1 minute read

DIAGNOSTIC CODE 5-4

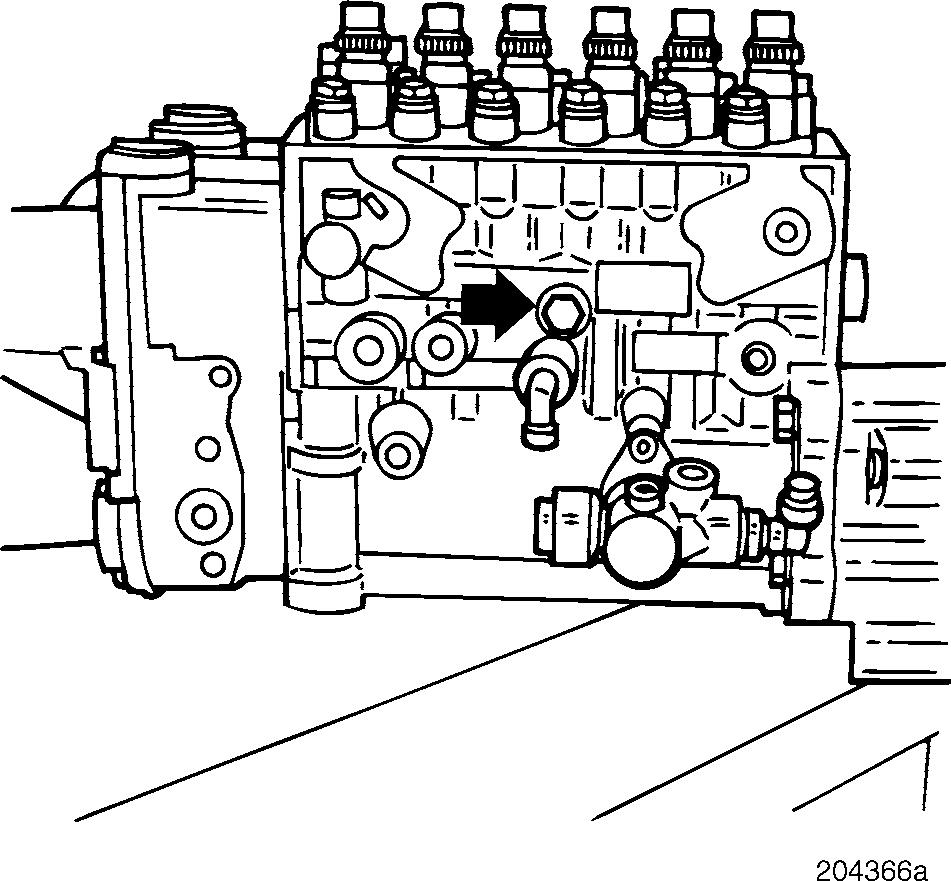

3.Note the position of the slot in the end of the adjustment screw. Then loosen the hex jam nut.

4.Using a small pocket-type screwdriver, turn the adjusting screw into the housing until it contacts the rack. Note the amount of rotation needed.

5.Back the adjusting screw out of the housing until it contacts the other side of the rack, noting the amount of rotation needed.

6.Finally, turn the adjusting screw halfway back into the housing to center it, by turning it back in exactly one-half of the total distance from fully in to fully out.

7.Tighten the jam nut and reinstall the hex acorn nut. Torque both to 9–11 lb-ft (12–15 N•m).

In rare cases, the injection pump control rod guide on the outboard side of the injection pump may be misadjusted, causing slower rack response. This can be adjusted using the following procedure:

1.Turn the ignition key to the OFF position.

2.Remove the hex acorn nut on the side of the pump. See illustration for location.

8.Reconnect the engine harness to the injection pump. Retest to be sure the problem has been corrected.

If code 5-4 returns and the truck will not start, send the pump to a certified pump shop for repair. Then retest to be sure the problem has been corrected.

If code 5-4 does not return, this procedure has corrected the problem.

DIAGNOSTIC CODE 5-5

DIAGNOSTIC BLINK CODE 5-5 FUEL

When performing electrical tests, it is important to wiggle wires and connectors to identify intermittent connection problems.