1 minute read

DIAGNOSTIC CODE 3-5 (BASIC)

Test 10

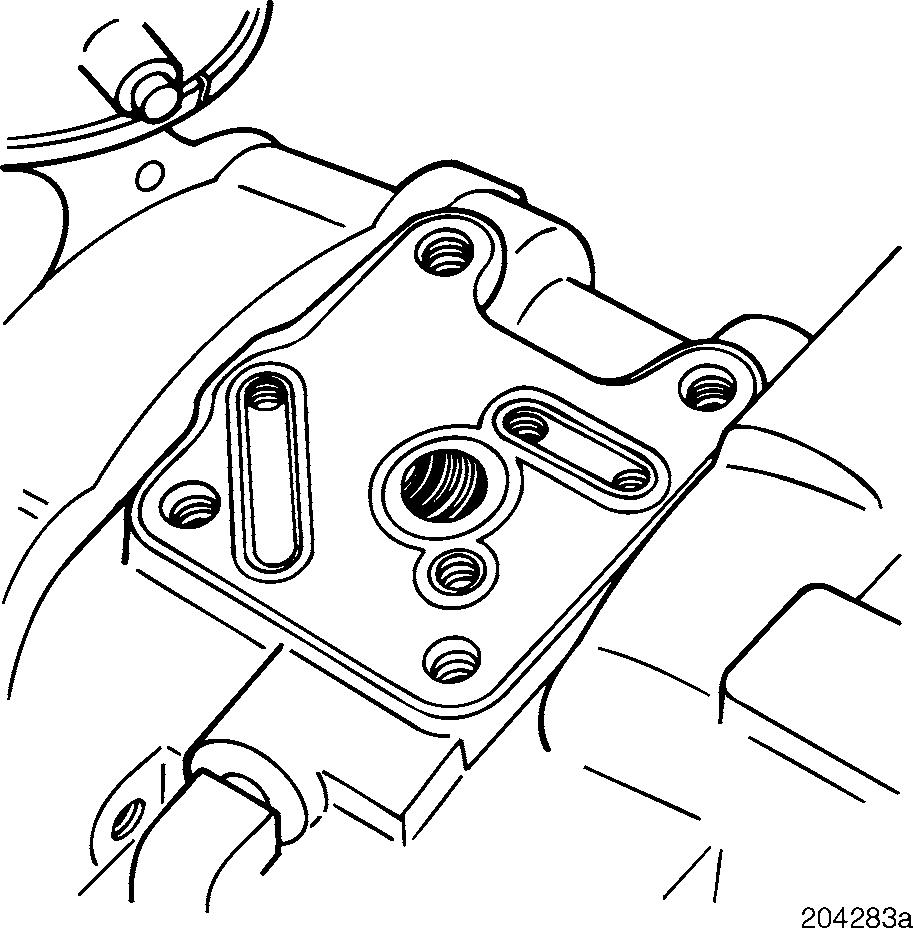

Checking the control valve gasket

Test 18

Checking for a defective V-MAC II module

1.Replace the V-MAC II module with a new module, or with a module from another truck. DO NOT REPROGRAM THE MODULE AT THIS TIME.

2.Run the engine at 800 rpm for at least 30 seconds and record the timing.

If the timing on the diagnostic tool is the same as the static timing (within 1 degree), the old V-MAC II module was defective. Install a new V-MAC II module.

If the timing on the diagnostic tool disagrees with the static timing by more than 1 degree, reinstall the original V-MAC II module. A potential flywheel problem may exist. Call Service Engineering.

Test 19

1.Remove the timing control valve and inspect the valve gasket.

If the gasket is installed properly, proceed to Test 20.

If the gasket is not installed properly, correctly install a new gasket. Reinstall the timing control valve. Retest to be sure the problem has been corrected.

Checking static timing against the emissions plate

If the static timing is more advanced than the number stamped on the emissions plate by more than 1 degree, proceed to Test 38.

If the static timing is more retarded than the number by more than 1 degree, proceed to Test 39.

DIAGNOSTIC CODE 3-5 (BASIC)

Test 20

Checking for bad ECONOVANCE seals

Test 38

Checking effects of advanced static timing on low idle timing

1.Replace the timing control valve.

2.With the new timing control valve disconnected and with a pressure gauge connected to the diagnostic port, start the engine. Record the low idle oil pressure displayed on the gauge.

If the oil pressure on the gauge is 0, the old control valve was defective and the procedure has corrected the problem.

If the pressure on the gauge is not 0, the old control valve was not defective and should be reinstalled. Replace the seals in the ECONOVANCE unit. Retest to be sure the problem has been corrected. Refer to the E7 Engine Service Manual for ECONOVANCE repair.

1.If the low idle timing status was correct in Test 1 (the diagnostic tool indicated that timing was OK), or was too retarded (the diagnostic tool displayed “--”), proceed to the Electrical Diagnostic Test Section.

2.If the low idle timing status in Test 1 was too advanced (the diagnostic tool displayed “++”), reset the static timing. Retest to be sure the problem has been corrected.

3.Make a note that the static timing has been reset. Then proceed to the Electrical Diagnostic Test Section.