2 minute read

Section 4. Planned Maintenance Toyota Orderpicker Model 7BPUE15 Service Manual

Interval 2

Interval 2

Moderate Usage: Every 6 Months or 500 Hours; Severe Usage: Every 3 Months or 250 Hours

What to do

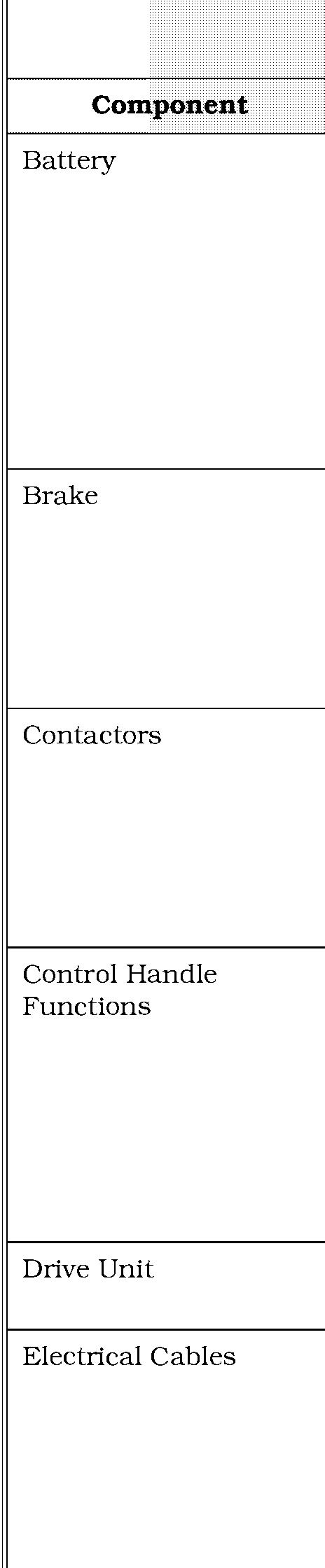

Check the weight stamped on the battery in the truck against the minimum and maximum allowable weights on the specification plate for the truck. Report any trucks that are running with batteries under the minimum or over the maximum allowable weight.

Inspect the battery connector and all leads for damage and cuts in protective coatings. Shorts to the truck frame will cause electronic component failure or intermittent electrical failures.

Check the brake for proper stopping distance. The truck should stop within 8 to 10 feet if brake is applied while the truck is loaded, traveling tractor-first at full speed.

Visually inspect the friction plate (rotor disk) with the brake released. Minimum thickness of the pad and steel backing plate is 1 /4 in. (6 mm).

Inspect the contactor tips for burnt or pitted surfaces. Failure to replace the tips may cause surfaces to weld together, causing unscheduled downtime.

Check the plunger for smooth operation with no binding. If binding occurs, the truck may exhibit intermittent fault codes.

Operate the lift/lower function. Verify the response is smooth and both speeds work.

Operate the travel function. Verify the full range of acceleration is smooth and responsive. Make sure the plugging is functioning properly.

Look for any play in the center position of the lift or travel. If there is free play, replace the return springs.

Check for proper fluid level in the drive unit. If the fluid level is low, investigate for leaks and determine the cause.

Inspect all power cables for nicks or cuts. Give special attention to those cables that are not stationary, for example, cables to the drive motor. Inspect the over-the - mast cable for chafing or wear. Replace any cable that is damaged or shows signs of excessive heat. Failure to do so will cause intermittent system shutdowns and/or electronic failures.

Refer to

Page 3-2

Page 7-28

Page 7-48

Page 7 - 46

Page 7 - 24

Page 5 - 8

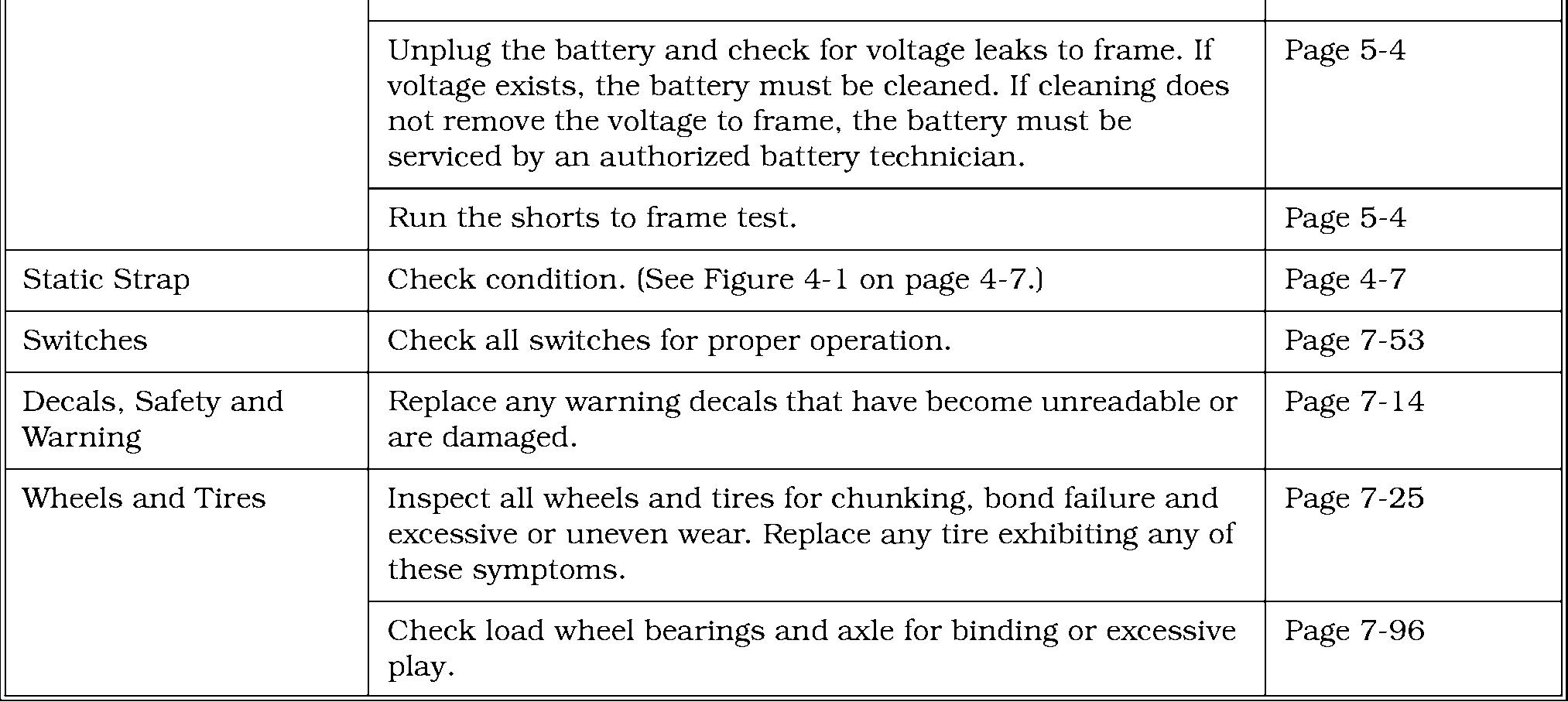

Component

Hardware

Moderate Usage: Every 6 Months or 500 Hours; Severe Usage: Every 3 Months or 250 Hours

What to do

Check the tightness of all wire and cable connections. This can be done by trying to move the connection with your hand.

Check for loose hardware for major truck components (steer motor, brake assembly, drive motor and drive unit, hydraulic assembly to tractor frame, electronic assemblies and hardware.)

Refer to

Forks

Inspect the forks for unauthorized modifications, bends, cracks or wear.

Acaution

If any of the imperfections above are found, replace the fork immediately.

Hydraulic Hoses Inspect the hydraulic hose and tubing for leaks, nicks, cuts, chafing and bulges. Replace defective hoses as soon as possible.

Inspect all fittings for leaks. Repair any leaks immediately. I

Page 7-94

Hydraulic Reservoir

Lift Chains

Check for proper fluid level and the proper fluid for the working environment.

Check for proper adjustment of the chains. Inspect chain anchors and pivot rocker.

Inspect the chains for excessive stretch or wear. There is a tool available to determine when lift chains must be replaced.

Lights Check operation.

Lubrication

Apply grease to both fittings on the drive unit. Apply grease to load wheels.

Wipe off old grease on the mast uprights and apply new grease. This will prevent damage from contamination in the grease.

Coat any chains with a film of spray lubricant to keep chains from rusting and wearing prematurely.

Mast Visually inspect the mast rails for abnormal wear. Inspect the inside of the main frame for wear.

Page 7 - 60

Page 7-76, Page 7-9 1 or Page 7-93

Page 7-76, Page 7-9 1 or Page 7-93

Page 7-73 do not reflect a normal wear pattern, the chance of intermittent error codes caused by shorts between maintenance intervals. It will also extend the life of cables and harnesses.