1 minute read

Hydraulics — Work System Pressure Tests

Work System Pressure Tests

Work Pressure Test

This test determines the condition of the work/pump.

STEP 1

Tilt the platform according to “Tilting the Platform” on page 61.

STEP 2

A

IMPORTANT: Start with a pressure gauge rated for a higher pressure than required, and move to lowerpressure gauges as needed. Gauges will be damaged if the pressure exceeds the capacity of the gauge.

Connect a pressure gauge rated for 414 bar (6000 psi) to test fitting (A) inside the front of the steering console pedestal.

NOTE: Early machines require removal of the front panel on the control column base to access test fitting (A).

STEP 3

Start the machine and allow it to warm to operating temperature (120° F / 49° C). Set the throttle to low idlle (1000 rpm).

STEP 4

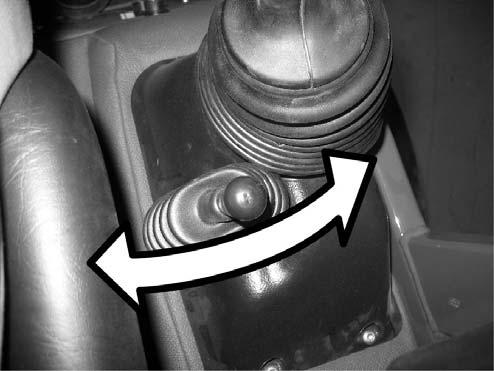

Later Machines

Early Machines

Operate the auxiliary hydraulic flow without connecting an attachment. This will cause the work system circuit to reach full pressure.

STEP 5

Pressure should be 207 ± 7 bar (3000 ± 100 psi).

Work Cylinder Leakage Test

This test determines the condition of the cylinder piston and seals.

STEP 1

Start the machine and allow it to warm to operating temperature.

STEP 2

Use the joystick to fully retract the cylinder to be tested.