I’m Hugo. I’m a second year student at Nottingham Trent University studying BSC product design. I enjoy fulfilling hobbies such as Drumming, Acoustic guitar, Herpetology and caring for exotic animals.

As well as being a designer, I want to be an inventor. This portfolio showcases some of my best work throughout my time at NTU. I have taken a profound interest in both CAD and rendering and aim to improve my skills as i progress, allowing me to bring my ideas to life.

GCSE - 8 + Maths/English

2013 - 2018

Abbeygate College

A-Level:

- Biology

- Business Studies

- Computer science

BSC - Product Design

2018 - 2019

Sir John deans college

2020

Nottingham Trent university

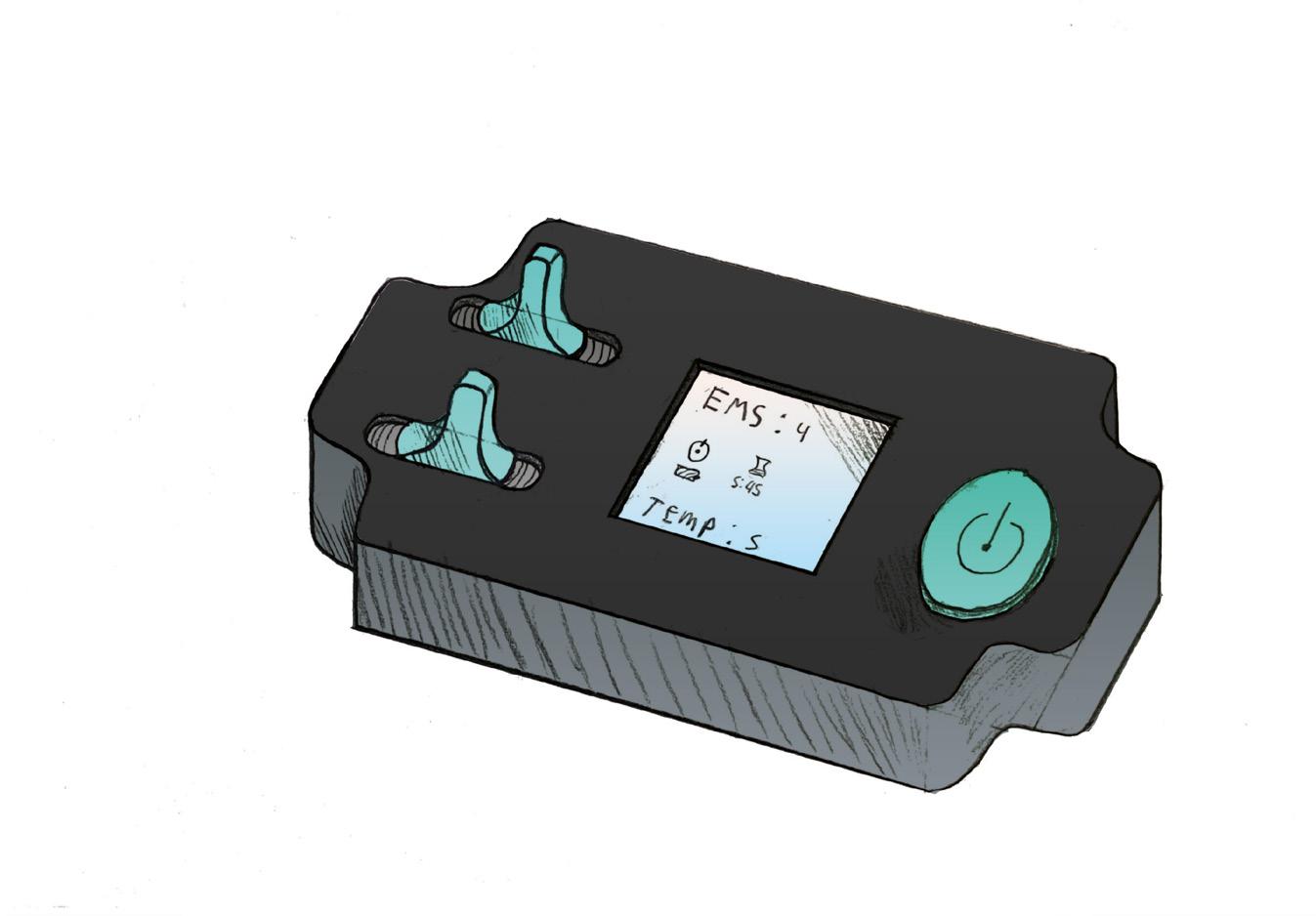

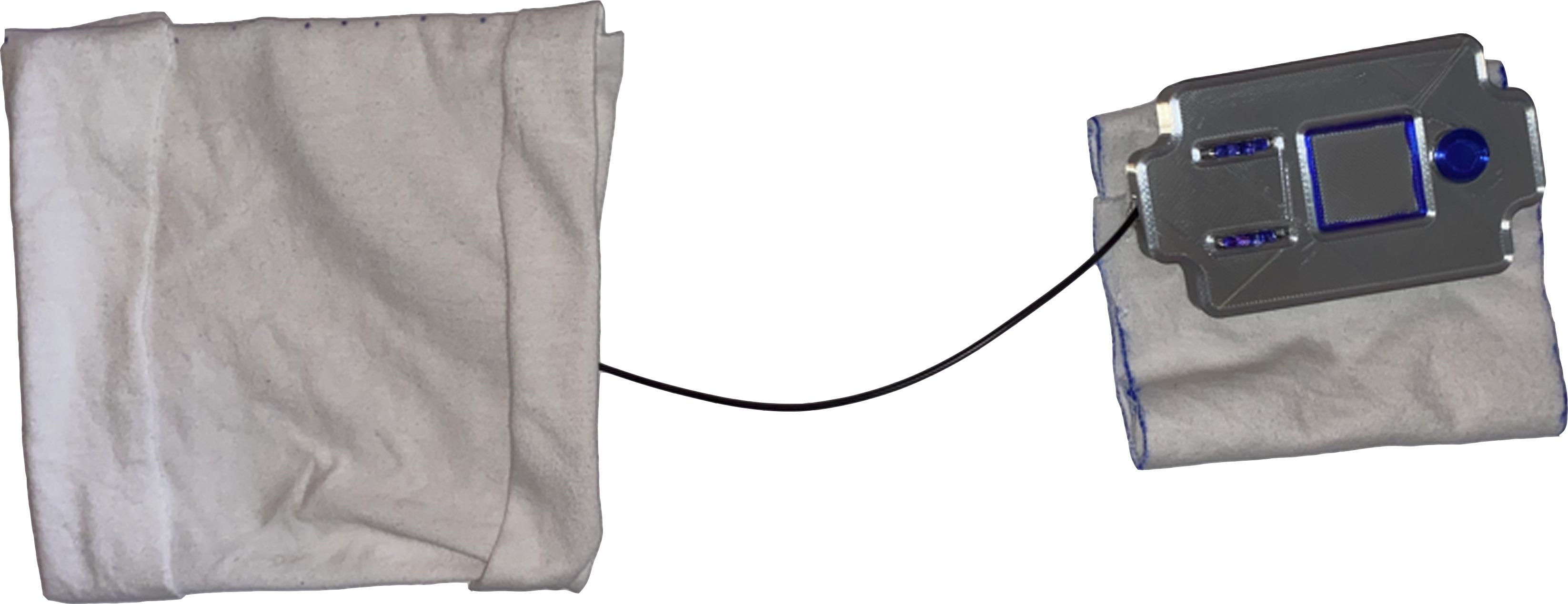

A sleek and simple pain relief and muscle stimulation device for arthritis patients in pre-habilitation

Design an innovative product to support the care of arthiritic patients in pre-habilitation and increase the chances of success during their surgery by reducing muscle wastage and inflammation

- Surgery does not guarantee that the patient will be relieved of their pain and it could potentially worsen it

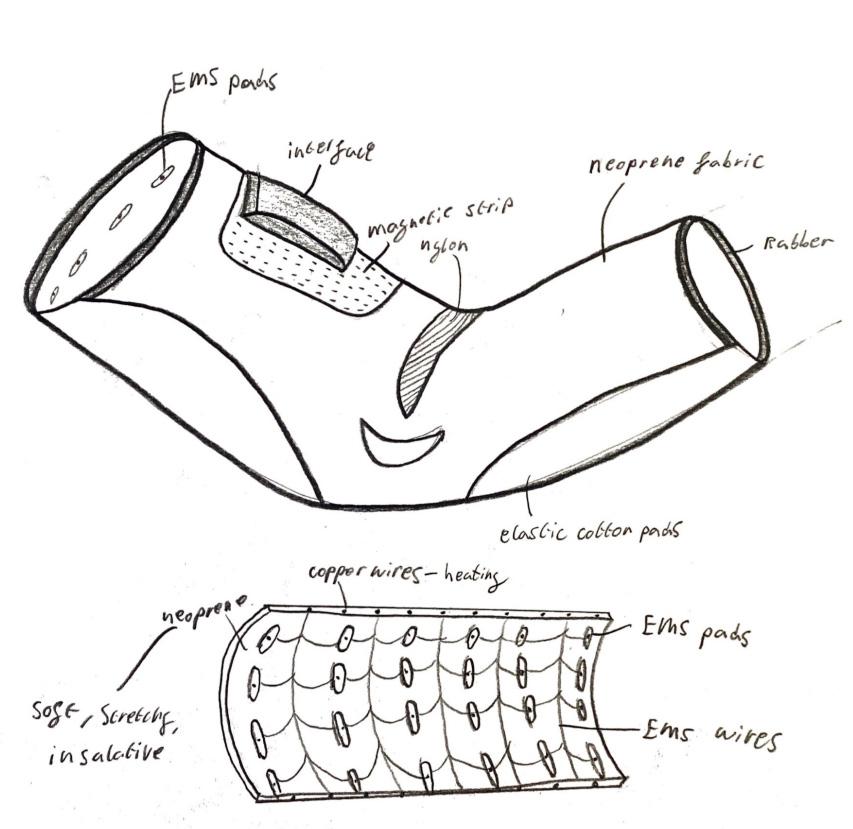

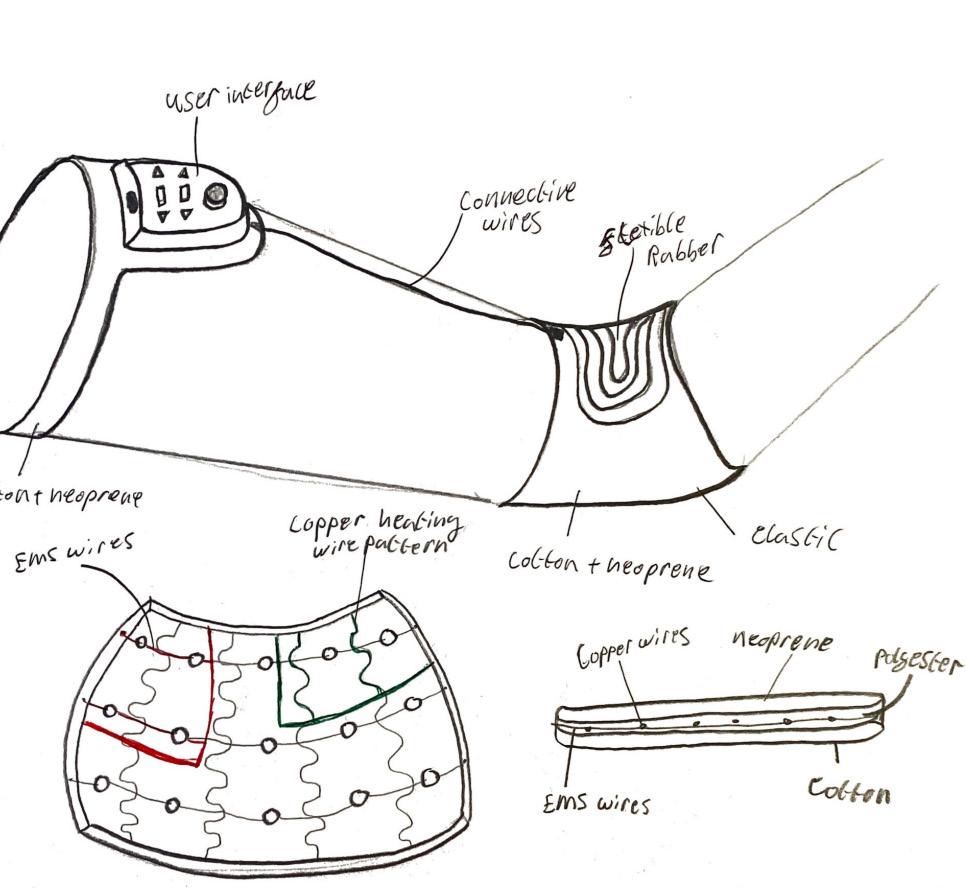

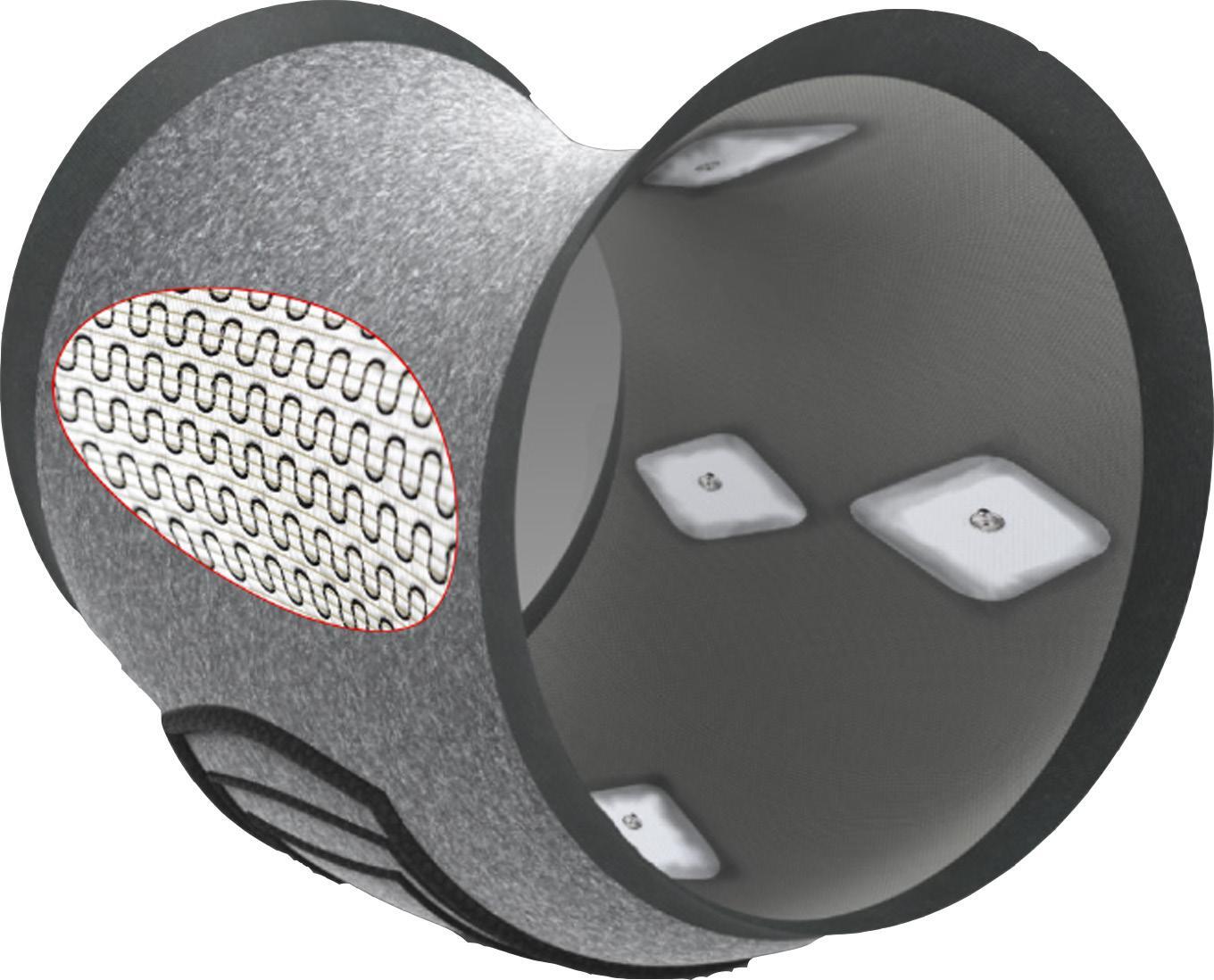

- Heating of the joint through internal copper wires reduces inflammation and relieves pain

- The joint may become worse after the surgery due to muscle wastage and poor connective tissue structure. Metal joints may contaminate blood and cause further health problems

- EMS stimulation pads activate weak muscles and strengthen the connective tissue around the joint

- Surgery’s may have to be repeated if not successful and can quickly become more expensive. Depending on the number of procedures the patient has, the joint can become more prone do fractures and decay

- Reduced inflammation and stronger muscles lead to a higher chance of a successful recovery from surgery

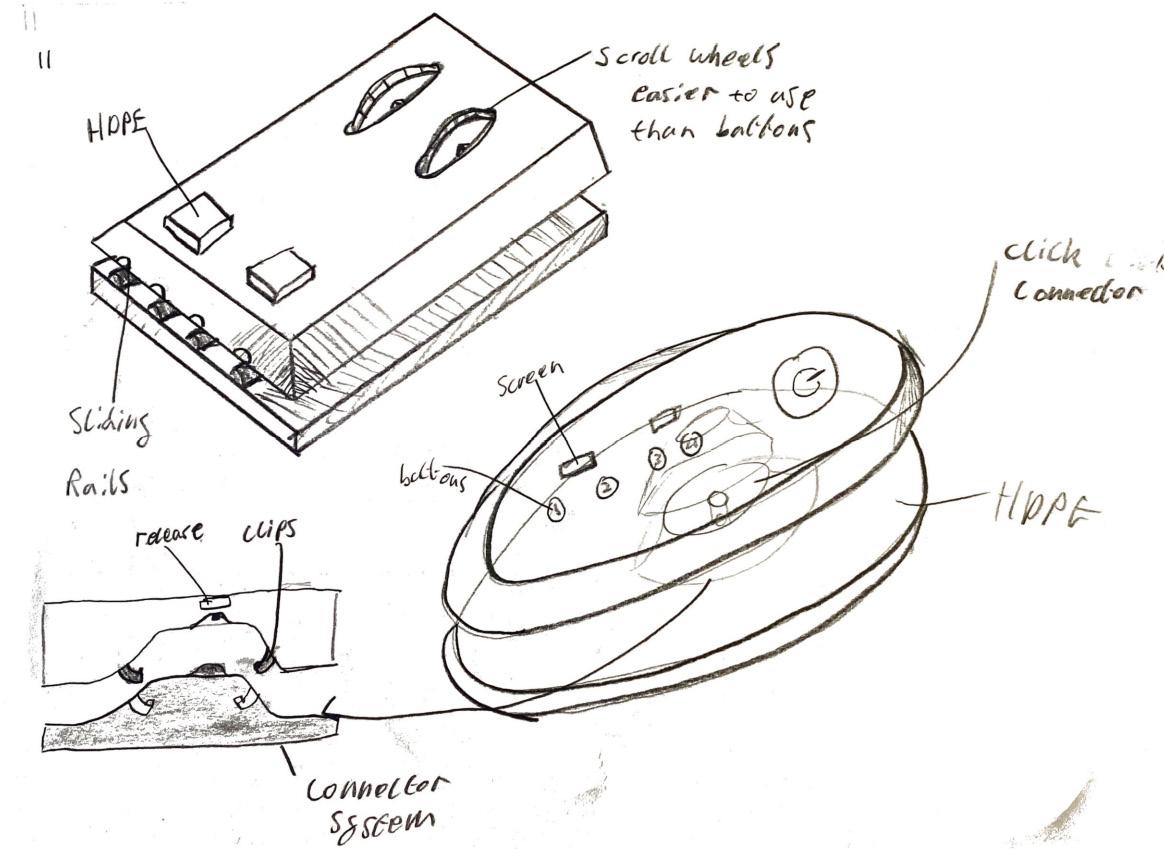

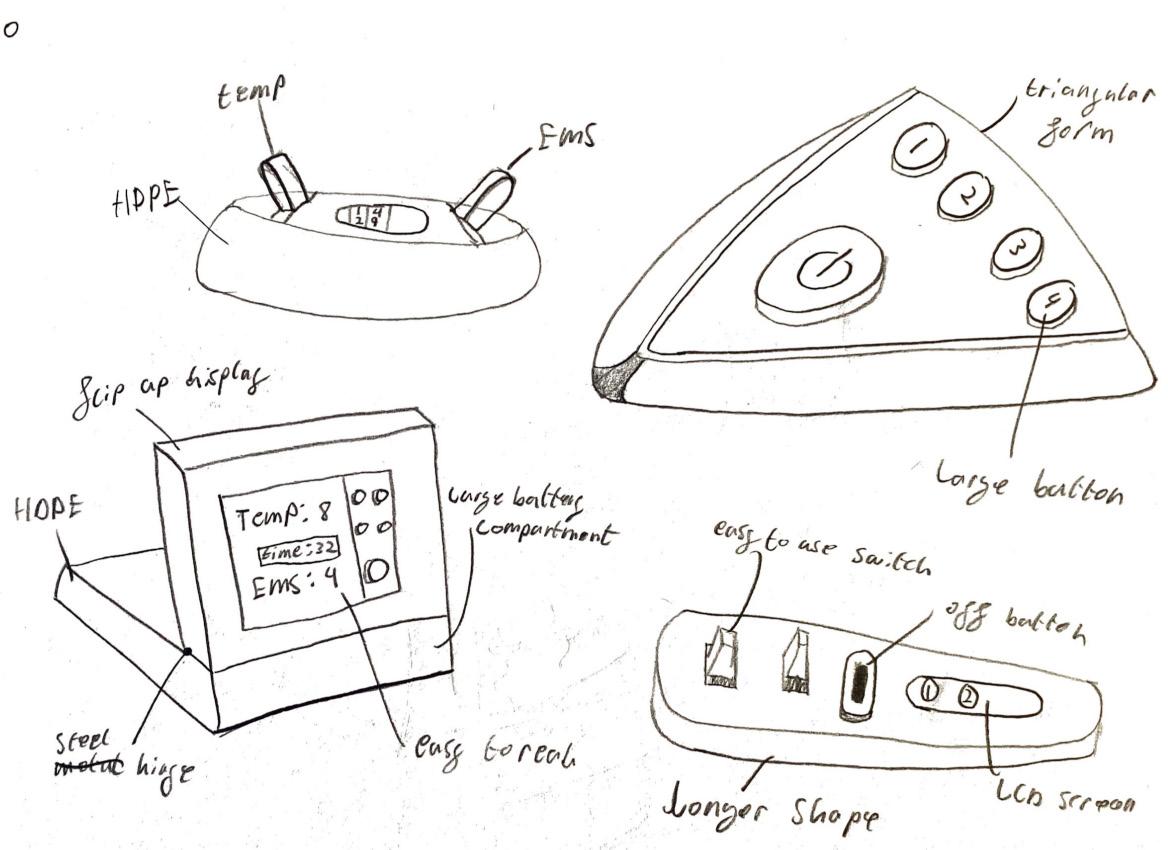

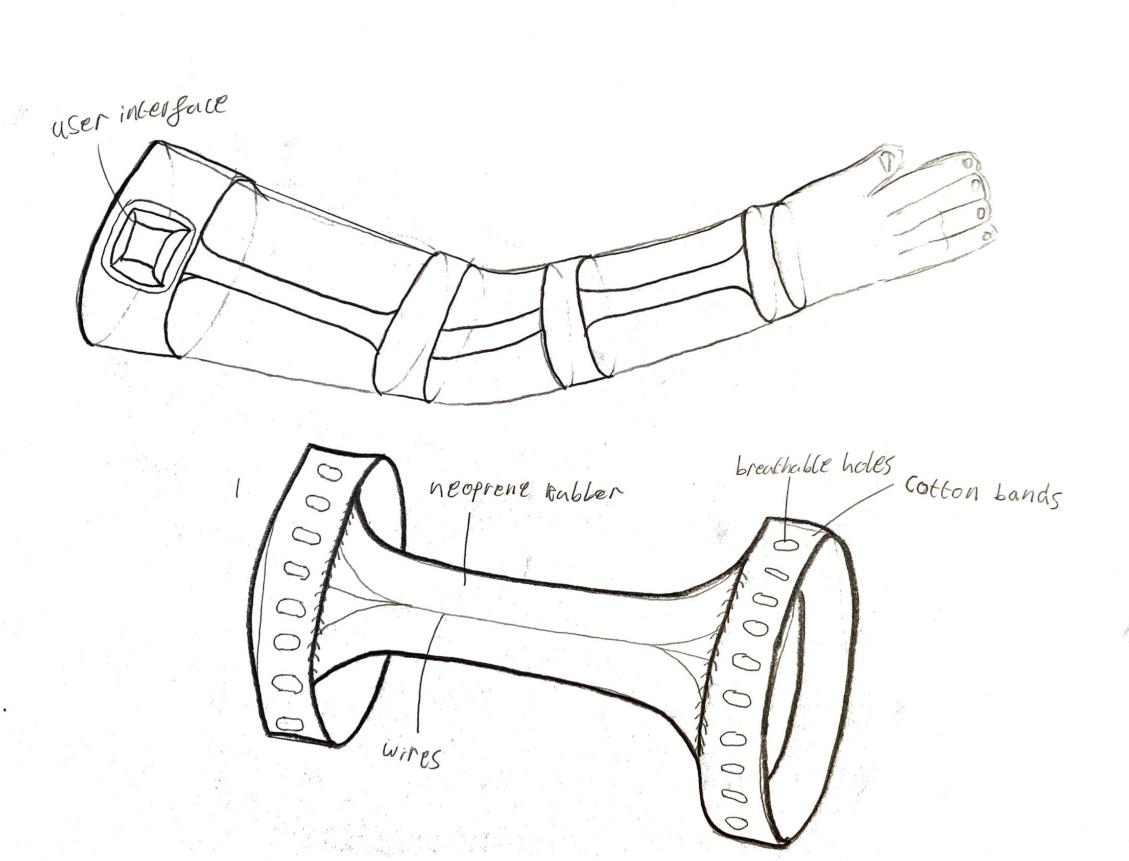

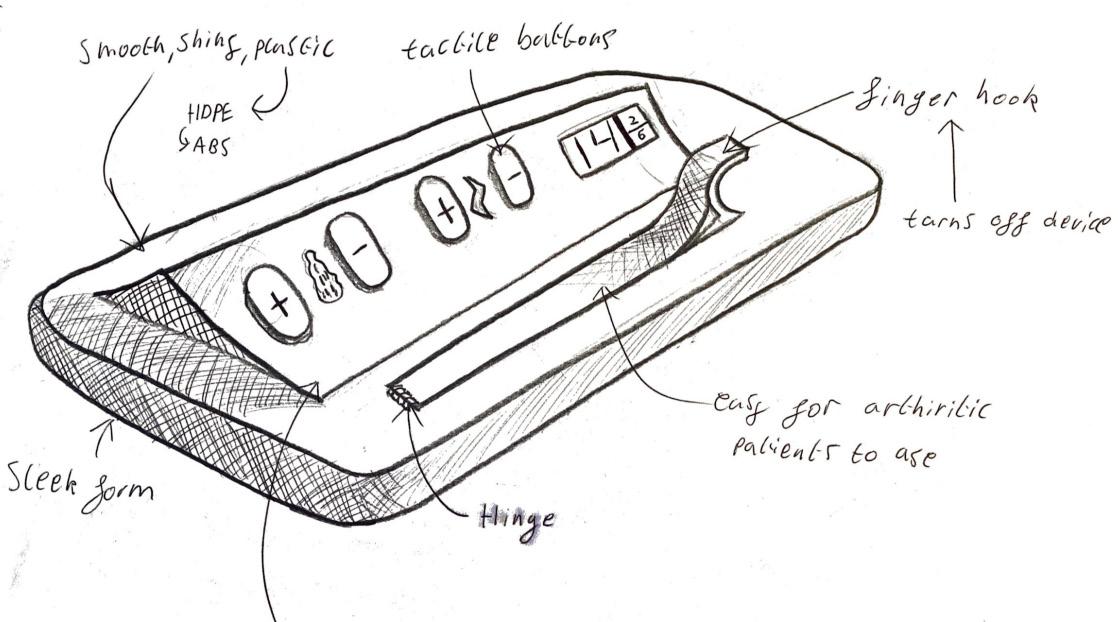

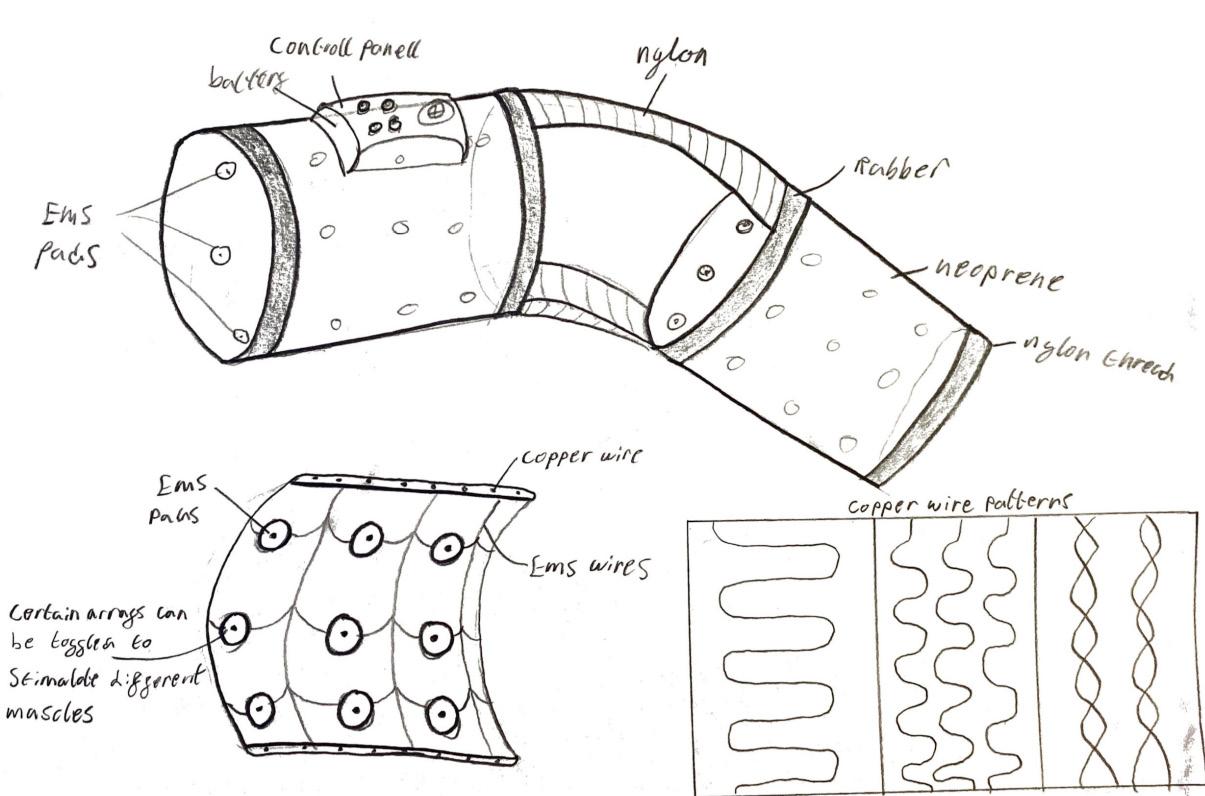

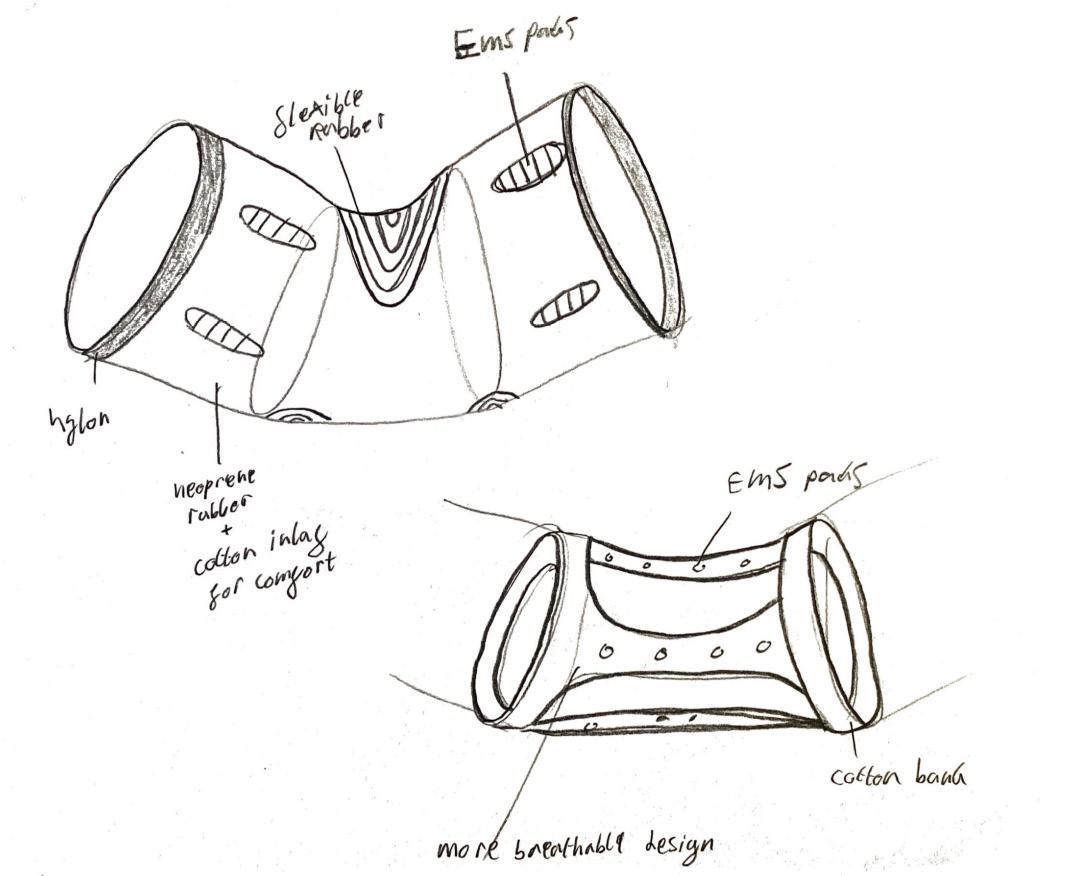

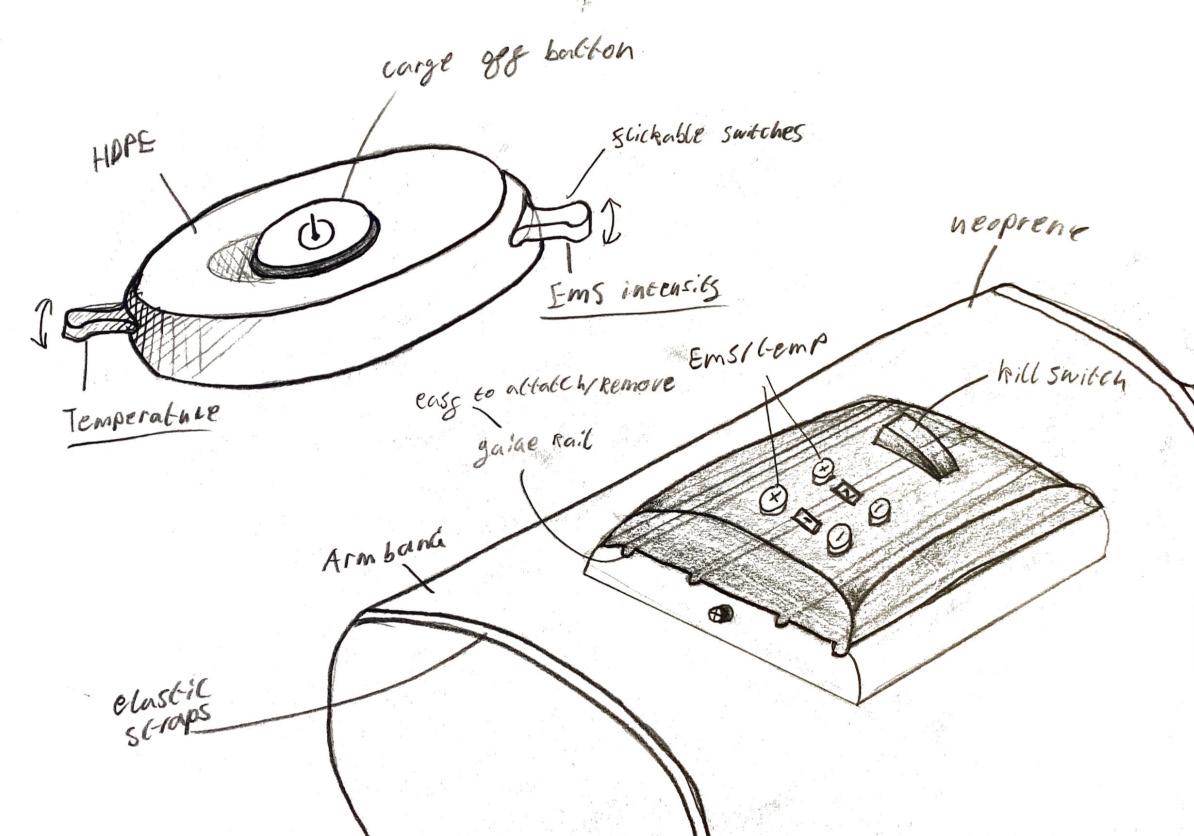

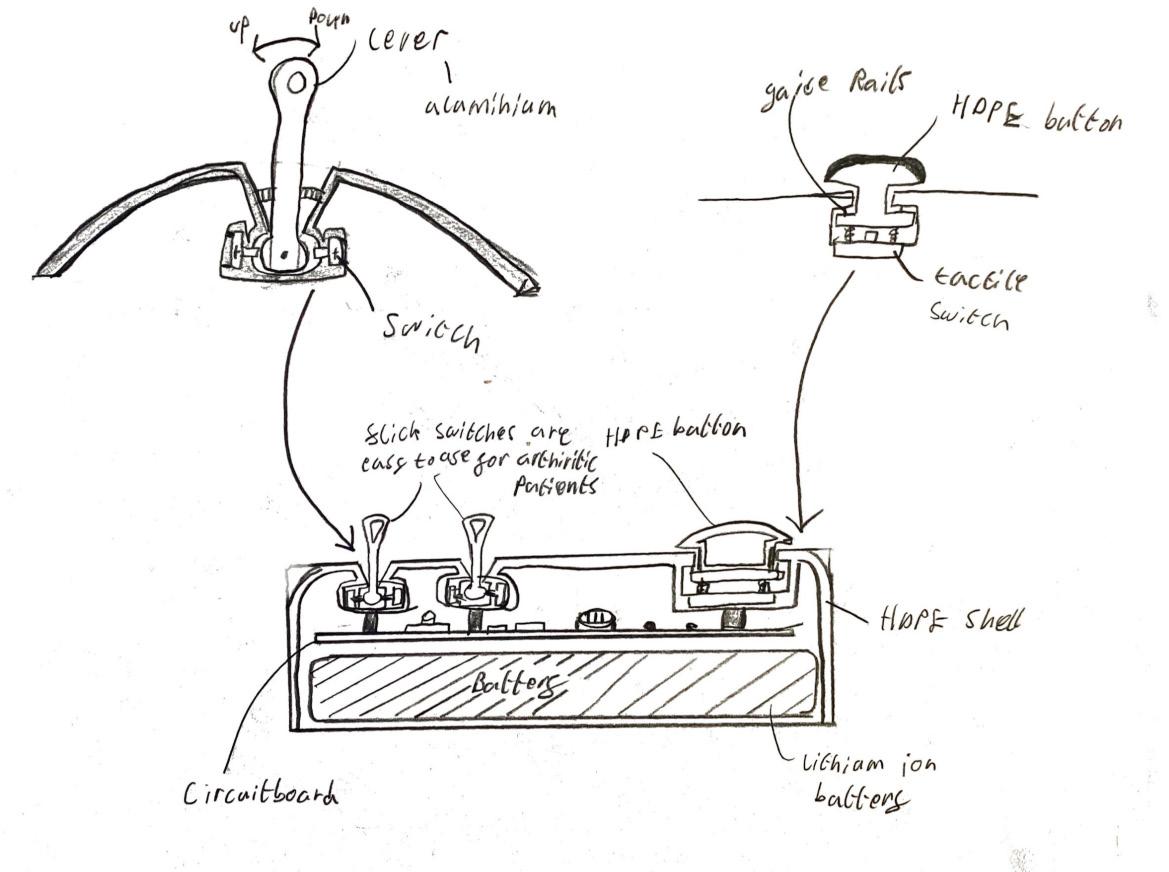

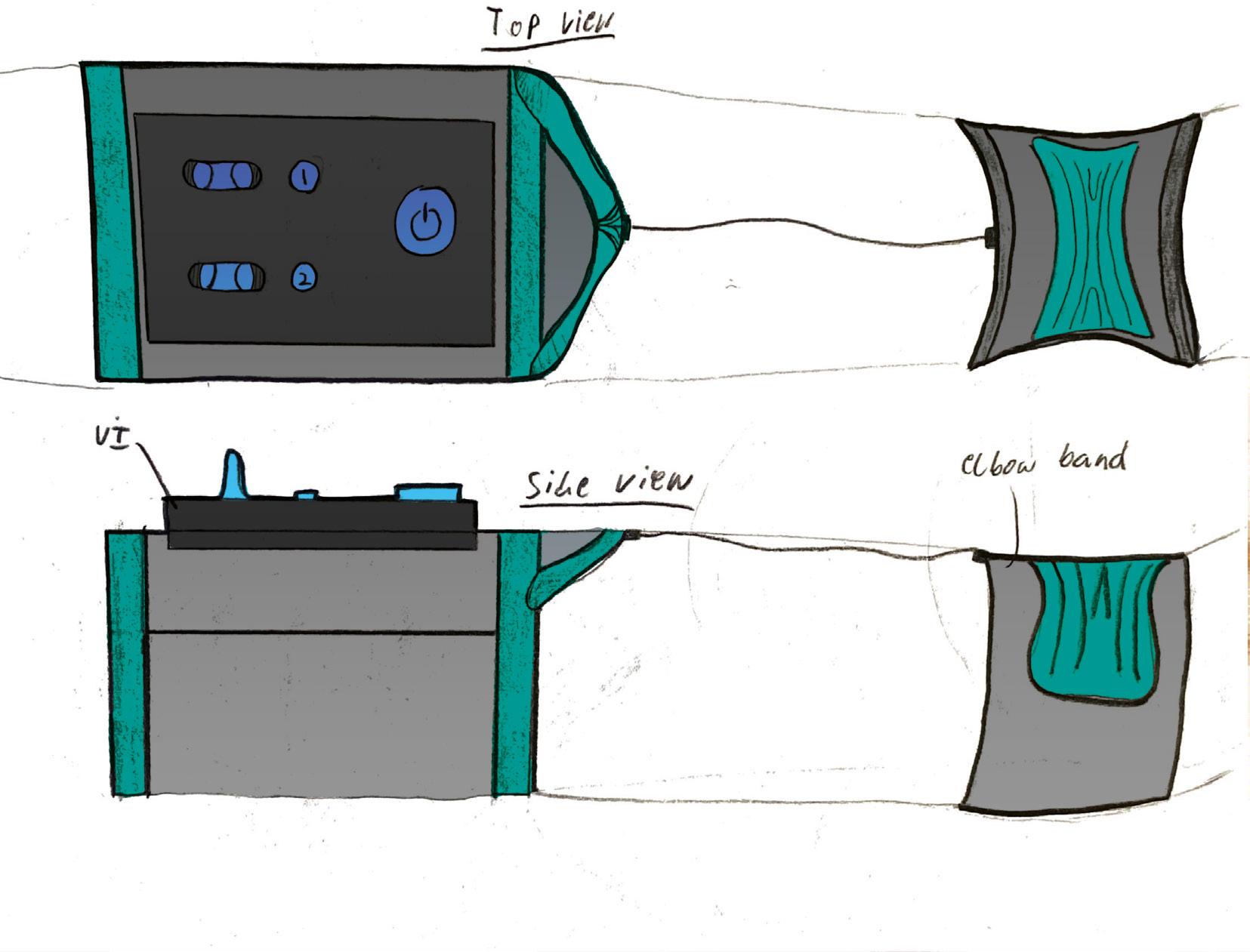

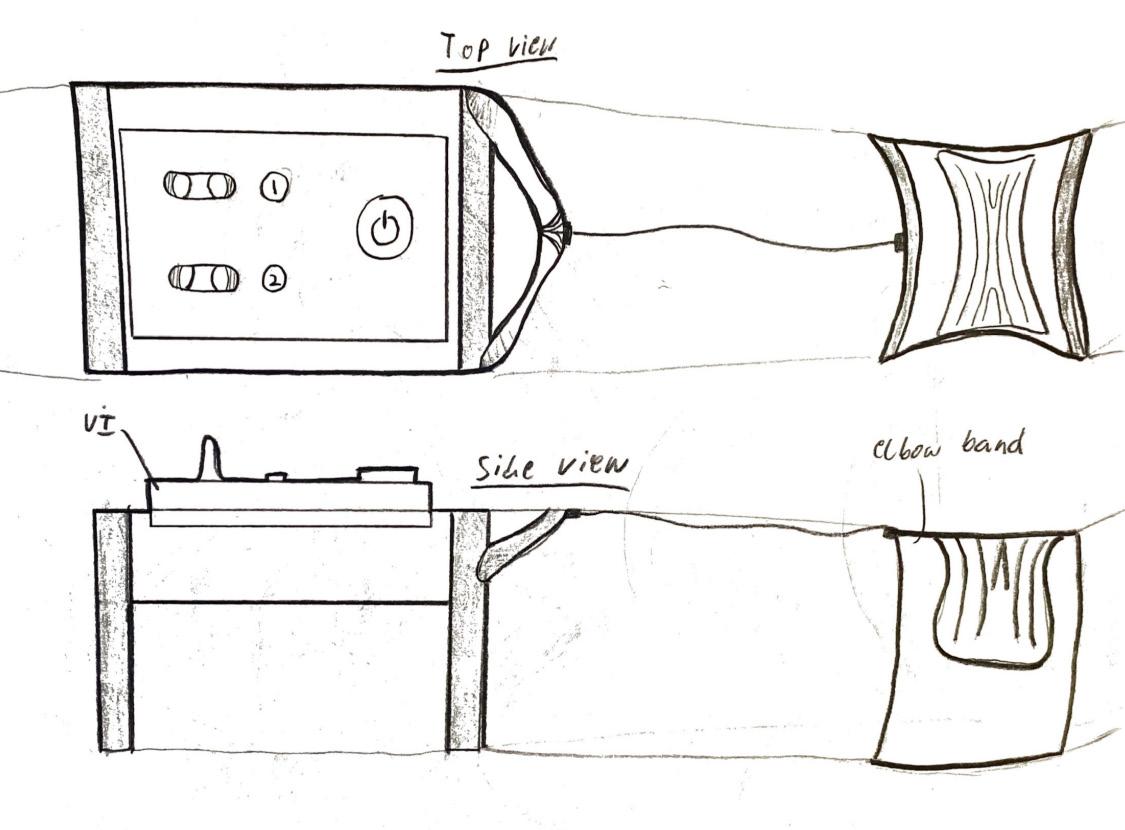

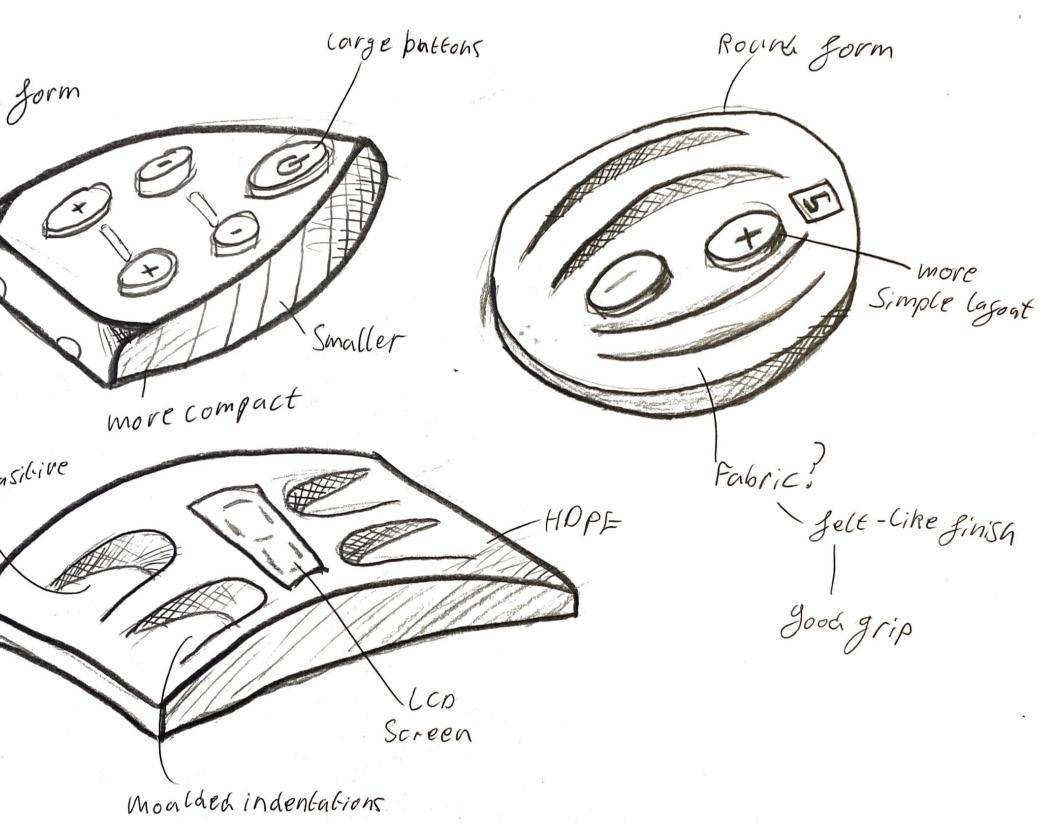

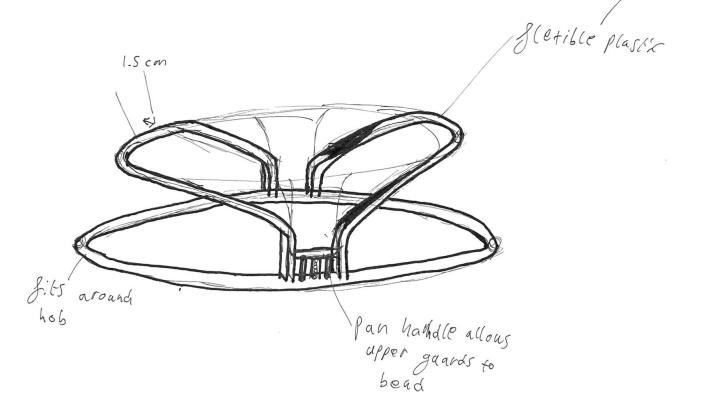

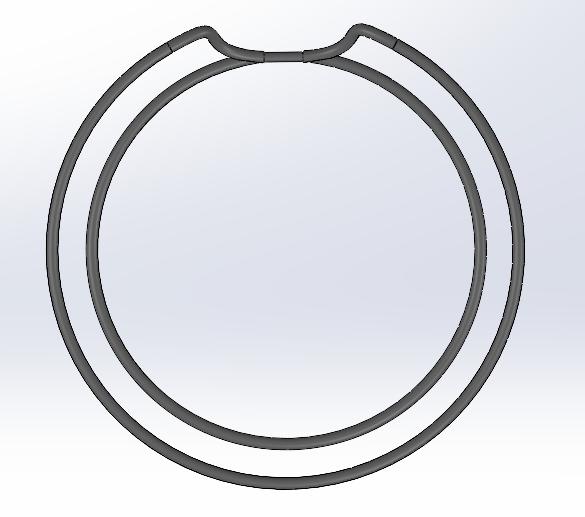

Development of form and ergonomic usibility, focusing on the needs of arthritic patients and how they will interact with the product

/Development

/Internal

/Concept

/Refinement

/Form Refinement

/ideation

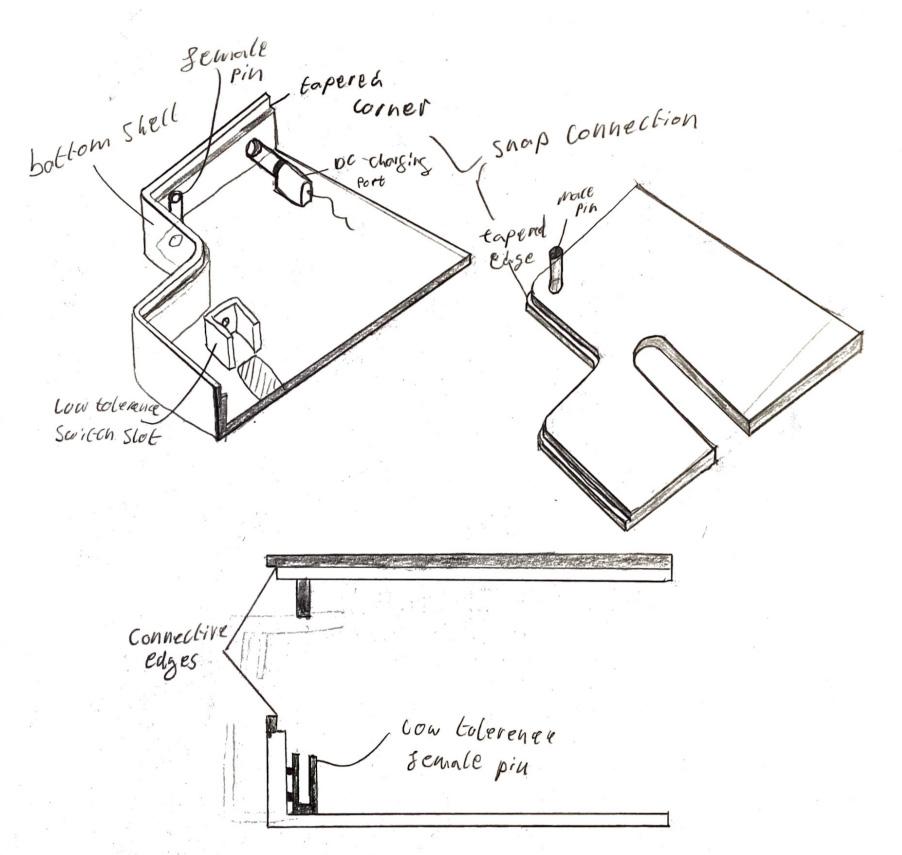

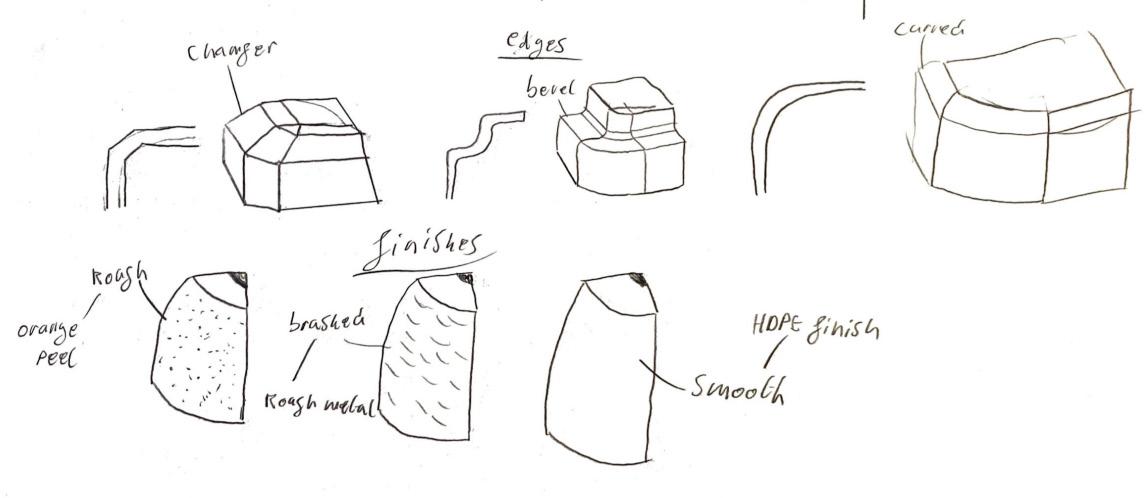

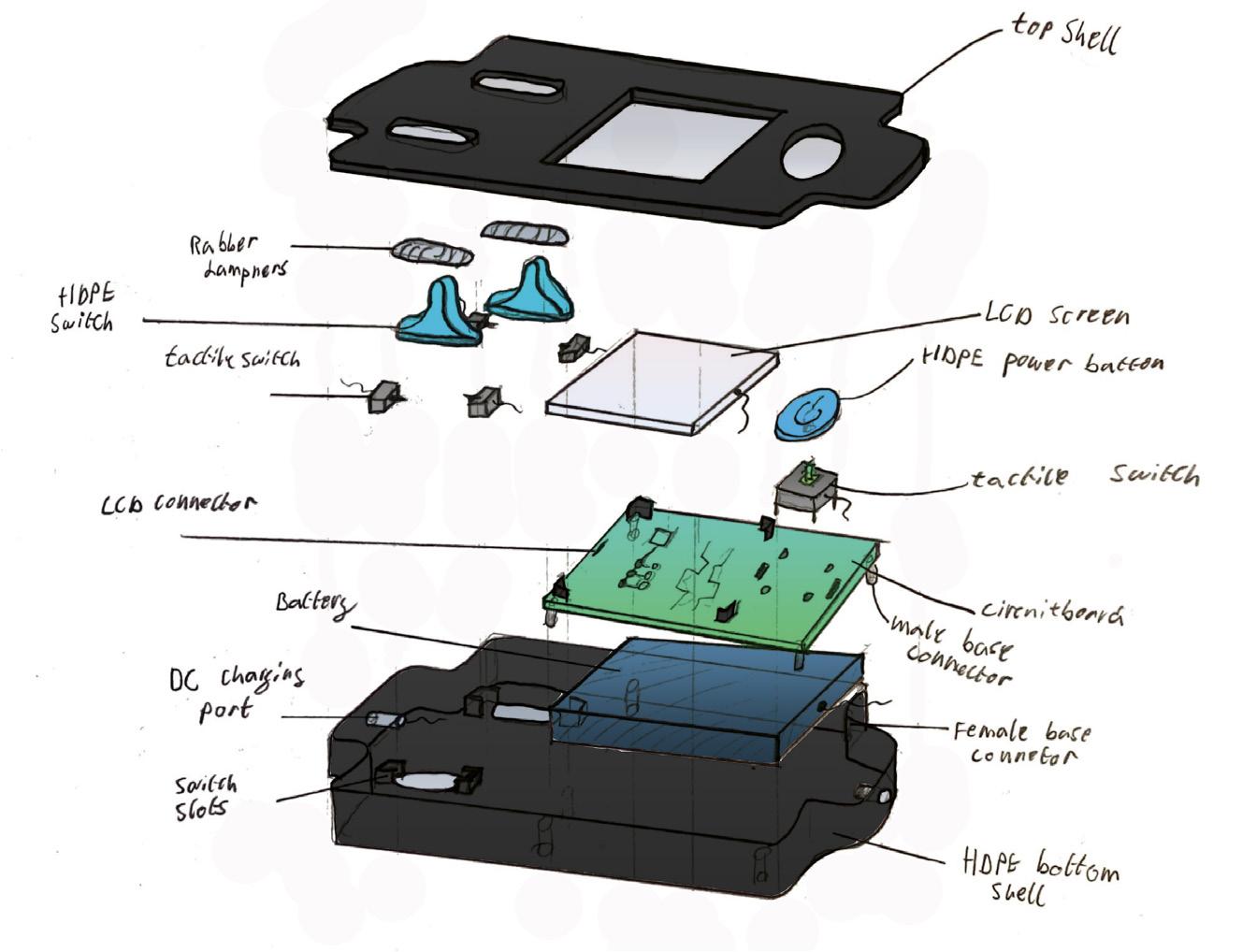

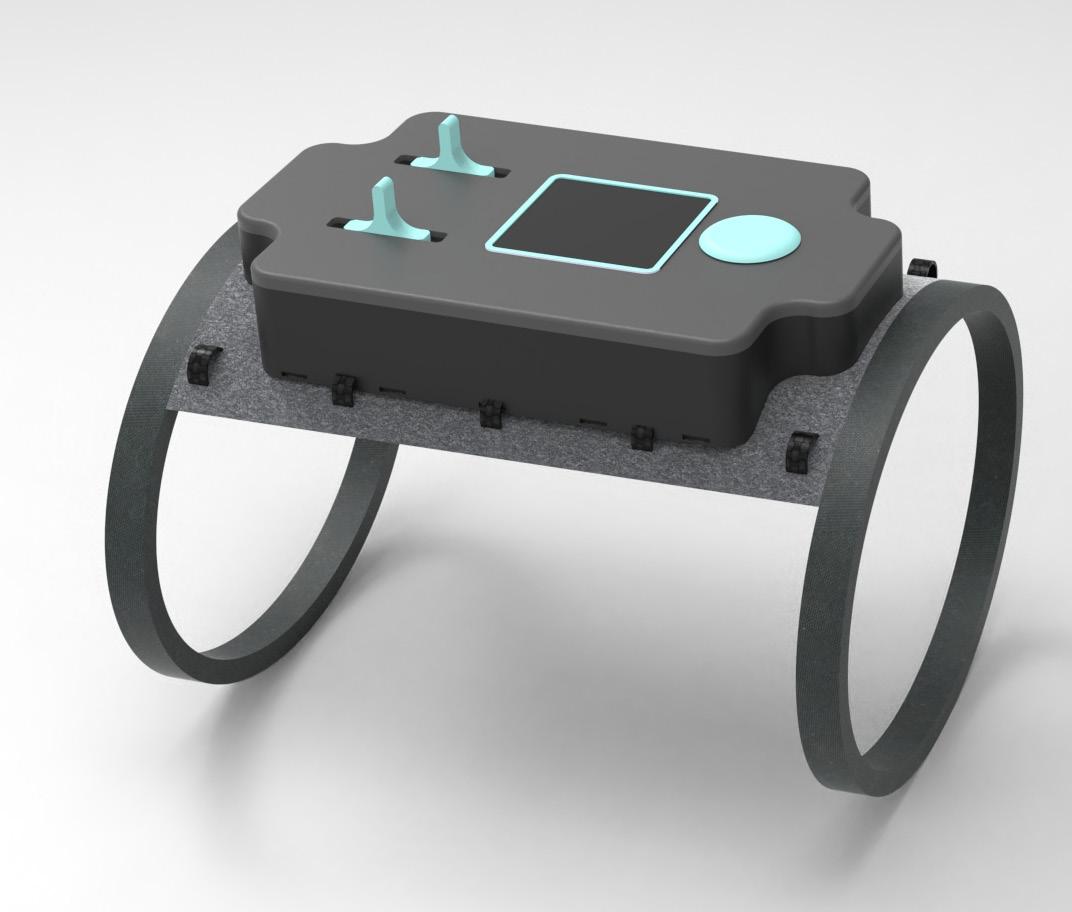

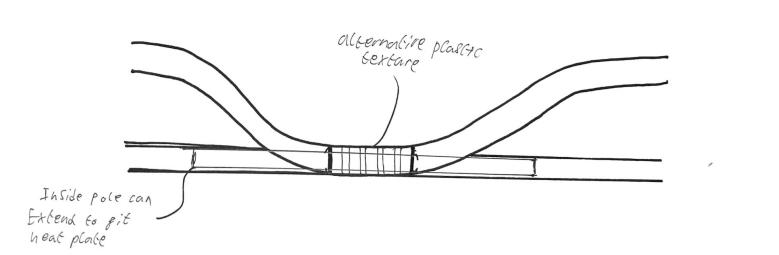

Sketches showing how the parts will be joint together, surface finishes and component placement/mechanisms

It was important to consider how the product would be joined to ensure it could not be opened by the user whilst maintaining its strength

A smooth surface finish was chosen as it would feel the nicest to the user and a rough surface is not needed for grip

The neoprene rubber material on the elbow brace ensures the user is comfortable and the copper wires can distribute heat evenly throughout the joint

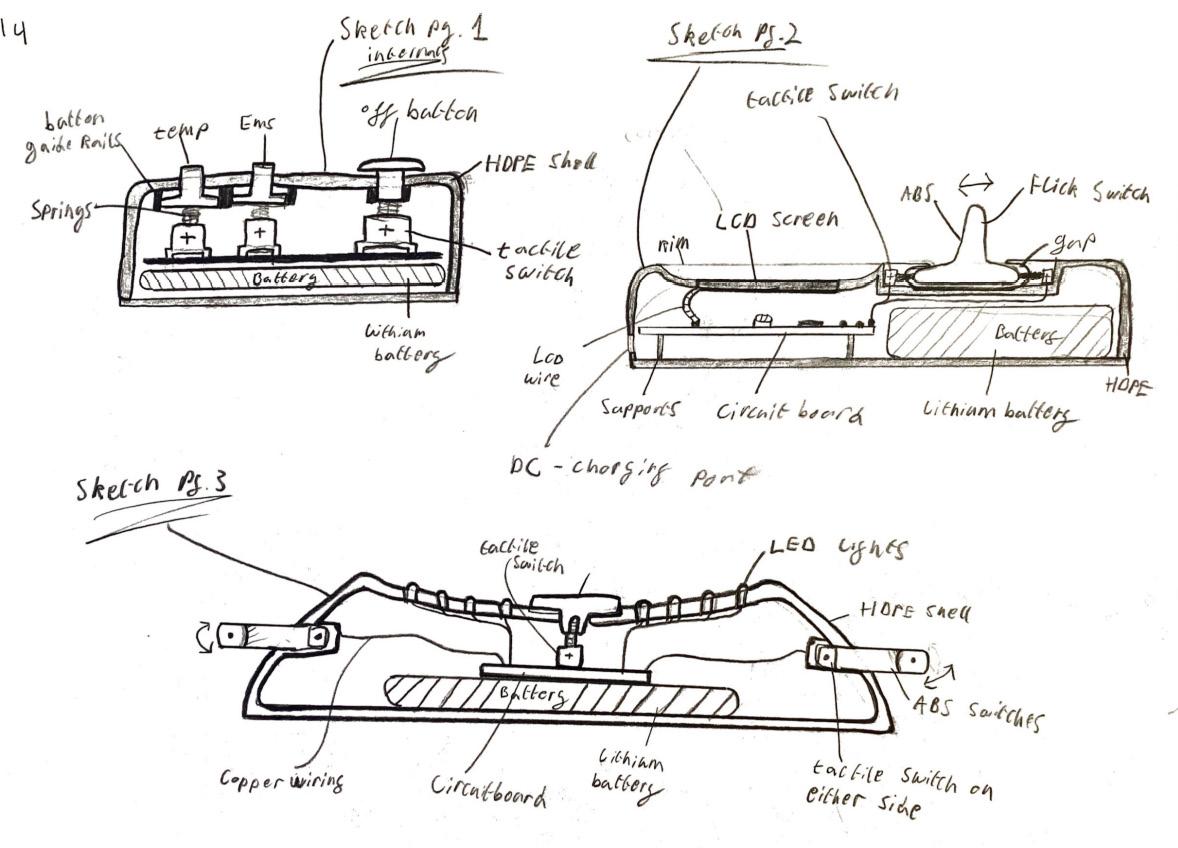

Large, tactile, lever switches make it easy for arthritic patients to use

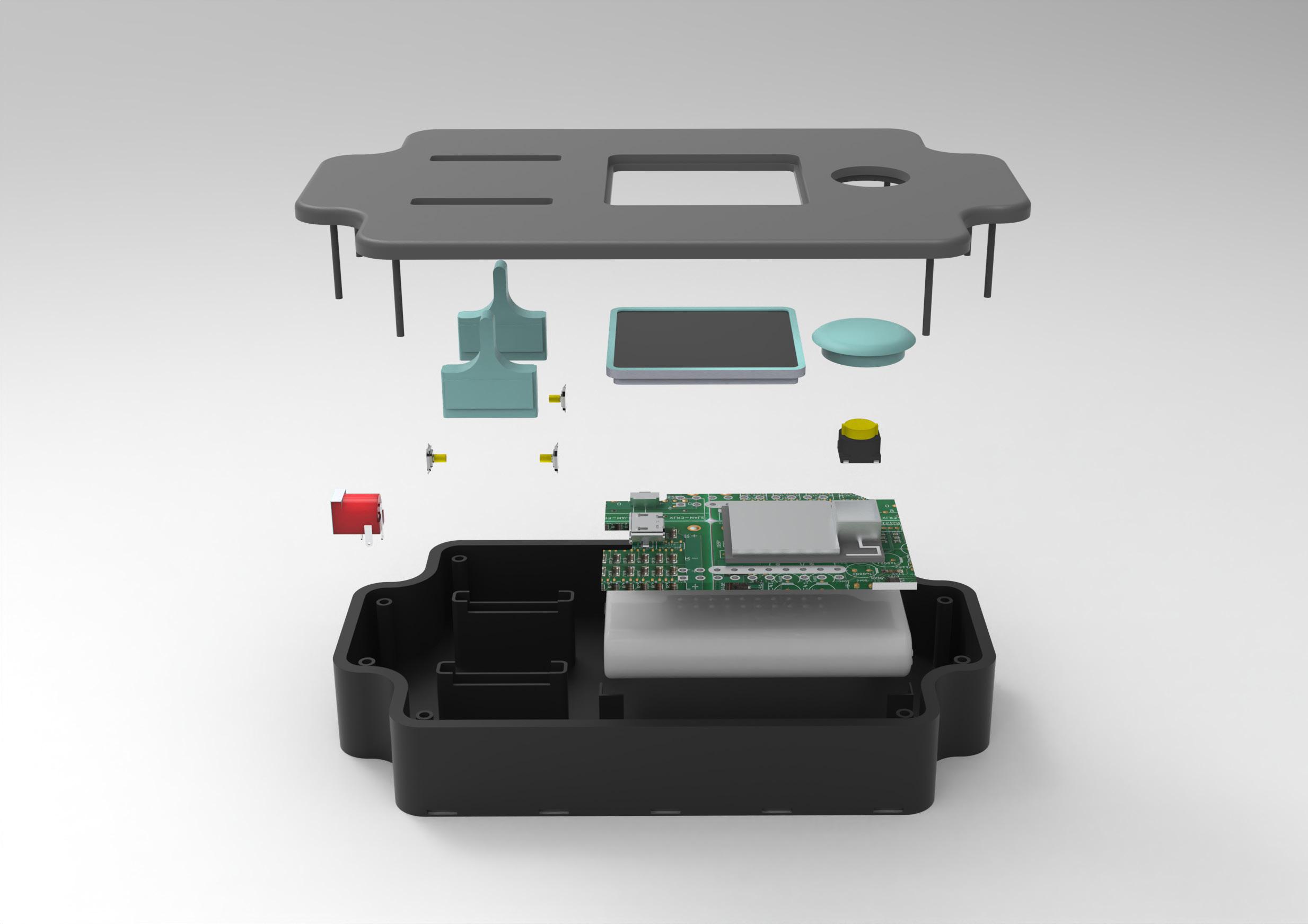

Render showing the internal components and manufacturing considerations

Smooth, HDPE top shell

High tolerance male pin

Fillited edge for LCD screen

LCD screen

Sliding lever switch

Tactile switch

1.7mm x 4mm DC female jack

Smooth, HDPE bottom shell

Tactile switch slot

HDPE power button

Tactile Switch

Power button switch slot

LCD connector

3.7V Lithium ion battery

High tolerance female pin

Arm-brace strap slots

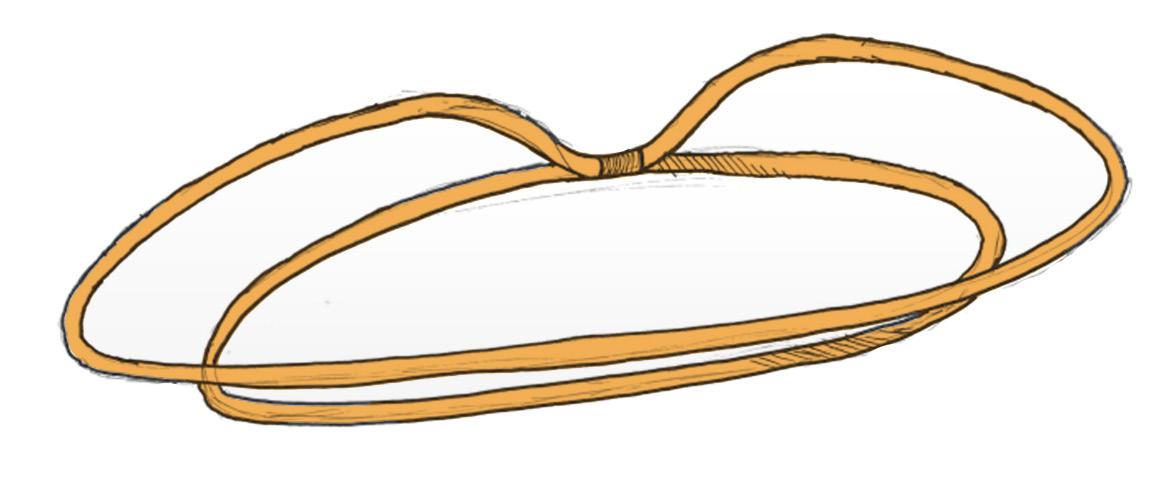

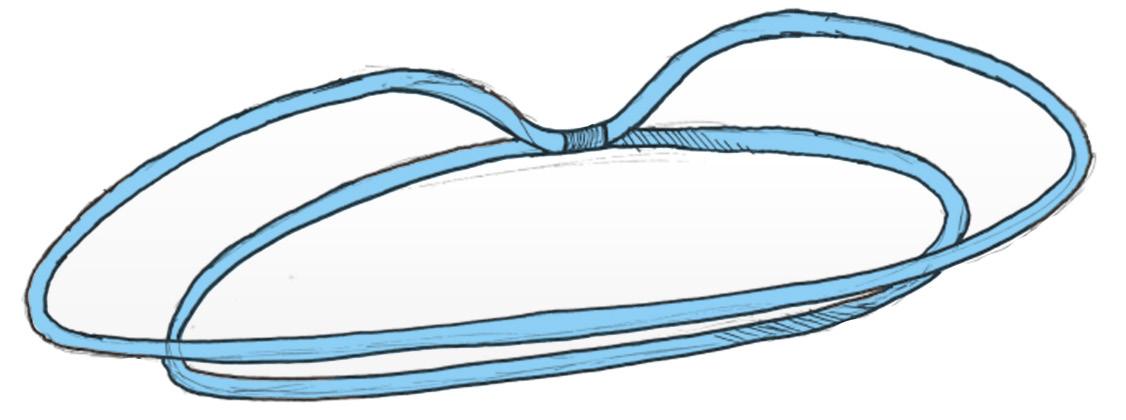

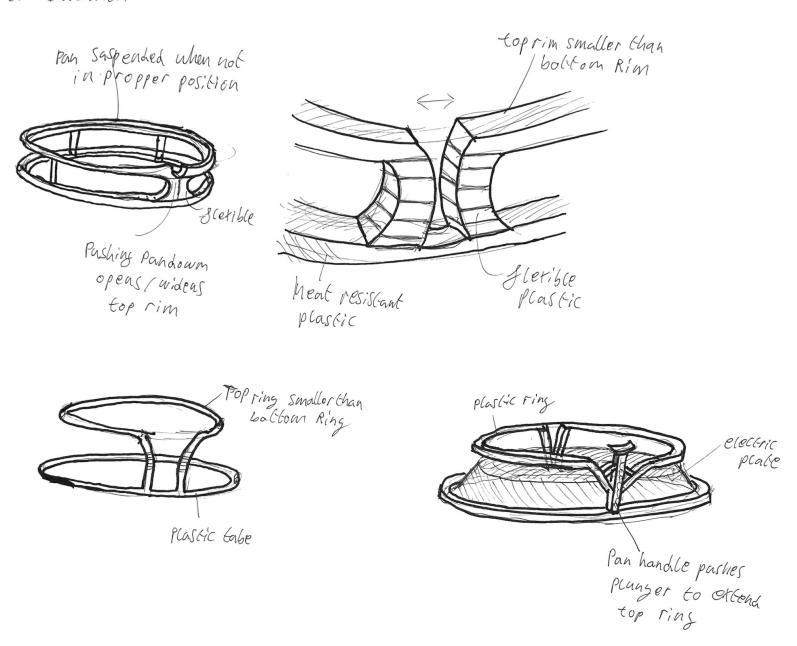

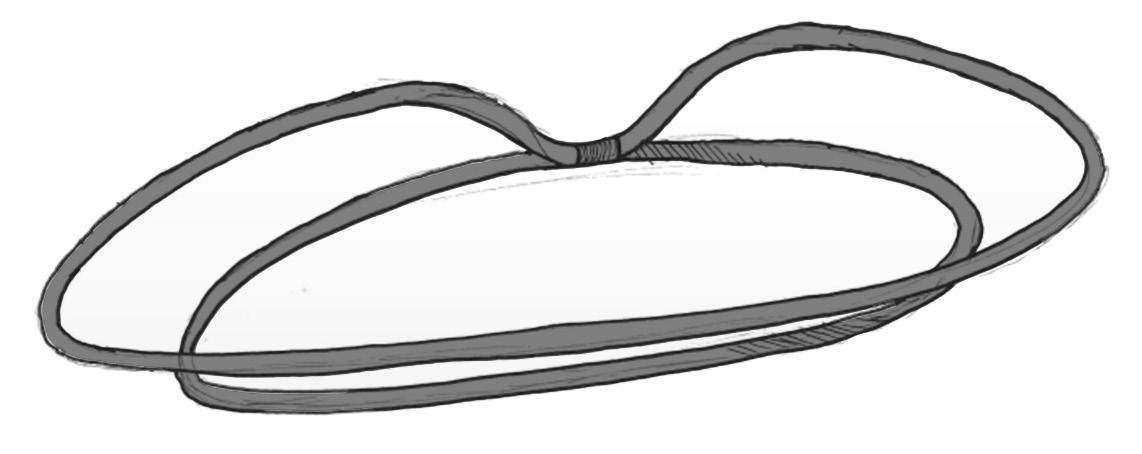

A simple and sustainable solution that utilised the properties of extreme heat plastics to prevent burns from hobs in children ages 1-5

Design a functional product that aims to reduce accidental burns in children ages 1-5 the product must utilise the unique properties of plastic and aim to have an increased lifespan

Child Saftey

causes of burns in households with children

A study in the US published on the TNYT found that emergency rooms treated more than 17,000 children between the ages of 1-5, that had burns caused by non-electric cookware

The most common cause for this was children pulling hot pans and liquids off the stove/hob

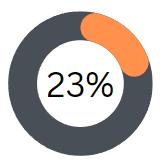

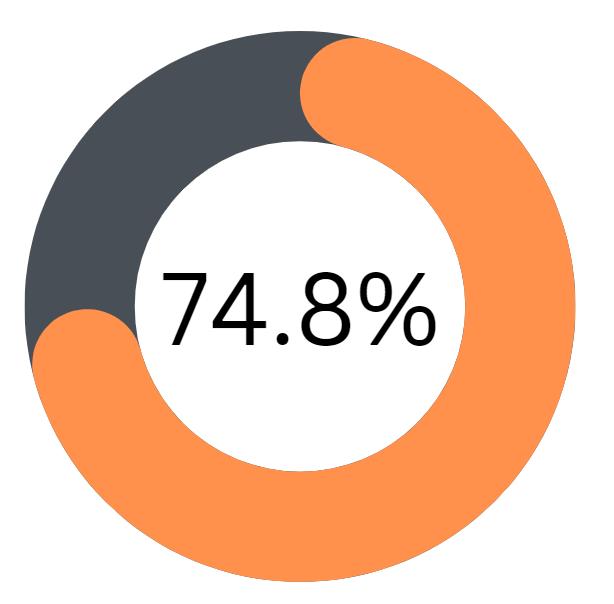

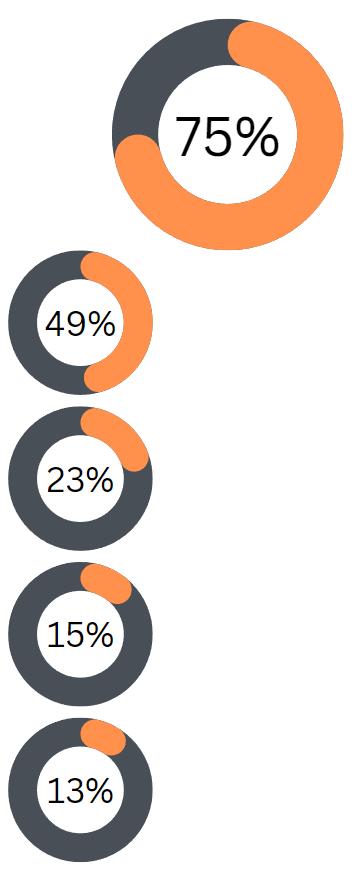

of all household accidents come from burn injuries

Cause by hot pans and liquids

75% of UK households have injured themselves in the kitchen before

- Knives

- Burns

- Slips/Falls

- Hot pans within reaching distance

- Hot contents can spill onto children

- Need a product that stops pan handles being in reach over the hob

- Other

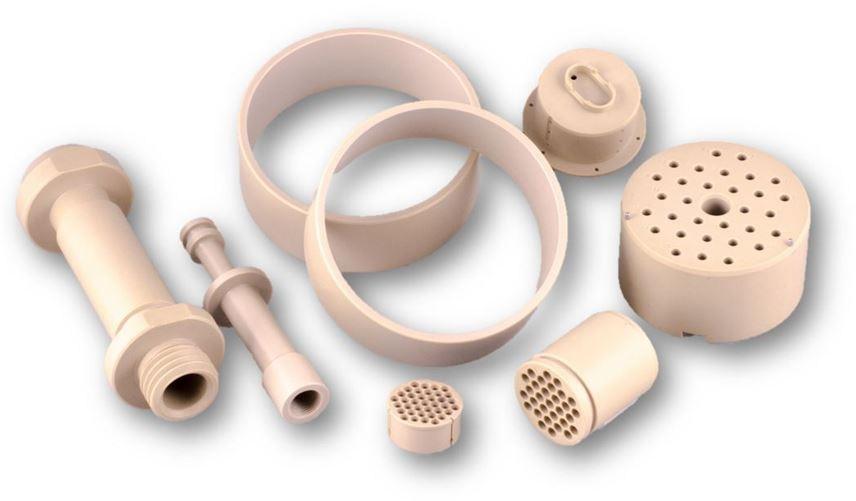

How can we make the design simple and exploit the properties of plastics

- Depending on the grade of PEEK, the temperature at which is can be moulded can fluctuate

- PEEK polymer must be dried before use to a moisture content of < 0.02

- Dried by 160’C ovens for 3 hours, cost must be taken into account

- TEKAPEEK MTGREEN melts in resin form at about 341’C

- PEEK can be moulded on standard injection moulding machines

-Single Material (TEEKAPEEK)

-No tear down required for recycling

-Simple but exploits the properties of extreme heat plastics

-Effective on a wide range of electric plate hobs

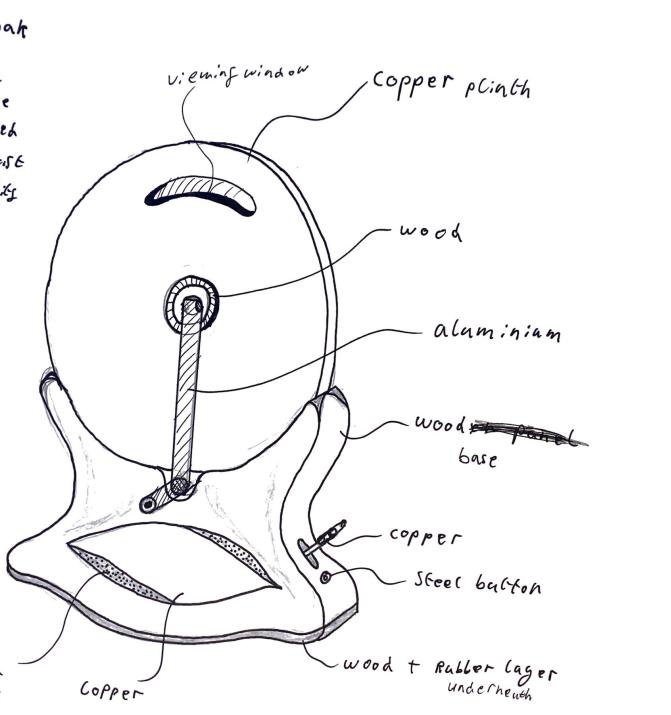

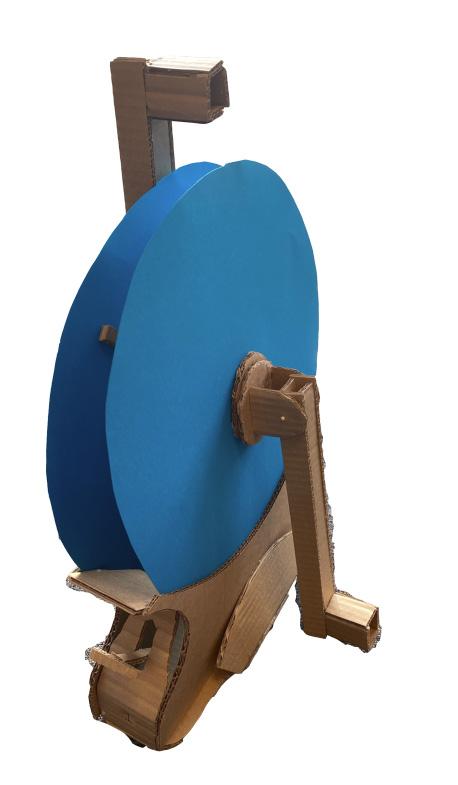

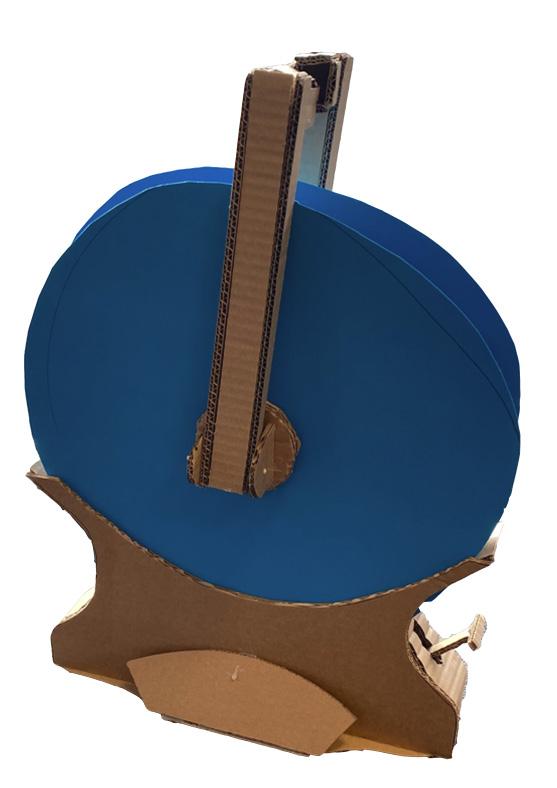

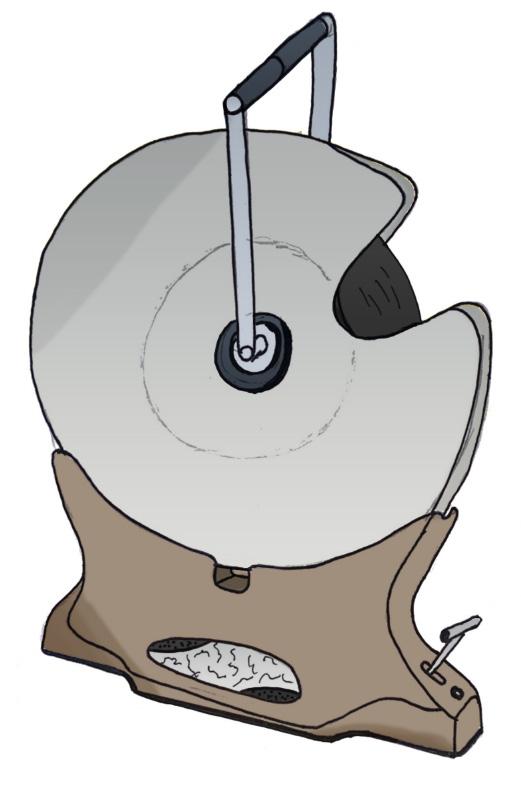

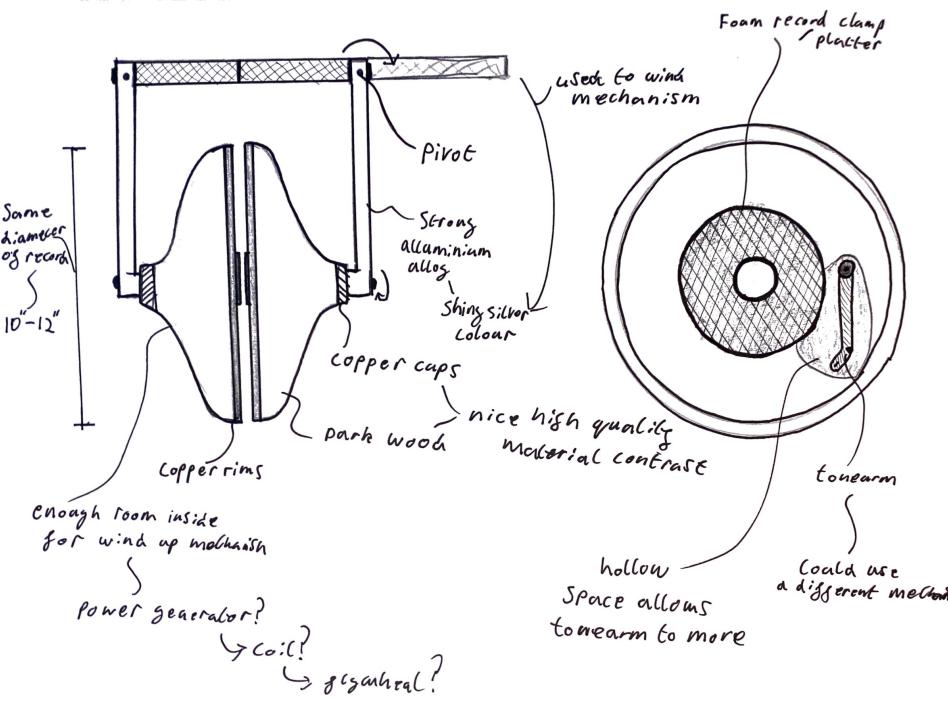

A high-end wind up record player made using high quality materials designed to promote quality bonding at bedtime

Design a record player that promotes healthy relationships, sleep and cooperative learning at bed-time that is powered by a wind up mechanism. the record player must be portable and made with high quality materials

- Parents enjoy interacting with their children when they can

- 2 children ages 4 and 7

- Lack of time for meaningful interaction

- Late work hours leads to an unstructured bedtime for their children

- Parents have a busy schedule

Excessive screen time in children

Anxiety + depression

Excessive Screen Time

Poor social skills

85% of children under age

6 have access to a smart phone or tablet

46%

Busy Parents:

Parents today work longer hours and have less time to bond with their children, 46% said they only interact with their child for four hours or less per week they need a regular and structured time where they can have high quality interactions

Working together is a great way to strengthen bonds

Creating a structured bedtime routine

Parents can bond with their children by sharing a loving interaction

Children with a bedtime routine slept on average 1 hour longer

A structured bedtime routine can help remove or reverse the effects of high smart-phone screen time

Structured routines can benefit a child’s sleep and mental well-being

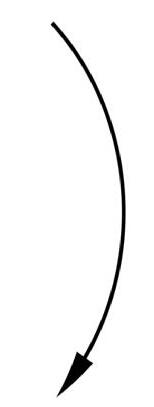

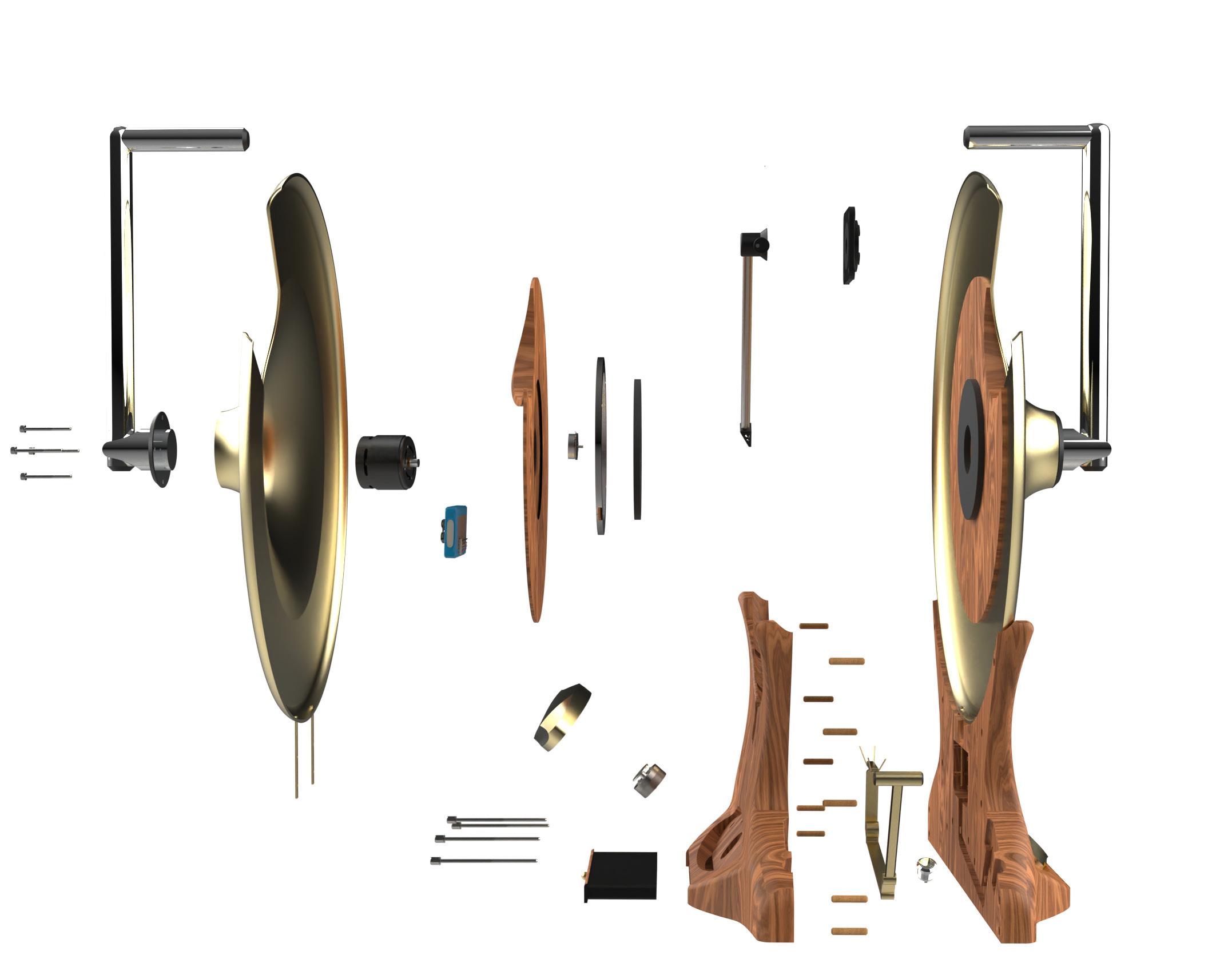

Handle

Tonearm Motor/ Positioner

Inner plinth

Hand-Crank Dynamo

Tonearm

Steel Bearing

Arm bolts

Li-Po battery

Plinth

Speaker cover

D-Drive Turntable motor

Foam Pad

Wooden Base half

Plinth struts

Base bolts

Pull-Out Stabiliser

25W resonance speaker

Dowel

Plinth opening mechanism Push button

Experimenting with glossy finishes and PBR textures

Close up detailed shot of glossy wood