TAILOR-MADE SOLUTIONS PRODUCT INNOVATION EXPERT TECHNICAL SUPPORT URBAN FURNITURE APPLIANCES GENERAL INDUSTRIAL FUNCTIONAL COATINGS AGRICULTURE & CONSTRUCTION EQUIPMENT (ACE) ARCHITECTURAL TRANSPORTATION FURNITURE Markets: ... we have everything covered NOVEMBER 2022 read online @ www.surfaceworld.com – follow us on twitter @surfaceworldmag – visit www.surfaceworld.com 4th & 5th October 2023 NEC, BIRMINGHAM www.surfaceworld.com

Welcome to the SURFACE WORLD team!

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826 e: nigelbean1@aol.com / nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com / janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

Sheena Burrus

e: sheenaburrus@hillmedia.com

EXHIBITION ORGANISER

Sheena Burrus

e: sheenaburrus@hillmedia.com

Hill Media Ltd, Marash House 2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd. Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents.

© Hill Media Ltd – 2022 ISSN 1757-367X

COMPANY SPOTLIGHT

INVESTING TO MEET POST-COVID DEMAND. 4 QUALICOAT UK & IRELAND AUTUMN MEMBERS MEETING. 6

GALVANIZERS ASSOCIATION

GA NAMES INDUSTRY EXPERT, DAVID WATKINS, CHAIRMAN OF THE BOARD. 10 SURFACE WORLD 2023 SURFACE WORLD 2023 - BRINGING OVER 20 YEARS OF SERVICE TO YOUR INDUSTRY. 14

INDUSTRY NEWS

NEW QUALICOAT LICENCE GRANTED. 16 BASF LAUNCHES CHEMETALL INNOVATION AND TECHNOLOGY CENTER FOR SURFACE TREATMENT SOLUTIONS IN CHINA. 18 HMG PAINTS RECOGNISED AMONGST FAMILY BUSINESS TOP 100. 20 HOW WE CAN INSPIRE OUR NEW GENERATION INTO ENGINEERING. 24 WATER & EFFLUENT TREATMENT SPLIT-O-MAT® LINE OF PRODUCTS. 28 BABCOCK WANSON BROCHURES HIGHLIGHT STEAM SOLUTIONS AND THERMAL FLUID HEATING APPLICATIONS. 30 PURE WATER FOR A PERFECT POWDER COAT. 32 IONPURETM FROM SIEBEC UK. 34 RAINWATER HARVESTING: AN INVESTMENT NOT TO BE MISSED. 36

PUMPS & FILTRATION

YOUR ONE STOP SHOP FOR A WIDE RANGE OF FILTRATION SOLUTIONS AND FILTER SUPPLIES. 38 HENDOR-PE UK LTD - CELEBRATING 20 YEARS. 42 CHEMICAL PUMPS & FILTRATION SYSTEMS50 YEARS OF EXCELLENCE. 46

PRE-TREATMENT,

SHOT BLAST, SHOT PEEN - THE NEXT LEVEL! 50 CLEANING - OWN THE PROCESS AND CUT THE COSTS. 54 SUSTAINABLE INDUSTRIAL CLEANING OF THE FUTURE .... NOW. 58 A SIMPLE ENERGY SAVING SOLUTION ... 60

PRODUCTS & PROCESSES

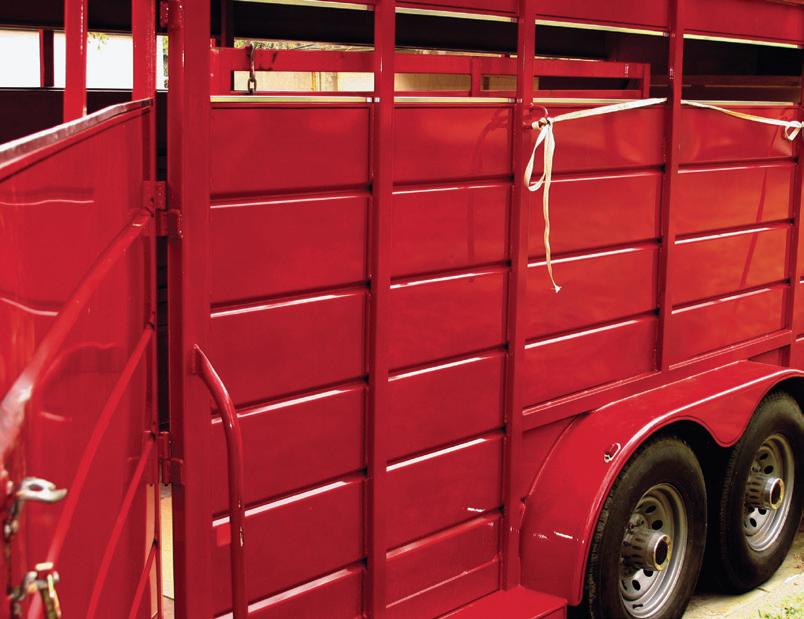

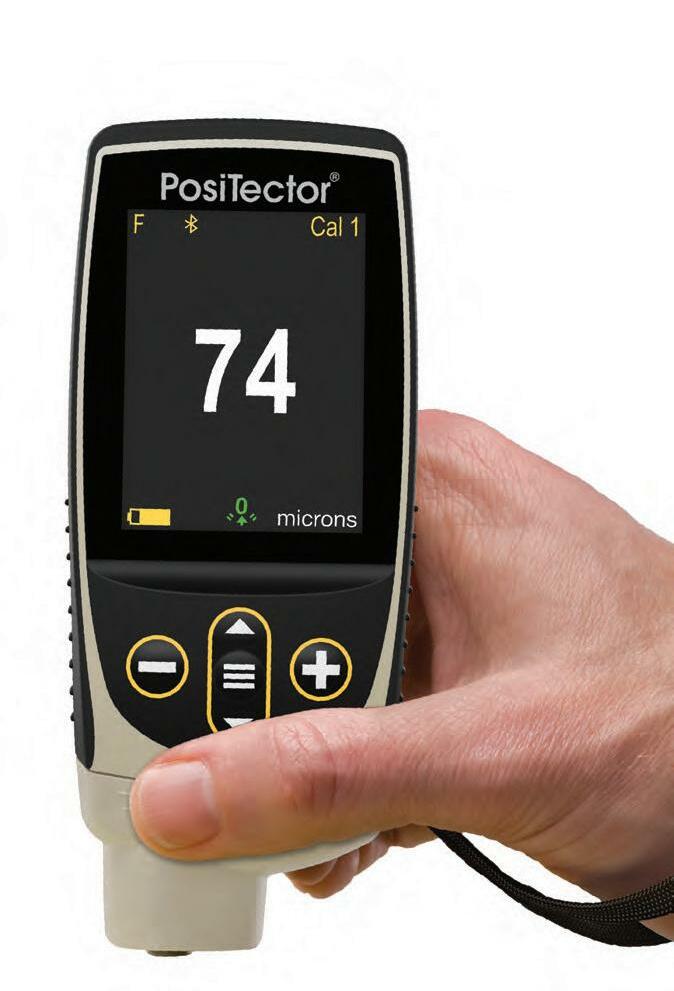

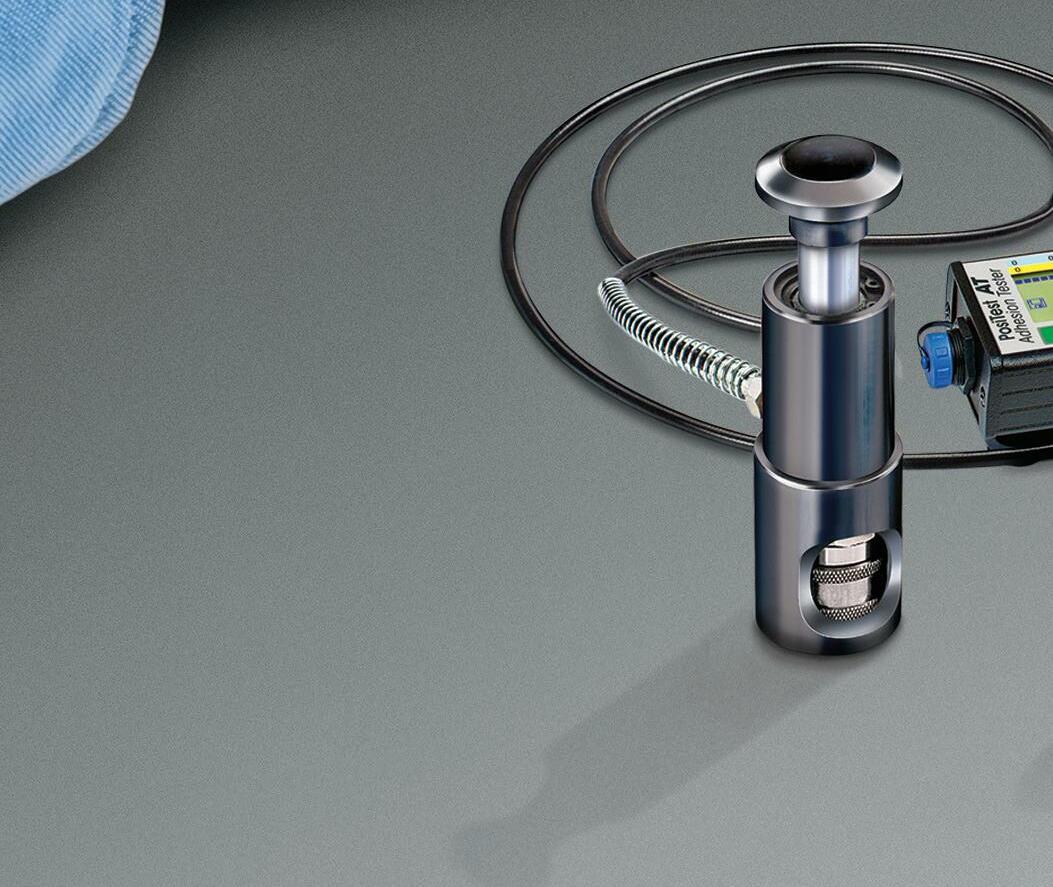

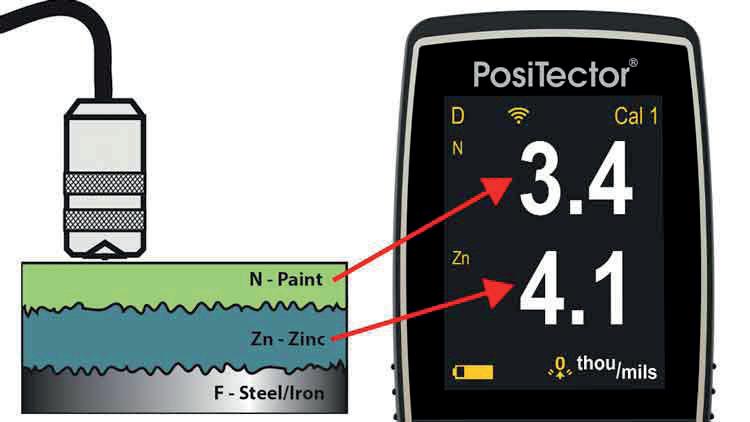

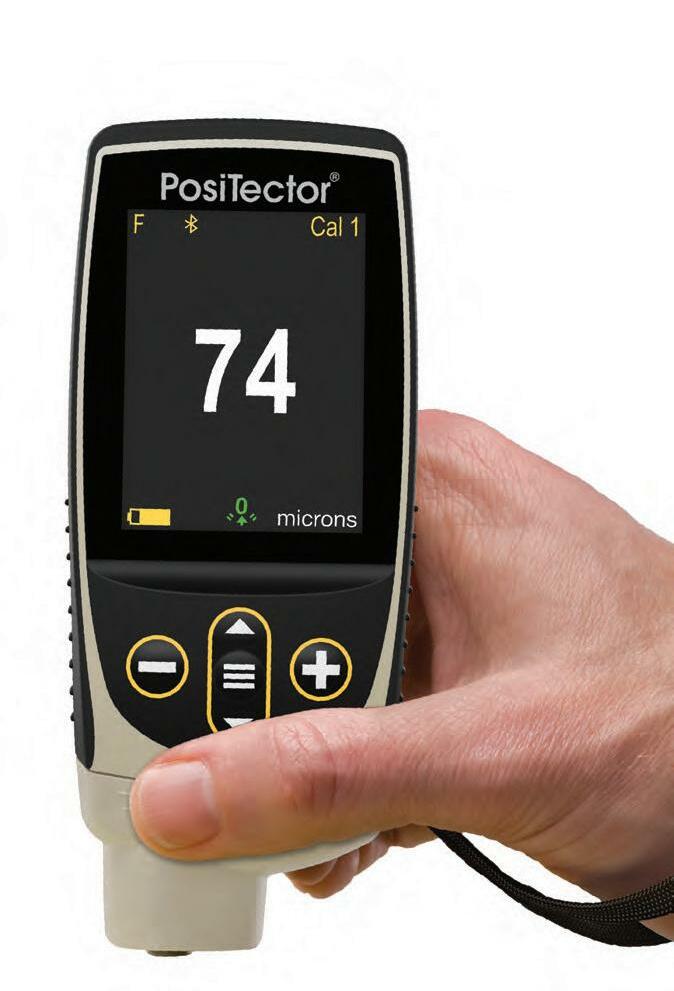

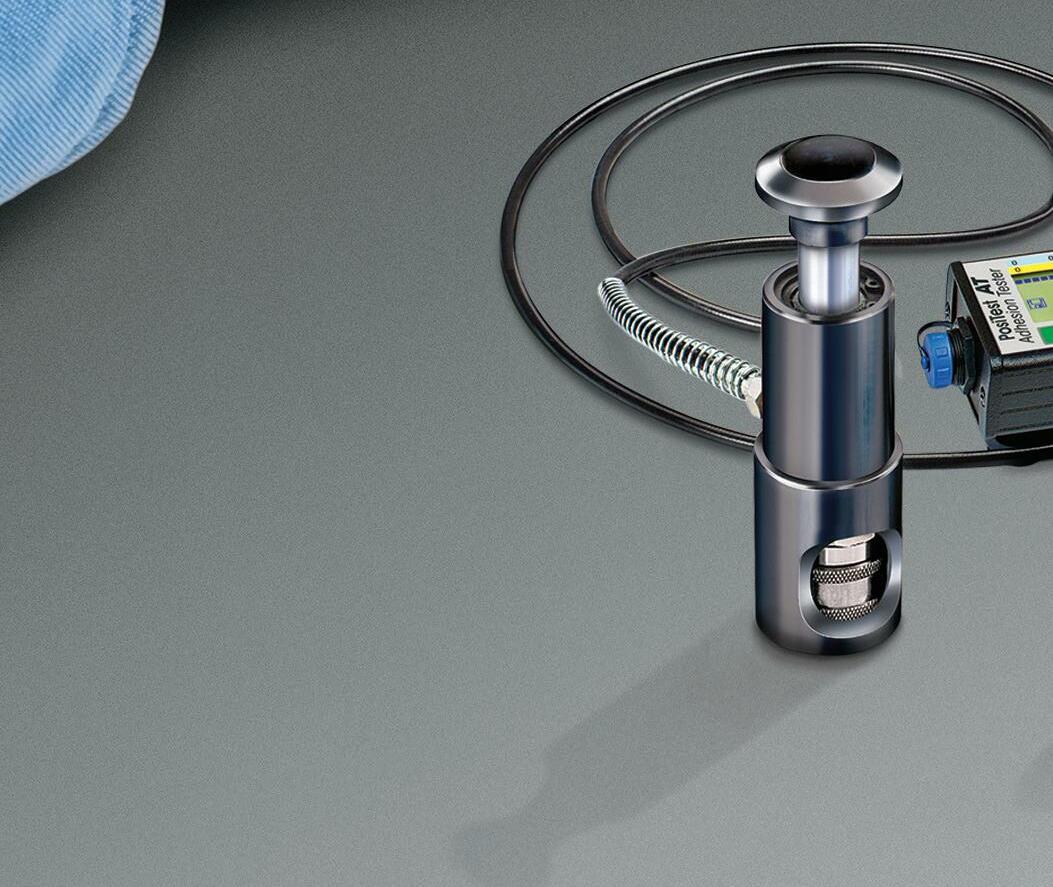

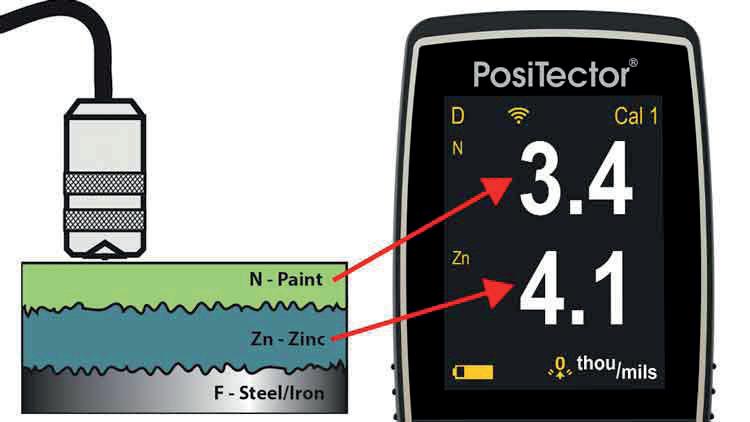

DUPLEX COATING SYSTEM THICKNESS MEASUREMENT WITH THE POSITECTOR FNDS FROM DFT INSTRUMENTS UK LTD. 62

THE WEAKEST LINK - THE HUMAN HAND. 66 CONSISTENT AND EFFICIENT REMOVAL OF SUPPORT STRUCTURES WITH AN AUTOMATED PROCESS. 68 COLOURS 2022. 70 CLARIANT'S NEW CLARICOAT. 71

MATERIAL & EQUIPMENT SUPPLIERS 73

TRADE FINISHERS 80

1 NOVEMBER 2022 CONTENTS

NOVEMBER 2022 - VOLUME 29 - NUMBER 11 twitter: @surfaceworldmag Specify QUALICOAT for all your architectural aluminium powder coating requirements qualicoatuki.org

Scan & Spray

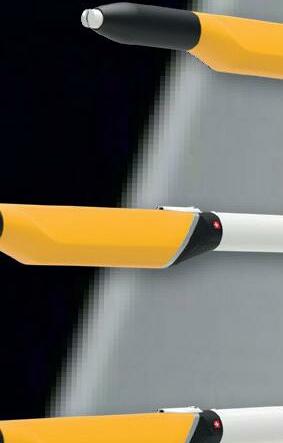

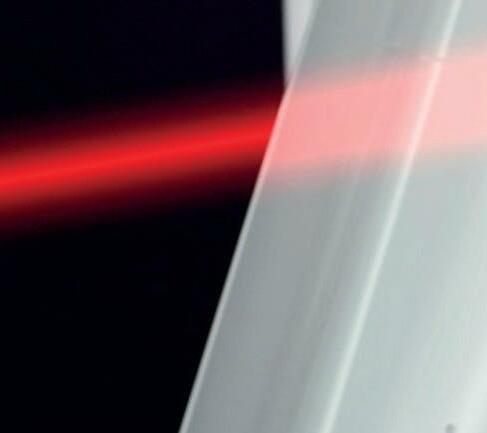

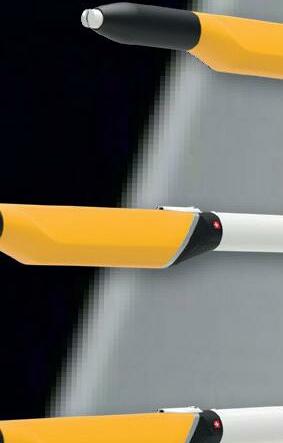

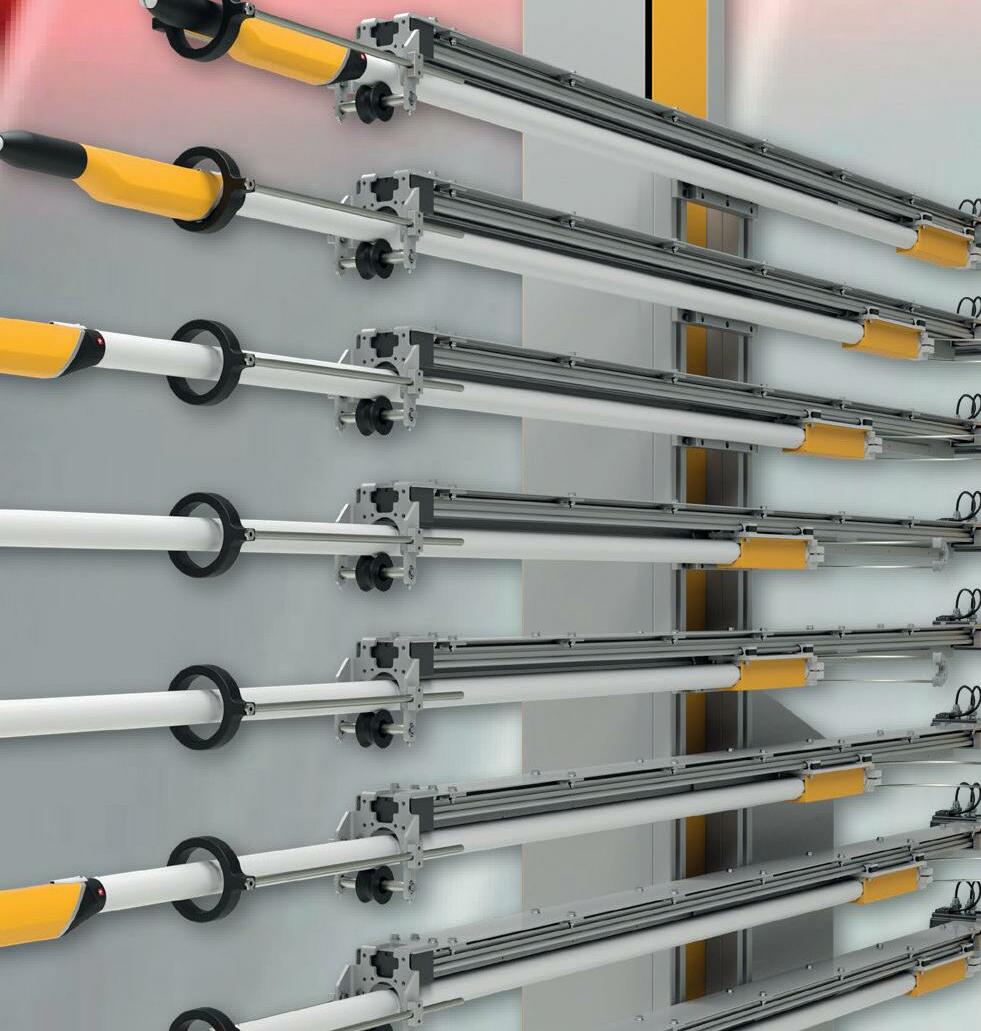

The second generation of Dynamic Contour Detection detects the object contour fully automatic and positions the guns individually even for thin objects and at high conveyor speeds. Due to the programming-free adaption of all relevant line settings the application range is significantly extended.

Gema Europe Srl – UK Branch

Tel: 0044 1202 763 942 Email: uk.sales@gema.eu.com

of any

Dynamic Contour Detection Programming-free coating

shape!

gemapowdercoating.com

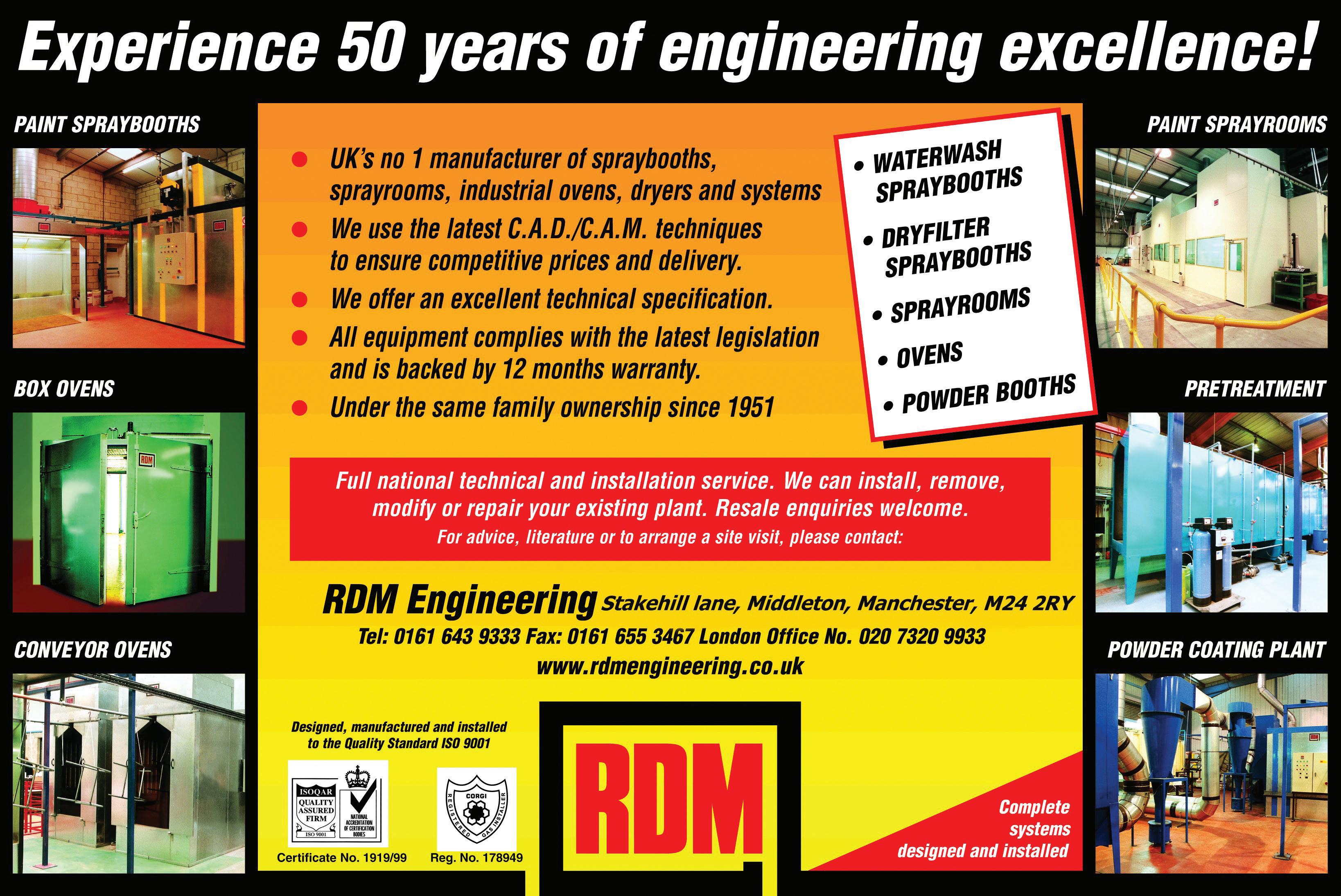

Investing to Meet Post-Covid Demand

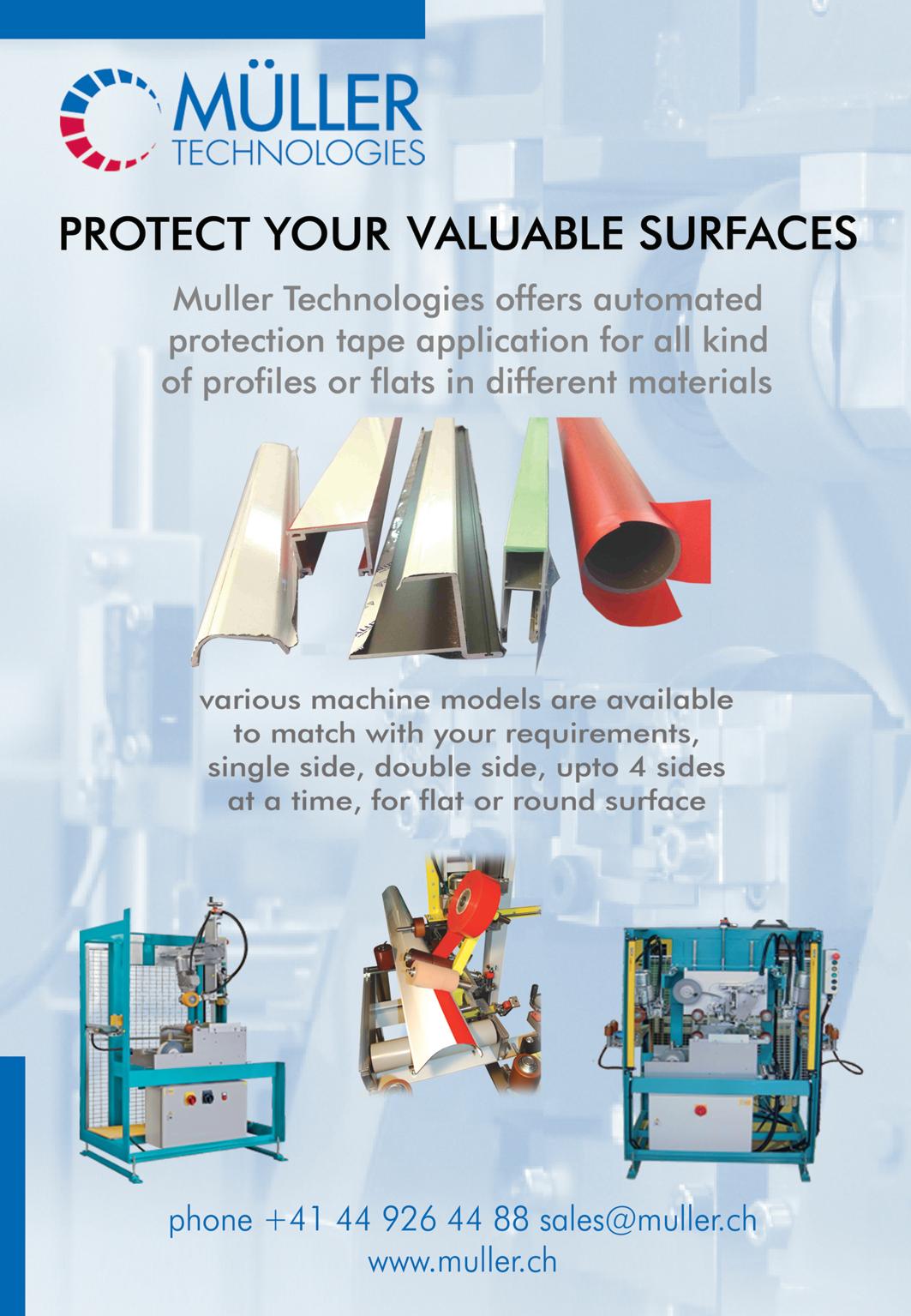

North East based engineering company Hydram, a leading specialist in precision sheet metal fabrications, has recently completed a significant programme of investments in an attempt to satisfy increasing demand from its customers.

Hydram’s customers cover a broad range of industries, and almost without exception, there has been a significant surge in requirements since the lifting of Covid restrictions. Meeting increasing demand presents challenges at the best of times, and currently, those challenges have multiplied and intensified, with both constrained labour and spiralling energy markets conspiring to make the task particularly difficult throughout the supply chain. Responsibility for overcoming market challenges and navigating through the current headwinds lies with Hydram’s Operations Director, Stephen Beacham.

Increasing the Tempo

“Over 45 years Hydram has always maintained a steady rhythm of investment and renewal to ensure we remain competitive and have capacity to grow with our customers,” says Stephen, “although there are times when you have to increase the tempo and do something exceptional to make the difference.” The difference in this case was a huge increase in the company’s powder coating and finishing capacity.

Hydram’s extensive capabilities range from laser cutting and punch profiling through to forming, welding, coating (both wet and powder painting) and assembly. “Analysis proved that our most significant bottleneck was in painting, which is an area where floorspace and energy use are significant constraints,” Stephen explains, “which together made this a significant project to undertake, entailing a great deal of planning and preparation, and two new paint plants, a batch line and a volume production line, with a budget of over £1.2M.”

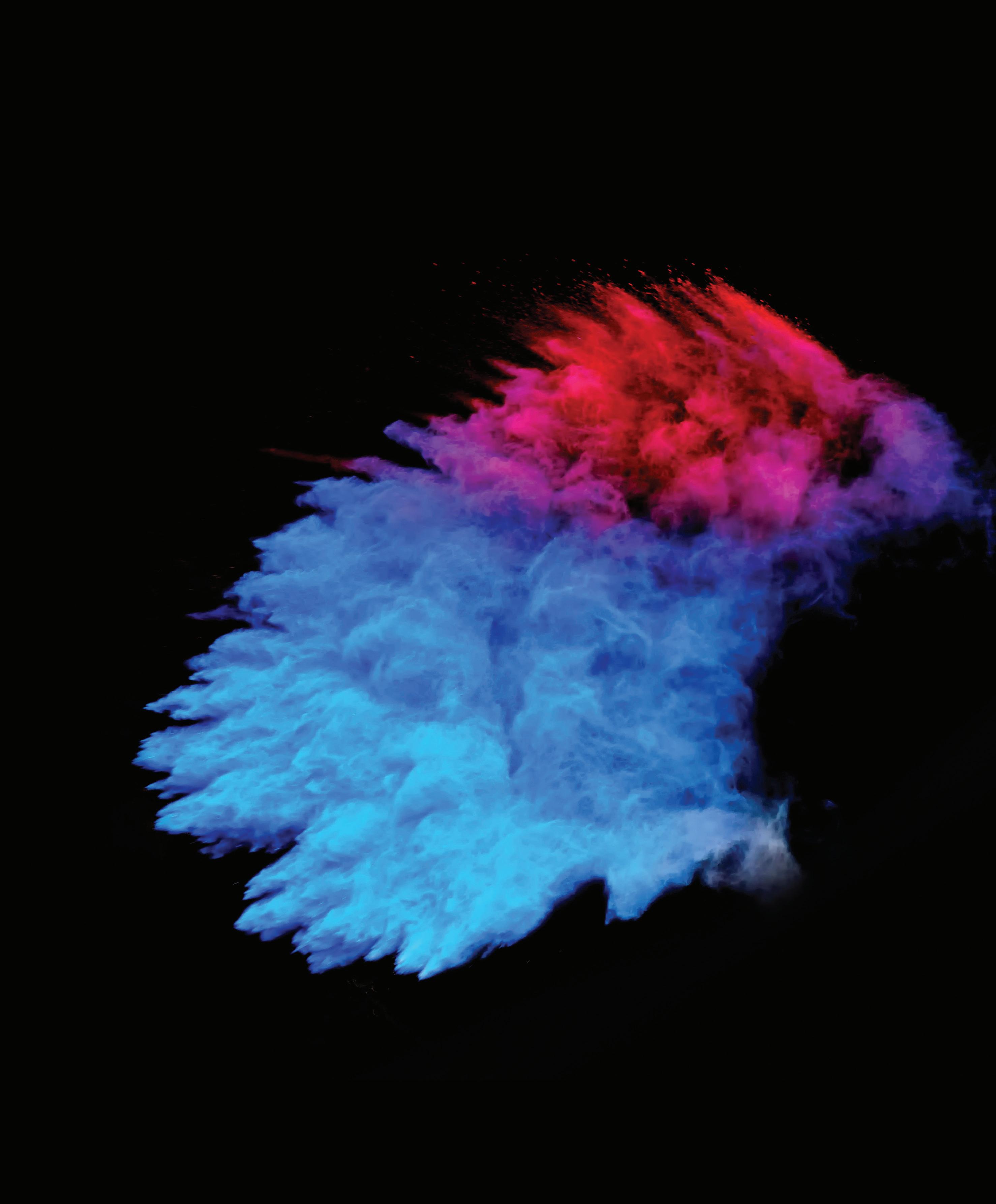

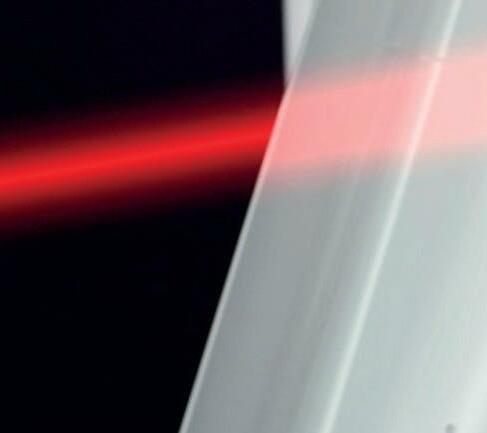

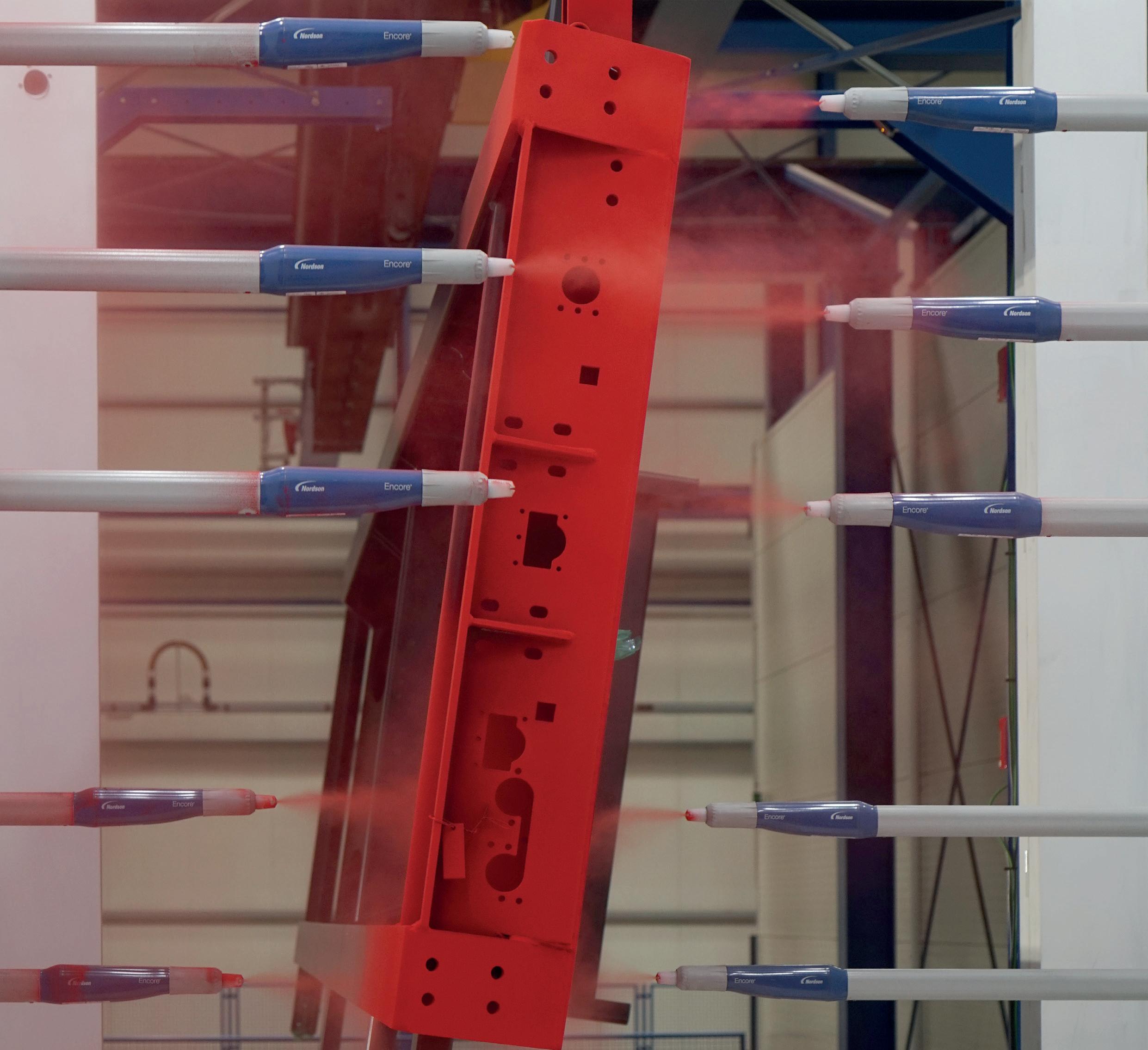

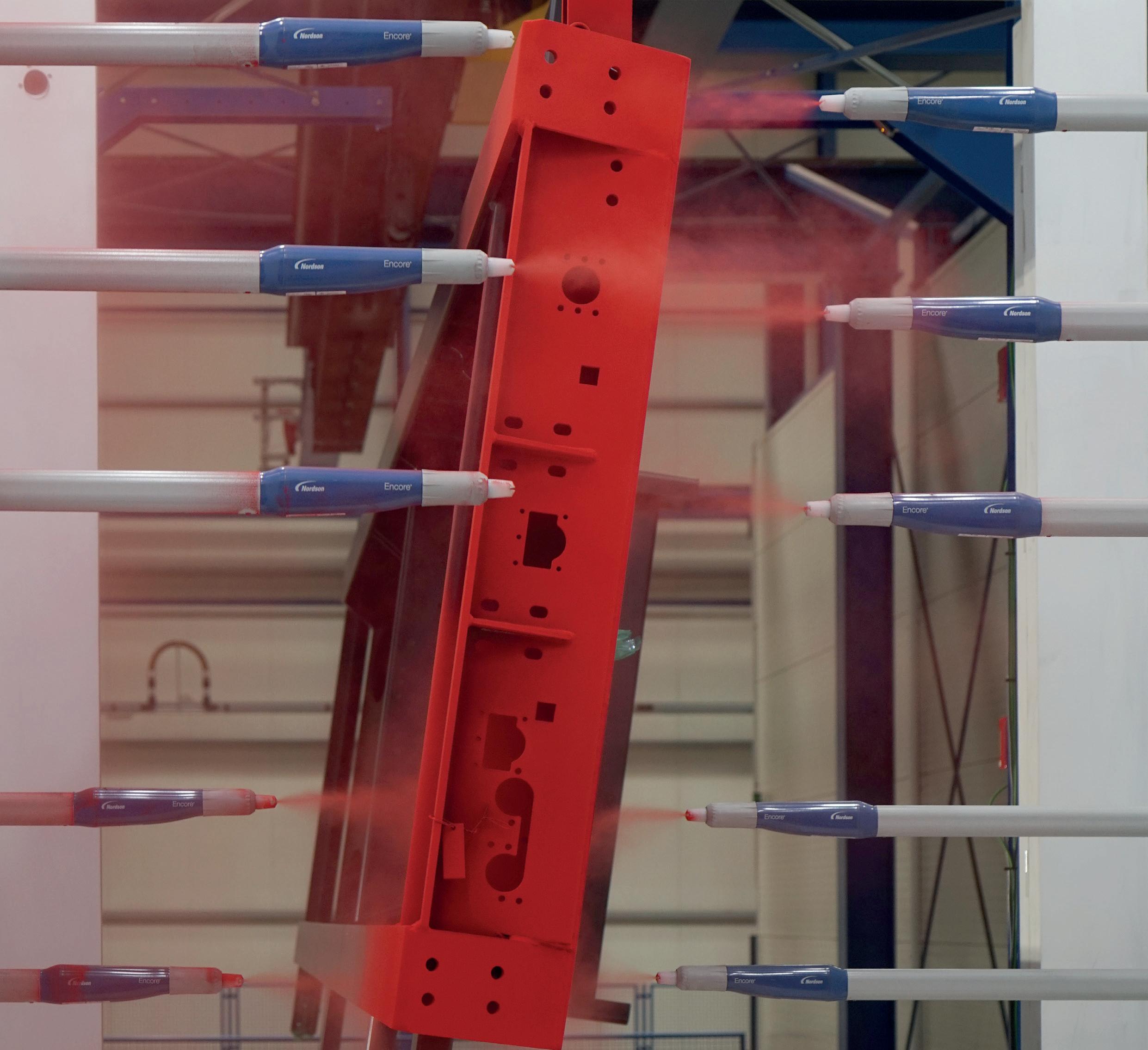

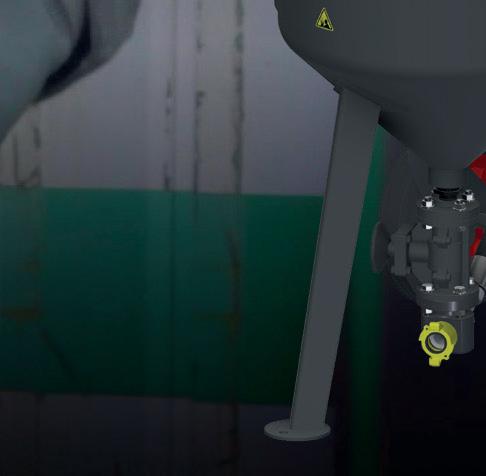

Increased Automation

A bespoke-designed batch line allows Hydram to optimise the low volume, highly variable parts with great flexibility in a compact footprint. The second line is a large, highly automated conveyorized line installed over a 6-week period. The plant has a 145m overhead conveyor capable of processing a full range of components, from flat parts to complex geometries, with high throughput capability. Pre-treatment is handled by a 20m-long five-stage plant with eco-friendly nano-ceramic multi-metal pre-treatment solution, coupled with a 15m-long dry-off oven. The automated process is supported by a fast colour change booth, provided by market leader Gema Europe (pictured above). The booth selected is the MagicCompact system with 2nd generation dynamic contouring guns, high efficiency powder reclamation and the recently launched GemaConnect cloudbased monitoring system. A 38m-long curing oven completes the plant and it is fitted with heat-recovery equipment.

Neil Snowdon, Production Manager at Hydram went on to explain “When selecting the suppliers for our new powder coating system, we carried out a detailed market study with visits to several manufacturing sites across the UK. In relation to the powder booth, with the new innovations from Gema,

4 NOVEMBER 2022

COMPANY SPOTLIGHT www.surfaceworld.com

it was clear that these new to market technologies would move our capabilities to a new level. The benefits of the dynamic contouring application guns that track the product geometries in real time are clear (pictured left). This revolutionises the level of automation and, combined with the SIT dense phase pumps, the powder coverage and consistency of application is on a new level. The booth is extremely quiet and offers a clean working environment with reduced carbon footprint thanks to its compressed air and energy optimisation systems.”

“The new conveyor plant was commissioned in July and it sits next to our two other conveyor plants,” Stephen says. “It has a higher throughput than our oldest plant, has more automation, a powder reclaim unit –which reduces the amount of powder wasted. Overall, we have increased capacity by more than 50%, with the benefits of reduced labour requirements and increased energy efficiency, which are our two other constraints.” Now, with three conveyor paint plants for powder coating and a separate batch plant for wet and powder coating, Hydram has impressive capacity for metal coating and can rightly claim to offer a complete manufacturing solution.

Maintaining the Rhythm

With the bottleneck in painting alleviated thanks to the £1.2M budget, the underlying rhythm of investment involved in maintaining Hydram’s capacity continued to be addressed in other processing areas in the factory.

Stephen concludes, “Our business is built on customer satisfaction – and maintaining a high level of service in the current climate is challenging for all businesses in this sector. We can prove that Hydram is working exceptionally hard and investing significant sums to continue meeting demand.”

Leon Hogg, Gema UK’s General Manager explained ‘It was clear during the evaluation stages that the team at Hydram were keen to invest in the very latest innovations that deliver quality and performance benefits to existing and future customers.

With the high demand for quality, repeatability and efficiency we quickly arrived at the Magic Compact fast colour change booth complete with contouring, a system that provided the perfect strategic fit when it comes to matching the level of performance and efficiency Neil Snowdon and his team

were looking for. This investment in the very latest technology puts Hydram at the forefront of premium finished products.

For more information on Gema UK’s Powder Coating solutions please visit www.gemapowdercoating.com or email uk.sales@gema.eu.com

4th & 5th October 2023,

5 NOVEMBER 2022 twitter: @surfaceworldmag

If you are interested in booking a stand call Nigel Bean on 01442 826826 or send an email to nigelbean1@aol.com

NEC, Birmingham

COMPANY SPOTLIGHT

QUALICOAT Autumn Members Meeting

By Angus Mackie - QUALICOAT UK & Ireland Chair

Members met at the Arden Hotel, Solihull for their Autumn meeting with most members opting to meet in person and several joining remotely. The format of the ‘hybrid’ meeting is proving to be very successful and gives more members the opportunity to attend meetings of the Association and partake in the updating of the QUALICOAT specification.

With regard to executive posts, the Association is pleased to announce that Chris Mansfield of Tomburn has stood and been voted in to be Vice-Chair of the Association. Chris is in regular attendance at the Member’s meetings and as an active contributor brings a wealth of experience to the Chair. Chris will be taking up the position in 2023.

Despite the economic outlook, Members reported that business remains healthy despite rising costs of materials and energy. Growth of the Association also continues with three new licences being granted in October, one further new member expected to gain their licence before the end of the year and a further three applicators progressing through

inspections. These initial inspections, undertaken by independent test house IFO, review both plant and processes to ensure that an applicator member can operate within the QUALICOAT Specification. Often a new applicator’s initial inspection will consist of a long list of non-conformities after their first inspection, this could include the need to upgrade equipment as well as introducing new processes. Working with the applicator, IFO will help guide new working practices to ensure the applicator can maintain the high specification laid down by QUALICOAT. Following further unannounced inspections, when the applicator can demonstrate full conformity, only then will a licence be awarded. It can take up to a year to become a licensed QUALICOAT Applicator, once approved current licence holders can be found on the associations website.

All licensed applicator members are then inspected twice yearly by IFO, through an unannounced visit, to ensure they continue to conform to the up to date QUALICOAT Specification. A further requirement is that all applicator members must send their laboratory technicians on a technical training day once every two years. This year the training was held at pretreatment system Member, Chemetall in Milton Keynes on the 8th November.

One of the Associations missions is to continually improve the quality of the final

coatings. In mid-October all the independent test houses who inspect members of the Association across the globe met in Spain to review feedback from inspections and put forward suggestions for further improvement in the specification. Of the points raised, two of the recommendations to be introduced in 2023 are as follows:

It has been the case that whilst all production lines are inspected on an unannounced visit, the member is then awarded an up to date single paper licence to show company compliance. In future each coating line will be issued a separate certificate and should the Applicator carry additional qualifications, such as ‘Seaside’ approval, these will also be issued separately.

For Applicators who wish to supply preanodised and powder coated finishes, QUALICOAT are now approving finishing between two plants in different locations as long as the process completes within a 72 hour period. Suitable pretreatment plants are expensive investments for an applicator, anodising plants are far more expensive, so very few powder coaters have the ability to utilise pre-anodising as a pretreatment prior to powder coating. Allowing pre-anodising to be conducted off site for an applicator will allow for a wider supply of pre-anodised powder coated profiles to specifiers.

Finally, it was reported that chrome-based pretreatments, which are still used by some

6 NOVEMBER 2022 QUALICOAT UK & IRELAND

CONTINUED ON PAGE 8 twitter: @surfaceworldmag

Halve your DFT inspection times using the Elcometer 456 Coating Thickness Gauge and Scan Probe. elcometer.com THICKNESSMeasure · FAST · REPEATABLE · ACCURATE · DURABLE DRY FILM Surface World - October 2022.indd 1 25/10/2022 12:08:41 WE’RE OBSESSED WITH COLOR YEARS OF EXPERIENCE IN RESEARCH & DEVELOPMENT OF CUSTOMIZED INDUSTRIAL COATINGS brands of The Sherwin-Williams Company A complete range of industrial coatings Waterborne | Powder | Solventborne | High solid | E-coat The Sherwin-Williams Company, Goodlass Road, Speke, Liverpool, L24 9HJ, United Kingdom | T: +44 (0)151 486 0486 | e-mail: liverpool.sales@sherwin.com

members, will receive a full ban, when used as a powder coat pretreatment. The European ban will come into effect in September 2024 and it is very likely that the UK will follow this lead. Since chrome-based pretreatments were identified as a potential carcinogenic, the industry has devised various chrome-free systems which have been demonstrated to be as substantial as their chrome based counterparts. Most of these systems are QUALICOAT approved.

The worldwide QUALICOAT Specification is continually and incrementally revised in real time with regular update sheets, the specification is completely rewritten at year end to include all updates. The Specification, its appendices and any update sheets are always freely available for download at www.qualicoat.net. For details on the availability of various colours and finishes contact any QUALICOAT UK & Ireland member for more information. For updated

information about the use and specification of QUALICOAT in the UK and Ireland, please visit the UK & Ireland Association new website at www.qualicoatuki.org.

UK & IRELAND Call Nigel Bean for more information on +44 (0) 1442 826826

QUALICOAT

Proud supplier of DeFelsko Inspection Instruments DFT Instruments UK LTD 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk PosiTector ® Inspection Unrivaled probe interchangeability for all of your inspection needs. Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012. Customized Inspection Kits... Build your own kit from a selection of gauge bodies and probes to suit your needs. Coating Thickness Surface Profile Environmental Conditions Ultrasonic Wall Thickness HardnessSalt Contamination Coating Thickness Probes n Ferrous n Non-Ferrous n Combination n Ultrasonic Surface Profile Probes n Depth Micrometer n Replica Tape Reader Environmental Conditions Probes n Integral n Cabled Magnetic Probe n Anemometer Probe n 1/2” NPT n Infrared Hardness Probes n Shore n Barcol Salt Contamination Probe n Bresle Method Ultrasonic Wall Thickness Probes n Corrosion n Multiple Echo Thru-Paint n Precision n Low Frequency n Xtreme NEW DesignandFeatures Proud supplier of DeFelsko Inspection Instruments DFT Instruments UK LTD 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk NEW DesignandFeatures

GA names industry expert, David Watkins, Chairman of the Board

With nearly four decades of galvanizing industry experience, Galvanizers Association decides David Watkins, the current Managing Director of Hereford Galvanizers, has the vision to lead their membership through the current economic environment and help position galvanized steel as a core material within circular construction. The new Chairman is also CEO of Zinco International, a global leader in technical services and products to the galvanizing industry.

Galvanizers Association, the representational body of the hot dip galvanizing industry in the UK and Ireland, announced recently that David Watkins will replace Ed Byrne, MD Galco Steel, as Chairman of the Board. Mr Watkins began working for Hereford Galvanizers in 1986 and after a variety of roles in galvanizing Sales, Marketing and Operations, he became Managing Director in 2005. He takes up his position with GA as the industry faces difficult decisions around energy, inflation, and rising costs.

Speaking recently Mr. Watkins said: “I am honoured to become chairman of our trade body and would like to give credit to the former chair for six years of hard work, helping the industry through Brexit and multiple Covid lockdowns. The challenges facing me today are somewhat different but by no means less, as we continue operating at a time of high inflation and amid unprecedented concerns around rising energy costs. I see my role very much being to support the membership through this period and promote the valuable role of hot dip galvanizing wherever possible.”

Based in the heart of the UK, Galvanizers Association has provided free authoritative information and advice on hot dip galvanizing to users and the specifican supply chain since it was first established in 1949.

Over 95% of all steel galvanized in the UK and Ireland is processed by members of the Galvanizers Association, whilst the Association itself fields a technical team of chemists, engineers, and metallurgists who advise on legislation, standards and specification.

William Smith, (Executive) Director of Galvanizers Association adds: “We are very pleased to be working with David to highlight the significant contribution that hot dip galvanized steel makes to the built environment throughout UK and Irish infrastructure.

He has a wealth of knowledge about the role galvanizing can play in helping the construction sector transition to net zero, and is excellently placed to help our members navigate the challenges presented by the current and emerging operating environment.”

For further information visit www.galvanizing.org.uk or call +44 (0) 121 355 8838.

Please check us out on our social channels too:

@Galvanize_it facebook.com/galvanizing linkedin.com/company/galvanizers-association

10 NOVEMBER 2022 GALVANIZERS ASSOCIATION

www.surfaceworld.com

6 K-type thermocouple ports High temperature stainless steel barrier box for long run times Download, view, and analyze data using PosiSoft Desktop Software or export to .CSV Oven Temperature Logger Measures and records oven temperature profiles 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk Customizable PDF Reports Prices starting at: Oven Temperature Logger .......... £1895 Temperature Probes ............ £100 Wide variety of spring clamp and magnetic temperature probes available NEW

“The Professionals” email info@pros trip.co.uk phone 01 1 5 91 1 2240 “Save up to 20% on your monthly s tripping cos ts” Send your enquir y today!! Sub contract specialists in Paint & Powder coat removal to the finishing industr y JIG CLEANING PAINT BOOTH GRID CLEANING COMPONENT RECLAMATION EST . 1989 Pro-Strip Ltd. Trent Lane, Daleside Road, Nottingham NG2 4DS web www.prostrip.co.uk

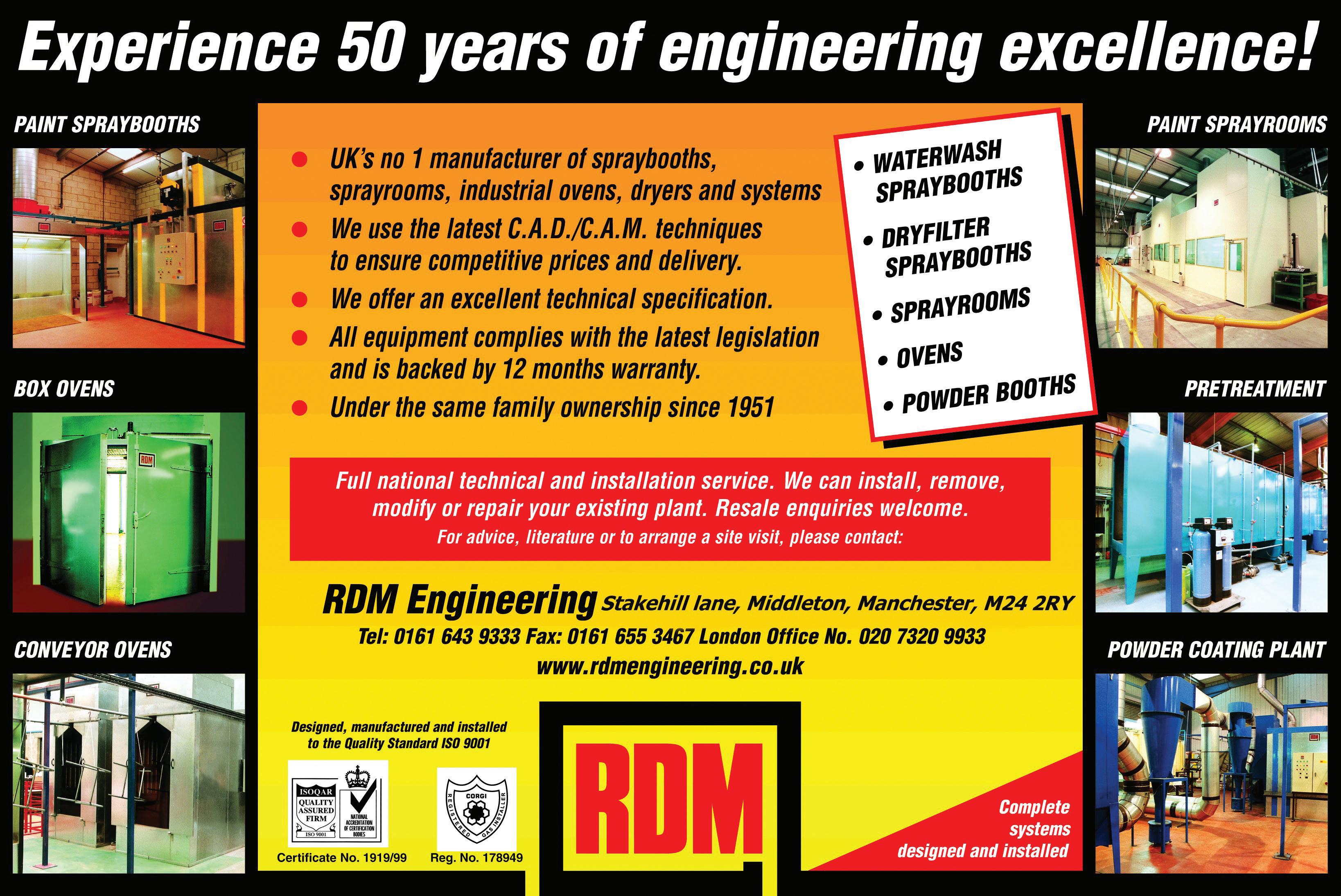

Surface World 2023 - bringing over 20 years of service to your industry

Trade shows, exhibitions and other events can be an excellent way to showcase your products and services. They give you the opportunity to increase awareness of your business, launch new products and services, network with industry members, explore partnership opportunities, see what competitors are offering, generate new business leads, attract and convert customers.

What is a Trade Show?

A trade show is a platform where businesses (exhibitors), professionals and business representatives (visitors) come together under one roof to exchange knowledge and make connections with other like-minded professionals.

Exhibitors book a stand and use this space to connect and engage with visitors to the event. Ideally, the event is used to generate leads, network, promote products and services, and hopefully close a few sales in an organic setting that’s tailored to them and their audience.

How can you benefit from exhibiting at a Trade Show?

There are many reasons why you would choose to exhibit at a trade show, which include:

Make sales – the golden ticket to trade show success, hitting a quota or making direct sales is the ultimate definition of winning.

Capture leads – without leads salespeople have nobody to convert, so generating enough leads for your marketing funnel is a must.

Analysing the competition – what technology are they using, what marketing angle are they taking? It’s good to know what the competition is up to.

Engage with existing customers – existing customers are more likely to invest in new products and services, so you can keep building relations and offering them more benefits.

Introduce new products/services – new and old customers could benefit from your new product.

Account-based marketing – go into a trade show with an idea of who you’d like to speak with, so you can create a strategy that’s more likely to convert them.

Gather feedback – feedback is how you improve services and sales and marketing; you

could receive advice that revolutionises how you do things.

Spot trends – spotting trends is vital if you want to stay relevant or avoid something that’s a flash in the pan.

What should you look at when selecting a trade show?

The best success can be gained from participating at an event that has a wellestablished history. These events usually draw the best reward. The event organiser should have proven methods in place to market the event to the right audience. They will have a database they have accrued over many years of business. The venue should be easily accessed by road or public transport and have plenty of parking. A venue with excellent nearby facilities, hotels, restaurants, entertainment, can also be a bonus if the event is held over more than one day.

Can You Make Money at a Trade Show?

Keeping costs down is a benefit when deciding which trade show to exhibit at. Smaller shows tend to be cheaper, so choosing an event that is aimed at your target audience is the key to a successful outcome from exhibiting.

Here are some ways you can get a healthy ROI from a trade show, including:

Only buy the space you need – the area you buy takes up a significant amount of your budget, so overdoing it can waste money, which is going to eat into your sales.

Get an enticing exhibition stand – you can have a tiny space and still attract people

14 NOVEMBER 2022

SURFACE WORLD 2023

www.surfaceworld.com

if your stand is attractive, making your area presentable promotes credibility.

Organisation is key – there’s a temptation to blindly hand out literature and marketing collateral, putting it at the back of your space makes reps think about engaging first, which is more likely to generate a lead or a sale.

Use tech where it’s useful – the whole purpose of a trade show is to generate business through face-to-face marketing, so don’t dehumanise the event by using too much technology.

Pick the right team – there’s no point in attending an event if you pick the wrong staff. Ideally, it would benefit you if you had people who understand and empathise with customer challenges, but also know when to close deals.

Work the aisles – do not limit yourself to the boundary of your stand, you can reach out to passers-by and engage in the aisle.

Tell people you’re exhibiting – use as many marketing techniques as you can to create a build-up to the event and get people excited. Utilise all marketing opportunities the event itself offer, these are generally targeted directly at your required audience.

What Do You Need for a Trade Show?

The last thing you want to do is under prepare. Get the following ticked off before you get to your event:

Event space – the first thing you need is event space, you’ll have a shock if you turn up and there’s nowhere for you to pitch!

Stand with supporting collateral – your stand and marketing collateral are what

attract people to your stand.

Travel plans – train, bus, plane, car? It would help if you had robust plans in place before you depart.

Accommodation – if you’re planning on staying over, which you may want to as events are long, tiring days, reserve in advance as hotels may get booked up prior to the event.

Marketing collateral – brochures, leaflets, business cards; get all the material you need and ensure you get plenty. You don’t want to run out.

Staff – ask your staff well before the event to ensure they are available to attend, cancelling holidays will not be seen as favourable to you! Remember your staff are the face of the business at the event, get them prepared.

Could You See Success at a Trade Show?

Trade shows aren’t an antiquated form of marketing and sales – they’re proven to generate targeted, high-quality leads and sales. Not every business can benefit from attending trade shows, but they’re certainly worth exploring. Just like trade shows give you the opportunity to better connect with prospective customers, exhibiting at a trade show also allows you to meet existing customers face-to-face. While most of today’s business is conducted over email or phone, face-to-face meetings are undeniably a fantastic way to do business.

The Wall Street Journal agrees. Citing a study by Oxford Economics, the well-known financial publication reports that face-to-face meetings are the most effective way to

strengthen relationships with both prospective customers and current customers.

Trade shows help bring all the different aspects of an industry together – consumers, distributors, suppliers and manufacturers, all in one place. With such a broad audience together in one place, businesses are able to schedule meetings, negotiate orders and other opportunities and collaborate on other projects. Trade shows allow businesses to facilitate discussions with their suppliers and even with other businesses, as well as move projects to another level if the opportunity arises.

Surface World 2023 is a well established trade event, with over 20 years of experience, specifically tailored to the Surface Finishing Industry.

If you are interested in exhibiting or visiting this event, please contact Nigel Bean at:

Telephone: +44 (0) 1442 826826 Email: nigelbean1@aol.com

Surface World – Connecting The Industry

15 NOVEMBER 2022

SURFACE WORLD 2023 twitter: @surfaceworldmag

New

Licence Granted

By Angus Mackie - QUALICOAT UK & Ireland Chair

Following QUALICOAT’s recent announcement that three new powder coating companies had completed inspections and been awarded licences from QUALICOAT, this month sees a further new coating company joining the association with the granting of licence approval.

Architectural Powder Coatings, (APC) based in Blaydon, Newcastle-uponTyne is a privately owned company specialising in the powder coating of all architectural aluminium components and systems.

Craig Johnson, Director of APC comments: ’At APC we have always strived to offer the best quality and service within the industry. Gaining our QUALICOAT licence gives our customers, and in turn their customers, piece of mind that the finished product will always

be of the highest possible standard. Going forward this enables APC to carry on working with some of the best fabricators in the country, on some of the most prestigious buildings in the UK.’

QUALICOAT welcomes APC into membership of the association alongside a growing number of powder coating applicators who wish to take advantage of the increasing level of specification among architects and specifiers for QUALICOAT approved finishes. A QUALICOAT specification, whilst encompassing the BS EN 12206 standard, ensures that coating applicators are independently third party inspected by IFO at regular intervals to ensure consistency of quality meeting the QUALICOAT specification. A BS EN 12206 specification alone does not incorporate such accreditation.

The QUALICOAT Specification is continually and incrementally revised in real time with regular update sheets, the specification is

completely rewritten at year end to include all updates. The global Specification, its appendices and any update sheets are always freely available for download at www.qualicoat.net. For details on the availability of various colours and finishes contact any QUALICOAT UK & Ireland member for more information. For updated information about the use and specification of QUALICOAT in the UK and Ireland, please visit the UK & Ireland Association website at www.qualicoatuki.org.

QUALICOAT

INDUSTRY NEWS elcometer.com Measure four Bresle equivalent readings, in less than three minutes , with the Elcometer 130 SSP Soluble Salt Profiler. CLEANLINESS Elcometer3045 Measure · FAST · REPEATABLE · ACCURATE · DURABLE SURFACE Surface World - October 2022.indd 2 25/10/2022 12:11:55

Hadleigh Enterprises Limited Unit 11, Buckingham Square Hurricane Way, Wickford Essex, SS11 8YQ Tel: 01268 572255 Fax: 01268 572121 Email: sales@hadleightapes.co.uk Web: www.hadleigh-tapes.co.uk Certificate No. FM10409 • AS9100 APPROVED • NO MINIMUM ORDER QUANTITY • ALL PRODUCTS FOR ALL PURPOSES • 48 HOUR DELIVERY SERVICE The Adhesive Tape Specialists

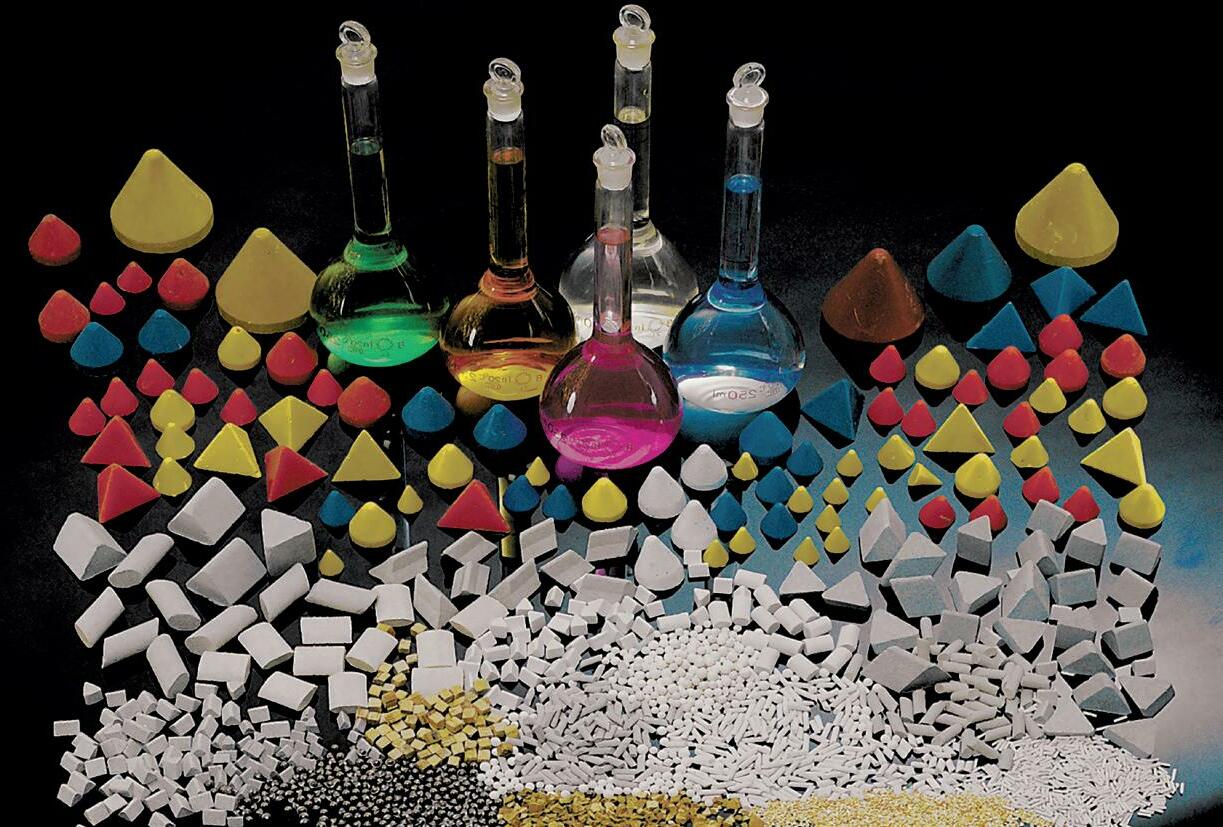

BASF launches Chemetall Innovation and Technology Center for surface treatment solutions in China

BASF’s first regional center for applied surface treatment technology in Asia Pacific

Advanced facility and dedicated expertise will address Asia’s growing demands for customized surface treatment innovations and solutions

The Surface Treatment global business unit of BASF’s Coatings division, operating under the Chemetall brand, opened its first regional innovation and technology center for applied surface treatment technology in Shanghai, China. The new 2,600 square meter center will focus on developing advanced surface treatment solutions and product innovations for a wide range of industries and market segments in Asia, for Asia.

“The opening of this Innovation and Technology Center is an important pillar of our growth strategy and strengthens our technical and innovation capabilities in Asia Pacific. It shows our commitment to further contribute to and support the long-term success of our customers in the fastestgrowing region,” said Christophe Cazabeau, Senior Vice President, Surface Treatment, Coatings Division, BASF.

“Innovation is key to powering growth for BASF. This new center’s ability to develop customized surface treatment solutions closer to the market will further underpin our technology leadership and our customers’ success,” said Dr. Jeffrey Lou, President and Chairman, BASF Greater China.

Equipped with multiple technical capabilities and operated by a highly experienced technology team, the new laboratories can provide a comprehensive range of tests and services including analytical, application, salt spray and climate testing as well as development work on a range of applied surface treatment technologies and applications for various market segments including but not limited to automotive OEM and components, coil, general industry, cold forming, aerospace, aluminum finishing and glass.

“Our regional innovation and technology center will help to accelerate our speed-to-

market of cuttingedge surface treatment solutions, drive customercentric product development and expand our innovation pipeline.

As an integrated technical hub, it can harness the synergies and competencies within our existing global network, as well as our local surface treatment analytical labs in Australia, China, India, Japan, New Zealand, Singapore and Thailand, to better serve the rising market demand for innovative and sustainable solutions in Asia,” said Dr. Mubarik Chowdhry, Head of Global Technology, Surface Treatment, Coatings Division, BASF.

The center also runs various state-of-the-art simulation lines for pre-treatment and coating processes including VIANT, a novel coating technology for corrosion protection.

For more details of the center, please refer to the introductory video: https://youtu.be/jOVGLaKbmBk

About BASF’s Coatings division

The Coatings division of BASF is a global expert in the development, production and marketing of innovative and sustainable automotive OEM and refinish coatings, decorative paints as well as applied surface treatments for metal, plastic and glass substrates in a wide range of industries. This portfolio is supplemented by "Beyond Paint Solutions", which enable new applications with innovative surfaces. We create advanced performance solutions and drive performance, design and new applications to meet our partners’ needs all over the world. BASF shares skills, knowledge and resources of interdisciplinary and global teams for the benefit of customers by operating a collaborative network of sites in Europe,

North America, South America and Asia Pacific. In 2021, the Coatings division achieved global sales of about €3.44 billion. Solutions beyond your imagination –Coatings by BASF. For more information about the Coatings division of BASF and its products, visit www.basf-coatings.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. Around 111,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio comprises six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €78.6 billion in 2021. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S.

Further information at www.basf.com

18 NOVEMBER 2022

Official ribbon-cutting ceremony at the launch of the Chemetall Innovation and Technology Center.

From left to right: Markus Wittig, Director, Global Supply Chain and Operations, Surface Treatment; Jin Hui, Managing Director, Shanghai Chemetall Chemicals Co., Ltd.; Dr. Jeffrey Lou, President and Chairman, BASF Greater China; Dr. Mubarik Chowdhry, Head of Global Technology, Surface Treatment; Dr. Han Wei, Vice President, Innovation Campus Asia Pacific; Lucia Königsmann, General Manager, BASF Shanghai Coatings Co., Ltd.

INDUSTRY NEWS twitter: @surfaceworldmag

The Chemetall Innovation and Technology Center is BASF’s first regional center for applied surface treatment technology in Shanghai, China.

Aluminium Anodizing

Chemetall’s Anodizing Technology. www.chemetall.com

HMG Paints recognised amongst Family Business Top 100

Family Business United recently released the first 50 individuals on the Family Business Top 100 list. Two of names listed are employees of 92-year-old business HMG Paints Ltd; John Falder, Chairman and Stephen ‘Paddy’ Dyson, Marketing Manager. The duo are recognised amongst other prominent leaders of family business such as John Thatcher of Thatchers Cider, Stephen Bagnall of Alfred Bagnall & Sons, Simon Brewer of Brewers Decorator Centre and Joyce Onuonga of John White & Son Ltd.

The inaugural Family Business Top 100, which showcases some of the best of family business individuals across the UK, was created by Family Business United this year to recognise these people, their efforts and collective importance to our national economy. “We wanted to do something special to celebrate ten years of Family Business United and what better way than to celebrate the individuals managing the businesses that are at the very heart of what

we do – championing family firms across the whole of the UK. Family businesses are the backbone of the UK economy and often the unsung heroes too. Family firms are significant contributors to the economy in terms of jobs provided, income generated, and wealth created and behind each family firm are individuals driving them, making decisions and looking to the future. Family firms take the long-term view and invest in their businesses and the communities in which they operate, and we wanted to create the Family Business Top 100 to recognise outstanding individuals within these organisations and to shine a light on the people that are making a difference within the business and more broadly too.” Said Paul Andrews, Founder of Family Business United.

HMG Paints are proud to have been recognised on the Top 100 list with John and Paddy both representing the business.

“It is an honour to be standing shoulder to shoulder with magnificent family business leaders on the Top 100 list. I’m very humbled to have been recognised for my time and achievements at HMG. Every step of my career has been a pleasure and I have been fortunate enough to work for a business that has encouraged my development and

engagement with other family businesses. There is no better culture than the one that family businesses create. Congratulations to the other worthy individuals on the list.” Commented Paddy Dyson.

Recently in 2021 HMG Paints Ltd were awarded the Essence of Family Business award by Family Business United “HMG Paints are truly great ambassadors of the family business sectors and in the eyes of the judges totally represent the essence of family business. They are worthy winners of this national award.” Said Paul Andrews.

Featured in the Family Business Top 100 list, John Falder has been in the paint industry and his family business, HMG Paints Ltd (formerly H. Marcel Guest) for almost his whole life. Venturing into the family business for the first time when he was about 7, accompanying his father, Brian and grandfather, Herbert Falder, founder of the business, John has never looked back.

“My very first job was sticking on labels, and packing tubes of adhesive this was fantastic, and a good Saturday morning which involved me earning some wages (2 shillings and 6 old pence to be exact), which were spent later in the day at a local toy shop.” said John in an interview.

20 NOVEMBER 2022 INDUSTRY NEWS

CONTINUED ON PAGE 22 www.surfaceworld.com

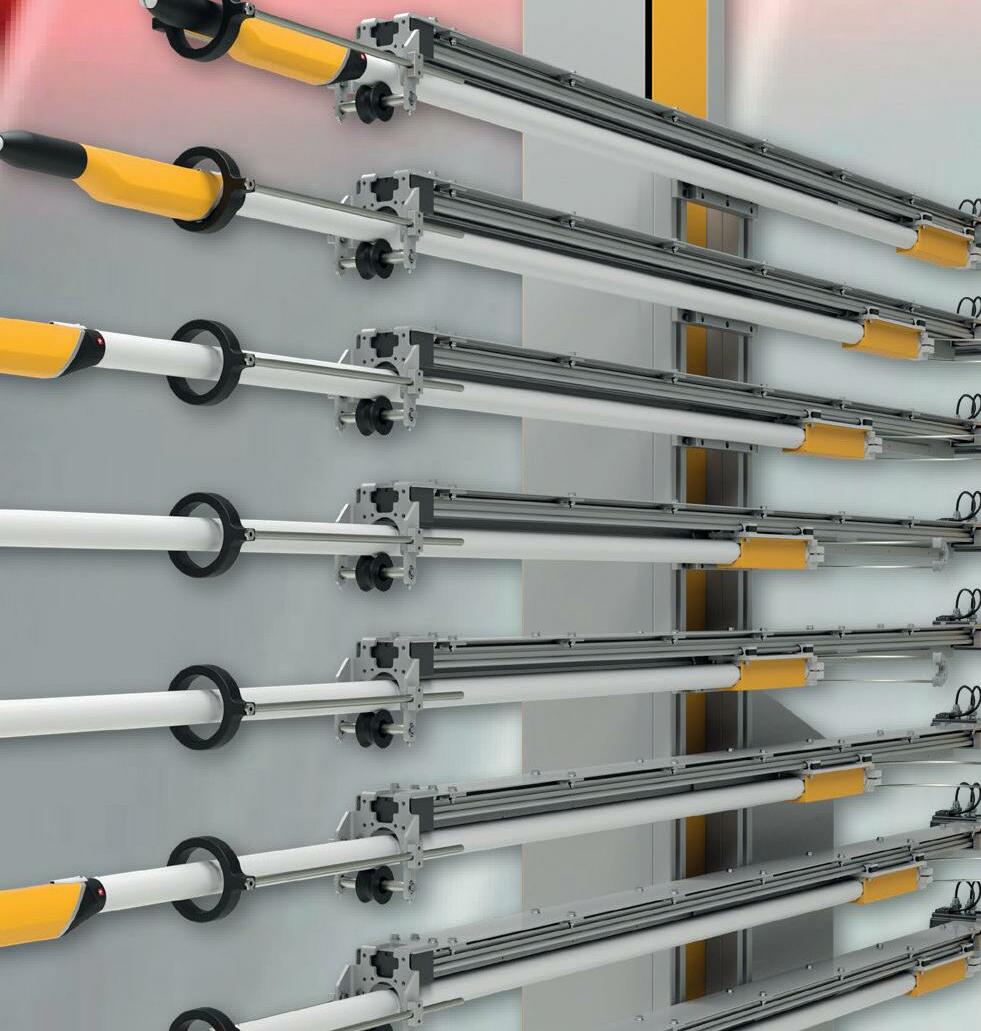

the crowd

Maximize the automatic coverage and save powder with Nordson Dynamic Contouring Movers. Combined with the soft spray of the Nordson HDLV® Technology, the Dynamic Contouring Movers System increases the automatic coverage of complex forms and achieves the highest process control in your powder coating application. Learn more about our superior spray systems online at www.nordson.com/hdlv or get in contact with us today ics.eu@nordson.com

MAKE YOUR POWDER COATING standing out from

INDUSTRY NEWS

After John graduated from Bangor University in chemistry and marine biology, he started his full-time career in HMG at 21 years old and remains a huge part of the business 46 years later, stepping down as Managing Director in 2021 and becoming Chairman.

In 2021 John Falder was awarded the paint industries highest honour with a lifetime achievement award from the British Coatings Federation. “John is a great example of someone that has dedicated his career to the family business and embraced each opportunity along the way. He thoroughly deserves recognition and his place in the Family Business Top 100” said Paul Andrews.

HMG Paints second recognition on the list is Stephen ‘Paddy’ Dyson who joined HMG Paints Ltd at just 18 years old (19 years ago) following in his father’s footsteps. Starting from humble beginnings in the label printing room, Paddy quickly became noticed by peers for his dedication & enthusiasm for the family business.

Paddy put himself forward for the new Marketing Manager position in 2008 and has since completely transformed the branding and marketing of HMG Paints with the family values at the core of everything that is done. Throughout his time in the business Paddy has also been an ambassador for HMG taking part in talks and judging panels for industry & family business events such as Family Business United.

In 2019 Paddy was a finalist for the Young Leader of the Year Award with the British Coatings Federation based on his achievements throughout his time at HMG. From creating internal engaging content for staff around the family values of the business to promoting them externally, Paddy has a skill set that is second to none and continues to go above and beyond for HMG and his peers.

“Paddy is an exceptional individual and totally committed to the family business in which he works, as well as the broader family business community and thoroughly deserves

recognition for all that he does and is a deserving recipient of a place in the Family Business Top 100.” Commented Paul Andrews.

The nominations for the Family Business Top 100 list were sought from all corners of the UK and all sectors of the economy. Entrants must have been working in a senior position within the business for at least five years.

If you require further information, please contact:

HMG Paints Communications

Telephone: 0161 205 7631 Email: sales@hmgpaint.com Visit: www.hmgpaint.com

22

NOVEMBER 2022

twitter: @surfaceworldmag

Solutions for Parts & Paint Spray gun cleaning WASHERS ASK FOR A FREE QUOTE Manual | Automatic Our high quality, advanced range of equipment provides the best way to clean paint spray guns or industrial parts. With numerous options, you can be sure that there is a model in our extensive range that meets your cleaning requirements using either solvents or water. ATEX certified • High quality alloy pumps Stainless steel construction • Wash cycle controlled by timer • Wash & rinse • Hot water wash • Inbuilt water recycling • Inbuilt solvent recycling Air extraction • 2 year warranty BUY OR LEASE www.solutex.co.uk info@solutex.co.uk | 01691 622 225 For more information visit: Head Office: Stafford Street, Willenhall, West Midlands, WV13 1RZ ISO 9001 Quality Management FM 00382 E: info@wggltd.co.uk T: 01902 601944 Hot dip galvanizing provides you with long-term protection against rust and corrosion of steel products.

structural

WEDGE GROUP GALVANIZING Your Galvanizing Partner

With 14 plants across the UK, Wedge Group Galvanizing is the UK’s largest hot dip galvanizing organisation offering a national service, collection and delivery and 24hr turnaround on request. The group can process anything from small components to 29m

beams.

How We Can Inspire Our New Generation Into Engineering

It’s no secret that the engineering sector is experiencing a shortage of workers. In fact, research shows that the industry will need to train and employ around 200,000 people by 2024 to fill the gap.

Here, we’ll explore how your business can inspire students and professionals to become the engineers of tomorrow.

Inspiring young people into engineering

First and foremost, your business can focus on encouraging young people into engineering, whether they’re secondaryschool leavers or graduates seeking roles within the industry.

Partnering with educational institutions

In order to do this, your business should consider partnering with educational institutions to inspire people before they enter higher education. One way you can do this is by offering career events in secondary schools. These events enlighten young people about the inner workings of the industry, such as using complex building design software that they would not have previously come into contact with.

As well as this, you can make graduate programmes available to those leaving university. Multiple institutions are willing to partner with reputable businesses, such as how Teesside University and ITS Ltd, a specialist automation systems developer, came together in an effort to tackle industry staff shortages within the North East of England.

Offering worthwhile apprenticeships

Your business can also offer engineering apprenticeships for school leavers. These can train people interested in an engineering career even if they don’t want to attend university. The benefits of these for students are endless, from being able to work alongside professionals within the engineering industry to prioritising 20% of their time to training and studying. Engineering apprenticeships, as well as other

industry placements, are also available to seasoned workers as long as they’re over the age of 16. This approach could be critical to rebuilding the workforce, especially considering that 71% of engineering employers who are experiencing difficulties filling employment positions claim the issue lies with a lack of engineering or technical skills in the talent pool.

Graduate schemes

As well as this, your business can offer graduate programmes. These are a great way to connect with emerging talent in the industry, especially while the engineering sector is experiencing a shortage of skilled workers.

Graduate programmes are beneficial for both employers and employees. It is an

24 NOVEMBER 2022 INDUSTRY NEWS

CONTINUED ON PAGE 26 www.surfaceworld.com

Detects holidays, pinholes, and other discontinuities using pulse DC High voltage Holiday Detector n Lightweight, ergonomic design reduces opera tor fa tigue n Regula ted pulse DC volta ge output ±5% accuracy n Industr y standard connectors and ada ptors for compa tibility with nearly all existing electrodes n Volta ge calcula tor fea ture choose one of 11 interna tional standards and input the coa ting thickness to automa tically calcula te the required test volta ge n Removable lithium ion ba tteries provide long lasting po wer Ch f ide us m SPECIAL DISCOUNTED RATE PosiTest HHD Basic Kit (HHDKITB) £ 1 9 5 0 + VAT sa ve over £400 Limited time only In stock t: 01442 879494 www.dftinstruments.co.uk Proud supplier of DeFelsko Inspection Instruments t : 0 1 4 4 2 8 7 9 4 9 4 n w w w d f t i n s t r u m e n t s c o u k n e : s a l e s @ d f t i n s t r u m e n t s . c o . u k

attractive route for people wanting to break into the engineering industry, with research showing that the average salary for graduate engineering programmes is £28,000 in the UK. On the other hand, they are a great way for businesses to employ and nurture new talent while they can.

Recruiting professionals into engineering

On the other hand, your business can help to solve the shortage of skilled workers by focusing on training and retaining professionals.

Back-to-work schemes

It’s not uncommon for people to take a break from their careers. This might be to upskill in other areas or to prioritise personal issues such as caring for family members. While common, it may be difficult for people to return to the workplace after this break.

In fact, this is also an issue within the engineering sector. Research shows that 40% of women who choose to take a prolonged break from their career in STEM to care for their children feel there are barriers to returning to their careers.

To tackle this and encourage people to return to their STEM jobs, including engineering jobs, businesses can offer back-to-work schemes. These are common practices around the nation, as companies run 12-week paid return schemes or training schemes to potential workers.

Improving company culture

It’s no secret that multiple businesses across the nation are struggling to retain their staff. The engineering sector is also experiencing this hardship, with research discovering that 32% of engineering workers left companies due to their employer’s company culture. The logical solution, therefore, would be to improve company culture wherever possible.

Your engineering company can boost company culture in a number of ways. This can come in the form of employee recognition, social events, hybrid working

schemes, or employee rewards. The trick is to have fun while doing it!

Career progression

Career progression is an attractive selling point in any career. No one wants to feel like they are stuck in the same position or same level for too long. This can become monotonous, possibly leading to your employees leaving their for another.

In fact, according to research, 86% of workers within engineering, as well as architecture and building industries, are eager to learn new work skills. And 28% believe career progression is one of the most important goals of their professional careers.

To ensure your employees feel fulfilled in their role, your business can create career progression plans. This can be something like offering educational courses that will continue to challenge their knowledge and work as a method of upskilling.

While it may take time and resources, there is hope that the industry will be able to fill the skills shortage in time. If, in this case, businesses do their part and encourage people – both school leavers and current employees – to become engineers.

Sources

https://www.crooton.com/2022/02/22/what-is-the-futureof-recruitment-in-the-engineering-sector/

https://educationhub.blog.gov.uk/2021/02/11/ women-in-stem-week-2021-how-were-empowering-thenext-generation/

https://www.mazakeu.co.uk/inspiring-the-next-generation/ https://www.tees.ac.uk/schools/scedt/news_story. cfm?story_id=7914

https://www.gov.uk/employing-an-apprentice https://pwemag.co.uk/news/fullstory.php/aid/4928/ Engineering_skills_crisis_prompts_calls_for_urgent_ government_action.html

https://uk.talent.com/ salary?job=Engineering+Graduate+Programme

https://employernews.co.uk/news/recruitment-biaspreventing-talented-engineers-from-returning-to-work-aftera-career-break/

https://engineering-jobs.theiet.org/article/returning-toyour-engineering-career

https://www.fenews.co.uk/employability/the-engineeringsector-has-trouble-retaining-staff-heres-why-your-workersneed-regular-training-and-motivation/

26 NOVEMBER 2022

INDUSTRY NEWS If you are interested in booking a stand call Nigel Bean on 01442 826826 or send an email to nigelbean1@aol.com 4th & 5th October 2023, NEC, Birmingham twitter: @surfaceworldmag

EASY OPERATION . DOUBLE PRODUCTIVITY. SuperCenter EVO Powder preparation & supply center • Ideal for frequent & fast color changes • High degree of automation for optimum efficiency • Double-designed fresh powder station for increased productivity

Contact Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone:

368410 enquiries@wagner-group.com

wagner-group.com

01327

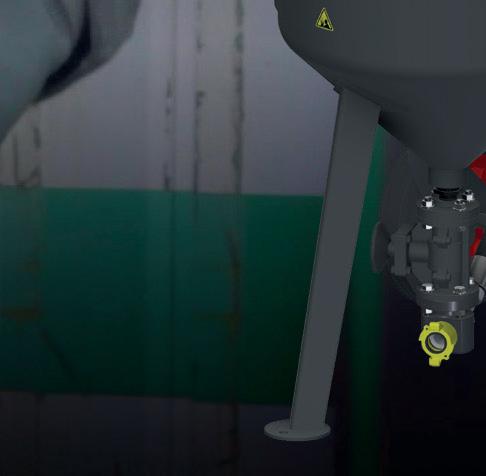

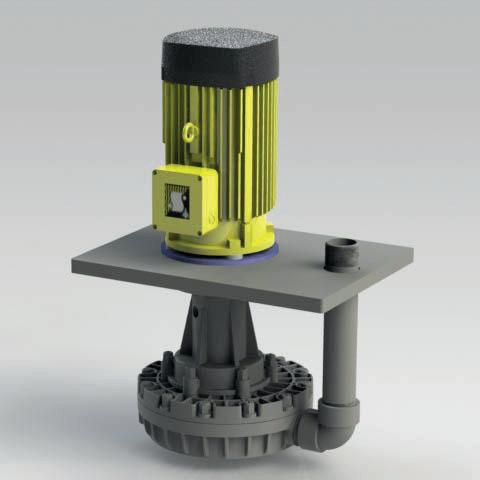

Split-O-Mat ® line of products for compact, reliable and effi cient wastewater treatment

Wastewater from surface treatment processes will contain heavy metals and other pollutants that need to be removed, prior to sewer discharge, to avoid breaches in consent limits.

EnviroChemie UK Ltd is the UK operation of EnviroChemie GmbH, the leading German industrial water technology company. EnviroChemie manufactures and implements solutions for its industrial customers, providing innovative technologies for wastewater treatment. These are supplied as prefabricated compact plant or bespoke solutions, to ensure your wastewater does not exceed specified limits.

Split-O-Mat® wastewater treatment plants have been in use in a wide range of industrial and commercial applications for more than 40 years. EnviroChemie has now optimised this tried-and-trusted product line to enhance its performance capabilities and ease of use.

The compact plants are designed for physico-chemical treatment of wastewater to ensure compliance with discharge consents. All plants are fully automated and are able treat batch volumes of between 200 and 1,500 litres.

The pre-assembled Split-O-Mat® plants with their plug-and-play design can be quickly connected and commissioned at a customer's site. EnviroChemie also supply chemicals that are tailored exactly to the water requiring treatment, thus assuring efficient operation of the plants. The new EnviroChemie app for users will be available shortly. It enables web-based online monitoring and assures the plants are run at optimum performance.

In addition, EnviroChemie offers an optional service model for the Split-O-Mat® plants. By opting for this model, customers benefit from application engineers and water experts who ensure the reliable operation of the plants and the efficient treatment of the wastewater.

EnviroChemie are experts in industrial water and wastewater technologies, providing our customers with reliable and innovative solutions. We can access global expertise to develop customised processes to meet our customers’ needs, delivered and supported locally by our UK team.

The UK team has recently strengthened with the appointment of Bradley Unwin as Head of Sales.

Bradley has over 10 years’ experience in Water Treatment, providing solutions for process water and recycling and reuse projects.

After completing his engineering apprenticeship Bradley went onto work some of the major Water Technology providers initially as a service engineer and then moving into commercial roles covering healthcare, Food & Beverage and industrial markets.

On joining EnviroChemie Bradley said:“This is an exciting opportunity to join EnviroChemie as Head of Sales, bringing my experience in Process water.

EnviroChemie’s experience in industrial water treatment and range of proven technologies in both effluent and process water allows us to offer solutions to all our customers water treatment requirements.

I look forward to supporting my customers alongside our technical teams in the UK and Germany”.

To use your water resources more efficiently, seek practical advice from our advanced water treatment specialists.

For more information please contact:Bradley Unwin

Telephone: +44 (0) 7940 172546 Email: bradley.unwin@envirochemie.uk

28 NOVEMBER 2022 WATER & EFFLUENT TREATMENT

www.surfaceworld.com

Babcock Wanson Brochures Highlight Steam Solutions and Thermal Fluid Heating Applications

Industrial process heating manufacturer Babcock Wanson launched two brochures: a guide to the company’s Steam Solutions, and a Thermal Fluid Heating Solutions brochure with a focus on the applications and industries most suited to this energy efficient, easy to use process heating technology.

The 12-page Steam Solutions brochure emphasises Babcock Wanson’s expertise and in-depth knowledge of industrial steam products and services, for which the company is renown. It features Babcock Wanson’s latest steam boilers, including Coil, Fire Tube, Water Tube and Electrical Steam boilers, along with the company’s generation of micro-modulation Burners with very low NOx. The brochure continues with a look at Water Treatment products, plus the range of services

available, from maintenance to equipment rental, training and latest digital services. Smart products and services, which are becoming increasingly popular, are also highlighted, which include unattended operating mode (up to 30 days), automation, HMI for easy day to day boiler operation, and cloud based Navinergy and e-Water remote monitoring Apps.

The Thermal Fluid Heating Solutions brochure takes a different approach, with the main focus on applications and industries that are best suited to thermal fluid heaters and that have potentially the most to gain from swapping to this process heat technology. This includes pressing, curing and moulding; tanks, vessels and cookers; printing, coating, laminating and drying; and heating and cooling, which can be combined in a single thermal fluid system for exothermic reaction control or simply to maximise the use of a plant. Each section is illustrated with

photography and clear graphics showing how a typical thermal fluid system works in that specific application. The brochure finishes with a brief overview of the thermal fluid heaters available from Babcock Wanson, including the TPC and EPS ranges, along with the services provided by the company.

For a PDF copy of the Babcock Wanson brochures go to www.babcock-wanson.com/ resources/brochures/ or request a hard copy from Babcock Wanson on 020 8953 7111 or info@babcock-wanson.com.

Babcock Wanson offers a complete range of products and services for boiler houses and other process heating needs, from steam boilers, thermal fluid heaters, rapid steam generators and hot water boilers to VOC and odour treatment by thermal oxidation, water treatment or process air heating solutions.

For information on Babcock Wanson, go to www.babcock-wanson.com

30 NOVEMBER 2022 WATER & EFFLUENT TREATMENT

twitter: @surfaceworldmag

Dedicated stand-alone unit is ready to measure right out of the box Fast measurement speed—ideal for moving lines and swinging parts Scan Mode continuously takes measurements—ideal for analyzing large areas Storage of 999 readings with onscreen averaging. Stored readings can be downloaded to PosiSoft Desktop Software Affordably measures uncured powder coatings using non-contact ultrasonic technology to predict a cured thickness 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk Non-contact Uncured Powder Thickness Gauge Powder Inspection Kits Complete solutions for measuring powder coating before and after cure are available Powder Checker

Pure water for a perfect powder coat

Powder coating is going green. In some cases this is the result of legislation which requires existing process cleaning solutions to be replaced with more environmentally friendly ones. Increasingly, however, it’s coating quality that is the driver. Some coating specifications now demand salt spray testing for more than 1000 hours, and that means that surface preparation is absolutely critical. One of the proven ways of achieving high quality surface preparation is the use of pure water. Mains water contains a wide range of dissolved salts. These are harmless in drinking water but can promote corrosion and poor adhesion of powders to metal surfaces.

Using pure water increases the life expectancies of cleaning tanks and sprays and is a proven way of making both the cleaning and protective barrier chemical more effective. This means longer periods between tank drain downs and cleans, extending process operating time and less maintenance. It also means less wastewater generation and lower operating costs. A more environmentally and sustainable process. All this and improved product quality too.

There are two main processes to produce pure water: ion exchange demineralisation and reverse osmosis (RO). Ion exchange uses a chemically active synthetic resin to remove dissolved ions from water, in exchange for hydrogen in the case of cations and, hydroxyl in the case of anions. The resulting hydrogen and hydroxyl ions form water molecules. On the other hand, RO passes the water through a semi-permeable membrane which effectively filters out the dissolved ions. Selecting the best process depends on the quality of the mains water supply and the water purity required.

Ion exchange demineralisation is a batch process. The ions removed from solution accumulate on the resins and then have to be removed by regeneration. This uses hydrochloric acid for the cation resin and caustic soda for the anion. The regeneration process isn’t 100% efficient, so some of the chemical – typically about 20% - is wasted, and the regenerated resins also have to be rinsed prior to returning to service. This generates a waste stream with volume equivalent to about 5 - 15% of the plant throughput depending on the raw water quality. RO is a continuous process that uses no chemicals but depends on a high operating pressure generated by an

electrically driven pump. This makes it appear more environmentally friendly than ion exchange. The ions removed from the raw water are concentrated into a waste stream that is typically 25% of the throughput suggesting that it is less sustainable. If the raw water is hard, RO can be fouled by scaling and this is normally prevented by softening upstream of the membranes, but this requires salt and produces more wastewater.

A simple two-stage ion exchange demineralisation system can produce purified water of >1µS/cm conductivity which is equivalent to about 0.5mg/l total dissolved solids (TDS) whilst RO permeate is typically about 5µS/cm (about 2mg/l TDS).

RO has a higher capital cost than ion exchange but operating costs for both processes depend on the system flow rate and the TDS of the raw water. The chemical consumption in ion exchange is directly proportional to the raw water TDS whilst the power consumption of RO remains fairly constant, so RO becomes more economic for higher TDS raw waters. The actual cut-off point will depend on the raw water composition, the costs of chemicals and the anticipated lifetime of the plant.

Using pure water in all stages of surface preparation will not only improve the adhesion of the coating but will also extend chemical life and reduce waste. Not only sustainable but also cost effective.

You can get in touch with the Adept Pure Water Ltd team for more information on water purification for surface finishing.

Telephone: +44 (0) 1933 677181

Email: enquiries@adeptpwt.co.uk

Visit: www.adeptpwt.co.uk

–

–

–

Call Nigel Bean for more information on +44 (0) 1442 826826

Meet and connect with prospective customers Strengthen your

with

customers

bond

existing

Learn about

your industry Meet new companies that can

your business

new developments in

help

Close deals with new customers during the show

Strengthen or establish your brand

Speak directly to your target market Optimise your sales and lead generation strategy

10 great

World 2023 WATER & EFFLUENT TREATMENT

– Learn what your competitors are doing right Rapidly expand your database of sales leads –

http://www.surfaceworld.com/surface-world-live/ floor-plan-exhibitor-list/

reasons to exhibit at Surface

elcometer.com Elcometer’s CONTRACTOR and PERFORMANCE abrasive blast equipment are engineered to last longer, work harder & perform better. dry abrasive blast machines | precision media valves blast hose | blast nozzles | personal protection equipment engineeredTAERGNIEDAM RB I T A I N FABRIQUÉEN GRANDE BRETAGNE HERG E S T TLLE NI NEINNATIRBSSORG engineered YTILAUQ ETNI E YGOLONHC GNINIART Surface World - Blast - April 22.indd 1 13/04/2022 14:35:26 These Systems include: Deionisers I‐on‐x Exchange Cylinders Reverse Osmosis UV (Ultra Violet) Filtra�on So�eners Pumps and Tanks We are Pure Water Equipment Specialists and provide an extensive range of water treatment systems and services to commercial and industrial clients throughout the UK. Providing a Full Turnkey Service means we can Design, Manufacture, Install and Commission a system based on specific produc�on needs or requirements. ADEPT Pure Water Ltd can also provide service for: Break Down & Repair on ALL makes of Water Purifica�on Equipment Re-Condi�oning of all types of Water Purifica�on Equipment Tailored Service Agreements –Standard or Responsive op�ons available Site Survey and System Efficiency Reports for prospec�ve clients or Repair and Service op�ons for pre-exis�ng systems. ADEPT Pure Water Limited 36 Huxley Close, Park Farm South, Wellingborough, Northants, NN8 6AB

and Consumables: ADEPT offer a choice of consumables including UV Lamps, Chemicals, Micron & Carbon Filters. We also offer Spare Parts, Tanks, Refurbished Water Equipment and more. Look out for the launch of our New ONLINE STORE COMING SOON

Spares

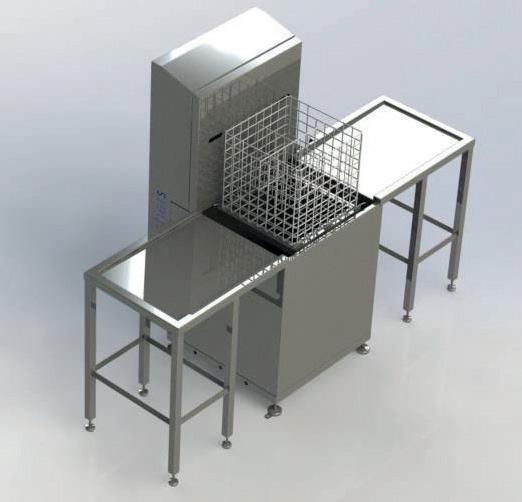

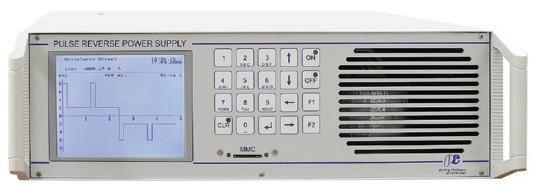

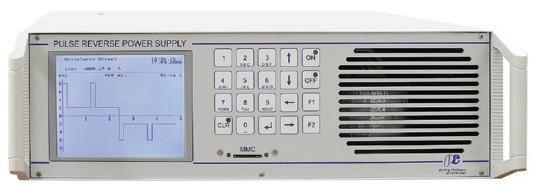

SIEBEC UK

A revolution for the chrome (III) bath treatment

Traditionally, to avoid massive pollution of the treatment baths, baths are often completely drained and refilled with brand new chromium (III) solution. Such maintenance represents a significant cost. It leads to a complete stop of the production, a major quantity of effluent to treat and a non-negligible cost of a brand new solution.

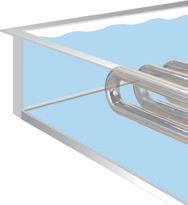

IONPURE™ treats the chromium (III) bath continuously, keeping metal ion pollution to a minimum. Thus, there is no interruption in production and the volume of effluent is minimal compared to the traditional method. Once the ion exchange resin is saturated (50 g of metal for 1 litre of resin), IONPURE™ switches to regeneration mode to clean the resin of impurities in order to reuse it in the next cycle.

Note: As IONPURE™ does not have an integrated analysis system, regular monitoring and analysis of the chrome plating bath is necessary to trigger the resin regeneration mode.

Quality parts. Guaranteed

Zero bath contamination due to the build-up of metal impurities.

Continuous high quality, every time.

Increased productivity

No production line interruption.

Reduced maintenance frequency.

Durable and profitable investment

Removal of a significant part of the cost linked to maintenance.

Reduced environmental footprint thanks to minimal effluent disposal.

Automatic regeneration mode

When the bath analysis reveals an abnormal level of polluting metals, it means that the resin is saturated and that it is time to regenerate it. The operator then activates the “automatic regeneration” mode. The IONPURE will then successively evacuate the metals and regenerate the resin.

Machine stop mode

This mode allows the IONPURE™ circuit to be completely emptied and cleaned, in order to avoid any risk of crystallization inside its various elements.

Product Features

10 µm pre-filtration, Ion exchange resin (40 or 80 l), Storage of regenerating solution, 100% polypropylene pneumatic valve, Special resin strainer, Compact design, Touch screen interface. Get in touch with SIEBEC UK today to learn more about products, support and service Telephone: 01785 227700 Email: sales@siebec.co.uk Visit: www.siebec.co.uk

New SIEBEC brochure: Dedicated Equipment Surface Treatment –please contact SIEBEC for a copy.

34 NOVEMBER 2022

WATER & EFFLUENT TREATMENT www.surfaceworld.com

IONPURE™ from

continuously eliminates metals polluting the chromium (III) baths in order to guarantee optimal concentration and constant parts quality. 4kg of polluting metal collected in one cycle!

FILTER MEDIA

SPECIAL SYSTEMS ACIDPURE | Acid recycling EASYPURE | Fluid recycling IONPURE | Ionic filtration ACIDVAC | Acid draining vacuum EDUCTORS | Bath agitation [...] PUMPS & FILTERS L SERIES | Medium flow rate filter P SERIES | Ultra-high flow rate filter A SERIES | Mechanical seals pump M SERIES | Magnetic drive pump T SERIES | Vertical pump [...] We solve our customers filtration, chemical transfer and treatment needs. Contact us SIEBEC UK Ltd, Stafford +44 (0) 1785 227700 sales@siebec.co.uk www.siebec.co.uk

L-TECH | Pleated cartridge BAGTECH | Filtration bag QUALITHERM | Extruded cartridge QUALIBOB | Wound cartridge ANODTECH | Anode bag [...] Automated Water & Effluent Ltd Since 1982 Automated Water & Effluent Ltd have been supplying process control equipment to the metal finishing and surface finishing industry. We have an in-house team of qualified engineers able to recommend and build control panels and process equipment specific to fit your requirements. A wide range of our control instrumentation, dosing pumps and chemical process equipment is available on short delivery. AWE House, Antom Court, Tollgate Industrial Estate, Stafford, ST16 3AF awe-ltd.co.uk 01785 254 597 Get in touch for a quote today! • Custom Designed & Built Control Panels • pH & Redox Controllers & Electrodes • Conductivity Controllers • Liquid Level Controllers • Open Chanel & Magnetic Flow Meters • Data Loggers • Dosing Pumps & Tanks Visitusat SurfaceWorldLive2020 atStandA9

Rainwater Harvesting: An investment not to be missed

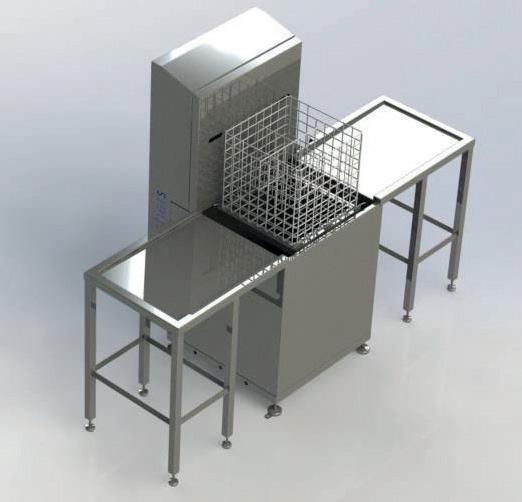

Plastratum Ltd, the Birmingham based manufacturer of both Manually operated and Fully Automatic Electroplating and Metal Finishing plant and equipment together with Effluent Treatment plant, Water Recirculation plant and Fume Extraction systems can provide the benefit of rainwater harvesting chemical engineering.

The costs of energy, materials and manufacturing operations are constantly increasing and unlikely to be reduced in the foreseeable future, so companies are required to work more efficiently and effectively to enable costs of production and operational costs to be standardised or even reduced.

The control of significant energy costs, both gas and electricity, is well understood but that of water is another commodity that is somewhat taken for granted and accepted, although the costs of water in and effluent out must be accounted for in the total company employment of capital and affect bottom line profits and profitability.

Rather than rely on the ever-increasing cost of water from the water companies in all industries and especially in the electroplating

and metal finishing sectors, significant water volume can be sourced from harvesting the rainwater collected on the company’s roof area into a bulk holding tank. This can augment a decreasing dependance on the supply from water companies or have a volume that can service the applications completely.

From the holding tank the collected rainwater is filtered, using Multimedia filtration and carbon filtration. The filtered water can then either be dosed with a biocide or sterilized using a UV lamp system. Conductivity monitoring and ion exchange operations can also be utilized to ensure water quality required by today’s increasingly water critical processes.

The treated process water can then be boosted to the required pressure and connected using the existing pipework systems to each application accordingly.

In some cases, the water can also be used for domestic applications.

Following its use, apart from that used for domestic purposes, the water can be recirculated, recycled and constantly reconstituted and reused following the application of ion exchange resins thus again

reducing the cost of incoming water from the supply companies and enhancing and reducing the effect on the environment.

It is not unusual to expect a payback on investment that could be within three and a half years.

With the ever-increasing production costs Rainwater Harvesting an investment not to be missed.

Please contact us for an evaluation of your potential.

Telephone: 0121-314-1191 Visit: www.plastratum.com

36 NOVEMBER 2022

WATER & EFFLUENT TREATMENT twitter: @surfaceworldmag

COMBUSTION ENGINEERING Gas Process Burners FD-GA modulating gas + air process air heating burners. TX high efficiency small diameter immersion tube tank heating systems. FD-E low cost high turndown oven/dryer air heating burners. FD-C high turndown oven/ dryer air heating burners. Midco HMA high efficiency, high turndown, air replacement or “make-up” air heating burners. Lanemark gas burner systems offer users reliable, high effi ciency, process heating solutions. FD Series Packaged Oven/Dryer Burners •Speci cally designed for process air heating applications in convection ovens and dryers •High turndown/short ame lengths providing accurate process temperature control •High ef ciency gas + air modulation, gas only modulation and simple high/low control options •Heat Input Range: 9 kW – 1550 kW TX Series Gas Fired Process Tank Heating Systems •High ef ciency (80%+) heating of all types of spray and dip process tanks •Compact high ef ciency small diameter immersion tube heat exchangers occupying minimum tank space •Accurate performance modelling using Lanemark TxCalc design software •Heat Input Range: 15 kW (1½") – 1150 kW (8") Midco HMA Series Air Replacement or “Make-Up” Air Heating Burners •Direct red, high ef ciency burner systems, for high volume air heating applications such as paint spray booths, ovens and dryers. •Supplied either as Midco burner heads for OEM system integration or as Lanemark DB or FDB complete packaged systems including modulating gas valve trains and controls •Wide range of ring rates to suit alternative temperature rise and air velocity system requirements •DbCalc system design software Lanemark Combustion Engineering Limited Lanemark House, Whitacre Road, Nuneaton, Warwickshire CV11 6BW United Kingdom Tel: +44 (0) 24 7635 2000 Fax: +44 (0) 24 7634 1166 E-mail: info@lanemark.com www.lanemark.com

Total Filtration is a Division of The Westbury Group of Filtration Companies and is your one stop shop for the manufacture and supply of liquid and dust filter cartridges and associated components.

Our Industrial Dust Extraction Collectors and filter cartridges span many industries including:

Aerospace - Agriculture - AutomotiveChemical - Construction - Food & Beverage - Gas Turbine - HVAC/Ventiliation - Defence - Material Handling - Paper, Pulp & Woodwork - Pharmaceutical - Plant Machinery - Plastic - Plasma/Laser CuttingRubber - Shotblast & Beadblast - TextileTransport

We carry a vast selection of filter media, including Cellulose blends, Polyester, Anti-Static Polyester, PTFE coated and Membrane, Nano, Flame Retardant coated, to name a few.

We pride ourselves on our bespoke, OEM and retrofit dust filter cartridge range which fit equipment from the following manufacturers and many more:

AAF - Airmaster - Altair - Camfil Farr - Clarcor - Dantherm - DCE - Donaldson - Freudenberg - Mahle / Dustcheck - Nordic - Unicell - WAM

Airmaster Retrofit

Camfil Farr Goldcone Retrofit

Our Airmaster Dust Filter equivalent is a pleated cartridge made in two lengths, 450mm (type 1) and 920mm (type 2). The end caps can be Galvanised Steel or Stainless Steel, there are three types of filters available with spun polyester standard, Anti-Static, PTFE media and Anti-Static PTFE.

We manufacture our own range of Goldcone style filters, without the cone, available in the length of 1000mml. These are available in a range of medias which include: - Cellulose blend 80/20FR, STD Polyester, A/Stat Polyester.

Camfil Tenkay Mark 1, 2, 3, 4 Retrofit

ALTAIR Retrofit

The Altair dust filter equivalent range are cartridge filters made in several lengths: 600mm, 660mm, 1000mm and 1200mm (Other lengths available). These are available in a range of medias as detailed below.

We manufacture a range of square top filters in both 325mm and 225mm (closed end cap sizes). These are also known as Camfill Farr Tenkay Mark 1, 2, 3 and 4 alternatives.

They are available in a choice of lengths and medias (All lengths are also available in the round end cap version).

38 NOVEMBER 2022

Your One Stop Shop

Range

Filtration Solutions And Filter Supplies Call Nigel Bean for more information on +44 (0) 1442 826826 Meet and connect with prospective customers Strengthen your bond with existing customers Learn about new developments in your industry Meet new companies that can help your business Close deals with new customers during the show Strengthen or establish your brand Learn what your competitors are doing right Rapidly expand your database of sales leads Speak directly to your target market Optimise your sales and lead generation strategy

floor-plan-exhibitor-list/ 10 great reasons to exhibit at Surface World 2023 PUMPS & FILTRATION twitter: @surfaceworldmag

For A Wide

Of

http://www.surfaceworld.com/surface-world-live/

Dantherm Cartridge Filter Retrofit

Our ABS Dantherm Cartridge Filter Alternative (also known as an Airmaster, Nederman or Disa Dust Filter Cartridge.) is made of lightweight strong plastic version of the Type 66,44,40,22 and 20. (Also available in carbon impregnated for Anti-static requirements).

Donaldson Siloair Filter Retrofit

Our DCE Torit Siloair Filter equivalents are perfect for silo vending machines. These filter cartridges are made in three lengths: 565mm, 800mm and 1000mm. They are available in a range of medias including Standard, Anti-Static, PTFE Standard and Anti-Static PTFE.

Donaldson TDS Equivalent Retrofit

The Donaldson TDS Equivalent single or double ended filter cartridges are available in three basic diameters (202mm, 325mm and 350mm) with six different lengths. They are available in different medias. (Depending on the application), these include Nano Fibre, Spun Bonded Polyester, PTFE, and anti-static.

Donaldson TORIT Equivalent Cartridge ECB/TDS/DF+ Retrofits

Our Donaldson TORIT Cartridge Filter retrofits come in two basic diameters (325mm and 350mm) with six different lengths. There are several medias to choose

from. (Depending on the application), these include Nano Fibre, Spun Bonded Polyester, PTFE and anti-static.

This dust filter is available in both Galvanised and Stainless-Steel finish. Available in several lengths from 200mml to 1200mml. Media Options include STD Polyester/ A/Static Polyester. STD PTFE Membrane/ Antistatic PTFE Membrane.

Nordic / Freudenberg 3 Lug Filter Retrofits

DONALDSON UNICELL Retrofits