7 minute read

Maserati GranCabrio

DC-motors

The NCP controls the DC-motor of each rear window lifter. The opening/closing movement of the window lifters is managed by inverting the polarity of the DC-motor. When the window lifter reaches its end position, the increased current draw as a result of the increased mechanical resistance enables the NCP to deactivate the DC-motor. By this way there is no need to use traditional end-of-run micro switches.

The front latch mechanism locks the roof to the windscreen frame The front latch motor is operated by a relay which is integrated inside the NCP

The motor of the electric pump of the roof hydraulic system is controlled directly by the NCP by means of an integrated relay. No external relay is used.

Each DC-motor output of the NCP is protected against short circuits. It uses voltage feedback to detect error situations and a shunt resistor to measure each motor current draw.

Solenoid valves

The NCP activates three solenoid valves, which control the direction and functionality of the roof hydraulic system The solenoid valves are integrated in the hydraulic unit

Maserati GranCabrio

Interaction with other vehicle nodes

The NCP receives the following information over the B-CAN line:

• Key On/Off status from the NBC

• Vehicle speed from the NBC

• Boot lid open/close status from the NBC

• Driver’s and passengers door status (open/close) from the NBC

• Driver’s door key switch signal from the NBC (for the Summer Opening function)

• External temperature from the NPG

• Drivers side and passengers side front window status (up/down) from the NPG and the NPP

• Up/down command signals from the NPG for the left and right side rear windows

The NCP sends the following information over the B-CAN line:

• Roof open/closed status to the NBC

• Roof movement information and roof status to the NQS for the info display

• Buzzer request signal to the NQS

• Front windows command signals to NPG and NPP to lower the front windows in order to allow the roof movement, and to close them again at the end of the roof movement.

• Front windows enable/disable message to NPG and NPP to prevent the user from operating the front windows when the roof is in movement

• Boot lid enable/disable message to NBC to prevent the user from opening the boot when the roof is in movement

• Roof system fail status to NBC, NPG, NPP, NIT, NCL and NQS in the event of an error in the system

Audio output

The NIT receives a hard wired signal about the roof open/closed status from the NCP to permit different audio settings when the vehicle is driven with the roof open or with the roof closed:

• Roof closed or in movement: 0V

• Roof open: 12V

Body

Servicing the roof system

The soft top system of the Maserati GranCabrio is designed to be completely maintenance free No periodic maintenance is required for both the mechanical and the hydraulic parts of the system

Cleaning the soft top

Generally it is not necessary to clean the soft top every time the vehicle is washed. In most cases it will be sufficient to rinse the soft top with water only.

It is advised to wash the soft top by hand only. Firstly remove dirt residues with a vacuum cleaner Wash the canvas with water and a neutral shampoo by using a soft brush only Do not use solvents, alcohol, petrol or generic detergents to clean the soft top Do not use high pressure cleaning systems to clean the soft top Avoid to wash the car in direct sunlight

After the canvas has dried, finish the cleaning treatment by rinsing the soft top with a d t t i i fl b t k th t ll t

Repair operations on the hydraulic circuit

The hydraulic circuit is designed to be maintenance free. If necessary repairs can be carried out:

• The hydraulic unit can be replaced as a complete component

• Hydraulic cylinders can be replaced individually

• The high pressure pipes can be replaced individually

Caution

In case interventions have been carried out on the hydraulic circuit, the fluid level must be checked and topped up if necessary. The hydraulic fluid is specific and can be purchased through the Maserati parts department.

Maximum attention must be paid that the roof does not move while the hydraulic circuit has been opened. This will lead to fluid spilling out of the circuit and the risk of oil stains on the roof fabric or inner lining.

The hydraulic pipes are locked to the hydraulic unit by means of a securing plate (1). They can be removed by loosening the securing plate bolts and moving it slightly to one side. The hydraulic pipes are numbered for identification, both at hydraulic unit side and at cylinder side (2).

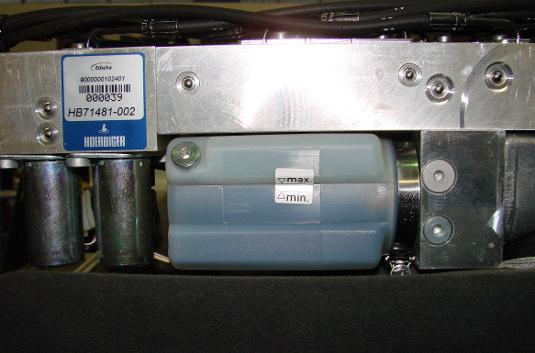

Hydraulic fluid level check procedure

• Bring the roof hydraulically (not manually!) in the position as can be seen in the picture below: tonneau cover open and roof folded away.

• Check if the fluid level in the reservoir is between the Min and Max filling marks (therefore the foam cover must be removed from the hydraulic unit)

Caution: do not overfill (danger of bursting the reservoir due to no venting)

Bleeding the hydraulic circuit

There is no specific system bleeding procedure as the hydraulic roof circuit is selfbleeding Open and close the roof a few times hydraulically after the hydraulic circuit has been opened, this operation will eliminate possible air in the circuit Check the fluid level afterwards and top up as necessary

Attenzione

Specific hydraulic fluid

Use exlusively the hydraulic fluid “Aral Vitamol” which can be ordered through the Maserati Parts Dept

This fluid is specific and not commercially available.

Emergency roof closing procedure

A manual procedure allows to close the roof in the event of a system failure

Important note: the manual closing procedure can only be performed after the hydraulic pressure has been released

When the hydraulic roof movement is interrupted at any stage, the system will remain under pressure, and therefore the roof will stay in position, for 10 minutes. After this time the NCP will release all solenoid valves, and by consequence also the system pressure. Only after this time it is possible to manually move the roof. Alternatively, disconnection of the battery earth terminal results in the same effect.

Notes:

• Make sure all side windows are lowered before executing the procedure

CAUTION

• Given the weight of the roof structure, it is recommended to perform this procedure with two persons.

Closing procedure:

• Turn the ignition key to the Off position and wait for 10 minutes.

• Open the boot compartment and remove the covers at both sides in the boot in order to access the tonneau cover emergency release cables

• Pull both cables to unlock the tonneau cover and close the boot lid.

• Open the tonneau cover and hold it in the vertical position.

• Lift up the soft top until about half way position so that it stays in an equilibrium position

Maserati GranCabrio

6 Lift the rear part of the roof and lower the tonneau cover until its fully closed

7. Lower the rear part of the roof to make it rest on the tonneau cover.

8 Approach the front part of the roof to the windscreen frame.

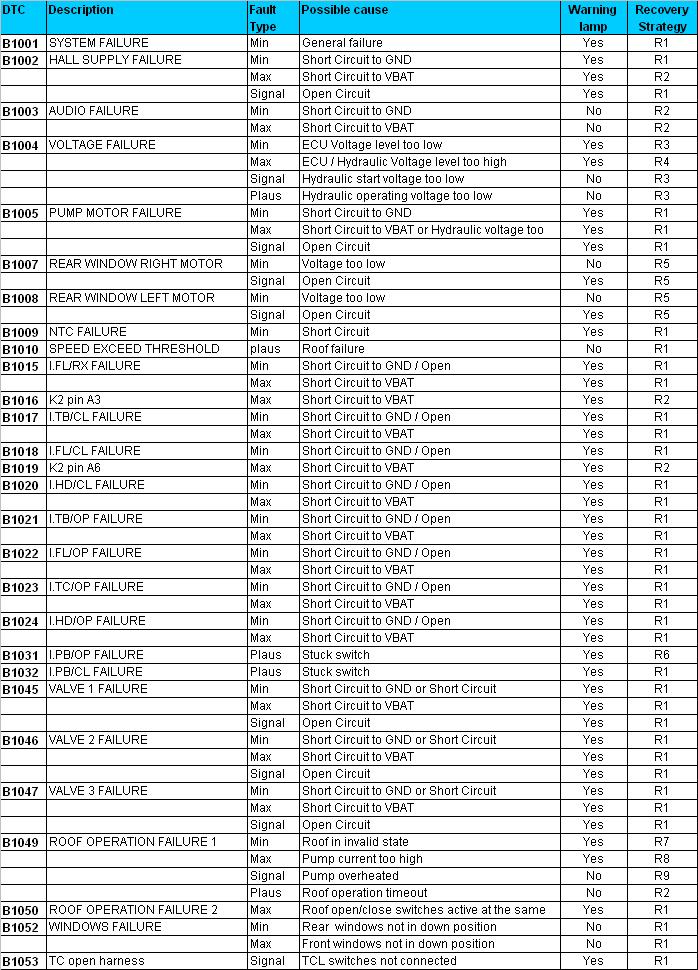

Fault Type:

• Min: the detected value is below the minimum value

• Max: the detected value is above the maximum value

• Signal: missing signal, no information available

• Plaus: failed plausibility check, invalid signal

Recovery strategies:

• R1: No roof movement possible as long as failure is present

• R2: Roof movement is possible

• R3: No roof movement possible as long as the voltage is below minimum threshold

• R4: No roof movement possible as long as the voltage is above maximum threshold

• R5: No roof movement possible as long as the rear windows are not in down position

• R6: Only roof close movement is possible

• R7: No roof movement possible as long as the roof is in an unknown sensor position

• R8: No roof movement possible as long as the hydraulic current is above maximum threshold

• R9: No roof open movement possible as long as the temperature is above maximum temperature threshold

Note: in case an error is present which makes no roof movement possible, the roof can be manually closed by performing the roof emergency closing procedure

Rear window lifters

The GranCabrio model features new rear side windows with lifter mechanisms. The window glass is bolted to the lifter assembly by means of three bolts which offer radial adjustment clearance.

The lifter assembly is composed of a black steel frame plate which contains guides for the window lifter The 12V DC motor is fitted on the frame plate and operates the window lifter by means of a bowden cable

The complete assembly is fitted in the vehicle body by means of three adjustable screws with lock nuts:

• The two top screws allow for adjustment of the window in its own plane

• One bottom screw is used to adjust the window preload

The assembly further contains adjustable stops to regulate the height and the angle of the window glass in the closed position.

In the event of a failure or breakage, the system can be replaced as a compete assembly or separately (window glass and lifter mechanism).

These rear window lifter mechanisms contain many adjustments in order to align the rear side window to the vehicle body, to the front side window and to the roof in case the system has to be removed or replaced Correct alignment of the rear windows is crucial in order to avoid premature wear, wind noises and water ingress.

Note: see the workshop manual for the adjustment procedures and specifications.

Adjustable window stop in closed position

Two adjustable stops allow to adjust the window angle in closed position

The window glass can be positioned on the lifter mechanism by means of three screws with adjustment clearance. Release these bolts only in case the window glass has to be replaced