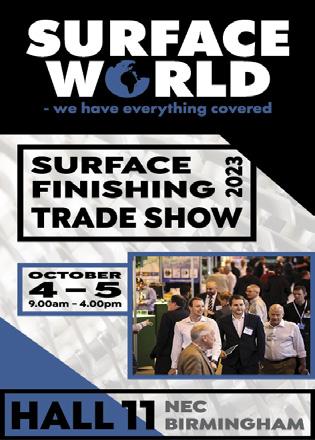

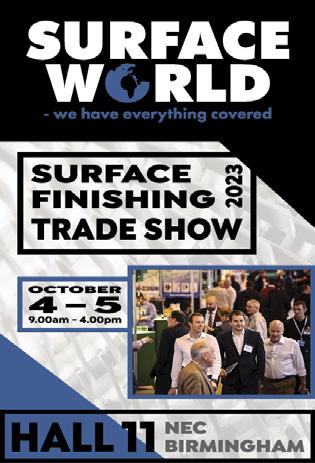

... we have everything covered SEPTEMBER 2023 REGISTER TO VISIT SURFACE WORLD 2023 4th & 5th October 2023 HALL 11, NEC, BIRMINGHAM read online @ www.surfaceworld.com – follow us on twitter @surfaceworldmag – visit www.surfaceworld.com

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826

e: nigelbean1@aol.com nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

Sheena Burrus e: sheenaburrus@hillmedia.com

EXHIBITION ORGANISER

Sheena Burrus e: sheenaburrus@hillmedia.com

Hill Media Ltd, Marash House

2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd. Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents.

© Hill Media Ltd – 2023 ISSN 1757-367X

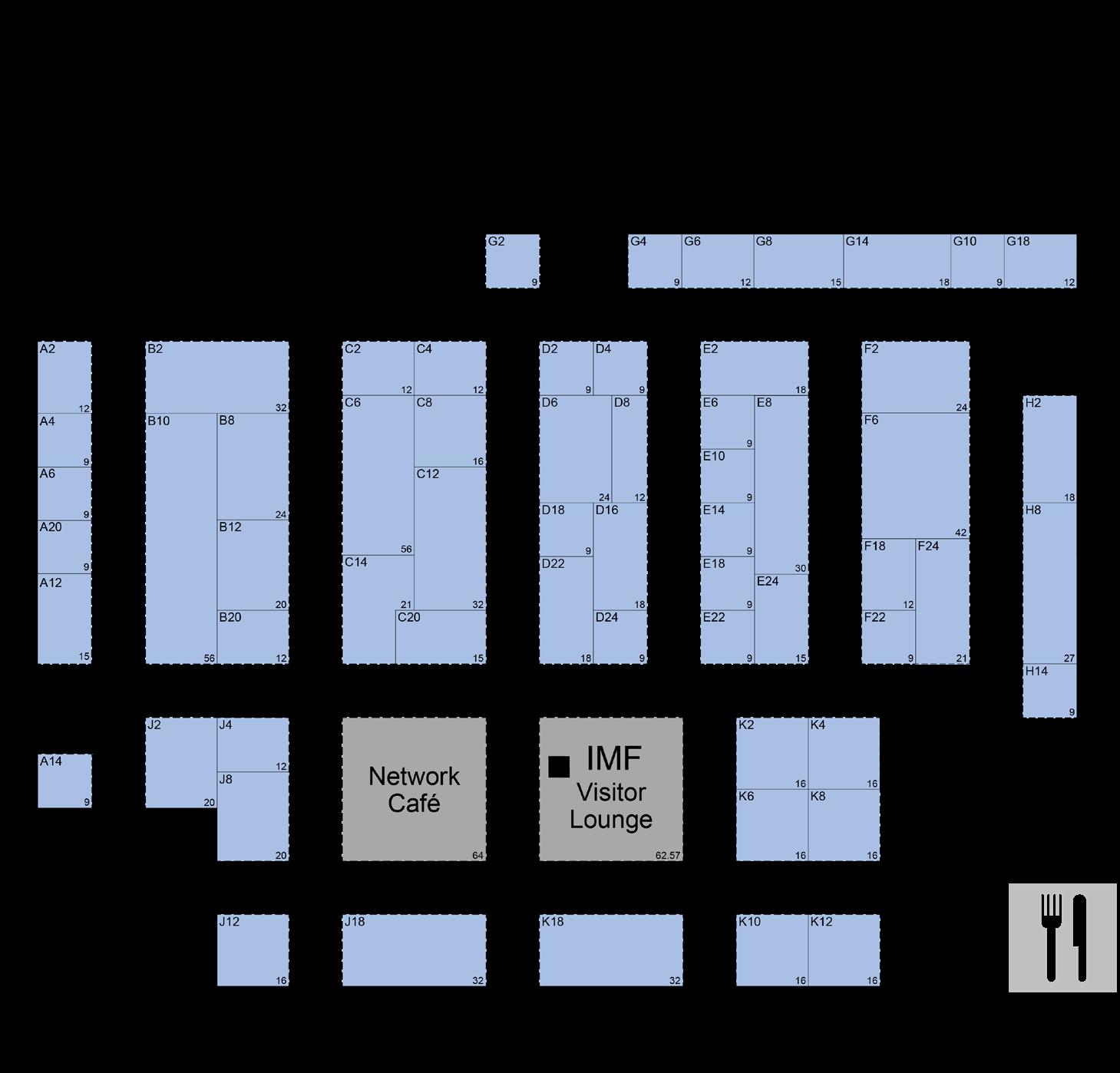

1 SEPTEMBER 2023 IMF: INSTITUTE OF MATERIALS FINISHING Industry Recognised Training Courses from the IMF. 6 QUALICOAT UK & IRELAND QUALICOAT Exhibits at Zak London. 8 CORRODERE ACADEMY Corrodere Academy introduces a new Powder Coatings course to the Train the Painter programme. 12 INDUSTRY NEWS Guide for Reliable Gloss Data. 18 Electron celebrate their 25th Anniversary. 24 Revolutionising Quality Control: DeFelsko’s Free PosiSoft Software Solutions. 30 General purpose industrial solvent cleanerssafe for users and the environment. 34 Help prevent workplace pollution…. 36 Are you a 3m® user looking to find a suitable alternative solvent? Don’t switch, improve! 38 Patented masks for wheel coating industry. 40 Dalby Evolution Spray Booths. 44 SurfacePrep – We Deliver Results Beyond The Surface. 46 Offering Intelligent Cleaning Solutions for Demanding Applications. 48 Cleaning Fluids that comply with Medical Device Regulations. 50 MecWash MWX300 drives efficiency and sustainability for APT Leicester. 52 Innovations in greener manufacturing and technology. 56 Painting a complete picture of your coating process!. 58 Again, Plastratum provides the latest automatic surface finishing technology equipment for Metal Finishing and Aerospace Applications. 62 AMS in Cork - Twenty Years Chromate Free. 66 Sherwin-Williams General Industrial Coatings. 68 Maximise the potential of your pre-treatment system. 70 25% ENERGY SAVING. 72 Unitech Machinery… Bringing your project to life. 74 Future-Proofing the Galvanizing Industry. 76 Your One Stop Shop For A Wide Range Of Filtration Solutions And Filter Supplies. 78 SURFACE WORLD 2023 The Unparalleled Benefits of Attending Surface World. 82 Plan your visit to Surface World 2023. 84 Exhibitor List & Floor Plan. 86 A - Z EXHIBITOR LISTING Show guide listings for all exhibitors attending Surface World. 88 MATERIAL & EQUIPMENT SUPPLIERS 110

SEPTEMBER 2023 VOLUME 30 NUMBER 9 Specify

qualicoatuki.org Visit us on stand A20 at Surface World Live

QUALICOAT for all your architectural aluminium powder coating requirements

We supply self-adhesive film for bespoke industrial grade cad-cut stencils.

Offering protection to a wide variety of substrates, these tough stencil films are used to mask off areas during the processes of painting, sandblasting and shotpeening. Our special adhesive coatings offer increased adhesion values to cope with this rigorous process while remaining completely residue free when removing them after use.

• Stencil films for wide variety of sectors including, Automotive, Aviation and Aerospace.

• Our industry experts are always happy to advice which film is right for the job in hand.

• All stencil film products are in stock for next-day delivery.

Paintmask Stencil Films

A selection of films with a thickness of 80 micron for paint masking protection on smooth and uneven surfaces.

Stencil Papers

PVC Free self-adhesive paper stencil films in two different tack levels.

Sandblast Stencil Films

A selection of films up to 600 micron thick for heavy duty sandblasting and shotpeen protection.

ShotPeen Stencil Films

With a higher level of adhesion, these films offer maximum protection against high pressure and pro-longed blasting and peening exposure.

www.dorotape.co.uk | Give your job a boost with a call to our experts 01858 431 642 sales@dorotape.co.uk

project

THE PER FECT FINISH for every

Plugin.Switchon. Dustandfumes? Allgone. Really,it’sthatsimple.

Ifwecouldsolveyourdustand fumeprobleminminutes...

• AirBench takesdustandfumes awayfromyourbreathingzone

• AirBench drawsthemthrough theworksurface,capturingthem insidethebench

• AirBench isavailableinawide rangeofsizesandfiltertypes tosuityourapplication

• AirBench isplugandgo-only needingunwrappingandplugging intoa13ampsocket

•Yougetextractionandwork benchinonecompactunit

...wouldyoubeinterested?

Doubtitcanbethatsimple?

Contactusforanon-sitedemonstration.

www. airbench.com • 01206 791191 • sales@airbench.com

Dustandfumes?

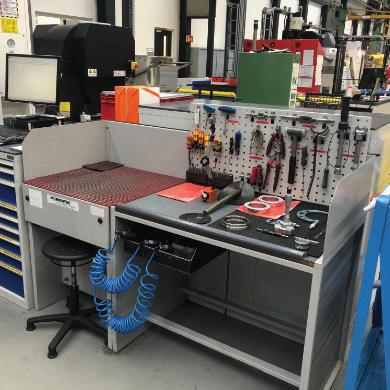

• Modular systemforfast installationandassembly.

• LowEnergy throughtheuse ofhighefficiencyfans-upto 20,000m3/hat3kw.

• FiltrationOptions fromthe standardAirBenchrange.

• WeldingandGrinding boothsalso availablewithHEPAfinalfilter.

• RapidReconfiguration -standard componentsmeanVertExbooths canbereconfiguredondemand.

www.ai rbench.com • T . 01206 791191 • E . sales@airbench.com ContactustoviewVertExinoperation.

Doubtitcanbethatsimple? TheVertExmodularbooth system.Dustissuessolved... Plugin.Switchon.

Allgone. Really,it’sthatsimple.

SUPERIOR TECHNOLOGY Significant Savings

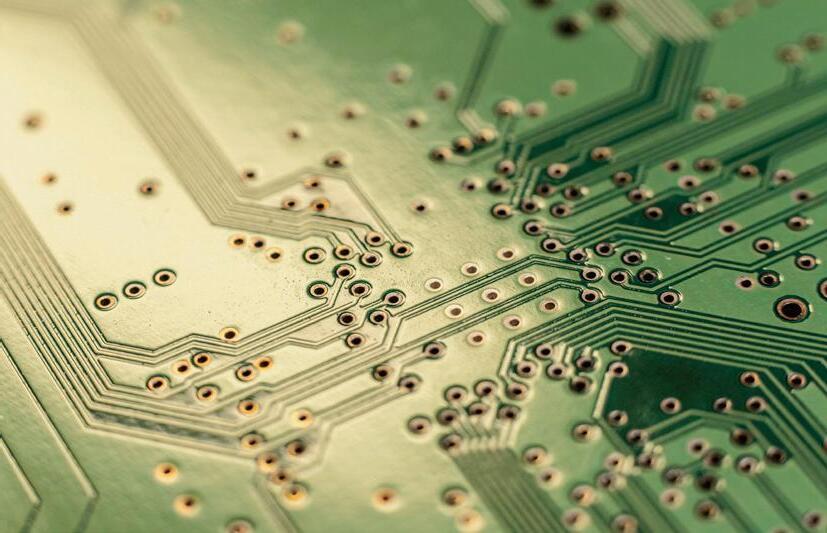

Nordson HDLV ® Dense-Phase Technology

Enhance productivity and maximize your product quality with Nordson powder coating equipment and HDLV technology. Our Encore® HD powder spray systems deliver superior efficiency and coating uniformity. Tight control of the coating process yields significant powder savings. Proven long-lasting performance maximizes up-time and productivity.

Get in contact with us today for more information ~ and look for us in Stand B8 at Surface World in Birmingham, 4 - 5 October!

www.nordson.com/hdlv | ics.eu@nordson.com

Become an Acknowledged Leader in Surface Engineering and Materials Finishing: Industry Recognised Training Courses from the IMF

Are you involved with the application of coatings to enhance and protect your products? Do you need to meet client specifications to ensure the longevity of your components? Does the complex world of surface engineering and materials finishing cause you headaches?

If so, the courses offered by the Institute of Materials Finishing (IMF) could be your solution!

The IMF have been promoting knowledge in the surface finishing industries, both inorganic surface treatments including plating and the application of organic paints, lacquers and varnishes for many years. Large numbers of engineers and technicians across a multitude of industries have benefitted from the knowledge gained to enhance their careers, their standing within industry and the ability to

problem solve the many challenges they face in their daily working lives!

Starting with the Foundation level course, students gain knowledge on all aspects of materials finishing, specifically aimed at their own industry requirements, but to include sections on Health & Safety, the Environment and Surface Finishing and Corrosion Protection. There is no need for a

science background to be able to successfully complete a foundation course.

The Foundation Course requires study of 15 sections and requires the submission of 2 marked assignments followed by an end examination. The course, conducted by distance learning will take 16 weeks to complete. There are three specific study routes to choose from; electroplating, organic coatings and aerospace finishing. On successful completion, the student is awarded the Foundation Certificate. To follow on, students can then elect to progress to the Technician level modules, which give more in-depth knowledge for key finishing technologies, their application and best practice methods. Again, both inorganic and organic technologies can be studied to match the industry requirements. There is a choice of eight modules, which provide study in applicable areas of surface finishing best matched to your needs.

Like the Foundation course, study is by distance learning, and the student is required to complete four marked assignments and pass an examination. Passing two technician modules leads to the award of Technician Certificate; passing four modules leads to the award of an Advanced Technician Certificate.

If you feel your career could benefit from being a recognised specialist in your particular branch of Surface Engineering or Materials Finishing, then contact the IMF today. Speak with our training manager Karen Yates on +44 (0)121 622 7287 or e-mail at karen@materialsfinishing.org.

Move your career to the next level and join the finishing community and all the benefits that gives through the IMF.

6 SEPTEMBER 2023 IMF: INSTITUTE OF MATERIALS FINISHING

QUALICOAT UK & IRELAND

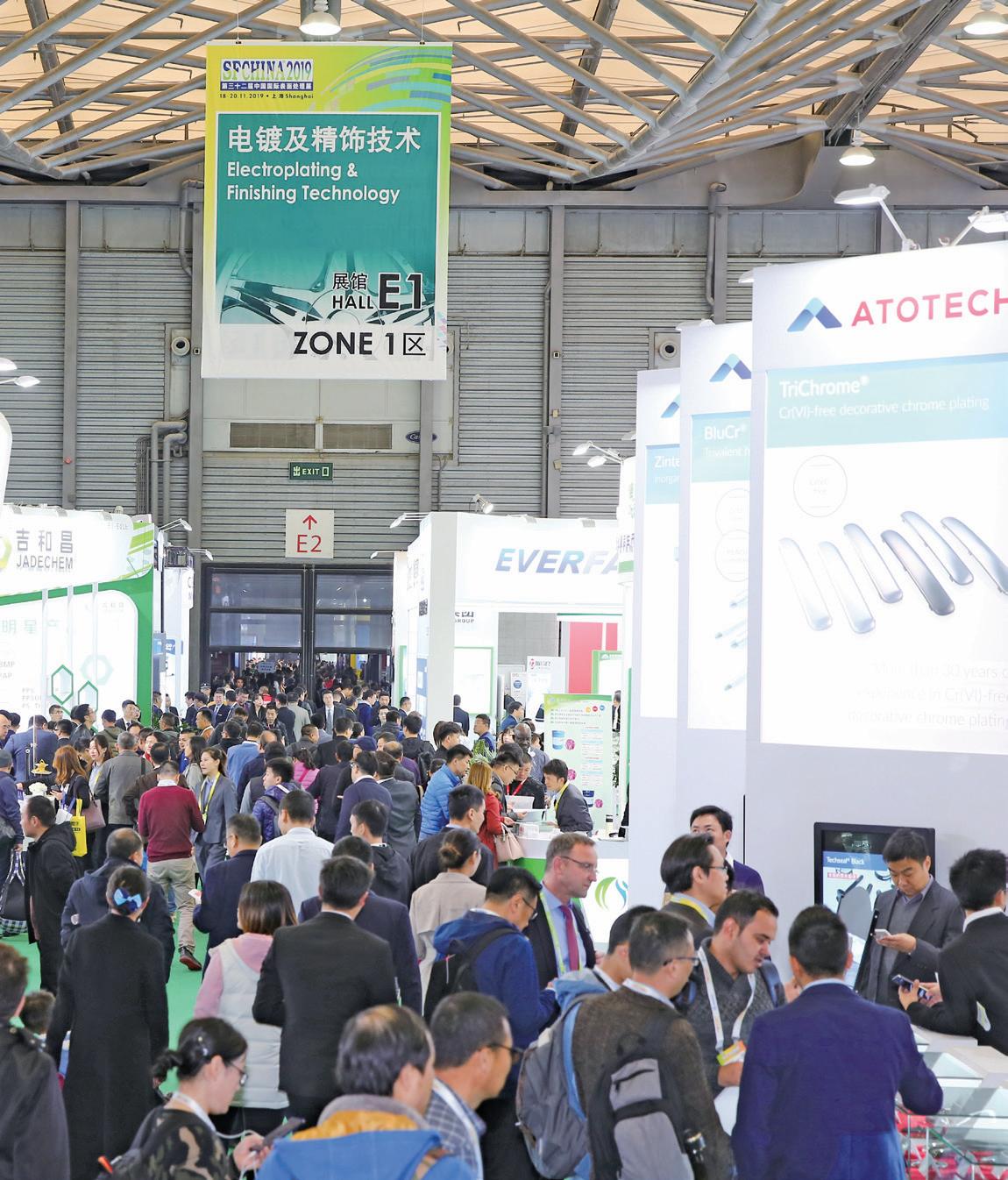

QUALICOAT Exhibits at Zak London

By Angus Mackie - QUALICOAT Chair

Over the last decade the QUALICOAT Specification for architectural powder coating has become a well established Specification across the UK and Ireland. The Association’s UK membership has now grown to 25 major UK & Ireland powder coat applicators, all of whom carry licences for the supply of QUALICOAT approved finishes. While the Specification continues to grow with more specifiers using it, education is key to ensure the continued reduction in powder coat failures.

To answer questions of the major facade specifiers in the UK, QUALICOAT has decided to support one of ZAK’s biggest global events held in London in November. Zak World of Facades is an international conference series specialising in facade design and engineering. Zak has already hosted over

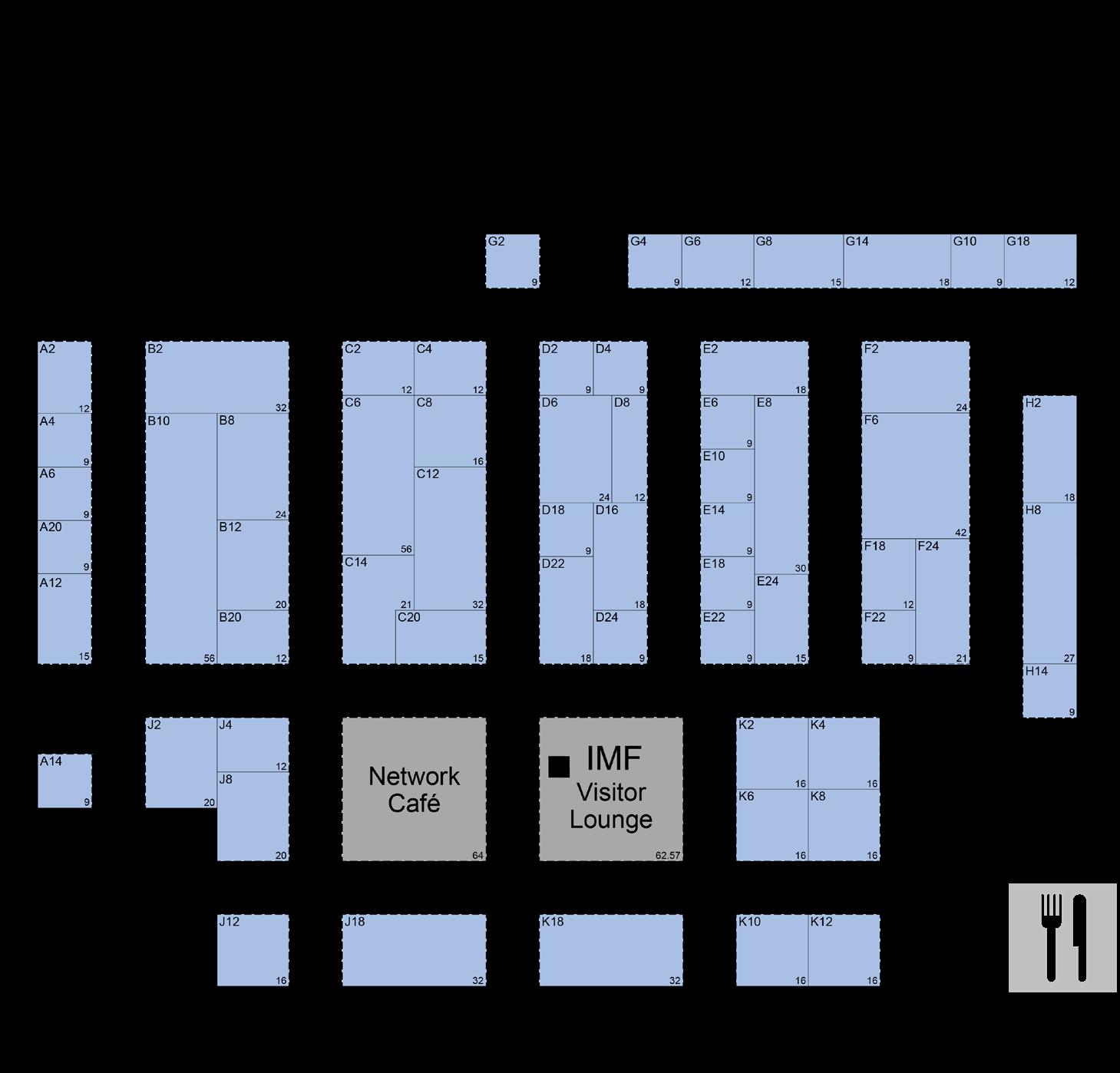

30,000 delegates across its 129 completed conferences with these one-day conferences held in over 35 countries around the globe. The events offer a unique opportunity to enhance knowledge and skills on key subjects pertaining to building envelope design, engineering, fabrication and installation from

industry experts across the complete value chain of the facade industry. Unlike many standards, a QUALICOAT Specification comes with third party accreditation. All Members of QUALICOAT, which includes powder coaters, pretreatment suppliers and powder manufacturers agree to allow an independent test house, nominated by QUALICOAT, to undertake unannounced inspections of their plant and processes. The intention of these inspections is to ensure that the current Specification is being followed by demonstrating compliance, the Member is then licensed to supply QUALICOAT approved products and coatings. Members who fail to demonstrate full compliance are reinspected and can lose their licence as a result of further non-compliance being reported.

8 SEPTEMBER 2023

One of the most recent developments within the Association is the launch of QUALICOAT 3.0. Part of a licence holders responsibility is the provision of regular coated samples for extended ‘acetic salt spray’ and in some cases ‘filiform corrosion’ testing at the appointed test house, in the case of QUALICOAT UK & Ireland, this is at IFO Netherlands BV. In a very small number of these test samples it was noticed that premature failure could occur following these very corrosive and accelerated tests. With the cause of the issue unknown, QUALICOAT set up a Working Group of Members to try to identify what was causing the issue and how this could be eliminated to further enhance powder coating durability.

It became obvious during research that the aluminium alloy itself was the contributing factor, so the Working Group began to develop a specification for the alloys used in fenestration, namely alloy 6060 and 6063. The resulting alloy specification, which now forms Appendix A13 of the QUALICOAT Specifications 2023, requires the alloys to fall within the EN573-3:2019 Standard, which can be met using primary or secondary (recycled) aluminium and requires the following three tests to be carried out, Optical Emission Spectroscopy (OES), Anodic Cyclic Polarisation (ACP) and Metallographic Study for Aluminium.

Whilst QUALICOAT 3.0 is a new Specification and is currently used on large facade projects, there are advances in other areas, such as pretreatment. Most members now use robust chrome free pretreatment systems but options also exist for anodic pretreatment of aluminium. Whilst putting your project into the hands of a QUALICOAT licence holder will ensure the correct questions are asked, learning the basics and knowing who to approach when specifying can help the design process. The team look forward to discussing powder coating in detail with conference delegates on 8th November at the Hilton Park Lane, London.

The current QUALICOAT Specification is freely available for download via the Association website, qualicoatuki.org and offers an up-to-date list of licensed UK and Ireland Powder Suppliers, Pretreatment Suppliers and Applicators. Telephone support is available from QUALICOAT UK & Ireland Head Office in Birmingham on 0330 236 2800, the Association can also be followed on Twitter @Qualicoatuki or on LinkedIn www.linkedin.com/company/ qualicoat-uk-&-ireland.

SEPTEMBER 2023 PASSION FOR MASKING SOLUTIONS www.global-mask.com WHEELS CUSTOM STANDARD

ECONOMICAL COATING. FLEXIBLE APPLICATIONS. GM 5000 & GA 5000 Manual & automatic electrostatic guns • High transfer efficiency with wrap-around effect • Suitable for water-based & solvent-based paint • Excellent finishing results wagner-group.com Contact Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone: 01327 368410 enquiries@wagner-group.com

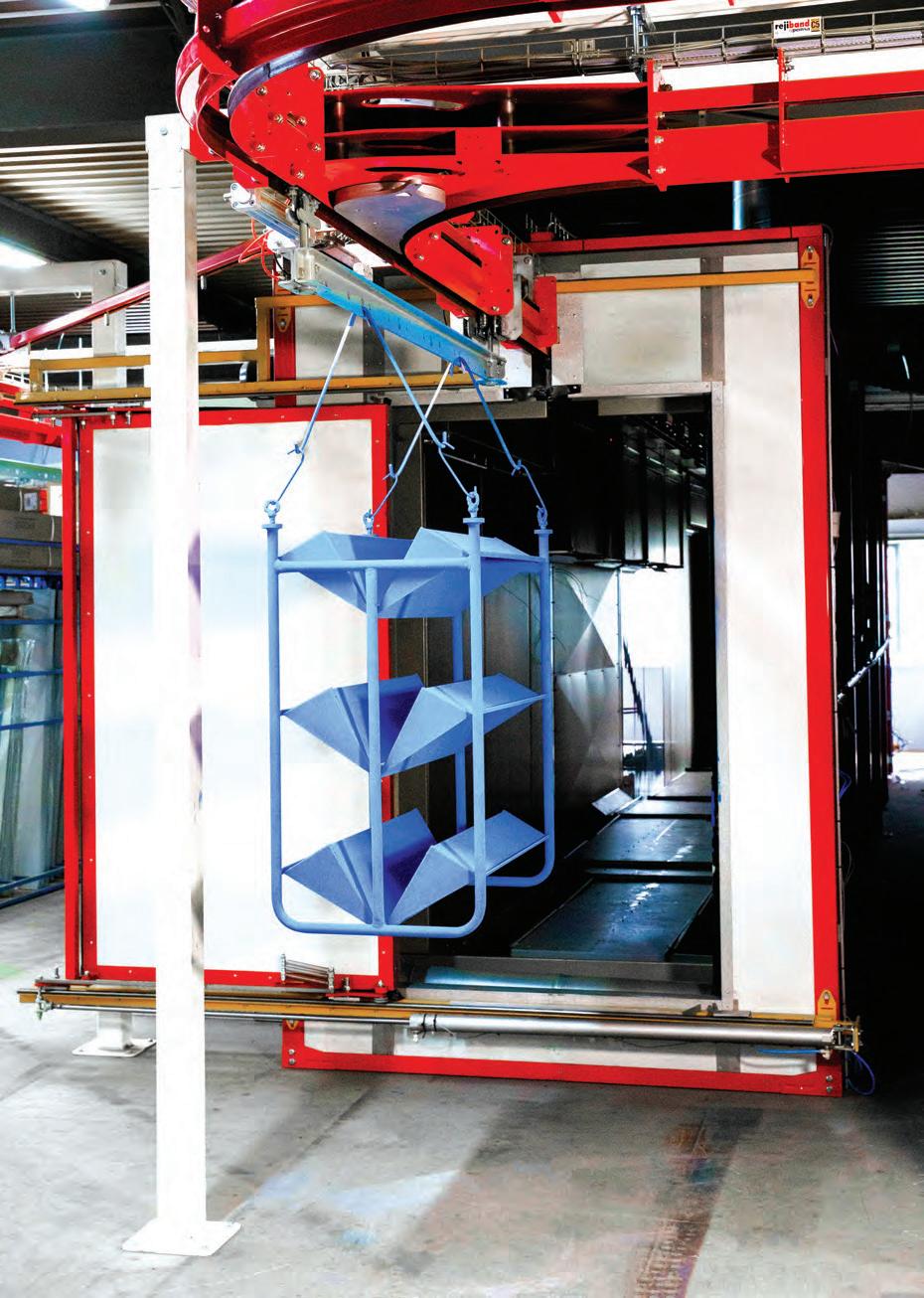

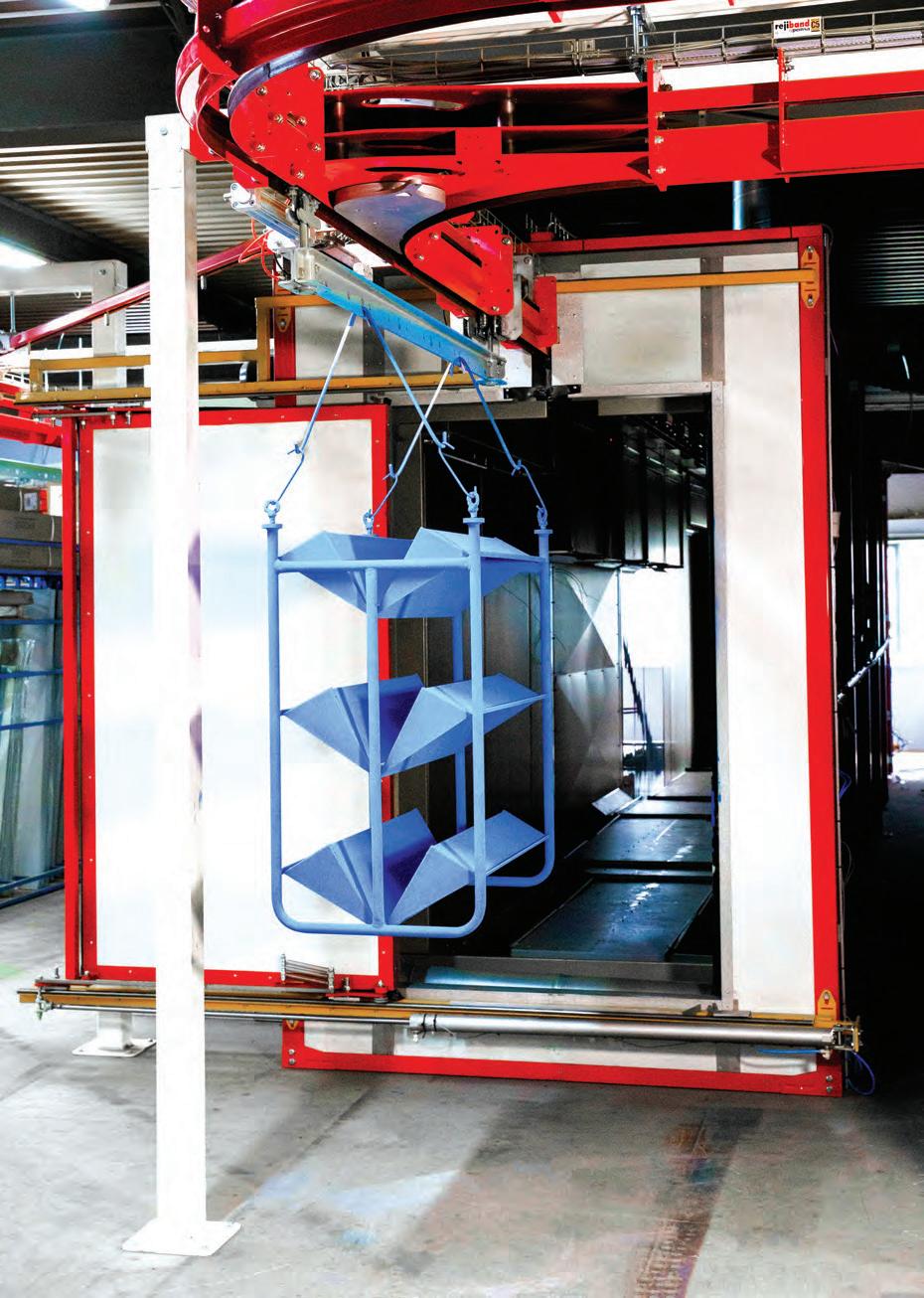

CALCULATE YOUR ENERGY SAVINGS

Energy costs are through the roof right now. A higher hanging density is often the most efficient way to both save energy and drastically lower the total coating cost. Find out how much you can save on your coating line at ccc.hangon.com

Coating Cost Calculation

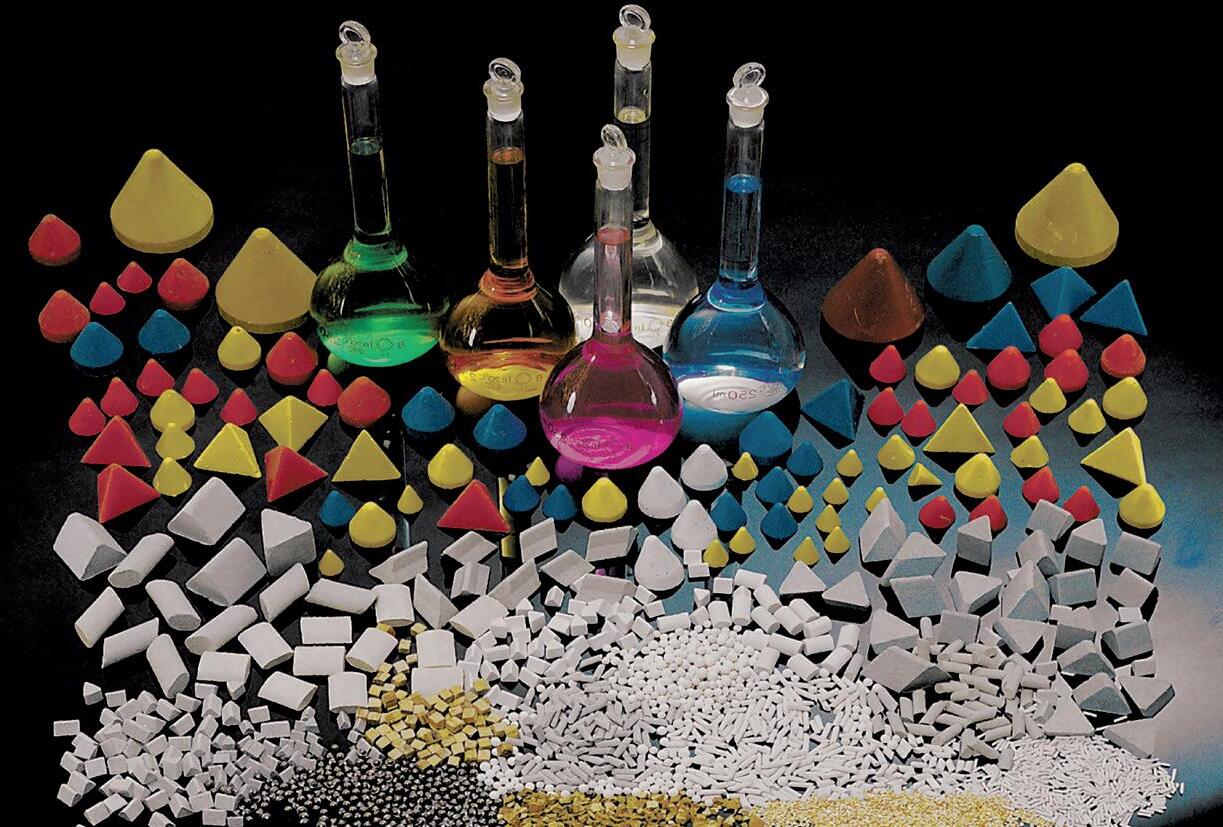

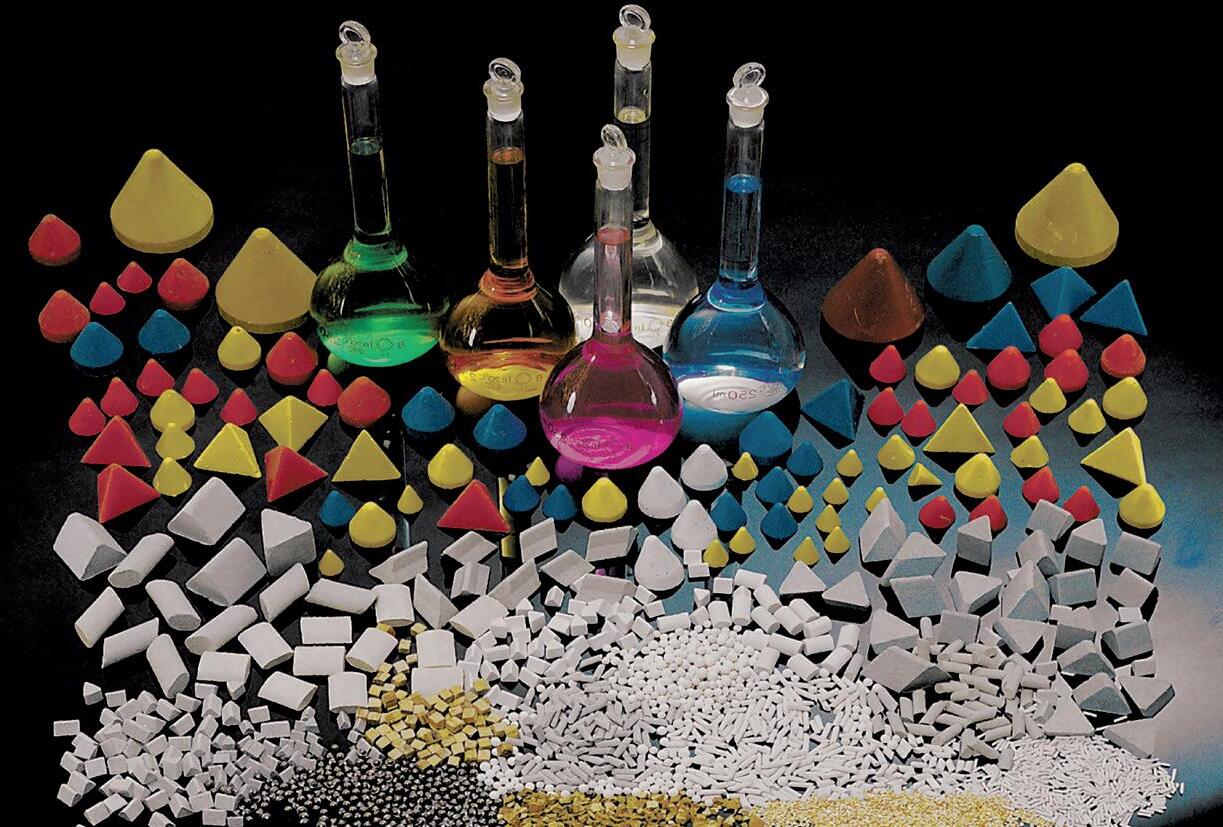

Corrodere Academy introduces a new Powder Coatings course to the Train the Painter programme

The coating industry is continually evolving, with advancements in technology and materials pushing the boundaries of what is possible. To ensure that professionals are equipped with the latest knowledge and best practices, continuous training and upskilling is essential. Recognising this, the Corrodere Academy is rolling out its latest offering: the Powder Coatings Course. This is part of the renowned Train the Painter programme, designed to raise industry standards across the globe

The Advantages of Powder Coatings

The powder coatings sector has seen tremendous growth and innovation in recent years. Powder coatings are used globally in numerous industries and the advantages include:

Environmental Friendliness: Unlike traditional liquid coatings, powder coatings emit zero or near-zero

volatile organic compounds (VOCs). This makes them environmentally friendly, contributing to reduced pollution and safer work environments.

Cost-Efficiency:

Over-spray from powder coatings can be retrieved, screened/cleaned and reused, resulting in nearly 100% usage of the product. This cuts down on waste, making the process more cost-effective.

Durability:

Powder coatings are known for their excellent resistance to corrosion, chipping, abrasions, and weathering. Their hard finish is tougher than conventional paints, ensuring longlasting protection and aesthetic appeal.

Thicker Coatings:

Unlike liquid coatings, it’s easy to apply thicker coats using powder without the risk of runs or sags. A consistent, even coating can be achieved.

Uniform Finish:

The electrostatic application process ensures that surfaces have a smooth and consistent finish without the appearance of brush strokes.

Wide Range of Finishes:

From high-gloss to matte, and textures from smooth to rough, powder coatings offer a broad spectrum of

12 SEPTEMBER 2023 CORRODERE ACADEMY

THICKNESSMeasure FAST REPEATABLE ACCURATE · DURABLE DRYFILM Halve your DFT inspection times using the Elcometer 456 Coating Thickness Gauge with Scan Probe. FAST & ACCURATE COATING INSPECTION elcometer.com Surface World - 456 July 23.indd 1 06/07/2023 15:05:38

finishing options, catering to various aesthetic and functional requirements. Quick Turnaround: Due to the nature of the application and curing process, products coated with powder coatings are ready for use or shipment more quickly than their liquid-coated counterparts.

The application of powder coatings can be an automated or manual electrostatic process. Articles can also be dipped in fluidised beds. Incorporating these advantages into your operations can offer businesses a competitive edge, not just in terms of product quality and longevity but also in eco-responsibility and cost savings. The move towards more sustainable and efficient solutions like powder coatings is not merely a trend but a forward-thinking approach to modern manufacturing and finishing processes.

What is the Power Coatings Course?

At its core, the Power Coatings Course is designed to provide in-depth knowledge and training in this field of advanced coatings. From the basics of surface preparation to the intricacies of application techniques, this course offers a comprehensive look into the world of powder coatings. Participants

will gain experience and become well-versed in the latest technologies, materials, and methodologies.

Training with the Best

Corrodere Academy’s reputation as a global leader in the corrosion and coatings training sector is wellestablished. Its Train the painter programme is globally recognised, ensuring that every graduate (student) is equipped with the skills and knowledge that meet international standards. The Powder Coatings Course is no exception. Crafted by industry experts, the theoretical course content ensures a well-rounded educational experience.

This Powder Coatings course is delivered through Train the painter Registered Companies

and Affiliate trainers. Whether you’re looking to upskill yourself, your team or offer external training, the Powder Coatings Course is the perfect platform for growth. To find a trainer near you or find out more about registering your company with Train the painter, so you can deliver training internally, contact Lucy Pavia at the Corrodere Academy.

Telephone: +44 (0) 1252 732 223

Email: lucy@corrodere.com

Visit: Corrodere.com

14 SEPTEMBER 2023

CORRODERE ACADEMY

“The Professionals” email info@pros trip.co.uk phone 01 1 5 91 1 2240 “Save up to 20% on your monthly s tripping cos ts” Send your enquir y today!! Sub contract specialists in Paint & Powder coat removal to the finishing industr y JIG CLEANING PAINT BOOTH GRID CLEANING COMPONENT RECLAMATION EST . 1989 Pro-Strip Ltd. Trent Lane, Daleside Road, Nottingham NG2 4DS web www.prostrip.co.uk

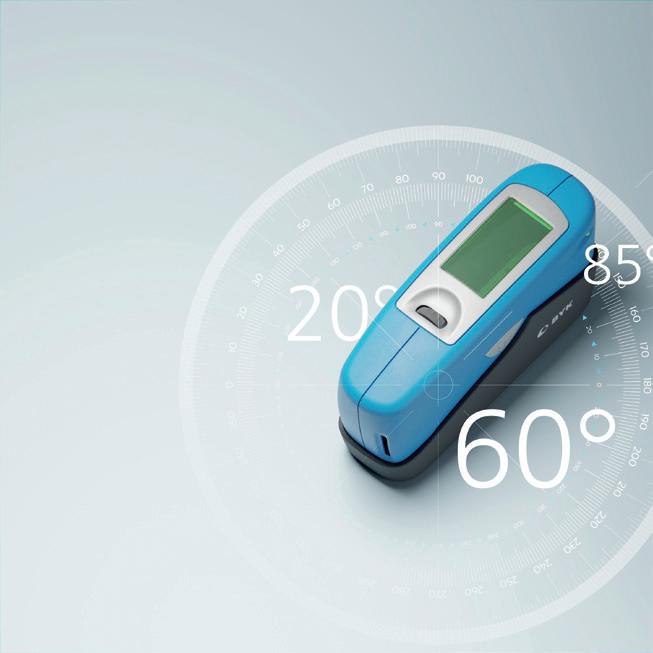

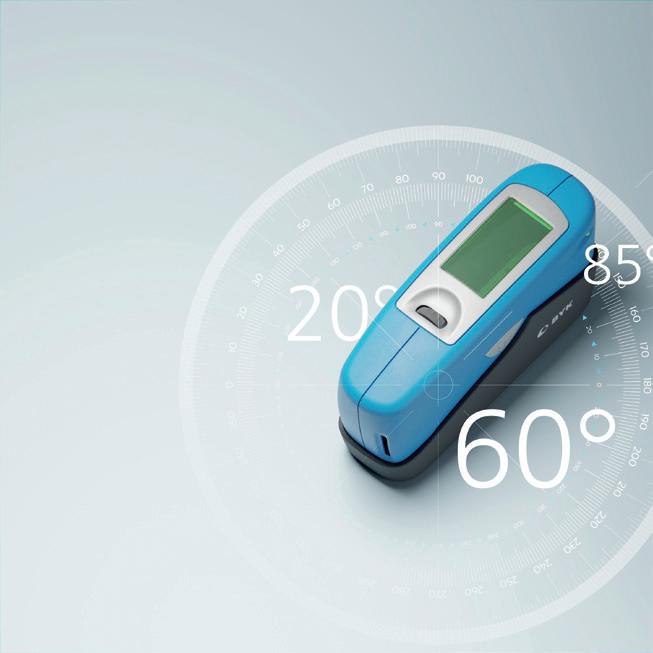

Guide for Reliable Gloss Data

Authors:

Gabi Kigle-Böckler, Vice President Marketing and Severin Wimmer, Produktmanager Appearance

Introduction

Uniform and consistent gloss are an essential quality criterion for a variety of products. Therefore, gloss needs to be objectively measured. Only what can be objectively measured, can be controlled and can be optimized which is of importance in product development as well as in production control. Especially in case of multi-component products a uniform gloss is an expression of “high quality”. Variations in gloss look like something is wrong and the end-user will perceive it as a defect. Therefore, gloss limits and tolerances are defined based on application and customer expectations.

The technical performance of the gloss meter used to objectively measure gloss is essential to obtain reliable data. Therefore, BYK-Gardner glossmeters are developed with focus on excellent technical performance under any circumstances.

Table of Contents

1 Technical performance: Essential for reliable data

1.1 Repeatable gloss data

1.2 Reproducible gloss data from glossmeter to glossmeter

1.3 Gloss measurement independent of temperature changes

2 A glossmeter needs “health check”

3 High gloss, semi gloss, matt - what geometry is best?

4 How many measurements should be taken or the importance of statistics

5 Gloss measurement digitalized

6 micro-TRI-gloss – The intelligence in gloss measurement

1 Technical performance: Essential for reliable data

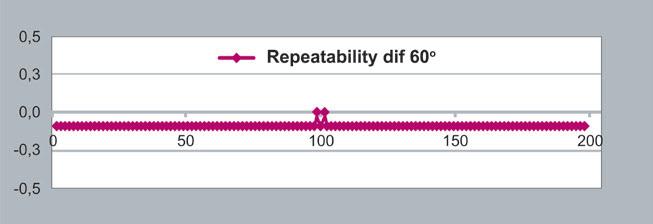

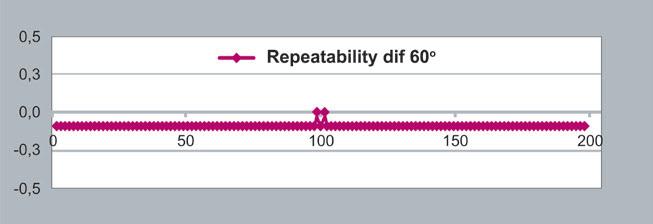

1.1 Repeatable gloss data

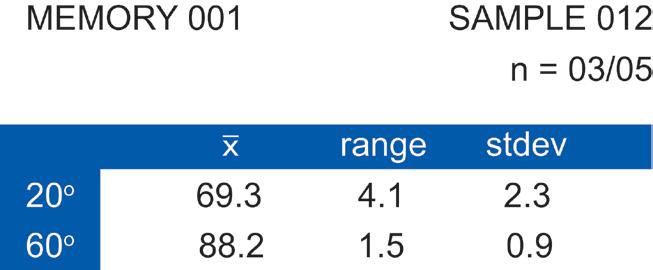

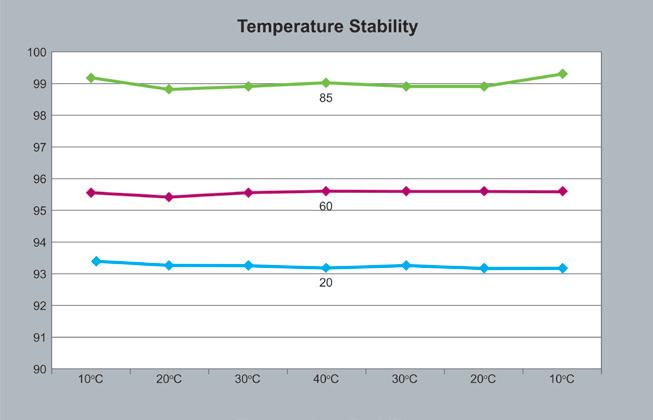

Goal is to meet the target value within a defined tolerance. Therefore, the glossmeter used should deliver repeatable measurement results i.e., excellent short- and long-term repeatability. (Fig. 1)

Fig. 1: Short- and long-term repeatable gloss data with BYK-Gardner micro-gloss: ±0.2 GU

Otherwise, you don’t know whether the gloss change is due to a glossmeter drift or a true product variation.

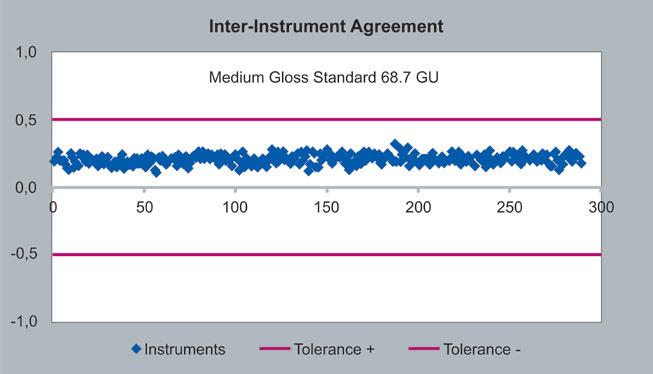

1.2 Reproducible gloss data from glossmeter to glossmeter

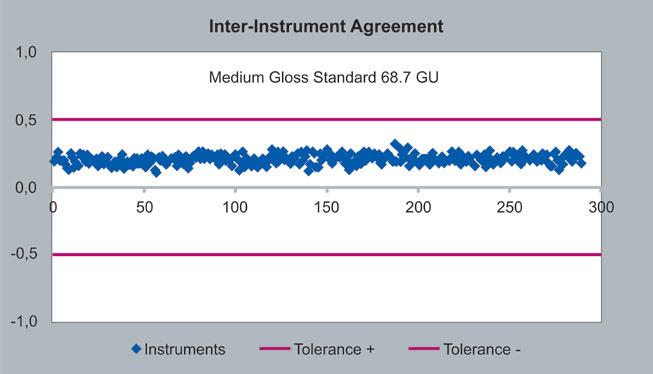

Reproducibility is as important as Repeatability as every production is part of a supply chain process. Gloss values need be communicated and exchanged within a supply chain. Gloss levels of various production facilities or several production lines need be consistent to achieve a uniform gloss within defined tolerances. (Fig. 2)

Fig. 2: Inter-instrument agreement of BYK-Gardner microgloss instruments: ±0.5 GU

Otherwise, a multi-component product will look like patchwork and the various component suppliers will always discuss who delivered the “part with the correct gloss level”.

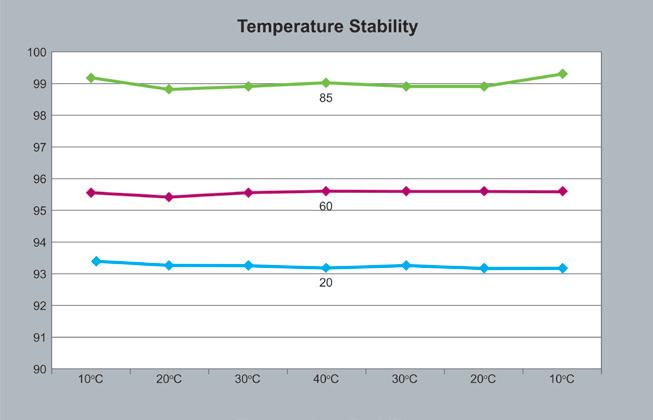

1.3 Gloss measurement independent of temperature changes

Depending on the season temperature in the production area can change. The temperature during day and night shift can be considerably different. The temperature in the lab might be controlled at 23°C, while in the production area the temperature is much higher due to baking ovens or other production machines.

Therefore, it is essential that the glossmeter used is not influenced by temperature changes and the gloss data is independent of the temperature. (Fig. 3)

18 SEPTEMBER 2023 BYK-GARDNER GMBH

Solutions for Parts & Paint Spray gun cleaning WASHERS ASK FOR A FREE QUOTE Manual | Automatic Our high quality, advanced range of equipment provides the best way to clean paint spray guns or industrial parts. With numerous options, you can be sure that there is a model in our extensive range that meets your cleaning requirements using either solvents or water. ATEX certified • High quality alloy pumps Stainless steel construction • Wash cycle controlled by timer • Wash & rinse • Hot water wash • Inbuilt water recycling • Inbuilt solvent recycling Air extraction • 2 year warranty BUY OR LEASE www.solutex.co.uk info@solutex.co.uk | 01691 622 225 For more information visit:

If gloss values are only stable within laboratory conditions, data cannot be compared. Temperature stability is as important as repeatability and reproducibility because you don’t know what the temperature conditions are at different production sites.

2 A glossmeter needs “health check”

Production environment is often rough and dusty which can affect the performance of your glossmeter as optics can accumulate dust on the lenses. Therefore, the “health status” of the used gloss meter is an important factor and needs to be checked. The BYK-Gardner micro-gloss instruments have an “auto-diagnosis” which checks the actual performance of the instrument and gives you instant feedback:

• Auto-diagnosis is OK

• Please clean standard

• Optics need cleaning Send in for service / recertification

The auto-diagnosis is your insurance for reliable measurement data.

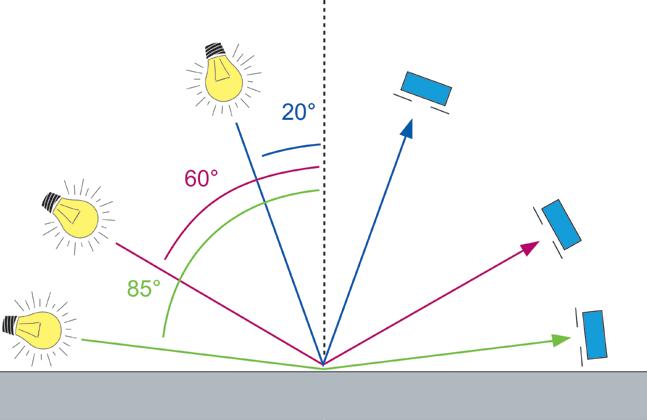

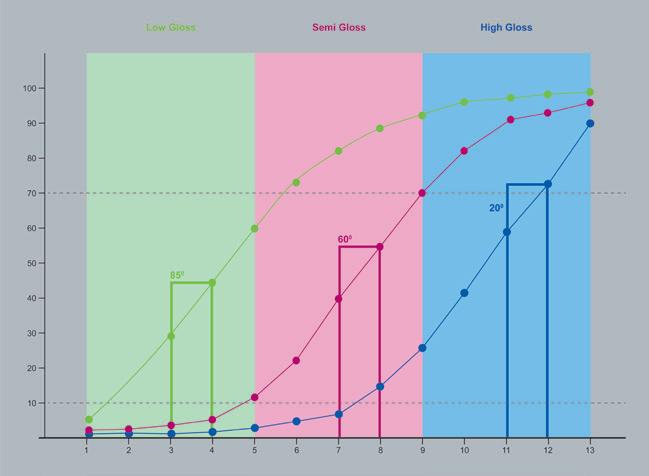

3 High gloss, semi gloss, matt - what geometry is best?

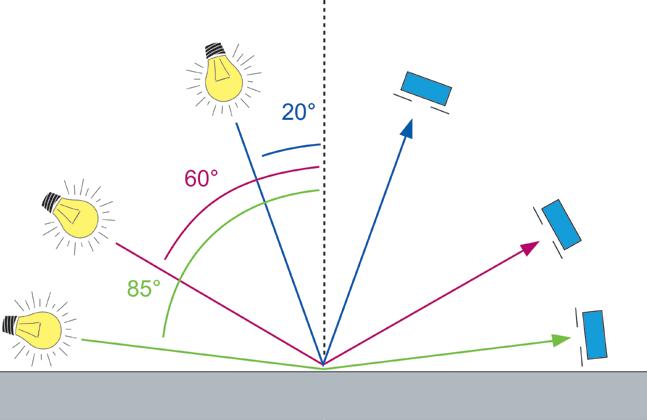

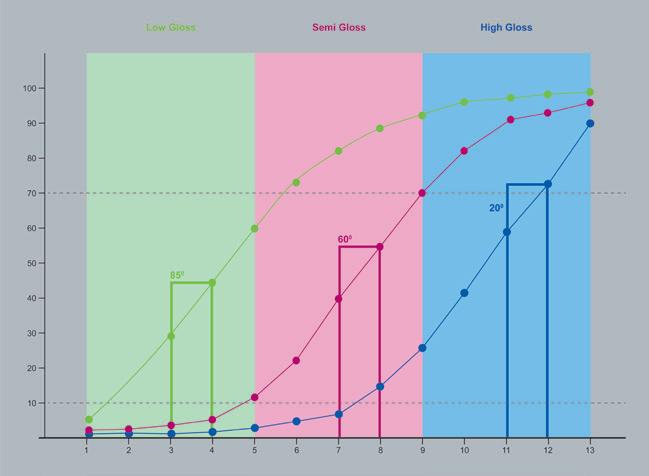

The answer is easy: micro-TRI-gloss. The universal glossmeter to measure high, medium and low gloss finishes accurately. Three different illumination angles (Fig. 4) are required to achieve good differentiation of the entire range from high to low gloss surfaces:

- 20° high-gloss surfaces - 60° semi-gloss surfaces - 85° low gloss surfaces

The 60° illumination is used as a general geometry for a wide range of applications with gloss values between 10 and 70 gloss units. If gloss data is higher than 70 GU or lower than 10 GU, this measurement geometry is no longer effective in showing differences as shown by the flat portion of the curve. Thus, the 60° geometry would show little or no difference in this range, while visually there is a clear difference. (Fig. 5)

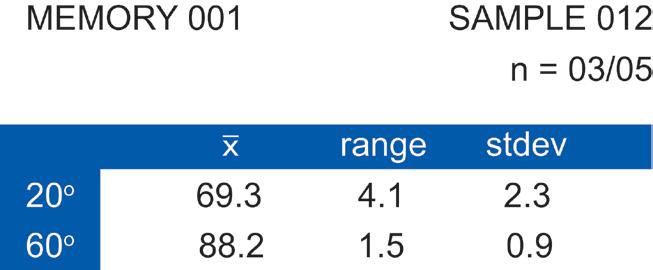

4 How many measurements should be taken or the importance of statistics

Here our answer is “ONE reading is like NO reading”.

In order to get a representative value of your product finish a minimum of 3 readings should be taken. And to evaluate the uniformity of your product’s surface finish the average with “std.dev. or range (min – max) should be recorded.

The micro-gloss instruments offer a statistic mode (Fig. 6) that can be defined by the user:

Fig.

micro-gloss display of statistic mode

A single reading does not give a true picture of the uniformity which is particularly important when evaluating larger surface areas.

20 SEPTEMBER 2023

Fig. 3: Temperature stability between 10°C – 40°C – 10°C

Fig. 4: Standardized geometric conditions

Fig. 5: Specular gloss values dependent on measuring angle

6:

BYK-GARDNER GMBH

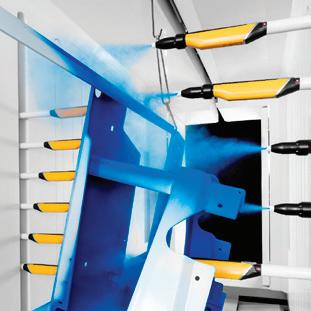

Scan & Spray

Dynamic Contour Detection

Programming-free coating of any shape!

The second generation of Dynamic Contour Detection detects the object contour fully automatic and positions the guns individually even for thin objects and at high conveyor speeds. Due to the programming-free adaption of all relevant line settings the application range is significantly extended.

Gema Europe Srl – UK Branch

0044

942

uk.sales@gema.eu.com gemapowdercoating.com

Tel:

1202 763

Email:

PosiTector ® Inspection

Unrivaled probe interchangeability for all of your inspection needs.

Coating Thickness Probes

n Ferrous n Non-Ferrous n Combination n Ultrasonic

Surface Profile Probes

n Depth Micrometer n Replica Tape Reader

Environmental Conditions Probes

n Integral n Cabled Magnetic Probe n Anemometer Probe

n 1/2” NPT n Infrared

Hardness Probes

n Shore n Barcol

Salt Contamination Probe

n Bresle Method

Ultrasonic Wall Thickness Probes

n Corrosion n Multiple Echo Thru-Paint n Precision

DesignandFeatures

Customized Inspection Kits... Build your own kit from a selection of gauge bodies and probes to suit your needs.

Coating Thickness Surface Profile

Conditions

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.

DFT Instruments UK LTD

DFT Instruments UK LTD

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN

01442 879494

01442 879595

Proud

supplier of DeFelsko Inspection Instruments

16A

t:

f:

www.dftinstruments.co.uk e:

sales@dftinstruments.co.uk

Ultrasonic

Environmental

Wall Thickness HardnessSalt Contamination

NEW

Proud

DeFelsko

16A

t:

f:

www.dftinstruments.co.uk e:

n Low Frequency n Xtreme NEW

supplier of

Inspection Instruments

01442 879494

01442 879595

sales@dftinstruments.co.uk

DesignandFeatures

5 Gloss measurement digitalized

Everyone is talking about digitalization. Why do you still write down gloss values or enter data manually in Excel?

The micro-gloss instruments come with the software smart-chart which allows you to transfer, save and analyze the data in easy-to-interpret trend charts. The saved data can be used for production monitoring with documentation in standardized reports as PDF-file or for transfer to other programs. Always ready for audits and optimization.

6 micro-TRI-gloss – The intelligence in gloss measurement

Repeatable +++ Reproducible +++ Temperature Stable +++ Auto-Diagnosis +++ Statistics +++ Gloss measurement digitized +++ High to low gloss finishes +++ UNSURPASSED

Visit

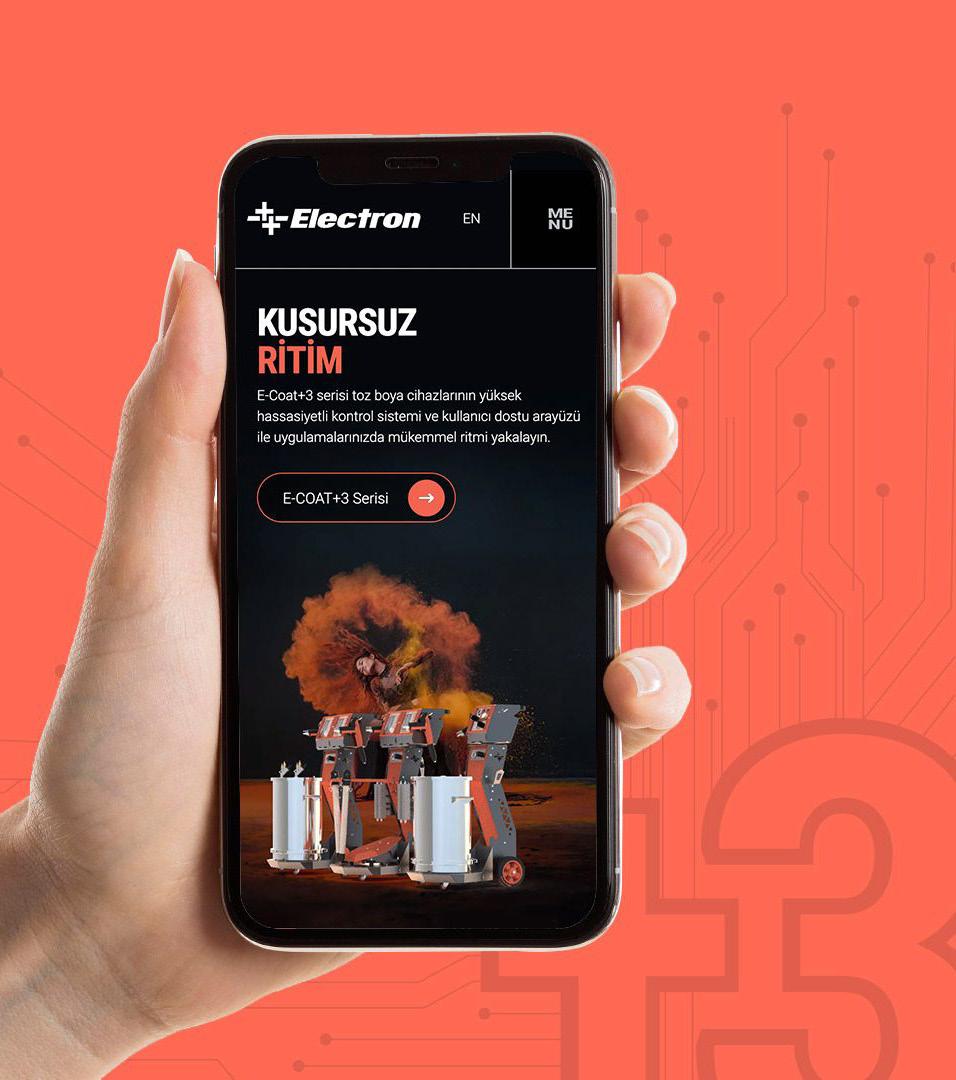

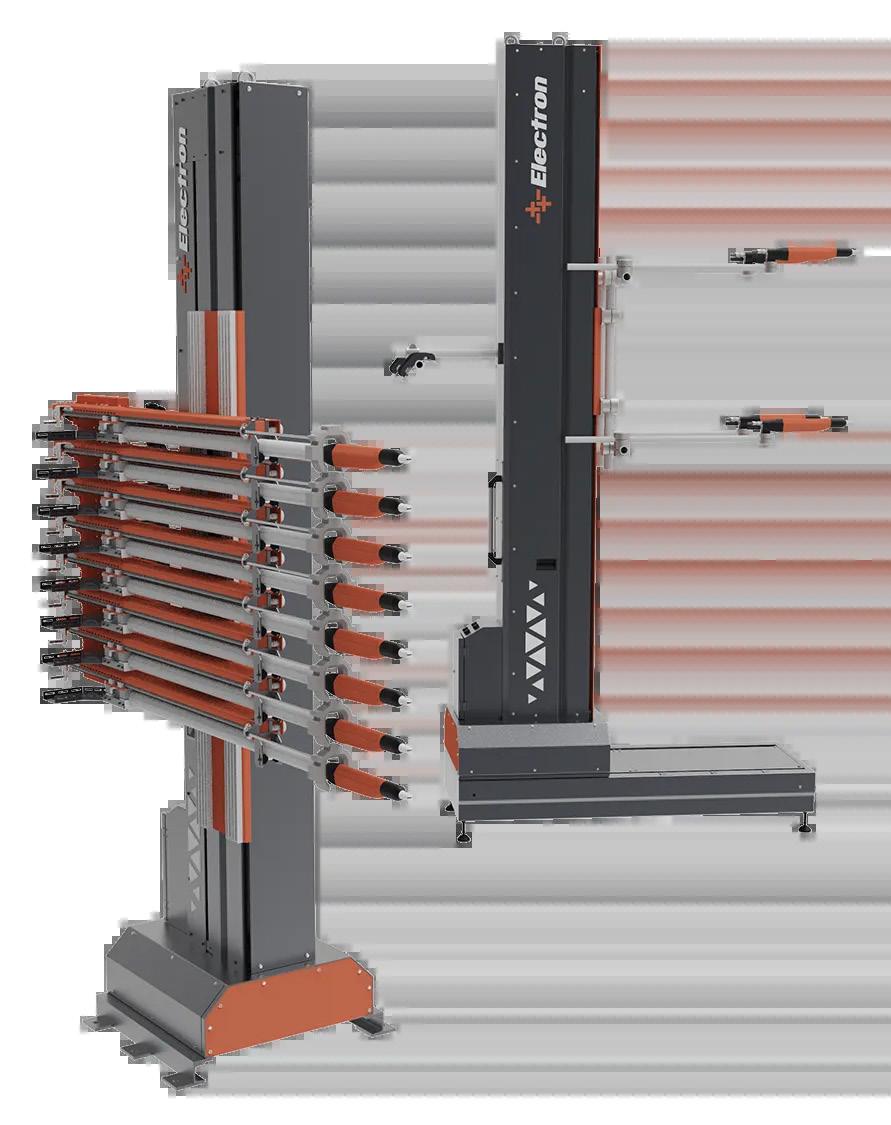

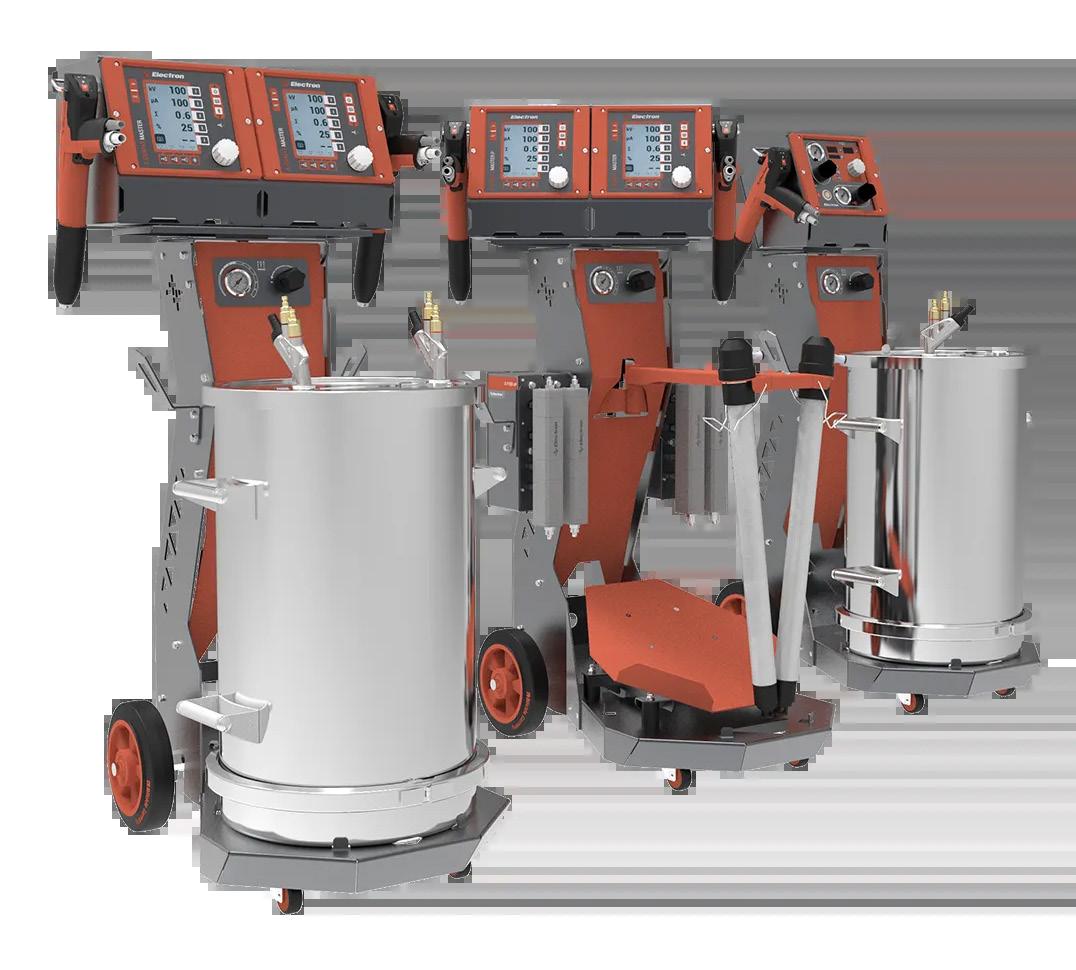

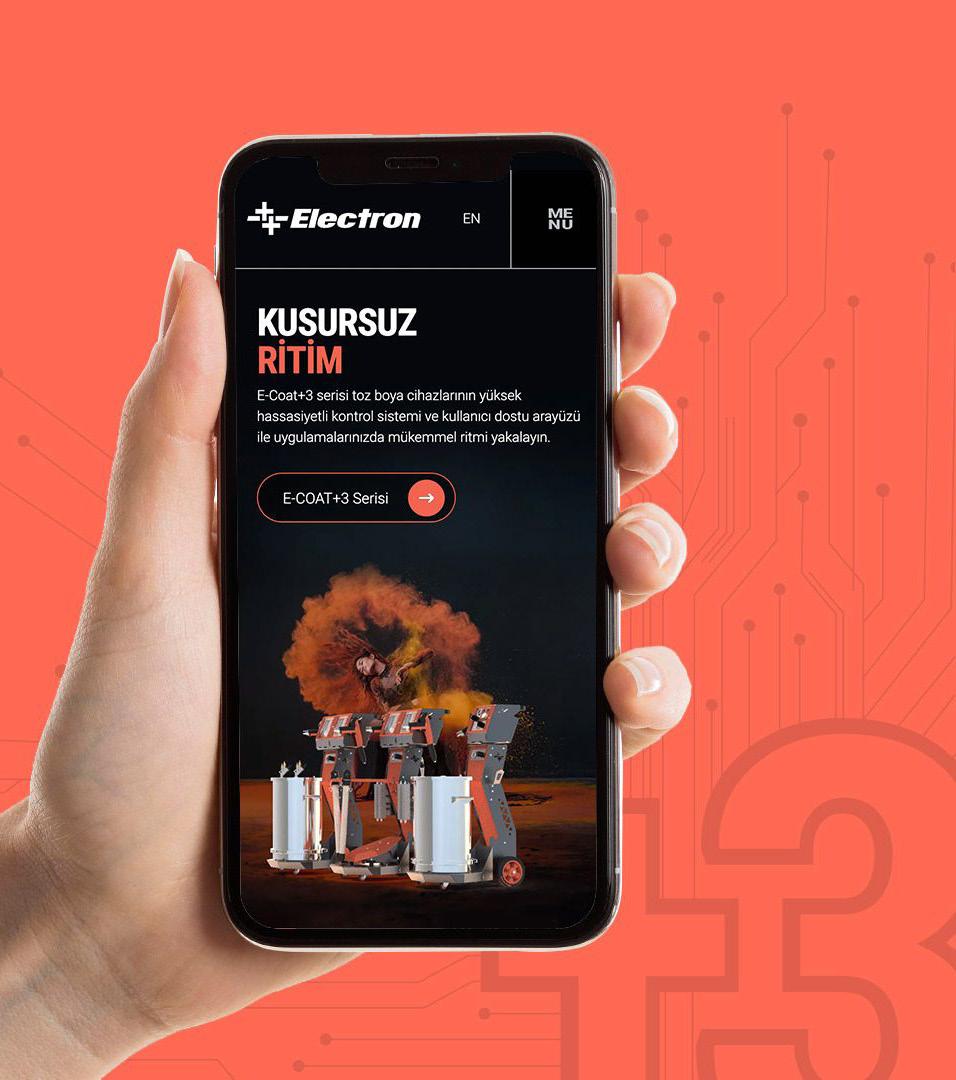

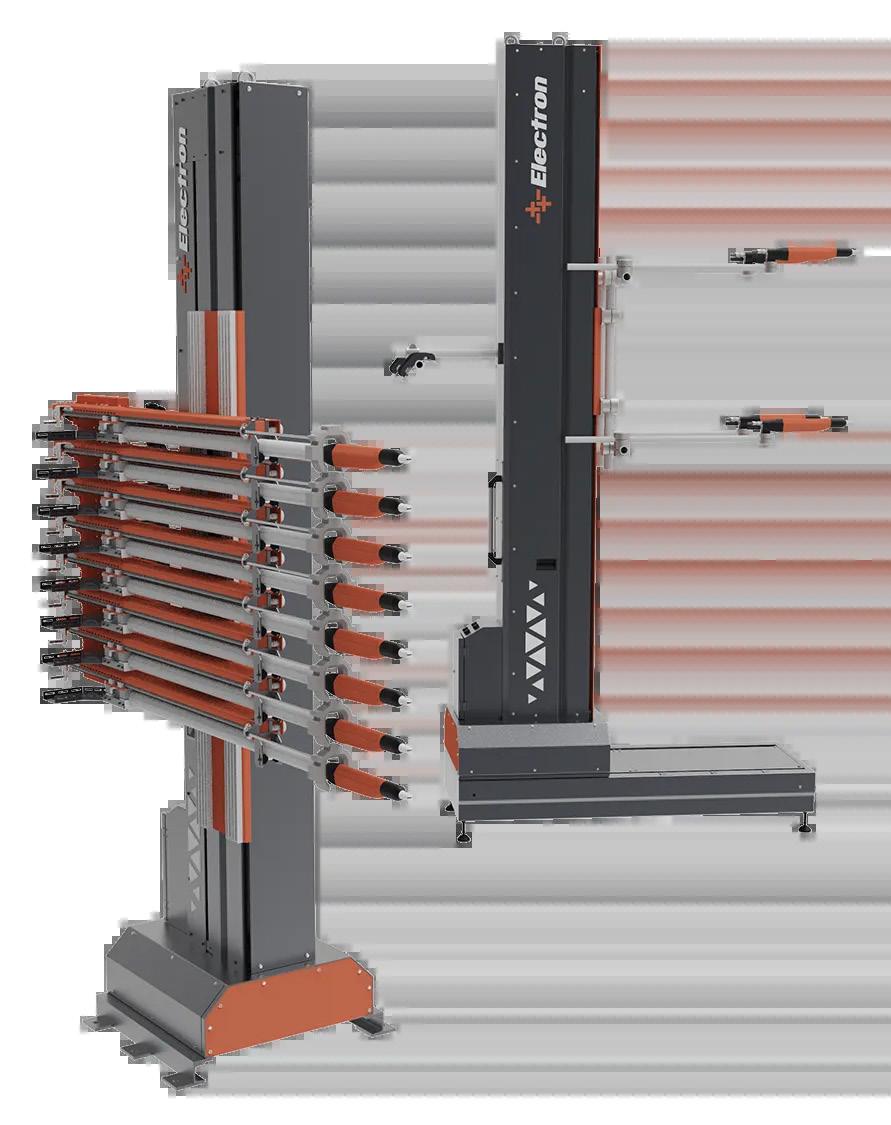

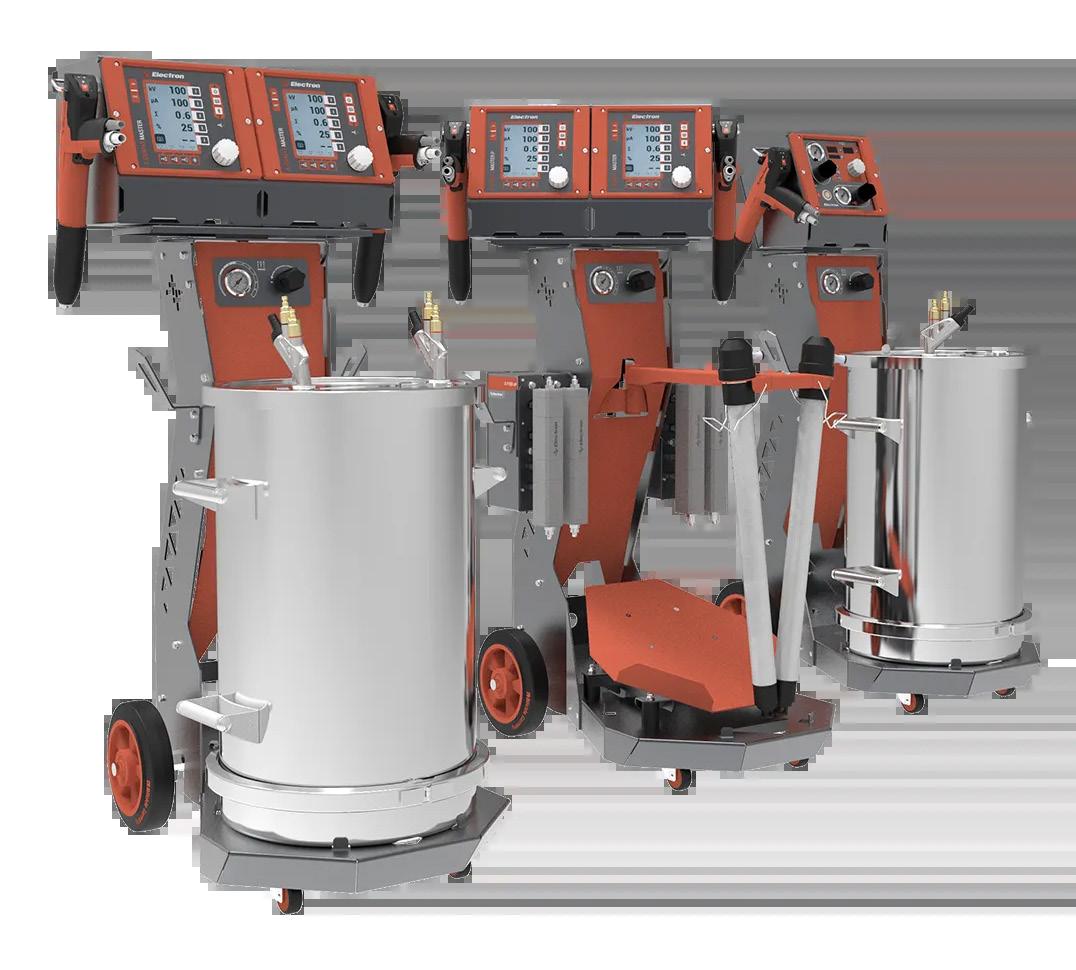

Electron celebrate their 25th Anniversary

This year, as Electron, we are back with our 3rd generation devices in a manner befitting our 25th anniversary. We aim to provide customers and followers with a better digital experience through our revamped website. Our 3rd generation devices, company policy, production philosophy, and our outlook on the future are now available on our new website. www.electron.com.tr

Our company is one of the leading companies in the sector specialised in the production of “Electrostatic Powder Coating Equipment and Complete Coating Systems” with more than a quarter century of knowledge and experience. Produced under the Electron brand with world quality standards, our products are widely accepted in Turkey thanks to our professional dealers and after-sales services, as well as production, assembly, spare parts and after-sales services in more than 50 countries in 5 continents all over the world.

24 SEPTEMBER 2023

byk-instruments.com for more information BYK-GARDNER GMBH

ELECTRON

Besides device production, we evaluate the needs and demands of our customers for project-based paint systems, offer the best solutions, add all the new technological developments in our sector to our applications and continue to develop without compromising on quality.

E-COAT+3 MASTER Series devices are upper segment devices where pneumatic and electrical parameters are digitally controlled from the front panel.

Its electrical controls give the opportunity to adjust the air values both independently and proportionally while remaining dependent on voltage and current. The factory settings, along with 50 different customisable electrical/pneumatic specifications, dual triggering options, PLC automation and bluetooth connectivity, make the E-COAT+3 MASTER the optimal solution for especially advanced manual and automated applications.

The sub-10 µA micro charge control option, as well as the 120kV-120µA maximum charge capacity and built-in LED lighting features create a unique coating experience for users. It can respond to different application needs with automatic, manual options and a wide range of accessories

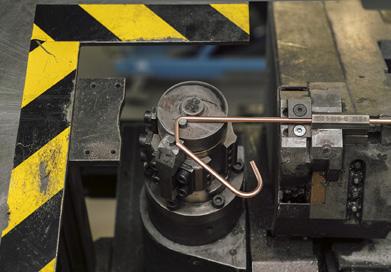

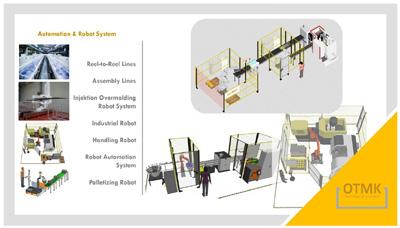

E-ROBOT+3 3D detects complex geometric shapes. The guns move according to the existing geometric shape and paint with precision. Energy and paint saving is achieved. Contour detection sensors subtract the distance from the product depending on the distance and carry the information to the guns. The pistols are activated in accordance with the geometry and the painting process is carried out.

Email: info@electron.com.tr

Visit: www.electron.com.tr

26 SEPTEMBER 2023

ELECTRON

Reverse Osmosis, Deionisation, EDI, UV. Industry Leading Equipment Standard and Bespoke Solutions Experienced Design Team Project Management Comprehensive Service Contracts Choose PuriteConsistent Quality, Robust Results. Purite: Pure Water for a Flawless Finish. 01844 217141 Bandet Way Thame UK www.purite.com

Detergents for Industrial Parts Cleaning Borer Chemie AG Gewerbestrasse 13 4528 Zuchwil / Switzerland www.borer.ch Bühler Ltd. Unit 8/9 Mercury Park, Mercury Way, M41 7LY Urmston, Manchester / United Kingdom Tel. +44 161 866 2800, Fax +44 161 866 2801 www.buhlergroup.com

Registered in England No. 1965748 Vat Reg No. 555-1648-32 Prices exclude VAT. See our web site for terms of business. +44 (0)1922 45 8000 www.rileysurfaceworld.co.uk Riley Industries Ltd, Middlemore Lane West, Aldridge, West Midlands, WS9 8BG, UK +44 (0) 1922 45 8000 sales@rileysurfaceworld.co.uk www.rileysurfaceworld.co.uk Brand New Machinery The marketplace for surface technology New and used process equipment & machinery In stock for your convenience ∙ Available immediately ∙ Refurbished or sold as seen ∙ Guarantees available Part Exchange your redundant surface treatment machinery Full catalogue and prices online at www.rileysurfaceworld.co.uk Direct From Site Used & Refurbished As used by... Call Steve on 01922 45 8000 With Your Requirements Today Curing / Industrial Ovens Shot Blasters Powder Booths Lab / Small Ovens Dust Extractors Component Cleaners From stock for immediate delivery or built to your specification ∙ Part Ex any surface treatment machine against new machinery ∙ Electroplating Lines Powder Coating Facilities ∙ Heat Treatment Equipment Factory Clearance Stock Factory to Clear? Turn your liabilities into assets and find buyers with Rileys Call Helen on 01922 45 8000

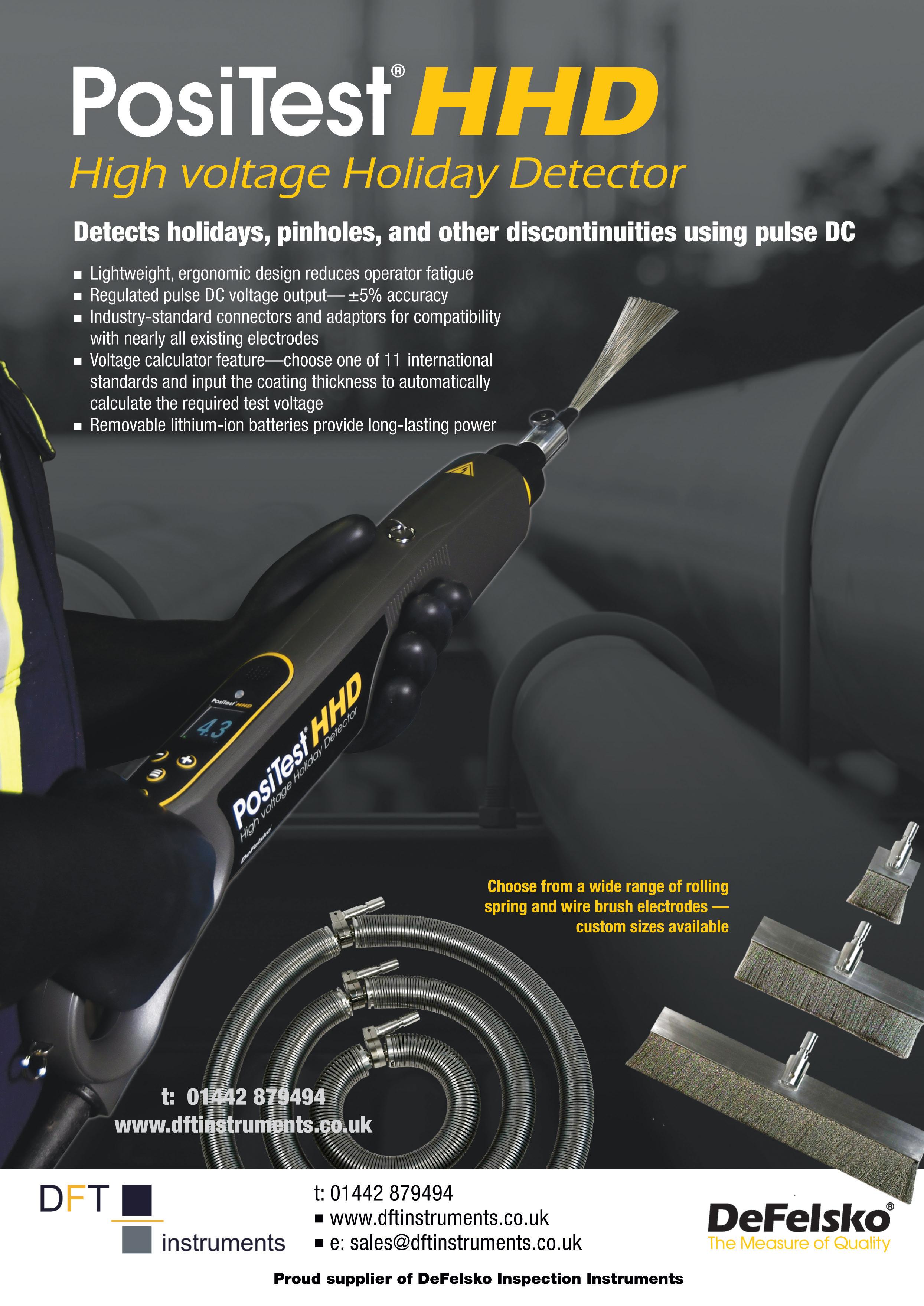

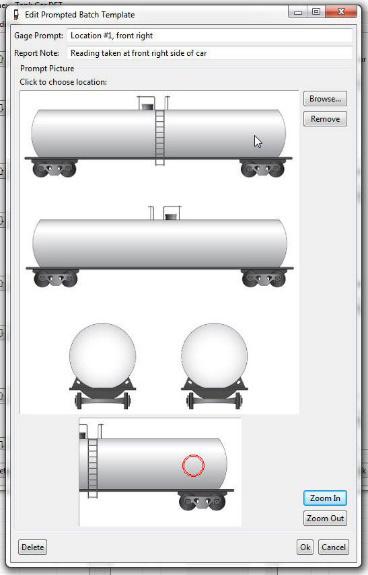

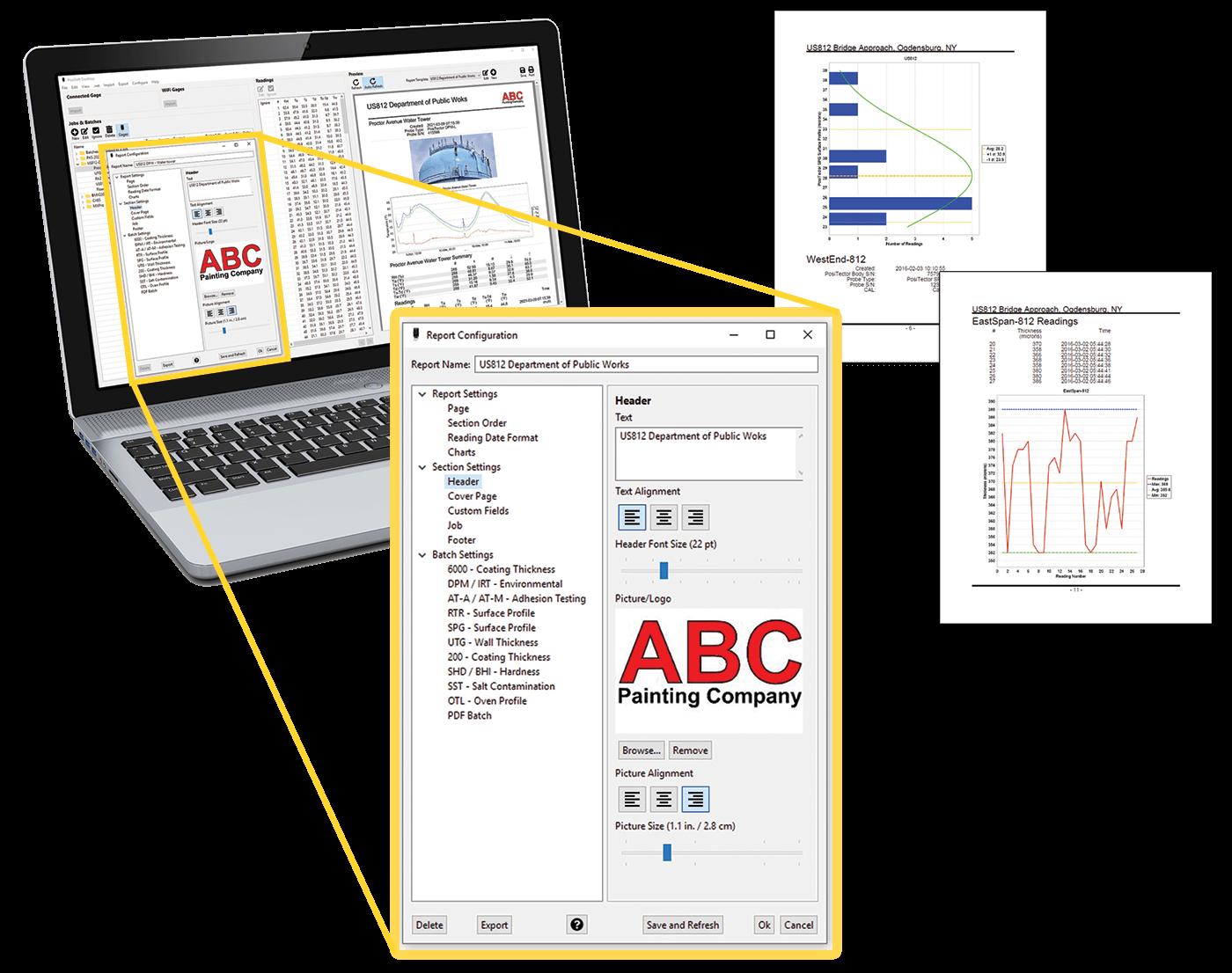

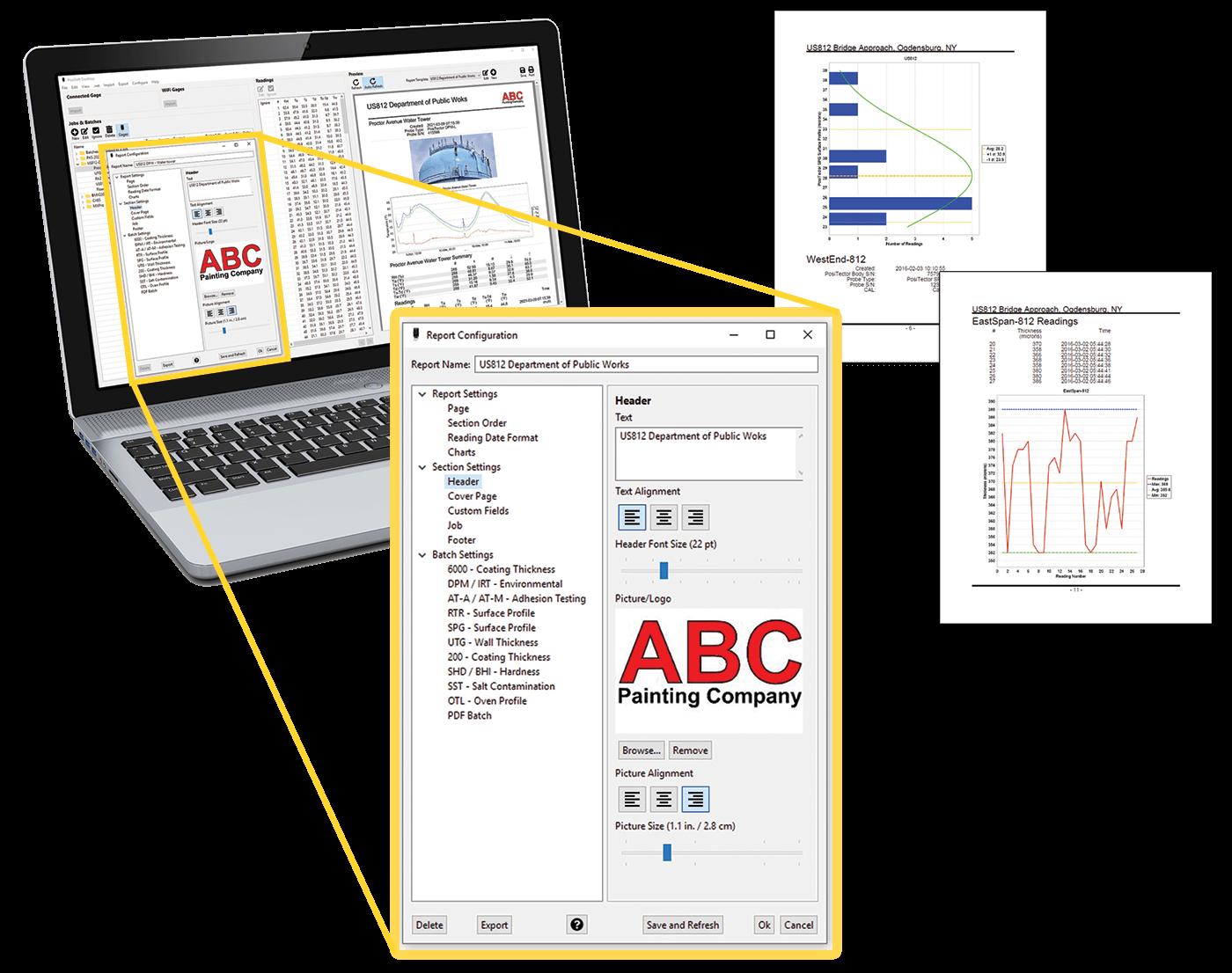

Revolutionising Quality Control: DeFelsko’s Free PosiSoft Software Solutions

In the ever-evolving landscape of quality control and inspection, DeFelsko Corporation stands as a beacon of innovation, and their Powerful PosiSoft Software Solutions have set a new standard in the industry. What sets these solutions apart is their seamless integration of DeFelsko’s PosiTector and PosiTest range of instruments, enabling connectivity through USB, Bluetooth, and Wi-Fi. Coupled with the other unique advantage like Prompted Batch Mode, these software solutions are revolutionising quality control.

With the PosiTector range of interchangeable probes, the user can store readings from all the PosiTector range of probes, including DFT probes, environmental, surface profile, wall thickness, gloss and more onto just one body. Then only the one body is required to link to a computer or smart device to transfer the data to easily produce customised reports on the free PosiSoft software and PosiTector mobile app. This obviously reduces time and potential problems, without the need to connect multiple gauges to the computer. This versatility is a significant selling point for professionals who require diverse measurement and reporting capabilities.

USB Lead Connectivity: A Strong Foundation

DeFelsko’s PosiSoft Software Solutions begin with the fundamentals. Instruments from the PosiTector and PosiTest range can connect to a computer via a USB lead, establishing a robust link between the measurement device and the software.

Bluetooth and Wi-Fi Connectivity: Bringing Inspections into the Digital Age

As the world continues its digital transformation, DeFelsko recognises the need for advanced connectivity options. The PosiTector and PosiTest range now include Bluetooth and Wi-Fi

connectivity, enhancing the way inspection data is collected and managed.

Bluetooth Connectivity: With the integration of Bluetooth, DeFelsko’s instruments can seamlessly connect to the PosiTector Mobile app. This feature allows users to monitor real-time measurements directly on their mobile devices, to produce and send customised reports in the field without the need to connect to a computer. It eliminates the need for manual note-taking, ensuring that data is transferred swiftly and accurately, reducing the risk of errors.

Wi-Fi Integration: Wi-Fi connectivity takes data management to a new level. Inspection data can be effortlessly uploaded to the cloud or a local network, allowing for instant collaboration and remote monitoring. This feature is particularly beneficial for large-scale projects, enabling multiple team members to access data simultaneously, regardless of their location.

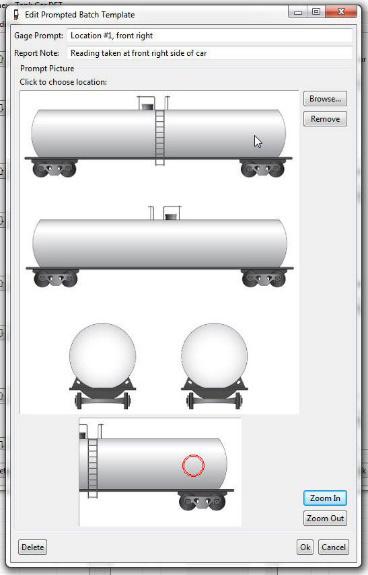

Efficiency Redefined with Prompted Batch Mode

One of the most significant challenges faced by quality control professionals is the time-consuming and error-prone process of data collection. DeFelsko’s Prompted Batch Mode tackles this issue head-on, streamlining the entire inspection process:

Guided Measurements: Once set up through the PosiSoft software and

uploaded, a PosiTector body will guides users, with customised pictures and write up with defined measurements area to ensure each reading it taken exactly where needed, through each measurement step by step. This removes any user error and ensures the correct data is taken.

30 SEPTEMBER 2023 DFT INSTRUMENTS UK LTD

Pull-Off Adhesion Testers

n Impact and scratch resistant color Touch Screen display with keypad

n Wirelessly connect the PosiTest AT-A to your smart device using our free app

n Record the results as pass/fail and the nature of fracture cohesive, adhesive and glue failures

W i F i Proud supplier of DeFelsko Inspection Instruments DFT Instruments UK LTD 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk AT Measure the adhesion of coatings to metal, wood, concrete and more AT-A Automatic Model Also available AT-M Manual Model A u t o m a t i c F e a t u r e s

Effortless Reporting: Once the measurements are complete, PosiSoft Software Solutions automatically compiles the data into comprehensive, customisable reports. Users can choose from a variety of templates and easily export their findings in various formats, including PDF and Excel, significantly reducing the time spent on post-inspection paperwork.

Audit Trail: PosiSoft maintains a comprehensive audit trail of all actions taken within the software, providing transparency and accountability. This is crucial for compliance and audit purposes.

Conclusion

DeFelsko’s PosiSoft Software Solutions, featuring Bluetooth and Wi-Fi connectivity alongside the efficient Prompted Batch Mode, are gamechangers in the realm of quality control and inspection. By simplifying data collection, reducing errors, and streamlining reporting, these tools empower professionals across industries to focus on maintaining the highest standards of quality.

In an era where precision and efficiency are paramount, PosiSoft Software Solutions prove to be

essential for any organization seeking to excel in their inspection processes. DeFelsko continues to lead the way in quality assurance, providing professionals with the advanced tools they need to excel in their work, and ultimately, deliver outstanding results.

For more information please contact Mark Conlon at DFT Instruments UK Ltd, proud UK and Ireland agents for DeFelsko.

Telephone: 01442 879494

Email: sales@dftinstruments.co.uk

Visit: www.dftinstruments.co.uk

32 SEPTEMBER 2023 DFT

INSTRUMENTS UK LTD

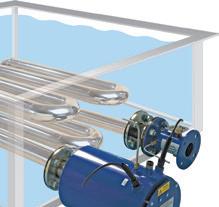

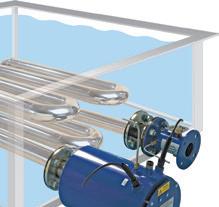

We solve our customers filtration, chemical transfer and treatment needs. Contact us

SIEBEC UK Ltd, Stafford +44 (0) 1785 227700 sales@siebec.co.uk www.siebec.co.uk

PUMPS & FILTERS

L SERIES | Medium flow rate filter

P SERIES | Ultra-high flow rate filter

A SERIES | Mechanical seals pump

M SERIES | Magnetic drive pump

T SERIES | Vertical pump [...]

FILTER MEDIA

L-TECH | Pleated cartridge

BAGTECH | Filtration bag

QUALITHERM | Extruded cartridge

QUALIBOB | Wound cartridge

ANODTECH | Anode bag [...]

SPECIAL SYSTEMS

ACIDPURE | Acid recycling

EASYPURE | Fluid recycling

IONPURE | Ionic filtration

ACIDVAC | Acid draining vacuum

EDUCTORS | Bath agitation [...]

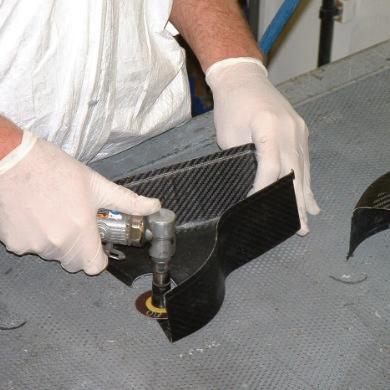

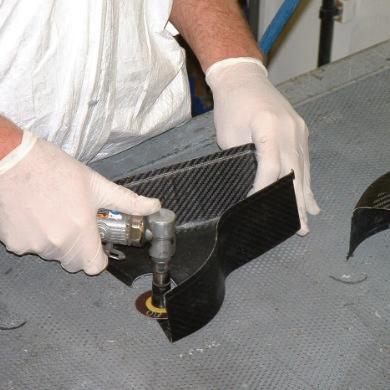

General purpose industrial solvent cleaners - safe for users and the environment

Clarea® non-chlorinated industrial solvent cleaners are compatible with all metals, composites and most plastics used to remove dirt, oil, grease, or other contaminants from surfaces without causing harm or leaving residue. They are used as immersion cleaners for component cleaning in manufacturing and engineering industries and as wipe cleaners for large surface areas prior to painting or powder coating.

The environmental concerns and health hazards of the chlorinated solvents used as industrial degreasing agents has led to the formulation of this EnviroTech range of safer cleaning solvents.

What to consider when choosing suitable solvent cleaning products?

Solvents used for cleaning must be highly refined and leave no residues on drying. They need to be highly effective removing oils and soils without causing damage or corrosion of the parts or components being processed and leave minimal residues.

Cleaning specifications vary widely from very demanding automotive and aerospace applications to less demanding applications where critical cleaning is not needed such as pre-used parts or assemblies from the transportation, aerospace, or manufacturing equipment sectors. Heavily contaminated when removed

from service these must be free of oils, soils, grease and dirt before disassembly prior to refurbishing and rebuilding. Much of this work will be manual and the considerations for the safety of operators, hand wiping or brush cleaning is paramount.

Clarea® products are aliphatic hydrocarbon based low odour degreasing solvents with specified flash points. They will remove oils, greases, hydraulic fluids cutting fluids and a wide variety of hydrocarbon based protective coatings. Clarea® solvents can be safely used with all metals and composites and most plastic and paint finishes.

Clarea® HC40 is low odour degreasing fast drying solvent with a flash point of 40°C. It is suitable for ultrasonic and dip systems and can be used with brush or in hand-wipe processes.

Clarea® HC62 is a degreasing solvent with a flash point over 60°C. It is suitable for hand-wipe applications when used externally.

EFFICIENT AND ECONOMICAL

Versatile and cost-effective solutions for all your industrial cleaning

Minimal odour and low toxicity for operators

Multipurpose uses can reduce the inventory of cleaning fluids.

Flexible uses - evaporation rates suitable for hand wipe, spray, or immersion tank cleaning

Clarea® HC40 for brush and hand wiping, air dries. Flash point 40°C

Clarea® HC62 for spray or immersion cleaning Flash point 62°C

Contains no chlorine, other halogens or stabilisers

Compatible with all metals and composites and most plastics

Excellent pre-cleaner for paint or powder coatings

Safe, reliable, environmentally friendly cleaning

FURTHER INFORMATION

Please visit our website www. envirotech-europe.com/solventcleaners/ for information about other uses and applications for Clarea® products. For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.

Visit www.envirotech-europe.com/ applications-and-case-studies for information about uses and applications for all EnviroTech Europe products.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

34 SEPTEMBER 2023 ENVIROTECH EUROPE LTD

WASHING SYSTEMS EFFICIENT - ROBUST - RELIABLE INNOVATION FOR ALL YOUR WASHING NEEDS • SMALL BATCH WASHING TO CONVEYORISED SYSTEMS • SPRAY, SOAK , ULTRASONIC OR COMBINATION MACHINES. • FULL AFTER SALES SUPPORT • IN HOUSE TEST FACILITY • EUROPEAN WIDE CUSTOMER BASE • STANDARD AND BESPOKE SYSTEMS AVAILABLE • COMPLIMENTARY CHEMICAL RANGE AVAILABLE Call 01543 675800 or visit our website www.unitechwashers.uk.com elcometer.com ERSKINE BRIDGE 700m+ hose runs 40m+ elevation LONG HOSE RUNS?... NO PROBLEM! dry abrasive blast machines | precision media valves blast hose | blast nozzles | personal protection equipment Elcometer’s PERFORMANCE HP 15bar abrasive blast machines are designed to provide ultimate productivity on large infrastructure projects. 6.8bar at the nozzle Surface World - Blast - July 23.indd 2 06/07/2023 13:34:59

Help prevent workplace pollution…

Covering open chemical and heated tanks will reduce evaporation by at least 91%, decreasing the number of toxic fumes coming off the tanks and entering the atmosphere. This will not only have a positive impact on the environment but on the health of workers and locals as well. In addition, it will reduce the number of accidents where harmful liquids splash and building life expectancy will be increased due to the reduction in toxic vapours creating corrosion.

Save your business money!

Conserving liquids in open surface tanks with balls will save your business 75% on energy bills!

Euro-Matic Croffles could help save a heap of cash in manufacturing processes. It’s surprising how many people don’t know about them or what a simple, cost-effective solution they are!

For factories or production plants with chemical processes, heat or cooling

tanks, there are inevitably several knock-on effects, such as maintaining tank temperature, nasty smells and toxins, or the damage evaporation can do to the workplace. But this longstanding, simple solution developed by Euro-Matic, solves these issues simply by pouring a blanket of balls onto open process tanks and creating a flexible cover. The cool thing is unlike a fixed cover which would need removing every time the tank is in use, the balls will move around any parts and machinery

and automatically slot back into place after, sitting on top of the liquid, minimizing chemical waste and heat loss at all times.

How to get some balls

Balls can be ordered online at www.euro-matic.co.uk or by calling 03303110003, where our friendly team will help with any questions and work out exactly how many balls you need with the correct material specification and size required for that tank.

Ball Calculator

There is also a ball calculator that enables you to insert the tank dimensions, and it will do the math for you! It is that easy! www.euromatic.co.uk/ball-calculator.

36 SEPTEMBER 2023 EURO-MATIC UK LTD

Designed and Built in Great Britain Supplied Across the World Manufacturer of materials handling systems and automation solutions for all industries CONVEYOR SYSTEMS FOR: PRODUCT FINISHING PLANTS | LOGISTICS | INDUSTRIAL EQUIPMENT | POINT OF DISPLAY | AUTOMOTIVE Midland Handling Equipment Ltd. Stretton Road, Great Glen, Leicester, LE8 9GN, England T: +44 (0)116 259 3175 F: +44 (0)116 259 2820 E: enquiry@mhel.co.uk W: mhel.co.uk Materials handling equipment for Spraying, Powdering, Curing, Treating, Dipping, Flipping and more ... Years Celebrating 1973 2023

Are you a 3m® user looking to find a suitable alternative solvent? Don’t switch, improve!

You may have heard the latest information from 3M® that they will exit from manufacturing their range of NovecTM cleaning fludis in the near future. If you are a current 3M® NovecTM user you will need to start to find 3M® alternative solvents. Fraser Technologies are here to help with the perfect solutions.

What is the update from 3M®?

3M® have announced that they will stop manufacturing the NovecTM HFE materials by the end of 2025. They have also have stated in a letter sent to all their customers that they cannot guarantee supply and that current users should be looking at alternatives as quickly as possible.

Are you a current 3M® user? If yes what does the update from 3M® mean for you?

While there are no immediate issues with supply it would be prudent to consider your options before the supply of the 3M® materials becomes an issue. Frasers can help with direct drop in alternatives to the NovecTM materials as well as alternative technologies such as water wash and solvent recovery systems etc.

What alternatives are available for me to switch to?

There are a few direct drop in alternatives available, but it should be noted that many of these contain HFE materials manufactured by 3M® which could also shortly fall low in supplies or be restricted by upcoming legislation. So Fraser Technologies are focusing on switching existing 3M customers not over to an alternative but actually an improvement.

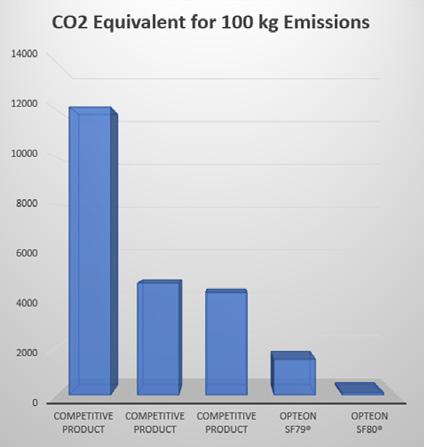

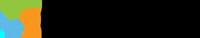

Why is the new 3M® alternative Chemours Opteon an improvement?

Our Optoen® range manufactured by Chemours (part of the DupontTM portfolio) are one of the largest chemical manufacturers in the world.

Chemours produce some of the highest quality chemicals improving cleaning performance than predecessors.

The Optoen® chemicals are some of the most environmentally friendly (by a long way!) as they have a GWP (global warming potential) <2, compared to some of 3M® NovecTM fluids had a GWP ranging from 40-300!

The Opteon® range have ZERO ODP and are accepted by all regulatory agencies globally.

Frasers can assist with evaluating your current application and offer free advice on legal compliance and safe, available alternatives such as the Chemours Opteon® speciality fluids which are direct drop in alternatives.

safe and non flammable and MSDS (material safety data sheets) can be supplied for all chemistries showcasing our transparent selling priority. At Frasers we can run application trials with suitable alternatives and advise on alternative chemistries and or equipment if relevant.

When do I need to make the switch?

You can either be proactive and line up suitable alternatives in advance or wait until supply ends or is interrupted. The choice is yours but, but supply will stop and switching systems can sometime take time, so allow time for this. We know this is now high on every 3M users agenda, and we have already commenced many Opteon® trials with current 3M users.

What shall I do now?

We are currently offering free 3M® switch reviews for any customers who are wanting some advice on when they should make their switch and how the process would work for them as remember every application is different. Contact us today to get this in your diary.

What to be aware of before you switch?

Suitability of equipment, material compatibility, product performance, legal compliance and safety categories are just some of the key areas to look at here. The Opteon® range are extremely

38 SEPTEMBER 2023 FRASER TECHNOLOGIES

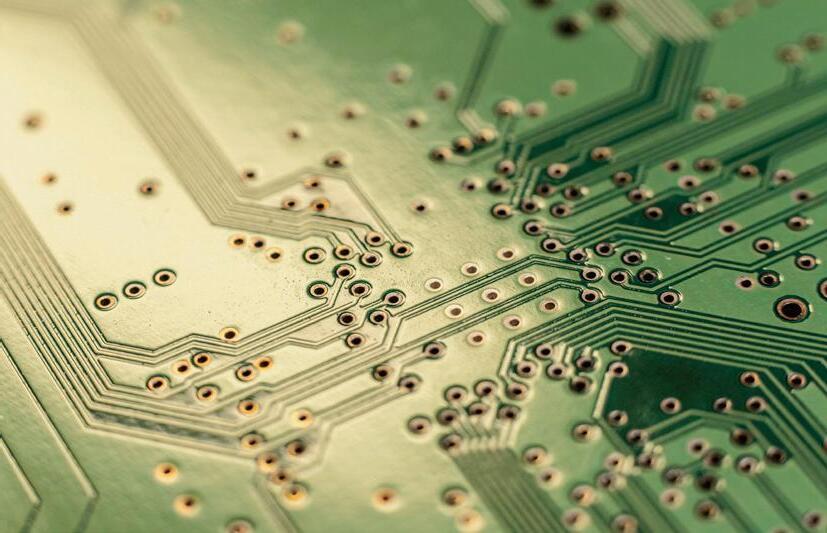

Leading-edge Metal Pre-treatment Technologies

SurTec 650 - Tri-chrome Passivation for Aluminium

Best-in-class bare metal corrosion protection and excellent paint adhesion

Outstanding filiform corrosion resistance

QPL-listed; Meets MIL-DTL-81706-B and MIL-DTL 5541-F

Specifically designed for the application in the architectural industry

Leading-edge performance in filiform corrosion resistance

Easy handling without additives as make-up/replenisher system

SurTec 609 EC - Phosphate Replacement for Multi-Metal Pre-Treatment

Corrosion resistance almost on the level of ZnPhos

Very high flash-rust stability

No mapping effect when E-coated

SurTec 643 - High-Performance Chrome-free Aluminium Conversion Coating SurTec Group

Office +44 7841 527552

Protection upgraded

UK

Nigel Wicks Nigel.Wicks@SurTec.com

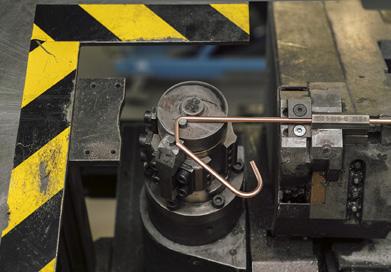

Patented masks for wheel coating industry

Quick and efficient wheel coating process using patented hight temperature resistant rubber masks. A reduced number of rubber masks has been created in order to cover most of wheel sizes in the market, protect bolt holes and back hub from paint and ensure a smooth finishing at once.

Global Mask International has always been focused on providing from the simplest standard masking solutions to the most demanding customized solutions in order to ensure a smother and easier coating process. This expertise has allowed the company to successfully provide solutions to several industries around the world specially on made to measure masking, nevertheless there was still a challenge on wheel coating refurbishment industry.

Back in Paint Expo 2018 in Karlsruhe Global Mask as usual was presenting several masking solutions for the coating industry in general and also

presenting the first Wheel Mask Prototype in the market. It was a success and had the opportunity to meet some of the top players on the wheel refurbishment industry, these meetings helped creating an alliance between Global Mask and some Wheel refurbishment companies to understand the authentic problems on the wheel refurbishment industry:

All bolt holes and back hub of the wheel must be perfectly covered from paint in order to ensure right assembly process and avoid potential claims from customers, on the other side wheel refurbishment companies are dealing

with small quantities but several wheel sizes what means it becomes very difficult to choose the right mask for each size. Despite there is a wide range of standard silicone products and disposal products like Green Polyester Discs there was no specific standard solution for masking on wheel coating. The solution was clear:

Create a reduced number of masks to cover several wheel sizes, make them High temperature resistant to stay from primer to final curing and make them reusable for a long last life.

40 SEPTEMBER 2023 GLOBAL MASK INTERNATIONAL SL

UK’S LEADING MANUFACTURER PYROLYSIS & BURN OFF OVENS Call Longworth today for a no obligation meeting on how we can help you and your business Longworth’s pyrolysis & burn off ovens are second to none in design and build quality, built to last and have the latest in technological features. Our ovens provide a quick and highly effective process for the removal of plastics, paints and resins from jigs, filters, shelving, food trays, motors, automotive parts and a multitude of other components. Our Pyrolysis ovens provide you with a quick and highly effective process for the removal of plastic, paints and resins Accreditations BS EN ISO 9001:2008 visit www.bmlongworth.com call 01254 680501 email enquiries@bmlongworth.com

After a long development period working together with some wheel refurbishment companies Global Mask is glad to introduce a new patented product branch under the brand Global Wheels to give a response to most of the wheel refurbishment industry needs.

A smart patented combination of Rubber Discs and Rubber Flanged Plugs to cover most of the wheel sizes in the market with a reduced number of masks. All plugs are combinable with all discs in order to cover several wheel sizes. Hard attaching of the masks is ensured by pulling flanged plug tail through discs holes. In order to provide an easier identification of the several mask sizes a colour system has been set up, each mask colour belongs to a specific wheel size.

The benefits of using rubber wheel masks are way greater than usual

disposal systems, they can be mentioned in 3 main points:

Quick and Efficient Coating

Wheel coating process will become a lot quicker and efficient due to an easier applying and removing of the mask, on top of that the masks are 315ºC resistant so it is possible to easily apply the mask in the very beginning of the process (Primer) and remove it at the very end (After curing) avoiding time waste.

Perfect Finishing

When the mask is placed and all sensible parts are covered, a perfect finishing on Bolt Holes and Back Hub of the wheel can be ensured at the first try avoiding any assembly problems, extra works or customer complains.

Cost Saving Solution

Since it is a reusable and multi sizing masks a lesser number of masks will be needed and last life of them will be a lot longer than usual disposal systems. Therefore, this solution will drastically reduce masking costs on coating jobs. On the other side it will also reduce waste on the garbage and help having a more sustainable production process. New developments and challenges are always coming on the wheel coating industry and specially on wheel refurbishment business where we can find many small companies with lots of different ongoing projects. It is important that big players in the market are taking one step ahead looking at the bigger picture, identifying all small needs and trying to provide a consolidated response freeing the small customer from uncertain investment and risk.

42 SEPTEMBER 2023

Visit: www.global-mask.com GLOBAL MASK INTERNATIONAL SL

Powder Checker

Non-contact Uncured Powder Thickness Gauge

Affordably measures uncured powder coatings using non-contact ultrasonic technology to predict a cured thickness

Dedicated stand-alone unit is ready to measure right out of the box

Fast measurement speed—ideal for moving lines and swinging parts

Scan Mode continuously takes measurements—ideal for analyzing large areas

Storage of 999 readings with onscreen averaging. Stored readings can be downloaded to PosiSoft Desktop Software

Powder Inspection Kits

Complete solutions for measuring powder coating before and after cure are available

16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk

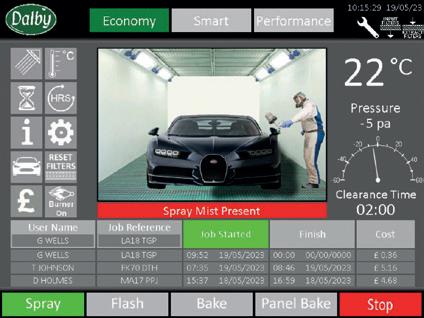

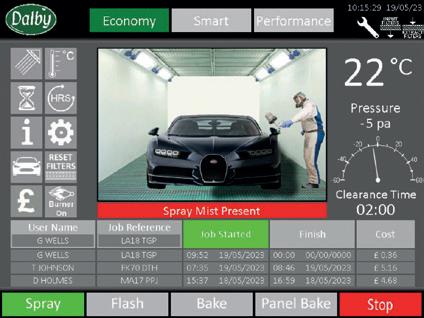

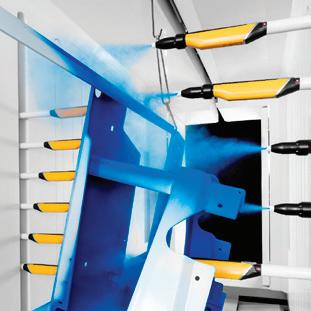

Dalby Evolution Spray Booths

The new Dalby Evolution EQ combination spray booth oven incorporates the very latest technology, providing the optimum paint application environment whilst minimising running costs.

The Evolutionary Dalby ‘ProActive’ touch screen control system constantly monitors the activity within the spray booth and automatically adjusts airflow, temperature and lighting to optimise overspray clearance and bake performance whilst minimising running costs.

Featuring Performance, Smart and Economy modes with invertor controlled automatic pressure balancing, the airflow is automatically controlled to provide power consumption as low as 1Kw in Economy mode. This unique technology allows the Booth to offer your business long term cost savings without compromising the quality or performance your business demands.

With the high visibility LED mode indicator and countdown timer display

fitted above the 3 leaf large window doors, the booth operating mode and count down timer is easily visible across any workshop.

The factory-built air handling unit incorporates the fans, dampers and pilotless burner into a single unit, enabling a fast installation and unrivalled levels of reliability. Maintenance access from within the booth saves vital workshop space by enabling the booth to be positioned into a corner with no side or rear access required. This space saving design helps maximise usable floorspace. With rear extraction no pit is required, but the Dalby EQ is also available with downdraft air movement via pit extraction or with an internally ramped raised floor.

New Evolution+ technology allows you to monitor and manage energy costs per job in real-time

Our Evolution+ technology delivers all the same energy saving innovation as the Evolution Booths but with the added advantage of allowing you to view and manage the energy costs of your spray booth in real-time.

Track energy usage

Record data against each job reference number

Monitor how long the booth is operational in each mode

Gain accurate energy costings per job

Download data for more detailed performance analysis

Enhance energy management and budget planning

Telephone: 0116 291600

Email: enquiries@dalby.co.uk

Visit: www.dalby.co.uk

44 SEPTEMBER 2023 HARRY DALBY ENGINEERING

DO YOU KNOW WHAT YOUR SPRAY BOOTH COSTS PER JOB? New Dalby Evolution+ Technology gives you real time energy costings of your booth enquiries@dalby.co.uk | 0116 291 6000 dalby.co.uk Accurate cost per job data on GAS and ELECTRIC consumption Costs logged against user and job reference Itemised costings for spray, bake and flash off modes Data displayed on new large touch screen control panels Downloadable data to your laptop Pumps up to 250m³/h Horizontal Magnetic Sealless Vertical Sealless Filtration Systems up to 60m³/h Cartridges Bags Papers Microfibres High Quality German DC Switch Mode Rectifiers DC Rectifiers Pulse Rectifiers High current rectifiers up to 10,000A For all your product finishing requirements Hendor-pe UK Ltd, 11 Clarendon Court, Warrington, Cheshire, WA2 8QP Tel: 01925 361400 | E : sales@hendo r-pe. co .u k | W: www.H endo r-pe. c o.u k For all applications Electroplating Anodising Hard Chrome Reel-to-Reel Plating E-Coat Celebrating more than 70 years providing excellence in pumps and filtration

SurfacePrep – We Deliver Results Beyond The Surface

SurfacePrep UK has consistently been the leading manufacturer and supplier of abrasive blasting equipment and surface finishing equipment. Our product portfolio ranges from portable abrasive blast cleaning equipment and hand blast cabinets to expendable and recyclable abrasives, abrasive recovery, and dust extraction & collection. We supply a range of surface preparation inspection equipment as well as powder coating plants and spray booths.

SurfacePrep UK is part of the wider SurfacePrep group, which is the largest network of regional distributors of surface finishing equipment in North America and Europe.

Through our placement of locations across the United States, Canada and the United Kingdom, we offer handson assistance to surface finishing projects enabling you to work one-on-one with a field expert.

At Surface Prep UK we offer a full portfolio of surface finishing solutions focusing on the circular economy. From blasting a surface clean to finishing with powder or paint. As well as offering servicing and training alongside refurbishing equipment and supplying parts.

We design and manufacture abrasive blasting machinery. From a small 1028 blast machine, perfect for small spaces and offshore, through to enclosed suction cabinets, to large, containerised blast rooms installed on site. We can supply the optimal solution for your project. Our design team and engineers are able to create turnkey solutions for your requirements. We stock a range of parts and spares for all our machinery.

Including an extensive collection of personal protective equipment.

We are the largest Gema distributor in the UK for all your powder coating equipment. The range of products include the Gema OptiFlex Pro, manual gun systems, Gema classic manual powder booths and fully automatic systems. We supply full-service backup and spare parts to support Gema equipment. We can also offer full turnkey powder coating plants including conveyor systems, dry ovens, cure ovens and pre-treatment systems.

We offer a full range of Graco paint spray equipment. This ranges from electric, petrol driven or air powered portable spray units. We have the solution for any paint spray application including plural component systems. The full range of paint hoses and accessories are also available.

We are able to offer a comprehensive servicing package and aftermarket care to our customers. SurfacePrep is the UK’s leading manufacturer of abrasive surface preparation equipment. We offer a full range of maintenance and repair options with packages to enable customers to optimise their blasting processes. Our servicing team can service all blasting equipment, Graco fluid

handling equipment and Gema powder coating equipment. Our team of service engineers can visit you onsite as well as having your equipment repaired and tested at our facilities.

We offer an extensive range of hire equipment. This includes a full range of portable blasting equipment, paint spray equipment, compressors, dust extraction and abrasive recovery systems. Hire can be arranged for a short- or long-term basis to suit your requirements. Delivery and collection can be arranged throughout the UK. For more information on SurfacePrep in the UK, visit www.surfaceprep.com/uk

46 SEPTEMBER 2023 SURFACEPREP UK

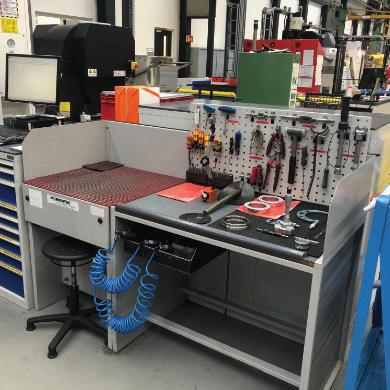

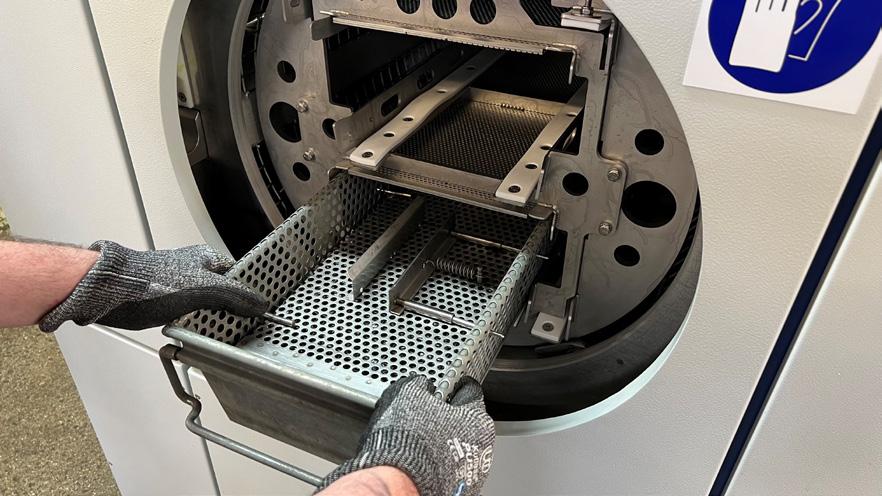

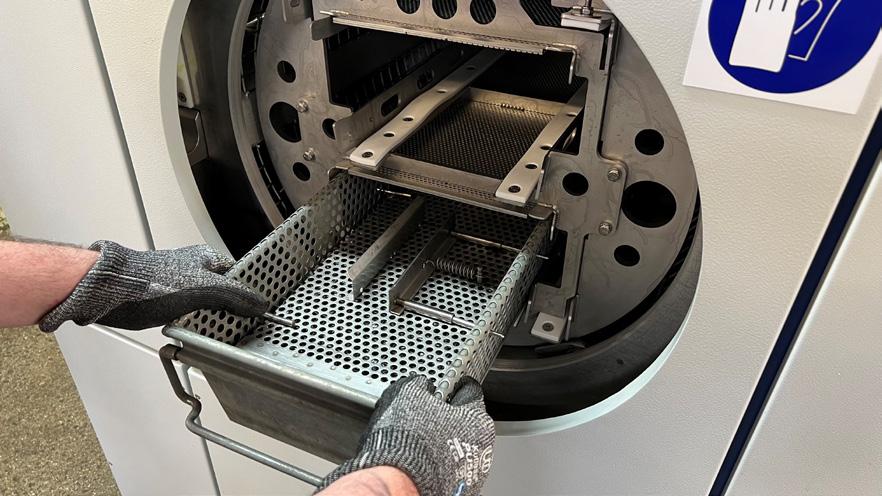

Offering Intelligent Cleaning Solutions for Demanding Applications

Kemet International is a leading provider of intelligent aqueous cleaning solutions that cover a wide range of industrydemanding applications. With a complete turnkey solution to your cleaning requirements, Kemet can help you find the optimal solutions to your cleaning needs, whether it’s a completely new cleaning project or a review of an existing one.

Achieving effective and efficient aqueous cleaning can be difficult, and it requires a harmonious interplay between chemistry and equipment. To address this challenge, Kemet offer more than 300 cleaning solutions, tailored to meet the specific needs and regulations of new applications. Additionally, Kemet has the resources of its partners at NGL’s Laboratories, where chemists study, formulate, develop, and manufacture cleaning solutions. This partnership assists in process validation and approval of preliminary tests, saving time in the

development of customer projects, and guidance and assistance in preparing specifications for equipment investment.

In addition to Aqueous Ultrasonic Cleaners, Kemet also offers;

Vacuum Solvent Cleaning machines operate in a complete vacuum treatment cycle in all phases, ensuring excellent cleaning of finished products from wastage and oily substances, without releasing harmful substances into the environment. Utilising modified alcohols with a flash point exceeding 60°C under vacuum, eliminates the need for manufacturing machines with ATEX approved ratings, resulting in reduced construction expenses.

Passivation machines are designed to comply with ISO 7 clean room standards, ensuring that your parts are properly prepared for their intended use. The machines are furnished with validation software compliant with ‘21 CFR part 11’. This software guarantees adherence to the stringent regulatory standards imposed by the aerospace and medical sectors, making them the

perfect choice for deployment in these tightly regulated domains.

Fluorescent Penetrant Inspection machines are specifically engineered as a highly efficient NDT method for detecting surface-breaking flaws, cracks, and defects that may remain undetected by other means. Engineered to adhere to the widely recognised ASTM E1417 FPI standard, extensively utilised in the aerospace and medical sectors.

Vapour Degreasing Cleaner is designed for efficient and safe degreasing using compatible solvents. This innovative cleaner offers a highly effective method for removing oils, grease, contaminants, and other unwanted substances from various surfaces. By harnessing the power of vapour degreasing, this system ensures thorough cleaning while minimising environmental impact and promoting operator safety.

Spray Washing machines for cleaning parts before maintenance or between production phases. Offers an optimal solution for swift and efficient part cleaning within a closed chamber, promoting a better working environment.

Contact Kemet International today for intelligent aqueous cleaning solutions. Benefit from their expertise and the feature-packed Versa Genius+ ultrasonic cleaning system at their dedicated test centre. Kemet, in partnership with NGL’s Laboratories, delivers tailored cleaning solutions for a wide range of industry applications. Trust Kemet International for exceptional cleaning solutions.

Visit www.Kemet.co.uk

or contact +44 (0) 1622 755287 or Sales@Kemet.co.uk for more information and to arrange cleaning trials.

48 SEPTEMBER 2023

KEMET INTERNATIONAL

Kemet

Cleaning Fluids

Specialist detergents available in neutral, alkaline and acid types. Kemet are a distributor of NGL Nordic A/S with more than 300 high performance formulations providing a solution to most cleaning challenges.

Vacuum Cleaning

Cleans component areas that are hard to reach with Aqueous/HFE solvents, including blind holes and tubes.

Distillation, separation, and filtration effectively removes and recovers oils and swarf particles, allowing 99% material waste recovery.

Passivation & Ultrasonic Cleaning Systems

Kemet International Ltd, Parkwood Trading Estate, Maidstone, Kent, ME15 9NJ, UK +44 (0) 1622 755287 sales@kemet.co.uk www.kemet.co.uk Precision Lapping | Polishing | Cleaning | Materialography

Cleaning Fluids that comply with Medical Device Regulations

Kemet and NGL’s goal is to provide suitable cleaning and surface treatment solutions to a wide range of known industry applications including:

Medical Sector - Cleaning and Surface Preparation of implants, tools and devices before passivation, anodization and electropolishing. Citric passivation solution available

Aerospace - Cleaning and Surface Preparation of production and maintenance components offering immersion and spray systems along NDT automated FPI lines

Luxury Items (Watch and Jewellery) - Cleaning and Surface Preparation of sensitive materials with complex geometries.

Metal Finishing and Cutting Tools – Cleaning and Surface Preparation prior to PVD/CVD coating, and removal of PVD/ CVD coatings

Before any cleaning process is adopted, it must pass rigorous regulatory and standardisation checks.

The REACH Regulation No1907/2006 places restrictions on certain substances in detergents, while CLP regulations define specific labelling requirements for medical applications. Medical Device Regulations (DM 2017.745) impose stringent restrictions on chemicals, encompassing those of animal origin and nano particles. In addition to regulatory compliance, safety for personnel and the absence of biocides are paramount considerations. NGL subjects its medical cleaning and passivation fluids to rigorous testing, ensuring they meet these standards and undergo successful validation to meet the expectations of its customers.

Following forging or casting, components undergo a series of processing steps, including machining, deburring, polishing, and welding. These processes often result in contamination, which can be effectively eliminated using our alkali solutions, specifically RODACLEAN 2018 for ultrasonic cleaning. Thanks to its high potassium and sodium hydroxide concentration, RODACLEAN 2018 efficiently eradicates soluble oils, polishing pastes, and most organic residues.

DECOCLEAN 440, a highly versatile product, is ideal for the removal of pure oil in ultrasonic or spray cleaners (an oil separator is required). It is effective against polishing paste and various organic residues and are fully compliant with medical device regulations.

For sensitive alloys and finishing applications, our mild alkali solution, GALVEX 20.01, is the ideal choice. It serves as a universal detergent devoid of amines and facilitates degreasing on all materials while ensuring excellent rinse-ability and a high-quality finish. Its versatility extends to interoperation

cleaning (removing polishing pastes), surface preparation before passivation, anodising, electrochemical polishing, or final cleaning prior to sterilisation.

DECOSPRAY TM, another mild alkali, targets the removal of pure oils on sensitive alloys through ultrasonic or spray processes, provided the machine incorporates an oil separator.

DECOMET was meticulously developed to meet the stringent requirements of ASTM standard A967. This citric acidbased passivation agent solubilises free iron oxides present on the surfaces of stainless steels, whether martensitic or austenitic. It promotes the oxidation of chromium, forming a passive layer as per the industry standards.

As well as cleaning fluids, Kemet also offer;

Ultrasonic Cleaning Tanks ranging from small benchtop units to fully automated systems

Vacuum Solvent Cleaning machines that can recover 99% of material waste Passivation lines that comply with ISO 7 clean room

Automated Fluorescent Penetrant Inspection systems

Email sales@Kemet.co.uk to arrange cleaning trials, so Kemet can find the ideal cleaning solution for you.

50 SEPTEMBER 2023 KEMET INTERNATIONAL

Hadleigh Enterprises Limited Unit 11, Buckingham Square Hurricane Way, Wickford Essex, SS11 8YQ Tel: 01268 572255 Fax: 01268 572121 Email: sales@hadleightapes.co.uk Web: www.hadleigh-tapes.co.uk Certificate No. FM10409 • AS9100 APPROVED • NO MINIMUM ORDER QUANTITY • ALL PRODUCTS FOR ALL PURPOSES • 48 HOUR DELIVERY SERVICE The Adhesive Tape Specialists

MecWash MWX300 drives efficiency and sustainability for APT Leicester

MecWash Systems created a bespoke aqueous cleaning system that has revolutionised the effectiveness of the washing and degreasing programme of leading precision mill turned parts and CNC specialists, APT Leicester. The upgrade from a perchloroethylene cleaning system to the MWX300 has streamlined the cleaning operation and enabled APT to simultaneously prioritise their environmental goals and increase their output, all whilst maintaining the highest standard of finish.

The initial research and analysis with APT allowed Paul Jarratt, sales manager at MecWash, to gauge the application and outline the machine specifications required. These discussions are essential to gain a full understanding of the geometries used and the contaminants involved.

APT Leicester manufactures precision turned parts and offers CNC machining services. The business supplies turned component parts to industries, including aerospace, where the stringent requirements regarding the quality of the components requires rigorous detail at every stage of the manufacturing process.

Paul Jarratt said: “APT’s CNC processes primarily focus on precision machining using a diverse range of materials such

as stainless steel, aluminium, brass, plastics and titanium. The MWX300 cleaning machine plays a crucial role by cleaning the mill turned parts before they are shipped to customers or undergo any additional heat or surface treatments. The former perchloroethylene cleaning system did an effective job, but APT transitioned from it due to environmental considerations.”

“The MWX300 was selected as the most appropriate system due to its compact size and powerful cleaning capabilities. The ultrasonics provide up to 30 watts/litre of high-power to unsettle any contaminants from the components. The MWX300 provides an immaculate surface finish with both hot and vacuum drying functions.

“Due to the limited floor area available the MWX300 was designed with roller shutter doors in place of conventional swing doors to aid access, APT were also particularly interested in adding our Aqua Save system to reduce water consumption and improve sustainability. This innovative MecWash system captures, filters, and recirculates the cleaning water,” said Paul.

Nick Baller, managing director at APT Leicester, comments: “Manufacturing top quality mill turned parts requires detailed cleaning, and we were confident that MecWash had the experience in manufacturing to create an efficient solution. The cleaning performance of the MWX300 has been a major step forward in our sustainability credentials. The results have been excellent, with parts that are oil free and ready for shipping.

“The productivity of the business has improved with the MWX300 system. We can effectively clean the turned parts that we manufacture, leaving them entirely free of oil, small swarf and debris. The system has helped to drive our mission of providing firstclass, sustainable CNC manufacturing to our customers,” said Nick.

John Pattison, managing director at MecWash, commented: “We were delighted to supply APT Leicester with the MWX300. This compact system is a suitable for applications such as turned parts production as it is proven to clean challenging components. The cost savings and environmental benefits of an efficient aqueous cleaning process are well established.

52 SEPTEMBER 2023 MECWASH

Product Overview

Manual Monorail Systems

Unit loads up to 3000kg

Handling Solutions

Stewart Gill Conveyors Ltd have been supplying overhead conveyors into all sectors of industry for over 70 years.

As a long time member of the Railtechniek van Herwijnen BV Group based in the Netherlands, Stewart Gill Conveyors can offer a comprehensive range of overhead conveyor products which are capable of handling unit loads up to 7000kg.

Monorail Chain Conveyors

Unit loads up to 300kg

Stewart Gill Conveyors Ltd offer complete manufacture, installation and commissioning, coupled with fully documented instruction, operation and maintenance manuals.

We do:

In-House 3D CAD engineering

In-House manufactoring in the UK and EU

Power & Free Conveyors

Unit loads up to 7000kg

In-House design of PLC/PC control systems

Industry 4.0

Worldwide installation and commissioning

Remote support, service & inspection

Part of the

Floor Conveyors

Unit loads up to 500kg

Gill Conveyors Ltd

3&4 Brook Business Park Brookhampton Lane Kineton, Warwickshire CV35 0JA, United Kingdom Tel: +44 (0)1926 641424 info@stewart-gill.co.uk www.stewart-gill.co.uk

Stewart

Unit

“The MWX series represents the highest standard of parts washing in the market and can clean large volumes to the same continuously high standard. The experience of the team in designing and building parts washing machines for customers from across aerospace, automotive, defence, engineering and medical, gives us total confidence in meeting and exceeding

the specific needs of manufacturers,” said John.

For three decades, MecWash has specialised in the design and manufacture of a complete range of aqueous parts washing and degreasing systems. These machines are custom made to clean specific applications for the manufacturing industry. With unparalleled technical expertise

and an inhouse laboratory, MecWash systems are capable of cleaning metal and plastic engineering components with complex geometries, difficult substrates and contaminants, without the use of harmful solvents.

Telephone: +44 (0) 1684 271600

Email: enquire@MecWash.co.uk

Visit: www.mecwash.co.uk

MECWASH Machined castings. Turned parts. Complex pressings and extrusions. Customers expect parts to be pristine. PRECISION AQUEOUS CLEANING demands MecWash. MecWash’s aqueous wash systems can accurately

hundreds of critical features

with

targeted

the

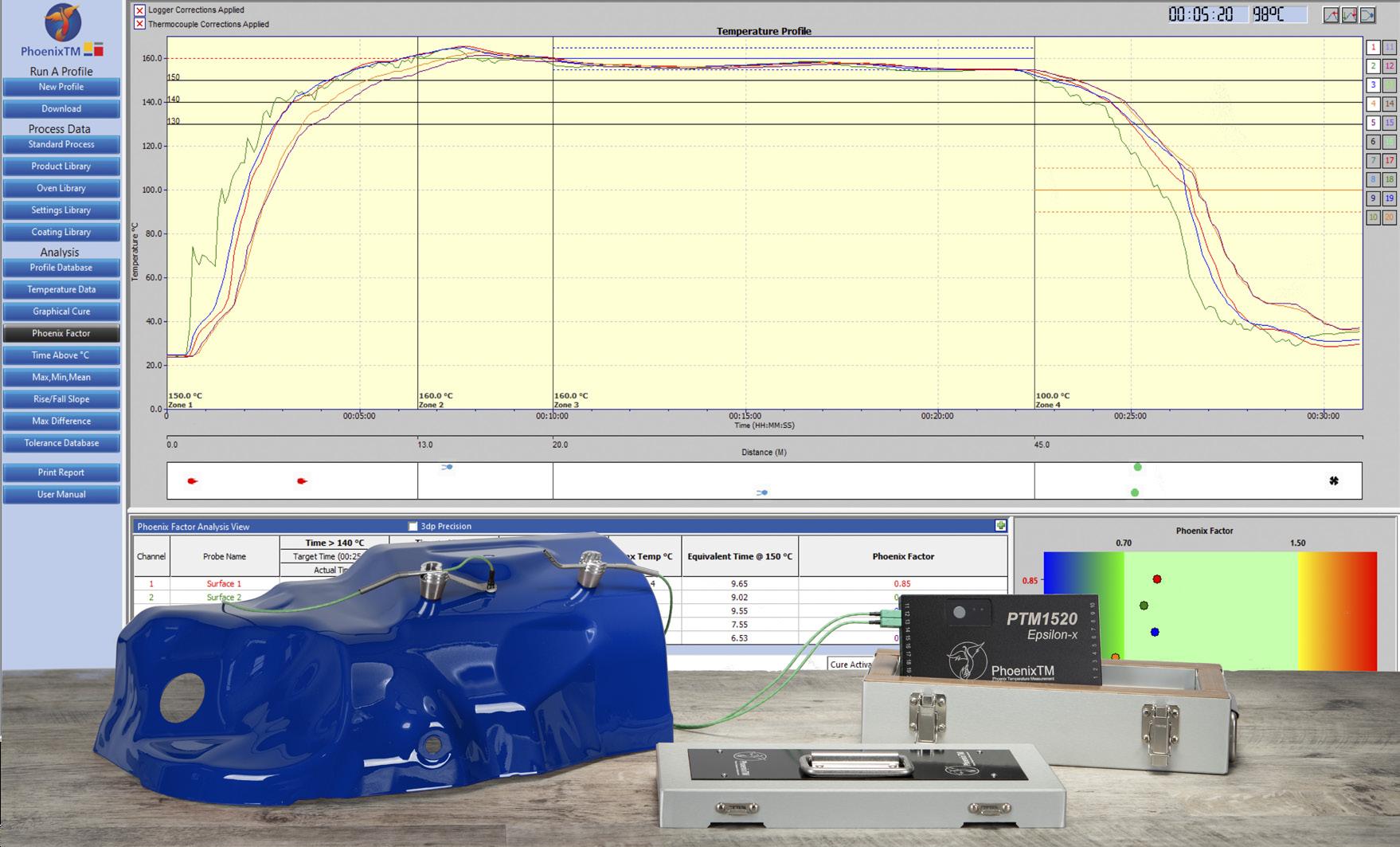

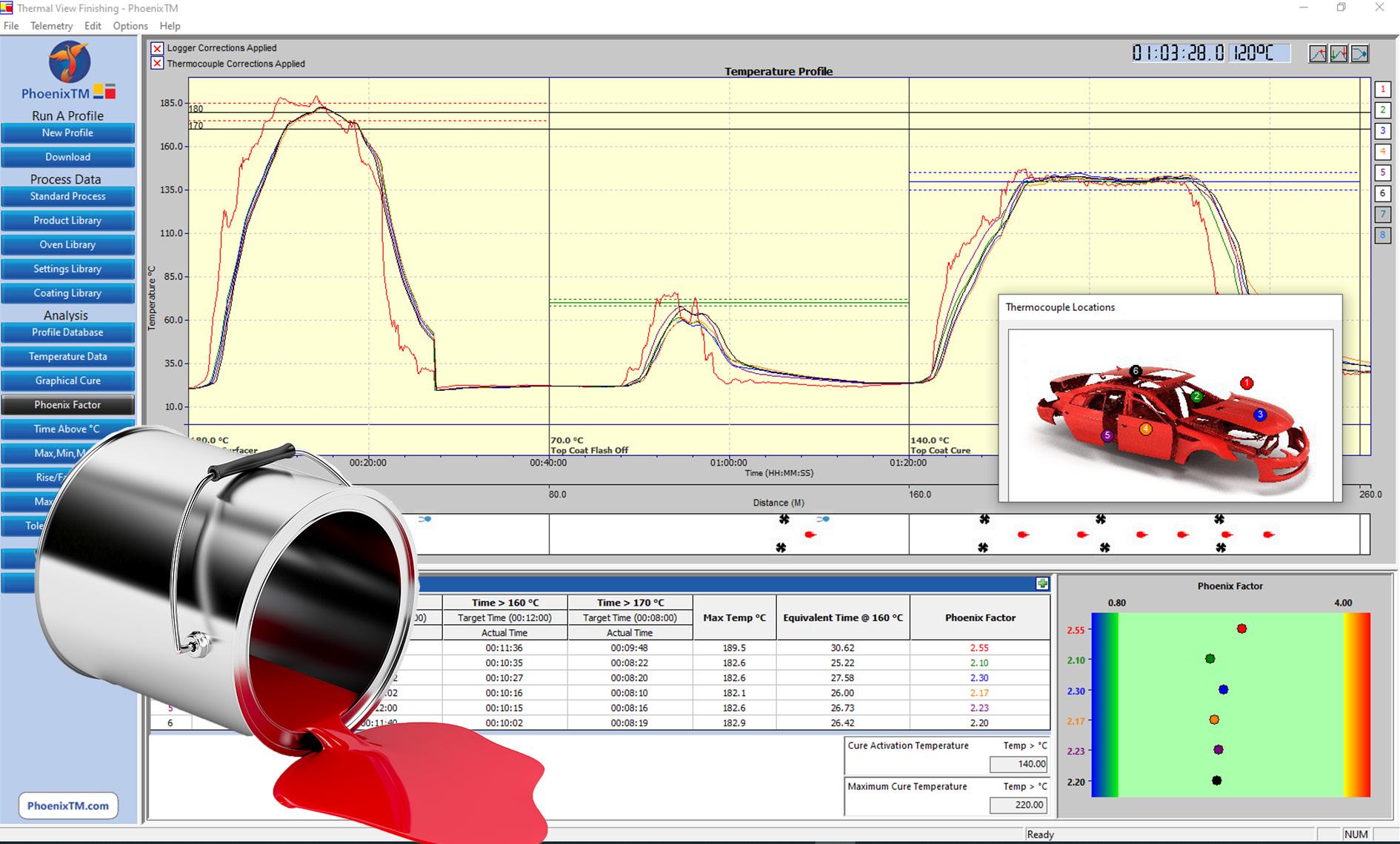

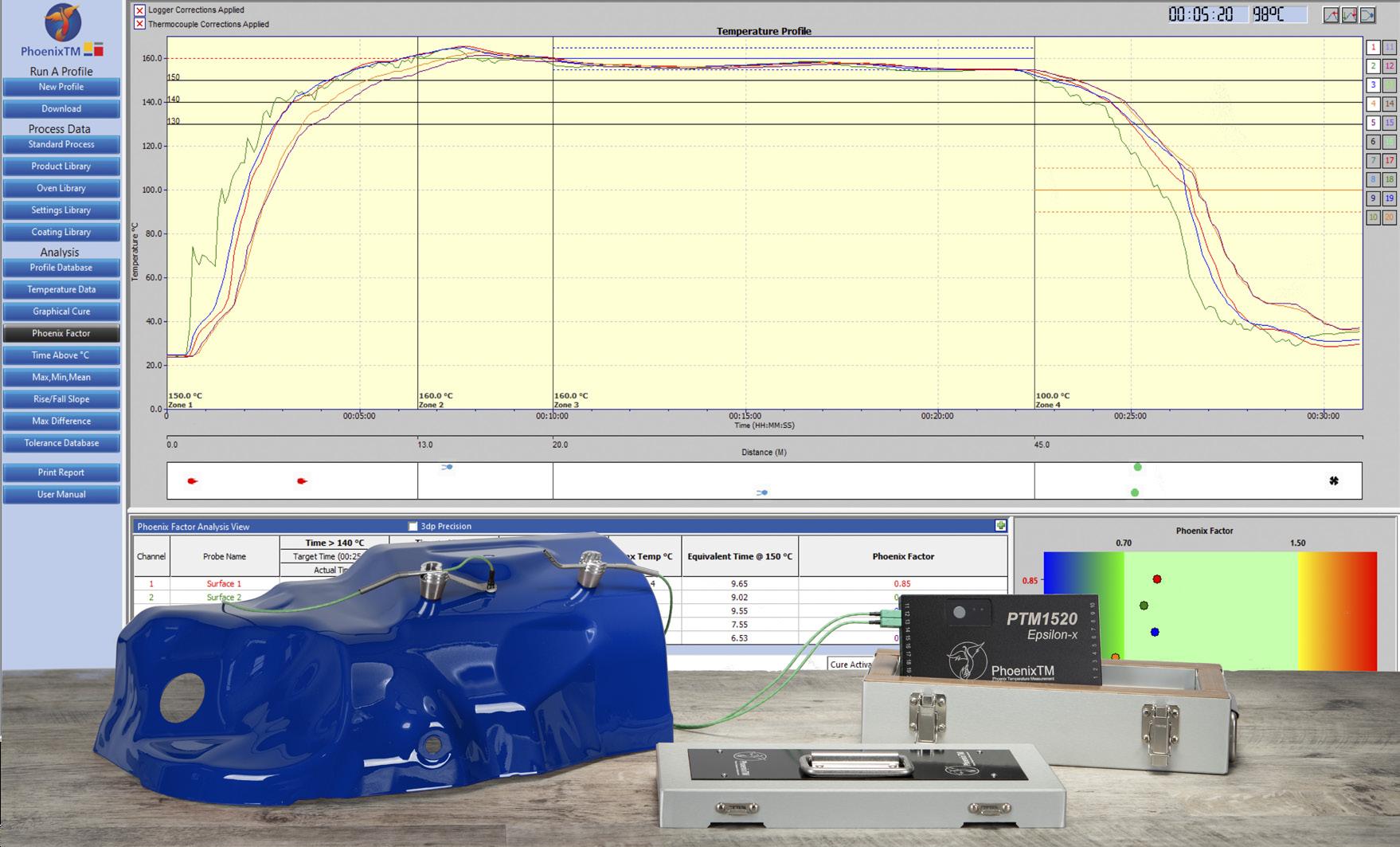

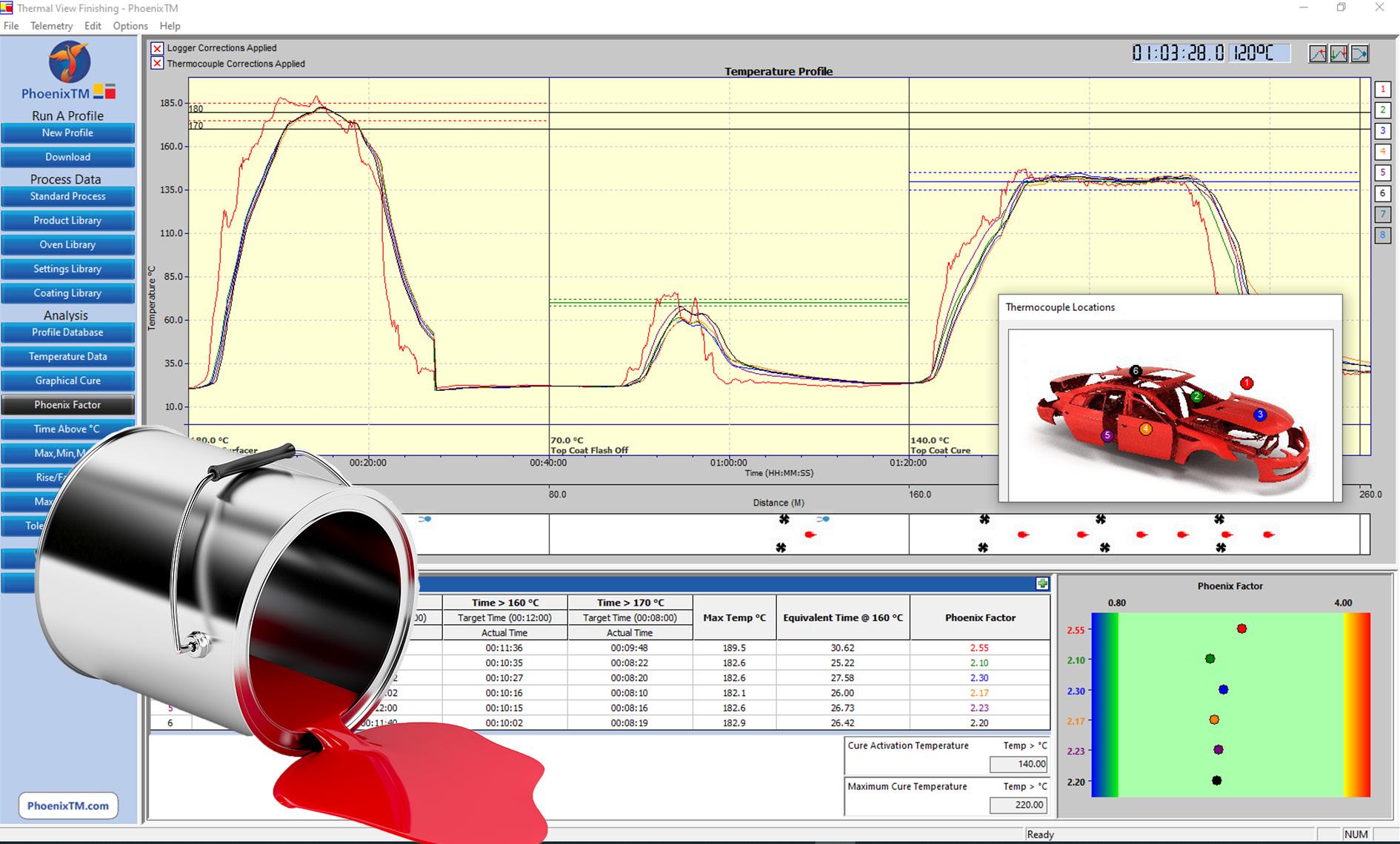

in