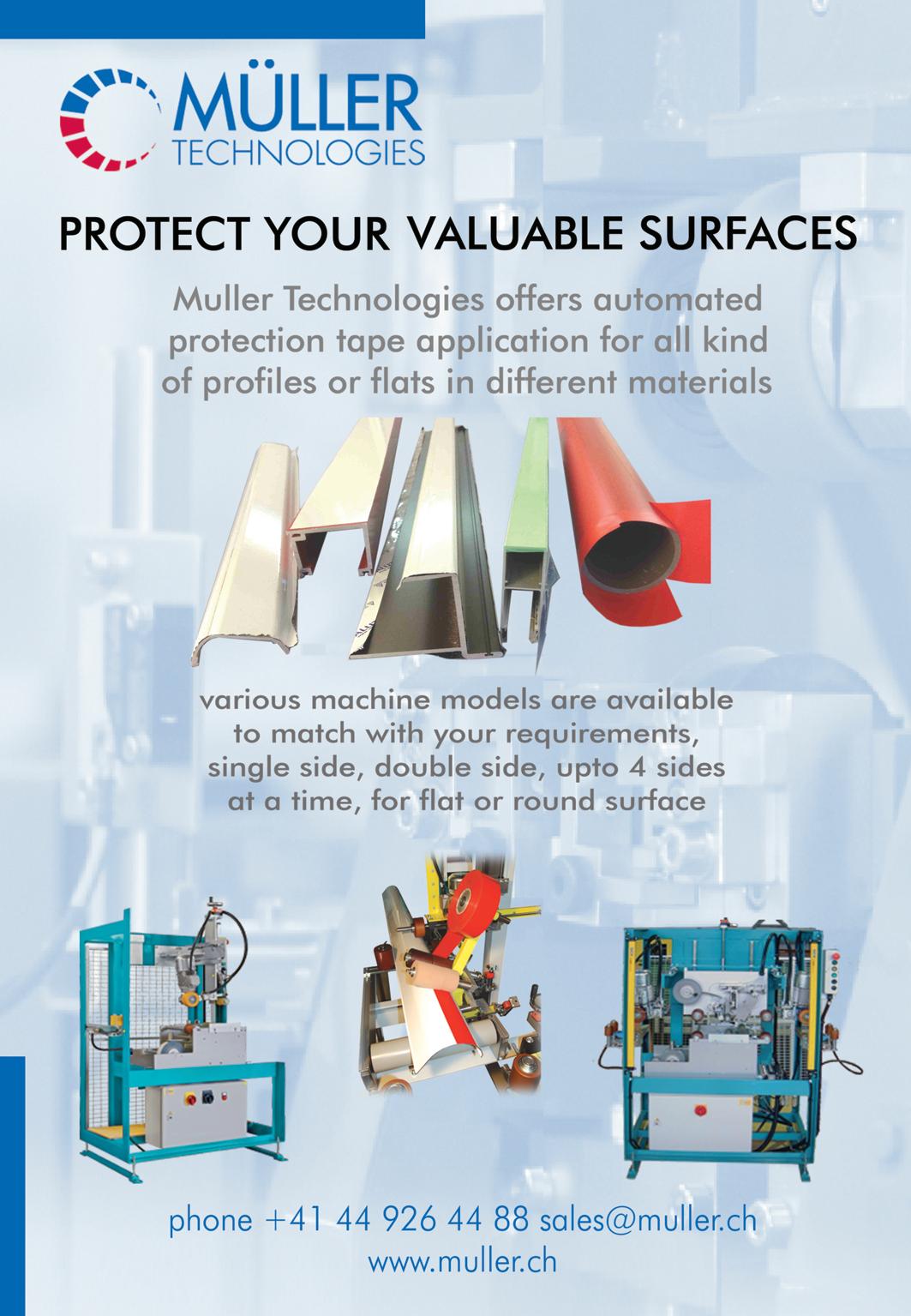

Gema Europe Srl | Via Goldoni, 29 20090 Trezzano s/N | Italy T +39 02 48 400 486 gemapowdercoating.com Gema Europe Srl – UK Branch Tel: 0044 1202 763 942 Email: uk.sales@gema.eu.com High-quality solutions for powder coating ... we have everything covered DECEMBER 2022 read online @ www.surfaceworld.com – follow us on twitter @surfaceworldmag – visit www.surfaceworld.com 4th & 5th October 2023 NEC, BIRMINGHAM www.surfaceworld.com

Welcome to the SURFACE WORLD team!

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826 e: nigelbean1@aol.com / nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com / janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

Sheena Burrus

e: sheenaburrus@hillmedia.com

EXHIBITION ORGANISER

Sheena Burrus e: sheenaburrus@hillmedia.com

Hill Media Ltd, Marash House 2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd. Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents.

© Hill Media Ltd – 2022 ISSN 1757-367X

COMPANY SPOTLIGHT

THE CASE FOR MASS FINISHING FOR AM PARTS AND COMPONENTS. 4

QUALICOAT UK & IRELAND

QUALICOAT TRAINS THE LAB TECHNICIAN. 6

SHEFFIELD HALLAM UNIVERSITY

UK’S FIRST RESEARCH PLATFORM FOR DIGITALISTION OF PVD PROCESSES AT INDUSTRIAL SCALE. 8 SURFACE WORLD 2023 SURFACE WORLD 2023 - BRINGING OVER 20 YEARS OF SERVICE TO YOUR INDUSTRY. 10

MASKING - TAPES, CAPS & PLUGS

HADLEIGH ENTERPRISES OFRFERS SPECIALIST MASKING TAPE EXPERIENCE AND CAPABILITY. 12 FOR GENERATIONS HANGON HAVE DEVELOPED WITH THEIR CUSTOMERS. 14 ADHESIVE TAPE MANUFACTURER. 18 PAINT & POWDER POWDER COATING & SEASIDE CLASS. 20 THE NEW GENERATION OF DIP COATING. 22 E-COAT MASTER P SERIES. 24 COMPLETE FINISHING SYSTEMS REDUCE ENERGY COSTS. 26 COAT ANY COLOUR, AT ANY TIME! 28

TESTING & MEASUREMENT

DUPLEX COATING SYSTEM THICKNESS MEASUREMENT. 30 MECHANICAL PROPERTIES OF HARD COATINGS ON MACHINING AND MILLING TOOLS. 36 A LAYMAN’S GUIDE TO ULTRASONIC INSPECTION. 38

PRE-TREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING AVIONIC AND ELECTRONIC COMPONENT CORROSION INHIBITOR. 46

FRASER TECHNOLOGIES LAUNCHES SF33 FOR FLUORINATED GREASE AND OXYGEN CLEANING. 48 STRAALTECHNIEK UK LTD PROVIDE BESPOKE SOLUTIONS & EQUIPMENT MODERNISATION PROGRAMMES TO THE SURFACE PREAPARATION INDUSTRY. 50 CLEANING FLUIDS THAT COMPLY WITH MEDICAL DEVICE REGULATIONS. 52 COMMITMENT TO CARBON NEUTRALITY. 54 WHEN ARE ULTRASONICS REQUIRED IN INDUSTRIAL PARTS CLEANING AND DEGREASING? 56

WATER & EFFLUENT TREATMENT

PLASTRATUM DIFFERENTIAL VOLUMETRIC FUME EXTRACTION. 60

MATERIAL & EQUIPMENT SUPPLIERS 65

TRADE FINISHERS 72

1 DECEMBER 2022 CONTENTS

DECEMBER 2022 - VOLUME 29 - NUMBER 12 twitter: @surfaceworldmag Specify QUALICOAT for all your architectural aluminium powder coating requirements qualicoatuki.org

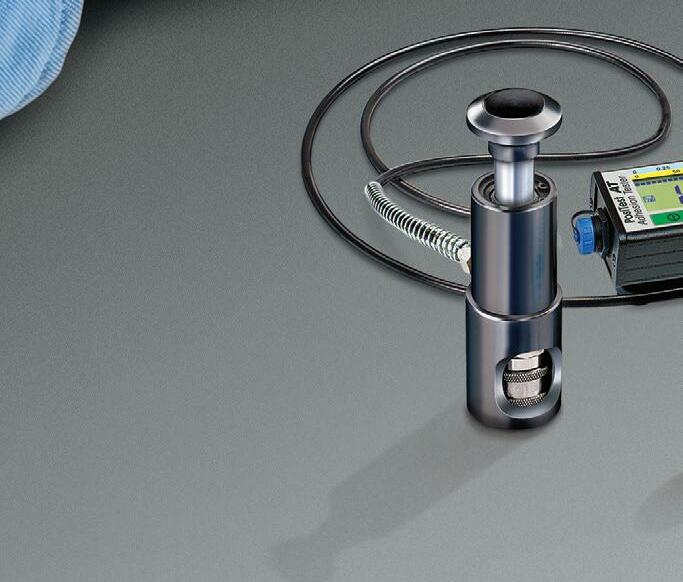

Pull-Off Adhesion Testers n Impact and scratch resistant color Touch Screen display with keypad n Wirelessly connect the PosiTest AT-A to your smart device using our free app n Record the results as pass/fail and the nature of fracture cohesive, adhesive and glue failures W i F i Proud supplier of DeFelsko Inspection Instruments DFT Instruments UK LTD 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk AT Measure the adhesion of coatings to metal, wood, concrete and more AT-A Automatic Model Also available AT-M Manual Model A u t o m a t i c F e a t u r e s

Surface Finishing is our DNA AM Solutions Shot Blasting Individual systems engineering and intelligent process solutions –reliable and energy efficient The full solution provider for 3D post processing equipment and 3D printing services Mass Finishing Efficient systems engineering and innovative technologies – powerful and economical Rösler UK Limited| 1 Unity Grove | Knowsley Business Park | Prescot | Merseyside | L34 9GT Tel: +44 (0)151 482 0444 | Fax: +44 (0)151 482 4400 | rosler-uk@rosler.com | www.rosler.com

THE CASE FOR MASS FINISHING FOR AM PARTS AND COMPONENTS

Daniel Tweer, Managing Director, Rösler UK /

Post processing is a hot topic in the area of additive manufacturing (AM), which is unsurprising as in many applications, the post-processing step(s) can account for upwards of 50% of the total unit cost for an AM part. So the drive is on to reduce the time and cost of the post-processing step in product development, while simultaneously keeping an eagle eye on the unswerving need for precision and repeatability in production.

This has led to the emergence of new innovations for AM post-processing, many coming from relatively inexperienced start-up companies, and many being disproportionately expensive and over-engineered. In this article, I will bang the drum for tried and tested technologies such as mass finishing that when applied to AM parts can cost-effectively fulfil all the requirements in terms of the nature and precision of AM parts.

Mass finishing is wrongly regarded by many as a relatively crude technology. However, it needs to be understood that it has been an established surface finishing technique for many decades for a reason, and delivers a whole range of surface finish characteristics from basic to exacting depending on end-use application. In some instances it can be used to create extremely precise surface finish on safety critical applications such as those found in the medical and aerospace sectors. The key is that mass finishing can be adapted to suit surface finish requirements, and is always the most cost-effective technology available.

Companies producing end-use products via AM need to realise that they are just like companies using traditional manufacturing processes. The goals are the same, namely to make end-use products that conform to design intent and are fit for purpose repeatably and cost-effectively. If the end use product produced does not need a sophisticated surface finish, then there is no point in paying a premium price for a technological post-processing solution that attains levels of surface finish that are unnecessary. If on the other hand exacting surface finish is required, then there is a

compelling argument to use a technology such as mass finishing that has stood the test of time, and which can contribute considerably to the reduction in the cost per part when using AM.

GOOD ENOUGH?

Mass finishing is arguably the most flexible surface treatment process. It is known to be uncomplicated, flexible, transparent, always repeatable and above all cost-effective.

For many decades, mass finishing has been used for the surface treatment of a huge array of products and components across countless industry sectors due to its enormous adaptability.

In the mass finishing process, workpieces embedded in the grinding/polishing media mass are set in a relative motion to each other by either through vibration, centrifugal force, rotation, or drag force. These different forces combined with a vast array of mass finishing media make the process infinitely customizable to a range of end-use products in a variety of geometries and materials.

AM produced parts present a whole set of unique challenges when looking at mass finishing. The unmachined surface of AM parts are much rougher than parts produced using legacy technologies. In addition, one huge advantage of AM as a production tool — namely its ability to manufacture highly complex geometries — can make smoothing and polishing extremely difficult. Add into the mix unique AM challenges such as unpacking, removal of loose or sintered powder residues, and removal of supports, and the requirement for bespoke solutions is obvious.

With the focus today being on the use of AM for production, the scrutiny on such issues as dimensional tolerance attainment, verifiable build

AM Solutions

quality and conformance to design intent, and surface features and finish becomes more and more intense. When used as a prototyping technology, absolute adherence to tolerances and precise design intent is not always necessary, and a “good enough” approach can be taken. Hence the proliferation of quite inexpensive desktop 3D printing machines that provide sufficiently accurate rapid prototypes that do the job without needing to be pitch perfect.

For production applications, however, “good enough” is no longer sufficient. If an AM part is integral to a safety critical aerospace or medical application as previously mentioned, it is essential to achieve surface finish requirements consistent with design intent. It is here that the role of post processing is so important, and it is also an area where mass finishing technology providers like AM Solutions can make a significant difference. And the starting point for making this difference is an understanding of the fact that while AM parts immediately “off build” do have unique characteristics, they are just parts, and like parts built using traditional manufacturing processes they need to be finished, and they need to be finished accurately, speedily, and costeffectively. Through a judicious combination of different machine technologies and different media, mass finishing can achieve these goals.

MASS FINISHING AND AM

In a traditional manufacturing scenario, the prospect of post-processing steps being

Parts being post-processed in a rotary vibrator. Rotary vibrators allow for practical and easy treatment of work pieces in different shape, sizes, and quantities. This mass finishing technology can be utilised for metal or plastic AM parts (filled or unfilled), and the work piece spectrum ranges from delicate parts to larger more rugged components.

4 DECEMBER 2022

COMPANY SPOTLIGHT www.surfaceworld.com

responsible for more than 50% of part costs would be untenable and certainly unsustainable. So what is being done about this anomalous and potentially prohibitive barrier to the viability of AM as a production technology?

Well, there is effectively a pincer movement at work. On the one side, AM technology platform developers are constantly refining processes to reduce the surface roughness of AM produced parts, and on the other side, companies such as AM Solutions (a division of Rösler which has an eight-decade history in industrial finishing) are applying their decades of experience in producing mass finishing solutions to cater for AM parts. The emphasis is on the use of the optimal mass finishing machine technology with the optimal mass finishing consumables for different AM applications, and providing mass finishing solutions that are customized to each AM application. AM Solutions is in a unique position to do this as it is one of the only mass finishing solutions providers that is truly vertically integrated, making its machines in-house and also developing, innovating, and creating a vast portfolio of consumables. Researching and optimizing the media used for AM parts is absolutely key to success.

This pincer movement will effectively erode the cost and time that is required to postprocess AM produced parts, and by so doing will facilitate the production of AM parts with surface characteristics and smoothness that rival those produced on legacy metal and plastic manufacturing processes at similar cost. In other words, the objective is to allow the manufacture of near net shape parts with superior surface characteristics without compromising part integrity. When this is achieved, the viability of AM as a production alternative will be recognised by a growing number of companies, and the technology will be in a better position to disrupt the traditional production paradigm.

AM Solutions positions itself as a company working in the AM ecosystem which has this objective as its primary focus.

DESIGN AND BUILD FOR POST PROCESSING

Various parameters can affect the efficiency of a post-processing operation for AM produced parts, all of which play to the fact that post-processing operations should be considered early in the design stage, and certainly before an AM part is built. For example, the orientation of build layers (i.e. deviation from horizontal) can be a decisive parameter in some applications, as can the chosen mass finishing media which will react differently depending upon the AM build process used. Also, the rate of material removal in some high energy stream mass finishing processes require parts to be designed to mitigate material loss in critical part locations. So DfAMPP (Design for AM Post-Processing) is a real thing!

This all plays to the fact that engagement with a qualified and experienced postprocessing expert company early in the design stage of product development is vital, as off-the-shelf, often inappropriate legacy technologies will not achieve the desired results when using AM for production, and some newer post-processing technologies are either too cumbersome, difficult to use, and over-engineered to make them a long term cost-effective solution for industrial applications.

QUESTIONS FOR SUPPLIERS

When you are short-listing your preferred AM post-processing technology provider, there are a number of questions that you must ask.

Key among these when looking at mass finishing technologies is to assess whether the processes are simply legacy processes that have now been applied to AM, or whether

the processes have been intelligently adapted to the vagaries of AM parts. As mentioned previously, mass finishing can be the most flexible, uncomplicated, transparent, repeatable and cost-effective surface treatment process, but only if the correct combination of machine technology and mass finishing consumables are used for AM parts. You should ask whether your short-listed supplier makes its own machines in house, is truly vertical integrated, and researches, innovates, and produces its own media. Only when a supplier has a proper grip on the effect that machine technology and media can have together will an optimal mass finishing process be achieved.

Second, you need to question the level of experience that your chosen technology supplier has. The post-processing environment is crowded with new postprocessing technologies designed for AM, but often the companies behind these innovations are start-ups and therefore lack the experience and also often the financial robustness to be a reliable product development partner. Also, choosing a supplier that has options for a range of materials (plastics, photopolymers, and metals) obviously has significant strategic importance if AM is being used throughout the supply chain.

When it comes to mass finishing, if suitably adapted to AM parts, it remains both the most efficient and cost-effective postprocessing method. There is a reason that mass finishing is more often than not the go-to post-processing technology used in conventional manufacturing, as it is costeffective and shortens the actual part processing time. Adapting mass finishing to AM parts affords the AM sector the same advantages, which is vital to reduce price per part by rationalising the post-processing cost.

www.solutions-for-am.com

5 DECEMBER 2022 twitter: @surfaceworldmag COMPANY SPOTLIGHT

A metal part being post-processed in a surf-finishing mass finishing machine. Surf-finishing is an intense mass finishing technology especially well suited to high-value components with complex shapes that can be easily clamped. Surf finishing is well suited for metal AM applications in the medical device and aerospace sectors for precise and rapid finishing processes and procedures.

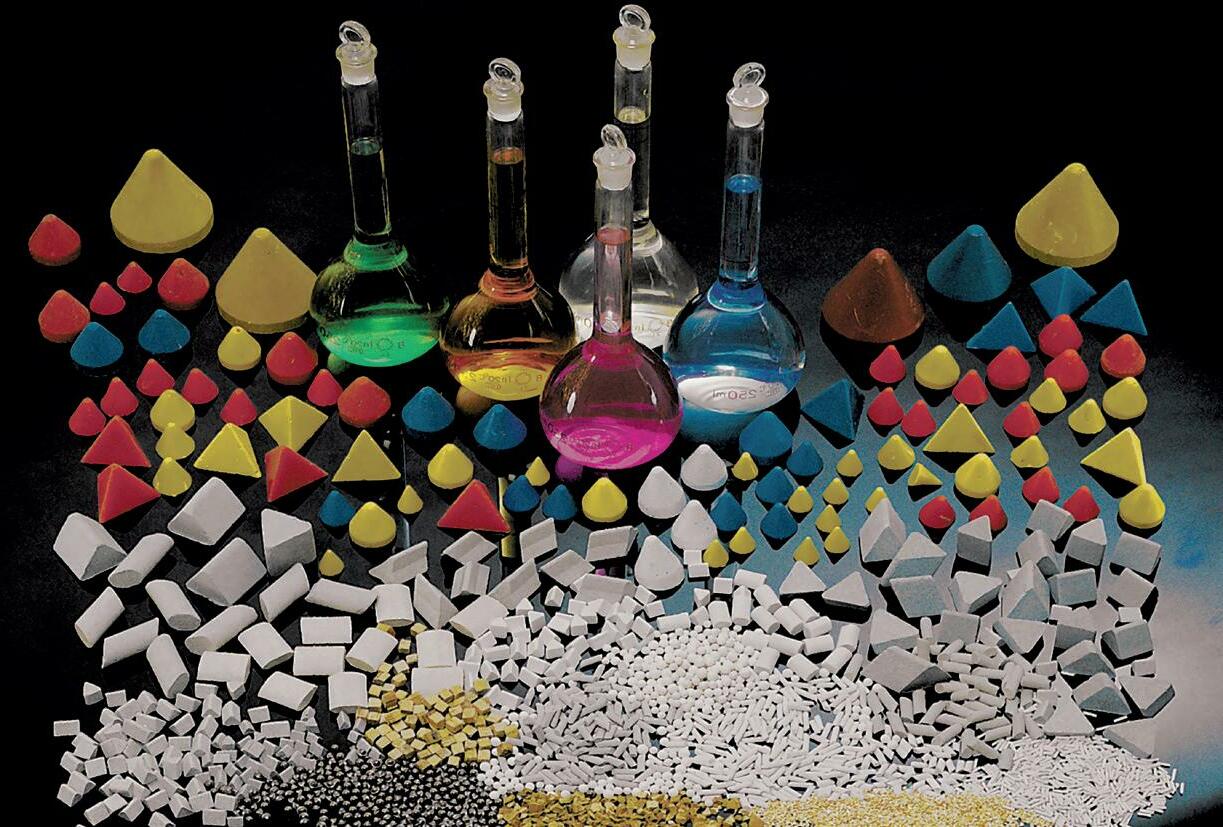

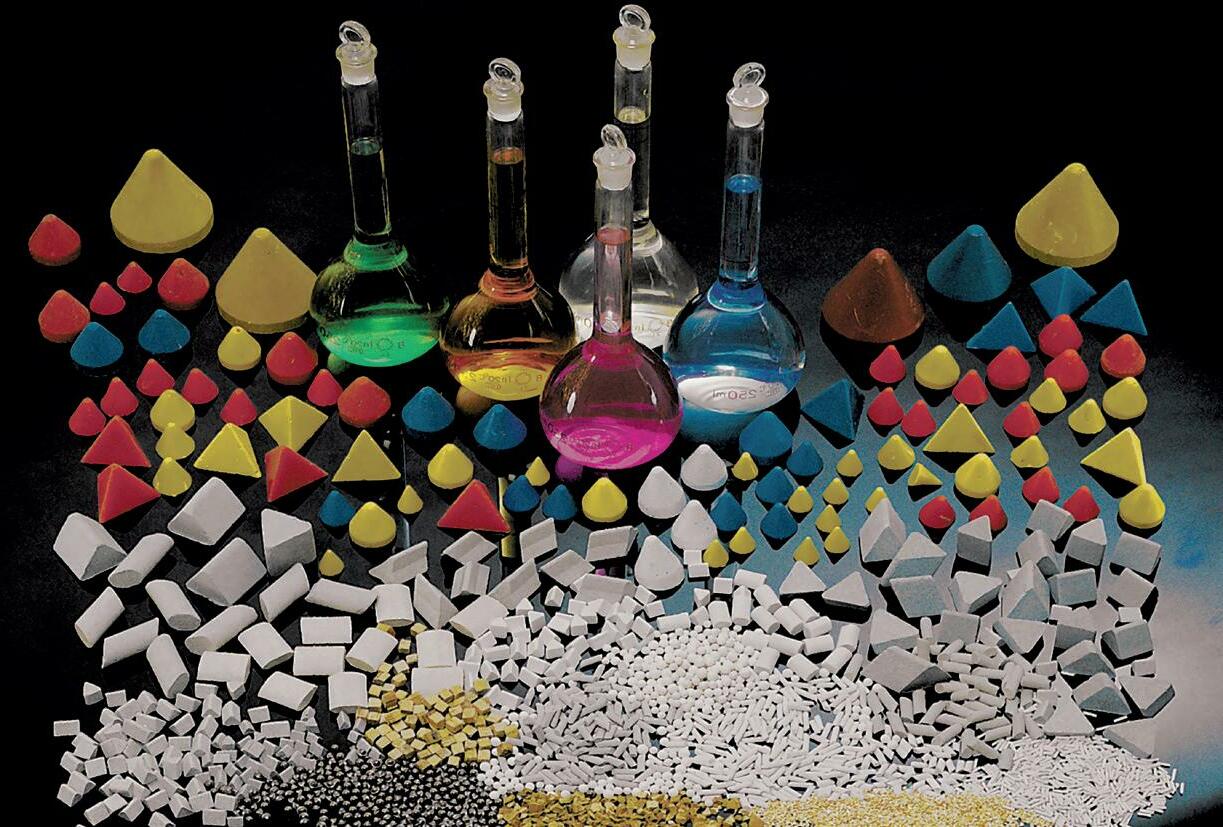

Plastic and metal AM parts in mass finishing media. Mass finishing is arguably the most flexible surface treatment process. It is known to be uncomplicated, flexible, transparent, always repeatable and above all cost-effective.

QUALICOAT Trains the Lab Technicians

By Angus Mackie -

By Angus Mackie -

As you would expect from the name of the QUALICOAT specification for powder coating architectural aluminium profiles, consistent quality is paramount for applicator licence holders of the Association. This is only achieved by regular monitoring of the powder coating process through the members test laboratory and this is where the Laboratory Technicians step in.

It is now mandatory that the applicator licence holders Laboratory Technicians attend a refresher training course at least once every two years. This ensures that the latest developments in the QUALICOAT

QUALICOAT UK & Ireland Chair

Specification for production monitoring and testing is implemented and maintained. This, in turn, will ensure compliance with the Specification when unannounced applicator plant inspections are undertaken every six months. Passing these quality audits ensures that an applicator maintains their licence to offer the QUALICOAT Specification. For specifiers this is a key reason why they specify QUALICOAT for all their architectural powder coating. The yearly training meetings, a QUALICOAT specification requirement, are organised by IFO who are QUALICOAT UK & Irelands independent test house located in Germany.

This years training day was for the first time in three years held in person hosted in Milton Keynes by pretreatment member Chemetall, who made available testing equipment for chrome-free analysis including photometers and a hand held x-ray machine. Twenty five participants from all over the UK attended to discuss specification updates and listen to technical presentations.

Industrial Physics, a global test and inspection equipment supplier, offered additional measurement equipment, specifically introducing and explaining equipment that monitors the cure index. Akzo Nobel offered a presentation explaining how powder formulations are produced,

specifically which materials were used to offer the various classes of coatings for extended gloss and colour retention. Oliver Boegler, Head of Inspections at IFO, gave an overview of coating various aluminium alloys, coating testing methods and an update on the latest QUALICOAT specifications.

With four new powder coating applicators receiving their licences recently and further applicators currently undergoing training and review by IFO, the majority of architectural powder coaters in the UK & Ireland are licensed to supply to the QUALICOAT specification and carry the QUALICOAT label.

The QUALICOAT Specification is continually and incrementally revised in real time with regular update sheets, the specification is completely rewritten at year end to include all updates. The global Specification, its appendices and any update sheets are always freely available for download at www.qualicoat.net. For details on the availability of various colours and finishes contact any QUALICOAT UK & Ireland member for more information. For updated information about the use and specification of QUALICOAT in the UK and Ireland, please visit the UK & Ireland Association website at www.qualicoatuki.org.

6 DECEMBER 2022 QUALICOAT UK & IRELAND

twitter: @surfaceworldmag

Angus Mackie - QUALICOAT UK & Ireland Chair

Lab technician training

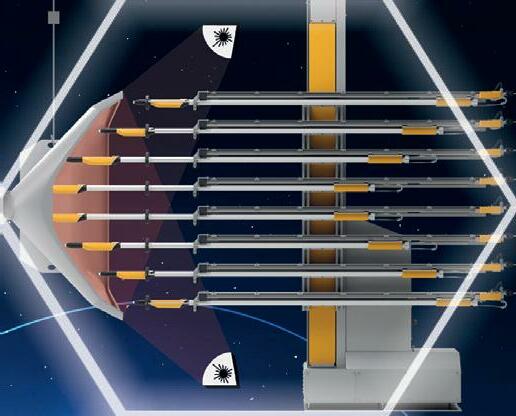

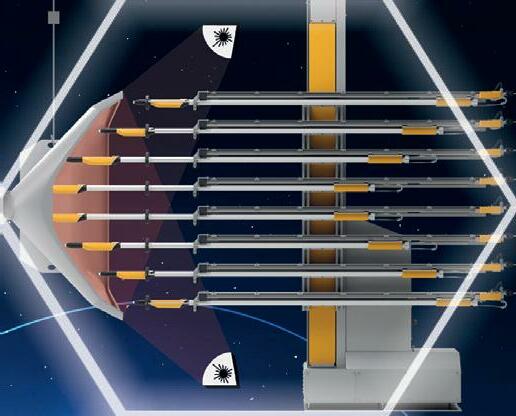

UK’s fi rst research platform for digitalisation of PVD processes at industrial scale

Sheffield Hallam University is set to deliver world class research and innovation capability to drive next generation physical vapour deposition (PVD) processing following major investment in full digitisation of equipment and technology.

Building on over 27 years of leading innovation and research in the field of PVD and plasma science, the University has made a major investment in capital infrastructure at the National HIPIMS Technology Centre to radically upgraded its Hauzer 1000/4 PVD system with the latest generation of control and communications hardware to enable digitalisation of the process.

High Power Impulse Magnetron Sputtering (HIPIMS) is used to produce advanced coatings across multiple applications including cutting tools, mobile phones, satellite systems, electronics, and biomedical implants - and the advanced capability in digitisation will help to deliver higher quality coatings with more efficient processing.

The first activities on digitalising the PVD process at the National HIPIMS Technology Centre started in 2018 when the team were awarded an Innovate UK project to develop strategies for real time monitoring and control of PVD processes towards creating a digital twin of the process.

Led by Professor Arutiun Ehiasarian, Head of the National HIPIMS Technology Centre, the University teamed up with Ionbond UK to conduct experiments and validate the main digitalisation algorithms in an industrial environment.

The approach achieved significant improvements in the efficiency of all critical steps in the deposition process which resulted in enhanced productivity, reproducibility, quality, and cost savings. The work has been highlighted by IUK for its innovative use of a single technology to monitor and control sputter deposition - eliminating inefficient modes of operation and reduced product wastage by enabling preventative maintenance and better reproducibility.

To achieve this, the University used noninvasive sensors compatible with the production environment including optical emission spectroscopy and electrical parameters of the plasma process. Strategies were developed to monitor and control all aspects of the coating position process including pumping, heating, substrate cleaning, coating thickness, coating composition, coating microstructure, crystallographic texture, as well as the chamber condition.

The University investment into this enhanced capability ensures that the National HIPIMS Technology Centre can continue to deliver

world leading research and innovation in partnership with industry and research facilities around the globe. The centre will operate an open-door policy to allow access to the new research platform to all PVD companies striving to find digital solutions to their manufacturing problems.

Dr Chris Constable, MD Ionbond UK said: “Ionbond is a leading provider to industry of functional thin film coatings. The digitalisation of PVD processes is an area of great interest and importance to our company as this provides a powerful tool for optimising resource and energy efficiency, which are crucial in maintaining competitiveness and plant viability. The research platform for digitalisation of PVD processes at the National HIPIMS Technology Centre will undoubtingly act as an accessible for industry playground for testing and materialising these new ideas.”

Professor Andy Alderson, Director of the Industry & Innovation Research Institute at Sheffield Hallam University, commented: “This important development from the collaboration between the National HIPIMS Technology Centre and Ionbond UK is an example of where our combined expertise in PVD coatings technology and digitalisation methods are providing improved industrial processes to maintain competitive advantage. This aligns strongly with our university vision to transform lives through applied research and is an example of how the work we do in the Industry & Innovation Research Institute is delivering research excellence meeting the development needs of industry.”

Dave Elliott, CEO of the Surface Engineering Association, UK noted: “High Power Impulse Magnetron Sputtering (HIPIMS) is the latest innovation in the PVD sector now recognised as a strategic plasma-based manufacturing technology in UK. Digitalisation of this novel technology will undoubtedly further advance its reliability and effectiveness where the new research platform for digitalisation of PVD processes developed at Sheffield Hallam University will play a decisive role in its industrialisation”.

Visit: www.shu.ac.uk

8 DECEMBER 2022 SHEFFIELD HALLAM UNIVERSITY

www.surfaceworld.com

National HIPIMS Technology Centre teaming up with engineers from IHI Hauzer TechnoCoating (The Netherlands) to create the first research platform for digitalisation of PVD (physical vapour deposition) technologies.

elcometer.com Elcometer’s range of high performance abrasive blast equipment is engineered to last longer, work harder & perform better. dry abrasive blast machines | precision media valves blast hose | blast nozzles | personal protection equipment TAERG TIRB engineered EDAM NI RG E A T BRITAIN FABRIQUÉ EN GRANDE-BRETAGNE H E R NEINNATIRBSSORGNITLLETSEG engineeredEDAM I N E U ROPE FABRIQUÉ ENEUROPE H E NITLLETSEGR APORUE LAUQ YGOLONHCE GNINIART Surface World - January 2022.indd 2 20/01/2022 14:38:15

Surface World 2023 - bringing over 20 years of service to your industry

Trade shows, exhibitions and other events can be an excellent way to showcase your products and services. They give you the opportunity to increase awareness of your business, launch new products and services, network with industry members, explore partnership opportunities, see what competitors are offering, generate new business leads, attract and convert customers.

What is a Trade Show?

A trade show is a platform where businesses (exhibitors), professionals and business representatives (visitors) come together under one roof to exchange knowledge and make connections with other like-minded professionals.

Exhibitors book a stand and use this space to connect and engage with visitors to the event. Ideally, the event is used to generate leads, network, promote products and services, and hopefully close a few sales in an organic setting that’s tailored to them and their audience.

How can you benefit from exhibiting at a Trade Show?

There are many reasons why you would choose to exhibit at a trade show, which include:

Make sales – the golden ticket to trade show success, hitting a quota or making direct sales is the ultimate definition of winning.

Capture leads – without leads salespeople have nobody to convert, so generating enough leads for your marketing funnel is a must.

Analysing the competition – what technology are they using, what marketing angle are they taking? It’s good to know what the competition is up to.

Engage with existing customers – existing customers are more likely to invest in new products and services, so you can keep building relations and offering them more benefits.

Introduce new products/services – new and old customers could benefit from your new product.

Account-based marketing – go into a trade show with an idea of who you’d like to speak with, so you can create a strategy that’s more likely to convert them.

Gather feedback – feedback is how you improve services and sales and marketing; you

could receive advice that revolutionises how you do things.

Spot trends – spotting trends is vital if you want to stay relevant or avoid something that’s a flash in the pan.

What should you look at when selecting a trade show?

The best success can be gained from participating at an event that has a wellestablished history. These events usually draw the best reward. The event organiser should have proven methods in place to market the event to the right audience. They will have a database they have accrued over many years of business. The venue should be easily accessed by road or public transport and have plenty of parking. A venue with excellent nearby facilities, hotels, restaurants, entertainment, can also be a bonus if the event is held over more than one day.

Can You Make Money at a Trade Show?

Keeping costs down is a benefit when deciding which trade show to exhibit at. Smaller shows tend to be cheaper, so choosing an event that is aimed at your target audience is the key to a successful outcome from exhibiting.

Here are some ways you can get a healthy ROI from a trade show, including:

Only buy the space you need – the area you buy takes up a significant amount of your budget, so overdoing it can waste money, which is going to eat into your sales.

Get an enticing exhibition stand – you can have a tiny space and still attract people

10 DECEMBER 2022

SURFACE WORLD 2023

twitter: @surfaceworldmag

if your stand is attractive, making your area presentable promotes credibility.

Organisation is key – there’s a temptation to blindly hand out literature and marketing collateral, putting it at the back of your space makes reps think about engaging first, which is more likely to generate a lead or a sale.

Use tech where it’s useful – the whole purpose of a trade show is to generate business through face-to-face marketing, so don’t dehumanise the event by using too much technology.

Pick the right team – there’s no point in attending an event if you pick the wrong staff. Ideally, it would benefit you if you had people who understand and empathise with customer challenges, but also know when to close deals.

Work the aisles – do not limit yourself to the boundary of your stand, you can reach out to passers-by and engage in the aisle.

Tell people you’re exhibiting – use as many marketing techniques as you can to create a build-up to the event and get people excited. Utilise all marketing opportunities the event itself offer, these are generally targeted directly at your required audience.

What Do You Need for a Trade Show?

The last thing you want to do is under prepare. Get the following ticked off before you get to your event:

Event space – the first thing you need is event space, you’ll have a shock if you turn up and there’s nowhere for you to pitch!

Stand with supporting collateral – your stand and marketing collateral are what

attract people to your stand.

Travel plans – train, bus, plane, car? It would help if you had robust plans in place before you depart.

Accommodation – if you’re planning on staying over, which you may want to as events are long, tiring days, reserve in advance as hotels may get booked up prior to the event.

Marketing collateral – brochures, leaflets, business cards; get all the material you need and ensure you get plenty. You don’t want to run out.

Staff – ask your staff well before the event to ensure they are available to attend, cancelling holidays will not be seen as favourable to you! Remember your staff are the face of the business at the event, get them prepared.

Could You See Success at a Trade Show?

Trade shows aren’t an antiquated form of marketing and sales – they’re proven to generate targeted, high-quality leads and sales. Not every business can benefit from attending trade shows, but they’re certainly worth exploring. Just like trade shows give you the opportunity to better connect with prospective customers, exhibiting at a trade show also allows you to meet existing customers face-to-face. While most of today’s business is conducted over email or phone, face-to-face meetings are undeniably a fantastic way to do business.

The Wall Street Journal agrees. Citing a study by Oxford Economics, the well-known financial publication reports that face-to-face meetings are the most effective way to

strengthen relationships with both prospective customers and current customers.

Trade shows help bring all the different aspects of an industry together – consumers, distributors, suppliers and manufacturers, all in one place. With such a broad audience together in one place, businesses are able to schedule meetings, negotiate orders and other opportunities and collaborate on other projects. Trade shows allow businesses to facilitate discussions with their suppliers and even with other businesses, as well as move projects to another level if the opportunity arises.

Surface World 2023 is a well established trade event, with over 20 years of experience, specifically tailored to the Surface Finishing Industry.

If you are interested in exhibiting or visiting this event, please contact Nigel Bean at:

Telephone: +44 (0) 1442 826826 Email: nigelbean1@aol.com

Surface World – Connecting The Industry

11 DECEMBER 2022

SURFACE WORLD 2023 www.surfaceworld.com

Hadleigh Enterprises off ers specialist masking tape experience and capability

With applications ranging from powder coating to corrosion protection, Hadleigh Enterprises Ltd. brings five decades’ of experience.

Hadleigh Enterprises Ltd has been trading since1971 as an independent family business, gaining ISO 9001 in 1992.

The Essex-based company stocks and supplies an extensive choice of masking products, all sourced from leading manufacturers. The metal processing and surface finishing sector is a key market for its services with a diverse range of needs met by Hadleigh’s ability to match product type, volume and design to exact requirements.

“So many individual masking tape applications are unique to specific processes, because of this we have found it is vital to work as closely as possible with each customer to develop highly specific solutions,” says David Ogles, Hadleigh Enterprises’ Managing Director.

“By being involved from the outset, and with ongoing production reviews, we can look not only to supply the most appropriate masking system, but can also ensure the customer benefits from continuous innovation – all as part of a structured application process.” This last point, he believes, is often crucial.

For example, the company’s willingness to develop prototype solutions that address key factors, such as masking accuracy and adhesion, is extremely important and can have a fundamental bearing on ongoing production operations. This also helps to ensure that leading edge developments, such as very high bond performance, the ability to fulfil metal-to-metal applications and high temperature capability of up to 380°C, come under the spotlight every time.

Hadleigh Enterprises hold the accreditation – EN9100:2016 certification – which is of particular note to those involved in the aerospace sector.

“Aerospace has long been one of the markets in which we operate and this accreditation –which is technically equivalent to AS9100D – marks a level of operational capability that will build on the confidence that our customers have in our services,” explains David Ogles.

“The standard reflects the importance attributed to supply chain quality, not least in the context of safety of goods throughout their life cycle which is a major factor, of course, in the aerospace sector,” adds David Ogles. “Overall, this is seen as part of the drive towards establishing commonality of aviation, space and defence quality systems

and we are delighted that it underscores our role in these extremely challenging fields.”

Hadleigh Enterprises sources master rolls from leading manufacturers before slitting and shaping them, often to produce die-cut shapes from engineering drawings, to meet exact customer requirements. The company undertakes all conversion in-house to optimise control of both quality and delivery, and can achieve slitting tolerances of +/– 0.2 mm.

“We are very happy to provide material in quantities of all sizes, even down to a single roll which may be all that is initially required for a prototyping operation,” continues David Ogles.

In so many sectors of the metal finishing and surface treatment industry, the benefits of Hadleigh Enterprises’ capability and experience will be widely acknowledged.

“As masking quality is often so closely linked to production results, it is vital that the need for optimised masking is not overlooked,” concludes David Ogles.

Full details are available by contacting Hadleigh Enterprises by phone or email.

Telephone: 01268 572255

Email: sales@hadleightapes.co.uk

Visit: www.hadleigh-tapes.co.uk

12 DECEMBER 2022

MASKING – TAPES, CAPS & PLUGS www.surfaceworld.com

Hadleigh Enterprises Limited Unit 11, Buckingham Square Hurricane Way, Wickford Essex, SS11 8YQ Tel: 01268 572255 Fax: 01268 572121 Email: sales@hadleightapes.co.uk Web: www.hadleigh-tapes.co.uk Certificate No. FM10409 • AS9100 APPROVED • NO MINIMUM ORDER QUANTITY • ALL PRODUCTS FOR ALL PURPOSES • 48 HOUR DELIVERY SERVICE The Adhesive Tape Specialists

MASKING – TAPES, CAPS & PLUGS

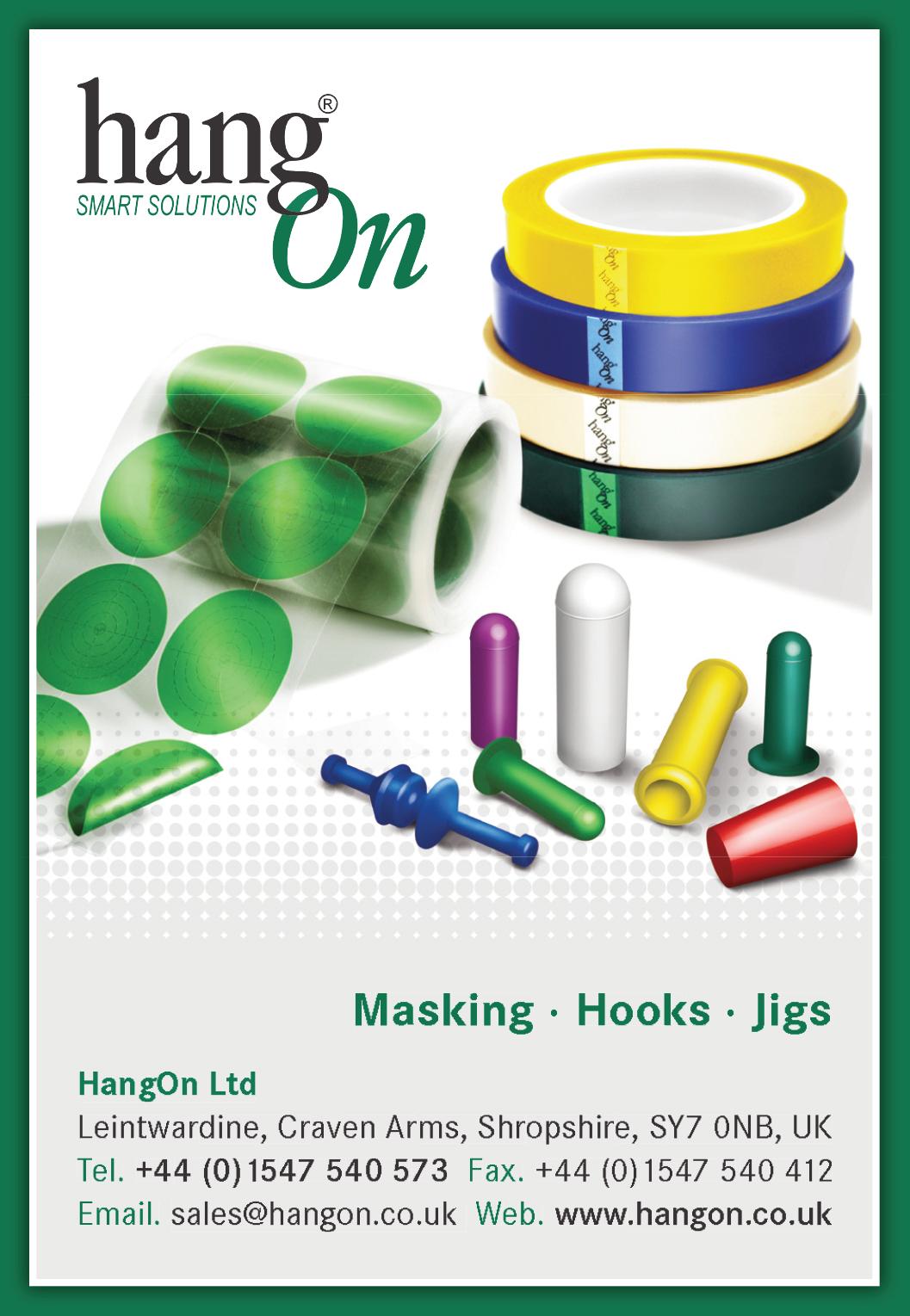

For generations HangOn have developed with their customers

Centuries of smart solutions have paid off. At HangOn know-how and industrial coating process experience run deep, which means that they quickly find the smartest solutions that give you the best result.

The Törefors family’s entrepreneurial spirit dates back to the 16th century. Early in the 19th century they founded their first steel wire company, and in the 1930s, business expanded internationally. Initial products for the coating industry were manufactured in the mid-1970s. In 1989, a new generation succeeded, and since then development has accelerated with further specialisation for the coating industry. New products have been launched, new services have been introduced, and new markets have been discovered. And above all, a multitude of smart solutions for better and more efficient coating have seen the light of day.

HangOn’s R&D is constantly focused on finding new solutions for your challenges. Sometimes they come up with answers before questions arise and solve yet unidentified problems. They are happy to provide advice on how to make your process more efficient, and can provide calculations that show exactly how much money you save or make with our smart solutions.

“Smart thinking is never stupid. HangOn focus on small solutions that make a big difference for your business. What you do with the resources saved, well, that is up to you.”

HangOn keeps on growing – with new colleagues, new technological possibilities and new smart solutions. Regardless of how big they grow, they will never grow apart – and will always grow with you. Always close, only a phone call away and delivering as promised, if not more.

Global presence

HangOn is present all over the world, with distributors in more than 40 countries. They are continuously developing their international operations to meet customer’s needs. The HangOn headquarters, R&D, production and main distribution hub are located in Hillerstorp, Sweden.

To offer superior logistics, their distribution hubs are strategically located around the world.

Patents

HangOn are constantly inventing new smart solutions while developing their products.

Many special projects for specific customers and products lead to solutions with wider applications. These often have the potential to make the coating industry much more efficient, which is why they apply for patents and design patents.

All of this ensures HangOn have the customer at the heart of their operation.

Telephone: 01547 540573 Email: sales@hangon.co.uk Visit: www.hangon.com/en

14 DECEMBER 2022 twitter: @surfaceworldmag

Solutions for recycling SOLVENTS Save Money | Recycle Any Solvent High Yield | Low Waste ASK FOR A FREE QUOTE SYSTEMS Units available for any quantity and application Safe and easy to use Recycled solvent as good as new Atex certified for flammable solvents The number one choice with over 38,000 units worldwide • BUY OR LEASE info@solutex.co.uk | 01691 622 225 For more information visit: www.solutex.co.uk Dedicated stand-alone unit is ready to measure right out of the box Fast measurement speed—ideal for moving lines and swinging parts Scan Mode continuously takes measurements—ideal for analyzing large areas Storage of 999 readings with onscreen averaging. Stored readings can be downloaded to PosiSoft Desktop Software Affordably measures uncured powder coatings using non-contact ultrasonic technology to predict a cured thickness 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk Non-contact Uncured Powder Thickness Gauge Powder Inspection Kits Complete solutions for measuring powder coating before and after cure are available Powder Checker

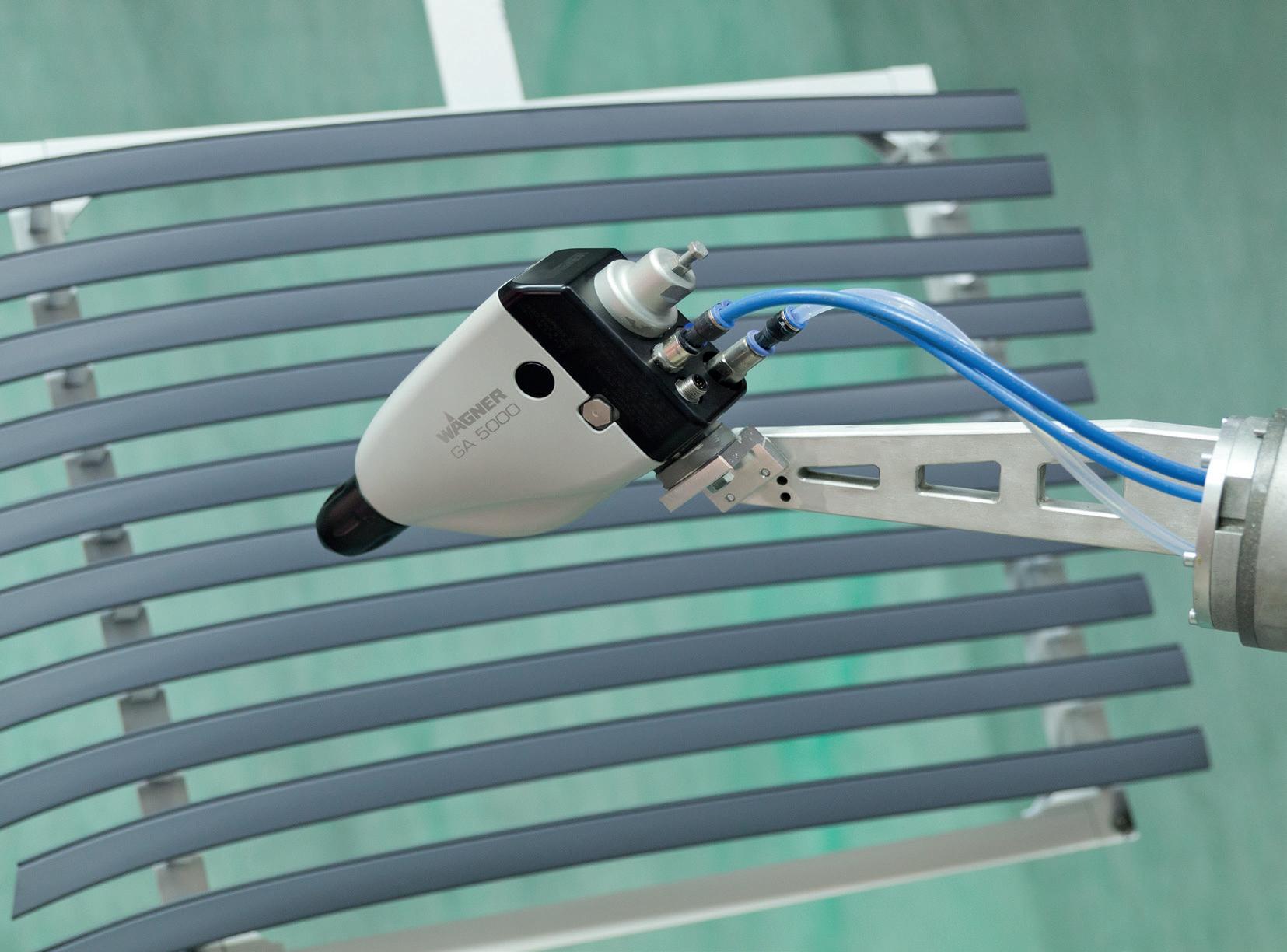

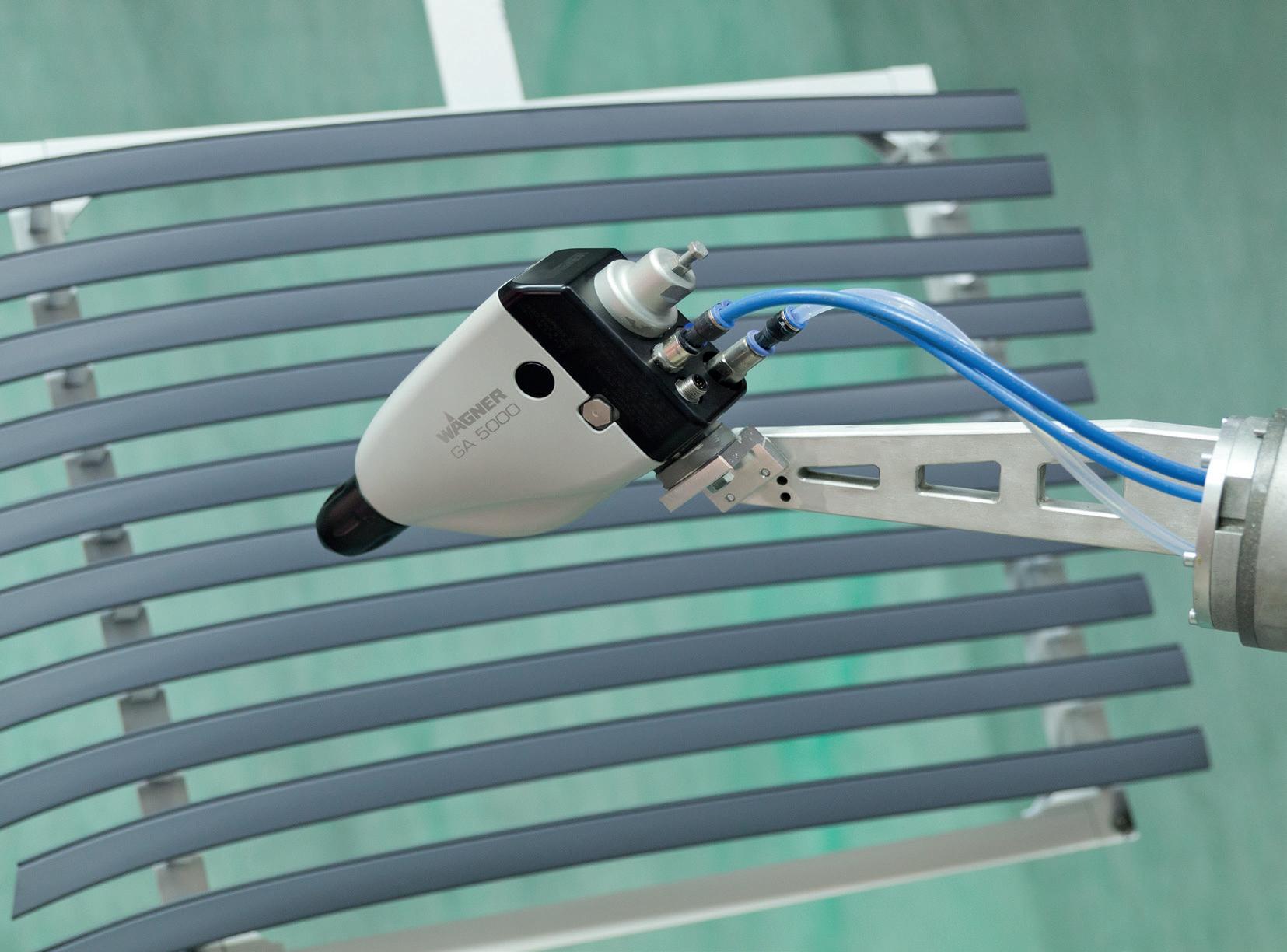

ECONOMICAL COATING. FLEXIBLE APPLICATIONS. GM 5000 & GA 5000 Manual & automatic electrostatic guns • High transfer efficiency with wrap-around effect • Suitable for water-based & solvent-based paint • Excellent finishing results wagner-group.com Contact Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone: 01327 368410 enquiries@wagner-group.com

C M

K

Y CM MY CY CMY

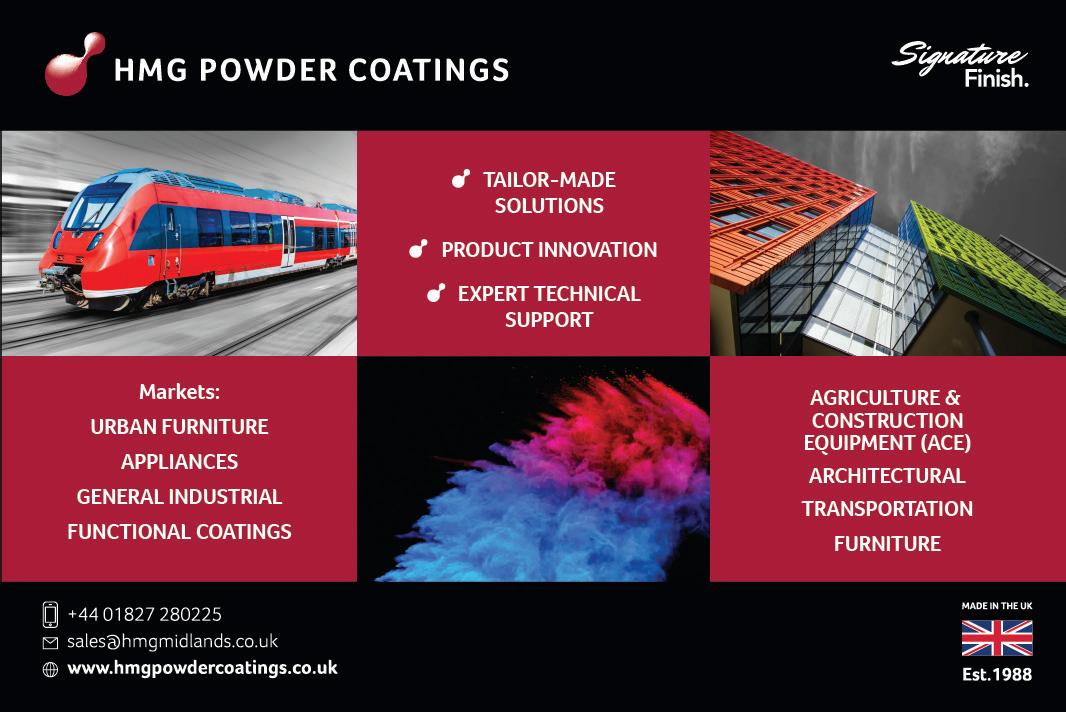

TAILOR-MADE SOLUTIONS PRODUCT INNOVATION EXPERT TECHNICAL SUPPORT URBAN FURNITURE APPLIANCES GENERAL INDUSTRIAL FUNCTIONAL COATINGS AGRICULTURE & CONSTRUCTION EQUIPMENT (ACE) ARCHITECTURAL TRANSPORTATION FURNITURE Markets: “OVER 100 NEW ENQUIRIES FROM SURFACE WORLD LIVE 2022” - WE’VE GOT YOU COVERED!

Powder Coating & Seaside Class

By Angus Mackie - QUALICOAT UK & Ireland Chair

By Angus Mackie - QUALICOAT UK & Ireland Chair

The quality of any architectural powder coating relies on its ability to adhere to the aluminium substrate. If there is no ‘key’ to adhere to, the powder coating is prone to chipping or flaking off in use. As powder coating is porous at the molecular level, an untreated aluminium substrate, subject to weathering, will oxidise under the coating if it is not completely sealed. So, no matter the quality of the powder coating that is applied, it will not offer the anticipated life expectancy should the thin ‘conversion coating’, part of the pretreatment process which offers the seal and key to the surface of the aluminium, be poor, or indeed not present.

The surface of the extruded aluminium also carries contaminants from the extrusion process which, if left on the surface of the aluminium, will reduce the performance of the ‘conversation coating’ so this needs to be removed. Removing the contaminants from the extrusion is part of the pretreatment process undertaken by either dipping or spraying an acid or alkaline solution which etches the surface removing a minimum of 1g/sm of aluminium. Without this surface etch potential corrosion could form around the contaminants on the aluminium substrate once coating has been completed. Given that the pretreatment process is undertaken correctly, architectural powder coated products will offer an extensive life expectancy in most locations. The pretreatment process is actively monitored by members of the Association and third party inspected by IFO, QUALICOAT UK & Ireland’s independent test house.

Introduced in 2008, QUALICOAT also offer a ‘Seaside’ class of powder coating where the minimum removal of aluminium surface is increased to 2g/sm using a dip or spray process of either an acid or a combination acid/alkaline etch. This deeper etch removes more contaminants and therefore offers a

more robust pretreatment for areas where atmospheres carry corrosive salts (chlorides) and other aggressive pollutants.

QUALICOAT licensed applicators who wish to offer ‘Seaside’ class coatings need to apply for an additional licence. The applicator needs to demonstrate that they can remove the 2g/sm by process and monitoring, plus the applicator must offer a coated ‘Seaside’ sample for an additional filiform corrosion test carried out in the IFO laboratory.

Filiform corrosion, is a spider like corrosion that creeps under the powder coating and runs along the aluminium grain boundaries. A deeper acid or alkaline etching removes more trace elements from these areas making the grain boundaries more resistant to corrosion. The pretreatment conversion coating can then be applied using any of the QUALICOAT approved systems. Statistically, with this greater etch of 2g/sm, filiform resistance is increased significantly.

Another method of increasing resistance to filiform corrosion is by using a ‘preanodisation’ process, sometimes referred to as PREOX or Flash Anodising. A more expensive pretreatment, this thin anodising film of just 4-8 µm (microns) totally removes all the grain boundaries, so there are no

places where filiform corrosion may take hold, consequently the protection rate is statistically increased to 100%. Licensed applicators may now source pre-anodised profiles from other licensed plants so that they may take advantage of the increased level of protection that this process can offer.

Technically, the QUALICOAT standard is the most robust specification readily available in the UK & Ireland as it specifies minimum etch requirements within the pretreatment process for enhanced ‘Seaside’ applications and includes regular finished powder coated surface laboratory tests for filiform corrosion resistance, something which BS EN 12206-1 does not require.

The QUALICOAT Specification is continually and incrementally revised in real time with regular update sheets, the specification is completely rewritten at year end to include all updates. The global Specification, its appendices and any update sheets are always freely available for download at www.qualicoat.net. For details on the availability of various colours and finishes contact any QUALICOAT UK & Ireland member for more information. For updated information about the use and specification of QUALICOAT in the UK and Ireland, please visit the UK & Ireland Association website at www.qualicoatuki.org.

20 DECEMBER 2022

PAINT & POWDER twitter: @surfaceworldmag

WE’RE OBSESSED WITH COLOR YEARS OF EXPERIENCE IN RESEARCH & DEVELOPMENT OF CUSTOMIZED INDUSTRIAL COATINGS brands of The Sherwin-Williams Company A complete range of industrial coatings Waterborne | Powder | Solventborne | High solid | E-coat The Sherwin-Williams Company, Goodlass Road, Speke, Liverpool, L24 9HJ, United Kingdom | T: +44 (0)151 486 0486 | e-mail: liverpool.sales@sherwin.com

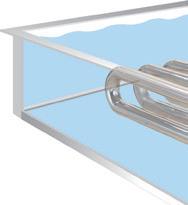

The new generation of dip coating

The combination of pretreatment and coating

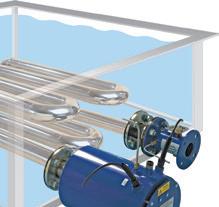

The Surface Treatment global business unit of the Coatings division within BASF, operating under the Chemetall brand, has developed an innovative coating technology. It is used successfully by selected customers in the metal finishing sector.

The new technology is a corrosion protection system designed for coating steel. This revolutionary process combines pretreatment and paint in one single step.

In contrast to conventional corrosion protection systems, the technology provides excellent and complete coating on both external and internal surfaces including cut edges. Internal threads are excellently coated with an even layer. Corrosion tests (field tests) so far show that creepage from scribe after 504h neutral salt spray testing was not more than 3 mm. Depending on the steel quality also good results after 720h have been reached.

Functionality

This innovative corrosion protection coating works without electricity in the immersion baths. The thickness of the coated layer is approximately 20 µm. Curing time ranges between 20 to 25 minutes at about 200 degrees Celsius peak metal temperature.

The unique coating technology meets the coaters’ market expectations including process cost and energy savings. Based on in-field evaluations during the pilot phase, we can assure process stability, bath output and reproducibility.

After a primary degreasing or degreasing/pickling phase, the new anticorrosive coating process takes place by immersing a component in a single tank, where the new coating technology is deposited on the metallic product in about one minute for 20 µm coating thickness. For the near future it is planned to make the coating also available for galvanized steel.

Savings

Due to the technology’s unique formulation of combining pretreatment and paint, multiple process cost savings are achieved. The process, which is applicable on steel, does not require an electrical current.

Accordingly, electricity costs can be reduced as the cooling of the baths contents is not required and the temperature control of the coating bath is no longer necessary.

Additionally, also the contents of the coating tank only need to be circulated slightly during production. As a result, the process footprint is significantly decreased with fewer baths used, water and electricity consumptions.

Advantages

The major advantage of the new technology is its high capacity of covering edges, such as cut edges and internal surfaces offering 100% complete coating. In addition, the new coating technology enables the significant reduction in both process costs and energy costs.

Results

Process optimization and sustainability (i.e. with regard to water and energy consumption) are key R&D drivers in the designing and development of Chemetall technologies.

That is why technologies incorporate the entire cost structure of customers’ processes rather than limiting to the individual parameters, e.g. chemical prices per square meters. The development of individualized solutions for customers are tailored to their specific business needs.

By reducing production and equipment costs while enhancing quality, efficiencies and sustainability, this new technology opens a new era offering opportunities in coating steel. Learn more about our innovative coating technology!

Telephone: 01908 649333/ 01908 361800 Email: chemetall.ukinfo@basf.com Visit: www.chemetall.com

22 DECEMBER 2022 PAINT & POWDER

www.surfaceworld.com

Aluminium Anodizing

with Chemetall’s Technology. www.chemetall.com

E-COAT MASTER P SERIES AUTOMATIC & MANUAL POWDER COATING EQUIPMENT

The Electron E-COAT AP Master Series range of equipment is suitable for both manual and automatic applications.

The AP Series rapidly applies powder on difficult coating surfaces, due to the dense phase powder feed pump. The dense phase transportation of powder allows the user precise control of the velocity of the powder on to the part.

Coating thickness is easily achieved with repeatability and control due to the elimination of the Venturi Style pump. The Electron Master E-FEED AP pump allows the user to achieve the best possible finish with ultimate control.

SPECIFICATION

High Density, Low Velocity TransferTechnology

Best Efficiency for thick and hot coating applications

Digital Statics Control

Digital Pneumatics Control

Remote Control on Gun

Recipe System

Rotary Knob Control

Double Trigger Option

TCP/IP Connection Option

Purge System Included

Fast-Corona Module Option

Immunity to Pneumatical Input Pressure Changes Double & Single Pump Compatibility

P SERIES (MASTER PUMP SERIES)

E-COAT MASTER P-B (BARE KIT)

E-COAT MASTER P-A (AUTOMATIC)

E-COAT MASTER P-H (HOPPER)

E-COAT MASTER P-M (MULTICOLOR)

OPTIONAL (DOUBLE PUMP) Certification

E-COAT MASTER P2-B (BARE KIT)

E-COAT MASTER P-A (AUTOMATIC)

E-COAT MASTER P2-H (HOPPER)

E-COAT MASTER P2-M (MULTICOLOR)

It can be used dual pump instead of single pump.

Email: info@electron.com.tr Visit: www.electron.com.tr

24 DECEMBER 2022

twitter: @surfaceworldmag

PAINT & POWDER

Bathing in non-reflective glory

When you are looking to push the boundaries of light, color and design, especially with an ultra matt surface, our Précis Ultra Matt range has the answers. With a finer mica effect that enables an ultra matt surface to change appearance depending on the way the light reflects on it, you can create a finish that not only looks amazing, but also offers stunning levels of superdurability.

With innovative solutions that push the boundaries of what’s possible, a vast range of sustainable products backed by industry leading certifications, and the best performing powder coatings on the market used and respected by architects around the world, your imagination starts with our finish. architectural.interpon.com

Complete Finishing Systems reduce energy costs

Energy costs are typically a major component of overall operating costs in surface finishing plants, and as manufacturers struggle to stay competitive in such a challenging economic climate, many companies are looking to energy savings to improve their bottom line.

Thankfully, a well-established U.K. based plant manufacturer has not only addressed this concern, but has successfully developed, and been installing carbon trust funded energy saving plant systems for several years.

Andrew Grice, General Manager of Midlands based Complete Finishing Systems explains.

Coming back into the surface finishing industry after a decade or so working in the automotive sector, it was clear that little had changed by way of the development or use of energy efficient technologies. The focus still appeared to be on how new plant equipment could be manufactured at the lowest price point, but with the inevitable impact of the increased and hidden operational costs for the end user remaining largely overlooked.

The approach of CFS was simple, to develop new and energy efficient technologies that could be manufactured to give our customers a plant with the highest levels of performance, efficiency, and quality. Furthermore, with the lowest possible operational costs and shortest return on investment.

Our first purpose-built energy saving plant system proved to reduce the total energy consumption of a pre-treatment plant by around 90%. The efficiency, quality, and reliability of all our systems have proven to demonstrate similar savings. This has enabled many of our customers to secure Government energy efficiency grants of up to 100% of the capital purchase price.

Complete Finishing Systems continues to demonstrate our unrelenting focus on carbon footprint reduction via innovation and technology. Our systems not only enable our customers to rapidly accelerate their Net Zero target, but the dramatic reduction in their operating costs also gives them a hugely competitive edge, and improved profit margins.

A case study of one of our recent installations of a fully automatic, ultra-high efficiency powder coating plant system showed that, when compared to a conventional plant system, we were able to reduce our customers operational energy costs from 3 shifts each consuming 841Kwh, to a single shift consuming only 290Kwh.

Whether it be a new plant, or a retrofitted system, the savings that our customers are making are so significant, that they are not only surviving in the current economic climate but are thriving with such a competitive edge over their rivals.

CFS are part of the Surface Finishing Equipment Group and have been well established within the surface finishing Industry for over 100 years. SFEG are a Surface Prep Company which consists of a group of UK based companies.

Complete Finishing Systems also employs Service/Commissioning Engineers and has an Internal Service & Spares Department available to look after clients after sales requirements. The group employs further engineers enabling unrivalled service coverage throughout UK.

Telephone: +44 (0) 1902 601

26 DECEMBER 2022 PAINT & POWDER

321

www.surfaceworld.com

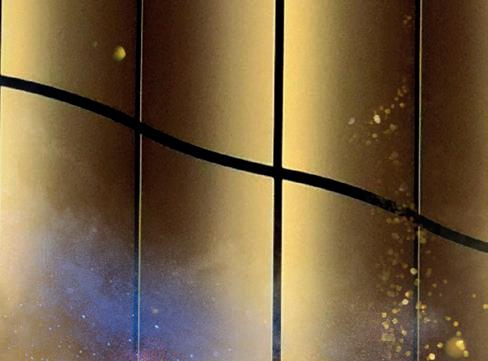

Maximum fl exibility in the powder coating business: Coat any colour, at any time!

Industrial powder coating companies know that a wide range of custom powder coatings in small batches is a challenging business. Colour changes can lead to longer downtimes and flexibility being close to zero. Those concerns can now be a thing of the past. It is so easy to enter the world of colours and convert to lean manufacturing. Achieve colour changes on your powder coating line in 20 seconds, allowing you to coat any colour at any time. Boost your business with the easy to use Color-onDemand® System of Nordson.

A key to flexible production is speed. Nordson’s CoD system gives you that capability through “Colour on Demand”, along with a very efficient production management system. The powder coating system always ensures uniform coating thickness and enables automatic, contamination-free, quality colour changes in less than 20 seconds. Thanks to the efficient production management, it minimises work-in-progress by dynamically adapting to production requirements.

The ultra-fast self-cleaning powder path of the Nordson HDLV® technology, ensures high quality and reduced downtime.

The entire colour change process is fully automated – no need to move or re-connect parts. This allows your business to achieve fast, high-quality production.

The automatic purge cycle cleans the entire feed line - from hopper to spray gun. There is no need for manually changing colours, thanks to its capacity of accommodating up to 28 different colours. This gives you maximum flexibility and more colour changes per shift, higher throughput, just-in-time manufacturing for zero inventory and improved production efficiency.

The Spectrum CoD powder feed center provides space for the powder hoppers and venting extract, making it a clean, safe and productive working environment at all times. The powder feed center is also available as a vibratory box feed version. It is configured

customer-specific to suit all requirements. The colour touch screen display has user-configurable keys that provide pre-programmed parameters at the touch of a button.

Visit: www.nordson.com/en

28 DECEMBER 2022 PAINT & POWDER

twitter: @surfaceworldmag

Color-on-Demand Powder Coating

Maximum flexibility – coat any colour, at any time! Do you handle a wide range of custom powder coatings in small batches? Boost your business with the Nordson Color-On-Demand® System – designed for precision finishing and ultra-fast quality colour changes! The system accommodates up to 28 colours at one time for more colour changes per shift and higher throughput, and just-in-time manufacturing for zero inventory and improved production efficiency. Explore the unique features of our powder coating systems online www.nordson.com/hdlv or get in contact for more information ics.eu@nordson.com!

PAINT & POWDER

TESTING & MEASUREMENT

Duplex Coating System Thickness Measurement

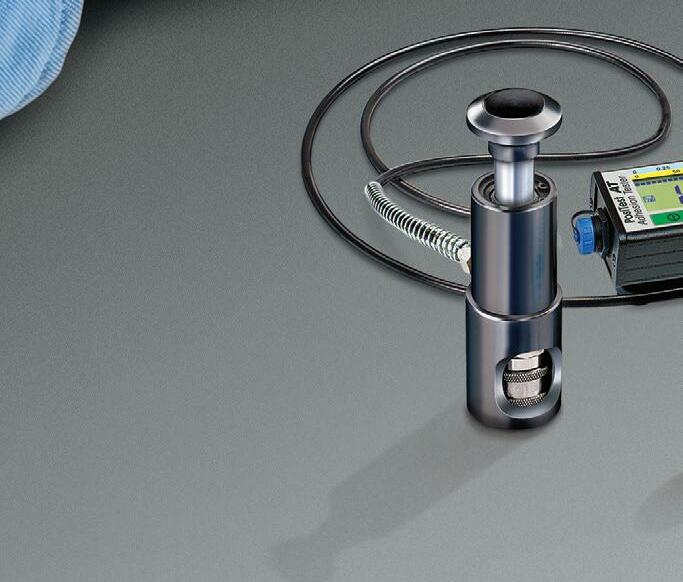

DeFelsko’s PosiTector 6000 FNDS coating thickness gage nondestructively measures the individual thicknesses of both the paint and the zinc galvanize layers in a duplex coating system with a single reading.

How Duplex Coatings Protect Steel from Corrosion

Steel corrodes when an electrolyte connects anodes and cathodes on a steel surface. The formation of the corrosion cell causes a flaky iron oxide known as rust.

To avoid rust, something must prevent the formation of the corrosion cell. Two common methods for preventing corrosion on steel are:

1. Cathodic protection (by using a sacrificial anode, such as zinc).

2. Creating a barrier to block electrolytes from contacting the steel, such as paint or other protective coatings.

Duplex coating systems use a combination of two corrosion protection systems—typically paint or powder coating over galvanized steel (hot-dip, electro, or zinc spray metallizing). The corrosion protection which results from a duplex coating system is superior to either protection system used independently.

Benefits of duplex coating systems:

Extended life of coating system and underlying substrate

Delayed maintenance cycle—less touch-up repairing, reduced maintenance costs

Color Coding

Aesthetics

30 DECEMBER 2022

CONTINUED ON PAGE 32 www.surfaceworld.com

Detects holidays, pinholes, and other discontinuities using pulse DC High voltage Holiday Detector n Lightweight, ergonomic design reduces opera tor fa tigue n Regula ted pulse DC volta ge output ±5% accuracy n Industr y-standard connectors and ada ptors for compa tibility with nearly all existing electrodes n Volta ge calcula tor fea ture choose one of 11 interna tional standards and input the coa ting thickness to automa tically calcula te the required test volta ge n Removable lithium-ion ba tteries provide long-lasting po wer Ch f ide us m SPECIAL DISCOUNTED RATE PosiTest HHD Basic Kit (HHDKITB) £ 1 9 5 0 + VAT sa ve over £400 Limited time only In stock t: 01442 879494 www.dftinstruments.co.uk Proud supplier of DeFelsko Inspection Instruments t : 0 1 4 4 2 8 7 9 4 9 4 n w w w d f t i n s t r u m e n t s c o u k n e : s a l e s @ d f t i n s t r u m e n t s . c o . u k

How to Measure the Coating Thickness of

a Duplex System

Measuring the thickness of duplex coating system layers with conventional instruments is challenging.

Typically, a magnetic coating thickness gauge such as a PosiTector 6000 F1 or PosiTest DFT Ferrous is first used to measure the zinc thickness. The same instrument then measures the total thickness of both the zinc and paint layers together. The difference between the two readings is taken to be the paint layer thickness. This method assumes the zinc thickness never varies.

In reality, zinc thickness is not always uniform over the entire part or structure. Coating thickness depends on the thickness, roughness, chemistry, and design of the steel being galvanized. Any or all of these factors could produce galvanized coatings of non-uniform thickness.

A second conventional method uses a combination magnetic and eddy-current probe such as the PosiTector 6000 FN3. Two readings are taken, the first in eddy-current mode to get the paint thickness, the second in magnetic mode to get the total coating system thickness.

The difference between the two readings is taken to be the zinc layer thickness. Again, this method assumes the zinc thickness does not vary over the structure.

Both methods are time consuming and error-prone. The PosiTector 6000 FNDS duplex coating thickness probe performs this operation with one reading—simply and accurately.

Duplex Coating Thickness Measurement Solution from DeFelsko

The PosiTector 6000 FNDS duplex coating thickness gage measures the individual thicknesses of both the paint and the zinc layers in a duplex coating system with a single reading. In Duplex mode, the PosiTector 6000 FNDS utilizes both magnetic (ferrous) and eddy current (non-ferrous) principles simultaneously to calculate and display the individual paint and zinc layer thicknesses.

The magnetic principle is used to measure the combined paint/zinc thickness over the ferrous substrate, and the eddy current principle is used to measure the paint thickness over the non-ferrous zinc coating.

The zinc thickness is calculated by subtracting the paint thickness from the combined paint/zinc thickness measurement.

When not in Duplex mode, the gauge will operate like a conventional combination ferrous/non-ferrous instrument (similar to PosiTector 6000 FNS probe). Ideal for measuring non-magnetic coatings over steel and non-conductive coatings over nonferrous metal substrates.

For more information on the PosiTector 6000 FNDS or any of the gauges in the DeFelsko range, please contact Mark Conlon at DFT Instruments UK Ltd, proud UK distributor for DeFelsko.

Telephone: 01442 879494

Email: sales@dftinstruments.co.uk Visit: www.dftinstruments.co.uk

32 DECEMBER 2022

TESTING & MEASUREMENT twitter: @surfaceworldmag

Head Office: Stafford Street, Willenhall, West Midlands, WV13 1RZ ISO 9001 Quality Management FM 00382 E: info@wggltd.co.uk T: 01902 601944 Hot dip galvanizing provides you with long-term protection against rust and corrosion of steel products. With 14 plants across the UK, Wedge Group Galvanizing is the UK’s largest hot dip galvanizing organisation offering a national service, collection and delivery and 24hr turnaround on request. The group can process anything from small components to 29m structural beams. WEDGE GROUP GALVANIZING Your Galvanizing Partner

“The Professionals” email info@pros trip.co.uk phone 01 1 5 91 1 2240 “Save up to 20% on your monthly s tripping cos ts” Send your enquir y today!! Sub contract specialists in Paint & Powder coat removal to the finishing industr y JIG CLEANING PAINT BOOTH GRID CLEANING COMPONENT RECLAMATION EST . 1989 Pro-Strip Ltd. Trent Lane, Daleside Road, Nottingham NG2 4DS web www.prostrip.co.uk

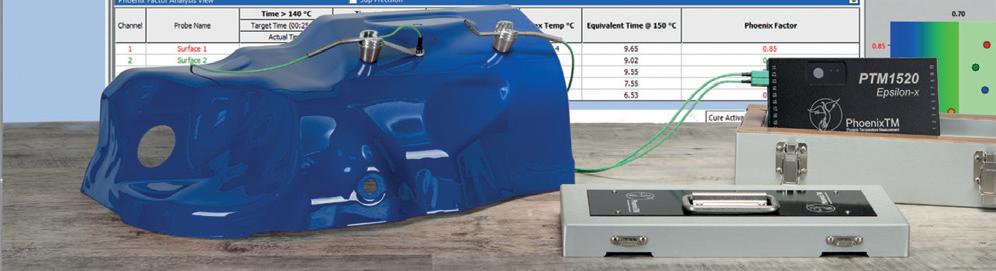

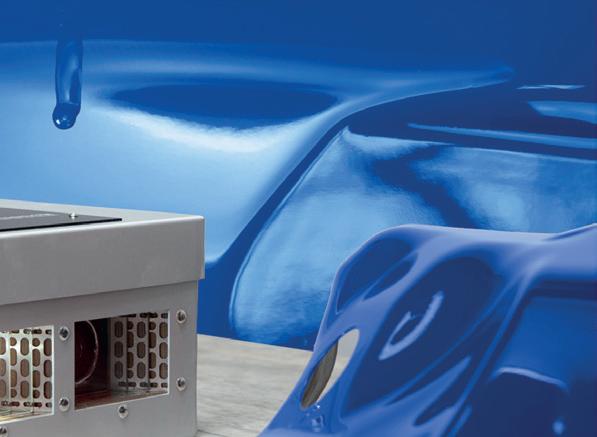

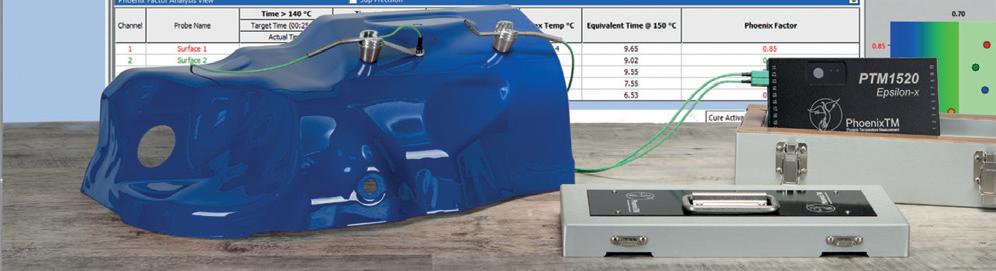

Innovation in Thru-Process Automotive Paint Monitoring Safe ATEX Certified Temperature Profiling New Optic Video Profiling System Intrinsically Safe • 20 measurement channels • Paint & Powder coating • Includes Phoenix Factor cure index calculation During Production • Detect paint runs, drips and defects • Spot transport problems • Identify oven damage Phoenix Temperature Measurement T:01353223100 E:sales@phoenixtm.com www.phoenixtm.com

Mechanical Properties of Hard Coatings on Machining and Milling Tools

Hard coatings are used for many industrial purposes. Especially for machining and milling, the tools used are made with hard-coated cutting materials. Depending on the application area, specialised coating solutions have been developed to enhance abrasion resistance and, therefore, durability. Controlling the quality of these coatings according to distinct material properties such as micro-hardness is a tough challenge for most measurement technologies.

Typically, machining tools like drill bits and indexable inserts are protected against abrasion by hard coatings, since the hardness and viscosity of the cutting edge are defined by the coating, not the softer substrate. But coatings applied by physical or chemical vapour deposition (PVD or CVD) such as titanium nitride (TiN) are often only a few micrometres thick, making it very difficult to determine their material properties via classic hardness measurement methods. However, the instrumented indentation test (“micro-hardness testing”) enables accurate measurement even on very thin coatings (requiring very shallow indenter penetration depths) while still preventing any influence of the substrate on the readings. The FISCHERSCOPE® HM2000 operates according to this measurement principle, accurately determining not only the Martens hardness (HM) of the layer but also other parameters, such as elastic deformation.

The instrument’s integrated microscope allows exact positioning even on small shapes. Since the coating process generates a rough surface, it is recommended to repeat the measurements several times in order to yield a meaningful average value; the HM2000’s precise positioning stages make it straightforward to program and automatically reproduce these measurements. Typical results for hardness determination of the TiN coating on a drill bit are shown in Figure 1.

Depth dependent Martens hardness of a 1µm thick TiN coating. Starting at one-tenth of the layer thickness the measurement results are influenced by the base material (Bückle rule).

The standard deviation reflects the degree of surface roughness on the coating. But despite the roughness, the repeat measurements

make it possible to characterise the coating’s hardness exactly. Between the easy sample preparation and its intuitive handling, the FISCHERSCOPE® HM2000 ensures quick and efficient micro-hardness testing on such hard, thin industrial coatings.

For the exact determination of essential wear resistance properties, such as hardness or ductility, of the hard coatings on machining and milling tools like drill bits or inserts, the easy-to-use FISCHERSCOPE® HM2000 is the right instrument.

HM2000 is a professional measurement instrument for the analysis of mechanical and elastic properties of materials by nanoindentation. For more information, please contact your local FISCHER representative: Tel.ephone: 01386 577370 visit: https://fischerinstrumentation.co.uk/

36 DECEMBER 2022 TESTING & MEASUREMENT www.surfaceworld.com

A Layman’s Guide to Ultrasonic Inspection

Non-destructive testing (NDT) is a large and increasingly multifaceted discipline, encompassing a wide range of techniques such as magnetic particle inspection, radiography, ultrasonic testing, eddy current testing and more. As of the end of 2020, Ultrasonic Testing (UT) was the most commonly used method, accounting for 27%1 of the total NDT equipment market share. In this article you’ll find a brief overview of the history, fundamentals, and current capabilities of UT as a technique.

A Short History of Ultrasonic Testing

Ultrasonic testing’s roots can be traced back to the classic ‘tap test’ of historical blacksmiths and metalworkers. In these tap tests, an experienced craftsman would give test pieces a firm whack with a hard object, such as a hammer or coin, and then listen for the resulting ring to tell whether or not the object

was ‘sound’ from the sharpness, tone and other sonic qualities of the produced noise.

While this is a long way practically from the scientific approach of modern UT, the concept of utilising sound to test materials was the driving constant throughout its subsequent development. The development of modern ultrasonics really got underway in the 1940s and 50s, with a marked acceleration in sophistication following the electronic revolution at the tail end of WW2.

In 1945 Floyd Firestone, an American physicist specialising in acoustics, patented a device built from modified RADAR instruments called ‘The Supersonic Reflectoscope’2 which he described as ‘a means of inspecting the interior of solid parts for flaws’. The Reflectoscope operated in a ‘pulse-echo’ configuration using a single quartz crystal search unit which both sent and received, which was notable in comparison to his contemporaries who made use of separate sending and receiving units.

The search unit emitted a 2.25MHz ultrasonic pulse into materials and then plotted the amplitude of returning echoes against time on an oscilloscope screen, making the Reflectoscope arguably the world’s first A-Scan flaw detector.

Firestone’s invention was a breakthrough moment for the field of ultrasonic testing, but it would take a number of years and a lot of innovative industrial design before UT developed into the mature and reliable inspection technique it’s considered to be today. For this to happen, certain technologies needed to be pioneered first, such as the discovery of high-power composite crystals to replace quartz or digital electronics to replace the analogue valve based oscilloscope systems used in the 40s.

What is Ultrasound?

Fundamentally, sound is just the name for a type of mechanical wave that travels through solids, liquids and gases by making their particles oscillate, or vibrate, between 20 and 20,000 times a second (Hz). Because this frequency region is what the human ear evolved to detect, it is also known as audible sound. Ultrasound, therefore, refers to the region of frequencies that are too high, i.e. that vibrate too fast, to be detected by the human ear. Conversely, Infrasound is the range of frequencies that are too low to be detected by the human ear.

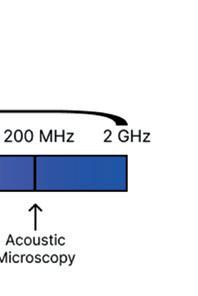

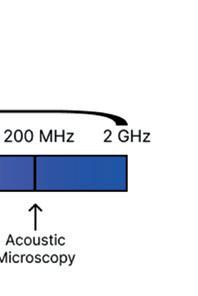

The waves used for non-destructive testing are extremely high pitched when compared to the audible range. The lowest commonly used frequency is around 1 MHz (1 million Hz), which is fifty times higher than the highest sound you’ll ever hear. For specialist applications like scanning acoustic microscopy the frequencies employed can go all the way up to a staggering 2,000 MHz3!

The important trade-off engineers consider when it comes to their choice of ultrasonic frequency is penetration vs. resolution; as ultrasonic waves increase in frequency they can be used to make out much smaller features within a material, but will lose much of their ability to penetrate deep into them. Conversely, lower frequency ultrasound will have a much easier time penetrating material, but have much lower resolving power.

The most commonly used frequencies within industrial testing sit within the 0.5MHz to 20MHz range. The bottom end of the range is employed when testing composites and highly attenuative polymers while the top end is more useful for very thin metals and high-precision applications like bolt tension measuring.

38 DECEMBER 2022

CONTINUED ON PAGE 40 twitter: @surfaceworldmag TESTING & MEASUREMENT

Floyd Firestone with his A-Type Supersonic Reflectoscope

elcometer.com Everything you need for fast and accurate coating inspection in one cost-effective, easy-to-use kit. climatic monitoring | surface profile | coating thickness INSPECTION KITS Elcometer3045 · FAST · REPEATABLE · ACCURATE · DURABLE COATING Surface World - December 2022.indd 2 19/12/2022 14:52:20

How Does Ultrasonic Testing Work?

On a conceptual level, ultrasonic testing is a fairly intuitive technique to understand and requires little abstraction or higher level understanding. An ultrasonic pulse is generated by a transducer which is acoustically coupled to the test piece. This ultrasonic pulse travels into the material, reflecting back to the transducer whenever it hits a boundary, such as an air bubble, crack or the back surface of the piece. The strength of these reflections and how long it took for them to come back are measured and then plotted on a 2D display.

The explanation and diagram above are descriptive of a specific type of ultrasonic inspection, in NDT jargon this is known as a ‘0° Single-Crystal A-Scan inspection’. ‘0°’ refers to the angle that the transducer is offset from the surface, ‘single-crystal’ refers to the specific construction of the transducer and ‘A-Scan’ refers to the way the results are displayed and interpreted. This type of inspection is the classic interpretation of UT and more or less the same setup pioneered by Firestone. However, as the field has developed, so too have the methods employed by inspectors.

As more powerful piezoelectric composites, the crystals that produce the ultrasound, began to see use, it became feasible to transmit the ultrasound into materials at an angle, allowing for the fusion face of welds to be inspected without radiography. Advances in transducer design and computing power saw the production of transducers with more than one piezoelectric crystal inside, leading to the development of dual crystal transducers for near surface inspection and eventually to the introduction of phased array ultrasonics in the 1980s,

where 12 or more individually fired crystals could be connected to one another. Increases in computing power also lead to different ways of displaying UT information, such as C-Scans and S-Scans, providing inspectors with much more easily interpretable results.

Where is Ultrasonic Testing Used?

UT makes up over a quarter of the total NDT market, and has achieved supremacy mainly as a result of its versatility as a technique with new developments continuously adding capabilities to a UT inspector’s arsenal. While earlier designs were limited to volumetric inspections of metals below a certain thickness, the current suite of options available to ultrasonic inspectors are very comprehensive. They include detection of surface flaws, measurement of coating thickness on non-metallic substrates, automatic full-body immersion scans of complex parts and some guided wave technologies even allow for long-range

ultrasonic inspection of pipelines up to 90m4 away from the transducer.

As a result of this versatility, and in combination with its high accuracy, UT is employed in some form in an overwhelming majority of high-tech industries. The top users by size are the oil & gas sector, aerospace industry and the utility & power sector. Within these sectors the most common use cases are often weld testing: the thorough scanning of welds to check for manufacturing defects, and corrosion monitoring: the periodic inspection of pipes & plates to check their rate of corrosive decay over time.

What Does the Future of Ultrasonic Testing Look Like?

One of the downsides of current UT methods is that even a basic A-Scan operator must be rigorously trained to be able to properly perform an inspection; in 2018 a Level 1 NDT technician in the US earned a median salary of $73,000 – about 40% higher than the median US salary across all occupations5. This is exacerbated by a general skills shortage within NDT as a whole that sees demand for operators outpacing supply.

There are two trends developing as businesses attempt to reconcile the expense of NDT with its absolute indispensability; increasing demand for low-cost, low-training UT solutions and a greater focus on automated UT systems. The former will most likely be achieved as manufacturers find ways to bring together the stunning images of advanced UT with the ease-of-use seen from traditional techniques like thickness measurement. The latter is already subject to frenzied development, and the last few years have seen autonomous drones and crawlers perform jobs in hours that may have taken multiple operators days to complete.

40 DECEMBER 2022

CONTINUED ON PAGE 42

A-Scan displays are interpreted based on an understanding of the part’s geometry.

TESTING & MEASUREMENT www.surfaceworld.com

Weld testing makes up a large proportion of the global ultrasonic testing market (Picture credit: loda.gov.ua, CC BY-SA 4.0, via Wikimedia Commons)

EASY OPERATION . DOUBLE PRODUCTIVITY. SuperCenter EVO Powder preparation & supply center • Ideal for frequent & fast color changes • High degree of automation for optimum efficiency • Double-designed fresh powder station for increased productivity

Contact Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone:

368410 enquiries@wagner-group.com

wagner-group.com

01327

Elcometer NDT Equipment

Elcometer NDT specialise in the manufacture of portable, user-friendly and highly robust ultrasonic equipment for the UT market. The comprehensive range of gauges represent exceptional value for money, without compromising on the features or build quality required by inspectors.

For less involved applications, such as to test for uniform corrosion or to take coating thickness measurements on non-metallic substrates, Elcometer have developed the MTG & PTG ranges (Material/Precision Thickness Gauge). These numerical thickness gauges are thoughtfully designed to make it

much easier to perform common inspection types such as corrosion mapping or thickness checking and feature an easy-to-learn user interface, intelligent transducer recognition and automatic 1 or 2 point calibration. All inspection data gathered can then be rapidly uploaded via Bluetooth® into ElcoMaster®, our bespoke data management platform, for analysis and reporting.