5 minute read

Section

Mast Bearings

The shims used under each roller bearing come in the following sizes: thin, medium, and thick. If the bearings are too loose, you should add shims to the bearing. If the roller bearings are shimmed too tight, causing wear along the I - beam or mast shaving, reduce the shim thickness. Although different combinations of shims may be used to obtain the proper adjustment, you should try to maintain equal shim thickness on each side of the main frame and masts.

Upper Mast Bearing Replacement

Use extreme care when blocking the mast for any reason. Never remove the block when it is supporting the mast.

1. Slightly elevate the carriage to gain access to the bearings.

2. Block the carriage before you attempt to remove the roller bearing. You may also use a lift hoist to pull the carriage upward to gain access to the roller bearing. Put a strap suitable to handle the weight of the carriage around the uppermost cross tie. Once the carriage is raised in place, block it into position.

3. Turn the key switch OFF and disconnect the battery connector.

Acaution

Do not damage the mast when prying with the screwdriver.

NOTE: For the upper mast bearings, wedge a screw driver between the roller bearing and the mast to prevent the bearing from falling.

NOTE: When removing the roller bearing, use caution not to let the bearing fall down into the mast assembly.

4. Remove the bolt securing the roller bearing to the respective mast or mast.

Mast Section

NOTE: If the bearings are worn or damaged, replace them.

5. Install the same number of shims under the bearing that were removed.

6. Make sure the roller bearing mounting bolts are clean before you install them.

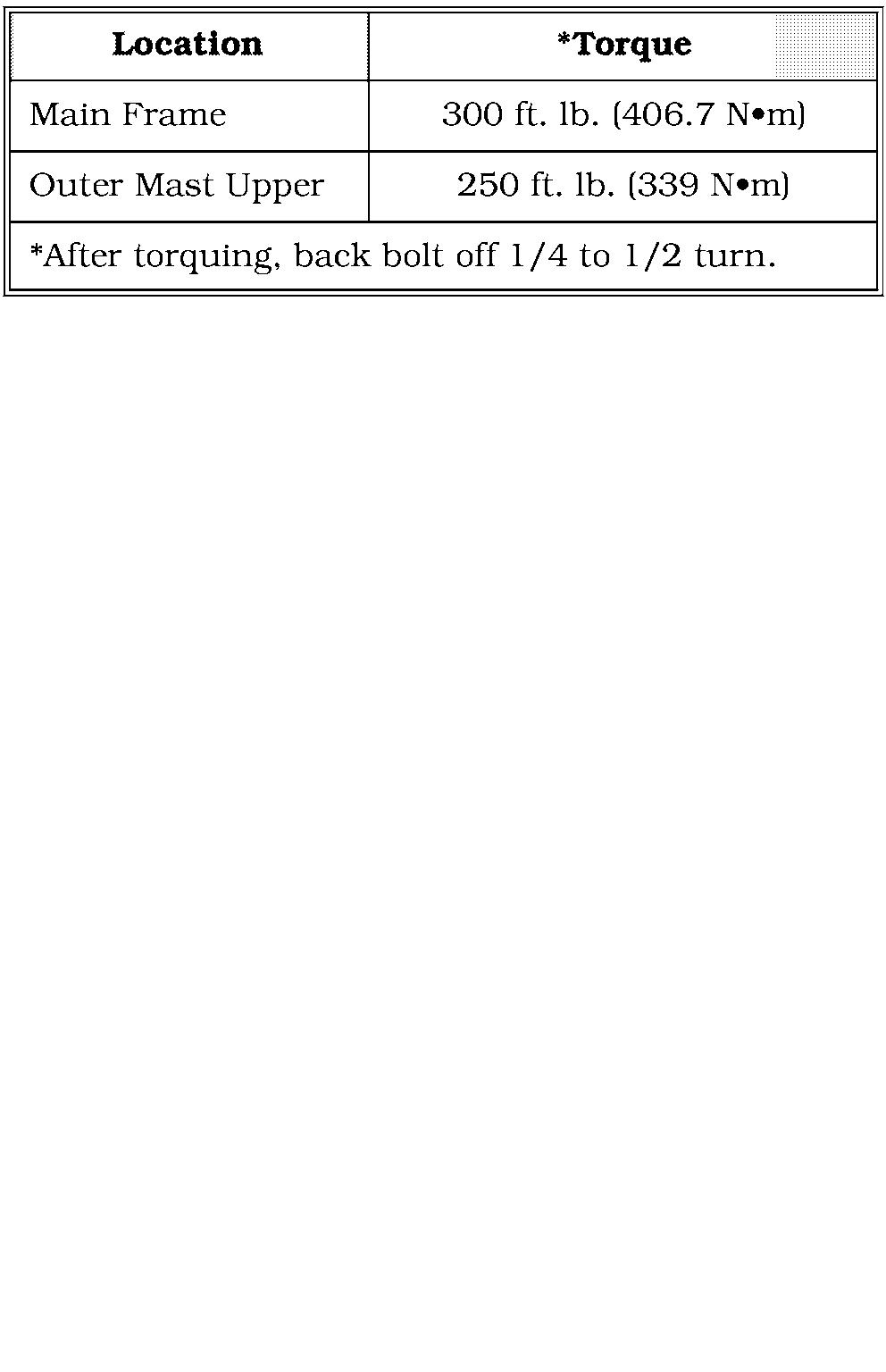

7. Apply thread - locking compound (P/N 00590 - 04964 - 71) on the threads. Torque the bolts per Table 7 - 2.

8. Reconnect the battery connector and turn the key switch ON.

9. Lift the carriage and mast and unblock the mast.

10. Test the operation of the masts.

1 1. Return the truck to service.

Mast Section

Mast Disassembly and Shimming

This section describes procedures for: Disassembling the three-stage mast

Shimming main frame to outer mast

Shimming outer mast to inner mast

Shimming inner mast to carriage

NOTE: Two-stage masts require similar procedures with the references to the center lift cylinder and inner mast not applying.

Mast Disassembly

1. Remove the forks and mast guard.

2. Fully lower the carriage and make sure the pressure is out of the cylinders.

3. Turn the key switch OFF and disconnect the battery connector. Remove the battery.

4. Disconnect the over-the-mast cables and hoses inside the tractor compartment and plug the hoses. Disconnect the lift hose to the side cylinders inside the tractor compartment and plug. Disconnect all other cables that run from the tractor to the mast.

5. Secure the main carriage and masts so they cannot move.

6. Remove the tractor from the mast and block each securely.

7. Disconnect and remove the lift chains from the center lift cylinder. Remove the over pulley cables and hoses. Remove the center cylinder end cap assembly.

Mast Disassembly and Shimming

9. Remove the main carriage by sliding it out the top of the inner mast. Set it aside for later reassembly.

10. Disconnect and remove the lift cylinders from the masts.

11. Attach the hoist to the inner mast.

12. Remove the upper roller bearing bosses and roller bearings from the outer mast.

13. Remove the masts and mainframe stops.

Failure to properly balance load may result in personal injury. Use extreme caution.

14. Slide the inner mast out of the top of the outer mast. Attach the hoist to the outer mast.

15. Remove the upper roller bearing bosses and roller bearings from the main frame.

Failure to properly balance load may result in personal injury. Use extreme caution.

16. Slide the outer mast out of the top of the main frame.

Shimming Main Frame to Outer Mast

1. Install the mast roller bearings at the bottom of the outer mast.

Mast assembly may swing free when lowering. Use extreme caution.

8. With a suitable hoist, carefully lay the mast assembly down and block securely in place. Remove the carriage stops from the inner mast.

Mast assembly may swing free when lifting. Use extreme caution.

2. Use a suitable lifting device and insert the outer mast into the main frame all the way to the bottom.

3. Using a pry bar, move the outer mast and roller bearing to one side.

Mast Disassembly and Shimming

4. Use spare shim(s)as a gauge to determine the amount required to move the roller bearings outward to make contact with the main frame.

5. Remove the outer mast from the main frame.

6. Remove the roller bearings from both roller bearing bosses at the bottom of the outer mast.

7. Install half of the total shim thickness required to each roller bearing boss at the bottom of the outer mast. (Applying one half of the total shim thickness to each side of the mast maintains the center line of the mast assembly.)

8. Reinstall the roller bearings. Torque the bolts per Table 7-2.

9. Use a suitable lifting device and reinstall the outer mast into the main frame. Check for tightness while moving the outer mast to the bottom of the main frame. Add/remove shims as necessary to maintain a snug, but free-running, fit.

NOTE: If the outer mast hangs up, a pry bar may be used to move the mast.

10. Assemble the two top mainframe roller bearings and bosses without shims.

11. Install the roller bearing assemblies, attach with a retaining bolt, and snug up to the main frame.

NOTE: Failure to snug the assemblies to the main frame will result in the wrong amount of shims, since the studs are canted.

12. With the outer mast fully nested, use a pry bar and carefully move the outer mast to the opposite side. Using spare shims between the bearing and outer mast, determine the amount of shims required to remove side play.

13. Remove the roller bearing assemblies.

14. Install half of the total shim thickness to each roller bearing assembly.

15. Install the roller bearing assemblies and attach with the mounting bolts and tighten.

Mast Section

16. With the outer mast fully nested, use a pry bar to check for bearing tightness. If more shims can be inserted between the bearing and the outer mast, remove the roller bearing assembly and install the shim(s). Reinstall the bearing assembly.

17. Check for proper shimming by pulling the outer mast out and then pushing it in all the way. The outer mast should not hang up while moving it in and out. Torque the bearing stud retaining bolts (refer to Table 7-2 on page 7-86) .

18. Install the stops in the mainframe.

Shimming Outer Mast to Inner Mast

1. Install the mast roller bearings at the bottom of the inner mast. Mast assembly may swing free when lifting. Use extreme caution.

2. Use a suitable lifting device and insert the inner mast into the outer mast all the way to the bottom.

3. Use a pry bar and carefully move the inner mast and bearings to one side.

4. Use spare shim($ as a gauge to determine the amount required to move the bearings outward to make contact with the outer mast.

Failure to properly balance load may result in personal injury. Use extreme caution.

5. Remove the inner mast from the outer mast.

6. Remove the bearings from both roller bosses at the bottom of the inner mast.

7. Install half the total shim thickness required to each roller boss at the bottom of the inner mast.