maintaining the operational flexibility that modern manufacturing demands," said Ramalingam Hariharan, a managing director at

Accenture.

"Industrial-grade networking protocols are critical for safety applications that require precise timing," said Fernandez. "Our TSN technology enables real-time, closed-loop control between AI systems and production equipment, which is fundamental for both safety and quality applications."

Belden’s physical AI systems also demonstrate real-time quality inspection capabilities. During another pilot project with pharmaceutical blister packs, AI-powered vision systems successfully identified incomplete or damaged packages and automatically triggered robotic removal systems while maintaining full production speed.

Belden’s new physical AI systems are the result of each company's core capabilities: Belden provides industrial networking infrastructure and protocol integration with embedded security; NVIDIA provides simulation, agentic AI and accelerated computing platforms; and Accenture brings expertise and capabilities in physical AI, manufacturing automation, systems integration, industry and reference architectures.

Supporting manufacturing transformation

Belden’s new physical AI systems address two key manufacturing challenges: labor shortages and enabling rapid facility modernization. As manufacturers struggle to find experienced workers, AI-enhanced safety systems help protect newer personnel by providing intelligent hazard detection and automated safety responses.

The integrated approach reduces both infrastructure costs and complexity while improving overall equipment effectiveness. The same network infrastructure that handles safety monitoring can simultaneously manage quality inspection and other industrial applications, demonstrating the multi-service network capabilities that distinguish the breadth of Belden's automation solutions.

Belden and Accenture

Learn More

Photo courtesy of Belden and Accenture.

AI-based tech cuts operational costs by 35 percent

Building X deployed as central operational system at the San Juan de Dios Hospital in Seville, Spain, has enhanced efficiency and sustainability. The digital building platform, with its AI-based apps, integrates energy management, security, and HVAC systems into a single solution.

SIEMENS SMART INFRASTRUCTURE HAS partnered with San Juan de Dios Hospital in Seville, Spain, to transform it into a smart and sustainable asset. With buildings accounting for around 40 percent of global carbon emissions, and healthcare facilities increasingly facing financial and sustainability pressures, improving operational efficiency is crucial.

Digital building technology

At San Juan de Dios Hospital, Siemens has turned this challenge into an opportunity with its AI-based digital building technology. By deploying its innovative solutions Siemens enabled the hospital to cut operating costs of the analyzed assets by 35 percent, setting another benchmark for hospitals across the globe.

San Juan de Dios Hospital, which enjoys a history spanning more than 450 years, has undergone impressive transformation using Siemens’ fully digital, AI-powered building platform Building X and digital services. The solution integrates energy and security

management, as well as Heating, Ventilation and Air Conditioning (HVAC) automation into a single system. This leads to significant operational as well as energy efficiency gains for building managers. Siemens’ technology and services are expected to enable a further reduction of 10 percent in operating costs, thanks to early fault detection and optimized equipment use.

BuildingX technology

“With Siemens’ technology, we have gone beyond simple automation. We now have an intelligent system that coordinates, optimizes, and anticipates the functioning of our facilities, improving care quality and the well-being of those around us,” said María Jesús Pareja, Managing Director at San Juan de Dios Hospital.

“This project sets another benchmark for hospital digitalization globally. By harnessing AI and interoperable platforms, healthcare facilities can transform operational complexity into simplicity and resilience – ultimately improving care outcomes while cutting costs,”

said Delphine Clément, Global Head of Verticals at Siemens Smart Infrastructure Buildings.

At San Juan de Dios Hospital in Seville, Siemens has deployed a digital layer that integrates remote digital services for fault detection and diagnostics, intrusion detection via Siemens’ Siveillance Suite, and the Desigo CC building management system. As part of the Building X platform, Operations Manager and Energy Manager provide real-time visibility into building performance and energy consumption, enabling smarter decision-making, improved operational efficiency, and measurable sustainability gains.

Building X is a digital building platform that supports customers to digitalize, manage, and optimize their building operations. It is part of Siemens Xcelerator, an open digital business platform that enables customers to accelerate their digital transformation easier, faster and at scale.

Siemens

Digital building platform, Building X, with its AI-based apps integrates energy management, security, and HVAC systems into a single solution.

AI and machine learning in autonomous trains and trolleys

Artificial Intelligence and Machine Learning technology applies reasoning with uncertainty, autonomous path planning, collision avoidance, swarm technology and sensor fusion support to autonomous trains and trolleys.

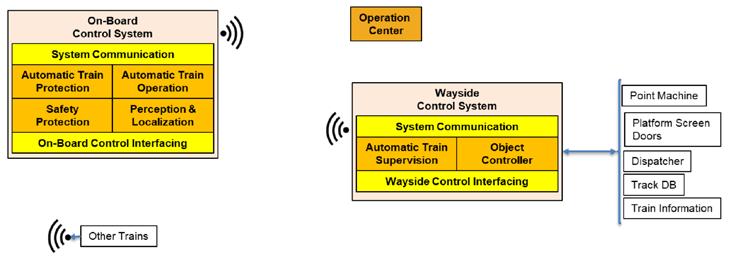

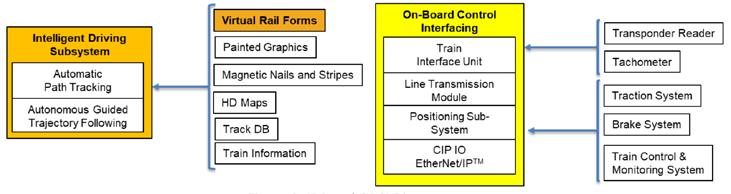

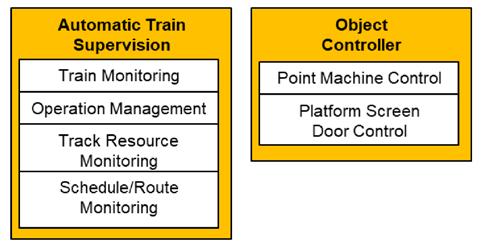

A TECHNICAL OVERVIEW ON THE USE OF Artificial Intelligence (AI)/Machine Learning (ML) illustrates how it can be applied in autonomous passenger and freight trains.

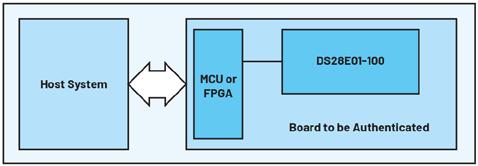

It describes how, on train wagons, AI/ ML applications can be connected to a single Gigabit Ethernet network that uses the Common Industrial Protocol (CIP). The network connects all sensors, controllers, and actuators in the wagons, as well as wired and wireless entertainment, and feeds the information to the AI/ML applications.

Artificial Intelligence/Machine Learning (AI/ML) subjects (reasoning with uncertainty, autonomous path planning, collision avoidance, swarm technology, sensor fusion, etc.) are used to support the use cases of trains and trolleys.

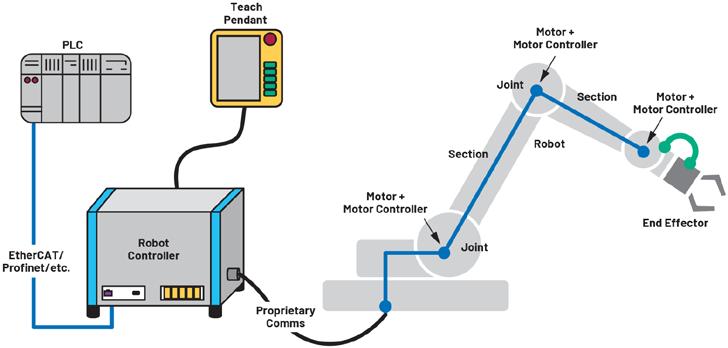

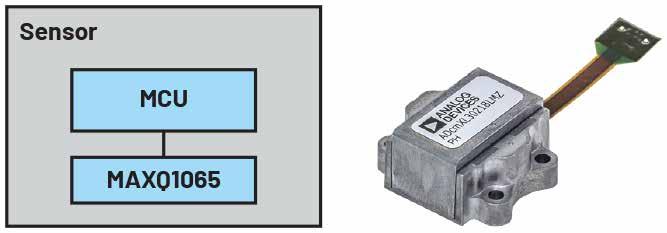

Grade of Automation