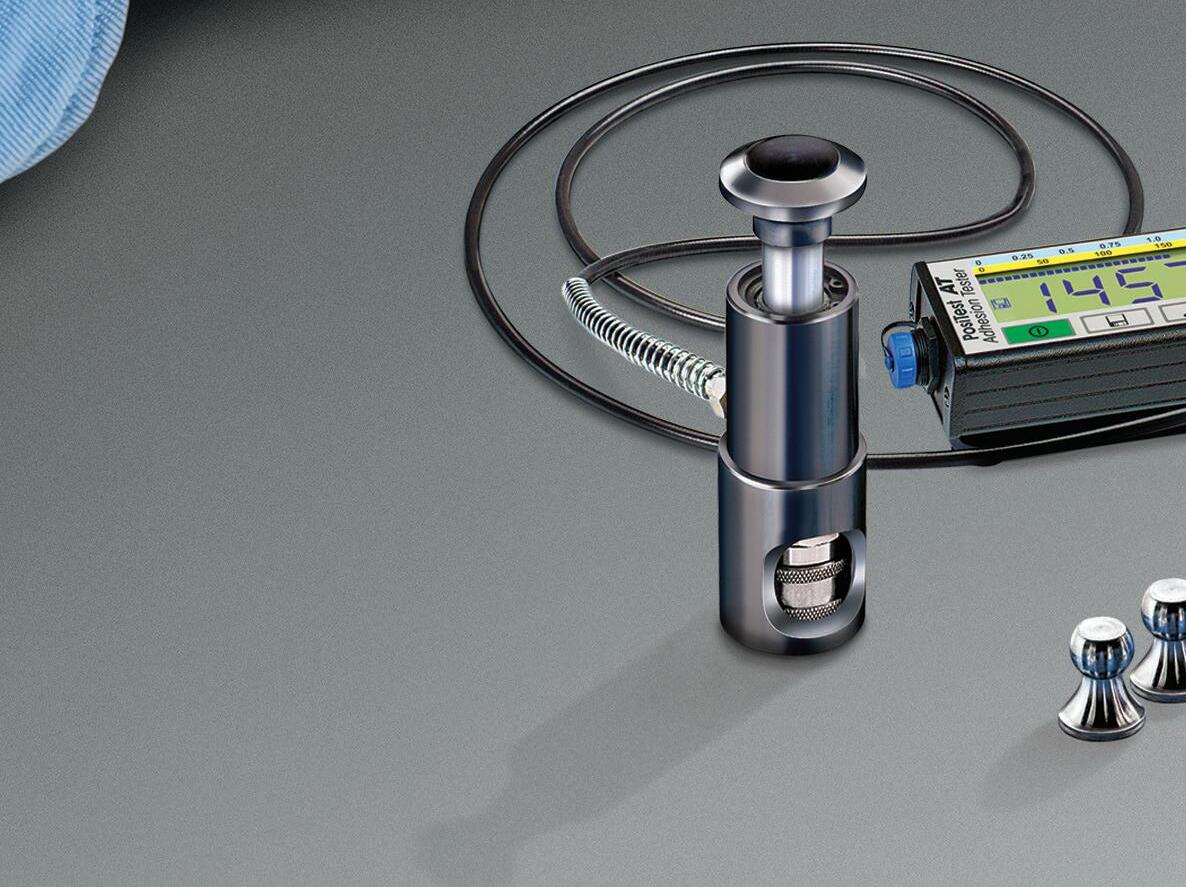

Measure the adhesion of coatings to metal, wood, concrete and more

n Impact and scratch resistant color Touch Screen display with keypad

n Wirelessly connect the PosiTest AT-A to your smart device using our free app

n Record the results as pass/fail and the nature of fracture cohesive, adhesive and glue failures

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826

e: nigelbean1@aol.com nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

t: +44 (0) 1442 826826

EXHIBITION ORGANISATION

t: +44 (0) 1442 826826

Hill Media Ltd, Marash House 2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd. Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents.

© Hill Media Ltd – 2025 ISSN 1757-367X

INDUSTRY

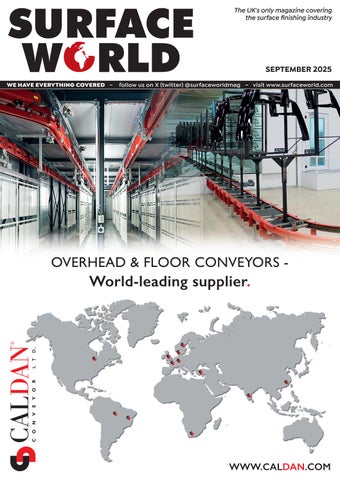

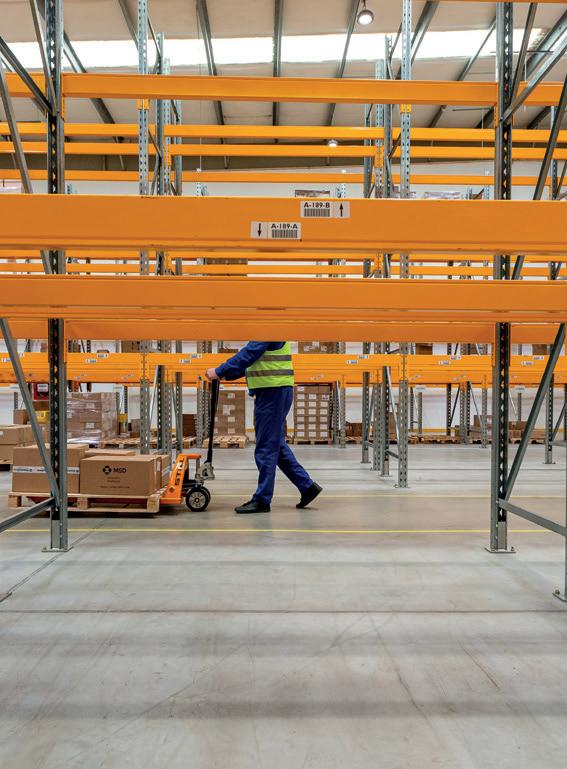

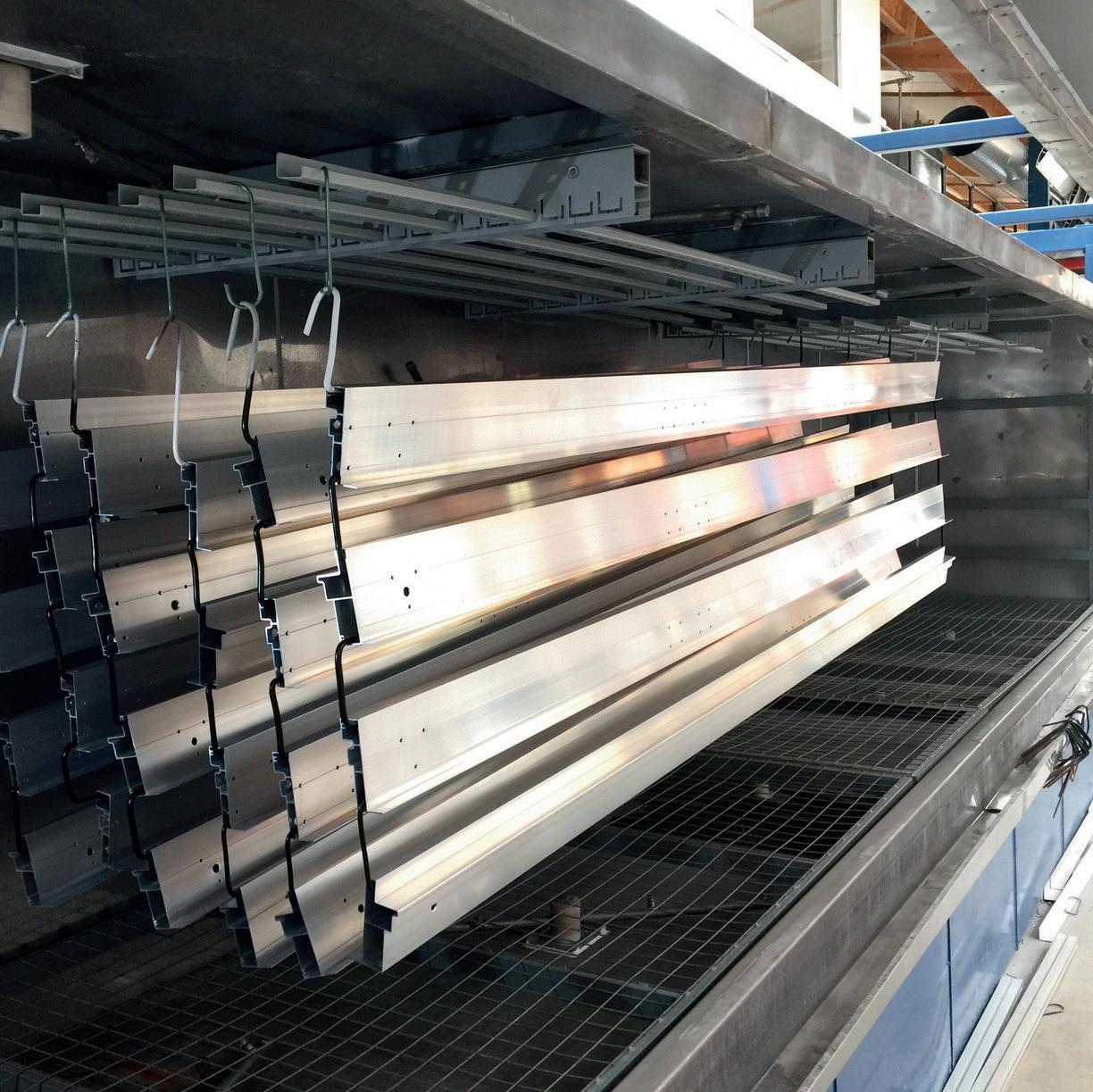

2025 sees another important achievement in the Caldan Conveyor Group of companies.

Caldan Conveyor Limited, have reached another milestone in their development, 10 years in business, 10 years anniversaries for the original employees and also moving into larger premises to allow for a further planned expansion.

After operating in the UK & Irish market since 2002 as a subsidiary office of the parent Danish company, it was decided in 2015 to expand the operations at the UK office to include sales, aftersales, project management and controls functions, over the past 10 years this has grown to a workforce of 16 employees operating throughout the UK and supporting customers globally.

The UK office now offers full project support for Caldan Group companies and also aftersales support for Caldan Group products.

CALDAN Conveyor is a worldwide leading supplier of conveyor systems for the surface treatment industry. The company is located in Aarhus, Denmark, and is a well-established, modern technology company with 60 years of industry experience. CALDAN designs, manufactures & installs internal transport systems for automated painting processes & materials handling worldwide.

CALDAN displays remarkable growth rates and has twice been awarded the prestigious “Gazelle Prize”. In addition, the CALDAN Group is financially well-funded and has a long-standing AAA rating. CALDAN has subsidiaries in Germany, England, USA, France, China & India and a staff of 160 dedicated employees. Additionally, through strategic alliances, we have CALDAN managed sales & support functions in Brazil, South Africa & Türkiye.

We are part of Axel Johnson International, a global industrial group which acquires and develops companies in strategically selected niche markets, primarily technical components and industrial process solutions. The group is an active and long-term owner whose mission is to drive business development and growth. It comprises 200 companies in 34 countries. Axel Johnson International is part of the Swedish family-owned corporate group Axel Johnson.

Visit: www.caldan.dk

1963 Company formed with the name Caljan A/S

1992 Successful MBO of chain conveyor division from parent company

2000 Opening of purpose built 3,000 m² design & manufacturing centre

2000 Opening of sales & technical office in Germany

2002 Opening of sales & technical office in UK

2004 Extension of 1,000 m² added to manufacturing centre

2009 Extension of 1,700 m² added to design & manufacturing centre in Denmark

2009 Establishment of the service company CSG (CALDAN Service GmbH) in Germany

2013 Opening of sales & technical office in Le Mans, France

Claus

Scott Parsons

(centre)Caldan Conveyor Group CEO

Service Engineer - Caldan Conveyor Ltd

2015 Establishment of CALDAN Conveyor Ltd in Kirkleatham Business Park, Redcar, UK

2018 AL-CON merges into CALDAN Group

2019 Extension of 2,700 m² added to design & manufacturing centre in Denmark

2019 Establishment of CALDAN China in Dongguan City

2020 Axel Johnson Intl. acquires share majority in CALDAN

2022 Establishment of CALDAN India Pvt. Ltd. in Pune

2024 Establishment of CALDAN Conveyor Inc. in Chicago, USA

2025 Acquisition and integration of SEMA France into Caldan Group

By Chris Mansfield - QUALICOAT Chair

The 25th edition of the QUALICOAT Specifications, approved in November 2024 and effective from January 1, 2025, introduces refined QUALIDECO criteria for decoration of coated aluminium used in architectural applications. This new appendix expands the specification to specifically address decorative finishes, including technologies like sublimation and powder-on-powder. Furthermore, it sets out rigorous requirements for gloss levels, measured at a 60° angle, coating thickness, with a minimum of 80% of the specified 60 µm across multiple points, resistance to humid atmospheres containing sulphur dioxide, and other environmental durability tests.

Additionally, the 2025 Specification includes clear procedures for licensing and quality control. Only QUALICOATapproved plants and materials may be used, new technologies are constantly reviewed prior to approval, based on detailed testing by accredited laboratories. The Specification also outlines the use of "self-tested decoration" lists, where suppliers must test each new Class 1 decorative finish in their own laboratories and maintain

accessible records for QUALICOAT’s independent inspectors to verify during license renewals. Overall, the 2025 update strengthens consistency, traceability, and performance of decorative coatings used on architectural aluminium projects.

The 2025 Specification also reflects QUALICOAT’s wider focus on sustainability and accountability in architectural finishes. With the growing

use of recycled aluminium and decorative surface treatments, the new rules ensure that performance is not compromised by material choice or design trends. By requiring tests such as sulphur dioxide exposure and accelerated weathering, the specification guarantees that coatings can endure aggressive urban or coastal environments while maintaining appearance and structural integrity. This is particularly important for projects where aesthetics and durability are equally critical, such as façades, curtain walling, and decorative elements.

Another notable element is the tightened inspection and compliance regime. Independent inspectors will continue to conduct unannounced visits, but now with expanded powers to cross-check laboratory data against on-site production and supplier records. This transparency helps prevent sub-standard finishes from entering the supply chain and reassures architects, specifiers, and clients that certified products truly meet the highest benchmarks. In short, the 2025 QUALICOAT Specification is not just an incremental update, it strengthens the system to support design freedom, long-term durability, and the Industry commitment to responsible, high-quality surface finishing.

QUALICOAT is the world’s only global specification for architectural powder coating. Since 1986 the Association has pioneered the development of powder coating technology through its membership and continue to improve specification documents that all of its members are obliged to follow. The Specification not only specifies the robustness of the finished coating, but also details process controls which are crucial to maintaining quality. By ensuring Members are third party assessed to demonstrate compliance with the Specification ensures consistent quality, a Member of the Association demonstrates this accreditation by proudly displaying their QUALICOAT logo and licence number.

Should you wish to attend a members meeting and apply for membership of QUALICOAT please get in touch. All QUALICOAT UK & Ireland members are available to offer advice and can be found on the Association website at qualicoatuki.org

It’s not just the Elcometer 456 Coating Thickness Gauge that’s fast... Generate professional inspection reports in seconds using the FREE ElcoMaster® Data Management Software.

Are you involved with the application of coatings to enhance and protect your products? Do you need to meet client specifications to ensure the longevity of your components? Does the complex world of surface engineering and materials finishing cause you headaches?

If so, the courses offered by the Institute of Materials Finishing (IMF) could be your solution!

The IMF have been promoting knowledge in the surface finishing industries, both inorganic surface treatments including plating and the application of organic paints, lacquers and varnishes for many years. Large numbers of engineers and technicians across a multitude of industries have benefitted from the knowledge gained to enhance their careers, their standing within industry and the ability to problem solve the many challenges they face in their daily working lives!

Starting with the Foundation level course, students gain knowledge on all aspects of materials finishing, specifically aimed at their own industry requirements, but to include sections on Health & Safety, the Environment and Surface Finishing and Corrosion Protection. There is no need for a science background to be able to successfully complete a foundation course.

The Foundation Course requires study of 15 sections and requires the submission of 2 marked assignments followed by an end examination. The course, conducted by distance learning will take 16 weeks to complete. There are three specific study routes to choose from; electroplating, organic coatings and aerospace finishing. On successful completion, the student is awarded the Foundation Certificate.

To follow on, students can then elect to progress to the Technician level modules, which give more in-depth knowledge for key finishing technologies, their application and best practice methods. Again, both inorganic and organic technologies can be studied to match the industry requirements. There is a choice of eight modules, which provide study in applicable areas of surface finishing best matched to your needs.

Like the Foundation course, study is by distance learning, and the student is required to complete four marked assignments and pass an examination.

Passing two technician modules leads to the award of Technician Certificate; passing four modules leads to the award of an Advanced Technician Certificate.

If you feel your career could benefit from being a recognised specialist in your particular branch of Surface Engineering or Materials Finishing, then contact the IMF today.

Speak with our training manager Karen Yates on +44 (0)121 622 7287 or email karen@materialsfinishing.org.

Move your career to the next level and join the finishing community and all the benefits that gives through the IMF.

Discover the Future of Surface Finishing at Surface World 2027! Explore the latest in surface treatment, finishing, and coatings at the UK’s leading event. Connect with top suppliers, discover cutting-edge technologies, and stay ahead in the industry. Don’t miss out—secure your place today!

supported by

AirBench is pleased to announce the launch of the new BSD solvent mist blowdown cabinet.

BDS is developed based on customer requests for a unit comparable to the existing BD – but suitable for use with solvents. This range uses zone 1 ATEX fans and carbon filtration to ensure safe capture of mists when blowing solvent contaminants from parts.

The base unit works on the same principles as BD, with a contained cabinet and blowdown gun; this new model extends the range of applications available for parts blowdown outside coolants and swarf.

Running from a 3ph supply through a high efficiency motor, BDS is simple and effective; solving an issue that has been ignored in industry.

Contact AirBench Ltd for further details and demonstrations, or visit www.airbench.com/bds.

Telephone: 01206 791 191

Email: sales@airbench.com

Visit: www.airbench.com

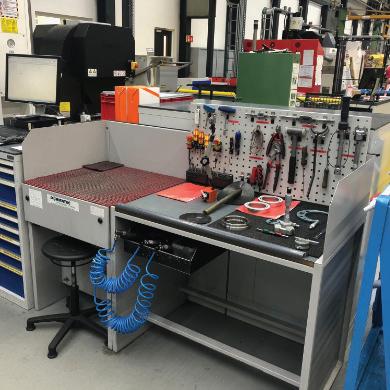

• AirBench takesdustandfumes awayfromyourbreathingzone

• AirBench drawsthemthrough theworksurface,capturingthem insidethebench

• AirBench isavailableinawide rangeofsizesandfiltertypes tosuityourapplication

• AirBench isplugandgo-only needingunwrappingandplugging intoa13ampsocket

•Yougetextractionandwork benchinonecompactunit

Contactusforanon-sitedemonstration. Doubtitcanbethatsimple?

TheVertExmodularbooth system.Dustissuessolved...

• Modular systemforfast installationandassembly.

• LowEnergy throughtheuse ofhighefficiencyfans-upto 20,000m3/hat3kw.

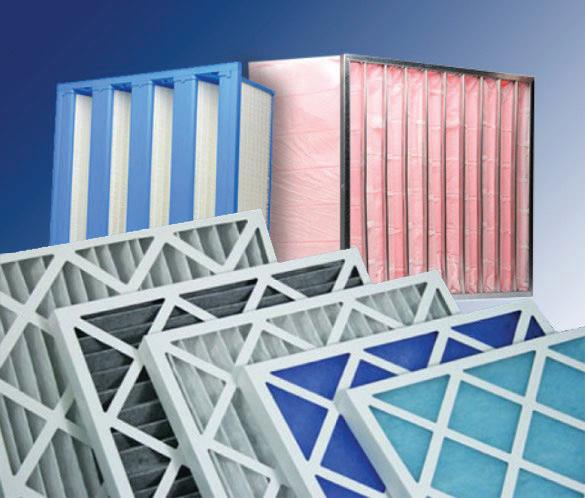

• FiltrationOptions fromthe standardAirBenchrange.

• WeldingandGrinding boothsalso availablewithHEPAfinalfilter.

• RapidReconfiguration -standard componentsmeanVertExbooths canbereconfiguredondemand.

Doubtitcanbethatsimple?

finishes, which deliver a consistent, natural metallic look with excellent resistance to UV, scratches and weathering.

Innocoat Systems has become the first company of its kind in India to achieve Interpon D3020

Approved Applicator status, a major milestone that gives Innocoat a competitive edge and reflects its commitment to delivering the highest standards of quality, durability and sustainability in architectural powder coatings.

The accreditation, from global paints and coatings leader AkzoNobel, gives Innocoat customers access to a hyperdurable Interpon D3020 powder coating engineered for extreme environments and offering exceptional gloss and color retention and the option to provide project warrantees up to 30 years. It is a high-performance, sustainable alternative to liquid PVDF2 systems.

Innocoat’s partnership with AkzoNobel spans more than a decade and underpins its leadership in the surface finishing sector. The company operates three state-of-the-art facilities across Peenya and Kunigal, coating more than 1,000 tonnes of aluminium each month for a range of applications - from commercial real estate to high-spec transport infrastructure.

“We continuously explore new technologies and sustainable processes to enhance quality, efficiency, and performance,” says Dilip Kumar, Managing Director at Innocoat. “Achieving D3020 Approved Applicator status from AkzoNobel is an important milestone for us, and one that reinforces our ability to meet the most demanding customer expectations.”

Next to Interpon D3020, Innocoat’s ‘go to’ powder coating is the Interpon D2525 series, chosen for its superdurable performance. Similar to all Interpon powder coatings these deliver a low environmental impact with an absence of VOCs and are backed by an Environmental Product Declaration (EPD), helping customers make informed, sustainability-focused choices. Innocoat also offers the Interpon D bonded metallic and anodic

“The D3020 range offers maximum gloss and color retention, even in harsh conditions,” says Mohan Dhandapani, General Manager at Innocoat, adding: “It supports our mission to provide advanced alternatives that outperform traditional systems. Ultimately, the Innovations delivered through the partnership with AkzoNobel Powder Coatings allow us to deliver added value and remain competitive in an increasingly demanding industry.”

Şirvan Canıtez, Commercial Director South Asia at AkzoNobel Powder Coatings, adds: “It is our joint responsibility to ensure that we continually innovate to find the best solutions to market challenges and requirements. Innocoat brings deep expertise of India’s architectural market, and we’re proud to support their growth with a wide range of innovative products that deliver excellent resistance, as well as on-trend finishes through the anodic and metallic ranges.”

To find out more about Innocoat, visit: https://www.interpon.com/insights/innocoat-testimonial

With our new Interpon D1036 Low-E powder coating, we’ve created an industry first: a powder coating that can cure as low as 150°C while still being Qualicoat class one certified. It can also cure up to 25% faster than conventional powders, reducing both energy consumption and carbon emissions, and significantly improving your coating line efficiency. Easy to apply Interpon D1036 Low-E has the same application properties as standard formulation, is backed by an Environmental Product Declaration (EPD) and has a global warranty of up to 15 years to deliver the quality performance, color and style your customers need. It is an innovation that supports our collective commitment to sustainability throughout the value chain.

Electron has signed a distributorship agreement with Professional Coating Solutions Limited, a respected and experienced company in the UK.

The partnership supports Electron’s strategy to grow in Europe and deliver faster, more reliable solutions to the UK market. Customers will benefit from innovative products combined with local expertise and support.

Professional Coating Solutions brings strong industry knowledge and an established network, helping make Electron’s products more accessible while improving technical and after-sales services.

A spokesperson described the collaboration as “an exciting new chapter,” highlighting the opportunity to be closer to UK customers and respond more effectively to their needs.

The agreement reflects Electron’s long-term goal of combining high-quality innovation with local partnerships that put customers first.

For more information visit: www.electron.com.tr

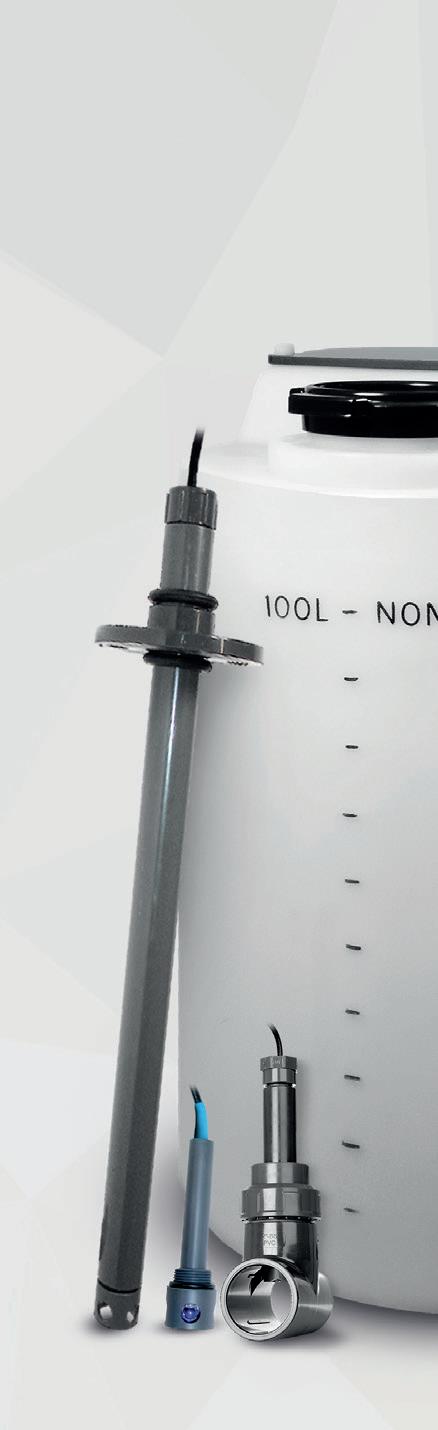

PUMPS & FILTERS

L SERIES | Medium flow rate filter

P SERIES | Ultra-high flow rate filter

L-TECH | Pleated cartridge BAGTECH | Filtration bag QUALITHERM | Extruded cartridge QUALIBOB | Wound cartridge

RAC® 5

RAC® X Tips

WIDE APPICATIONS

Use one guard for all your airless spraying needs — production, high-pressure, fine finish, low-pressure, wide-angle, line marking and more.

Insert two tips. On one side RAC® 5, RAC® XHD and SC-6 tips and on the other side RAC® X tips and switch instantly for speed and flexibility.

+ Pressure rated up to 530 BAR / 7,700 PSI

+ Fits RAC® 5, RAC® XHD, SC-6 and RAC® X tips

Engineered for convenience. TWINFIT® connects seamlessly to almost any professional airless spray gun. Tighten by hand or wrench to any 7/8” or 11/16” connection.

Only two seats and seals required. Our unique SealEx® 6 for RAC® 5, RAC® XHD, and SC-6 tips, and SealEx® 7 for RAC® X tips ensure reliable performance and perfect adaptability.

FIRST PAINTING

Maximize control, and protect the user: TWINFIT® is built to support professionals ‘under pressure’.

+ Perfect match for ExitFlex® Speedy 6 and Speedy 7 airless tips

+ Rugged, durable and ready for all-day use

VERSATILITY AT ITS CORE

+ Universal compatibility with all major airless systems and guards.

+ 715+ tip sizes for production, fine finish, line striping and more.

+ Ergonomic handle with built in seal and tIp positioning tool

+ Ideal for daily use with your existing equipment.

+ Perfect fit with TWINFIT® for seamless operation.

+ Tip locking mechanism for extra safety on high-pressure jobs.

+ Designed for tough conditions - shipbuilding, heavy industry and more.

+ 715+ tip sizes, ergonomic excellence.

+ Perfect fit with TWINFIT® for optimal safety amd performance.

+ The go-to for heavy duty professionals demanding precision, protection and perfection.

Vixen Surface Treatments have been manufacturing dust collectors for over 35 years on our dry blasting machines. It seemed the natural progression to expand our dust collector range and we have decided to launch a new range of dust extraction, powder coating equipment and thermal process ovens.

We’re excited to apply our expertise to this new product line and have the opportunity to provide our customers with entire solutions.

Having manufactured our own integral and free-standing dust extraction

systems to work alongside our blast cleaning equipment, we felt it was only natural to introduce a new range of larger, standalone, modular systems for practically all dust and fume applications.

We really believe that we have a design and performance that will rival any of the

current dust extractors available on today’s marketplace and at a very competitive price.

All of our dust extraction systems are made in the UK and can be tailored to meet your specific needs, ensuring quality and that you get the most out of your machine.

When it comes to ovens, we’re going all out. We’ll be providing a fantastic range, focusing on laboratory ovens and furnaces, industrial ovens and furnaces and bespoke, tailor-made solutions. We’ll have over 100 different types of ovens available, meaning we’ll be easily able to provide exactly what you’re looking for.

Our ovens will be designed by a group of professional engineers to be economical and made from high quality materials to be long-lasting.

This ensures optimal results for thermal processing of various materials and parts up to a temperature of 1300 °C.

At Vixen, we pride ourselves on providing our customers with a solution every step of the way, rather than just a machine. Alongside our curing ovens, we’re going to be offering high quality, top-of-therange powder coating booths and gun applicators.

The Vixen range of powder coating booths allow for painting multiple components by hand directly placed on the worktable or suspended from optional roof mounted hanging rails.

They will be fitted with aluminum fans rather than standard steel, as they in themselves won't cause sparks to appear within the metal casing. Thanks to their low weight they also consume less energy and thus less costs.

The state-of-the-art powder coating guns we’ll offer will be built of the highest quality materials and incorporate the most

advanced technological features of all the powder coating corona guns developed by Romer.

Romer Profispray v powder coating guns are characterized by their ability to provide high productivity and efficiency rates in the application of sprayed powders. They offer a simple operation to deliver excellent coverage even in the most difficult to reach places with plastic or metallic powders.

Adjustment features of the powder gun allow for overlapping elements with a homogeneous powder stream, whilst also allowing you to control the thickness of the coating, giving optimum coverage.

We’ll be ensuring high quality, as the products are built and tested by a company that uses powder coating equipment every day. We’re not just selling a product; we know the equipment inside and out.

Telephone: 01642 056259

Email: info@vixen.co.uk

Visit: www.vixen.co.uk

Product Overview

Manual Monorail Systems

Unit loads up to 3000kg

Monorail Chain Conveyors

Unit loads up to 300kg

Power & Free Conveyors

Unit loads up to 7000kg

Floor Conveyors

Unit loads up to 500kg

Stewart Gill Conveyors Ltd have been supplying overhead conveyors into all sectors of industry for over 70 years.

As a long time member of the Railtechniek van Herwijnen BV Group based in the Netherlands, Stewart Gill Conveyors can offer a comprehensive range of overhead conveyor products which are capable of handling unit loads up to 7000kg.

Stewart Gill Conveyors Ltd offer complete manufacture, installation and commissioning, coupled with fully documented instruction, operation and maintenance manuals.

We do:

In-House 3D CAD engineering

In-House manufactoring in the UK and EU

In-House design of PLC/PC control systems

Industry 4.0

Worldwide installation and commissioning

Remote support, service & inspection Stewart

Part of the

Specialist Metallic Coatings (SMC), a leader in highperformance metal coating solutions, proudly announces the launch of its new brand identity and website. This marks a major milestone in the company's evolution, bringing together more than a century of heritage with a commitment to cutting-edge technology, sustainability, and customer-focused service.

Tracing its roots back to Zinc Alloy Rust Proofing Co Ltd, SMC has continuously pioneered advanced coating techniques from its longstanding base on Shakespeare

Street in Wolverhampton. The rebrand, which includes a new logo, modernised visual identity, and a digital-first customer experience, underscores the company’s role as a future-facing coatings partner across a range of critical sectors.

“This is more than just a new logo or website - it’s a signal of our determination to innovate within this industry,” said Harvey Bahra, Business Development Manager at SMC. “We are combining over 100 years of knowledge with today’s most advanced technology, quality control, and customer support to serve industries that are shaping the future, from renewable energy to defence and automotive.”

The new website offers an improved user experience, showcasing SMC’s full range of services including Sherardising, Dip Spin Coating, Zinc Phosphate, and zinc plating line, one of the largest in the UK. The site also features an engaging history timeline, accreditations, industry applications, and quality assurance documentation.

Most recently, Specialist Metallic Coatings was named Enterprise of the Year at the Nachural Summer Business

Awards 2025, a recognition of the team’s innovation, dedication, and trusted industry partnerships.

Revamped identity and website for a streamlined, modern experience

Major investment in one of the UK’s largest zinc plating lines

A renewed focus on sustainability, with a goal of achieving ISO 14001 certification

Reinforcement of SMC’s position in industries such as automotive, aerospace, oil & gas, medical, and defence

Expansion to over 70 employees, while retaining a personal, family-led service ethos

SMC continues to partner with some of the UK’s and Europe’s most innovative manufacturers, providing durable, performance-tested coatings that support global supply chains.

Visit the new website at specialistmetalliccoatings.co.uk

Thermaset

By Chris Mansfield - QUALICOAT Chair

Offering a presentation at Zak World of Façades London is an important opportunity for QUALICOAT as the event is recognised as one of the most influential global conferences dedicated to façade design and engineering. It attracts a unique audience of architects, developers, contractors, consultants, and suppliers who are actively shaping the built environment. Presenting at this forum allows QUALICOAT to share their powder coating expertise, including their third party inspection regime, licensing, and global leadership directly with key decision-makers, enhancing visibility and credibility i n a highly competent sector of the Construction Industry.

The London edition of Zak is particularly significant because it sits at the heart of one of the world’s most advanced construction markets where façade performance, sustainability, and compliance with evolving regulations are critical. By delivering an informative presentation we can demonstrate how our solutions meet pressing industry challenges such as energy efficiency,

fire safety, durability, and circularity of applied finishes. Zak provides us an excellent platform to influence specifications, highlight project case studies, and position our quality label as a trusted partner in achieving both design ambition and regulatory compliance.

In addition, participating as a speaker strengthens our professional network and creates direct engagement with potential

clients and collaborators. We know that offering presentations often spark meaningful dialogue that continues beyond the conference floor, opening the door to new specification opportunities and collaborations. In a market where differentiation is increasingly based on technical knowledge and sustainability credentials, presenting at Zak World of Façades

Let‘s talk about powder coating. A technology that is proven since decades and actually, it‘s just getting started with FLOWSENSE. FLOWSENSE? It‘s a software masterpiece and a bunch of small sensors that do big things: Consistent powder output from the first to the last workpiece. Reliability, measured in real time. Put quality on repeat!

London offers us a chance not only to showcase our expertise but also to help shape the Industry direction and priorities.

Coby Armar is the Secretary General of QUALICOAT and our conference speaker at Zak. In his current role, he leads the implementation and oversight of QUALICOAT’s international specifications, certification processes, and strategic initiatives within the aluminium finishing and construction industries. Coby holds a background in Mechanical Engineering, complemented by additional qualifications in Engineering Management and Entrepreneurship. Before joining QUALICOAT, he gained valuable, hands-on experience in the UK property sector: he worked as a real estate agent in Southwest London, a property manager for a co-working operator, and a project manager overseeing renovation projects, speculative builds, and brownfield developments. He also served as a Clerk of Works and Quality Assurance

Inspector, providing professional certification and compliance services known as CML Certificate services to architectural firms. This blending of technical, commercial, and field-level project expertise gives Coby a distinctive and well-rounded perspective in leading QUALICOAT’s quality standards globally.

Coby’s presentation at Zak on the 5th November at Old Billingsgate will offer an insight to the QUALICOAT label, explaining how the current architectural powder coating supply chain is vertically integrated by the use of licensing and third party inspections. Team QUALICOAT will also be manning an exhibition space at Zak where delegates may learn more about the Specification.

QUALICOAT is the worlds only global specification for architectural powder coating. Since 1986 the Association has pioneered the development of powder coating technology through its membership and continues to improve

specification documents that all of its members are obliged to follow. The Specification not only specifies the robustness of the finished coating, but also details process controls which are crucial to maintaining quality. By ensuring Members are third party assessed to demonstrate compliance with the Specification ensures consistent quality, a Member of the Association demonstrates this accreditation by proudly displaying their QUALICOAT logo and licence number.

Should you wish to attend a members meeting and apply for membership of QUALICOAT please get in touch. All QUALICOAT UK & Ireland members are available to offer advice and can be found on the Association website at qualicoatuki.org

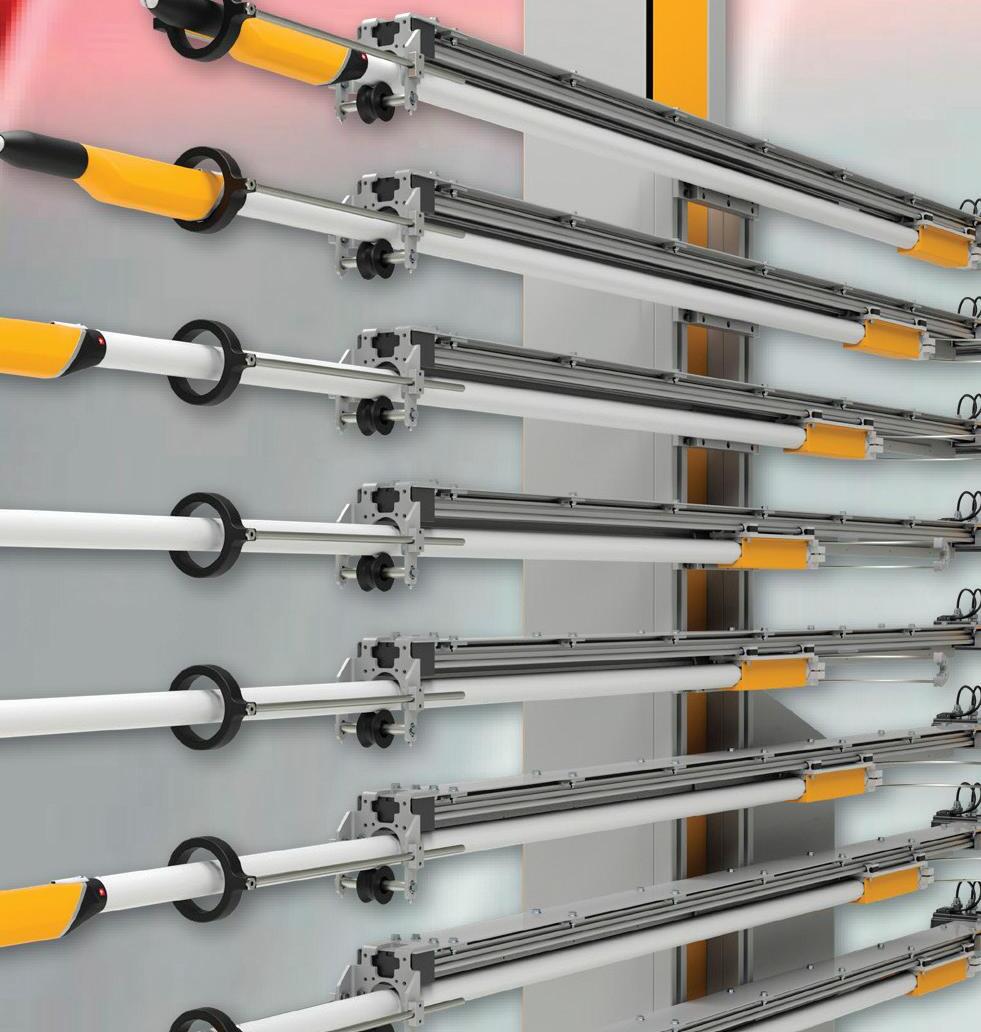

Programming-free coating of any shape! Gema

The second generation of Dynamic Contour Detection detects the object contour fully automatic and positions the guns individually even for thin objects and at high conveyor speeds. Due to the programming-free adaption of all relevant line settings the application range is significantly extended.

Email: uk.sales@gema.eu.com

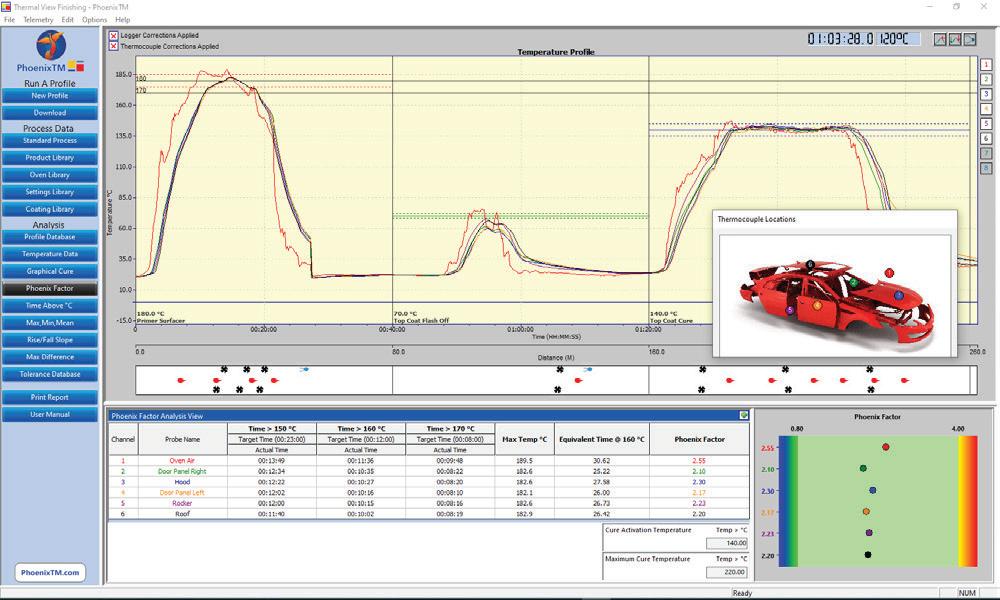

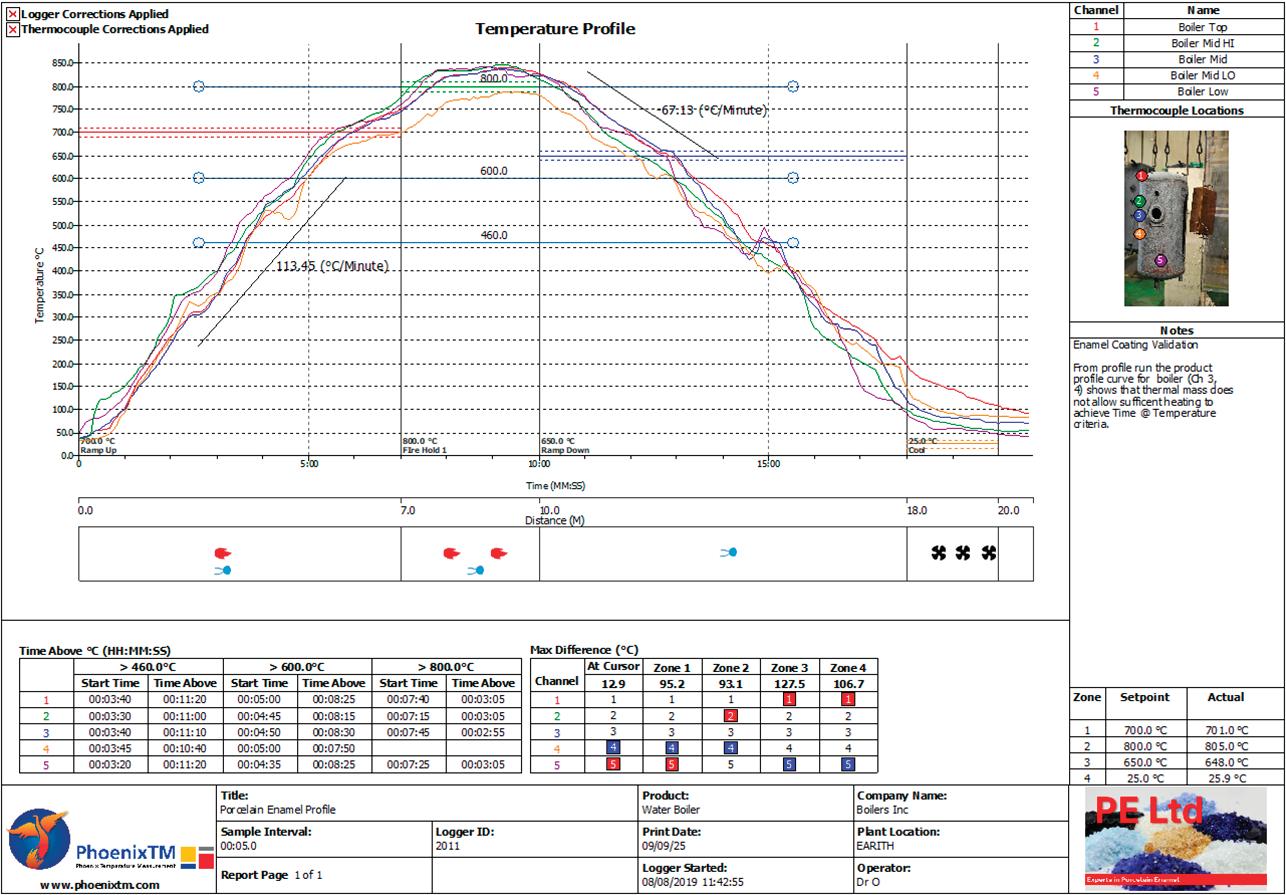

For anyone involved in vitreous enamel (porcelain enamel) a critical need of any firing process is the ability to measure and control both process and product temperature. The temperature control of the firing application, typically between 750 and 950 °C is critical to ensure that the powdered glass “Vitreum” fuses correctly to the substrate. Aesthetic and functional properties of the vitreous enamel surface coating are very temperature dependent. Temperature and rate of temperature change of the product will influence the melt, flow and fusing characteristics of the final coating and its performance.

The PhoenixTM ‘thru-process’ temperature profiling system used in the paint and powder coating markets comes with an option specifically designed for the challenges of the vitreous enamel process.

The PTM1200 multi-channel data logger (6-20 thermocouples) is able to monitor multiple points on either the product(s) or in the furnace environment with an accuracy of +/- 0.3 °C and sampling rate of down to 0.2 s to give high resolution profile data. The thermal barrier (TS01-125) protects the data logger as it travels through the furnace. With a typical protection of 1 hour at 800 °C the thermal barrier keeps the data logger below its maximum operating temperature of 80 °C to guarantee measurement accuracy and prevent thermal damage. The thermal barrier employs dual thermal protection using a combination of high-performance microporous insulation and a phase change heat sink. Despite the high protection the barrier is compact 125 x 240 x 588 mm (h x w x l) and weighs only 13 kg.

Temperature measurement is achieved in-process typically with short type K thermocouples attached, to key parts of the product, record temperature during the journey at specified intervals recording the accurate temperature of the product/ enamel surface interface.

The thermocouple of choice for enamel firing is an exposed junction thermocouple. The thermocouple is insulated either by a high temperature Nextel or Mineral insulated sheath protecting the core thermocouple wires. Complying to ANSI-96.1 the thermocouple accuracy is certified to +/-0.4% of the temperature measured or +/- 1.1 °C (whichever is greater). For a vitreous enamel firing temperature of 800 °C the measurement accuracy of the system, which is the sum of data logger accuracy and thermocouple accuracy, is therefore ±3.5 °C.

• Data Logger and Thermal Barrier choice (6 to 20 Thermocouples)

• Extensive Thermocouple range

• ATEX approved options

• Real Time RF Telemetry options

• Full UK service and calibration support

• Thermal View or enhanced Thermal View Finishing software

- Match Analysis Tools to suit.

• CQI-12 Temperature Uniformity Survey solution options

Innovative Video Capture Thru the operating oven

• Detect paint runs, chips and defects

• Spot transport problems

• Identify oven damage

• Locate dust and inclusion risk areas

A critical component of the vitreous enamel profiling system is the profile analysis software such as Thermal View Finishing software. Designed specifically for the needs of the coating market it allows not only the set-up/download of the data logger but the raw process data to be converted into meaningful information. Such information can be used to understand exactly how the process is operating, allow informed changes and provide certified evidence to prove to others the quality you are providing.

From the thermal profile trace a full understanding of the firing conditions experienced by the product can be reviewed and analysed in a clear and accurate fashion. Such information can help significantly overcome some of the inherent problems experienced by the application and identify the potential root cause(s).

After corrective actions have been completed the temperature profile can be rerun to check that firing anomalies are resolved.

Obtaining the thermal profile “Thermal fingerprint” of the product/process gives the production management and or quality team invaluable insight into how the process is

performing against specifications to guarantee product quality and efficient furnace operation.

PhoenixTM your Furnace to Find, Fix and Forget your Firing problems! www.phoenixtm.com

l Controlled Shot Peening

l

l

l

l

l Organic and Inorganic Coatings

l

l Superfinishing

l On-site Processing

l Material Testing and Analysis

l

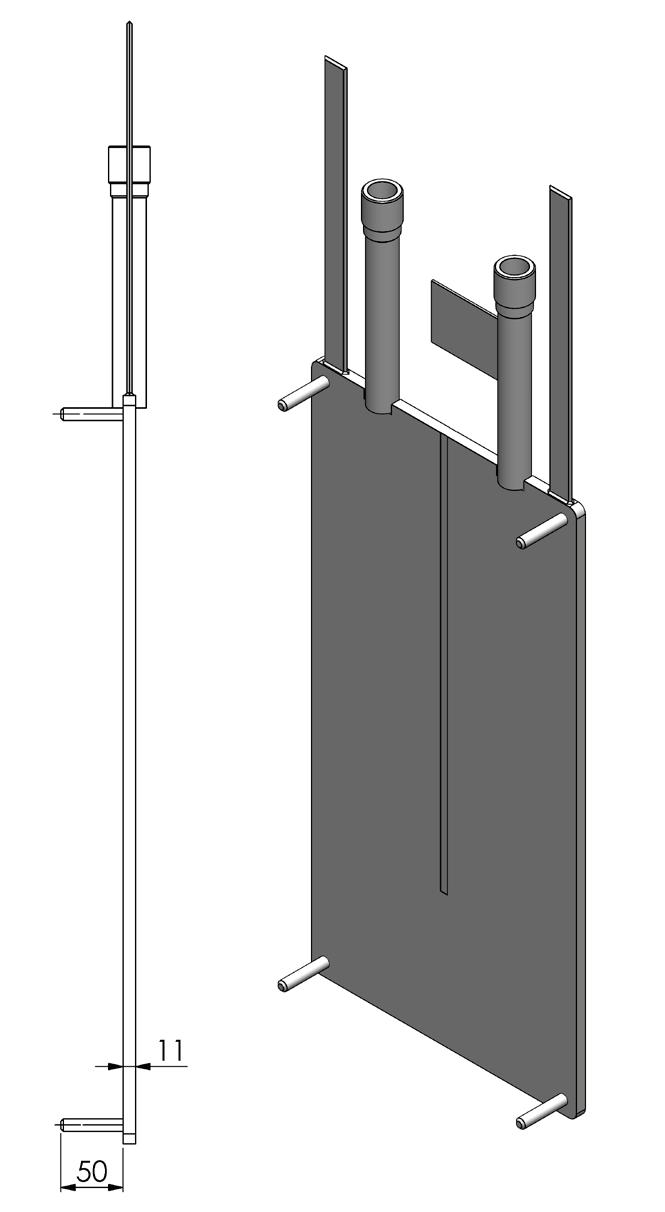

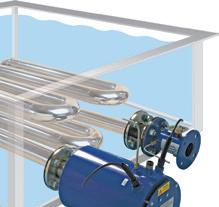

PFA-coated plate heat exchanger with angled pipework

SYNOTHERM® heat exchangers allow for use in heat exchange loop systems through which a hot liquid (such as hot water, steam, hot oil) is passed through the panel. Heat energy from the hot liquid then transfers through the internal surface of the panel into the process solution tank. The spotwelded, perforated design creates turbulence through the channels, ensuring heated liquid molecules all touch with the internal surfaces of the panel therefore increasing heat exchange efficiency. Heat losses during the production process are compensated. A process generated heat input (e.g., from ambient heat, rectifier, or an exothermic reaction), can be compensated with the aid of heat exchangers by passing a cold liquid (e.g. cold water, glycol) through the panel.

SYNOTHERM® PFA-coated plate heat exchangers exhibit a metallic base build. The compact, lightweight and pressureresistant design of the metallic base enables a long service life and high operational reliability of the heat exchanger.

In a multi-stage coating process, a fluoropolymer coating is applied to the metallic base build.

Zero porosity of the coating is verified by conducting a 100% high voltage test.

Thanks to the PFA-coating, SYNOTHERM® PFA-coated plate heat exchangers feature excellent chemical resistance and anti-adhesion properties, thus fulfilling two key requirements for use in chemical apparatus engineering. They are suitable for tempering highly acidic process liquids.

The anti-adhesive fluoropolymer coating ensures homogeneous heat transfer in conditions where

incrustations, build-ups and deposits restrict the heat transfer capacity of heat exchangers. Fluoropolymers have significantly better heat transfer properties than other coating materials and plastic heat exchanger.

The incrustation tendency from media that cause heavy incrustation, such as zinc phosphates, is reduced considerably.

Easy cleaning and extended maintenance intervals reduce maintenance costs and ensure the availability of your plant in the long term. Falling parts or sediments cannot deposit on or get caught in the heat exchanger body.

The coated plate heat exchangers have a high surface density. This means that a large heat exchanger surface

area (in m2) can be provided in relation to the required construction volume (in m3).

The total installation depth (see image) is 61 mm (11 mm heat exchanger body + 50 mm spacer to tank wall).

The space saving reduces the size and cost requirement for tanks. More space is available for other components in the tank or plant (pumps, rectifiers, barrels etc.).

Telephone 01509/673656

Email: sales@gmfequipment.co.uk

Visit: www.gmfequipment.co.uk

Reducing Dust, Waste & Disposal

4 operators can blast all day

4 operators can blast all day

Reduce abrasive consumption by up to 20%

Reduce abrasive consumption by up to 20%

Increase blasting production by up to 30%

Increase blasting production by up to 30%

EASILY SWITCH BETWEEN 4 FUNC Mist Blast Dry Blast Wash Down Blow Down TIONS

AVAILABLE IN 3 DIFFERENT PACKAGES

Single Outlet Blast Pot (6.5 cu ft) Combo Skid with Air Dryer 4-Outlet Mega MistBlaster

Does the Work of 5 manual blasters

Up to 646 ft² per hour

Use 3 (#10) nozzles simultaneously

Automate timing and speed

Blast walls, floors, even upside-down

our powder coating efficiency, with potential for further benefits once other parts of the process are improved.”

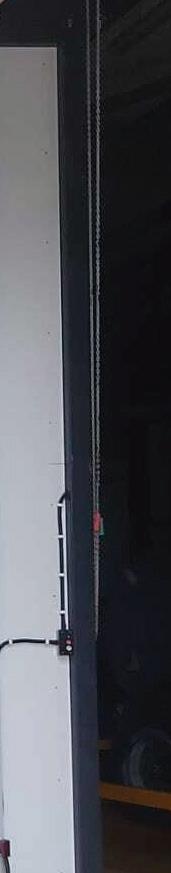

A retrofitted, infra-red booster oven from Excelitas Noblelight (formerly Heraeus Noblelight) has allowed South Staffs Industries Ltd (SSI)to increase throughput and improve quality on the powder-coating line at their Tipton LPG gas cylinder re-qualification factory.

SSI repairs, refurbishes and requalifies low pressure propane and butane cylinders and ammonia, nitrogen and refrigerant gas cylinders to British Standards, with facilities to requalify cylinders up to 50 Bar. Refurbishment of LPG cylinders, which typically takes place after 15 years in service, includes making cylinders gas-safe before processing, hydraulic testing, removal of old paint, shotblasting, zinc coating, powder coating and curing. screen printing, valve fitting and testing and weighing cylinders for tare weight.

Powder coating is carried out to restore the colour scheme of the original cylinder manufacturer and, historically, the coating has been gelled and cured in a gas-radiant oven, which emits long wave infra-red. However, this oven could prove inefficient and SSI decided to investigate ways to improve the overall efficiency of the process and increase the powder-coating line speed.

On the advice of powder-coating specialists NDK Finishing Systems, SSI contacted leading infra-red experts Excelitas, who carried out preliminary investigations on the existing gas radiant system, using a Datapaq oven tracker. These established that the maximum temperature achieved after 405 seconds was 170°C, a temperature which could fail to achieve full curing of the powder.

After carrying out tests on a range of cylinders at its Neston Applications centre, Excelitas proposed that an electric, 156kW medium wave infra-red booster oven should be retrofitted in front of the existing gas radiant oven. This has four zones to cater for the different size of cylinder. Subsequent Datapaq readings have shown that the booster oven very quickly raises the body temperature of the coated cylinders so that dwell time in the gas radiant oven is substantially reduced, allowing line speeds to be increased by 19%. In addition, optimum curing temperatures can be achieved consistently, leading to quality improvements.

As Ryan Cummings, operations director at SSI, comments, “The booster oven has allowed us to significantly increase

Excelitas Technologies® is a leading industrial technology manufacturer focused on delivering innovative, market-driven solutions to meet the critical sensing, detection, imaging and illumination needs of our OEM and end-user customers. Serving a vast array of applications across medical, life science, industrial, semiconductor, smart building, aerospace and defense sectors, Excelitas stands committed to enabling its customers’ success in their many various end-markets. The Excelitas team consists of more than 7,500 professionals working across North America, Europe and Asia to serve customers worldwide.

Noblelight® counts itself among the market and technology leaders worldwide for specialty light sources with wavelengths from ultraviolet to infrared for industrial, scientific, and medical applications. With operations located across Europe, Asia and the United States, Noblelight designs and manufactures infrared, flash and ultraviolet emitters, systems and solutions for applications in industrial manufacturing, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques with a high level of vertical integration.

Telephone: 0151 353 2710

Email: ian.bartley@excelitas.com

Visit: www.excelitas.com

Alongside the high-quality of design and product, a large part of the Junair ethos have always been the pursuit of process efficiency, energy saving and reduction of cost for our customers. With the recent push for carbon reduction, Junair are leading the way within the industry in providing fully electric paint finishing plant.

Junair have recently installed a number of electric process ovens, spray booths and early next year will be delivering the UK’s firsts fully-electric powder coating line, including spray pre-treatment, drying and curing ovens.

The client has set a global target for carbon emissions across all of its operations of net zero by the year 2030.

In order to achieve this, the client reviewed all energy usage across the site, with a view to reducing power consumption, eliminating gas consumption, and installing renewables as a local source of energy for the plant.

The existing paint line is currently responsible for over 80% of total gas usage and nearly 60% of the overall energy consumption for the site. It is therefore the key focus for energy reduction and ultimately achieving the global goal of net zero carbon emissions by 2030.

Junairs flagship spray booths and spray booth ovens, including the 1 series, 3 series, 5 series and commercial

booths are now all available with electrically heated air handling systems.

These booths are all available with all our standard energy saving features, which, when combined mean we can supply a combination spray booth with power supply as low as 63A. Our standard energy saving features include:

The original auxiliary air movement assisted drying system, which can reduce drying times by up to 40%.

In turn reducing running costs and increasing product throughput. Designed to minimise dust contamination QADs also provides excellent temperature uniformity and allows product to come to temperature faster than with rival systems.

During periods of inactivity, between spraying or baking cycles, Junair booths automatically enter a reduced power mode which prevents unintentional energy use. This feature has exceptional energy saving over the 20 years life expectancy of a booth. This also allows Junair to supply a booth with one of the

lowest whole life costs of any booth on the market. On resuming spraying the booth will automatically revert to 100% exhaust.

Junair booths have automatic recirculation of 90% of air volume during Flash Off (QADs), BAKE and

ECO modes, dramatically reducing energy consumption for most of the booth operation.

Junair booths are fitted as standard with LED lighting for reduced energy use and extended life. Working with industry leading component manufacturers, Junair have developed a class leading LED light solution with optimised light levels at the point of painting, excellent colour rendition, with a suitably diffused light to reduce dazzle, and located to minimise effects on cabin airflow. These are a booth specific, highly optimised flat LED solution, not an off the shelf LED tube replacement Lighting is automatically controlled and is turned off when not required.

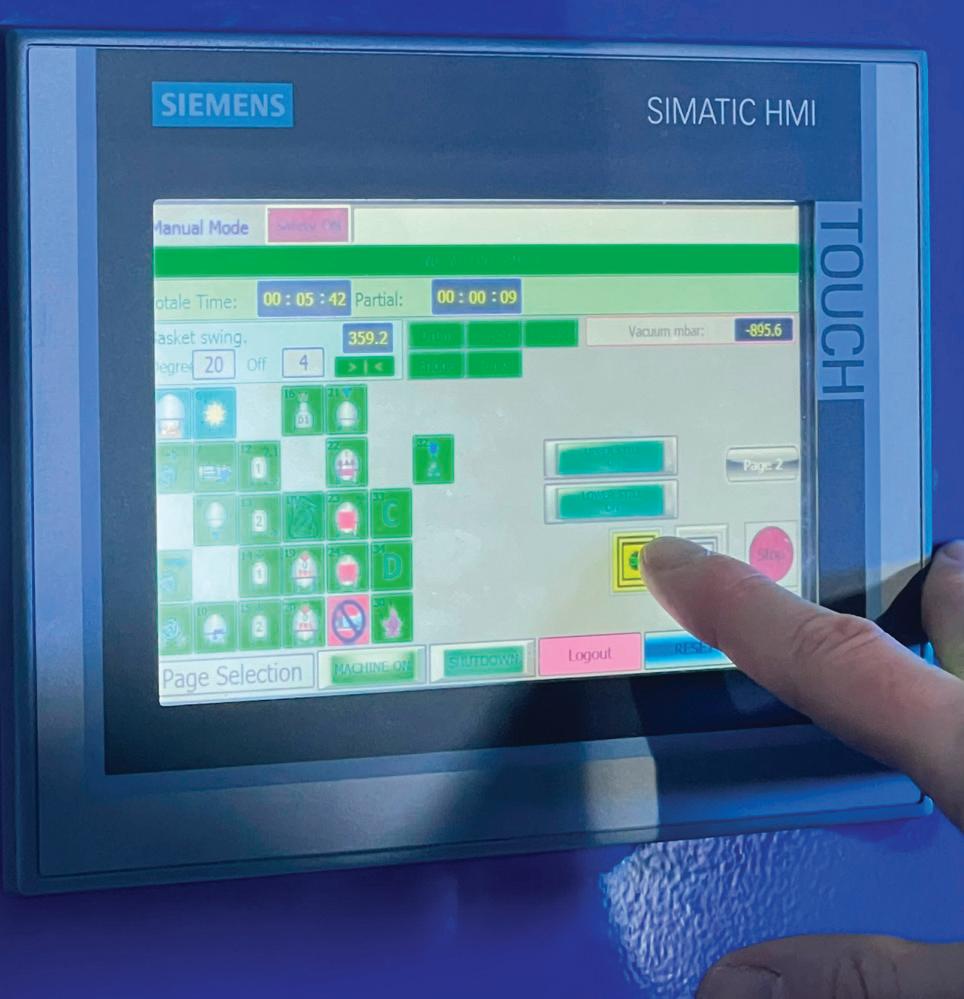

An advanced PLC and HMI based control system which allows recipe based bake cycle control to ensure each bake profile is optimised for temperature and time according to paint systems being used. Air speeds are automatically varied throughout the process to meet the process requirements

High visibility LED lights on the front of the booth clearly show the booth mode operation for ECO, SPRAY, QADs, BAKE to allow the painter and paint shop manager to have excellent visibility for all operations

Junair Ovens and booths, are fitted with variable speed fan controllers (Inverters), which allow the fan speeds to be set on commissioning for optimum performance and the lower energy usage.

Variable speed drives also allow ECO-ACTIVE automatic airflow control for the thermal process within the iSystem control package.

The option is available to add heat recovery to Junairs electric spraybooths and ovens.

Cross plate heat exchangers allow recovery of energy from waste exhaust air and transfer of that energy to pre-heat the clean replacement input air prior to it getting to the heating system. The system includes additional air filters to remove any particulate which has passed the booth extraction system to allow the system to maintain efficiency over the system life.

The system works on Fuel Saver/bake/ spray modes. Expected energy saving to heat the booth are in the region of 60%.

Heat recovery systems when fitted to our ovens can be used to assist the pretreatment heated tanks among other processes.

Junair have recently supported several customers with the supply of electric spray booths and ovens to the advanced AMS2750 specification for aerospace furnace applications. This specification relates to the control functions and for the recording and temperature uniformity for industrial thermal processing equipment.

Three recently supplied AMS2750 ovens (pictured) were supplied to one of our aerospace customers based in Scotland. These ovens are supplied as electrically heated, and with a comprehensive air distribution ductwork system. These ovens have a specialised frame and panel

design, which allows us to maintain a cool exterior, whilst achieving a working internal temperature of 425°C

When mapping the ovens, Junair carry out a detailed multi-point temperature uniformity survey, with a minimum of 9-thermocouple positions. This allows us to correctly balance airflows and heat distribution to ensure any thermal process requirements are met within the whole area of the booth or oven.

Where a conveyor has been supplied the equipment will then have a full throughprocess temperature profile carried out.

Temperature uniformity is a critical factor in all heated paint and powder coating processes, and it plays a crucial role in determining the quality and consistency of the final product.

AMS2750 provides a good guide by utilising the furnace classes which range from class 1-6 (±3°C to ±28°C).

Whilst Junair equipment as standard can achieve some of the highest uniformity standards, to achieve the most stringent standards equipment is typically supplied with electric heating with P&ID control. Electric heating not only delivers the benefit of a sustainable green process, but it also allows for a more accurate control of temperature.

If you are in need of high quality, efficient paint finishing or heat process equipment for your operations, Junair are here to assist. Our extensive range of reliable and efficient machinery is designed to meet the demands of your business. Whether you're looking for specific equipment, need a custom solution, or simply want to learn more about our offerings, we're just a call or click away. Contact us today, and let's find the right equipment to power your success!

Telephone: +44 1706 363 555

Email: sales@junair.co.uk

Visit: www.junair-spraybooths.co.uk

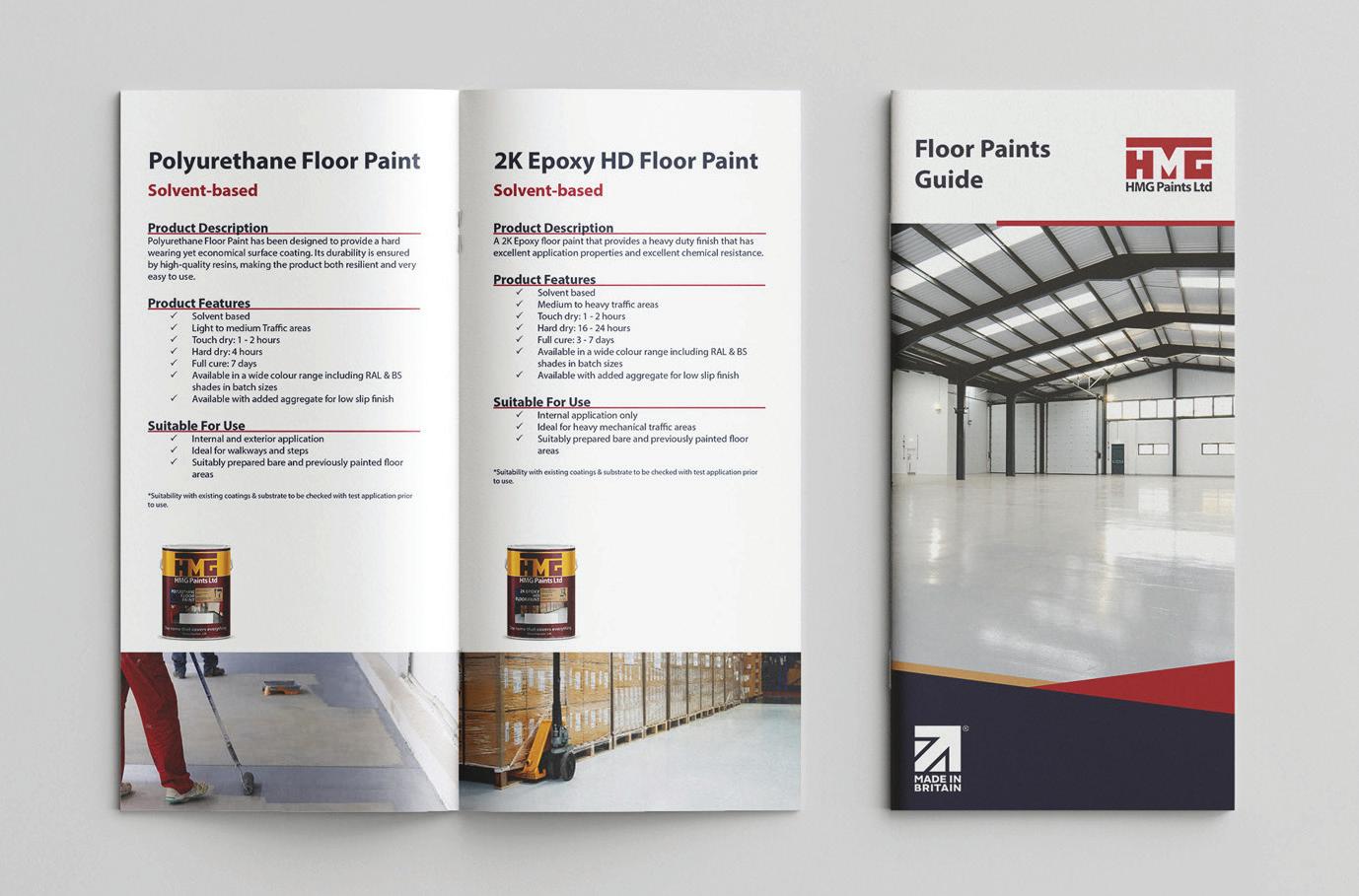

HMG Paints, the UK’s leading independent paint manufacturer, is making it easier than ever to choose the right floor paint for every job. The Manchester based company has relaunched its Floor Paint Range, complete with redesigned packaging, a simplified selection process, and an enhanced colour offering — all created with the end-user in mind.

As part of HMG’s ongoing mission to make high-performance coatings more accessible, the updated floor paint range helps customers quickly identify the right product for their specific needs, whether it’s for light-use walkways or heavy-duty industrial spaces. The range has already been used on projects across the country by Belle Vue Aces, FC United, Arriva Bus and many more.

“We listened to our customers and knew the floor paint buying process needed to be simpler,” commented Paddy Dyson, Marketing Manager at HMG Paints.

“Our updated range is designed to remove complexity and give users

confidence in their choices — from professionals managing large-scale projects to DIY users repainting a garage floor, HMG has it covered.”

The revamped range consists of three high-performance solutions, now clearly segmented by usage and traffic levels:

HydroPro Floor Paint – A water-based, low odour option for interior and exterior spaces with light to medium foot traffic. Fast-drying and environmentally conscious.

Polyurethane Floor Paint – A solventbased, choice for light to medium traffic areas. Ready to use, quick drying and ideal for both internal and external use.

2K Epoxy HD Floor Paint – A heavy-duty, two-pack solvent-based system designed for internal areas with medium to heavy traffic. Delivers excellent chemical resistance and long-lasting durability.

Packaging now features updated labelling with icons, usage scenarios, and clear product benefits, making it easier to match the right paint to the job whilst consumers are browsing shelves. The updated Floor Paint Guide, along with new Product Information Sheets, supports stockists, contractors, and specifiers in choosing the ideal solution.

The guide is available from HMG’s partners or online via: https://shop. hmgpaint.com/news/hmg-paints-newfloor-paint-guide-release/

With fresh, modernised packaging and a ready-mixed colour range of nine of the most in-demand shades — including Light Grey, Tile Red, and Safety Yellow — HMG’s updated floor coatings deliver both aesthetic appeal and technical excellence. The range is also available for tinting with customers able to select from HMG’s extensive library of BS, RAL,

Decorative and other popular colour ranges. As always, the products are Made in Britain certified with each batch being manufactured at HMG’s Riverside Works production facility.

“With our improved floor paint range, users get the same trusted performance with a more intuitive, streamlined product experience,” said Paddy Dyson of HMG Paints.

The full HMG Floor Paint range is available now direct from HMG or through HMG stockists and distributors nationwide. The new brochure, application guides, and technical specifications are available for download at shop.hmgpaint.com.

process heating solutions.

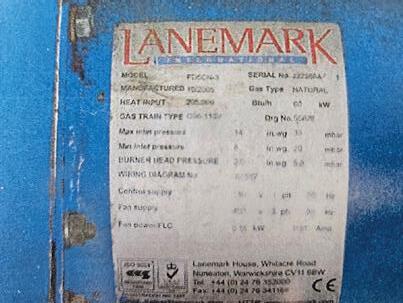

FD Series Packaged Oven/Dryer Burners

•Speci cally designed for process air heating applications in convection ovens and dryers

•High turndown/short ame lengths providing accurate process temperature control

•High ef ciency gas + air modulation, gas only modulation and simple high/low control options

•Heat Input Range: 9 kW – 1550 kW

TX Series Gas Fired Process Tank Heating Systems

•High ef ciency (80%+) heating of all types of spray and dip process tanks

•Compact high ef ciency small diameter immersion tube heat exchangers occupying minimum tank space

•Accurate performance modelling using Lanemark TxCalc design software

•Heat Input Range: 15 kW (1½") – 1150 kW (8")

Midco HMA Series Air Replacement or “Make-Up” Air Heating Burners

•Direct red, high ef ciency burner systems, for high volume air heating applications such as paint spray booths, ovens and dryers.

•Supplied either as Midco burner heads for OEM system integration or as Lanemark DB or FDB complete packaged systems including modulating gas valve trains and controls

•Wide range of ring rates to suit alternative temperature rise and air velocity system requirements

•DbCalc system design software

Pre-Treatment Solutions Group Ltd supply unique chemistries for an array of metal processes.

Our Phos-Prep® range of chemicals are chrome free, eco-friendly and cost effective all while maintaining quality and performance.

With over 50 years experience within the industry we pride ourselves on finding the right solution for your metal treatment. Whether that be degreasing, etching, phosphating, paint stripping and more!

“We have been a customer of PTS for over 20 years and during our time we have relocated our business, changed our pretreatment process with the full support and expert advice to implement changes from the PTS team. A great company who always go the extra mile to support their customers.”

P.Allen, West Midlands.

“We have been fortunate to have partnered with PTS for over ten years now. They are consummate professionals and always exceed expectations in terms of delivery of service, knowledge and customer care.”

E.Smith, Hampshire.

, queries whole

“We have had the great pleasure in working with PTS for over 5 years. No matter how big or small our queries are, PTS always come up trumps and in rapid time. The team are always willing to visit our site to help out with any issues we have or just for a general catch up with our staff. We have a very good relationship with the whole team at PTS and long may this continue.”

R.Glasbey, West Yorkshire.

The PosiTector series, developed by DeFelsko, the leading US manufacturer of paint inspection equipment, offers a versatile and cost-effective solution for coating applicators and inspectors. The system allows users to easily swap interchangeable probes with a single PosiTector gauge body, streamlining multiple inspection tasks with one device.

The PosiTector gauge body is available in two models: Standard and Advanced. Both feature a large touchscreen display, user-friendly navigation, internal memory, and an IP65-rated enclosure. The Advanced model adds Wi-Fi, Bluetooth, additional memory, onscreen graphing, and advanced probe features, such as the ability to take over 180 readings per minute in scan mode (PosiTector 6000) or measure up to three layers on non-metal substrates between 13-7800um with the 200 series probe.

The latest PosiTector gauge body is fully compatible with all PosiTector probes manufactured since 2012. This backward compatibility allows the gauge body to easily convert into various inspection tools, such as a dew point meter, surface profile meter, soluble salt tester, hardness tester, gloss meter, or ultrasonic wall thickness gauge, making it highly adaptable to different needs.

Changing probes on the PosiTector system is simple. There is no need to turn off the device—just slide the probe out, following the arrows on the back, and insert another probe. The gauge body automatically recognizes the new probe and retains all settings, including calibration, language preferences, and measurement units. This seamless probe switching eliminates the need to relearn menu functions, saving time during inspections.

The system also helps reduce costs and space by allowing users to consolidate all inspection equipment into one compact case. You can start with a single probe and expand your collection over time or opt for a standard or custom kit to suit your specific needs.

The PosiTector Advanced gauge body offers additional features that enhance inspection efficiency. When connected to the PosiTector 6000, users can access specialized modes like PA2, 90/10, and 19840, along with Smartbatch functionality for the PosiTector SPG. The dew point meter includes trend charts and live graphing, providing deeper insights during inspections.

PosiTector’s integration with the PosiSoft Software Suite makes it easy to compile professional reports. You can download readings from multiple probes and generate multi-batch PDF reports, simplifying data analysis and presentation.

Unrivaled probe interchangeability for all of your inspection needs.

Coating Thickness Probes

n Ferrous n Non-Ferrous n Combination n Ultrasonic

Surface Profile Probes

n Depth Micrometer n Replica Tape Reader

Environmental Conditions Probes

n Integral n Cabled Magnetic Probe n Anemometer Probe

n 1/2” NPT n Infrared

Hardness Probes

n Shore n Barcol

Salt Contamination Probe

n Bresle Method

Ultrasonic Wall Thickness Probes

n Corrosion n Multiple Echo Thru-Paint n Precision

n Low Frequency n Xtreme

Customized Inspection Kits...

Build your own kit from a selection of gauge bodies and probes to suit your needs.

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.

01442 879494 f: 01442 879595

www.dftinstruments.co.uk e: sales@dftinstruments.co.uk

Bluetooth and Wi-Fi connectivity allow for easy report generation in the field or remote data transfer to a computer.

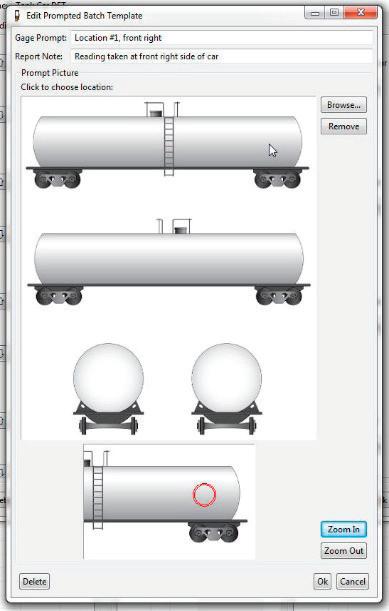

The PosiTector 6000, 200, and UTG gauges feature a “Prompted Batch Mode,” which simplifies inspections by providing onscreen prompts for each measurement. This is particularly useful for repetitive jobs or when specific measurement locations are required. Multiple templates can be stored, allowing for consistent and efficient inspections.

For companies with multiple probes, the PosiTector system reduces downtime by allowing only the probes to be sent for recertification, not the entire gauge body. This means the gauge body remains in service, eliminating the need for recalibration.

The PosiTector range offers significant cost savings by allowing multiple probes to share a single gauge body. Kits are available in medium, large, and heavy-duty Pelican cases with customizable interiors, saving space and reducing the number of cases needed.

For more information contact Mark Conlon at DFT Instruments UK Ltd, the official UK and Ireland distributor for DeFelsko.

Telephone: 01442 879494

Email: sales@dftinstruments.co.uk

Visit: www.dftinstruments.co.uk

Affordably measures uncured powder coatings using non-contact ultrasonic technology to predict a cured thickness

Dedicated stand-alone unit is ready to measure right out of the box

Fast measurement speed—ideal for moving lines and swinging parts

Scan Mode continuously takes measurements—ideal for analyzing large areas

Storage of 999 readings with onscreen averaging. Stored readings can be downloaded to PosiSoft Desktop Software

Powder Inspection Kits

Complete solutions for measuring powder coating before and after

SurTec 883 XT - Trivalent Decorative Chromium Process

Identical colour values as chromium(VI) surfaces

Integration into existing lines possible

Excellent layer thickness distribution between 0.2 and 0.4 μm

SurTec 851 - Exclusive Satin Nickel Finish

Semigloss & non-reflecting nickel coatings with extreme uniform finish

Long bath lifetime due to using a continous system

Broad range of satin effects to match automotive OEM requirements

SurTec 866 - Bright Acid Copper Process

For extremely bright copper deposits with excellent levelling

Well suited for parts with deep recesses or complicate shapes

Very efficient additive system with low maintenance cost

AkzoNobel, a global leader in high-performance powder coatings, has launched the Interpon D2525 Trends Collection, designed to offer designers and architects a striking selection of colours and finishes that complement the unique architectural style and natural beauty of the Middle East.

Building on the success of the Interpon D Futura powder coatings collection, a favourite of the architectural industry for more than 20 years, the Trends Collection includes three curated colour palettes: Desert Sands; Shimmering Mirage; and Arabian Nights. Inspired by the rich tones of the desert and the avant-garde architectural styles of the Middle East,

the Trends collection blends effortlessly with both modern and traditional regional designs to bring fresh, lasting appeal to a building’s facade, windows and doors.

Desert Sands features a warm blend of reds, soft greys, earthy tones, and natural stone capturing the essence of the desert while honouring traditional craftsmanship. Shimmering Mirage is a serene mix of gentle greys and whites with a metallic sheen, adding a touch of magic and sophistication to any design. Arabian Nights evokes the rich colours of the desert at dusk, with earthy browns, deep coffee shades, and dusky blues that connect buildings to their natural surroundings.

AkzoNobel’s Trends Collection is backed by an Environmental Product Declaration (EPD), meaning the collection’s raw materials, manufacturing processes, and transportation have been thoroughly assessed for their sustainability. This provides important assurances to

architects and designers that their choice of powder coating is environmentally responsible and contributes to a building’s environmental rating.

The Superdurable Interpon D2525 collection also boasts exceptional durability, as well as offering superior gloss retention, colour stability, and UV resistance. With a 25-year warranty and certifications such as Qualicoat Class 2 and GSB Master, the Trends Collection is built to withstand the test of time, making it ideal for demanding climates.

Sanal Limoncuoğlu, Commercial Director Powder Coatings South & East Europe, Middle East and Africa at AkzoNobel Powder Coatings, says the collection is more than just a colour palette - it's an invitation to create: “At AkzoNobel, we believe that great design starts with the right finish. With the Trends Collection, we’ve created a range of colours and finishes that not only reflect the splendour of the Middle East but also offer architects and designers the freedom to bring their most innovative ideas to life. We are excited to continue supporting the architectural community with products that combine beauty, durability, and sustainability.”

The Trends Collection is available on stock (Ready-to-Ship) to ensure that even the most time-sensitive projects stay on schedule.

For more information, visit: http://www.interpon.com/insights/ new-middle-east-trends-collection

3. Nail the assessment stage

Time is money in the body shop business. Whether it’s a quick cosmetic fix or a complex structural repair, every minute counts and every mistake costs. But, with rising customer expectations and tightening margins, how can today’s repairers stay ahead of the curve?

According to Paul Buckingham, Sales Director for North EMEAI at Sherwin-Williams Automotive Finishes, the answer lies in working smarter, not harder. “Efficiency doesn’t mean cutting corners, it means creating a process that runs like clockwork,” he explains. And with the right strategies in place, even small improvements can lead to big gains.

Here, Buckingham reveals five practical tips to help body shops boost efficiency, reduce delays, and keep customers coming back.

1.Build better habits from the ground up

The most successful body shops are often the most disciplined. “It starts with setting clear goals and helping to make every business interaction is a win-win,” says Buckingham. Creating a culture of consistency and communication within your team can help reduce errors, boost morale, and get everyone moving in the same direction.

2. Rethink your workshop layout

A tidy, well-organised space isn't just visually appealing, it’s also better for productivity. Optimising the layout of your workshop can drastically improve workflow, reduce bottlenecks, and make each step of the repair process more efficient. Small changes in station placement or tool access can translate into big time savings.

“A well-planned job is a well-executed job,” says Buckingham. Taking the time to get things right at the assessment stage can prevent costly rework down the line. Thorough inspections, clear documentation, and realistic timelines help make sure that everything goes smoothly once the tools come out.

4. Keep customers at the heart of the process

Customer satisfaction is more than just good service, it’s the key to repeat business. Regular updates, transparent pricing, and a commitment to quality are all vital. By focusing on the customer experience, body shops can build trust and long-term relationships that support sustained success.

5. Choose the right partner

When it comes to efficiency, the paint and coatings you use matter and so does your supplier. “Working with a manufacturer that understands your business can bring invaluable support,” Buckingham adds. A strong partner will offer tailored solutions, product training, technical support, and innovations that keep your business moving forward.

Sherwin-Williams doesn’t just provide paint. It brings colour expertise, sustainability, and a commitment to partnership that helps body shops streamline operations and drive growth. From cutting-edge technologies to hands-on support, Sherwin-Williams works closely with repairers and distributers to deliver products and solutions that match the pace of modern automotive repair.

For more information on how Sherwin-Williams can help your body shop improve efficiency, get in touch with our team.

Visit: www.sherwin-williams.com

• Conductivity Controllers

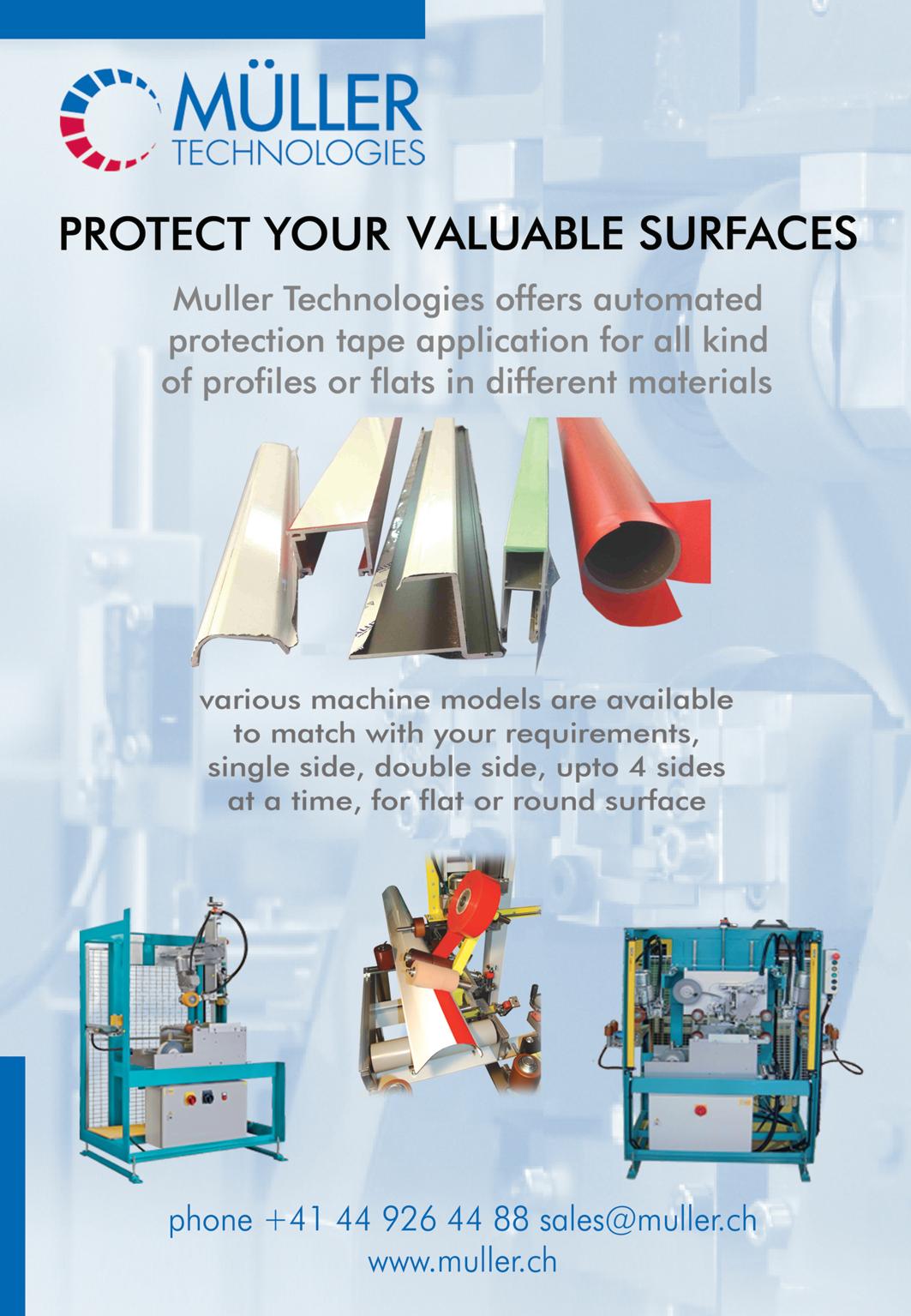

ELECTRON Powder Coating Booths are vital for powder applications in production processes. The aim is to protect human health and maximise powder savings. Ergonomic designs and demountable structures provide easy installation and maintenance.

Automatic Powder Coating Booths:

Fast and high-quality coating with uninterrupted powder supply.

Filtered or monocyclone system options.

Production specific to the customer's needs.

In order to minimise time and productivity loss during colour change, we develop cabins that can be cleaned quickly and have high recycling efficiency. Thanks to plastic structures, rapid colour changes are possible.

Models:

Cyclone or Filter Type:

Designed for effective powder retention and easy maintenance.

Metal Body Type:

Durable and long-lasting use.

Plastic Body, Floor Blown

Quick Color Change Booth:

Easy to clean and ideal for quick colour changes.

Conveyor Pass or Closed Type:

It is designed to be suitable for continuous production lines.

Movable Platform or Fixed Type:

Flexible for different coating processes.

Features:

Maximum Energy Saving: Advanced technology insulation and energy efficient designs.

Emission Amounts Compliant with CE Standards: Environmentally friendly operations.

Fast Color Change: Flexibility and time savings in production processes.

High Powder Retention Percentage: Minimum powder loss and highquality coating.

Sound Insulation Compliant with CE Standards: Increases the comfort of the working environment

Each powder coating booth model is designed to increase efficiency and quality in industrial coating processes, ensuring excellent results in your production processes.

Visit: www.electron.com.tr

NO PRICE INCREASES FOR 2025

Dürr has built a paint shop designed to slash CO2 emissions at one of the Volkswagen Group’s largest manufacturing facilities. The plant in Puebla, Mexico, was inaugurated in January 2025. The turnkey project includes two identical painting lines that are particularly environmentally friendly due to their electrified equipment, such as the electric drying system. Dürr is also implementing key components of its new “Paint Shop of the Future” concept with a highbay warehouse and driverless transport systems.

Since January 2025, the Puebla Volkswagen plant paints 90 vehicle bodies per hour of different models. Dürr was awarded the contract in 2022. The innovative paint shop is engineered to seamlessly accommodate additional models and emerging future technologies. This adaptive capability aligns with the high-output nature of the production plant and is made possible by a central high-bay warehouse and the EcoProFleet driverless transport system. DXQ software controls the AGV (automated guided vehicle) developed specifically for paint shops that predictively sorts the bodies in combination with the high-bay warehouse and brings them to the right work deck or collects them with pinpoint accuracy. Dividing rigid production lines is a central tenet of Dürr’s “Paint Shop of the Future” concept and shortens the overall process by tailoring the process time exactly to the individual vehicle.

This fact alone significantly reduces overall CO2 emissions.

The two identical painting lines feature 170 sealing and painting robots, with the corresponding application technology for sealing and coating the different Volkswagen models in the future. This encompasses EcoRS Clean F, a prime example of Dürr’s efforts to bolster system technology to equip it for growing model diversity. It combines the thorough, gentle cleaning prowess of a feather roller system with the high flexibility inherent to a robotic setup. This makes it perfect for lines that paint many body variations with complex contours. The contract scope also includes the complete paint and PVC supply and software solutions with AI applications from Dürr’s proprietary DXQ product family.

EcoDryScrubber uses limestone powder as a natural binder to separate paint overspray.

A central factor in CO2 emissions reduction is body drying since it consumes the most energy in the painting process. Operating the ovens with regenerative energy, like green electricity, reduces the CO2 emissions from the overall system by around 40 percent compared to a paint shop using natural gas. “This was one of the reasons why Volkswagen opted for the EcoInCure electric drying system,” explains Bruno Welsch, COO Automotive at Dürr.

“Another is its special air duct system that heats the bodies from the inside out. This technology results in more uniform heating and cooling behaviour and reaches solid body components like the rocker panels more directly than conventional systems, cutting the body heating times by 30 percent.”

Another cornerstone for minimising CO2 emissions is linking the electric oven to an

electric air pollution control system. Dürr is the only provider on the market with an overall blended concept of this kind. It combines the EcoInCure with an Oxi.X.RV, an electric exhaust air aftertreatment system that purifies the polluted exhaust air using the principle of regenerative thermal oxidation (RTO) –with no open flame. Unlike conventional combustion processes, no additional

CO2 is produced by the operation. The system is also extremely energy efficient and achieves autothermal operation even with small quantities of solvent, i.e., it maintains its operating temperature by itself. It uses the significant energy produced during oxidation of the solvents to keep its process going.

Dürr has also installed an energy-saving, environmentally friendly system for overspray separation. EcoDryScrubber uses limestone powder as a natural binder to separate paint overspray. Highly efficient HEPA12 filters remove all particles from the process air. The saturated limestone powder is disposed of fully automatically via a piping system – with no process interruption. The dry separation system at Volkswagen Puebla minimises the required fresh air supply to 5 percent maximizing the proportion of recirculated air. This reduces the paint booth’s energy consumption by well over 60 percent compared with wet scrubbing.

For more information visit: www.durr.com

In the aerospace sector, there is no such thing as "good enough." Every part, from the smallest turbine blade to the largest landing gear component, must meet extreme standards of precision, performance, and reliability. Failure is not an option when lives depend on the perfection of every surface, every edge, and every micron of tolerance.

This is why mass finishing and shot blasting technologies are so critical to aerospace manufacturing — and why Rösler continues to be a trusted partner for the world’s leading aerospace OEMs and suppliers.

Mass finishing and shot blasting are often the unsung heroes of aerospace excellence. They don't create the part, but they are absolutely essential in making the part fit for flight.

Mass finishing processes, such as vibratory finishing, high-

energy centrifuge finishing, and drag finishing, perform the vital tasks of deburring, edge radiusing, polishing, and surface smoothing. Shot blasting, by contrast, enhances surface properties by removing contaminants, preparing parts for coating, or introducing controlled compressive stresses that dramatically improve fatigue resistance.

Both technologies, when applied correctly, increase a component’s lifespan, improve aerodynamic efficiency, reduce friction and wear, and ensure robust performance even under the harshest operational conditions. In short, they build confidence into every part that leaves the production line.

In aerospace, surface quality isn't just about appearances — it's a functional requirement. A single imperfection, a microscopic burr, or an inconsistent surface texture can lead to stress risers, premature cracking, or compromised coating adhesion.

Consider turbine blades, which endure immense thermal and mechanical stresses. Their surfaces must be smooth to optimise airflow yet tough enough to resist erosion. Or think about structural fasteners. A sharp edge or scratch could act as a nucleation point for fatigue failure under cyclic loading.

Mass finishing, through controlled mechanical abrasion, ensures uniform surface quality across complex geometries — critical when the margin between safe operation and catastrophic failure is measured in thousandths of a millimetre. Shot blasting, meanwhile, not only cleans surfaces but also strengthens them, creating a compressive layer that helps prevent microcracks from propagating. This synergy between form and function is where mass finishing and shot blasting truly shine. They don't just prepare parts, they prepare parts for the excesses of end-use functionality.

At Rösler, we understand that aerospace finishing demands more than just technology — it demands precision, repeatability, and validation. Every aerospace project we take on is underpinned by a commitment to process control and traceability that mirrors our customers' own stringent quality management systems.

We work closely with aerospace manufacturers to design bespoke finishing solutions, often beginning with detailed surface analysis, sample processing, and process validation trials. Our finishing technologies are fully documented, auditable, and capable of achieving consistent results from the first part to the ten-thousandth.

Moreover, with our expansive portfolio of mass finishing and shot blasting technologies, we are uniquely equipped to match the right process to the right material and application — be it titanium, Inconel, aluminium alloys, or carbon composites.

From drag finishing of critical rotating parts to specialised shot peening of load-bearing structures, our approach ensures that aerospace components are optimally finished.

The aerospace industry is evolving rapidly. Lightweight materials, additive manufacturing (AM), and new propulsion concepts are redefining what is possible — and each new innovation introduces new finishing challenges.