12 minute read

DIAGNOSTIC CODE 5-5

Checking for a short in the actuator circuit

Test 2

Checking for a short to ground in the pump

1.Turn

2.Disconnect

3.Measure the resistance between

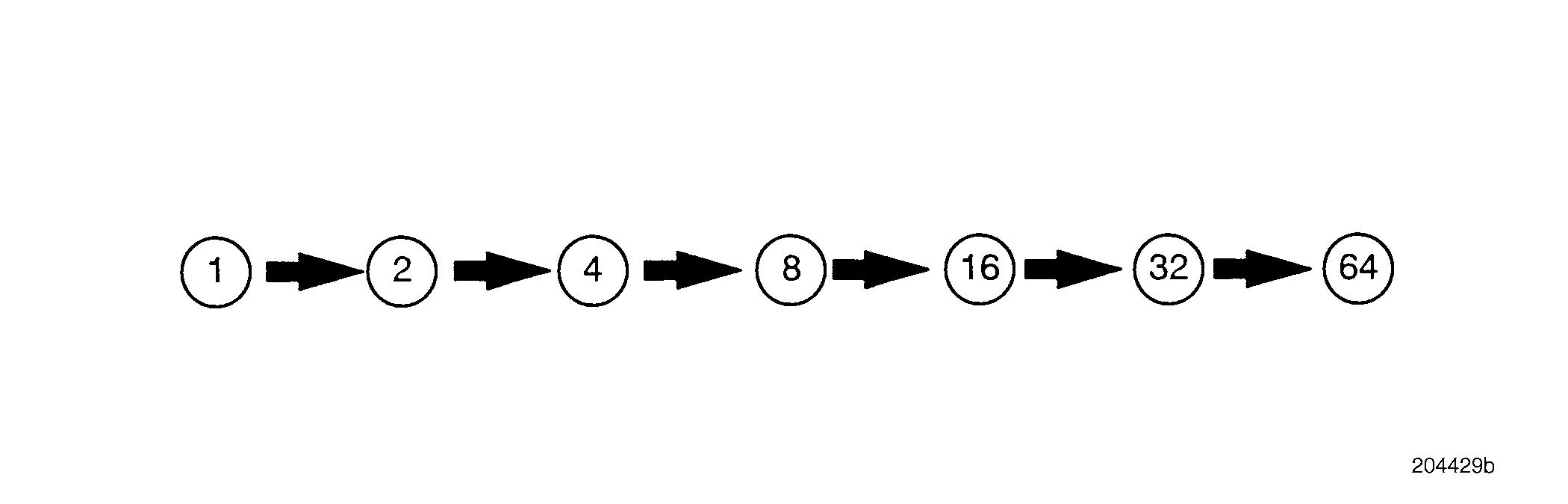

If the resistance is between 0.5 and 1.5 ohms, proceed to Test 2.

If the resistance is not between 0.5 and 1.5 ohms, continue with the next step.

4.Visually inspect the pins and crimps in the injection pump connector, at the pump end of the harness, for the cause of the open.

If there is a repairable condition, repair. Retest to be sure the problem has been corrected.

If there is not a repairable condition, send the pump to a certified pump shop for repair of the pump or integral jumper harness. Then retest to be sure the problem has been corrected.

1.Check

If there is continuity, there is a short to ground inside the pump cover. Send the pump to a certified pump shop for repair of the pump actuator assembly. Retest to be sure the problem has been corrected.

If there is no continuity, proceed to Test 4.

Test 4

DIAGNOSTIC CODE 5-5

Checking for a pin-to-pin short in the pump

Test 8

Checking for a short to voltage in the harness

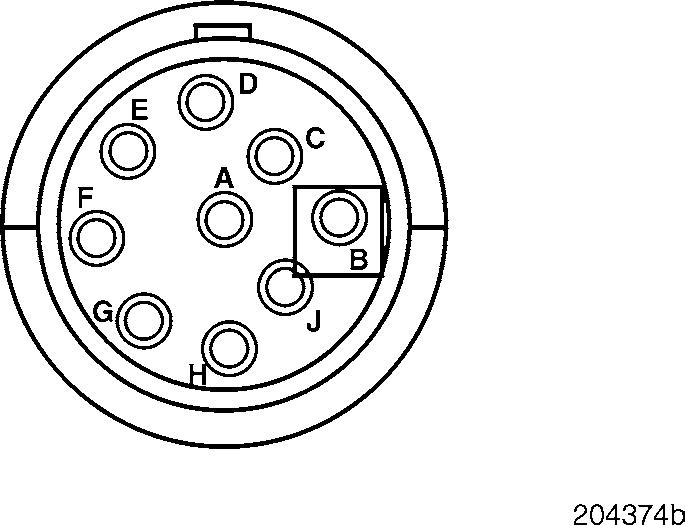

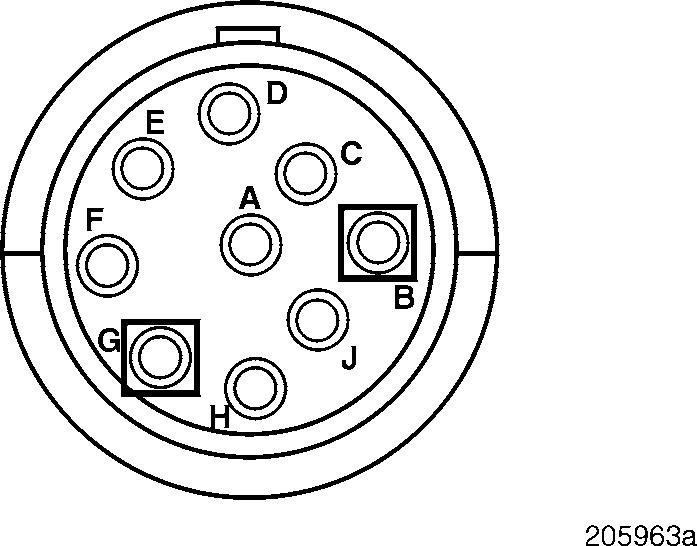

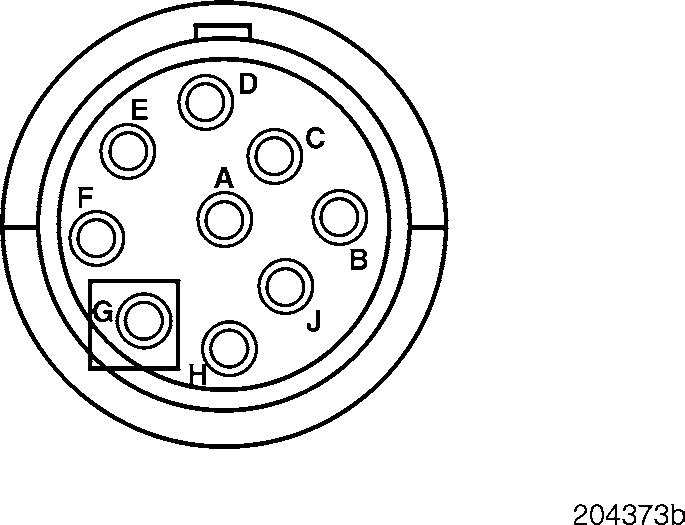

1.Check for continuity between Deutsch

2.Repeat the test for Deutsch pin G and Deutsch pins A, E, and F (one at a time) on the injection pump connector.

If there is continuity between any of these pins, send the pump to a certified pump shop for repair of the pump or integral jumper harness. Retest to be sure the problem has been corrected. If there is no continuity, proceed to Test 8.

DIAGNOSTIC CODE 5-5

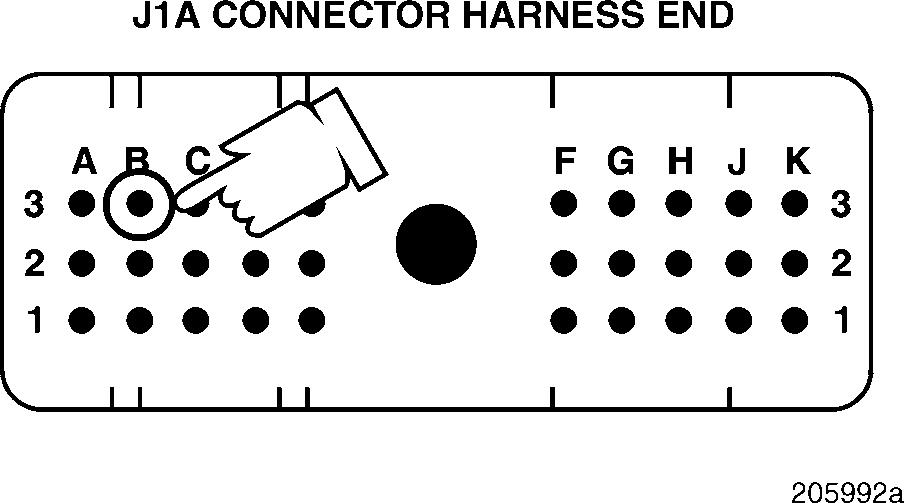

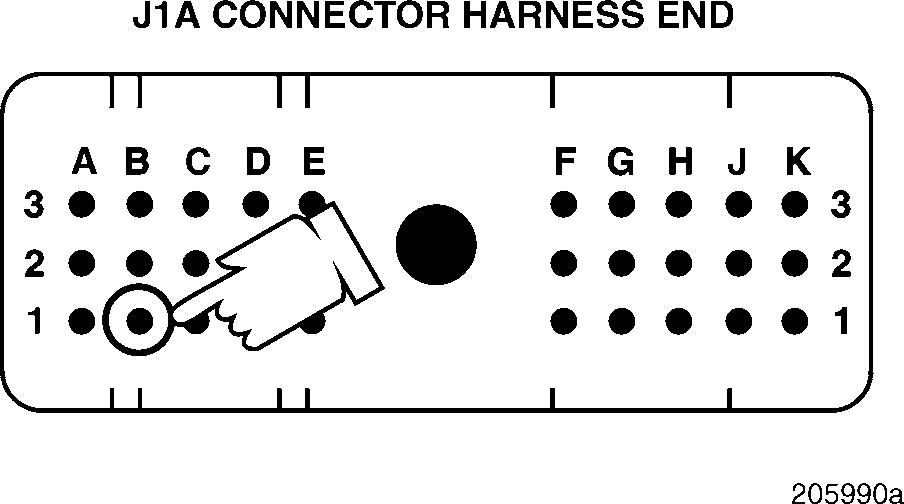

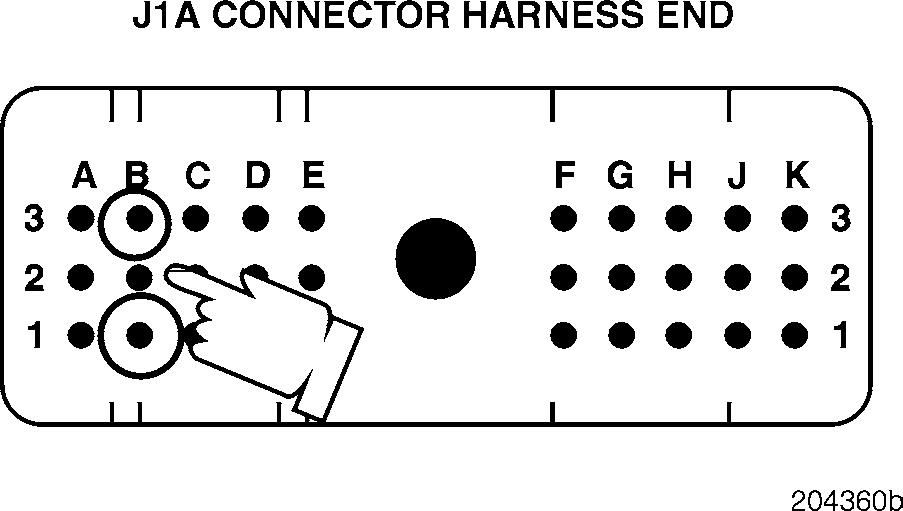

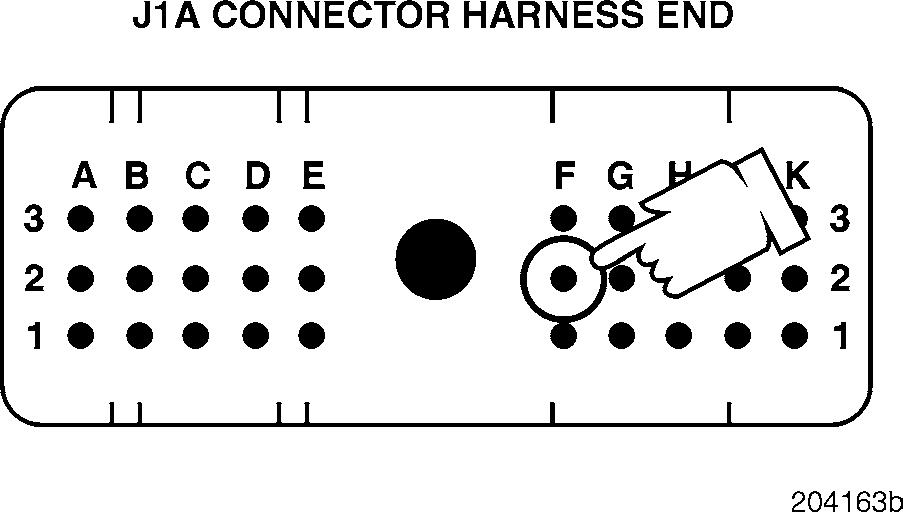

1.Disconnect the J1A and J1B connectors from the V-MAC II module.

2.Connect the serial link jumper into the serial communication port.

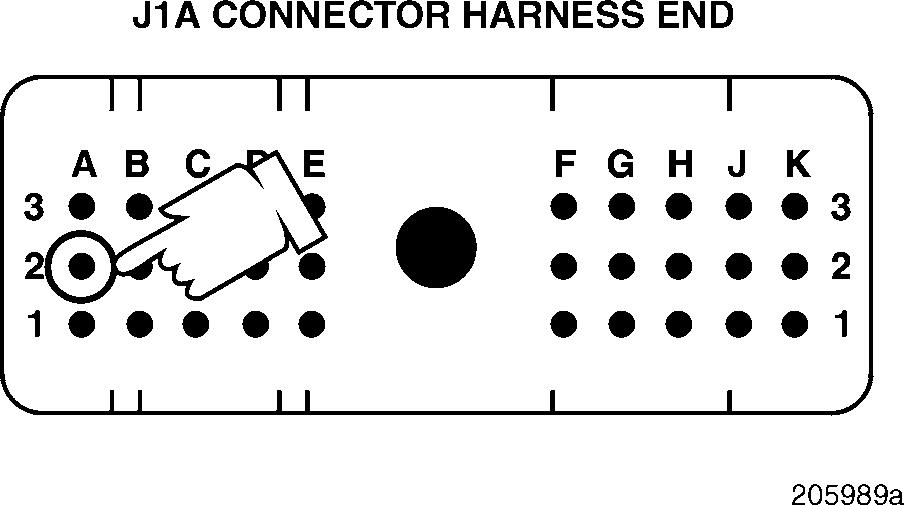

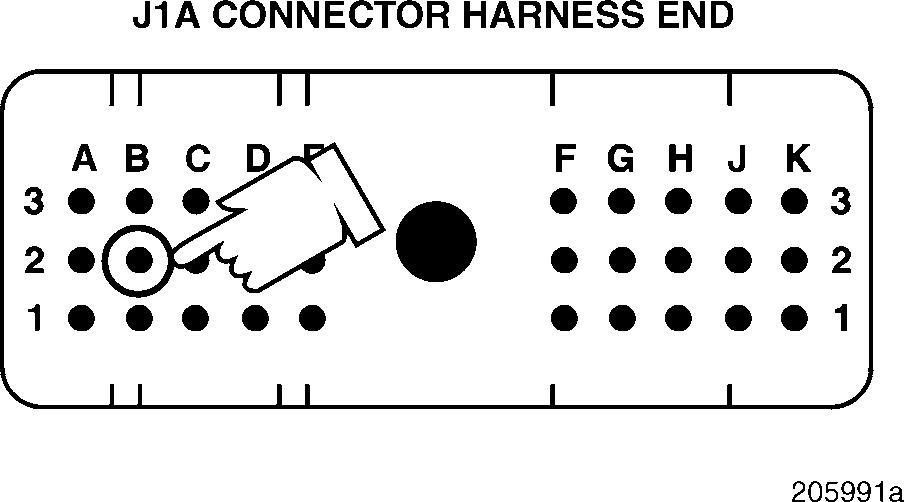

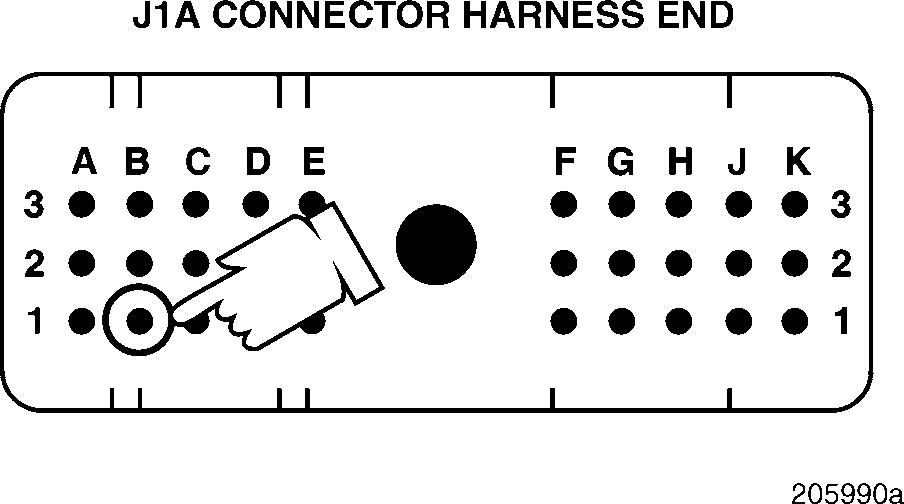

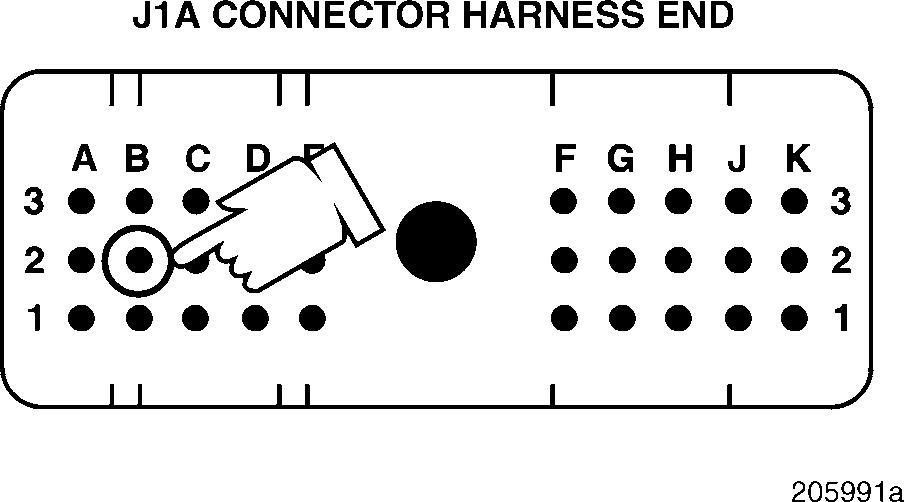

3.Measure the voltage on the J1A engine connector, from pins B1 and B2 (the actuator PLUS [+] lines) to a good ground.

4.Measure the voltage on the J1A engine connector, pins A2 and B3 (the actuator MINUS [ ] lines) to a good ground.

If the voltage on either line is greater than 0.5 volts, that line is shorted to another line in the harness. Locate and repair the short. Retest to be sure the problem has been corrected.

If the voltage on both lines is less than 0.5 volts, proceed to Test 16.

Test 16

Checking for a pin-to-pin short in the harness

1.Disconnect the serial link jumper.

2.Disconnect the J2 connector from the V-MAC II module.

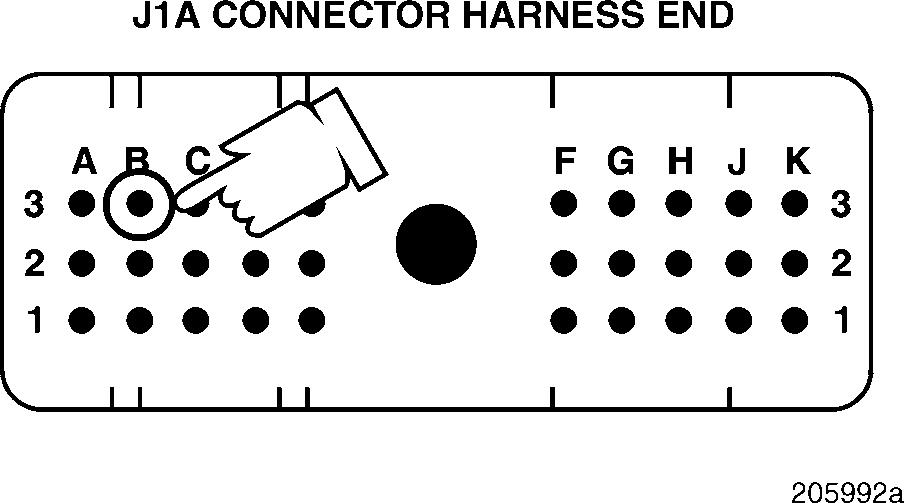

3.Check for continuity between J1A connector pin B1 (the actuator PLUS [+] line) and each of the other pins (one at a time) on the J1A, J1B and J2 connectors.

Do not check continuity from pin B1 to pin B2.

4.Check for continuity between J1A connector pin B2 (the actuator PLUS [+] line) and each of the other pins (one at a time) on the J1A, J1B and J2 connectors.

Do not check continuity from pin B1 to pin B2.

DIAGNOSTIC CODE 5-5

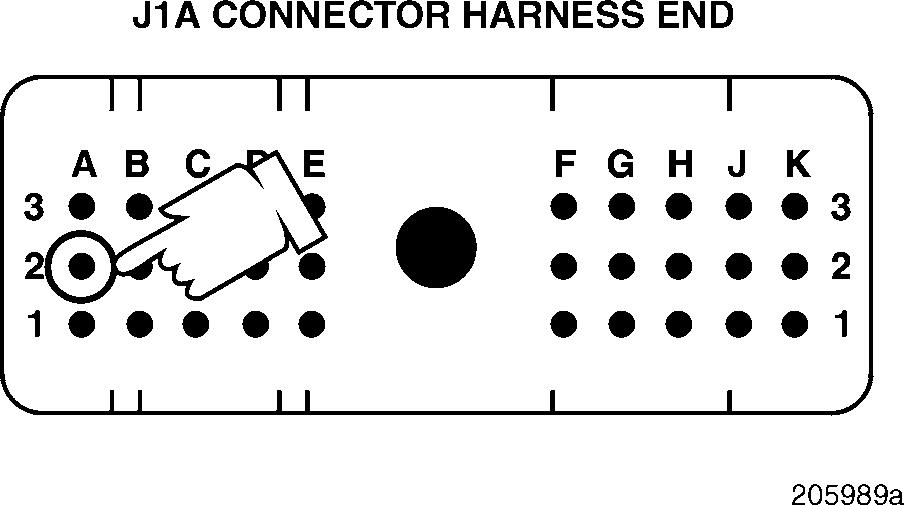

5.Check for continuity between J1A connector pin A2 (the actuator MINUS [ ] lines) and each of the other pins (one at a time) on the J1A, J1B and J2 connectors.

Do not check continuity from pin A2 to pin B3.

6.Check for continuity between J1A connector pin B3 (the actuator MINUS [ ] lines) and each of the other pins (one at a time) on the J1A, J1B and J2 connectors.

Do not check continuity from pin A2 to pin B3.

If there is continuity with another pin, repair the short in the harness between the pins which showed continuity. Retest to be sure the problem has been corrected.

If there is no continuity, proceed to Test 32.

If there is continuity with J1B connector pins P1 and P2 (ground pins) or J2 connector pin F2, there may also be continuity with other pins. Repair the short to pins P1, P2 and F2 first. Retest to be sure the problem has been corrected.

Test 32

Checking for an open on the pump end of the harness

1.Reconnect the pump end of the harness to the injection pump connector.

2.Measure the resistance between J1A connector pins B1 (the fuel rack actuator PLUS [+] line) and B3 (the fuel rack actuator MINUS [ ] line).

If the resistance is between 0.5 and 1.5 ohms, proceed to Test 64.

If the resistance is not between 0.5 and 1.5 ohms, the actuator PLUS [+] or MINUS [ ] lines are shorted or faulty in the injection pump connector or the pump end of the harness. Disconnect the connection and look for dirt or contamination which may cause the wires to short. Retest to be sure the problem has been corrected.

Test 64

Checking for a defective V-MAC II module or loose connector

1.With the ignition key in the OFF position, reconnect the V-MAC II connectors.

2.Turn the ignition key to the ON position.

If code 5-5 is still active, check the V-MAC II module and connector for dirt, loose or broken pins, or repairable damage. If no problems are evident, replace the V-MAC II module. Retest to be sure the problem has been corrected.

If code 5-5 is not active, the procedures have corrected the problem. Check all connectors to ensure proper connections.

DIAGNOSTIC CODE 5-6

DIAGNOSTIC BLINK CODE 5-6

FUEL CONTROL ACTUATOR TESTS

When performing electrical tests, it is important to wiggle wires and connectors to identify intermittent connection problems.

Test 1

Checking for adequate voltage out of the accessory relay

1.Turn the ignition key to the ON position.

2.Measure the voltage from the output of the accessory relay going to the electrical equipment panel to a good ground.

If the voltage is greater than 11 volts, or after correcting the low voltage problem the fault becomes active, proceed to Test 2.

An unexpected failure has occurred in the fuel rack actuator control system. This fault could be logged if there is insufficient voltage to the module.

If the voltage is less than 11 volts, the active fault may be caused by insufficient voltage at the module. Check battery and accessory relay connections, ground connections and proper accessory relay operation. If a problem is found and corrected, cycle the key for 5 seconds and check for an active fault again. Retest to be sure the problem has been corrected.

Test 2

DIAGNOSTIC CODE 5-6

Checking for a change in the code when the pump is disconnected

1.Turn the ignition key to the OFF position.

2.Disconnect the engine harness from the injection pump connector on the pump end of the harness.

3.Turn the ignition key to the ON position.

If the code changes from 5-6 to 5-3, proceed to Test 4.

A 7-5 code should also be present.

If the code does not change from 5-6 to 5-3, contact Service Engineering.

Test 4

Checking for an intermittent open or short in the wiring

1.Turn the ignition key to the OFF position.

2.Reconnect the engine harness to the injection pump connector on the pump end of the harness.

3.Turn the ignition key to the ON position.

4.Flex the engine harness from the bulkhead to the injection pump connector and the pump jumper harness.

If, at any time, the fault goes from active to inactive while flexing the harness, there is an intermittent rack actuator open or short at that location in the harness. Contact Service Engineering before repairing the open or short.

If the fault does not go from active to inactive while flexing the harness, proceed to Test 8.

Test 8

Checking for intermittent contact at the pump

1.Turn the ignition key to the OFF position.

2.Disconnect the engine harness from the injection pump connector on the pump end of the harness.

3.Examine the connector pins for evidence of dirt, wear, debris or intermittent contact.

If there is a repairable condition, repair the damage. Retest to be sure the problem has been corrected.

If there is no evidence of damage, proceed to Test 16.

Test 16

Checking for intermittent contact at the module

1.Disconnect the J1A and J1B connectors from the V-MAC II module.

2.Examine the connector pins for evidence of dirt, wear, foreign debris or intermittent contact.

If there is a repairable condition, repair the damage. Retest to be sure the problem has been corrected.

If there is no evidence of damage, proceed to Test 32.

Test 32

DIAGNOSTIC CODE 5-6

Checking for good ground connections

1.Turn off all electrical devices in the truck, including dome lights.

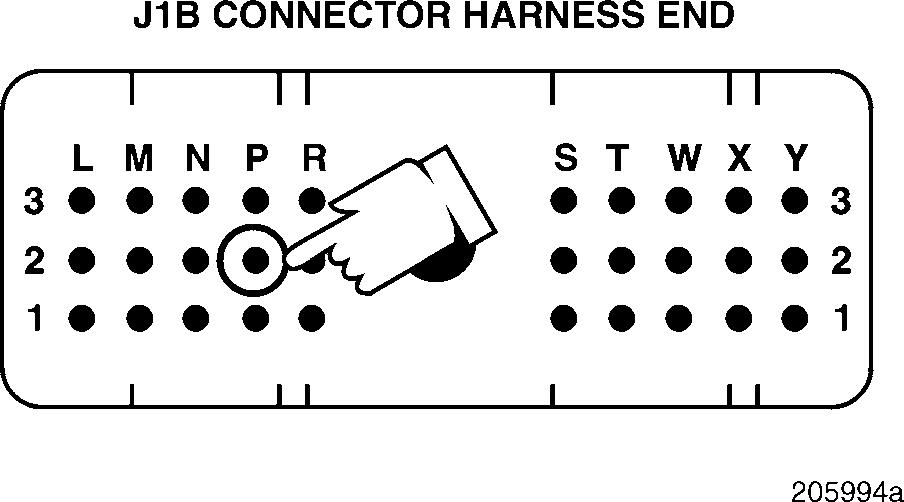

2.Check the resistance from each of the module ground wires (J1B connector pins P1 and P2 and J2 connector pin F2) to the negative battery post.

If the resistance to the battery post is greater than 1 ohm, clean the connections between the module and battery ground. Reconnect the J1A and J1B connectors to the V-MAC II module. Retest to be sure the problem has been corrected.

If the is resistance is less than 1 ohm or the fault is still active, proceed to Test 64.

Test 64

Checking for good battery and alternator POSITIVE connections

1.Clean the battery and alternator POSITIVE connections. Retest to be sure the problem has been corrected.

If the fault is still active, contact Service Engineering.

DIAGNOSTIC CODE 5-7 OR 5-8

DIAGNOSTIC BLINK CODE 5-7 OR 5-8

DRIVER ALARM OUTPUT TESTS

When performing electrical tests, it is important to wiggle wires and connectors to identify intermittent connection problems.

Blink Code 5-75-8

PID

SID 238238

FMI 43

MID 142142

Name Driver Alarm Output Driver Alarm Output

Voltage above normal or shorted high

This diagnostic blink code is unique in that if the fault becomes active, the electronic malfunction lamp will turn ON until the ignition key is turned OFF, even if the electrical condition which caused the fault disappears.

DIAGNOSTIC CODE 5-7 OR 5-8

Test 1

Checking the code

1.Verify which code is active.

If code 5-7 is active, proceed to Test 2.

If code 5-8 is active, proceed to Test 3.

If neither code is active, wiggle the harness and connectors to try to activate the code. Visually inspect the connectors for frayed, loose or corroded connections.

Test 2

Checking for continuous operation

1.Connect the Pro-Link 9000 or PC.

2.Turn the ignition key to the ON position.

If code 5-7 becomes active and the shutdown lamp and driver alarm stay ON continuously, proceed to Test 4.

If code 5-7 becomes active but the shutdown lamp and driver alarm do not stay ON continuously, proceed to Test 5.

If code 5-7 does not become active and either the shutdown lamp or driver alarm is inoperative, replace the inoperative component. Retest to be sure the problem has been corrected.

Test 3

Checking for continuous operation

This diagnostic procedure will detect a short to voltage only if the module is attempting to turn the shutdown lamp and driver alarm ON.

1.Connect Pro-Link 9000 or PC.

2.Turn the ignition key to the ON position.

3.Disconnect the coolant level sensor. This will activate code 1-7 and cause the V-MAC II module to attempt to turn the shutdown lamp ON.

4.After fault 1-7 has become active, reconnect the coolant level sensor.

5.After 30 seconds, observe the electronic malfunction indicator and Active Fault Table (in Service Diagnostics) to see if the lamp remains ON and the fault 5-8 remains active.

If the electronic malfunction lamp remains ON and fault 5-8 is active, proceed to Test 6.

If the electronic malfunction lamp does not remain ON and fault 5-8 is not active, the problem may be intermittent and hard to diagnose. Check the connections at the shutdown lamp and driver alarm and J1B connector for a short to voltage. Retest to be sure the problem has been corrected.

Test 4

Checking for a short to ground

1.Turn the ignition key to the OFF position.

2.Disconnect the J1B connector from the V-MAC II module.

3.Connect the serial link jumper into the serial communications port.

If the shutdown lamp and driver alarm come ON, there is a short to ground in the shutdown lamp and alarm signal [+] line. Proceed to Test 8.

If the shutdown lamp and driver alarm do not come ON, there is a short to ground in the V-MAC II module. Proceed to Test 9.

Test 5

DIAGNOSTIC CODE 5-7 OR 5-8

Checking the power supply circuit

Circuit 5-A-1.0 provides power to several gauges and indicators in the dash. An open or short to ground in this circuit may cause problems with these shared components. Some components powered by this circuit are: r Multipurpose buzzer r Oil level indicator lamp r Malfunction indicator lamp r Parking brake warning lamp switch

If there are electrical problems with other components in the dash, there may be an open or short to ground in circuit 5-A-1.0. Locate and repair the open or short to ground. Retest to be sure the problem has been corrected.

If there are no other obvious electrical problems with components in the dash, proceed to Test 10.

Test 6

Checking for a short to voltage

If the voltage is greater than 0.5 volts, there is short to voltage. Proceed to Test 12.

If the voltage is less than 0.5 volts, proceed to Test 13.

Test 8

Short to ground isolation test

Other Pins

1.Disconnect the serial link jumper.

2.Remove the shutdown lamp bulb and disconnect the driver alarm buzzer.

3.Disconnect the J1A, J1B and J2 connectors from the V-MAC II module.

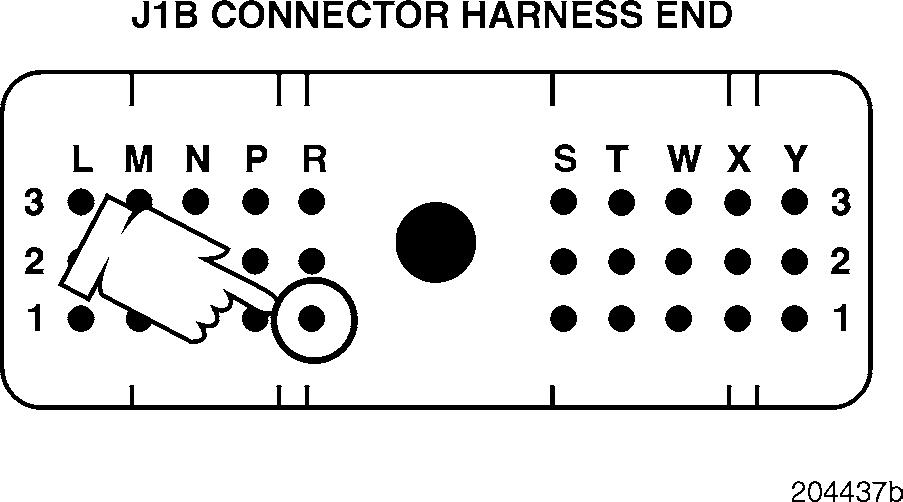

4.Check for continuity between J1B connector pin R1 (the shutdown lamp and alarm signal [+] line) and each of the other pins (one at a time) on the J1A, J1B and J2 connectors.

If there is another pin which shows continuity, J1B connector pin R1 is shorted to that pin. Locate and repair the short. Retest to be sure the problem has been corrected.

1.Turn the ignition key to the OFF position.

2.Remove the shutdown lamp bulb and disconnect the driver alarm buzzer.

3.Disconnect the J1B connector from the V-MAC II module.

4.Connect the serial link jumper into the serial communications port.

5.Measure the voltage from J1B connector pin R1 (the shutdown lamp and alarm signal [+] line) to a good ground.

If there is no continuity, proceed to Test 16.

Test 9

DIAGNOSTIC CODE 5-7 OR 5-8

Rechecking the blink code

1.Turn the ignition key to the OFF position.

2.Reconnect the J1B connector.

3.Turn the ignition key to the ON position.

If code 5-7 is still active, check the V-MAC II module and connector J1B for dirt, loose or shorted pins or any other repairable damage. If no repairable conditions are found, replace the module. Retest to be sure the problem has been corrected.

If code 5-7 is not active, the procedures have corrected the problem. Check all connectors to ensure proper connections.

Test 10

Checking for battery voltage

Test 12

Short-to-voltage isolation test

1.Turn the ignition key to the OFF position.

2.Disconnect the J1B connector from the V-MAC II module.

3.Connect the serial link jumper into the serial communications port.

4.Measure the voltage from J1B connector pin R1 (the shutdown lamp and alarm signal [+] line) to a good ground.

If battery voltage is present, proceed to Test 20.

If no voltage is present, check circuit 5-A-0.8 for an open. If circuit 5-A-0.8 is not faulty, check circuit 5-A-1.0 for an open.

1.Disconnect the serial link jumper.

2.Remove the shutdown lamp bulb and disconnect the driver alarm buzzer.

3.Disconnect the J1A, J1B and J2 connectors from the V-MAC II module.

4.Check for continuity between J1B connector pin R1 (the shutdown lamp and alarm signal [+] line) and each of the other pins (one at a time) on the J1A, J1B and J2 connectors.

If there is another pin which shows continuity, J1B connector pin R1 is shorted to the pin which showed continuity. Locate and repair the short. Retest to be sure the problem has been corrected.

If there is no continuity, J1B connector pin R1 is shorted to voltage somewhere else in the harness. Locate and repair the short to voltage.

Test 13

DIAGNOSTIC CODE 5-7 OR 5-8

Checking the V-MAC II module

1.Disconnect the serial link jumper.

2.Reconnect the J1B connector.

3.Install the shutdown lamp bulb and connect the driver alarm buzzer.

4.Turn the ignition key to the ON position.

5.Disconnect the coolant level sensor. This will activate code 1-7 and cause the V-MAC II module to attempt to turn the shutdown lamp ON.

6.After fault 1-7 has become active, reconnect the coolant level sensor.

7.After 30 seconds, observe the electronic malfunction indicator and Active Fault Table (in Service Diagnostics) to see if the lamp remains ON and the fault 5-8 remains active.

If the electronic malfunction lamp goes ON and code 5-8 is active, check the V-MAC II module and connector for a repairable condition. If no repairable condition is found, replace the module. Retest to be sure the problem has been corrected.

If the electronic malfunction lamp does not go ON, the procedures have corrected the problem. Check all connectors to ensure proper connection.

Test 16

Checking for a failed unit

1.Disconnect the serial link jumper.

2.Reconnect the J1B connector.

3.Replace the shutdown lamp bulb with a bulb that is known to be good.

4.Turn the ignition key to the ON position.

If code 5-7 does not become active, the old lamp had a short to ground. Replacing the bulb has corrected the problem.

If code 5-7 is still active, there is a short to ground somewhere else in the harness. Locate and repair the short to ground. Retest to be sure the problem has been corrected.

Test 20

Checking J1B connector for an open

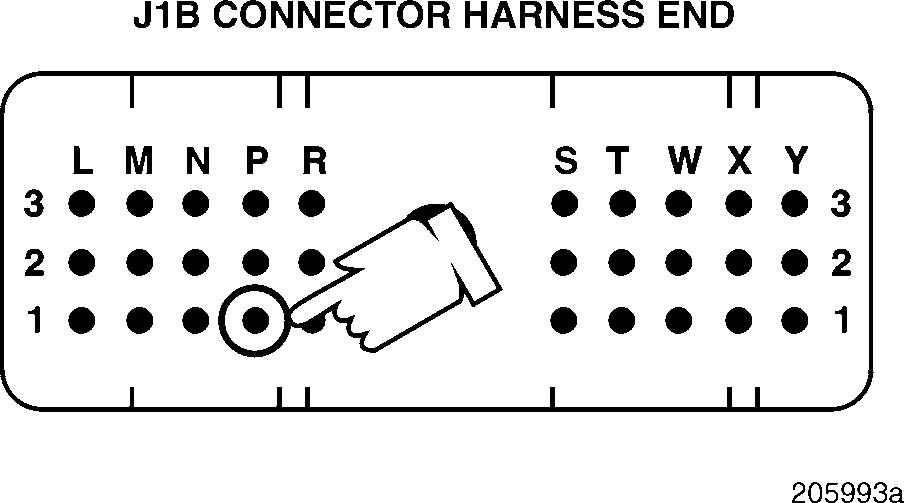

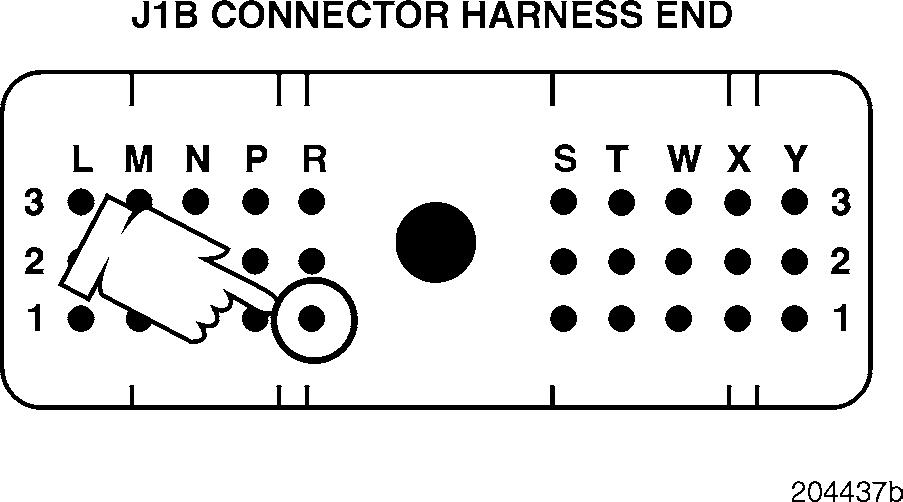

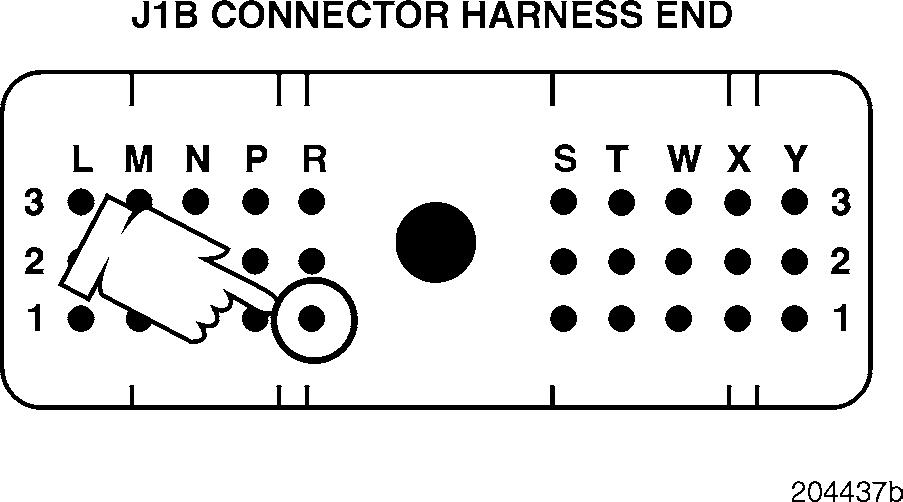

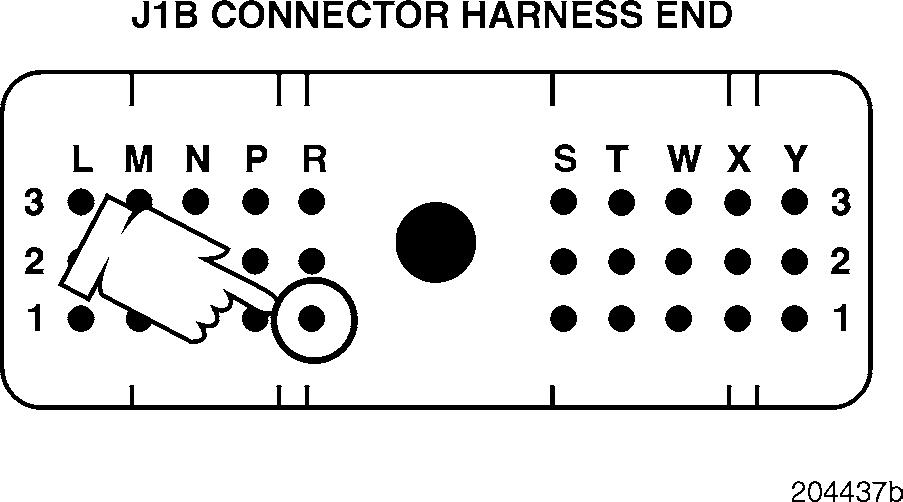

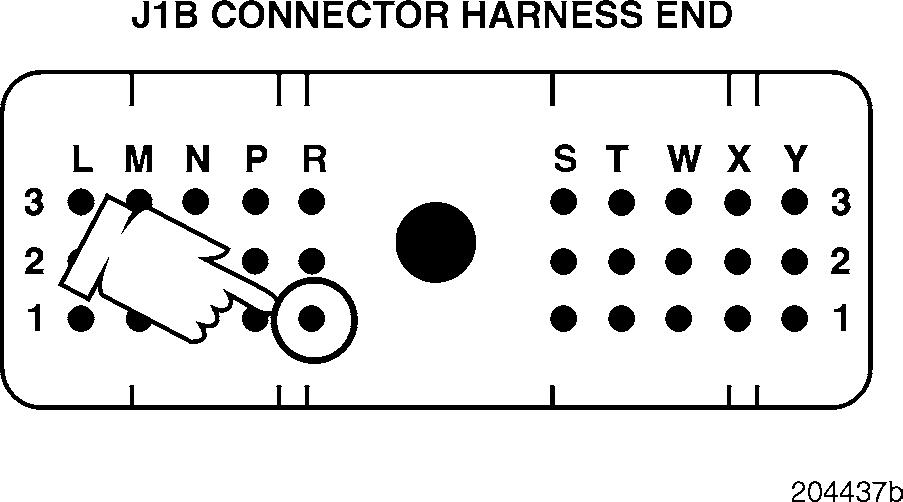

Figure 236 — Visually Inspect Pin R1

1.Turn the ignition key to the OFF position.

2.Disconnect the J1B connector from the V-MAC II module.

3.Visually inspect J1B connector pin R1 for dirt, loose pins or deformed contacts.

4.Align the J 35616-2 male test lead (found in the J 38581 V-MAC jumper wire kit) with J1B connector pin R1. Gently push the test lead into pin R1 and check for looseness.

If a repairable open is found or the terminal feels lose, repair the J1B connector. Retest to be sure the problem has been corrected.

If the test lead is making good contact with J1B connector pin R1, proceed to Test 40.