At MacDermid Enthone, we go beyond the surface.

We stand together with our customers in driving progress forward. We listen, learn, and test, working hand-in-hand to ensure the innovations we deliver are the solutions they need.

At MacDermid Enthone, we go beyond the surface. We stand together with our customers in driving progress forward. We listen, learn, and test, working hand-in-hand to ensure the innovations we deliver are the solutions they need.

Because our

Because our finish is just the beginning.

macdermidenthone.com/beyondthesurface Let’s talk about how we can move your business into the future, Finishing? We’re just getting started.

finish

beginning. macdermidenthone.com/beyondthesurface Let’s talk about how we can move your business into the future, together.

We’re just getting started.

is just the

Finishing?

WE HAVE EVERYTHING COVERED – follow us on X (twitter) @surfaceworldmag – visit www.surfaceworld.com Now the only magazine in the UK covering the surface finishing industry APRIL 2024

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826

e: nigelbean1@aol.com nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

Sheena Burrus e: sheenaburrus@hillmedia.com

EXHIBITION ORGANISER

Sheena Burrus e: sheenaburrus@hillmedia.com

Hill Media Ltd, Marash House 2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd. Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents. © Hill Media Ltd – 2024 ISSN 1757-367X

All the major UK & Ireland architectural powder coaters are either licenced QUALICOAT members or in the process of approval.

With coating specifications now requiring QUALICOAT, should you not be looking to join?

COMPANY SPOTLIGHT

SECURING THE FUTURE OF YOUR SOLVENT CLEANING PROCESS. 2

SURFACE WORLD 2025

RESHAPING THE SURFACE FINISHING SECTOR: Learn, Connect and Shape the Future – Under One Roof, Over Two Days. 6

IMF: INSTITUTE OF MATERIALS FINISHING

SECRETARY GENERAL’S LETTER 8

JOIN US AS WE CELEBRATE 100 YEARS. 10

QUALICOAT UK & IRELAND

SPECIFYING & MAINTAINING ARCHITECTURAL POWDER COATINGS. 12

BCF: BRITISH COATINGS FEDERATION

UK COATINGS INDUSTRY LAUNCHES EQUITY, DIVERSITY AND INCLUSION CHARTER. 17

INDUSTRY NEWS

CELEBRATING 65 YEARS OF HODGE CLEMCO: A LEGACY OF EXCELLENCE. 18 GALVANIZERS DONATE TO WAR MEMORIAL GARDEN. 22

AKZONOBEL INVESTS IN DUTCH RESEARCH LABS TO CONTINUE INNOVATING WITH IMPACT. 24 A RANGE OF DROP-IN REPLACEMENTS FOR 3M™ NOVEC™ SOLVENTS FROM ENVIROTECH EUROPE. 28 LATEST PRODUCT LAUNCH FROM AIRBENCH – AIRTOWER AIR CLEANING SYSTEM. 30

FRASER TECHNOLOGIES THE EXCLUSIVE UK SUPPLIER OF THE PIONEERING MIELE PROFESSIONAL AQUEOUS CLEANING SYSTEM. 32 NEW INTERPON STRUCTURA POWDER COATING COLLECTION BRINGS STYLE AND PERFORMANCE TO THE NORTH AMERICAN ARCHITECTURAL MARKET.

CHAIRMAN OF UK GALVANIZERS AWARDED INDUSTRY ACCOLADE.

PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING A GLOBAL LEADER IN WET BLASTING & SURFACE TREATMENT SOLUTIONS. 44 IN-LINE SURFACE TREATMENT & CLEANING. 45 VIXEN DEGREASING, CLEANING & ULTRASONIC SOLUTIONS.

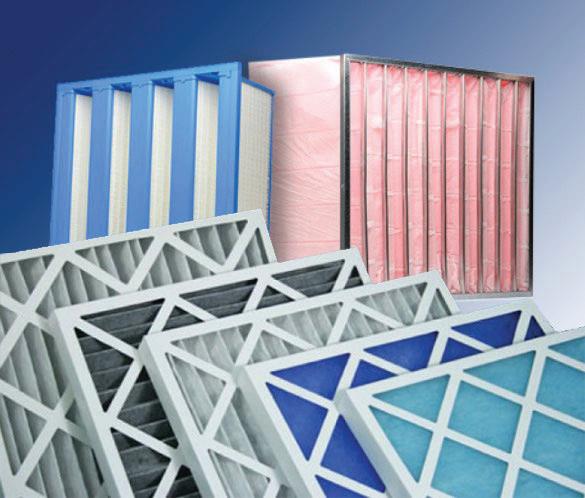

YOUR ONE STOP SHOP FOR A WIDE RANGE OF FILTRATION

34

36 AAC GAIN QUALICOAT SEASIDE LICENCE. 38

46 25% ENERGY SAVINGUSING STRAALTECHNIEK WHEEL BLASTING TECHNOLOGY 48 PUMPS & FILTRATION

SOLUTIONS AND FILTER SUPPLIES. 50 HENDOR-PE UK LTD – Celebrating over 20 Years supplying products to the UK surface treatment industry! 56 WATER & EFFLUENT TREATMENT THE IMPACT OF EXCHANGEABLE DI CYLINDER SERVICES ON PURIFIED WATER SUPPLY. 60 PIONEERING EXCELLENCE WITH PURITE: Leading the Way to Advanced Water Purifi cation in the Surface Finishing Industry. 64 AUTOMATED WATER & EFFLUENT LTD TRADING SINCE 1982. 66 FAST RESPONSE TO THE URGENT NEED FOR A WASTEWATER SOLUTION. 68 PRODUCTS & PROCESSES HOW CURRENT RIPPLES AFFECT THROWING POWER AND PLATING QUALITY. 72 MATERIAL & EQUIPMENT SUPPLIERS 73

qualicoatuki.org

1 APRIL 2024 VOLUME 31 NUMBER 4

SECURING THE FUTURE OF YOUR SOLVENT CLEANING PROCESS

For many years, solvent cleaning has been widely accepted as a fast, effective way of removing oils, greases etc. from metal components. In its early days, the process, known as ‘vapour degreasing’ involved placing contaminated, metal components in hot solvent vapour, which would condense on the cooler metal and the generated liquid would dissolve any oil and grease present. When components were removed from the process, the residual solvent would evaporate, leaving parts clean and dry.

The term vapour degreasing is still widely used today, although most modern solvent cleaning processes employ complete immersion of components in the cleaning fluid, often assisted by ultrasonic agitation. This change is due, in no small part, to solvent cleaning having to adapt and evolve as manufacturing processes have changed, newer processing fluids have been developed, polymeric materials and composites have seen wider application and ever more stringent cleanliness standards have been demanded. Added to these changes in manufacturing practice there

has also been the ongoing tightening of health and safety and environmental legislation. Despite these demands however, ongoing development of fluid formulations and more efficient cleaning machines have helped solvent cleaning remain the process of choice for many companies.

D&S Ultra-Clean Ltd is the UK distributor for TergoTM precision cleaning fluids manufactured by MicrocareTM LLC, a company with over 40 years’ experience of providing cost effective solutions to critical cleaning problems. Because MicrocareTM is absolutely committed to research and development, we are well placed to provide sustainable, long term solutions to today’s component cleaning challenges.

The TergoTM family of precision cleaning fluids includes products that have been specially formulated to provide the highest standards of cleanliness across a wide range of applications in industries such as: aerospace, automotive, medical devices, electronics, telecommunications and precision engineering.

All are highly effective, provide low cost-per-clean and reduce environmental impact. We have readily available alternatives to NovecTM fluids for anyone currently looking to find replacements ahead of their impending withdrawal from the market. We are also now delighted to announce that we have launched the TergoTM XCF range, the latest additions to the family that are formulated to be completely PFAS free, thus underlining our long-term commitment to the supply of precision cleaning fluids to the UK market.

TergoTM precision cleaning fluids have been designed to operate safely and efficiently in modern vapour degreasing equipment such as our ‘Cleanseal’ ultrasonic cleaning machines. Our customers tell us that the combination of TergoTM and ‘Cleanseal’ combines excellent cleaning performance with low running costs, many enjoying significant cost savings since switching from competitive fluids.

Making the switch to TergoTM is simple and straightforward and we can manage the whole process. First step is that a member of our technical team will make an initial evaluation of the current cleaning process and fluid to allow us to recommend the most appropriate TergoTM alternative. Step two involves carrying out free, no obligation, cleaning trials on sample components to confirm that we achieve at least an equivalent standard of cleanliness. Thus far, many customers making the switch have told us that they have seen an improvement in cleaning performance. Finally, our service team will carry out the conversion of the cleaning machine, optimising process conditions etc. to provide maximum benefit from running with TergoTM.

If you would like more information on making the switch to TergoTM and securing the long-term future of your component cleaning process, contact us on sales@ds-ultra.com or visit our website at www.ds-ultra.com.

Microcare and Tergo are trademarks or registered trademarks of Microcare LLC

2 COMPANY SPOTLIGHT

ENVIRONMENTALLY SUSTAINABLE PRECISION CLEANING FLUIDS

Introducing the new Tergo™ XCF range of PFAS-free products. Designed to replace HFEs, HFCs and other PFAS containing solvents in cleaning, degreasing and flushing applications. The answer to your long-term component cleaning needs and available TODAY! Used in conjunction with our Cleanseal range of ultrasonic cleaning machines, Tergo™ solvents provide a complete, sustainable, component cleaning package. If you would like to find out more about these exciting new products or arrange cleaning trials on your sample components, contact us on: More information can also be found on our website: 01928 580460 sales@ds-ultra.com www.ds-ultra.com THE BENEFITS Low global warning potential Zero ozone depletion Non flammable Considerable cost savings on competitor fluids D&S Ultra-Clean Ltd 6 Berkeley Court, Manor Park, Runcorn, Cheshire, WA7 1TQ, United Kingdom

Tergo™ A family of safe, non-flammable precision cleaning fluids which offer excellent cleaning performance and can be used in most types of modern, vapour degreasing equipment. Tergo is a registered trademark of MicroCare, LLC

ECONOMICAL COATING. FLEXIBLE APPLICATIONS. GM 5000 & GA 5000

Manual & automatic electrostatic guns

• High transfer efficiency with wrap-around effect

• Suitable for water-based & solvent-based paint

Contact Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone: 01327 368410 enquiries@wagner-group.com

• Excellent finishing results wagner-group.com

SURFACE WORLD 2025:

Learn, Connect and Shape the

Future

– Under One Roof, Over Two Days

Surface World 2025 is more than just a typical trade show – it’s an event that’s all about transforming the surface finishing industry. Set to take place on Wednesday 26th and Thursday 27th February, it’s a two-day gathering where professionals from the industry come together to learn, connect, and shape the future.

This two-day event is more than just a showcase of products; it’s a platform for innovation, learning, and networking. Attendees can expect to see the latest advancements in surface finishing technologies, from state-of-the-art machinery to cutting-edge techniques that are pushing the boundaries of what’s possible in the industry.

Surface World 2025 provides the perfect opportunity to get hands-on experience with the newest technologies and ideas shaping the future of surface finishing. From environmentally friendly coatings designed to minimise ecological impact or delving into the intricacies of advanced automation systems streamlining production processes, participants can explore diverse innovations first-hand.

With a vast array of specialist experts from within the industry and interactive demonstrations taking place on the exhibitor’s stands, attendees will have the chance to gain valuable insights and knowledge that can help them stay ahead of the curve in this fast-paced industry.

Networking plays a crucial role at Surface World 2025, offering attendees a valuable

opportunity to expand their professional connections within the surface finishing industry. Beyond merely exchanging business cards, this event provides a dynamic platform for forging meaningful partnerships and exploring collaborative ventures. Attendees will have the chance to engage with like-minded professionals, share insights, and cultivate relationships that can lead to new opportunities for growth and innovation. Whether it’s discovering potential collaborators for projects or finding mentors to offer guidance, the networking opportunities at Surface World 2025 are bound to leave a lasting impact on attendees’ careers and businesses.

Surface World 2025 represents a pivotal moment for the surface finishing industry. It’s a chance for professionals to come together, share ideas, and shape the future of the industry. Whether you’re a seasoned veteran or just starting out in the industry, there’s something for everyone at Surface World 2025.

So mark your calendars and get ready for an unforgettable experience at Surface World 2025. It’s sure to be an event that will leave a lasting impact on the surface finishing industry for years to come.

Surface World 2025

Hall 11, NEC, Birmingham 26th & 27th February 2025

For more information about Surface World 2025, please contact Nigel Bean: nigelbean1@aol.com

6 SURFACE WORLD 2025

Surface World 2025 - Wednesday 26th & Thursday 27th February

The Surface World Trade Show is an exciting event that brings together professionals from the surface treatment and coating industries, providing an excellent opportunity to explore, learn, and collaborate in this ever-evolving sector. Discover the latest trends, advancements and innovations in surface treatment and coating techniques. Find practical and effective solutions to enhance the durability, aesthetics, and performance of surfaces. Connect with manufacturers, suppliers, and fellow industry peers to build valuable business relationships.

2025

SECRETARY GENERAL’S LETTER

SECRETARY GENERAL ’S COLUMN (i)

Institute of Materials Finishing

So, Easter has been and gone in a flash and it’s back to work with a bang! I don’t know if it’s just me, but the hours, days and weeks just disappear. As you may know, I’m now supposed to be semi-retired and now work just three days a week, but no sooner has the alarm sounded at 5.00am on a Tuesday morning, I’m driving home on the Thursday evening after three very full days of meetings and virtual conferences.

I’ve been pretty involved with the issue of data gathering on measurements of operators, tanks, spraying and exhaust systems where surface treatments containing Chromium Trioxide are used.

Greetings from seat 19D on Emirates flight 040 to Dubai and on to Singapore. Yes, once again I ’m off on my travels! This was planned in late 2023 and seemed a long way off but it’s come round so quickly! Yet again it leaves me wondering where time goes. At least on this trip I have the enjoyment of 4 days at the Singapore Airshow, and catching up with old friends I haven ’t seen since before Covid. I stop off in Dubai on the way home to run some training so not back in the UK until mid -March.

Whilst I think most of us are aware, the UK HSE have said that they will grant a re-authorisation for continued specific uses of Chromium Trioxide, and we are told that this order will be signed by the UK Secretary of State before the September 2024 end of current authorisation deadline.

however make some sense and promote some serious thought on working practices.

In Europe, however, it’s a different scenario. No recommendations have yet been issued by the European Chemicals Agency (ECHA) to the European Commission as to whether or not a reauthorisation will be the recommendation.

The Aerospace and Defence Chrome Re-authorisation (ADCR) grouping, and their consultants have instigated a Spring Data Collection regime, and really do need responses on monitoring information. A very tight deadline of the end of April has needed to be set to enable a full report to be compiled for submission to ECHA. ADCR are concerned that a lack of or minimal data will impact negatively on the recommendation. If you receive one of the data collection Excel spreadsheets, please do your best to complete and return.

The first 6 weeks of 2024 have seen some amazing business involvement hope Indestructible are not the exception to the rule by being so busy. Surely of us involved in material finishing must be seeing an upturn in business as sure all the world is becoming dynamically active.

I’m aware of the RICEP proposed guidelines on changes to the handling of chrome flake, but at present these are only suggestions. These guidelines do

On a more hopeful note, even though some analysts are still predicting doom and gloom, in my experience things in surface engineering and materials finishing certainly appear to be on the up! I’m involved in several new coatings projects that really bode well for the future; I hope you are all seeing some growth and new exciting projects coming forward.

Now less than a year away, the Institute will be celebrating their 100th anniversary in 2025. The year of celebration kicks off with a celebratory dinner on the middle night of the 2025 Surface World Live exhibition on Wednesday 26th February. Helen is already well into the planning of this very special event, so please get in touch with her to book your table! Other events will be planned for throughout 2025 so keep watching announcements in IMFormation and on the website.

I have to say I ’m pleased to hear the good news from the UK HSE on the results their investigation into the re -authorisation analysis on Chromium Trioxide. It be remembered that two requests for re -authorisation of CrO3 had submitted, both to the UK HSE for UK REACH, but also ECHA for EU REACH. Whilst ECHA seem to enjoy prevarication, the HSE have got down to business, with outcome that they are recommending a 12 -year re-authorisation for use in slurry coatings, for both flight and industrial applications. now has to be signed off by the Secretary of state, this is expected to be a formality, and will mean chrome -based slurry coatings can continue to manufactured in the UK and applied both in the UK throughout the world (except Europe!!) until 2036.

vironl Environmental and H&S Consultancy Services

On the social front, there are several exciting activities coming in the near future. Don’t miss out on the joint IMF/ OCCA golf day planned for Wednesday May 22nd, to be held at the Windmill Village hotel, golf club and spa on the outskirts of Coventry. Teams of up to four golfers are invited from both individuals and member companies. Bacon baps will be served on arrival, and after the golf competition there will be a late lunch and prize presentation. Last year proved to be a great day, with perhaps a little too much alcohol in the evening!

For those of you not aware of the history, the Institute was founded in 1925 as the Electrodepositers Society. The name was firstly changed to the Institute of Metal Finishing during the 1950’s and to the Institute of Materials Finishing more recently in 2012, better to reflect the much wider range of coatings systems we now support! Personally, it was a great pleasure and honour to be the first President under the new banner!

So, here’s looking forward to starting our second centenary with continued success with our education programmes continuing to educate our youngsters in the chemistry of surface finishing!

Graham Armstrong April 2024

8 INSTITUTE OF MATERIALS FINISHING

IMFORMATION FEBRUARY 2024 www.materials - finishing.org IMF & OCCA GOLF DAY 22nd MAY 2024 At Windmill Village Hotel £50 per Golfer Includes Bacon Bap, Coffee on arrival and Lunch To Book Email Helen@materialsfinishing.org

JOIN US AS WE CELEBRATE 100 YEARS

THE IMF ARE 100 YEARS

OLD IN 2025

In 2025 the Institute of Materials Finishing is celebrating our 100 birthday.

Founded in 1925 as the Electrodepositors Society to serve the electroplating industries, we became the Institute of Metal Finishing in the 1950’s. In 2012 we re-badged ourselves as the Institute of Materials Finishing, to better reflect our involvement with all aspects of surface engineering.

Our celebrations begin in February 2025 at the Surface World exhibition, with a centenary dinner taking place on the first evening, Wednesday 26th February 2025.

Tickets will be £35 per person or a table of 10 for £300.

There will be a 3 course dinner followed by entertainment.

Please let Helen know soonest if you would like to attend by email: helen@materialsfinishing.org.

Further events are being planned throughout 2025, which we are sure will interest and engage all our members. Please keep an eye out for announcements in future editions of IMFormation! Please try to join us as we mark our Centenary!

Email: helen@materialsfinishing.org

10

INSTITUTE OF MATERIALS FINISHING

SPECIFYING & MAINTAINING ARCHITECTURAL POWDER COATINGS

By

Angus Mackie - QUALICOAT Chair

Powder coating was once seen as something that could be applied to aluminium to cover any irregularities, such as damage, corrosion, etc. Whilst this approach may allow the aluminium to look good for a few weeks or months after being coated, once weathered, the powder coating will quickly peel and fail. The reason for this is that powder coated finish is porous which allows moisture to reach the aluminium substrate where oxidisation will take place under the coating. Adhesion of the finish is also crucial and if the substrate does not offer a key, the powder coating can easily be chipped off. A quality pretreatment system is required if the powder coating is to offer a sustainable finish which can be maintained over several decades.

Often overlooked in the specification process, the pretreatment of the aluminium substrate is crucial as it has to firmly bond onto the aluminium. If the pretreatment is poorly applied, oxidisation of the aluminium over time can cause the powder coating to lose its adhesion. Licensed QUALICOAT applicators across the globe are routinely inspected by independent test houses to ensure the latest QUALICOAT Specification for pretreatment application is being followed.

Before any pretreatment system can be applied to the aluminium, the surface of the aluminium is cleaned of any surface greasy deposits from the extrusion process through an immersion or a

cascade process. Following this the surface of the aluminium is then etched to remove surface contaminants in the aluminium. These processes ensure that the pretreatment system, bonds well with the aluminium substrate and once completed the profiles are oven dried prior to powder coating. It is important to note that the pretreatment system can be varied slightly to offer increased levels of protection.

The recently released Technical Information Sheet No.4 from QUALICOAT ‘Recommendations for the Corrosion protection’ now offers specifiers guidance on the recommended pretreatment system to specify for various “Corrosivity categories” according to ISO 18768-1:2022 Table 1 and ISO 9223:2012 Table C.1. Whilst it is still strongly recommended that specifiers continue to seek guidance from a QUALICOAT licensed powder coater or powder manufacturer when specifying finishes, the guide offers an insight as to the levels of protection offered when specifying QUALICOAT architectural powder coating.

As with any applied finish exposed to British weather, it is important that a maintenance regime is undertaken to keep it performing and looking well for many years. Pollutants and airborne debris, which are deposited on powder coated finishes through weathering, can simply be cleaned down at the same time as window cleaning using mild detergent solutions. Aluminium window

12 QUALICOAT UK & IRELAND

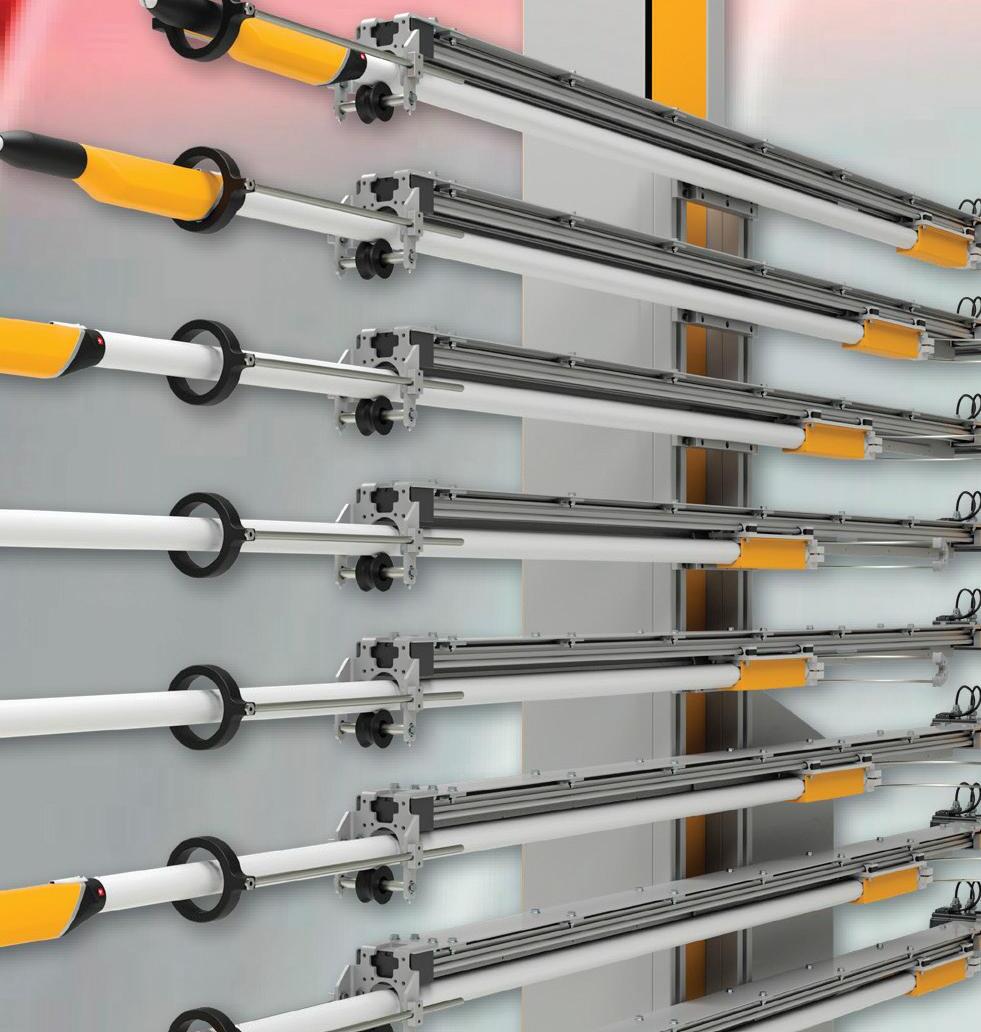

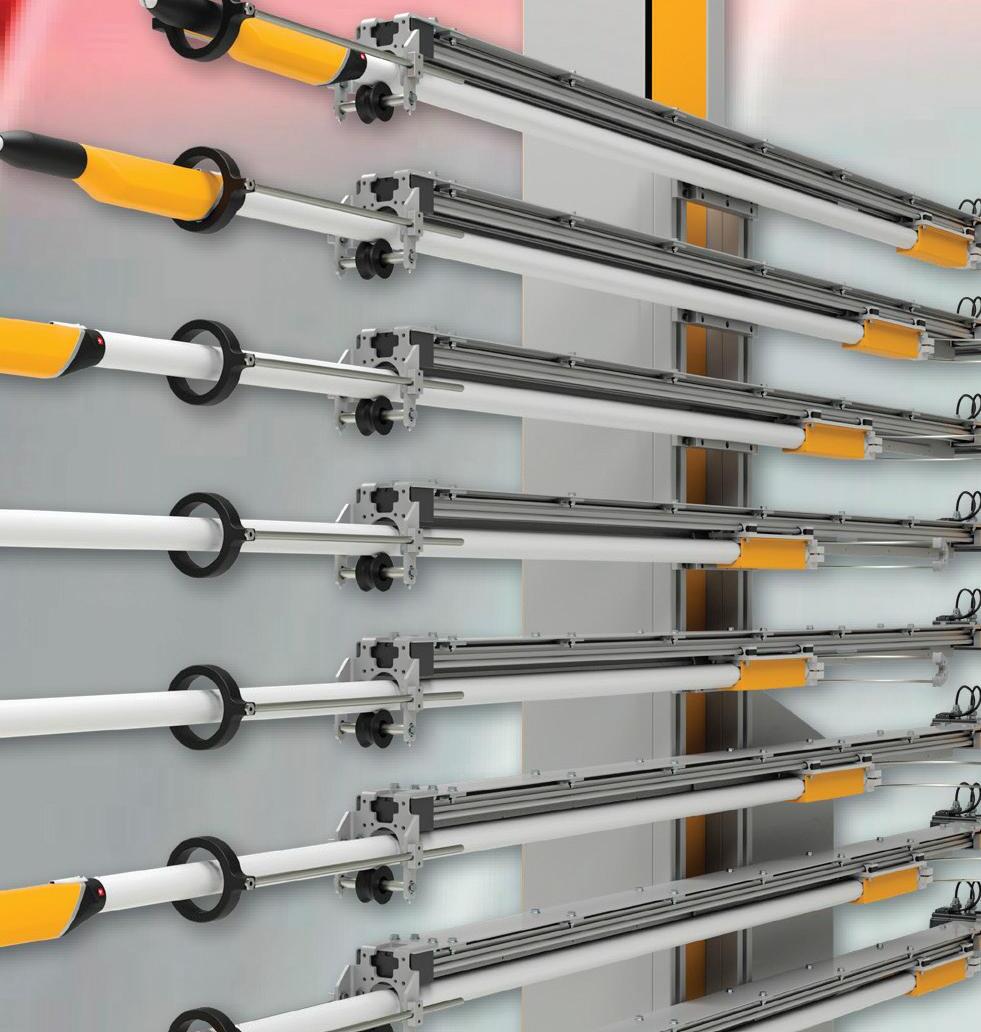

Scan & Spray

Dynamic Contour Detection

Programming-free coating of any shape! Gema

The second generation of Dynamic Contour Detection detects the object contour fully automatic and positions the guns individually even for thin objects and at high conveyor speeds. Due to the programming-free adaption of all relevant line settings the application range is significantly extended.

Email: uk.sales@gema.eu.com

Europe Srl – UK Branch

Tel: 0044 1202 763 942

gemapowdercoating.com

and facade longevity starts with a high quality aluminium substrate pretreatment and powder coat finish as provided by a licensed QUALICOAT applicator.

Prior to handover of any new installation or building, coated aluminium fenestration will be cleaned down professionally to ensure that the finish is not damaged. It is crucial to have any areas of impact or abrasion damage repaired, should it be present. During cleaning, all the protective tape must be removed from the inside and outside of powder coated surfaces as if this is left on for an extensive time, the tapes low-tack adhesive can often degrade, especially in UV light, and become firmly attached to the powder coating.

Once handed over to the client, in normal use such as in cities, the powder coat finish should simply be washed down at yearly intervals with clean water or with a ph neutral mild detergent solution in water. This should be enough to protect the visible surface of the powder coat for many years and can simply be done during the cleaning of windows. The powder coat finish wash

down is especially important where squeegee bars are used to clean the glass, as their use tends to place the residue of the airborne contaminants directly on the powder coated frame which could begin to etch into the surface finish of the coating. Window cleaners must ensure that all powder coated surfaces are wiped clear of cleaning residue on every window clean.

On new and refurbished building projects, powder coated finishes will always come with a cleaning and maintenance regime from the company who coated the aluminium profiles. These will offer minimum cleaning requirements and need to be adhered to as well as being recorded when completed. This will ensure the coated finish is maintained within the applicators warranty and will help, should there be any claim in the future. Warranties vary in length and are dependent on the powder coat finish used and the location of the installation. For example, where the coating is close to the sea, a QUALICOAT ‘Seaside’ specification for the coating should be specified and the

cleaning regime will often be increased to three-monthly intervals as the atmosphere is more corrosive.

Crucial to any maintenance regime is preventative maintenance and powder coating is no exception, if the coating in use has become damaged, exposing the aluminium, it should be repaired as soon as possible. For repair, either contact the original coater, or approach any QUALICOAT approved application who can normally offer guidance.

The up-to-date QUALICOAT Specification is freely available for download via the UK & Ireland Association website, qualicoatuki.org and the website offers an up-to-date list of licensed UK and Ireland Powder Suppliers, Pretreatment Suppliers and Applicators including the applicators who carry the Seaside class accreditation. Telephone support is available from QUALICOAT UK & Ireland Head Office in the Midlands on 0330 240 9735, the Association can also be followed on Twitter @Qualicoatuki or on LinkedIn www.linkedin.com/ company/qualicoat-uk-&-ireland.

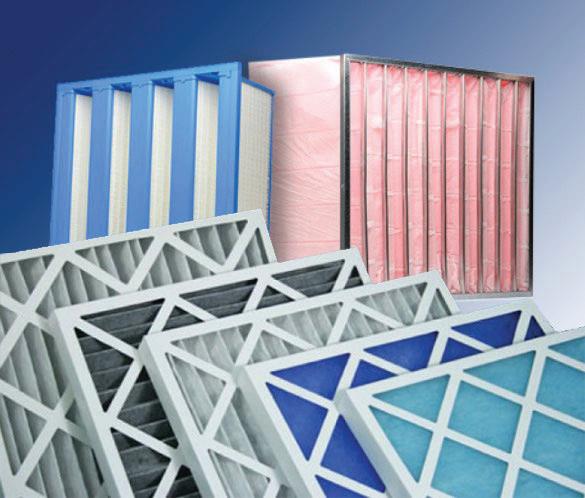

QUALICOAT UK & IRELAND Pleated Polymeric Filters We provide an enviable range of ltration solutions, supplies and cleaning services to a wide range of sectors Get in touch or visit us at www.total ltration.com Total Filtration is your one stop shop for all your Dust and Air Filtration requirements whether it is OEM or retrofit. Our filter cartridges and socks are made to any specification and are manufactured in the UK.

WAM Silotop

Donaldson Camfil Goldcone Air Filtration Telephone: 01282 459744 Email: sales@totalfiltration.com Call us on 01282 459744 to find out how we can help you Filtration TOTAL

Airmaster

• AirBench takesdustandfumes awayfromyourbreathingzone

• AirBench drawsthemthrough theworksurface,capturingthem insidethebench

• AirBench isavailableinawide rangeofsizesandfiltertypes tosuityourapplication

• AirBench isplugandgo-only needingunwrappingandplugging intoa13ampsocket

•Yougetextractionandwork benchinonecompactunit

Contactusforanon-sitedemonstration. Doubtitcanbethatsimple?

www. airbench.com • 01206 791191 • sales@airbench.com

...wouldyoubeinterested? Ifwecouldsolveyourdustand fumeprobleminminutes... Plugin.Switchon. Dustandfumes? Allgone. Really,it’sthatsimple.

TheVertExmodularbooth system.Dustissuessolved...

• Modular systemforfast installationandassembly.

• LowEnergy throughtheuse ofhighefficiencyfans-upto 20,000m3/hat3kw.

• FiltrationOptions fromthe standardAirBenchrange.

• WeldingandGrinding boothsalso availablewithHEPAfinalfilter.

• RapidReconfiguration -standard componentsmeanVertExbooths canbereconfiguredondemand.

Doubtitcanbethatsimple?

www.ai rbench.com • T . 01206 791191 • E . sales@airbench.com ContactustoviewVertExinoperation.

...quicklyandeffectively.

Plugin.Switchon. Dustandfumes? Allgone. Really,it’sthatsimple.

UK COATINGS INDUSTRY LAUNCHES EQUITY, DIVERSITY AND INCLUSION CHARTER

are taking towards making this goal a reality.’

On 8th April 2024, the British Coatings Federation (BCF) announced the launch of the UK Coatings industry’s first Equity, Diversity, and Inclusion (ED&I) Charter, a public commitment that recognises and celebrates companies in our sector who are committed to working towards a more balanced, fair and high-performing sector.

Through the work of BCF’s ED&I Committee since 2021 and following the BCF Board of Directors’ commitment in 2023 to championing ED&I principles throughout the industry, the Charter is the industry’s next stage in its ED&I journey.

Head of BTC UK & Ireland (A brand of BASF) and BCF ED&I Committee Chair Lisa Kelly, commented on the launch:

‘Diversity and inclusion are increasingly important to the coatings industry, our customers, stakeholders and investors so I am delighted that we have launched the British Coatings Federation’s Equity Diversity and Inclusion Charter. By signing up to the Charter, companies are not only demonstrating their commitment to an inclusive workforce but also the steps they

WASHING SYSTEMS

BCF CEO Tom Bowtell added: ‘By signing the Charter, over 30 BCF members have committed to showing leadership to embed ED&I in their organisations, which is a fantastic start. The Charter includes company commitments to proactively support the BCF in benchmarking, monitoring and reporting on their progress. The Charter is only the beginning of the journey, and I’m looking forward to working with Lisa and the ED&I Committee to move this important issue forward.’

For more information and to see the full list of signatory companies, please visit: https://coatings.org.uk /page/EDICharter

BRITISH COATINGS FEDERATION LTD

EFFICIENT - ROBUST - RELIABLE INNOVATION FOR ALL YOUR WASHING NEEDS • SMALL BATCH WASHING TO CONVEYORISED SYSTEMS • SPRAY, SOAK , ULTRASONIC OR COMBINATION MACHINES.

FULL AFTER SALES SUPPORT

IN HOUSE TEST FACILITY

EUROPEAN WIDE CUSTOMER BASE

STANDARD AND BESPOKE SYSTEMS AVAILABLE

COMPLIMENTARY CHEMICAL RANGE AVAILABLE Call 01543 675800 or visit our website www.unitechwashers.uk.com

•

•

•

•

•

CELEBRATING 65 YEARS OF HODGE CLEMCO: A LEGACY OF EXCELLENCE

As Hodge Clemco marks its 65th anniversary on April 20, 2024, it’s not just a milestone; it’s a testament to decades of unwavering commitment to excellence, innovation, and integrity. Founded in 1959 as part of the esteemed Samuel Hodge Group, Hodge Clemco has evolved into the leader in the surface finishing industry.

Beginning with a focus on portable equipment and abrasives, Hodge Clemco’s journey from modest origins to industry titan is marked by iconic products like “Contractor,” “JBlast,” and the renowned “Clemco.” The evolution of the name “Clemco” itself reflects the company’s agility and foresight.

A pivotal moment came with the formation of Hodge Clemco in 1959, expanding the company’s reach into the UK market and laying the groundwork for global prominence. But beyond products and partnerships lies a profound

philosophy rooted in serving people—a legacy of respect, honesty, and genuine human connection left by Al Cleary.

For Hodge Clemco, growth isn’t just about expansion—it’s about nurturing relationships and delivering exceptional service. This ethos has driven the company forward, even amidst economic challenges, guided by principles of integrity and human connection.

Recent years have seen Hodge Clemco deepen its commitment to innovation, with acquisitions and partnerships broadening its offerings and capabilities.

The integration into the SurfacePrep Group in 2021 marked a significant moment, aligning with a shared vision of advancing surface preparation through technology and service.

The synergy between Hodge Clemco and SurfacePrep Group has been evident, offering customers a comprehensive suite of solutions tailored to the most demanding surface preparation challenges.

18 INDUSTRY NEWS

elcometer.com dry abrasive blast machines | precision media valves blast hose | blast nozzles | personal protection equipment BLAST IT Elcometer’s CONTRACTOR and PERFORMANCE abrasive blast equipment is engineered to last longer, work harder & perform better. Surface World - HP Spray Draft.indd 1 16/04/2024 11:26:48

With SurfacePrep Group’s backing, Hodge Clemco has expanded its market presence and enhanced customer service capabilities.

Today, as an integral part of the SurfacePrep Group, Hodge Clemco continues its legacy of excellence while driving innovation in surface preparation technology. Together, they are pioneering new solutions, setting industry standards, and shaping the future of surface finishing worldwide.

In essence, Hodge Clemco’s integration into the SurfacePrep Group represents not only a strategic business decision but also a commitment to delivering results beyond the surface—creating value for customers and driving positive change in the industry. With SurfacePrep Group’s support, Hodge Clemco is poised for continued success and growth in the years ahead.

Visit: www.hodgeclemco.co.uk

20 INDUSTRY NEWS

GALVANIZERS DONATE TO WAR MEMORIAL GARDEN

Thanks to a combined community effort, the Bilston War Memorial has been tended to, allowing for it to flourish for the future.

Following a call for support from a member of Bilston Royal British Legion, Edward Howell Galvanizers Ltd offered to provide the soil required for two brandnew timber planters installed at the War Memorial site, situated at the gateway to Bilston Town Centre.

Wendy Binder, Royal British Legion member, said: “Earlier this year, two planters were installed into the garden that surrounds the Bilston War Memorial. After calling out to our local community for support, we were thrilled with the positive response – many local volunteer veterans from Wolverhampton Armed Forces & Veterans Breakfast Club (AFVBC) donated their time to assist throughout the project, allowing the site to blossom into a peaceful and poignant place.

“Once the planters were fitted, we began shopping around local merchants for soil to be able to fill them and were quoted around £300. However, I then received an email from Edward Howell Galvanizers who’d seen our latest project in a local magazine, and they offered to donate the soil in full.

“It was an absolute pleasure dealing with Edward Howell Galvanizers - they were kind, supportive and accommodating. We are tremendously grateful for their incredible generosity, and to commemorate this, we will be installing a plaque on the planters to thank them for their support.”

The soil for the planters was delivered on Saturday 1st July, ready for the planting of flowers to commence, which was completed at the end of August. The planters are to enhance the colour and nature of the gardens that surround the War Memorial which was originally unveiled in 1921.

Charmaine Robertson, Administrator at Edward Howell Galvanizers added: “It’s always a pleasure to work with and support our local community. The hard work and dedication displayed by the Royal British Legion to maintain the grounds of the

War Memorial doesn’t go unnoticed, and it’s a privilege to know that we played a part in enhancing this very special place where many people can sit and remember those that fought for our country.”

Originally made by Messrs Dove & Co of London, and designed by Sir Richard Blomfield, the War Memorial at Bilston is made of Portland stone and decorated with an elongated bronze cross. Names of the fallen are recorded on separate plaques on the brick wall at the rear of the gardens, along with a memorial stone to Victoria Cross recipient Lance Corporal George Onions VC (later Major George Onions VC).

Edward Howell Galvanizers Ltd is part of Wedge Group Galvanizing Ltd, the largest hot-dip galvanizing organisation in the UK with a history dating back over 150 years. With 14 plants strategically placed across the country, the firm offers a truly national galvanizing service.

For more information, please contact Wedge Group Galvanizing on 01902 601944 or visit www.wedge-galv.co.uk.

22

INDUSTRY NEWS

Hot dip galvanizing provides you with long-term protection against rust and corrosion of steel products.

With 14 plants across the UK, Wedge Group

Galvanizing is the UK’s largest hot dip galvanizing organisation offering a national service, collection and delivery and 24hr turnaround on request. The group can process anything from small components to 29m structural beams.

Solutions for Parts & Paint Spray gun cleaning WASHERS ASK FOR A FREE QUOTE Manual | Automatic Our high quality, advanced range of equipment provides the best way to clean paint spray guns or industrial parts. With numerous options, you can be sure that there is a model in our extensive range that meets your cleaning requirements using either solvents or water. • ATEX certified High quality alloy pumps • Stainless steel construction • Wash cycle controlled by timer • Wash & rinse Hot water wash • Inbuilt water recycling Inbuilt solvent recycling • Air extraction • 2 year warranty BUY OR LEASE www.solutex.co.uk info@solutex.co.uk | 01691 622 225 For more information visit: Head Office: Stafford Street, Willenhall, West Midlands, WV13 1RZ SO 9001 Quality Management FM 00382 E: info@wggltd.co.uk T: 01902 601944

WEDGE GROUP GALVANIZING Your Galvanizing Partner

AKZONOBEL INVESTS IN DUTCH RESEARCH LABS TO CONTINUE INNOVATING WITH IMPACT

Two new research labs are being built by AkzoNobel at its Sassenheim site in the Netherlands to further propel the company’s pioneering product development.

Work is about to start on building a technology center for Powder Coatings, while a new polymer lab has just opened which will develop innovative resin technologies for all the company’s businesses. The total investment in the Sassenheim site – AkzoNobel’s largest global R&D center – amounts to around €8 million. The facility already houses the biggest R&D teams in Europe for the company’s Decorative Paint and Automotive and Specialty Coatings businesses. The addition of the two new labs will help the company further build on its global reputation for pioneering product development focused on providing creative solutions for customers.

“Creating the new Powder Coatings lab will enable us to carry out the fundamental research needed to continue to innovate with impact and bring more sustainable products to the market,” explains Roger Jakeman, AkzoNobel’s Chief Technology Officer.

Mayor of Teylingen, Carla Breuer, is pictured

with a symbolic powder-coated tulip during a ceremony held inside the building that will become the new powder technology center. Also pictured, left to right, are: Alderman Heleen Hooij; Roger Jakeman, AkzoNobel’s Chief Technology Officer; David Williams, AkzoNobel’s Chief Innovation Officer; and Kees-Jan Starrenburg, AkzoNobel’s Country Director for the Netherlands.

“By developing new technologies for the future, we’ll unlock more customer and application opportunities while supporting multiple options, including low bake cure. This will further enhance our ability to cut carbon emissions across the value chain.” The recently opened polymer lab – part of the company’s Research organization –will accommodate 15 scientists. It will mainly focus on the development of more sustainable polymer technologies and new coatings to support AkzoNobel’s ambition to halve carbon emissions across the value chain by 2030.

“The performance of a paint or coating is largely defined by the design of the resins used,” continues Jakeman. “They’re a vital ingredient in the manufacturing process. The new lab will therefore play an important role in boosting our capabilities and strengthen our industry-leading expertise.”

Adds Carla Breuer, Mayor of Teylingen, the municipality where Sassenheim is located: “AkzoNobel’s investment in these two new research laboratories underlines the company’s commitment to sustainable product development in our region and in the Netherlands. We’re proud that this initiative is taking shape in our municipality.”

AkzoNobel employs around 3,000 R&D professionals worldwide in 70 laboratories, with more than €1.25 billion having been spent on research and development over the last five years.

Visit: www.akzonobel.com

24

INDUSTRY NEWS

First for Sustainability

With our new Interpon D1036 Low-E powder coating, we’ve created an industry first: a powder coating that can cure as low as 150°C while still being Qualicoat class one certified. It can also cure up to 25% faster than conventional powders, reducing both energy consumption and carbon emissions, and significantly improving your coating line efficiency. Easy to apply Interpon D1036 Low-E has the same application properties as standard formulation, is backed by an Environmental Product Declaration (EPD) and has a global warranty of up to 15 years to deliver the quality performance, color and style your customers need. It is an innovation that supports our collective commitment to sustainability throughout the value chain.

architectural.interpon.com

New and used vibratory finishing machines and systems from 2 litres to 4000 litres

Finishing media; Ceramic, Plastic, Wood, Steel and Maizorb

Liquid / powdered / paste compounds

Abrasive finishing wheels

Vibratory separators / sieving machines and re-meshing service

Repairs and relines

Effluent water treatment systems

Redundant machines purchased

Consultancy

Subcontracted finishing and industrial sieving services

SHARMIC FOR FAST, FRIENDLY SERVICE

Experienced Engineers After sales technical support Nationwide deliveries

Sharmic Engineering Ltd

Tel: +44 (0)1299 822135 / 878123/4/5

Email: info@sharmic.co.uk www.sharmic.co.uk

ALL

FINISHING

FOR

YOUR VIBRATORY

EQUIPMENT AND MATERIALS

Hadleigh Enterprises Limited Unit 11, Buckingham Square Hurricane Way, Wickford Essex, SS11 8YQ Tel: 01268 572255 Fax: 01268 572121 Email: sales@hadleightapes.co.uk Web: www.hadleigh-tapes.co.uk Certificate No. FM10409 • AS9100 APPROVED • NO MINIMUM ORDER QUANTITY • ALL PRODUCTS FOR ALL PURPOSES • 48 HOUR DELIVERY SERVICE The Adhesive Tape Specialists

A RANGE OF DROP-IN REPLACEMENTS FOR 3M™ NOVEC™ SOLVENTS FROM ENVIROTECH EUROPE

FUTURE-PROOF YOUR CLEANING PROCESS WITH OUR NEW ProSolv® RANGE ADDITIONS

In December 2022, 3M™ announced their plans to stop producing per- and polyfluoroalkyl substances (PFAS) in its product line by the end of 2025.

This phase-out affects the following 3M™ product lines:

3M™ Novec™ Engineered Fluids

3M™ Fluorinert™ Electronic Liquids

ARE YOU AFFECTED BY THE PHASE-OUT OF 3M™ NOVEC™ ENGINEERED FLUIDS?

At EnviroTech Europe we can offer replacements with our ProSolv® range for all 3M™ Novec™ solvent cleaning fluids. We understand the uniqueness of every precision cleaning application and provide free on-site visits, technical support and cleaning trials when required. We can provide a full assessment of your current precision cleaning process to put in a plan to help ensure a seamless transition.

We have added several cost effective and efficient precision cleaning process formulations to our range of ProSolv® vapour degreasing solvents, offering immediate drop-in replacements for 3M™ Novec™ engineered fluids.

Introducing ProSolv®5408e, a next generation PFAS free fluorinated solvent with low GWP and zero ODP

ProSolv®5408e is a next generation PFAS free fluorinated solvent with low Global Warming Potential (GWP) & zero Ozone Depletion Potential (ODP). ProSolv®5408e is a general multipurpose vapour degreasing cleaning solvent that can act as an immediate drop-in replacement for most of the 3M™ Novec™ engineering fluids. We can also deliver an exact formulation replacement of your current solvent should that be your requirements.

EnviroTech Europe | ProSolv5408e | Press Release | April 2024

Introducing ProSolv®5408e, a next generation PFAS free fluorinated solvent offering Zero GWP and Zero ODP

ProSolv®5408e

28 INDUSTRY NEWS

a next generation PFAS free fluorinated solvent offering low Global Warming

is

6 K-type thermocouple ports

High temperature

long run times

Download, view, and analyze

or export

barrier box for

stainless steel

data

PosiSoft

temperature

16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk Customizable PDF Reports Prices starting at: Oven Temperature Logger .......... £1895 Temperature Probes ............ £100 Wide variety of spring clamp and magnetic temperature probes available NEW

using

Desktop Software

to .CSV Oven Temperature Logger Measures and records oven

profiles

EnviroTech Europe have many years of experience and our experts are available to guide you through your solvent cleaner changeover procedures or to advise on equipment. We have extensive partnerships with equipment manufacturers through our global distributors and can provide information and advice on solvents and solvent systems.

For more information about our range of products please visit www.envirotech-europe.com.

Alternatively please telephone us on +44 (0) 20 8281 6370

All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

LATEST PRODUCT LAUNCH FROM AIRBENCH – AIRTOWER AIR CLEANING SYSTEM

AirBench Ltd are pleased to announce the release of our Air Cleaning System for large halls –the AirTower AT range.

Designed for general dust and fume capture in large working areas, the AT range runs continuously, capturing weld fume, smoke, and particulate and exhausting clean filtered air back to the room.

Air Towers are a backup system designed to assist with general room air cleanliness, where existing extraction is not fully capturing contamination.

As weld fume settles at around

3m height, the AT range is perfectly placed to capture this layer, with the main inlet at 2.5m – making it the ideal solution for large welding halls.

With airflows up to 15000m3/h, AT can continuously improve air cleanliness in even the largest workplaces.

AT joins our air cleaning range, providing the large-area equivalent to the existing small units – the wall mounted MF600 and floor mount MF2000 and MF3000 models.

Contact AirBench Ltd for more information, a recommendation, or to see an AirTower in action.

Visit www.airbench.com/at for more information.

30

INDUSTRY NEWS

Allgone.

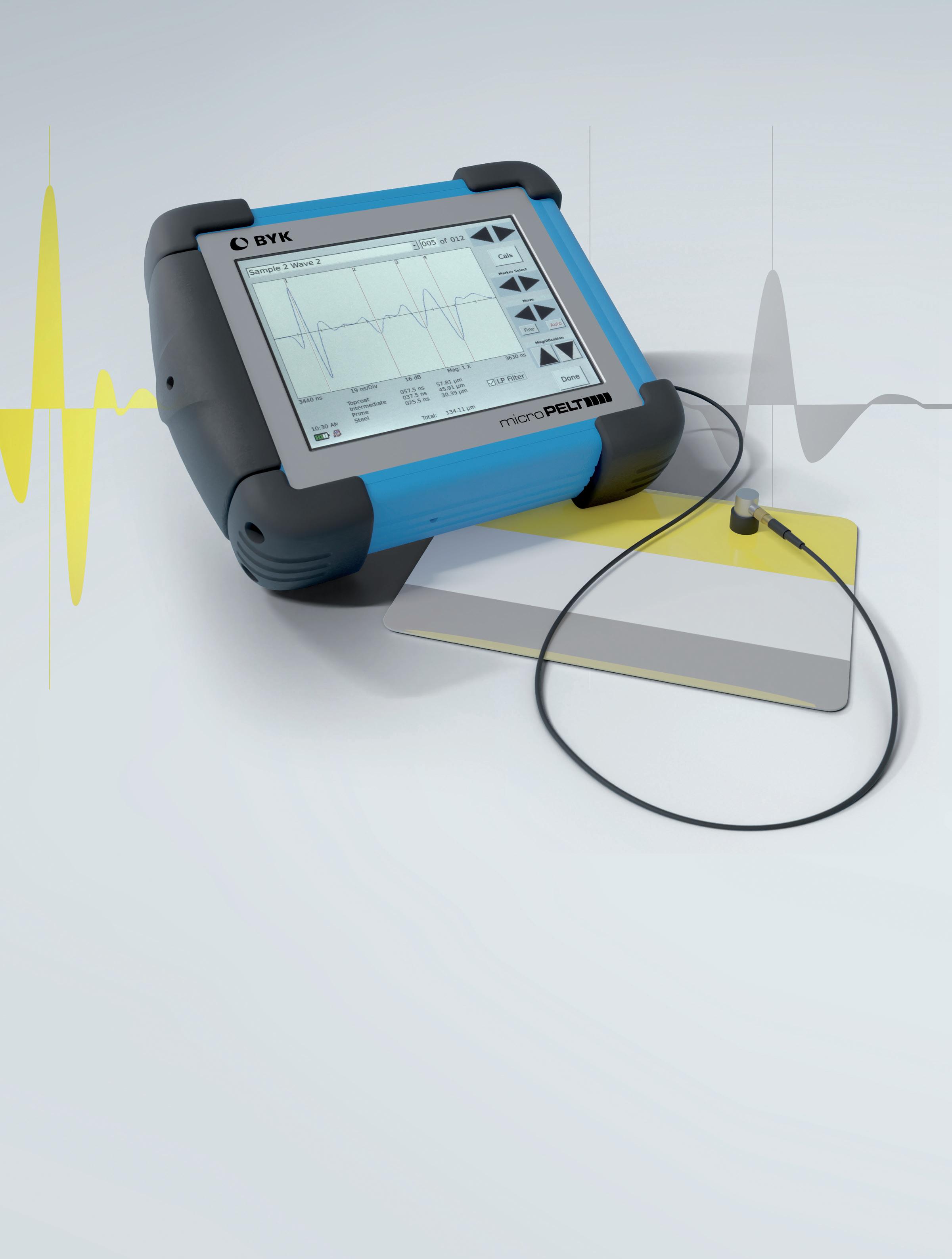

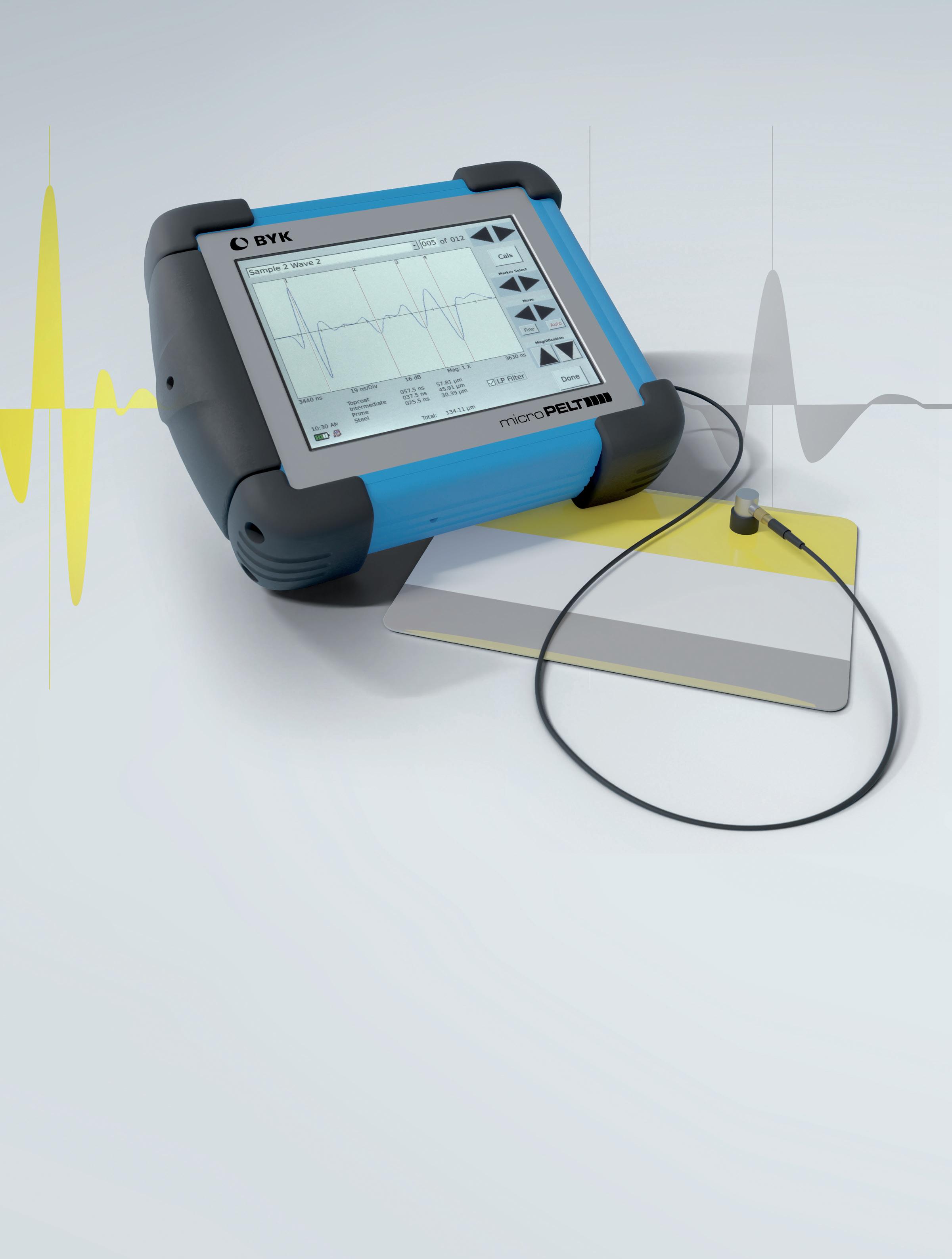

PELT Ultrasound

Accurate echoes from layer to layer

PELT high-resolution ultrasound sets the global standard for precise multi-layer thickness gauging. Obtain multi-layer measurements on virtually any substrate material including plastics, composites, glass, wood, steel, aluminum, and even paper. PELT ultrasound provides the power of acoustic microscopy in a hand-held gauge. Easily verify thickness of critical performance and protective coatings, visualize re-coats and repairs, and monitor and tune your coating application processes.

Measure what you see.

| www.PELTGauge.com Have a chat with us: Surfex 2024 Booth 216

www.byk-instruments.com

FRASER TECHNOLOGIES

THE EXCLUSIVE UK SUPPLIER OF THE PIONEERING MIELE PROFESSIONAL AQUEOUS CLEANING SYSTEM

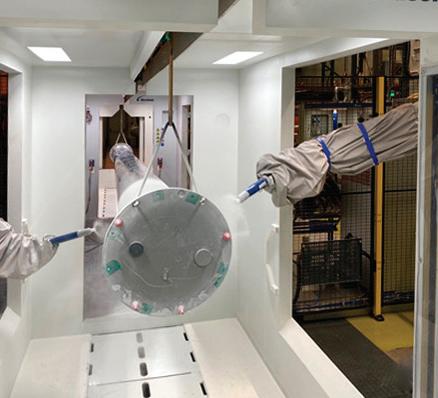

Fraser Technologies Ltd, a leading and specialist expert in the component cleaning market, has achieved remarkable success with the SlimLine PLW 6011 & PLW 6111 aqueous cleaning systems from Miele Professional since its launch in 2022.

The exclusive supplier of this equipment in the UK, Fraser Technologies works with customers to create a bespoke cleaning system and process to meet their individual needs and standards. These machines are single chamber aqueous cleaning systems offering time, energy and cost-saving efficiencies, and can meet the stringent cleaning requirements for high-reliability industrial sectors.

At only 65cm wide, the footprint is very compact, whilst still providing a large and flexible internal chamber space. This size, flexibility and smart load system allows a variety of components to be cleaned highly efficiently all at once, whilst utilising much less space compared with a standard sized machine.

Suitable for a wide variety of components and specialist electronics cleaning applications in the automotive, medical devices and aerospace industries, the Miele SlimLine PLW 6011 & PLW 6111, combined with the right chemical combination, are especially effective for flux removal from PCB boards and other cleaning and degreasing applications.

Aqueous chemical cleaning solutions, which can be used in this system, can be applied to a variety of metals such as copper, stainless steel, and brass to remove grease, cutting fluids and general particulate.

Graham Fraser, Managing Director of Fraser Technologies, said,

“The equipment offers a high level of flexibility with intelligent controls, including a wide range of load carriers and accessories. And with the added value of our custom-made chemical isolation tank, this system can recirculate and reuse the chemistry, further reducing costs and environmental impact.”

“We have already completed a number of successful customer trials with the system and have a fast-growing customer base. This includes a specialist in the assembly of PCBs, who were so impressed by the results of the Miele system in their trials that they placed an order immediately. We also switched a leading defence systems manufacturer from an inline batch cleaning system to the new Miele system, saving time and space, reducing energy costs, and increasing efficiency.”

An Electronic PCB assembly services provider, has also recently taken delivery of its new Miele PLW6111 aqueous cleaning system to satisfy a new high reliability contract. The high-reliability project requires the PCBs to meet all standards of IPC-A-610 Class 3, which specifies that there are less than 1.56 μg CaCl/cm²

The Miele machine meets these requirements, while also providing gentle cleaning on delicate boards.

The Miele option provides a complete solution and the team at Fraser Technologies conducted several trials to ensure our client achieved its optimal results and met all cleanliness standards. They also provided a final specification, including a purposebuilt, externally-heated chemical isolation tank, and bespoke basket options with dedicated inserts for supporting the PCBs.

32

INDUSTRY NEWS

New Miele Slimline Aqueous cleaning system.

Once installed, the engineers at the company were able to tweak the programmes, experimenting with the variety of wash times and temperatures. Whilst the first run of boards were cleaned immaculately, the team discovered they could reduce the time by a quarter and achieve the same results! As a bonus, they found it could also clean its wave solder pallets, further enhancing the value proposition.

Graham Fraser, Managing Director of Fraser Technologies Ltd, describes some of the wider benefits of aqueous cleaning with the Miele equipment across industries:

“The assembly of printed circuit boards (PCBs) requires precision and expertise to ensure the boards are reliable and fully meet customer specifications and expectations.

“Not only is the correct assembly crucial, but for many assemblies and products, it is essential that all traces of flux residue from the soldering processes have been removed. Occasionally this is only for aesthetics, but more usually this is to ensure high reliability, and provide a clean surface for other processes, such as conformal coating or potting, and remove any residue that could inhibit performance.

“For high-reliability industries, such as automotive (EVs), energy, aerospace and defence, etc, it is even more imperative that the PCBs perform exactly as required with minimal risk of failure.

One of the many ways assemblers ensure this high quality is through rigorous cleaning of the PCBs.

Graham Fraser, MD said of Fraser Technologies’ relationship with Miele,

“We have a strong relationship with Miele after years of collaboration, and very much share their values for high quality, sustainable and innovative cleaning systems. As the only UK distributor of this equipment, we have been really pleased with the results our customers have seen to date. We’re looking forward to rolling the system out to more manufacturers across the country.”

Moreover, Miele stands out by providing a unique guarantee ensuring that parts utilised in the production of their equipment remain available for a minimum of 15 years. This assurance empowers clients with the confidence that their investment is safeguarded, promising enduring value.

Fraser Technologies offers trials and personalised customer service to ensure products are correct for individual business and performance requirements.

For further information, please contact us at sales@ frasertech.co.uk or call 01506 443 058 and speak to one of our team.

33

The new Miele system which was installed with a bespoke heated chemical isolation tank for an electronic PCB assembler.

New miele system fitted with bespoke PCB loading drawers.

NEW INTERPON STRUCTURA POWDER COATING COLLECTION

BRINGS STYLE AND PERFORMANCE TO THE NORTH AMERICAN

ARCHITECTURAL

MARKET

AkzoNobel is supporting the needs of North America’s leading architects, designers and original equipment manufacturers (OEMs) with the launch of its popular Structura range of Interpon D powder coatings, where in-demand colours and refined textures combine with a superdurable performance to create lasting impressions.

Offering more than 40 of the most popular RAL colours, you can be assured that projects are always on-trend.

Interpon D Structura’s fine textured finish gives aluminium and steel surfaces an intriguing sense of quality and depth, with significantly higher gloss retention and strong resistance to colour change.

The Structura range matches aesthetic appearance with exceptional durability and weatherability, making it ideal for surfaces that may be challenged by a diverse range of climates. The range boasts a 20-year integrity warranty on the coating performance when applied by an Interpon D approved applicator and meets the performance requirements of AMAA 2604.

The textured finish of the coating gives it greater resistance to scratching and marring, reducing the need for wasteful

touchups or re-spraying which consume energy, cost, and time. The finish also helps cover minor defects on the substrate. The superdurability of Structura helps make the coating more sustainable by extending the gap between cleans, so that less water and fewer chemicals are needed.

Alan Alex, Regional Commercial Director for AkzoNobel Powder Coatings in North America, says the Interpon D Structura Collection stands out as the premier choice for architects, OEMs, and designers seeking on-trend, high-quality products, and protection they can rely on: “The diversity of this range and the meticulous attention given to the design and science behind it is yet another example of our commitment to delivering resilient coatings in demanding environments that endure over time without compromising on style.”

The Structura range is backed by an Environmental Product Declaration (EPD). This means the raw materials, manufacture and

transportation associated with creating this latest Interpon innovation have been assessed by an independent third-party for transparent sustainability credentials.

To find out more about the Structura range of Interpon D powder coatings follow the link - https://www. interpon.com/nl/en/products/ architectural/interpon-d-structura

34 INDUSTRY NEWS

These Systems include: Deionisers

I‐on‐x Exchange Cylinders

Reverse Osmosis

UV (Ultra Violet)

Filtra�on

So�eners

Pumps and Tanks

Spares and Consumables:

We are Pure Water Equipment Specialists and provide an extensive range of water treatment systems and services to commercial and industrial clients throughout the UK. Providing a Full Turnkey Service means we can Design, Manufacture, Install and Commission a system based on specific produc�on needs or requirements.

ADEPT Pure Water Ltd can also provide service for: Break Down & Repair on ALL makes of Water Purifica�on Equipment Re-Condi�oning of all types of Water Purifica�on Equipment

Tailored Service Agreements –Standard or Responsive op�ons available Site Survey and System Efficiency Reports for prospec�ve clients or Repair and Service op�ons for pre-exis�ng systems.

ADEPT offer a choice of consumables including UV Lamps, Chemicals, Micron & Carbon Filters. We also offer Spare Parts, Tanks, Refurbished Water Equipment and more. Look out for the launch of our New ONLINE STORE COMING SOON

ADEPT Pure Water Limited

36 Huxley Close, Park Farm South, Wellingborough,

Northants, NN8 6AB

Northants, NN8 6AB

CHAIRMAN OF UK GALVANIZERS AWARDED INDUSTRY ACCOLADE

An impressive contribution to his industry has seen the Executive Chairman of a UK company scoop a prestigious accolade.

Jeremy Woolridge, Executive Chairman of Wedge Group Galvanizing Ltd was awarded a Bablik medal - given to mark outstanding activities of direct benefit to the sector - at the European General Galvanizers Association (EGGA) Gala dinner in Austria last year.

He said: “It is an incredible honour to have been recognised in this way, and to be named alongside some fantastic individuals within our profession. I have immense respect for the industry, and the membership bodies such as the

EGGA, and so this truly is a wondrous occasion, and one that I don’t take for granted.

“For over 150 years, Wedge Group Galvanizing has been making significant advancements within the galvanizing industry, and we’re proud to be huge advocates for the sector. We’re committed to making a difference – not only to provide a stellar service to our clients across the nation, but to ensure the galvanizing industry as a whole continues to succeed and evolve.”

Jeremy is one of only ten people to have a Bablik Medal - the first two were awarded to Professor Bablik and Mr Sendzimir (in gold) with all medals since being silver.

Andrew Harrison, Sales and Marketing Director at Wedge Group Galvanizing, added: “It’s absolutely fantastic to learn

of Jeremy’s award. His contribution to Wedge Group Galvanizing and to the whole galvanizing industry is one to be acknowledged and appreciated, and we’re delighted to congratulate him on this brilliant achievement.”

The EGGA is the industry organisation for Europe’s galvanizing sector, bringing together many national associations from across the continent which collectively represent around 600 galvanizing plants worldwide.

Wedge Group Galvanizing Ltd is the largest hot-dip galvanizing organisation in the UK with a history dating back over 150 years. With 14 plants strategically placed across the country, the firm offers a truly national galvanizing service.

For further information please contact Wedge Group Galvanizing on 01902 601944 or visit www.wedge-galv.co.uk.

36 INDUSTRY NEWS

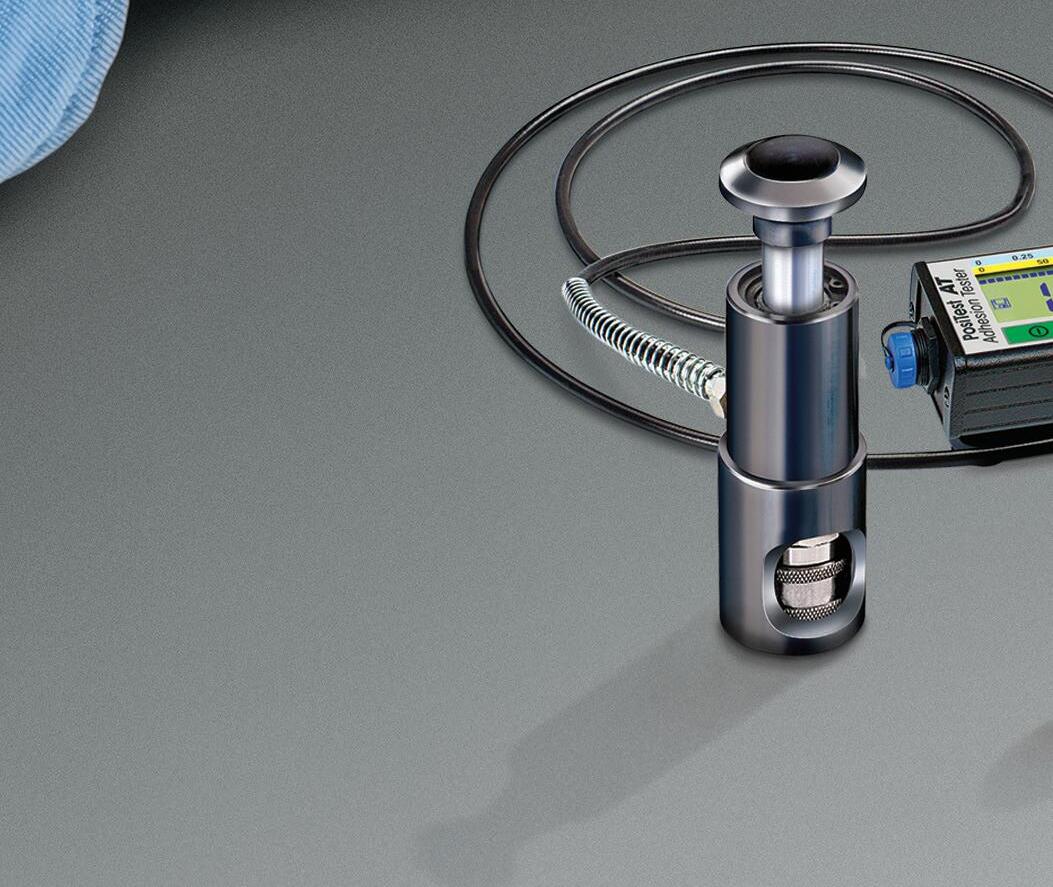

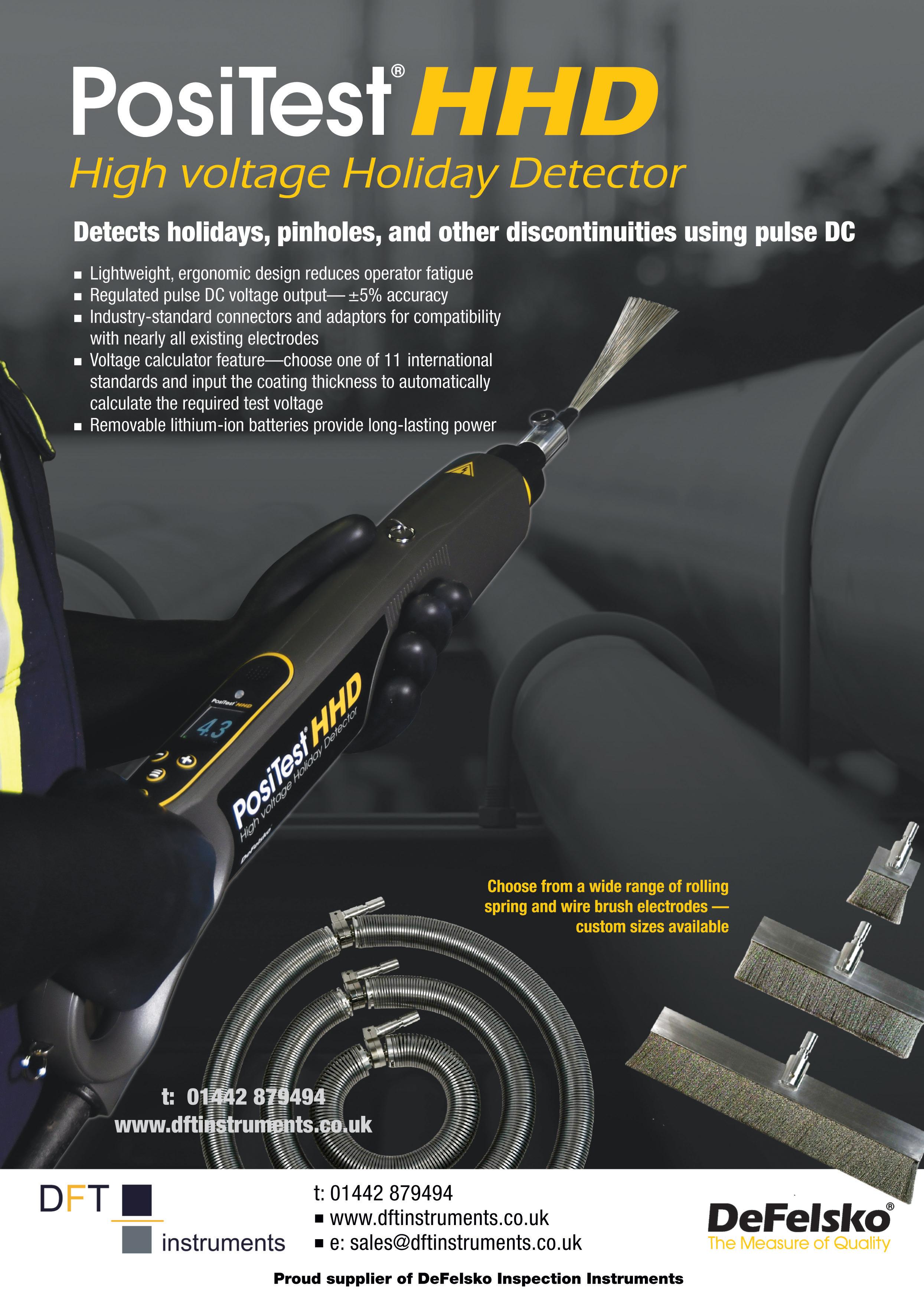

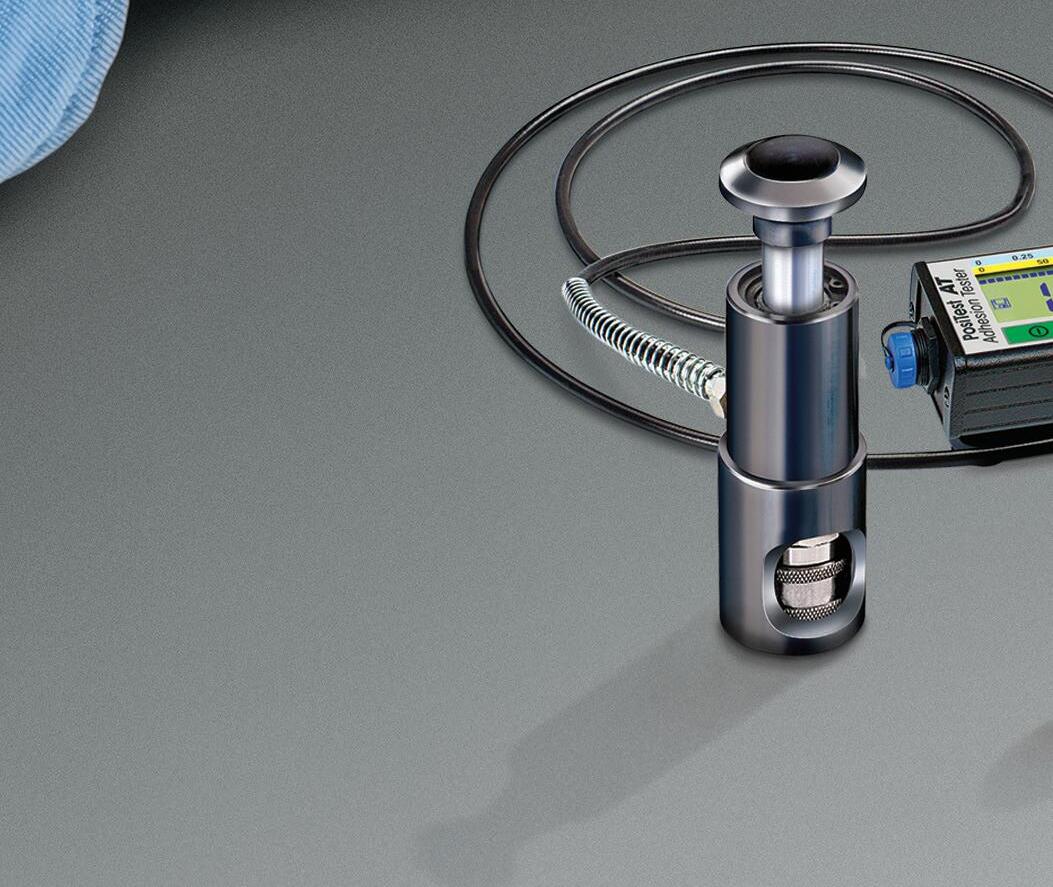

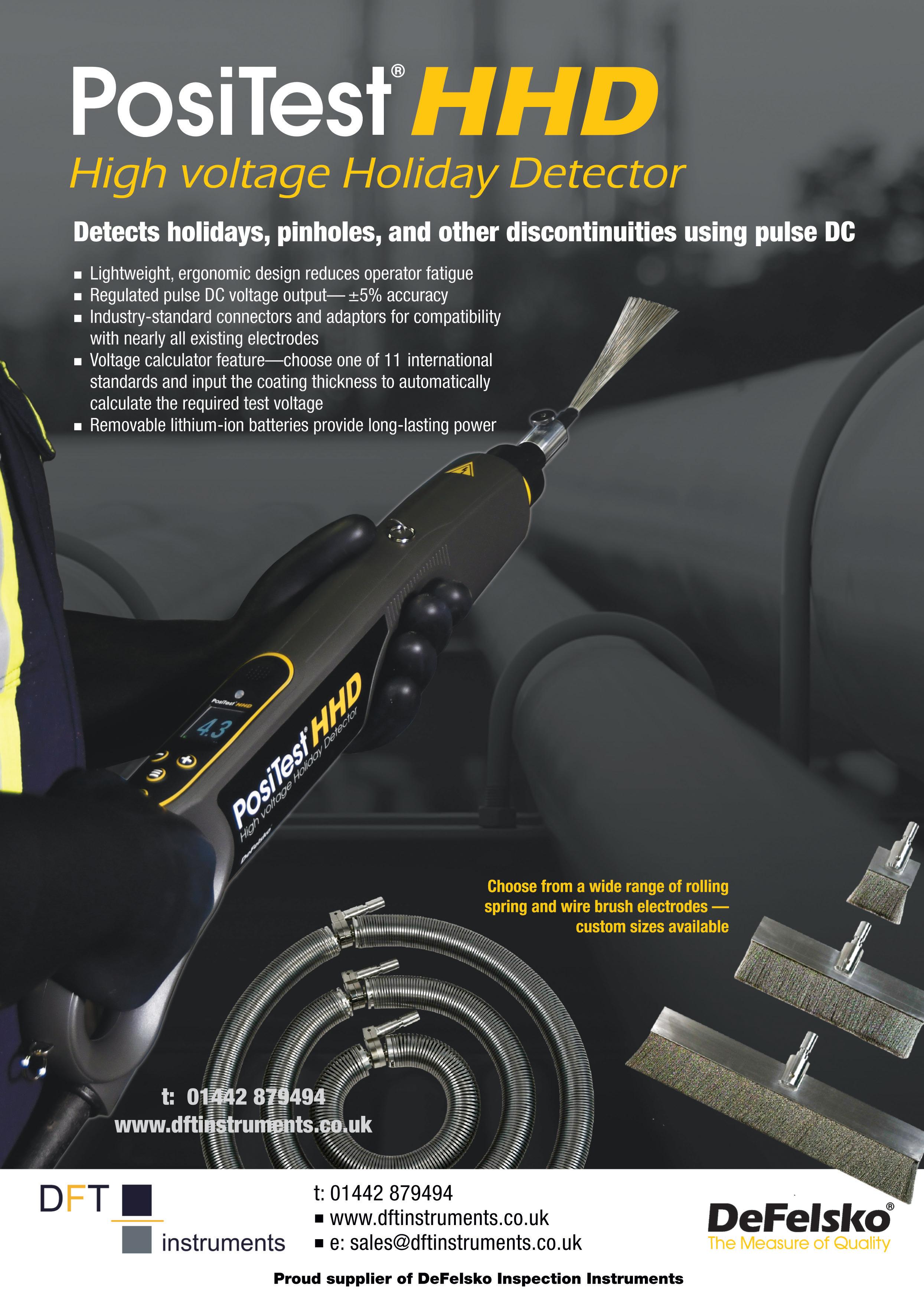

PosiTector ® Inspection

Unrivaled probe interchangeability for all of your inspection needs.

Coating Thickness Probes

n Ferrous n Non-Ferrous n Combination n Ultrasonic

Surface Profile Probes

n Depth Micrometer n Replica Tape Reader

Environmental Conditions Probes

n Integral n Cabled Magnetic Probe n Anemometer Probe

n 1/2” NPT n Infrared

Hardness Probes

n Shore n Barcol

Salt Contamination Probe

n Bresle Method

Ultrasonic Wall Thickness Probes

n Corrosion n Multiple Echo Thru-Paint n Precision

n Low Frequency n Xtreme

Customized Inspection Kits...

Build your own kit from a selection of gauge bodies and probes to suit your needs.

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595

www.dftinstruments.co.uk e: sales@dftinstruments.co.uk

Proud supplier of DeFelsko Inspection Instruments

LTD

DFT Instruments UK

16A

Coating Thickness Surface Profile Environmental Conditions Ultrasonic Wall Thickness HardnessSalt Contamination

NEW

Proud supplier of DeFelsko Inspection Instruments DFT Instruments UK LTD 16A

www.dftinstruments.co.uk e: sales@dftinstruments.co.uk NEW DesignandFeatures

DesignandFeatures

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 f: 01442 879595

AAC GAIN QUALICOAT SEASIDE LICENCE

By Angus Mackie - QUALICOAT Chair

As more architectural powder coating companies adapt their coating processes and apply to QUALICOAT UK & Ireland to gain a coveted coating licence, existing licensed members seek further accreditations to further enhance their coating sustainability when required in harsher environments. I am therefore delighted to announce that AAC have recently been awarded their licence for ‘Seaside Class’.

‘Seaside Class’ is a third party inspected process which further enhances the pretreatment of the aluminium prior to powder application and is used in environments such as projects within three miles of the UK coastline.

Greg Fowler, Director of AAC comments: “In the continued quest for quality and sustainability, AAC is thrilled to announce its recent achievement of the prestigious Qualicoat Seaside certification, marking a significant milestone in the company’s continual growth and excellence. This esteemed certification, coupled with AAC’s unwavering partnership with Qualicoat, underscores a shared commitment to superior quality standards and a steadfast belief in delivering top-tier products.

“Demonstrating the dedication to quality, AAC proudly holds not only the Qualicoat Seaside accreditation but also the BSI 9001 certification, solidifying its status as an approved applicator for all major powder manufacturers and an accredited member of ALFED.

The current QUALICOAT Specification is available for download via the UK & Ireland Association website, qualicoatuki.org and the website offers an up-to-date list of licensed UK and Ireland Powder Suppliers, Pretreatment Suppliers and Applicators including the applicators who carry the Seaside class accreditation. Telephone support is available from QUALICOAT UK & Ireland Head Office in the Midlands on 0330 240 9735, the Association can also be followed on Twitter @Qualicoatuki or on LinkedIn www.linkedin.com/company/ qualicoat-uk-&-ireland.

38 INDUSTRY NEWS

“The Professionals” email info@pros trip.co.uk phone 01 1 5 91 1 2240 “Save up to 20% on your monthly s tripping cos ts” Send your enquir y today!! Sub contract specialists in Paint & Powder coat removal to the finishing industr y JIG CLEANING PAINT BOOTH GRID CLEANING COMPONENT RECLAMATION EST . 1989 Pro-Strip Ltd. Trent Lane, Daleside Road, Nottingham NG2 4DS web www.prostrip.co.uk

Mass Finishing

Efficient systems engineering and innovative technologies – powerful and economical

Shot Blasting

Individual systems engineering and intelligent process solutions –reliable and energy efficient

AM Solutions

The full solution provider for 3D post processing equipment and 3D printing services

Surface Finishing is our DNA

Rösler UK Limited| 1 Unity Grove | Knowsley Business Park | Prescot | Merseyside | L34 9GT Tel: +44 (0)151 482 0444 | Fax: +44 (0)151 482 4400 | rosler-uk@rosler.com | www.rosler.com

Coating Cost Calculation

CALCULATE YOUR ENERGY SAVINGS

Energy costs are through the roof right now. A higher hanging density is often the most efficient way to both save energy and drastically lower the total coating cost. Find out how much you can save on your coating line at ccc.hangon.com

The Global Leaders in Wet Blasting & Surface Treatment Solutions

A GLOBAL LEADER IN WET BLASTING & SURFACE TREATMENT SOLUTIONS

Established in 1990 under the leadership of our managing director, Aidan Mallon, Vixen has been dedicated to continuous growth and technological advancement. This unwavering commitment has propelled us to the forefront of the global market as leaders in the design and manufacturing of wet blasting solutions. With over three decades of experience, we have at the forefront of innovation in wet blasting, washing, and degreasing, often customizing solutions to meet the unique needs of customers, especially when stringent parameters and high tolerances are involved.

Established in 1990 under the leadership of our managing director, Aidan Mallon, Vixen has been dedicated to continuous growth and technological advancement. This unwavering commitment has propelled us to the forefront of the global market as leaders in the design and manufacturing of wet blasting solutions. With over three decades of experience, we have been at the forefront of innovation in wet blasting, washing, and degreasing, often customizing solutions to meet the unique needs of our customers, especially when stringent parameters and high tolerances are involved.

product offerings include a range of standard wet blasting, washing, and degreasing machines, available both as standalone and as multi-stage systems tailored to specific customer requirements. Through ongoing improvement initiatives and strategic investments, we strive to nurture a culture of innovation within our organization.

Our product offerings include a range of standard wet blasting, washing, and degreasing machines, available both as standalone units and as multistage systems tailored to specific customer requirements. Through ongoing improvement initiatives and strategic investments, we strive to nurture a culture of innovation within our organization.

As a global entity, we maintain a network of business partners, distributors, and sample processing test labs worldwide. At Vixen, we pride ourselves on our collaborative approach, working closely with customers to deliver tailored solutions that precisely meet their needs. This collaborative process has been instrumental in providing effective surface treatment solutions.

The Global Leaders in Surface Treatment

Established in 1990 under the leadership of our managing dedicated to continuous growth and technological advancement. propelled us to the forefront of the global market as leaders blasting solutions. With over three decades of experience, been at the forefront of innovation in wet blasting, washing, degreasing, often customizing solutions to meet the unique our customers, especially when stringent parameters and tolerances are involved.

Our product offerings include a range of standard wet washing, and degreasing machines, available both units and as multi-stage systems tailored to specific requirements. Through ongoing improvement initiatives strategic investments, we strive to nurture a culture innovation within our organization.

Central to our success is the synergy within our team and manufacturing entirely in-house. This vertical integration chain, quality, and efficiency, earning us trust and recognition Located in the Northeast of England, our integrated manufacturing seamless communication and collaboration across departments,

Central to our success is the synergy within our team and our ability to handle design and manufacturing entirely in-house. This vertical integration affords us complete control over supply quality, and efficiency, earning us trust and recognition o n a global scale. Located in the Northeast of England, our integrated manufacturing facility and headquarters ensure seamless communication and collaboration across departments, fostering efficiency and cohesion.

Central to our success is the synergy within our team and our ability to handle design and manufacturing entirely in-house. This vertical integration affords us complete control over supply chain,

Trusted by manufacturers and customers spanning various industries, from aerospace OEMs to medical device manufacturers, we offer cutting-edge solutions to address diverse surface treatment requirements

Our comprehensive range of wet blasting solutions encompasses everything from standard manually operated cabinets to inline systems and fully automated, integrated robotic systems. Additionally, we offer washing, degreasing, and Ultrasonic solutions to

meet a wide array of surface treatment requirements.

For further details on our offerings, including applications and industries served, as well as in-depth information and operational videos, we invite you to visit our website at www.vixenaquablast.com

As a global partners, worldwide. collaborative to deliver needs. This instrumental solutions.

As a global entity, we maintain a network of business partners, distributors, and sample processing test labs worldwide. At Vixen, we pride ourselves on our collaborative approach, working closely with customers to deliver tailored solutions that precisely meet their needs. This collaborative process has been instrumental in providing effective surface treatment solutions.

There, you’ll find a wealth of resources to help you explore our solutions and determine the best fit for your needs

We work across a large number of industries covering multiple applications, visit our website and view application and industry pages or go straight to our solutions page.

WWW.VIXENAQUABLAST.COM

44 PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING

VIXEN The Global Leaders in Wet Blasting & VIXEN

VIXEN

The Vixen Inline Tumbler surface treats components (In this

In-line Surface Treatment & Cleaning

Process steps all completed in one automated solution with auto 1. Wet blasting to remove surface contaminants or coatings

IN-LINE SURFACE TREATMENT & CLEANING

MULTIPLE STEP PROCESS INTERGRATED INTO A ONE STEP INLINE SOLUTION CAPABLE OF BEING SCALLED FOR VARIOUS PARTS AND INDUSTRIES.

The Vixen Inline Tumbler surface treats components (In this case fasteners)

Process steps all completed in one automated solution with auto load/unload options

1. Wet blasting to remove surface contaminants or coatings

2. Basic rinse to remove excess media

3. Up

Multiple step process intergrated into a one step inline solution capable of being scalled for various parts and industries.

The Vixen Inline Tumbler surface treats components (In this case fasteners)

Process steps all completed in one automated solution with auto load/ unload options:

1. Wet blasting to remove surface contaminants or coatings

The Aquablast Tumbler line solution presents a versatile option for processing small to medium-sized components either in batches or continuously inline, streamlining the entire process into a single step.

The Aquablast Tumbler line solution presents a versatile option for processing small to medium-sized components either in batches or continuously inline, streamlining the entire process into a single step.

process development, guaranteeing complete process control, consistency, and reliable results.

Our Tumbler process is characterized by its exceptional controllability, allowing for precise adjustments of parameters to tailor the intensity and action of tumbling, as well as the blast guns and other process variables, ensuring optimal treatment for your components.

2. Basic rinse to remove excess media

3. Up to 3 stage wash/rinse

4. Dry

The Aquablast Tumbler line solution presents a versatile option for processing small to medium-sized components either in batches or continuously inline, streamlining the entire process into a single step.

Our Tumbler process is characterized by its exceptional controllability, allowing for precise adjustments of parameters to tailor the intensity and action of tumbling, as well as the blast guns and other process variables, ensuring optimal treatment for yo ur components.

To achieve the desired outcomes, these parameters can be fine-tuned through our sample processing and subsequent process development, guaranteeing complete process control, consistency, and reliable results.

To achieve the desired outcomes, these parameters can be fine-tuned through our sample processing and subsequent complete process control, consistency, and reliable results.

Tailored to your specific requirements, our tumbler solutions can be customized with barrel sizes to accommodate component size and quantity, as well as the desired number of nozzles. By integrating both blasting and washing capabilities, our systems enable components to enter, undergo stripping or cleaning, washing, and drying, all in

asingle process step, minimizing handling and maximizing efficiency.

WWW.VIXENAQUABLAST.COM

Tailored to your specific requirements, our tumbler solutions can be customized with barrel sizes to accommodate component size and quantity, as well as the desired number of nozzles. By

Our Tumbler process is characterized by its exceptional controllability, allowing for precise adjustments of parameters to tailor the intensity and action of tumbling, as well as the blast guns and other process variables, ensuring optimal treatment for your components.

To achieve the desired outcomes, these parameters can be fine-tuned through our sample processing and subsequent

Tailored to your specific requirements, our tumbler solutions accommodate as well integrating capabilities, to enter, washing, step, efficiency.

to 3 stage wash/rinse 4. Dry

OF BEING SCALLED FOR VARIOUS PARTS AND INDUSTRIES.

2. Basic rinse to remove excess media 3. Up to 3 stage wash/rinse 4. Dry

WWW VIXENAQUA BL

efficiency and ultrasonic solutions through continuous gleaned from

our manufacturing

VIXEN DEGREASING, CLEANING & ULTRASONIC SOLUTIONS

facilities and processes,

often serving as extensive experience and expertise

customers in adding

extra value and

Agi Cleaning Lines

and

At Vixen, our uniqueness stems from our ability to design and manufacture a diverse range of surface treatment solutions that can be used individually or seamlessly integrated with one another. For instance, our wet blasting and washing systems can be combined to enhance efficiency and effectiveness.

Over the years, we’ve refined our degreasing, washing, and ultrasonic solutions through continuous innovation and a commitment to incorporating improvements gleaned from our manufacturing endeavours and customer relationships.

Cleaning solutions play a crucial role in many manufacturing facilities and processes, often serving as pre- and posttreatment steps around other processes. Here, our extensive experience and expertise in various surface processing techniques enable us to assist customers in adding extra value and efficiency to their production flows.

customized solutions for can be tailored to meet your specific ting and process development

bespoke

PROCESS DRIVEN SOLUTIONS FOR INDUSTRY

system, we are dedicated to

effectively. rinsing, lines agitation, tailored to can dryer and thoroug h

We specialize in the design and manufacture of both standard and customized solutions for degreasing, cleaning, and integrating ultrasonics. Our offerings can be tailored to meet your specific process requirements, or you can bring your needs to us for testing and process development purposes. Whether you require a standardized solution or a bespoke system, we are dedicated to delivering optimal performance and meeting your unique needs effectively.

Our ultrasonic tank lines boast multiple stages of washing, rinsing, and drying zones to accommodate diverse needs. These tank lines are equipped with various agitation methods including air agitation, pump agitation, vertical agitation, and simulated rotation, tailored to the specific requirements of your components. These features can be seamlessly integrated into ultrasonic tanks, wash tanks, and dryer zones, all of which are controlled automatically through our pick and place or sledge drive systems. This ensures efficient and thorough processing of components with precision and consistency.

Jetwash Front Loading Wash

Our Jet Wash front loading solutions are available in several standard variants, carefully crafted to meet the needs of our most commonly served industries and requests.

Jet wash Front Loading Wash

However, we understand that some projects may have unique component or process requirements. In such cases, our Jet Wash solutions can be fully customized to suit your specific needs.

46

PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING combined to

enhance

variants, served However, or fully specialized tailor optimal In addition to our comprehensive

Our

Front Loading Wash