WE HAVE EVERYTHING COVERED – follow us on X (twitter) @surfaceworldmag – visit www.surfaceworld.com Now the only magazine in the UK covering the surface finishing industry MAY 2024

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826

e: nigelbean1@aol.com nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

Sheena Burrus e: sheenaburrus@hillmedia.com

EXHIBITION ORGANISER

Sheena Burrus e: sheenaburrus@hillmedia.com

Hill Media Ltd, Marash House 2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd. Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents. © Hill Media Ltd – 2024 ISSN 1757-367X

All the major UK & Ireland architectural powder coaters are either licenced QUALICOAT members or in the process of approval. With coating specifications now requiring QUALICOAT, should you not be looking to join?

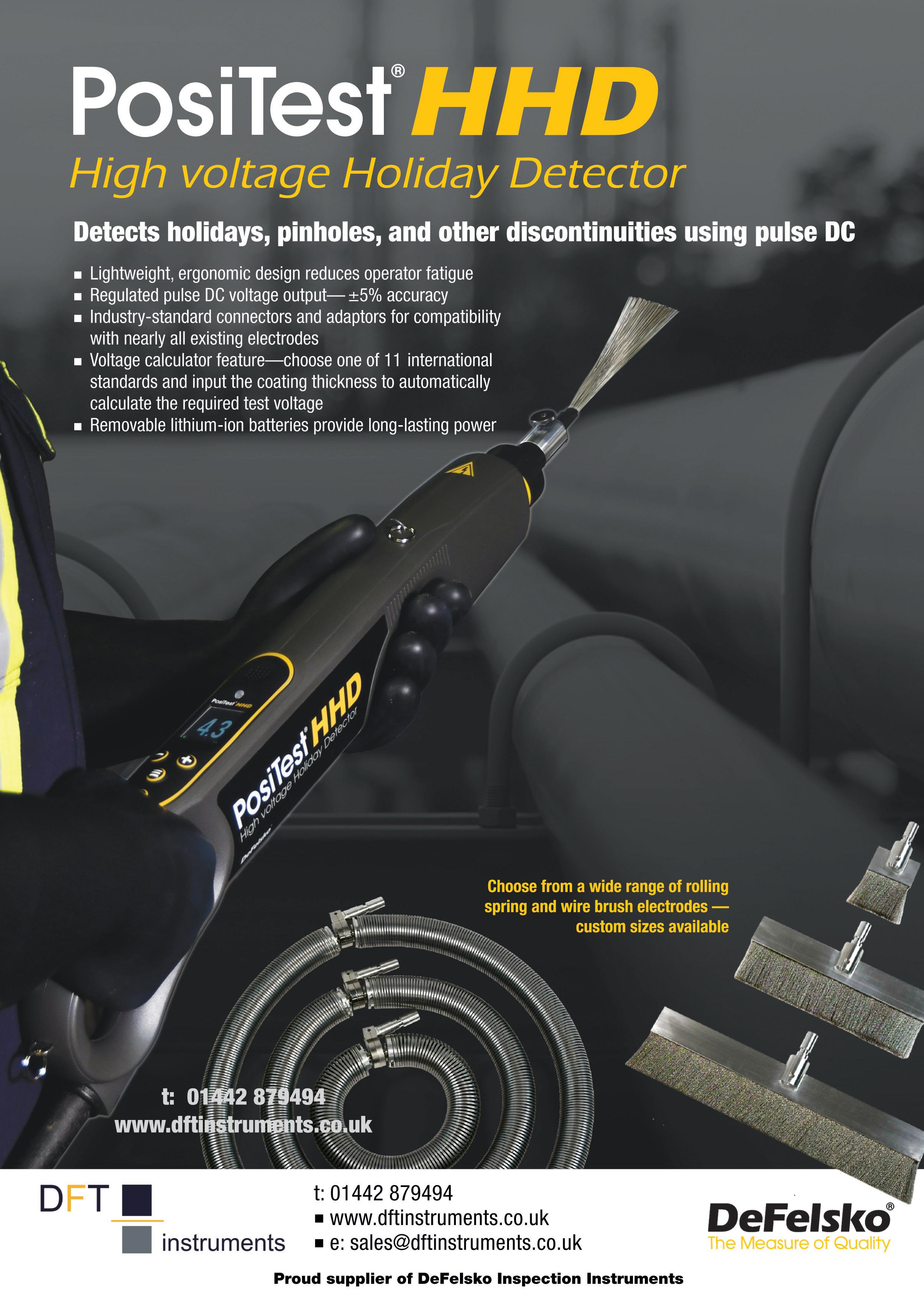

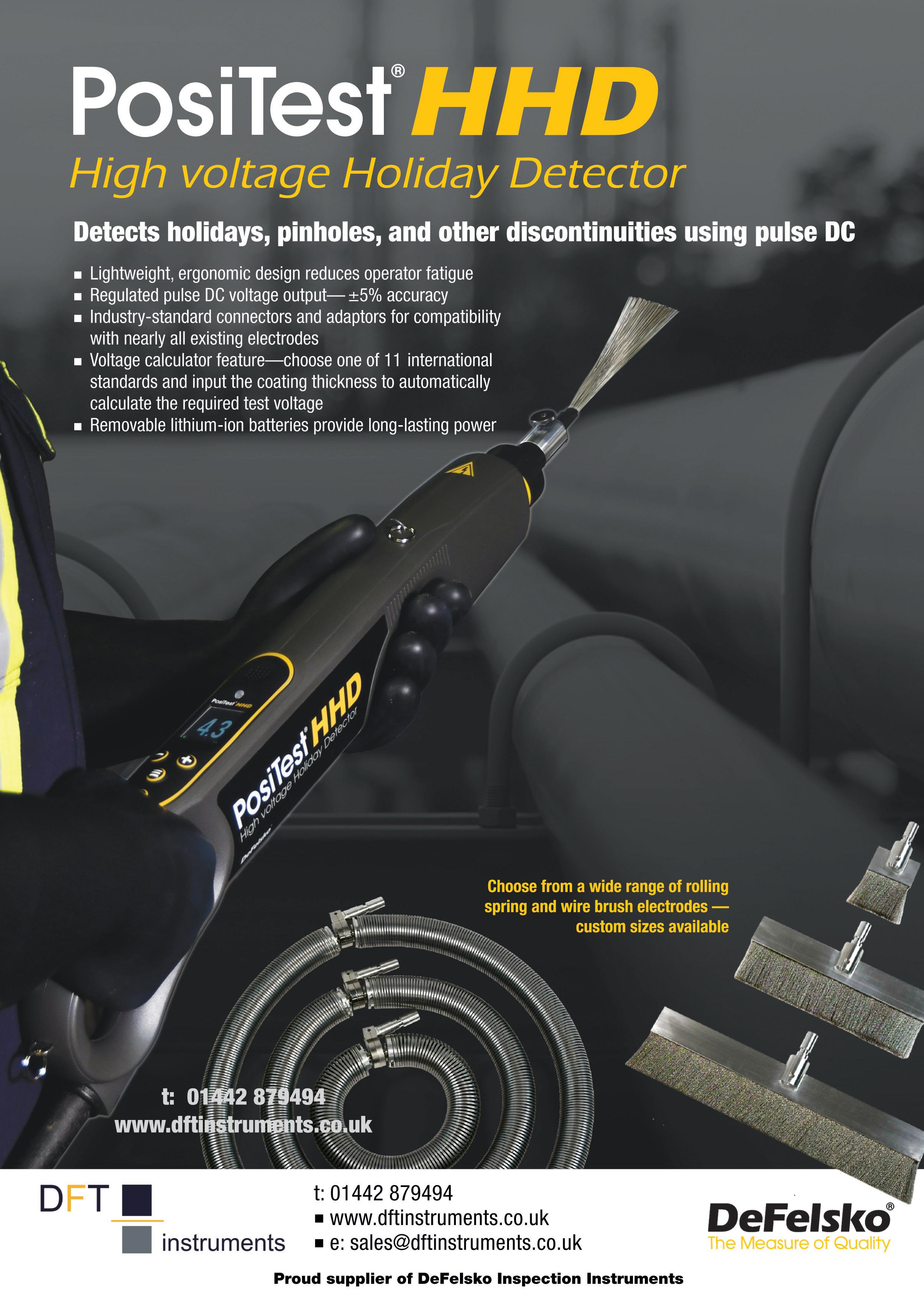

SPOTLIGHT MEASUREMENT

2 QUALICOAT UK &

IN PURSUIT OF EXCELLENCE. 9 IMF: INSTITUTE

FINISHING JOIN US AS WE CELEBRATE 100 YEARS. 12 INDUSTRY NEWS AKZONOBEL’S COMO SITE ACHIEVES HIGHEST AUTOMOTIVE INDUSTRY QUALITY CERTIFICATION. 14 BASF PAVES THE WAY

FINALS LYON 2024. 18 BOROUGH CHROME APPOINTS NEW QUALITY

20 3M® NOVEC IS BEING DISCONTINUED, DON’T JUST SWITCH

22 LEADING NATIONAL GALVANIZERS PROUD TO BE CHROME-FREE. 24 ROSPA HEALTH AND SAFETY AWARDS 2024 - WINNER OF THE COVETED BEST NEW ENTRY AWARD. 26 EVOPHASE RECOGNISED AS FINALIST IN PRESTIGIOUS MANCHESTER PRIZE. 30 SURFACE WORLD 2025 SURFACE WORLD 2025: Learn, Connect and Shape the Future – Under One Roof, Over Two Days. 32 TESTING & MEASUREMENT REDUCE COSTS WITH INLINE MEASUREMENT FOR ELECTROPLATING REEL-TO-REEL APPLICATIONS. 34 TUNE IN TO SEE YOUR PAINT CURE OPERATION LIVE! 36 BLAST IT, SPRAY IT AND INSPECT IT WITH ELCOMETER. 40 MASKING - TAPES, CAPS & PLUGS HADLEIGH ENTERPRISES OFFERS SPECIALIST MASKING TAPE EXPERIENCE AND CAPABILITY. 44 HANGON QUICK WIRE SHAFT. 46 FOR GENERATIONS HANGON HAVE DEVELOPED WITH THEIR CUSTOMERS. 46 PRE-TREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING REDUCING ENERGY COSTS FOR SURFACE FINISHING PLANTS. 48 EMBRACING NEW TECHNOLOGIES IN SURFACE TREATMENT. 50 ELECTRICAL CORROSION PROTECTION - Prevent hydrogen sulphide corrosion in electrical and electronic equipment. 52 SELECTING THE RIGHT ABRASIVE BLASTING CABINET FOR YOUR NEEDS. 56 EFFICIENT, INNOVATIVE, AND SUSTAINABLE COMPONENT CLEANING FOR THE ENTIRE PRODUCTION CHAIN. 60 PRODUCTS & PROCESSES HOW STANDARDIZED RECTIFIERS CAN DELIVER CUSTOMIZED SOLUTIONS. 64 PLATING LINE ADVICE - Peace of Mind through Confidence. 66 MATERIAL & EQUIPMENT SUPPLIERS 69

COMPANY

OF UNCURED DRY POWDER TO GIVE PREDICTED CURED THICKNESS WITH DEFELSKO’S POSITEST PC.

IRELAND

OF MATERIALS

FOR YOUNG PAINTERS AT WORLDSKILLS

MANAGER.

IMPROVE.

qualicoatuki.org

MAY 2024 VOLUME 31 NUMBER 5

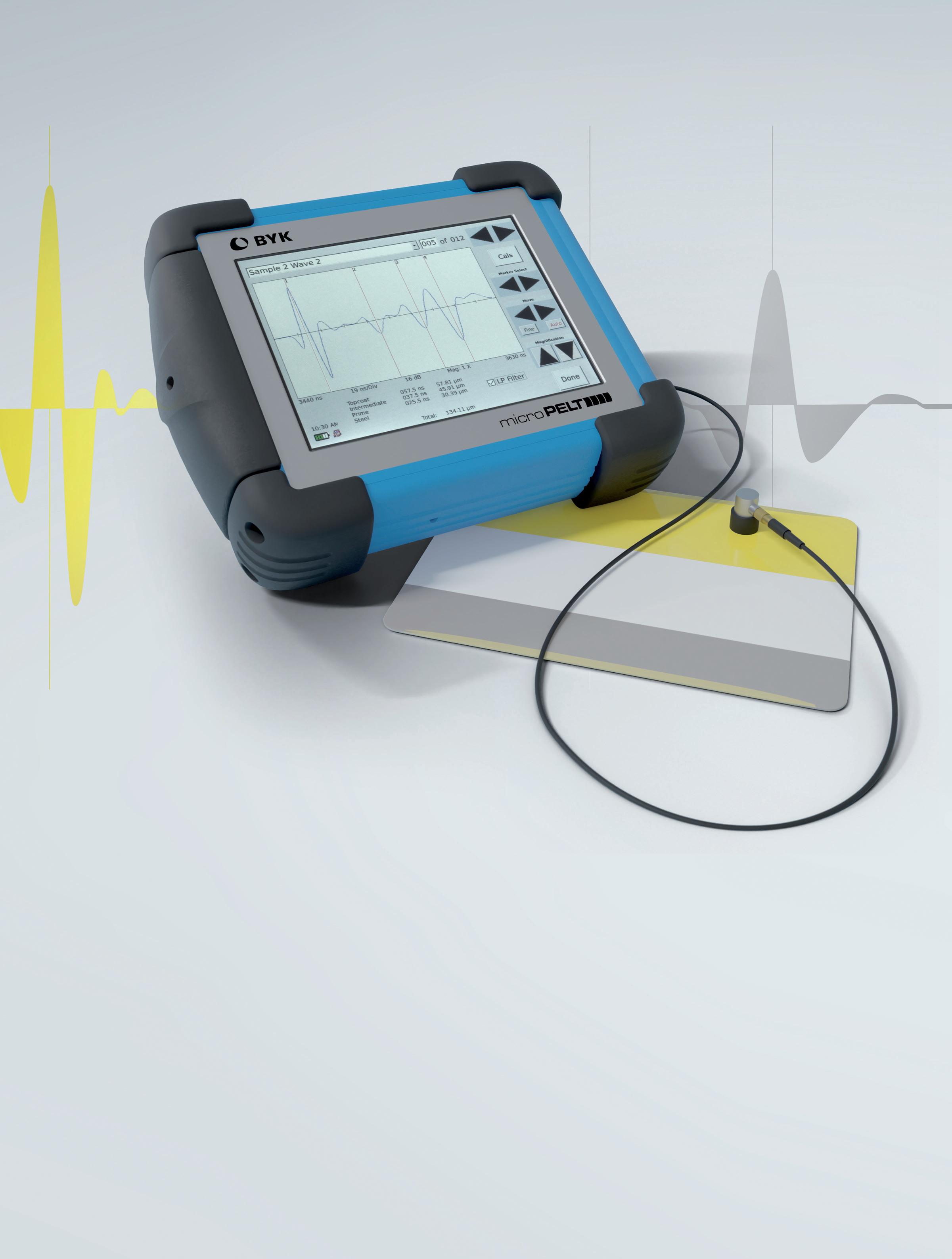

MEASUREMENT OF UNCURED DRY POWDER TO GIVE PREDICTED CURED THICKNESS WITH DEFELSKO’S POSITEST PC

Overview

Measurement of film thickness should be a routine event for all powder coaters. Regular measurement helps control material cost, manage application efficiency, maintain finish quality and to ensure specific standard are maintained. Powder coating manufacturers and certain associations recommend target film thickness ranges to achieve the best performance characteristics and customers expect these parameters to be met. The PosiTest PC gives you the ability to nondestructively measure the uncured dry powder to give you the predicted cured thickness between 20-100um without leaving marks that affect the finish.

Reasons to measure film thickness

Film thickness is arguably the single most important measurement made during the application and inspection of protective coatings. Powder coatings are designed to perform their intended function when applied within a thickness range specified by the manufacturer. Many physical and appearance properties of the finished coating are directly affected by the dry film thickness (DFT). DFT can affect the colour, gloss, surface profile, adhesion, flexibility, impact resistance, and hardness of the coating. The fit of pieces assembled after coating can also be affected when film thickness isn’t within tolerance.

Precisely measuring finish thickness has other benefits, too. Whether to meet International Organisation for Standardisation (ISO), certain association tolerances, or customer requirements for process control, companies need to verify coating quality to avoid wasting money reworking products. By checking their application equipment, they ensure the coating is being applied in compliance with the manufacturers’ recommendations.

Applicators must apply the powder evenly and according to the product specification sheet. Applying excessive DFT not only is wasteful, but also risks the possibility of incomplete cure and can drastically reduce overall performance of the coating system. High film builds often result in poor adhesion. The coating tends to peel or chip from the substrate. Regular testing can reduce the number of internal reworks and customer returns due to finishing defects.

Pre-cure film thickness measurement

It is possible, and in some circumstances more desirable, to measure a coating immediately after application, prior to cure, to predict the thickness of the cured powder.

If a coating has been improperly applied, correction after it has dried or chemically cured requires costly extra labour time, may lead to contamination of the film, and may introduce problems of adhesion and integrity of the coating system. Measuring film thickness during application can determine the need for immediate correction and adjustment by the applicator.

Dry powder measurement

Most powder coating specifications give cured thickness targets, it’s possible to determine if applied powder is within thickness specifications before the finality of curing.

There are good reasons for wanting an accurate prediction of cured DFT, especially on moving lines. Depending upon the length of the oven, the number of parts being cured, as well as

2 COMPANY SPOTLIGHT

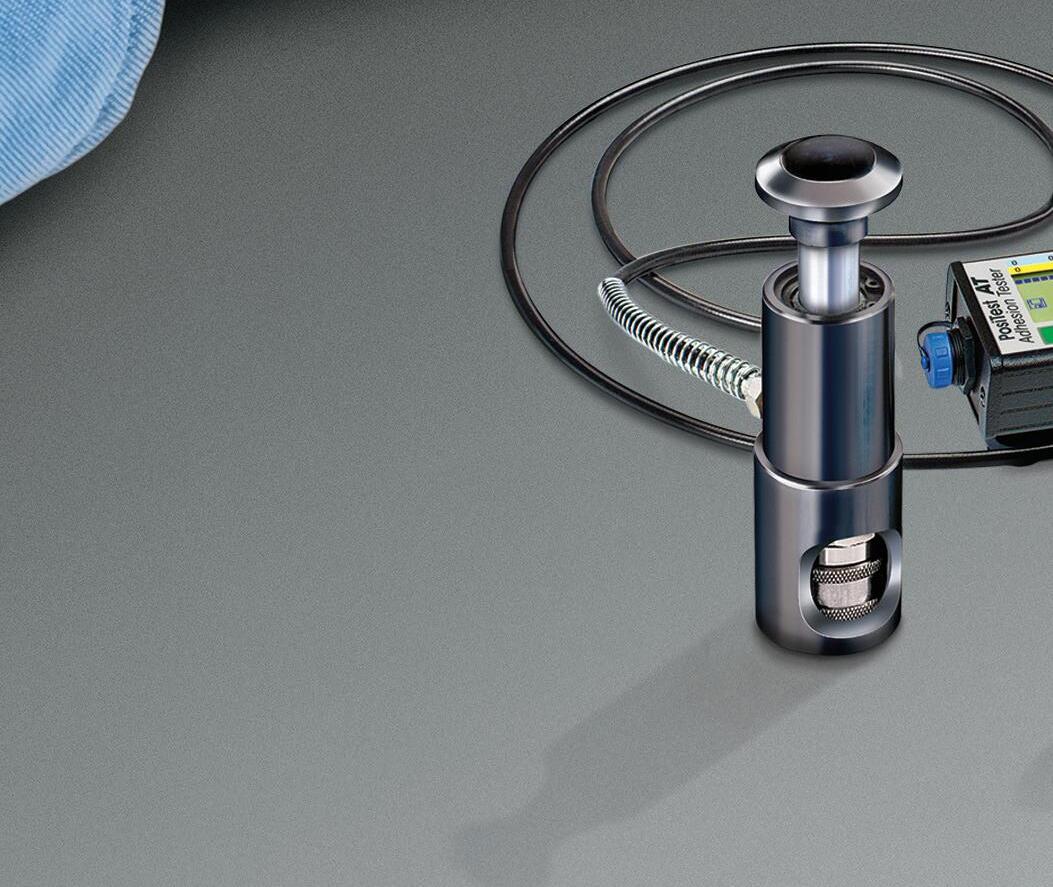

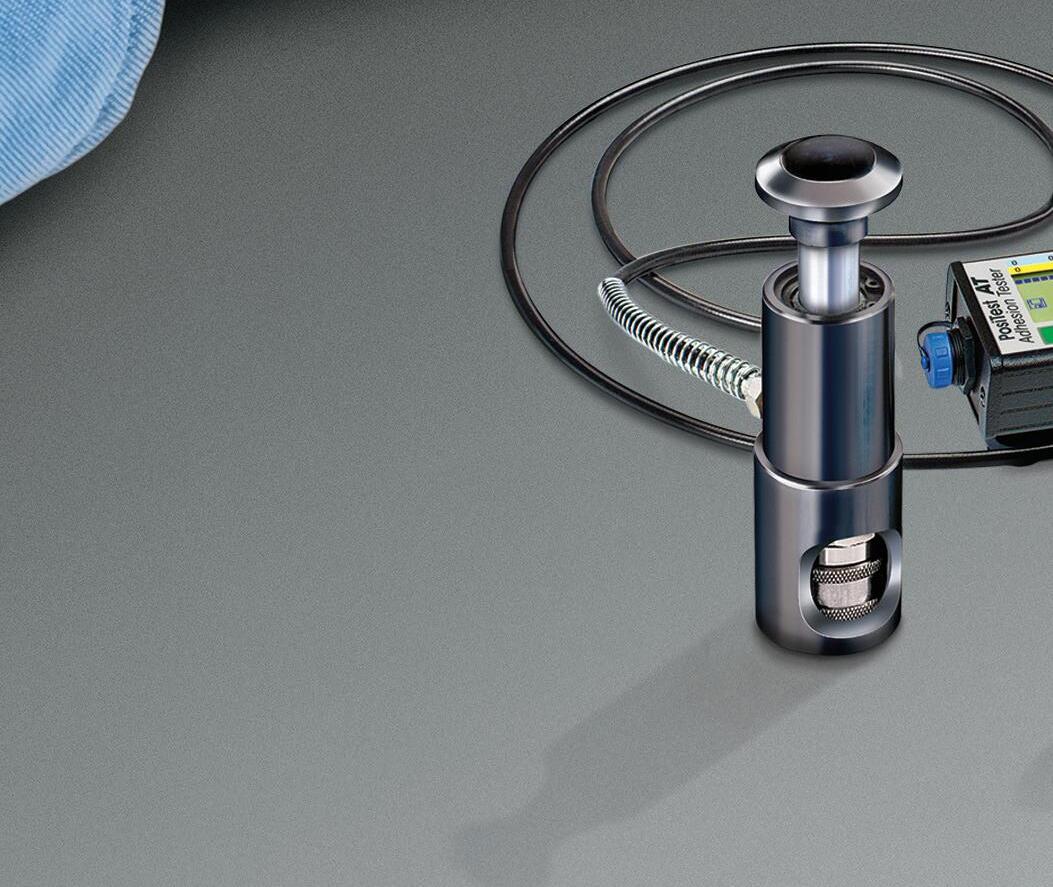

Pull-Off Adhesion Testers

Measure the adhesion of coatings to metal, wood, concrete and more

n Impact and scratch resistant color Touch Screen display with keypad

n Wirelessly connect the PosiTest AT-A to your smart device using our free app

n Record the results as pass/fail and the nature of fracture cohesive, adhesive and glue failures

W i F i Proud supplier of DeFelsko Inspection Instruments DFT Instruments UK LTD 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk AT

AT-A Automatic Model Also available AT-M Manual Model A u t o m a t i c F e a t u r e s

the time required for the curing process and for manual DFT measurement after curing, there is a considerable delay before the operator can intervene in the application process to make any necessary changes.

If coating defects are discovered, a considerable number of coated parts have to be reworked in a repair loop, or if reworking proves to be too expensive, they may even have to be scrapped. For some operations, these disadvantages are no longer acceptable for meeting the demands of modern finishing processes.

Measuring powder in the pre-cured, pre-gelled state ensures correct cured film thickness. It enables the application system to be set up and fine-tuned prior to curing. In turn, this will reduce the amount of scrap and over-spray. Accurate predictions help avoid stripping and re-coating, which can cause problems with adhesion and coating integrity.

The PosiTest PC

The PosiTest PC is hand-held and battery-powered, and will work right out of the box for most powders. Their simplicity of

operation and ergonomic design allow them to be used quickly and efficiently by line operators.

Non-contact coating thickness measurement instruments have the decisive advantage of being non-destructive. This means that, after measurement, the measured components can be re-introduced into the ongoing process. The PosiTest PC can also be recalibrated to your specific powder if you find it reads out of tolerance with your pre and post cured DFT checks. It also has a scan mode to continuously take measurements, ideal for ensuring powder coverage over large areas.

For more information on the PosiTest PC and the full range of paint test equipment available from DeFelsko, please contact Mark Conlon at DFT Instruments, proud UK agent for DeFelsko.

Telephone: 01442 879494

Email: sales@dftinstruments.co.uk

Visit: www.dftinstruments.co.uk

4

COMPANY SPOTLIGHT

Innovation Oxsilan®: high-performing and suited for multi-metal applications

Technological turning point in metal pretreatment: The eco-friendly Oxsilan® technology offers long-term corrosion protection and excellent paint adhesion – and at the same time more safety, economics, flexibility and sustainability. The thin-film technology is free of heavy metals, suited for multi-metal applications and allows an unlimited throughput of common metal substrates. Expect more from Chemetall: innovative technologies, environmentally-sound processes, comprehensive technical support, a global network and dedicated people – inspired for your success.

www.chemetall.com/oxsilan · oxsilan@chemetall.com

www.chemetall.com

Metal protection, the next generation:

eco-friendly and multi-metal

pretreatment technology.

The

Oxsilan®

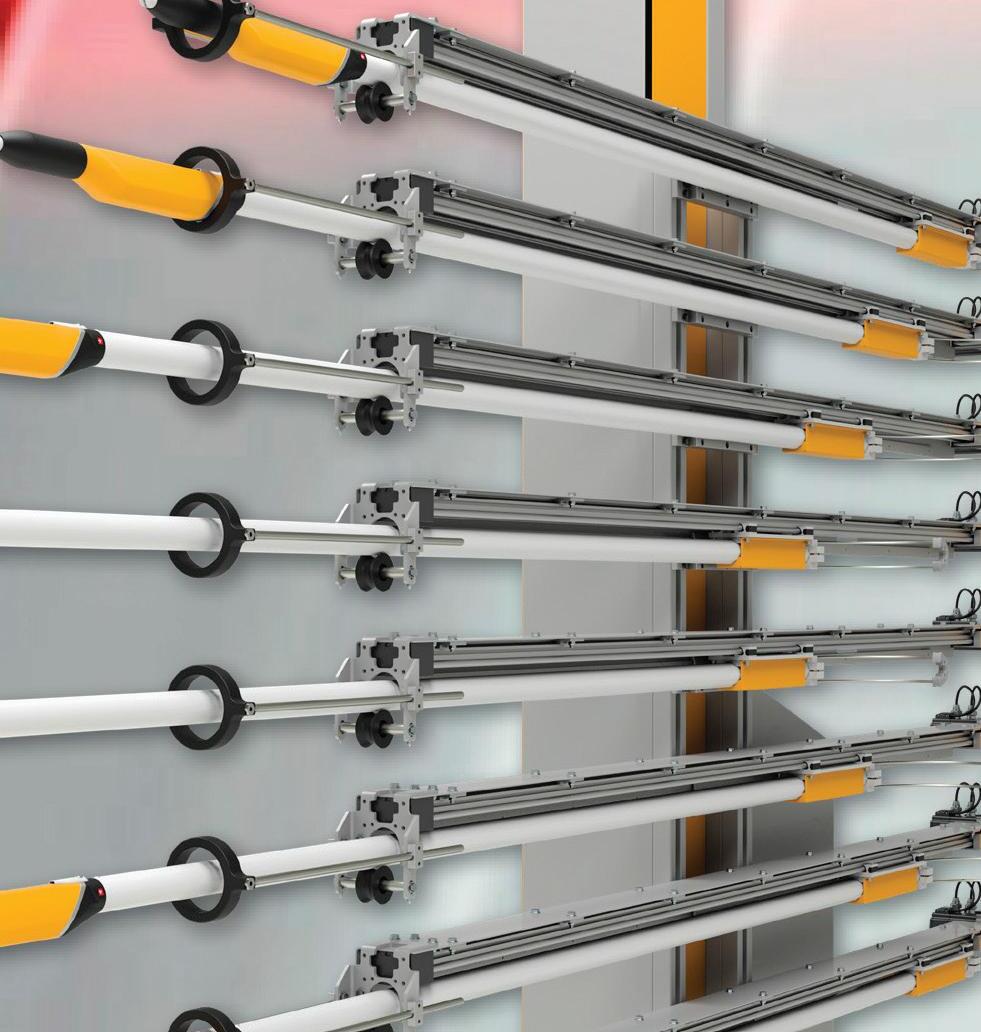

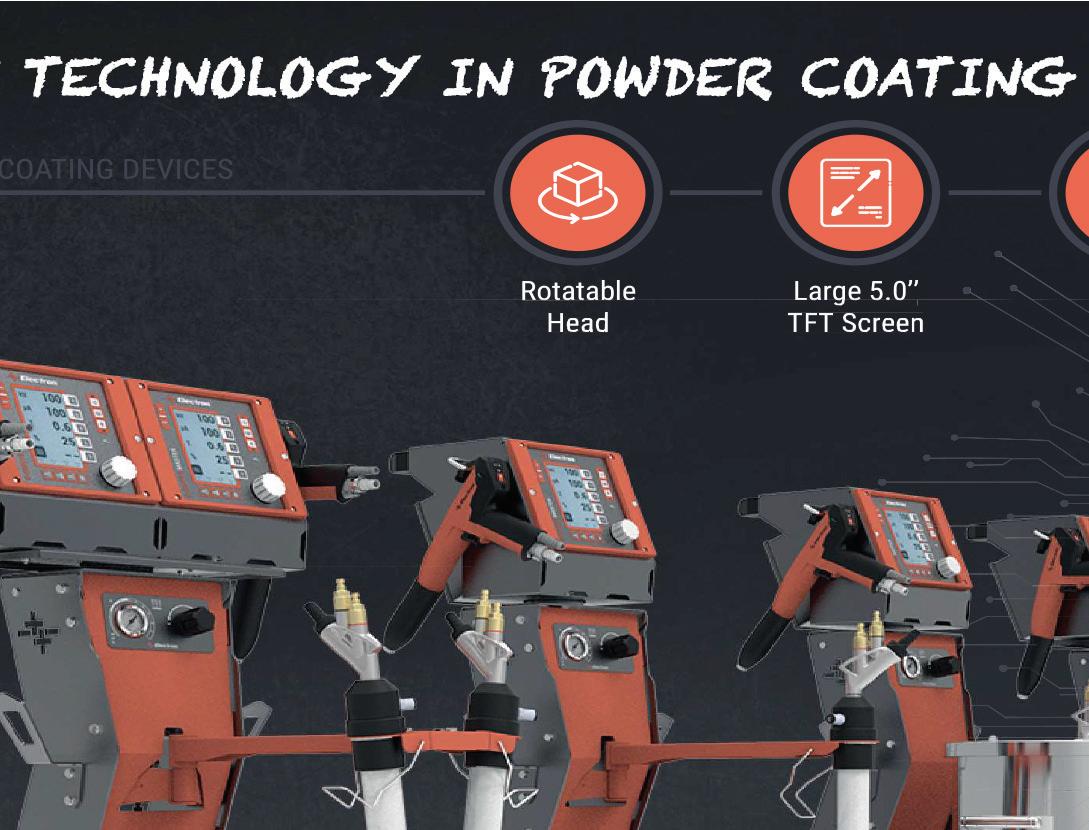

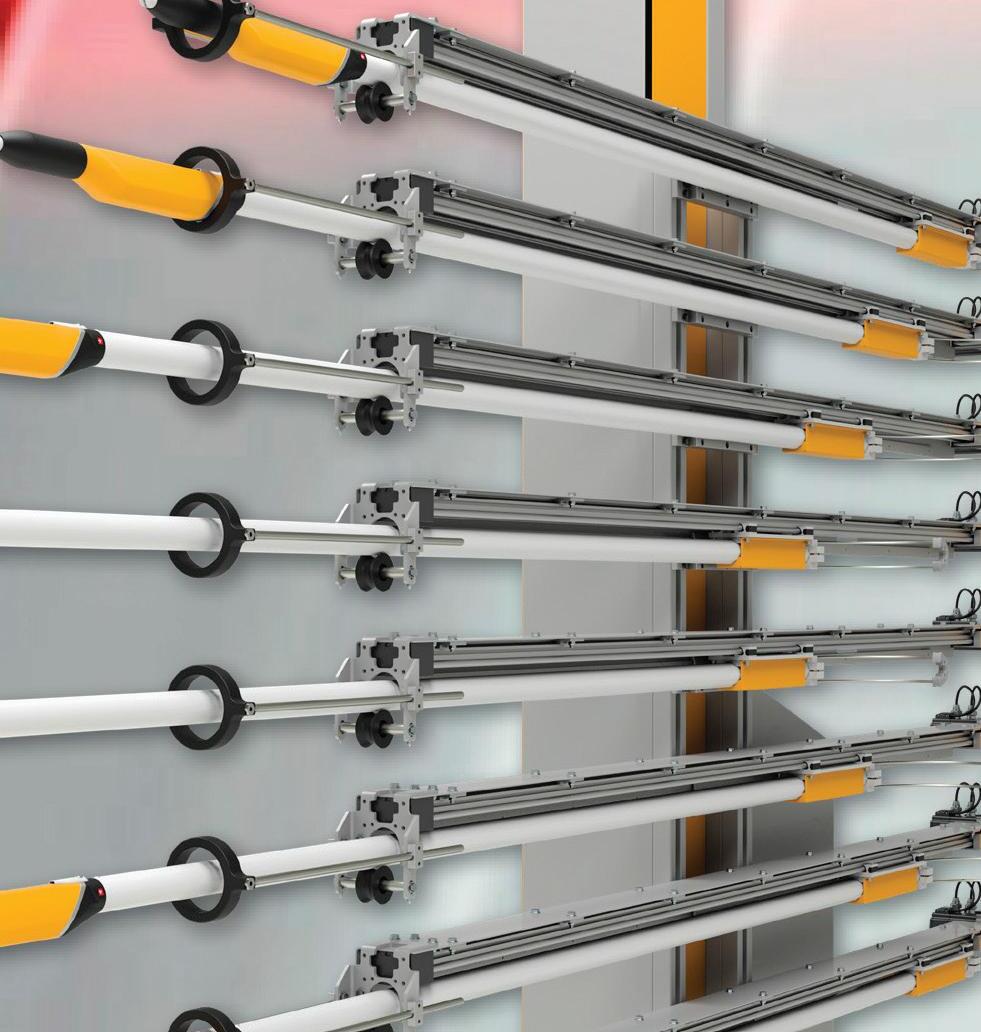

• Ideal for frequent & fast color changes

• High degree of automation for optimum efficiency

• Double-designed fresh powder station for increased productivity

EASY OPERATION . DOUBLE PRODUCTIVITY.

SuperCenter EVO Powder preparation & supply center

wagner-group.com Contact Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone: 01327 368410 enquiries@wagner-group.com

• AirBench takesdustandfumes awayfromyourbreathingzone

• AirBench drawsthemthrough theworksurface,capturingthem insidethebench

• AirBench isavailableinawide rangeofsizesandfiltertypes tosuityourapplication

• AirBench isplugandgo-only needingunwrappingandplugging intoa13ampsocket

•Yougetextractionandwork benchinonecompactunit

Contactusforanon-sitedemonstration. Doubtitcanbethatsimple?

www. airbench.com • 01206 791191 • sales@airbench.com

...wouldyoubeinterested? Ifwecouldsolveyourdustand fumeprobleminminutes... Plugin.Switchon. Dustandfumes? Allgone. Really,it’sthatsimple.

TheVertExmodularbooth system.Dustissuessolved...

• Modular systemforfast installationandassembly.

• LowEnergy throughtheuse ofhighefficiencyfans-upto 20,000m3/hat3kw.

• FiltrationOptions fromthe standardAirBenchrange.

• WeldingandGrinding boothsalso availablewithHEPAfinalfilter.

• RapidReconfiguration -standard componentsmeanVertExbooths canbereconfiguredondemand.

Doubtitcanbethatsimple?

www.ai rbench.com • T . 01206 791191 • E . sales@airbench.com ContactustoviewVertExinoperation.

...quicklyandeffectively.

Plugin.Switchon. Dustandfumes? Allgone. Really,it’sthatsimple.

IN PURSUIT OF EXCELLENCE

By Angus Mackie - QUALICOAT Chair

It is rare to find an industry where competitors work together to jointly research and raise the quality of their product or service, even rarer when it takes place on a global stage. As technology continues to evolve at a rapid rate, the pursuit of excellence is ever ongoing, something the QUALICOAT Membership has been working on for the last 38 years.

Architectural powder coating was once considered as just a form of ‘paint’ to coat aluminium profiles to cover up imperfections such as profile marks and oxidisation to offer a coloured appearance. Coatings at that time lasted a few years, longer if the coater prepared the profiles correctly. How this has changed to today. Architectural powder coatings used on many high rise buildings are expected to offer a lifetime of protection. Most of the work

undertaken over the last few decades to achieve these high performance finishes, has been completed in working groups of licensed QUALICOAT Members who form the complete supply chain of powder manufacturers, pretreatment suppliers, applicators, equipment suppliers and test houses.

Today, all specifiers of architectural aluminium know the benefit of specifying the QUALICOAT label and involving members at an early stage in any development to get the very best coating specification for a project in any location across the globe. Supporting the Association Specification, which is updated yearly and is freely available from the Association website, is third party accreditation. All licensed members are subject to independent, unannounced inspections by an independent accredited test house to ensure the complete membership are following the latest edition of the Specification. Only when it can be demonstrated that a member is in compliance will they be offered a licence to use the QUALICOAT label.

Members of QUALICOAT UK & Ireland are inspected by the independent test house IFO which is located in Schwäbisch Gmünd, Germany. All QUALICOAT licensed powder coaters across the UK & Ireland are inspected twice a year where a report and samples are taken. Reports are issued to the Association and licences can be revoked if procedures laid down in the latest Specification are not being met.

Key to quality control is the licensed member’s Laboratory Technician who constantly monitors process parameters and the testing of product finishes during each working shift. Over the last few years the Association has made it mandatory that all QUALICOAT licence holders own laboratory technicians attend a refresher training course at least once every two years. Run by IFO in the UK, this ensures that the latest developments in the QUALICOAT Specification for production monitoring and production testing is implemented and maintained. This, in turn, ensures compliance with the Specification when unannounced applicator plant inspections are undertaken every six months. Passing these quality audits ensures that an applicator maintains their licence to offer the QUALICOAT Specification.

9 QUALICOAT UK & IRELAND

Members present

Members of the UK & Ireland Association meet four times a year to discuss the latest developments in the Specification with the last meeting being held at IFO’s testing laboratory and offices in Germany. At the meeting Members not present attended via weblink.

It was reported that a further six powder coat applicators in the UK & Ireland are being inspected this year and hoping to become licensed QUALICOAT applicators. This will bring the number of licensed applicators in the region to over thirty.

Discussion on harmonising more closely with BS EN 12206 is something that is being worked on. Already the associations Specification covers most this national standard, but work is underway to try and fully encompass the standard in the associations Specification.

QUALICOAT 3.0 which aims to tighten the specification of aluminium extrusion, especially when recycled content is present, seems to be gathering pace. Currently specified on a per project basis, some extruders are now showing an interest in offering the alloy specification

as a standard product. The tighter specification has proven that the tighter alloy specification offers an extended life expectancy for coatings.

Finally it was discussed that a further optional label was to be added to a licensed member status. Currently members can apply for a ‘Seaside’ qualification, it is hoped that a further

‘Preox’ label will be added which will indicate that a QUALICOAT member can also offer an anodisation pretreatment process alongside more traditional applied pretreatment systems.

Following the Members meeting, delegates were treated to a visit around the IFO testing facilities.

The up-to-date QUALICOAT Specification is available for download via the UK & Ireland Association website, qualicoatuki.org and the website offers an up-to-date list of licensed UK and Ireland Powder Suppliers, Pretreatment Suppliers and Applicators including the applicators who carry the Seaside class accreditation. Telephone support is available from QUALICOAT UK & Ireland Head Office in the Midlands on 0330 240 9735, the Association can also be followed on Twitter @Qualicoatuki or on LinkedIn www.linkedin.com/company/ qualicoat-uk-&-ireland.

10

Members meeting

QUALICOAT UK & IRELAND

IFO laboratory tour

air spray pumps | airless pumps | air assisted airless pumps | pressure pots | spray guns | air filtration & heating | elcometer.com SPRAY IT Designed for the most demanding applications, from high quality fine finish to durable industrial coatings, Elcometer Industrial Spray Equipment is engineered to work as hard as you. Surface World - Changed background CB.indd 3 15/05/2024 11:55:25 Total Filtration design and install dust collection systems for many sectors. After installation we provide maintenance support and replacement filters for your dust and air collection equipment. Our mission is to provide cleaner working environments in your workplace. ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ Reverse Jet Dust Collectors Downflow Dust Collectors Crossflow Dust Collectors Unicell Style Dust Collectors Design & Engineering LEV Inspections by qualified P601 & P602 Engineers Service inspections Cartridge & Bag Installations Tel: 01282 459744 Email: sales@totalfiltration.com We provide an enviable range of ltration solutions, supplies and cleaning services to a wide range of sectors Get in touch or visit us at www.total ltration.com TOTALFLO Bag Collector TOTALFLO Cartridge Collector Engineering & Design LEV Testing Call us on 01282 459744 to find out how we can help you LEV Testing Filtration TOTAL

JOIN US AS WE CELEBRATE 100 YEARS

THE IMF ARE 100 YEARS

OLD IN 2025

In 2025 the Institute of Materials Finishing is celebrating our 100 birthday.

Founded in 1925 as the Electrodepositors Society to serve the electroplating industries, we became the Institute of Metal Finishing in the 1950’s. In 2012 we re-badged ourselves as the Institute of Materials Finishing, to better reflect our involvement with all aspects of surface engineering.

Our celebrations begin in February 2025 at the Surface World exhibition, with a centenary dinner taking place on the first evening, Wednesday 26th February 2025.

Tickets will be £35 per person or a table of 10 for £300.

There will be a 3 course dinner followed by entertainment.

Please let Helen know soonest if you would like to attend by email: helen@materialsfinishing.org.

Further events are being planned throughout 2025, which we are sure will interest and engage all our members. Please keep an eye out for announcements in future editions of IMFormation! Please try to join us as we mark our Centenary!

Email: helen@materialsfinishing.org

INSTITUTE OF MATERIALS FINISHING

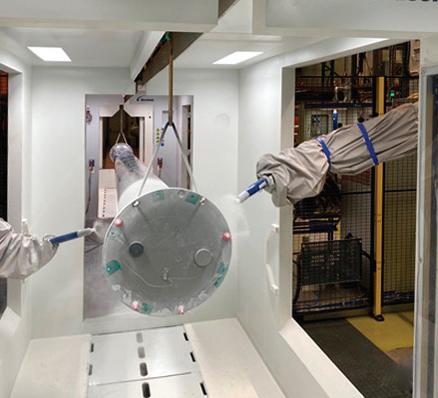

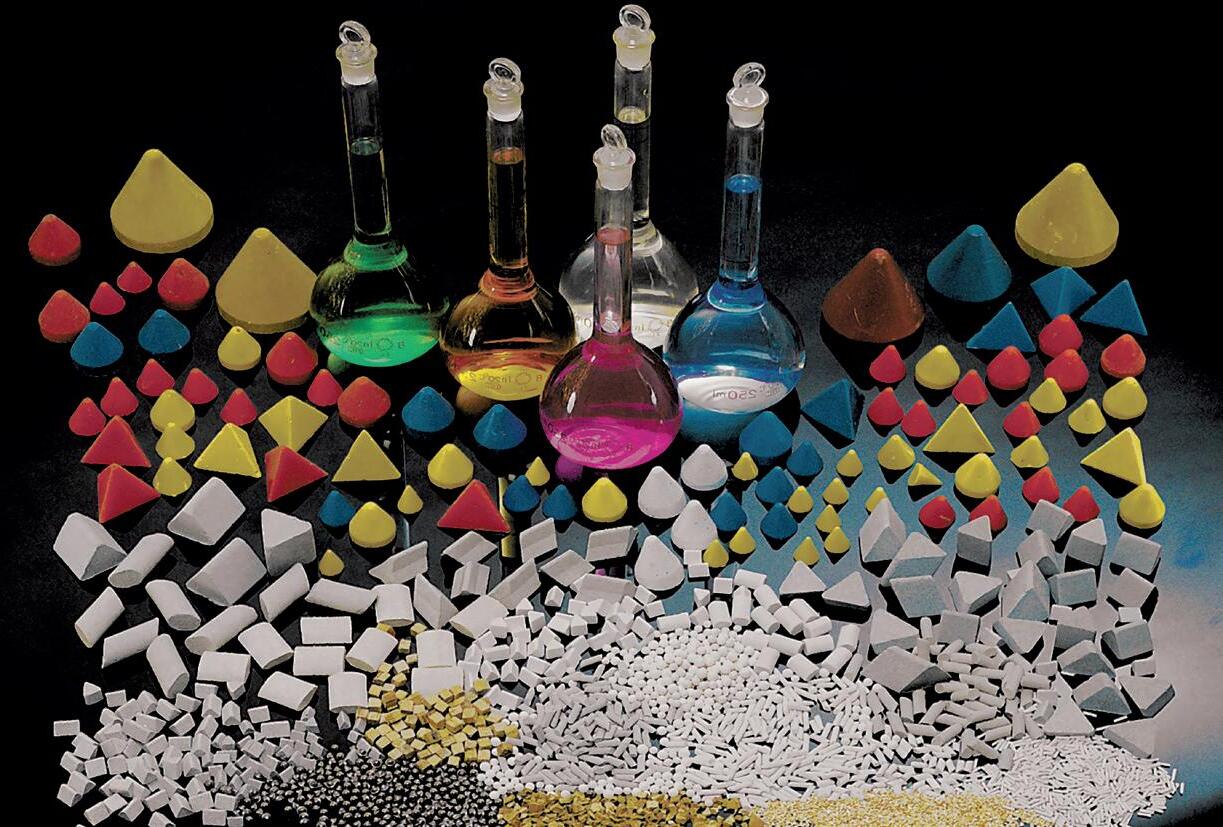

AKZONOBEL’S COMO SITE ACHIEVES HIGHEST AUTOMOTIVE INDUSTRY QUALITY CERTIFICATION

AkzoNobel’s relentless drive to maintain the highest standards and deliver for its customers has been rewarded with automotive industry recognition for the company’s powder coatings site in Como, Italy.

The site – which recently completed a major capacity expansion – has received International Automotive Task Force (IATF) 16949 certification. Awarded following an extensive third-party audit, it recognizes the highest levels of product quality and customer satisfaction.

IATF 16949 certification is the global

technical specification and quality management standard for the automotive industry. It focuses on several key areas, including continuous improvement, defect prevention and waste reduction within the automotive supply chain.

“We’re very proud that our Como site has received this certification,” says Jeff Jirak, Director of AkzoNobel’s Powder Coatings business. “It means we now have three certified powder sites in Europe –following Arnsberg in Germany and Izmir in Türkiye – which demonstrates our unwavering commitment to excellence and customer satisfaction.”

The Como site is the company’s largest powder coatings facility. The recent expansion, which was completed early this year, included the installation of two state-of-the-art lines for automotive

primers, as well as two for architectural coatings.

“Our search for better never stops,” continues Jirak. “Receiving IATF 16949 accreditation is recognition for our tireless efforts to continuously improve and meet the stringent requirements of the automotive industry.”

AkzoNobel supplies high-performance powder and liquid coating solutions to the automotive industry worldwide. The company’s products are approved for use by leading automotive manufacturers such as BMW, Daimler, Porsche, VW, Audi, Ford, Fiat, Renault and Hyundai.

To learn more about AkzoNobel’s powder coatings for the automotive industry, visit https://www.interpon. com/nl/en/automotive

INDUSTRY NEWS

First for Sustainability

With our new Interpon D1036 Low-E powder coating, we’ve created an industry first: a powder coating that can cure as low as 150°C while still being Qualicoat class one certified. It can also cure up to 25% faster than conventional powders, reducing both energy consumption and carbon emissions, and significantly improving your coating line efficiency. Easy to apply Interpon D1036 Low-E has the same application properties as standard formulation, is backed by an Environmental Product Declaration (EPD) and has a global warranty of up to 15 years to deliver the quality performance, color and style your customers need. It is an innovation that supports our collective commitment to sustainability throughout the value chain.

architectural.interpon.com

Mass Finishing

Efficient systems engineering and innovative technologies – powerful and economical

Shot Blasting

Individual systems engineering and intelligent process solutions –reliable and energy efficient

AM Solutions

The full solution provider for 3D post processing equipment and 3D printing services

Surface Finishing is our DNA

Rösler UK Limited| 1 Unity Grove | Knowsley Business Park | Prescot | Merseyside | L34 9GT Tel: +44 (0)151 482 0444 | Fax: +44 (0)151 482 4400 | rosler-uk@rosler.com | www.rosler.com

PosiTector ® Inspection

Unrivaled probe interchangeability for all of your inspection needs.

Coating Thickness Probes

n Ferrous n Non-Ferrous n Combination n Ultrasonic

Surface Profile Probes

n Depth Micrometer n Replica Tape Reader

Environmental Conditions Probes

n Integral n Cabled Magnetic Probe n Anemometer Probe

n 1/2” NPT n Infrared

Hardness Probes

n Shore n Barcol

Salt Contamination Probe

n Bresle Method

Ultrasonic Wall Thickness Probes

n Corrosion n Multiple Echo Thru-Paint n Precision

n Low Frequency n Xtreme

Customized Inspection Kits...

Build your own kit from a selection of gauge bodies and probes to suit your needs.

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595

www.dftinstruments.co.uk e: sales@dftinstruments.co.uk

Proud supplier of DeFelsko Inspection Instruments

LTD

DFT Instruments UK

16A

Coating Thickness Surface Profile Environmental Conditions Ultrasonic Wall Thickness HardnessSalt Contamination

NEW

Proud supplier of DeFelsko Inspection Instruments DFT Instruments UK LTD 16A

www.dftinstruments.co.uk e: sales@dftinstruments.co.uk NEW DesignandFeatures

DesignandFeatures

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595

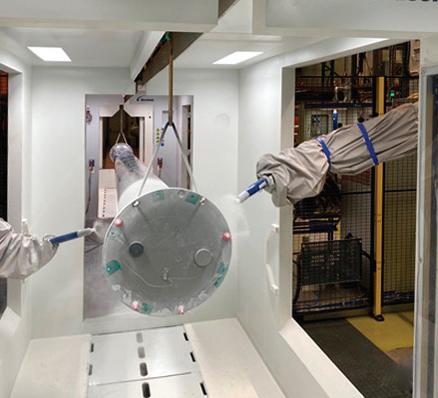

BASF PAVES THE WAY FOR YOUNG PAINTERS AT WORLDSKILLS FINALS LYON 2024

WorldSkills helps to promote worldwide vocational education and training

BASF is exclusive sponsor of the Car Painting category

Participants will use the waterborne paint system Glasurit 100 Line

In 2022, BASF signed a multi-year global industry partnership as the exclusive sponsor of the Car Painting category of WorldSkills International and will be the global silver partner of the 47th WorldSkills Competition in Lyon, France,

with its premium refinish paint brand Glasurit. From September 10–15, over 1,500 participants from more than 65 countries will compete in 62 skill competitions at WorldSkills Lyon 2024. The organization helps to promote worldwide vocational education and training and to show current and future employment needs.

For the car painting skills category, 24 countries are registered to compete with the best talents for the WorldSkills Competition 2024. BASF will support the competition, providing its most advanced waterborne paint system Glasurit 100 Line, backed with outstanding proven benchmark results as the world’s leading waterborne refinish paint system, for outstanding performance in process time, consumption, and sustainability.

“At BASF, we wholeheartedly support the WorldSkills promise, ‘Where is a skill, there is a way!’, and we are very excited to support the most important international skills competition in 2024 in Car Painting skills yet again,” said Chris Titmarsh, Senior Vice President, Global BASF Automotive Refinish Coatings Solutions at BASF.

“We want to empower our next generation of young painters and continue to inspire and motivate them to build a career in the spray-painting profession. That’s why this year, we have stepped up our promise with our most advanced Glasurit 100 Line and AraClass solutions, which will raise the overall bar for training and development as it leads the industry in process time, consumption, and sustainability and will provide an outstanding experience for our young talents.”

With its Glasurit brand, BASF offers the latest in training for products, processes, and color with Know-how via its digital platform Refinity®, one of the most extensive refinish information platforms in the industry. All finalists and WorldSkills experts will be given the opportunity to be trained by Glasurit’s experts via a series of webinars, online training courses and select exclusive training courses at the worldclass Refinish Competence Centers running up to the WorldSkills Competition. “As part of WorldSkills, I am responsible for guiding young painters during their training period. I am excited to explore the capabilities of Glasurit 100 Line and use it to surpass all expectations”, said Bastien Vairé, winner of the Competition EuroSkills Gdansk 2023, and ambassador of WorldSkills France, and part of the French Skills Team.

“Sustainability has become an important element embedded in the assessment of each skill competition as well as an integral skill for every painter to master. By supporting WorldSkills Lyon 2024, BASF again demonstrates the strongest commitment to promoting sustainable solutions and practices for future generations of skilled talent and education systems,” said David Hoey, CEO WorldSkills International.

For more information about the Coatings division of BASF and its products, visit www.basf-coatings.com

18 INDUSTRY NEWS

Solutions for recycling SOLVENTS Save Money | Recycle Any Solvent High Yield | Low Waste ASK FOR A FREE QUOTE SYSTEMS Units available for any quantity and application Safe and easy to use Recycled solvent as good as new Atex certified for flammable solvents The number one choice with over 38,000 units worldwide • BUY OR LEASE info@solutex.co.uk | 01691 622 225 For more information visit: www.solutex.co.uk

BOROUGH CHROME APPOINTS

NEW QUALITY MANAGER

Injection moulding and chrome plating specialist Borough Chrome has announced David Burtonshaw as the company’s new Quality Manager, responsible for working closely with customers and suppliers to ensure continuous quality improvement.

He brings a wealth of experience to the role, with a proven track record of increasing responsibility in quality control practices, whilst demonstrating his ability to implement innovative solutions that drive better performance, decrease exposure and strengthen systems.

David Brereton, Joint Managing Director at Borough Chrome, commented: “We are building a talented team here at Borough and David is the latest recruit that brings a new perspective to the service we provide as injection moulders and chrome paters of plastic components.

“Our business is shaped by the needs of our growing client base across a range of different sectors, who all have unique requirements, but share the same desire for high quality components, whether chrome plated or not. David will help our service reflect these needs.

“After meeting with him and explaining our ambition to be Europe’s go-to chrome plating specialist, it was obvious he will be a great fit for the team and our growth, with lots of hands-on experience leading all stages of system development efforts.

“David is an effective problem solver, who will help us improve the quality of our service in the face of major challenges, such as energy costs, raw material costs and the move away from hexavalent chrome later this year. It’s great to have him on board

Borough Chrome Quality Manager David Burtonshaw said: “I’ve been involved in quality assurance and management for more than 30 years and in that time, I have encountered and resolved every conceivable quality issue, so I’m confident I have what Borough needs.

“Our aim is to continuously improve the quality of the products and services we provide, to the point when we are not just the UK’s leading chrome plater of plastic components, but Europe’s. It will take a lot of hard work and innovation, but that encapsulates the Borough approach.

“As a local to the Leigh-on-Sea facility, I’ve known the business for many years and watched its growth and transformation with interest. The opportunity to work with the senior team to help build

Borough for a busier, brighter future, was one I could not pass up on.”

Brereton concludes: David’s not just a highly qualified quality manager, but a really friendly approachable individual, with a determination to succeed. There will be challenges ahead, but we are building a team capable of delivering results, whatever we’re faced with. And that’s good for Borough Chrome, the workforce and the UK economy.”

Visit: www.borough.co.uk

INDUSTRY NEWS

Scan & Spray

Dynamic Contour Detection

Programming-free coating of any shape! Gema

The second generation of Dynamic Contour Detection detects the object contour fully automatic and positions the guns individually even for thin objects and at high conveyor speeds. Due to the programming-free adaption of all relevant line settings the application range is significantly extended.

Email: uk.sales@gema.eu.com

Europe Srl – UK Branch

Tel: 0044 1202 763 942

gemapowdercoating.com

3M® NOVEC IS BEING DISCONTINUED,

DON’T JUST SWITCH IMPROVE

You may have heard the latest information from 3M® that they will exit from the manufacturing of Cleaning solvents in the near future. If you are a current 3M® cleaning solvent product user you will need to start to find 3M® alternative solvents. Find out what steps you have to take below…

What

is the update from 3M®?

3M® have announced that they will stop manufacturing the Novec HFE materials by the end of 2025. Please click here to see a copy of the notice. They also have stated in a letter sent to all their customers last year that they cannot guarantee supply and that current users should be looking at alternatives as quickly as possible.

Are you a current 3M® user? If yes what does the update from 3M® mean for you?

While there are no immediate issues with supply it would be prudent to consider your options before the supply of the 3M® materials becomes an issue. Frasers can help with direct drop in alternatives to the Novec materials as well as alternative technologies such as water wash and solvent recovery systems etc.

What alternatives are available for me to switch to?

There are a few direct drop in alternatives available, but it should be noted that many of these contain HFE materials manufactured by 3M®. These can sometimes be hidden away and not openly declared so it is important to know what is in any alternative you are considering and the source of these materials. Frasers can assist with evaluating your current application and offer free advice on legal compliance and safe, available alternatives such as the Chemours Opteon™ speciality fluids which are direct drop in alternatives.

What to be aware of before you switch?

Suitability of equipment, material compatibility, product performance and legal compliance are just some of the key areas to look at here. At Frasers we can run application trials with suitable alternatives and advise on alternative chemistries and or equipment if relevant.

Don’t Just Switch from 3M® Novec, Improve Outcomes with Opteon SF80®

If you’re among those looking for a suitable replacement,

consider not just switching but also improving your outcomes with Opteon™ SF80®. When evaluating cleaning solvents, solvency power is a critical factor. The Kb value, measured by ASTM D1133, is a common indicator of a solvent’s cleaning strength. Solubility Opteon™ SF80 has the highest cleaning power of any cleaning fluid in its class as measured by the Kb value (Kb value = 99). The Kb value is determined by ASTM D1133 and is a well-known measurement of solvency strength. In general, the higher the Kb value, the greater the cleaning power.

Opteon™ SF80® is a superior alternative to 3M® Novec products, offering higher solvency power and lower environmental impact. In this article, we explore the benefits of Opteon SF80®, compare its performance with 3M® Novec products, and outline key considerations when making the switch.

Opteon™ SF80 is a safe, non-flammable, and environmentally friendly solvent with low global warming potential (GWP)(<2.5) does not contain any fluorinated greenhouse gases (as listed in Annex 1 of the EU regulations 517/2014), which are all highly desirable in industrial cleaning applications like vapor degreasing.

What is the Global Warming Potential of SF80®?

SF80® has a GWP of less than 2.5 meaning it has an exceptionally low GWP of any fluorinated solvent on the market today by a significant margin.

What does Global Warming Potential mean?

Global-warming potential (GWP) is a relative measure of how much heat a greenhouse gas traps in the atmosphere. It compares the amount of heat trapped by a certain mass of the gas in question to the amount of heat trapped by a similar mass of carbon dioxide. A GWP is calculated over a specific time interval, commonly 20, 100 or 500 years. GWP is expressed as a factor of carbon dioxide (whose GWP is standardized to 1). For example, the 20 year GWP of methane is 72, which means that if the same mass of methane and carbon dioxide were introduced into the atmosphere, that methane will trap 72 times more heat than the carbon dioxide over the next 20 years.

Is SF80® affected by F-gas regulations?

SF80® contains no materials regulated under the F-Gas regulations.

22 INDUSTRY NEWS

Is SF80® affected by the Solvent Emissions Directive?

SF80® is an R20 based solvent and as such the SED does apply however the SED threshold limit for SF80® is 2 metric tons.

What shall I do now?

Try Before You Buy: Experience the benefits of Opteon™ SF80® through our trial program.

Full Process Evaluation Trials: We’ll help you optimise your cleaning processes with comprehensive evaluations.

On-Site Chemical Changeover

Support: Our team provides on-site assistance to ensure a smooth transition.

Process Optimisation: We guide you through every step, from chemical changeover to process refinement.

We will assist you in considering alternates that could improve outcomes, whether cleaning or environmental, and how we can support your transition and enhance your cleaning processes.

We are currently offering free 3M® switch reviews for any customers who are wanting some advice on when they should make their switch and how the process would work for them as remember every application is different. Contact us today by visiting www.frasertech.co.uk to get this in your diary.

Powder Checker

Non-contact Uncured Powder Thickness Gauge

Affordably measures uncured powder coatings using non-contact ultrasonic technology to predict a cured thickness

Dedicated stand-alone unit is ready to measure right out of the box

Fast measurement speed—ideal for moving lines and swinging parts

Scan Mode continuously takes measurements—ideal for analyzing large areas

Storage of 999 readings with onscreen averaging. Stored readings can be downloaded to PosiSoft Desktop Software

Powder Inspection Kits

Complete solutions for measuring powder coating before and after cure are available

16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk

LEADING NATIONAL GALVANIZERS

PROUD TO BE CHROME-FREE

As part of their ongoing mission to become a truly sustainable business, a national galvanizing company has successfully become completely Chromium Trioxide free.

After dedicating several years and significantly investing into the research, development and trials of alternative chemicals, Wedge Group Galvanizing Ltd is proud to have completely removed Chromium Trioxide from their processes – months ahead of the latest legislation set to govern this industry-wide.

David Nobes, Technical Services Director at Wedge Group Galvanizing Ltd, said:

“Over the past few years in particular, we’ve made a conscious effort to reduce or remove high-risk and non-sustainable chemicals and metals from the galvanizing process – to ensure it’s safer for our team, compliant with legislation, and in line with our sustainability targets (and that of our customers too).

“With no direct equivalent to Chromium Trioxide available, it’s challenging for businesseslike ourselveswho want to not only adopt new procedures ahead of changing rules and regulations, but who want to also discover innovative, sustainable, and safer solutions.”

Chromium Trioxide is traditionally used in the passivation process during galvanizing. It creates a protective surface on the galvanizing coating that keeps the surface bright and shiny for up to 12 weeks, and minimises wet storage stain on the coating for the immediate period after galvanizing.

But as of September 2024, the European Union’s REACH legislation is banning the use of Chromium Trioxide in most manufacturing processes (including galvanizing). Due to this, the leading UK supplier will cease manufacture of the chemical ahead of this upcoming deadline.

David added: “This isn’t a new phenomenon to us and so we’ve luckily been unaffected by the regulation change. We’ve spent many years searching for an alternative solution, and one product in particular stood out to us as it works in a similar way alongside existing equipment and processes. Since 2020, we’ve been successfully

trialling this non-chrome product at several of our plants, and it became common practice across all 14 at the end of April.

“To date, our customers have been pleased with the results – with the majority not even able to notice the difference, and we’re delighted that the transition to using a chrome-free process has been smooth. We’re working tirelessly to ensure we continue to achieve a consistent, quality, and aestheticallypleasing finish for all that complies with legislation, and is kinder to our team and our planet.”

Wedge Group Galvanizing Ltd is the largest hot-dip galvanizing organisation in the UK with a history dating back over 150 years. With 14 plants strategically placed across the country, the firm offers a truly national galvanizing service.

For further information, please contact Wedge Group Galvanizing Ltd on 01902 601944 or visit www.wedge-galv.co.uk.

24

INDUSTRY NEWS

•

•

•

•

Hot dip galvanizing provides you with long-term protection against rust and corrosion of steel products.

With 14 plants across the UK, Wedge Group Galvanizing is the UK’s largest hot dip galvanizing organisation offering a national service, collection and delivery and 24hr turnaround on request. The group can process anything from small components to 29m structural beams.

ASK FOR A FREE QUOTE Manual | Automatic Our high quality, advanced range of equipment provides the best way to clean paint spray guns or industrial parts. With numerous options, you can be sure that there is a model in our extensive range that meets your cleaning requirements using either solvents or water.

ATEX certified High quality alloy pumps

Stainless steel construction

Solutions for Parts & Paint Spray gun cleaning WASHERS

•

•

Wash cycle controlled by timer

Wash & rinse Hot water wash

Inbuilt water recycling

Inbuilt solvent recycling

Air extraction

2 year warranty BUY OR LEASE www.solutex.co.uk info@solutex.co.uk | 01691 622 225 For more information visit: Head Office: Stafford Street, Willenhall, West Midlands, WV13 1RZ SO 9001 Quality Management FM 00382 E: info@wggltd.co.uk T: 01902 601944

•

•

WEDGE GROUP GALVANIZING Your Galvanizing Partner

ROSPA HEALTH AND SAFETY AWARDS 2024 - WINNER OF THE COVETED BEST NEW ENTRY AWARD

Hydro Aluminium UK Ltd, a subsidiary of the global aluminium and renewable energy company Norsk Hydro, has demonstrated its commitment to elevating health and safety standards by entering the UK’s leading health and safety awards scheme and scooping two accolades from The Royal Society for the Prevention of Accidents (RoSPA).

Hydro Aluminium UK Ltd was awarded both a Gold Achievement Award and a Best New Entry Award (UK) at this year’s RoSPA Awards for its strong commitment to health and safety. It was awarded the accolade after it took a thorough approach to clearly explaining and demonstrating its health and safety management system in action during the past year. The organisation also ran a series of initiatives such as a family fun day, safety stand down days and extracurricular first aid training, and installed a series of defibrillators for general public use.

Erika Curnow, an apprentice interim manager at Hydro Aluminium UK Ltd,

was also announced as the winner of RoSPA’s Inspiring Women in Safety Award, for her own personal inspirational impact within health and safety at the organisation.

Sponsored by EcoOnline, a leading provider of EHSQ software solutions, RoSPA’s Best New Entry Award recognises outstanding submissions made by organisations entering the RoSPA Awards for the very first time.

The RoSPA Health and Safety Awards is one of the largest occupational health and safety awards programme in the world. Now in its 68th year, the Awards have almost 2,000 entries annually, covering nearly 60 countries and reaching millions of employees. The programme recognises an organisation’s commitment to continuous improvement in the prevention of accidents and ill health at work by looking at entrants’ overarching health and safety management systems, including practices such as leadership and workforce involvement.

RoSPA Award judges include a wealth of highly experienced senior occupational health and safety professionals and consultants, and a main award judging panel chaired by Dee Arp, Chief Operations Officer at NEBOSH, and other in-house experts and selection panels.

Ian Bould from Hydro Aluminium UK, said:

“We’re thrilled to win RoSPA’s Best New Entry Award (UK) and a Gold Achievement Award during our first year in the scheme. Safety is paramount at Hydro Aluminium UK, and this award reflects our team’s dedication and determination to make health and safety an absolute priority.”

Matt Cryer, Head of the RoSPA Awards said:

“As a newcomer to the RoSPA Awards, Hydro Aluminium UK has made a remarkable impression with their approach and commitment to health and safety. Their comprehensive approach to workplace safety sets a high standard for other organisations to follow.

“Hydro Aluminium UK’s recognition with the Best New Entry Award (UK) highlights their proactive efforts in promoting a safe working environment for their employees, aligning with RoSPA’s mission to prevent accidents and save lives.”

Matt Rouse, SVP Customer Success, Europe at EcoOnline, the organisation that sponsored the Best New Entry Award, said:

“We are proud to sponsor RoSPA’s Best New Entry Award and are excited to see the determination organisations have to ensure their employees get home safely at the end of the working day. We extend a huge congratulations to Hydro Aluminium UK and look forward to seeing how they progress within the RoSPA Awards Scheme.”

For more information please visit: https://www.rospa.com/awards

26 INDUSTRY NEWS

Ian Bould, HSEQS Director UK, (centre right) and members of the Hydro Aluminium team

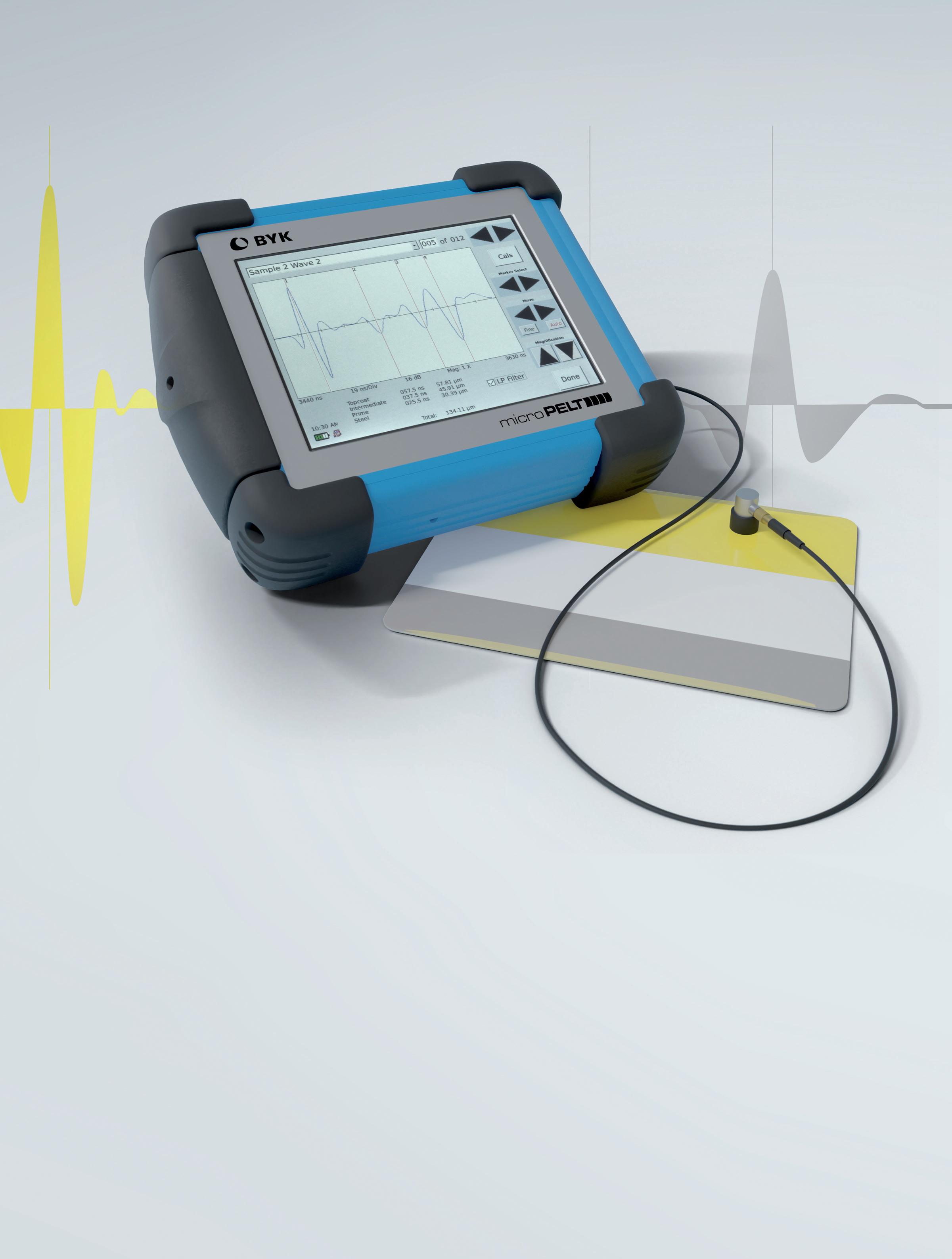

PELT Ultrasound

Accurate echoes from layer to layer

PELT high-resolution ultrasound sets the global standard for precise multi-layer thickness gauging. Obtain multi-layer measurements on virtually any substrate material including plastics, composites, glass, wood, steel, aluminum, and even paper. PELT ultrasound provides the power of acoustic microscopy in a hand-held gauge. Easily verify thickness of critical performance and protective coatings, visualize re-coats and repairs, and monitor and tune your coating application processes.

Measure what you see.

| www.PELTGauge.com Have a chat with us: Surfex 2024 Booth 216

www.byk-instruments.com

“The Professionals” email info@pros trip.co.uk phone 01 1 5 91 1 2240 “Save up to 20% on your monthly s tripping cos ts” Send your enquir y today!! Sub contract specialists in Paint & Powder coat removal to the finishing industr y JIG CLEANING PAINT BOOTH GRID CLEANING COMPONENT RECLAMATION EST . 1989 Pro-Strip Ltd. Trent Lane, Daleside Road, Nottingham NG2 4DS web www.prostrip.co.uk

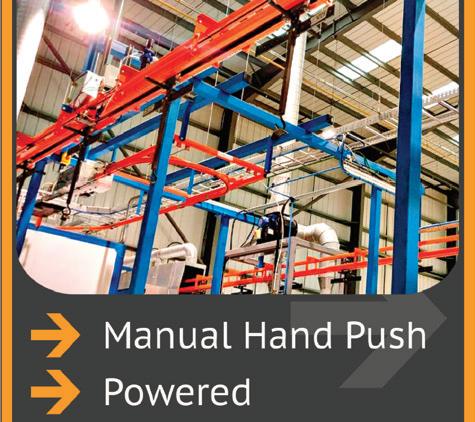

Handling Solutions

Product Overview

Manual Monorail Systems

Unit loads up to 3000kg

Monorail Chain Conveyors

Unit loads up to 300kg

Power & Free Conveyors

Unit loads up to 7000kg

Floor Conveyors

Unit loads up to 500kg

Stewart Gill Conveyors Ltd have been supplying overhead conveyors into all sectors of industry for over 70 years.

As a long time member of the Railtechniek van Herwijnen BV Group based in the Netherlands, Stewart Gill Conveyors can offer a comprehensive range of overhead conveyor products which are capable of handling unit loads up to 7000kg.

Stewart Gill Conveyors Ltd offer complete manufacture, installation and commissioning, coupled with fully documented instruction, operation and maintenance manuals.

We do:

In-House 3D CAD engineering

In-House manufactoring in the UK and EU

In-House design of PLC/PC control systems

Industry 4.0

Worldwide installation and commissioning

Remote support, service & inspection Stewart

Part of the

Gill Conveyors Ltd Unit 3&4 Brook Business Park Brookhampton Lane Kineton, Warwickshire CV35 0JA, United Kingdom Tel: +44 (0)1926 641424 info@stewart-gill.co.uk www.stewart-gill.co.uk

EVOPHASE RECOGNISED AS FINALIST IN PRESTIGIOUS MANCHESTER PRIZE

EvoPhase, which enhances the performance of industrial process equipment, has been selected as a finalist for the inaugural Manchester Prize.

Announced by Chancellor Jeremy Hunt last Spring and launched in December 2023, the Manchester Prize celebrates teams of innovators that develop AI solutions to overcome challenges in the fields of energy, environment and infrastructure.

EvoPhase was chosen as one of just ten finalists, recognising the potential of the team’s work using novel evolutioninspired AI methodologies to improve the design of manufacturing equipment.

This AI-led ‘evolutionary design’ approach is applicable to a diverse range of process equipment, including mills, dryers, roasters, coaters, fluidised beds, stirred tanks and more.

The EvoPhase team is using their technology to develop EvoPhase Explore, a software-as-a-service platform that optimizes the geometry of processing equipment, to meet requirements in energy, throughput and mixing rate.

It is expected to transform industrial processes by significantly reducing energy consumption and enhancing operational efficiency while also making a meaningful contribution to environmental sustainability by reducing waste.

Explore addresses some of the most pressing challenges in the fields targeted by

the Manchester Prize. As EvoPhase continues to refine and advance EvoPhase Explore, the team is excited to leverage the support and opportunities provided by the Manchester Prize to bring their solution to the forefront of industrial technology.

The Manchester Prize finalists were chosen by independent assessors based on rigorous criteria that include innovation, impact, long-term viability, feasibility, and adherence to safety and ethical standards. EvoPhase’s selection highlights its commitment to these values and its potential to influence significant positive change within the industry.

“We are immensely proud to be acknowledged as a finalist for the Manchester Prize,” said Dominik Werner, Co-founder and CEO of EvoPhase. “This recognition is a testament to our team’s dedication and innovative approach to harnessing the power of AI for real-world impact. EvoPhase Explore represents a major advancement in our mission to support industries in becoming more efficient and environmentally responsible.”

EvoPhase was launched by University of Birmingham Enterprise last year, using a unique model of commercialisation known as an Operating Division, which allows industry rapid access to flexible, cutting-edge services from the University of Birmingham’s academic innovators.

CEO Dominik Werner will be hosting a webinar on EvoPhase Explore on June 25th at 4 pm (BST).

To sign up for the event please visit www.evophase.co.uk/webinar

For more information about EvoPhase, visit https://evophase.co.uk/

30 INDUSTRY NEWS

(left to right): Chief Executive Officer Dominik Werner, Chief Scientific Officer Dr Kit Windows-Yule, Chief Operating Officer Jack Sykes, and Chief Technology Officer Leonard Nicusan are all from Birmingham’s School of Chemical Engineering.

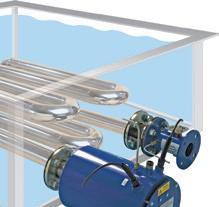

climatic conditions | surface cleanliness | coating thickness surface profile | weld inspection | surface inspection Everything you need for fast and accurate coating inspection in one cost-effective, easy-to-use kit. elcometer.com INSPECT IT Surface World - Changed background CB.indd 2 15/05/2024 11:55:23 SPECIAL SYSTEMS ACIDPURE | Acid recycling EASYPURE | Fluid recycling IONPURE | Ionic filtration ACIDVAC | Acid draining vacuum EDUCTORS | Bath agitation [...] PUMPS & FILTERS L SERIES | Medium flow rate filter P SERIES | Ultra-high flow rate filter A SERIES | Mechanical seals pump M SERIES | Magnetic drive pump T SERIES | Vertical pump [...] We solve our customers filtration, chemical transfer and treatment needs. Contact us SIEBEC UK Ltd, Stafford +44 (0) 1785 227700 sales@siebec.co.uk www.siebec.co.uk FILTER MEDIA L-TECH | Pleated cartridge BAGTECH | Filtration bag QUALITHERM | Extruded cartridge QUALIBOB | Wound cartridge ANODTECH | Anode bag [...]

SURFACE WORLD 2025:

Learn, Connect and Shape the

Future

– Under One Roof, Over Two Days

Surface World 2025 is more than just a typical trade show – it’s an event that’s all about transforming the surface finishing industry. Set to take place on Wednesday 26th and Thursday 27th February, it’s a two-day gathering where professionals from the industry come together to learn, connect, and shape the future.

This two-day event is more than just a showcase of products; it’s a platform for innovation, learning, and networking. Attendees can expect to see the latest advancements in surface finishing technologies, from state-of-the-art machinery to cutting-edge techniques that are pushing the boundaries of what’s possible in the industry.

Surface World 2025 provides the perfect opportunity to get hands-on experience with the newest technologies and ideas shaping the future of surface finishing. From environmentally friendly coatings designed to minimise ecological impact or delving into the intricacies of advanced automation systems streamlining production processes, participants can explore diverse innovations first-hand.

With a vast array of specialist experts from within the industry and interactive demonstrations taking place on the exhibitor’s stands, attendees will have the chance to gain valuable insights and knowledge that can help them stay ahead of the curve in this fast-paced industry.

Networking plays a crucial role at Surface World 2025, offering attendees a valuable

opportunity to expand their professional connections within the surface finishing industry. Beyond merely exchanging business cards, this event provides a dynamic platform for forging meaningful partnerships and exploring collaborative ventures. Attendees will have the chance to engage with like-minded professionals, share insights, and cultivate relationships that can lead to new opportunities for growth and innovation. Whether it’s discovering potential collaborators for projects or finding mentors to offer guidance, the networking opportunities at Surface World 2025 are bound to leave a lasting impact on attendees’ careers and businesses.

Surface World 2025 represents a pivotal moment for the surface finishing industry. It’s a chance for professionals to come together, share ideas, and shape the future of the industry. Whether you’re a seasoned veteran or just starting out in the industry, there’s something for everyone at Surface World 2025.

So mark your calendars and get ready for an unforgettable experience at Surface World 2025. It’s sure to be an event that will leave a lasting impact on the surface finishing industry for years to come.

Surface World 2025

Hall 11, NEC, Birmingham 26th & 27th February 2025

For more information about Surface World 2025, please contact Nigel Bean: nigelbean1@aol.com

32 SURFACE WORLD 2025

Surface World 2025 - Wednesday 26th & Thursday 27th February

The Surface World Trade Show is an exciting event that brings together professionals from the surface treatment and coating industries, providing an excellent opportunity to explore, learn, and collaborate in this ever-evolving sector. Discover the latest trends, advancements and innovations in surface treatment and coating techniques. Find practical and effective solutions to enhance the durability, aesthetics, and performance of surfaces. Connect with manufacturers, suppliers, and fellow industry peers to build valuable business relationships.

2025

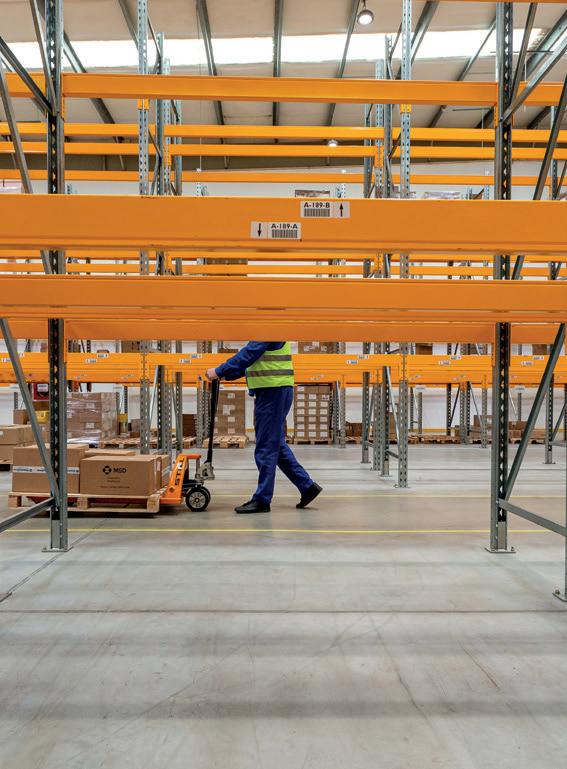

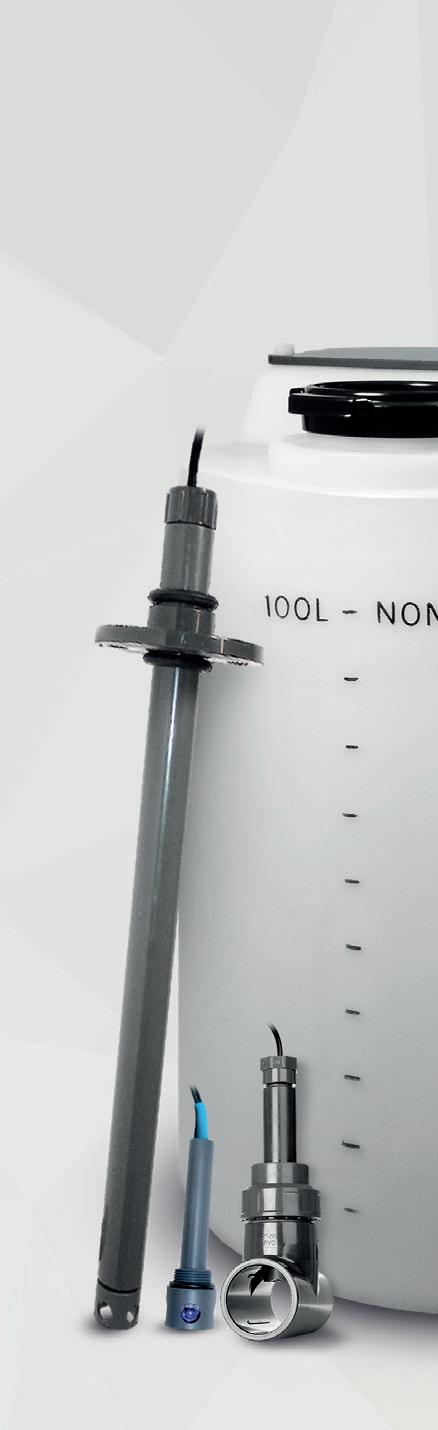

REDUCE COSTS WITH INLINE

MEASUREMENT FOR ELECTROPLATING

REEL-TO-REEL APPLICATIONS

Keeping the tolerance limits for layer thicknesses

Electroplating reel-to-reel production lines need to maintain minimum and maximum tolerance limits for the applied coatings. To save costs, layers are coated as thin as possible - especially when using precious materials. However, a certain margin between the minimum limit and the nominal applied layer thickness is necessary to ensure the adherence of the lower tolerance limit due to process variations.

Efficient Coating Processes

Usually, strips at the beginning and at the end of a reel are cut out manually and measured offline. This is time consuming for the staff and the reaction time is too long: If a tolerance limit is violated, it is too late to interfere since the coating process is finished and the reel already left the production line.

The X-ray fluorescence method (XRF)

Inline measurement equipment – based on the x-ray fluorescence (XRF) principle – provides continuous data about the applied coating thickness and allows immediate production process control. Feedback loops can be set up either with automatic communication between XRF instrument and coating line or manually by the operator. Therefore, the nominal applied thickness can be chosen to be closer to the minimum tolerance limit which significantly saves costs. Obviously,

this is most effective for valuable metals but it also adds up for other coating materials. Additionally, products with rather tight tolerance limits can be manufactured only if there is a measurement system in the production line to determine the actual applied coating.

Saving Cost and Time with the Right Measurement Technology

The following example where a gold (Au) coating of 2 – 4 µm needed to be applied shows the cost saving effects of such inline process control: Using offline instruments for quality control the nominal coating thickness was set to 2.8 µm Au to ensure not to violate the tolerance limit. After installing the inline measurement system FISCHERSCOPE® X-RAY 4000, the nominal coating thickness could be lowered to 2.3 µm Au.

Just by saving the 0.5 µm gold coating, the investment was amortized within half a year! Additionally, the production is now 100% documented. Every customer buying an electroplated reel gets a protocol with a statistical summary and a profile ensuring that the whole strip is coated properly within defined tolerance limits.

The Optimum Measurement Device for Production-Lines

Using the FISCHERSCOPE® X-RAY 4000 production cost can be lowered significantly by reducing material consumption, especially effective for precious materials, and by eliminating scrap production. Additionally, 100% of the applied coatings on the product are recorded and therefore traceable to comply with ISO9000 standards. For further information, your local FISCHER partner will be glad to assist you.

For more information, please contact your local FISCHER representative:

FISCHER INSTRUMENTATION (GB) LTD - 12 Goodwood Road, Keytec 7 Business Park, Pershore, Worcestershire, WR10 2JL.

Telephone: +44 (0)1386 577370 Or visit: www.fischerinstrumentation.co.uk

34

TESTING & MEASUREMENT

The FISCHERSCOPE® X-RAY 4000

TUNE IN TO SEE YOUR PAINT

CURE OPERATION LIVE!

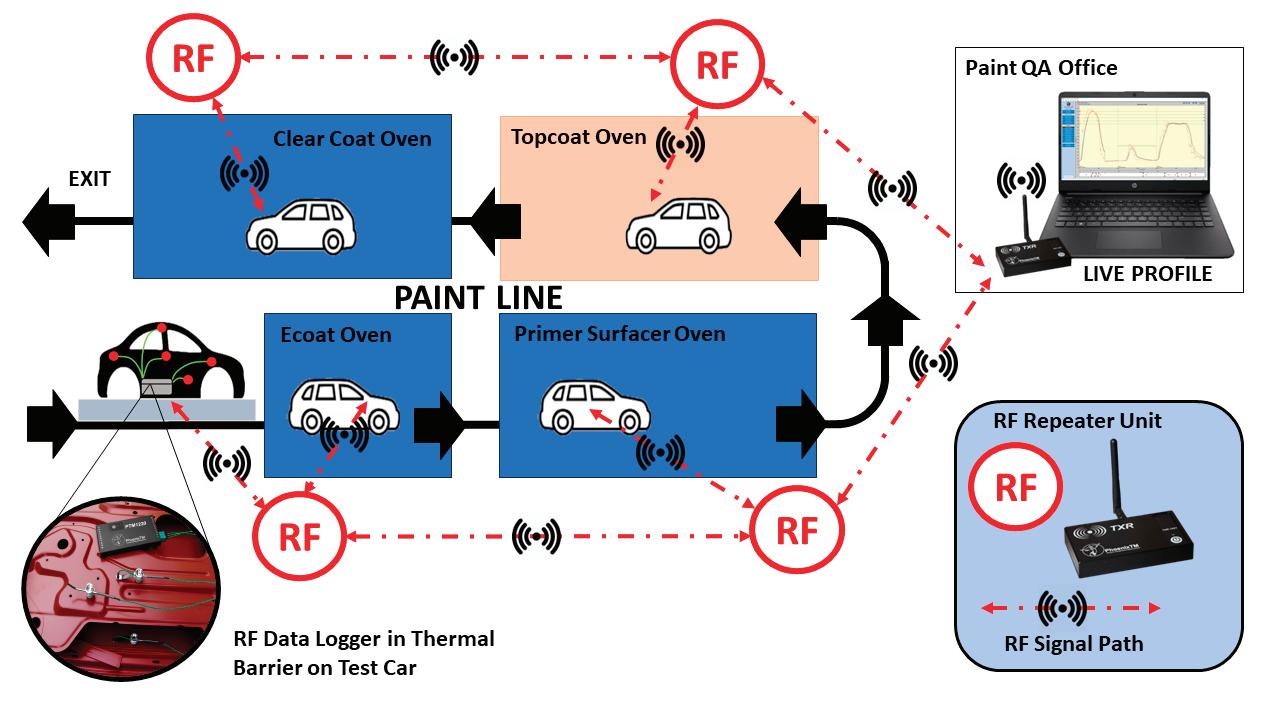

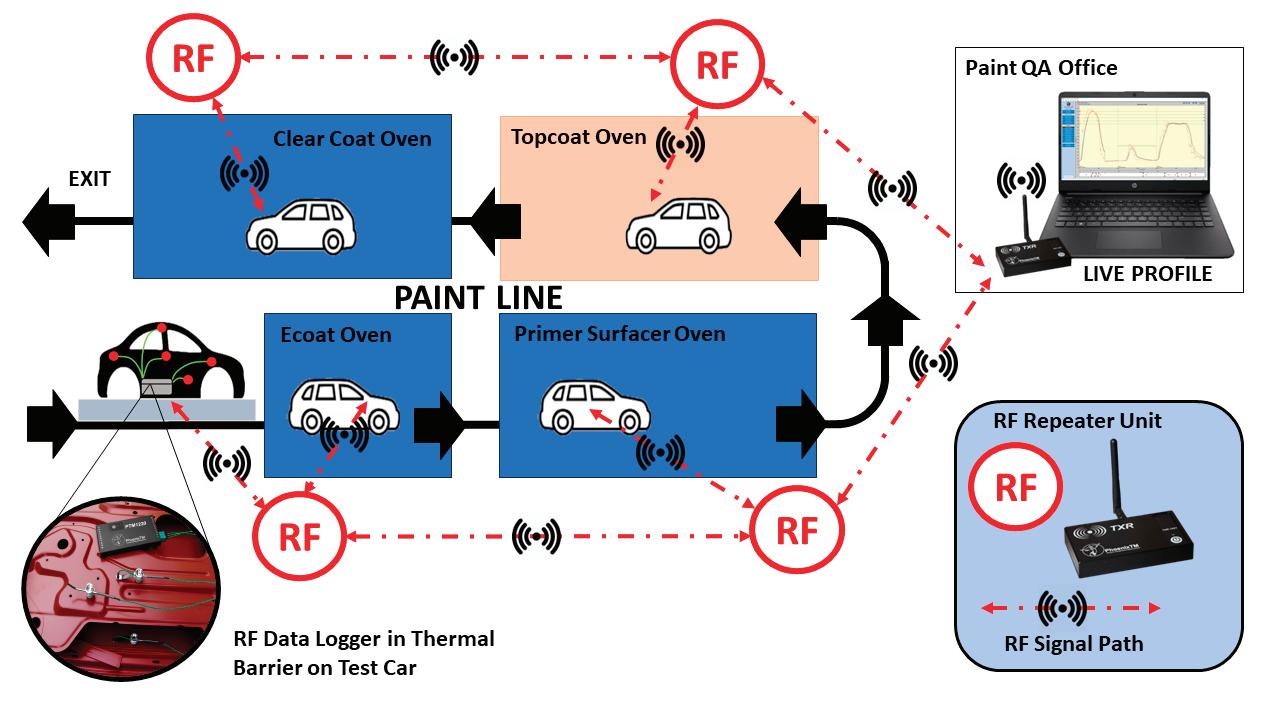

RF Telemetry technology opens scope for live paint cure product temperature monitoring

In today’s modern coating industry instant access to information is becoming more and more important. This applies equally to temperature profiling in the paint and powder coating market. Provided with a unique two-way RF telemetry capability option the PTM1210 data logger, part of the PhoenixTM thru-process temperature profiling system, allows you to see your product temperature(s) live through the entire continuous oven process.

Although well known the technology has rarely been applied to temperature profiling in the automotive paint market with success. The reasons for this are

generally down to the distance over which the signal needs to be transmitted (Oven to QA Office), number of receivers needed to detect a signal out of the

oven and the costs associated with configuring receiver units hard linked by cable and needing external power to operate. Even with expensive RF configuration any data gaps in the process, due to large ovens, faraday gage effects and transient RF interferences can make comprehensive monitoring difficult and non-conclusive.

To overcome the inherent technical limitations of existing RF system on the market PhoenixTM has developed its own unique RF telemetry system. The system has been designed in such a way as to overcome the inherent

36

TESTING & MEASUREMENT

PhoenixTM RF Telemetry Thru-process Temperature Monitoring System for Paint and Powder Coating applications

Intrinsically Safe

• 20 measurement channels

• Paint & Powder coating

• Includes Phoenix Factor cure index calculation During Production

• Detect paint runs,

and defects

• Spot transport problems

• Identify oven damage

Innovation in Thru-Process Automotive Paint Monitoring Safe ATEX Certified Temperature Profiling New Optic Video Profiling System

drips

Phoenix Temperature Measurement T:01353223100 E:sales@phoenixtm.com www.phoenixtm.com

challenges of the automotive and other industrial paint lines. The two-way RF system not only monitors temperature data recorded by the data logger but allows direct control of the data logger itself. The data logger can be reset or downloaded direct from the oven without any need to access the data logger inside the thermal barrier. Measured temperature data is transmitted direct from the data logger via a thermally insulated RF antenna exiting the barrier with the thermocouple cables.

The RF signal transmitted out of the oven is then passed along a series of repeater units (‘Lwmesh’ networking protocol) back to the main coordinator connected to the monitoring PC. The repeater units are powered by battery and are not physically linked by any cable. As such they can be positioned where needed and moved with ease (No expensive infrastructure or installation costs). For a paint line it is possible

therefore that each oven has its own allocated repeater(s). A very valuable feature of the system is a unique ‘catch up feature’. Any missed data from RF black spots is automatically re-transmitted as soon as the RF signal is reestablished ensuring that profile data is complete. Combining RF telemetry with the performance of the profiling system it is possible to monitor the complete paint process in one continuous run live using a car body test rig . This approach eliminates a lot of the intensive labour required for traditional manual profiling of each oven. System set-up installation

and retrieval for each oven is tedious, time consuming, not forgetting the travel time from oven back to the QA office to download the profile data.

The thermal barrier (TS04-135) used in the temperature monitoring system provides up to 5 hours protection @ 200 °C. So, with the delays between ovens (cooling period) the thermal barrier has enough thermal protection to allow all coating ovens to be run in one profile pass. With RF operation the data is collected automatically, and process issues can be detected immediately within the Thermal View Finishing software. With a battery life of up to 1000 hours and 3.8 M data point memory in theory the system could run continuously in RF mode for a complete manufacturing week (6.5 days).

Why not consider PhoenixTM RF Telemetry technology as a means of automating your thru-process product temperature monitoring making it easier, quicker, less labour intensive and live!

PhoenixTM Ltd

Email: sales@phoenixtm.com

Visit: www.phoenixtm.com

38

TESTING & MEASUREMENT

RF Telemetry Repeater transferring the live RF signal from the oven to the monitoring PC.

Schematic of RF Telemetry system configured for an automotive paint line allowing real time monitoring of all ovens in a single continuous pass.

Lets work together Thermaset offers an extensive range of powder coating products and solutions. We provide a fast, accurate and bespoke colour matching service - we can colour match almost anything; RAL 3016 RAL 2008 RAL 5012 Challenge us to find you a solution! RAL 1032 01827 55777 enquiries@thermaset.co.uk www.thermaset.co.uk 2040 Trade Mag Advert_TradeAd [V6 REPRO].indd 1 15/05/2024 17:34 Pleated

We provide an enviable range of ltration solutions, supplies and cleaning services to a wide range of sectors Get in touch or visit us at www.total ltration.com Total Filtration is your one stop shop for all your Dust and Air Filtration requirements whether it is OEM or retrofit. Our filter cartridges and socks are made to any specification and are manufactured in the UK.

Polymeric Filters

WAM Silotop

Airmaster

Donaldson

Telephone: 01282 459744 Email: sales@totalfiltration.com Call us on 01282 459744 to find out how we can help you Filtration TOTAL

Camfil Goldcone Air Filtration

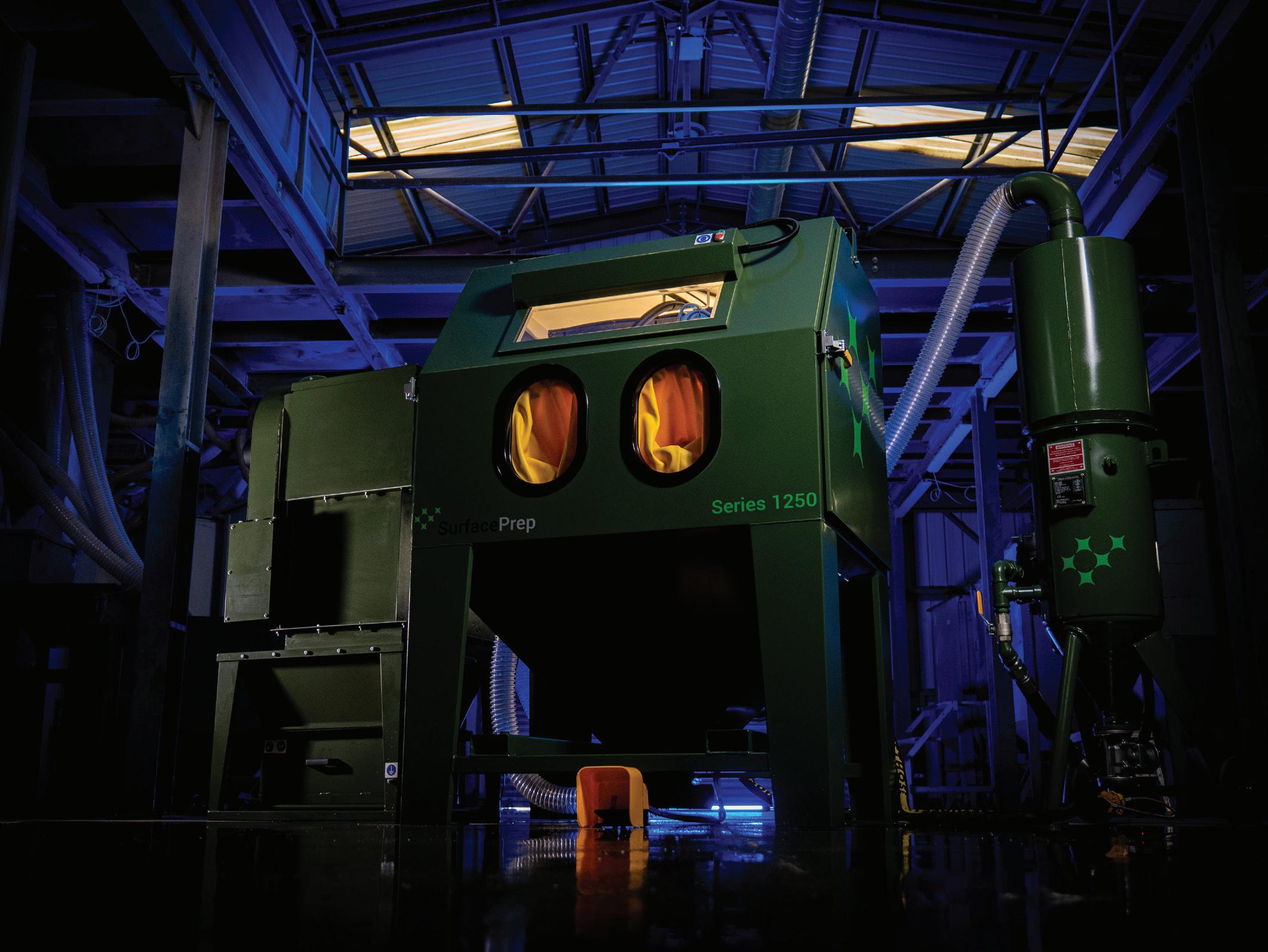

BLAST IT, SPRAY IT AND INSPECT IT WITH ELCOMETER

Elcometer provides a diverse selection of inspection, laboratory, and physical test equipment designed for surface preparation, inspection, and testing within the realm of industrial coatings. Additionally, the company offers a variety of industrial spray equipment tailored to meet the rigorous requirements of the coatings industry.

BLAST IT

From abrasive blast machines to blast nozzles, blast hoses, and operator safety equipment - Elcometer offers a comprehensive range of products designed with efficiency and precision in mind. Their blast equipment is engineered with a unique airflow design with advanced features such as precision controls and vastly reduced pressure loss to ensure optimal performance and maximum productivity.

SPRAY IT

Engineered to deliver high-quality finishes every time, Elcometer’s NEW comprehensive range of spray guns, pumps, pressure pots, air filters and accessories offers a solution for almost any coating application. From high quality fine finish to durable industrial coatings, from wood workshops to metal fabricators, automated paint lines to contractors, the Elcometer range of industrial spray equipment is designed and manufactured to work harder, last longer and perform better.

INSPECT IT

For over 70 years, Elcometer has been at the forefront of inspection technology manufacturing and supplying the coatings industry with accurate and reliable equipment to ensure the quality and longevity of coatings. Elcometer’s range of inspection equipment includes laboratory and physical test, industrial finishing inspection, industrial protective inspection and ultrasonic NDT equipment designed to meet the needs of the coatings industry.

REPORT IT

Since 2007, ElcoMaster® Data Management Software has provided Coating Inspectors

worldwide with a faster, easier, and more accurate solution to manual reporting allowing them to produce accurate, professional inspection reports at the click of a button.

The NEW ElcoMaster® software upgrade provides enhanced functionality for even better performance, allowing you to:

Connect to gauges and download data (via Bluetooth or USB) fast and easily using the ElcoMaster gauge wizard to a wide range of Elcometer Digital Inspection Gauges

Generate bespoke, professional reports in minutes

Combine multiple parameters such as Dry Film Thickness, Surface Profile, Surface Cleanliness, Climate, Adhesion and Gloss

Save readings into batches and store into easy to manage folders

Add detail by making comments, adding notes, inserting photographs

Export, print, pdf or email inspection reports to share with colleagues

Elcometer’s inspection, blast and industrial spray equipment is designed and manufactured to meet the needs of professionals in the coatings industry from beginning to end, and we are confident that our new range of industrial spray equipment will set a new standard for the industry.”

To find out more about the full range of Elcometer Blast and Industrial Spray Equipment visit the Elcometer website at www.elcometer.com

40

Blast Equipment Spray Equipment Inspection Equipment ElcoMaster® Software

TESTING & MEASUREMENT

elcometer.com dry abrasive blast machines | precision media valves blast hose | blast nozzles | personal protection equipment BLAST IT Elcometer’s CONTRACTOR and PERFORMANCE abrasive blast equipment is engineered to last longer, work harder & perform better. Surface World - Changed background CB.indd 1 15/05/2024 11:55:14 WE’RE OBSESSED WITH COLOR YEARS OF EXPERIENCE IN RESEARCH & DEVELOPMENT OF CUSTOMIZED INDUSTRIAL COATINGS brands of The Sherwin-Williams Company A complete range of industrial coatings Waterborne | Powder | Solventborne | High solid | E-coat The Sherwin-Williams Company, Goodlass Road, Speke, Liverpool, L24 9HJ, United Kingdom | T: +44 (0)151 486 0486 | e-mail: liverpool.sales@sherwin.com

New and used vibratory finishing machines and systems from 2 litres to 4000 litres

Finishing media; Ceramic, Plastic, Wood, Steel and Maizorb

Liquid / powdered / paste compounds

Abrasive finishing wheels

Vibratory separators / sieving machines and re-meshing service

Repairs and relines

Effluent water treatment systems

Redundant machines purchased

Consultancy

Subcontracted finishing and industrial sieving services

SHARMIC FOR FAST, FRIENDLY SERVICE

Experienced Engineers After sales technical support Nationwide deliveries

Sharmic Engineering Ltd

Tel: +44 (0)1299 822135 / 878123/4/5

Email: info@sharmic.co.uk www.sharmic.co.uk

ALL

FINISHING

FOR

YOUR VIBRATORY

EQUIPMENT AND MATERIALS

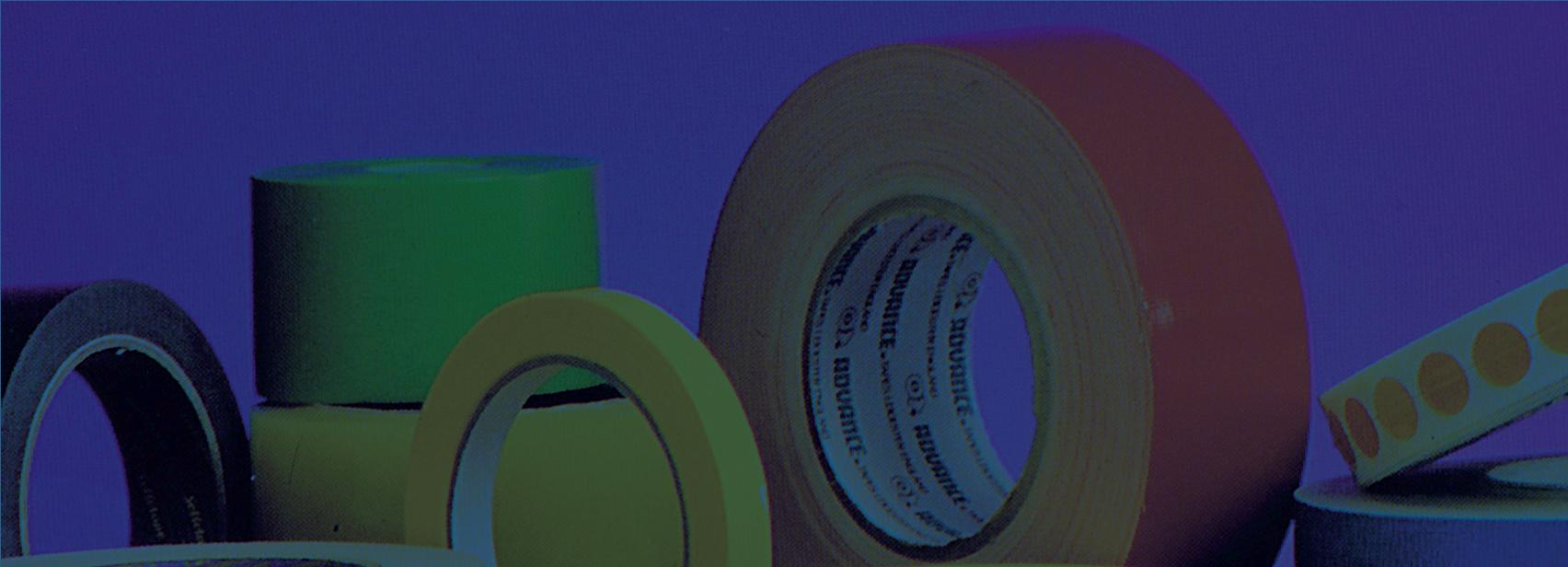

HADLEIGH ENTERPRISES OFFERS SPECIALIST MASKING TAPE

EXPERIENCE AND CAPABILITY

With applications ranging from powder coating to corrosion protection, Hadleigh Enterprises Ltd. brings five decades’ of experience.

Hadleigh Enterprises Ltd has been trading since 1971 as an independent family business, gaining ISO 9001 in 1992.

The Essex-based company stocks and supplies an extensive choice of masking products, all sourced from leading manufacturers. The metal processing and surface finishing sector is a key market for its services with a diverse range of needs met by Hadleigh’s ability to match product type, volume and design to exact requirements.

“So many individual masking tape applications are unique to specific processes, because of this we have found it is vital to work as closely as possible with each customer to develop highly specific solutions,” says David Ogles, Hadleigh Enterprises’ Managing Director.

“By being involved from the outset, and with ongoing production reviews, we can look not only to supply the most appropriate masking system, but can also ensure the customer benefits from continuous innovation – all as part of a structured application process.” This last point, he believes, is often crucial.

For example, the company’s willingness to develop prototype solutions that address key factors, such as masking accuracy and adhesion, is extremely important and can have a fundamental bearing on ongoing production operations. This also helps to ensure that leading edge developments, such as very high bond performance, the ability to fulfil metal-to-metal applications and high temperature capability of up to 380°C, come under the spotlight every time.

Hadleigh Enterprises hold the accreditation – EN9100:2016 certification – which is of particular note to those involved in the aerospace sector.

“Aerospace has long been one of the markets in which we operate and this accreditation – which is technically equivalent to AS9100D – marks a level of operational capability that will build on the confidence that our customers have in our services,” explains David Ogles.

“The standard reflects the importance attributed to supply chain quality, not least in the context of safety of goods throughout their life cycle which is a major factor, of course, in the aerospace sector,” adds David Ogles. “Overall, this is seen as part of the drive towards establishing commonality of aviation, space and defence quality systems and we are delighted that it underscores our role in these extremely challenging fields.”

Hadleigh Enterprises sources master rolls from leading manufacturers before slitting and shaping them, often to produce die-cut shapes from engineering drawings, to meet exact customer requirements. The company undertakes all conversion in-house to optimise control of both quality and delivery, and can achieve slitting tolerances of +/– 0.2 mm.

“We are very happy to provide material in quantities of all sizes, even down to a single roll which may be all that is initially required for a prototyping operation,” continues David Ogles.

In so many sectors of the metal finishing and surface treatment industry, the benefits of Hadleigh Enterprises’ capability and experience will be widely acknowledged. “As masking quality is often so closely linked to production results, it is vital that the need for optimised masking is not overlooked,” concludes David Ogles.

Full details are available by contacting Hadleigh Enterprises by phone or email.

Telephone: 01268 572255

Email: sales@hadleightapes.co.uk

Visit: www.hadleigh-tapes.co.uk

44

MASKING - TAPES, CAPS & PLUGS

Hadleigh Enterprises Limited Unit 11, Buckingham Square Hurricane Way, Wickford Essex, SS11 8YQ Tel: 01268 572255 Fax: 01268 572121 Email: sales@hadleightapes.co.uk Web: www.hadleigh-tapes.co.uk Certificate No. FM10409 • AS9100 APPROVED • NO MINIMUM ORDER QUANTITY • ALL PRODUCTS FOR ALL PURPOSES • 48 HOUR DELIVERY SERVICE The Adhesive Tape Specialists

HANGON QUICK WIRE SHAFT

HangOn proudly present a new cost effective disposable hanger, HQW D.

It’s unique and Innovative design, with thin wire in a framework shape provides strong stability as well as allowing for flexibility in how it is suspended on the line. It is a standard, stock, product that is quick to use and easy to pack. Filling the line has never been easier!

Quick, 3 times faster than daisy chain hanging Efficient packing, easy start up

Low pricing

Easy handling and stable design

Flexible, can be used with hooks, shafts or frames

Standard program on stock makes HQW D very accessable

FOR GENERATIONS HANGON HAVE DEVELOPED WITH THEIR CUSTOMERS

Centuries of smart solutions have paid off. At HangOn know-how and industrial coating process experience run deep, which means that they quickly find the smartest solutions that give you the best result.

HangOn’s R&D is constantly focused on finding new solutions for your challenges. Sometimes they come up with answers before questions arise and solve yet

unidentified problems. They are happy to provide advice on how to make your process more efficient, and can provide calculations that show exactly how much money you save or make with our smart solutions.

“Smart thinking is never stupid. HangOn focus on small solutions that make a big difference for your business. What you do with the resources saved, well, that is up to you.”

HangOn keeps on growing – with new colleagues, new technological possibilities and new smart solutions. Regardless of how big they grow, they will never grow apart – and will always grow with you. Always close, only a phone call away and delivering as promised, if not more.

Global presence

HangOn is present all over the world, with distributors in more than 40 countries. They are continuously developing their international

operations to meet customer’s needs. The HangOn headquarters, R&D, production and main distribution hub are located in Hillerstorp, Sweden.

To offer superior logistics, their distribution hubs are strategically located around the world.

Patents

HangOn are constantly inventing new smart solutions while developing their products.

Many special projects for specific customers and products lead to solutions with wider applications. These often have the potential to make the coating industry much more efficient, which is why they apply for patents and design patents.

All of this ensures HangOn have the customer at the heart of their operation. Telephone: 01547 540573 Email: sales@hangon.co.uk Visit: www.hangon.com/en

46

MASKING - TAPES, CAPS & PLUGS

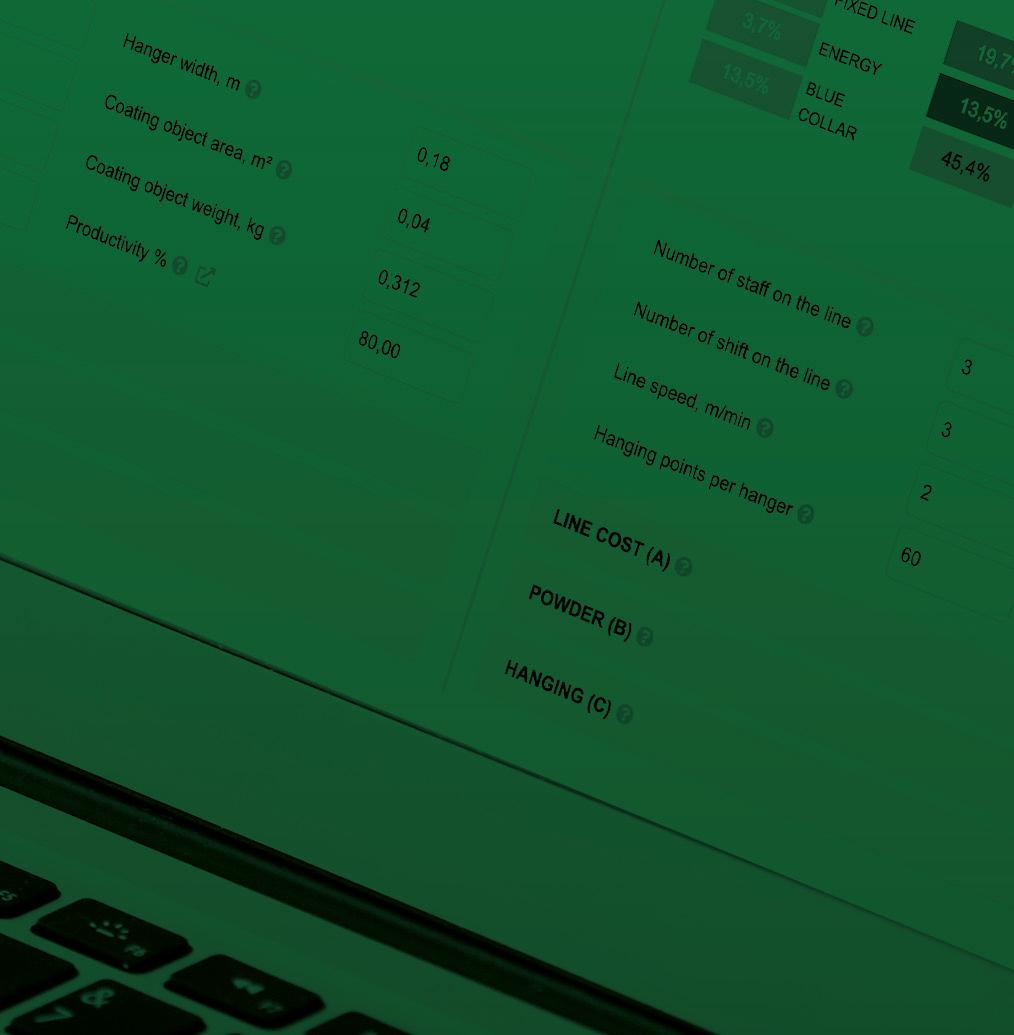

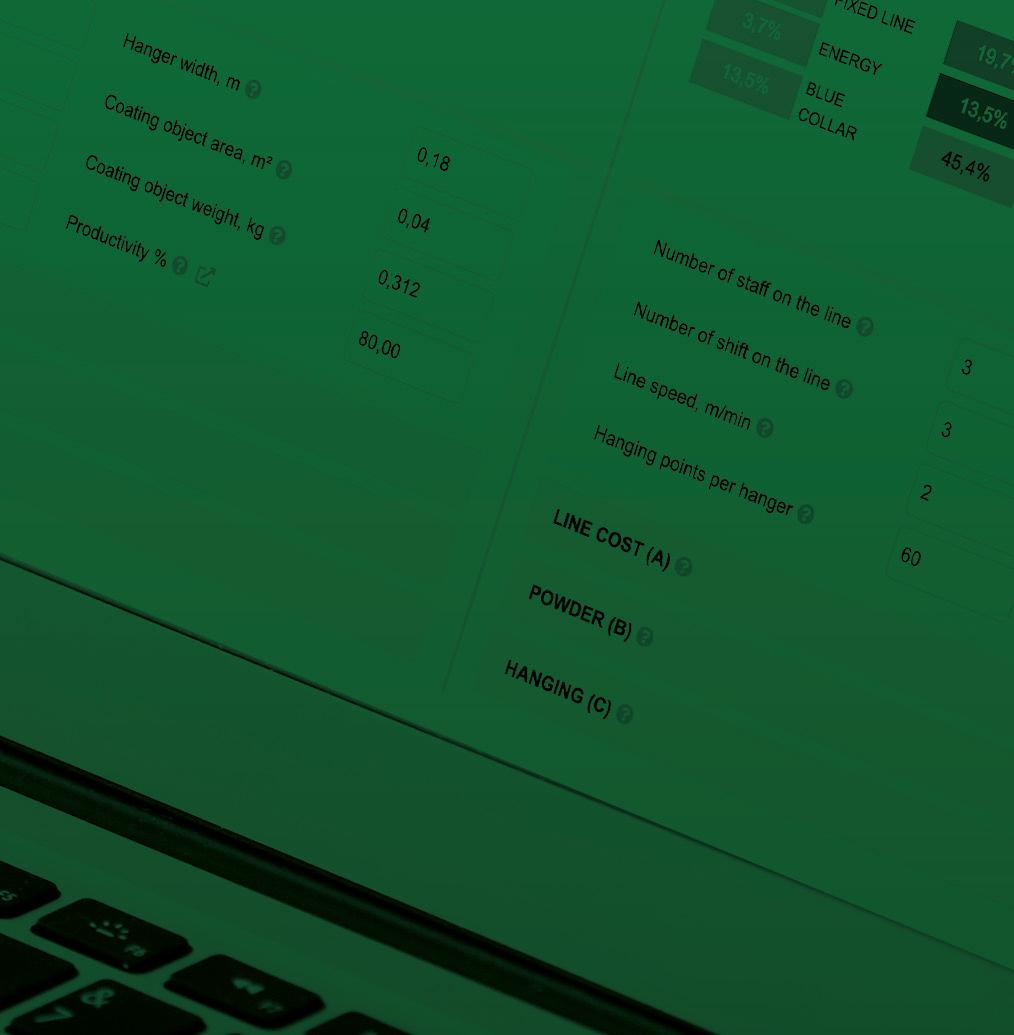

Coating Cost Calculation

CALCULATE YOUR ENERGY SAVINGS

Energy costs are through the roof right now. A higher hanging density is often the most efficient way to both save energy and drastically lower the total coating cost. Find out how much you can save on your coating line at ccc.hangon.com

REDUCING ENERGY COSTS FOR SURFACE FINISHING PLANTS

Energy costs continue to be a major component of overall operating costs in surface finishing plants, and as manufacturers struggle to stay competitive in such a challenging economic climate, many companies are looking to energy savings to improve their bottom line.

Thankfully, a well-established U.K based plant manufacturer has not only addressed this concern but continues to go from strength to strength in their successful development, and installation of energy saving plant systems.

Andrew Grice, General Manager of Midlands based Complete Finishing Systems explains.

“Coming back into the surface finishing industry after a decade or so working in the automotive sector, it was clear that little had changed by way of the development or use of energy efficient technologies. The focus still appeared to be on how a new plant could be manufactured at the lowest price point, but with the hidden operational costs for the end user remaining largely overlooked.”

The approach of CFS was simple, to develop new and energy efficient technologies that could be manufactured to give our customers a plant with the highest levels of performance, efficiency, and quality, but with the lowest possible operational costs and shortest return on investment.