3 minute read

3.Diagnostic Trouble Code (Monitor display

3 Travel Motor Operator's Manual 1.Foreword

This manual provides instruction for handling the swash plate-type piston motor with case rotation type reduction gear for the open circuit MAG-170VP-3800E series. This manual helps first-time users to understand handling issues as well as assists experienced users to review the swash plate-type piston motor with case rotation type reduction gear for the open circuit manufactured by KYB Co., Ltd. Read this operator's manual well and come to an understanding of its contents before operating the motor. It is recommended that users keep this manual ready at hand during operation.

This manual mainly explains (1) basic functions and component functions, (2) explanation of component operation, (3) operation procedures, (4) troubleshooting, (5) daily maintenance and inspection of the MAG-170VP-3800E series, swash plate-type piston motor with case rotation type reduction gear for the open circuit.

The MAG-170VP-3800E series, swash plate-type piston motor with case rotation type reduction gear for the open circuit produced by KYB Co., Ltd. is the actuator used in the hydraulic unit of the mother machine. Therefore, this operator's manual should be used along with the operator's manual of the mother machine. Always refer to the operator's manual of the mother machine when using this operator's manual.

2.For Safety Operation

Safety Cautions Be sure to follow the instructions below:

Warning

Never lift the motor by the tap on the base plate when transporting by crane. Doing so may cause the motor to fall, which may cause personal injury or damage to the machine.

Warning Always wear a helmet, safety shoes, gloves and protective goggles when disassembling the motor for transportation, installation, maintenance and inspection, etc.

Lifting prohibited

Eyebolt Lifting recommended

Eyebolt Eyebolt

Safety Cautions Be sure to follow the instructions below:

Warning

Do not run the motor when the hydraulic oil level is low in the hydraulic tank (near the outlet port), or when the hydraulic tank is empty. Doing so may cause air to enter the motor, and the motor may go out of control, which may cause personal injury or damage to the machine.

Inlet Hydraulic tank

Outlet

Warning

Do not run the motor when the pipe is empty.

Doing so may cause air to enter the motor, and the motor may go out of control, which may cause personal injury or damage to the machine.

Warning

Never remove the oil fill, oil discharge or oil check ports of the reduction gear lubricating oil within 1 hour after the motor has stopped. Doing so may cause high-temperature lubricating oil to squirt out and may cause burns. High-temperature lubricating oil will squirt out and may cause loss of eyesight if it gets into the eyes.

Safety Cautions Be sure to follow the instructions below:

Warning

Never remove the pressure detection port or oil drain port when the pipe is pressurized. Doing so may cause pressurized oil to squirt out and may cause loss of eyesight if it gets into the eyes. Always release the pressure inside the pipe to atmosphere level before removing it.

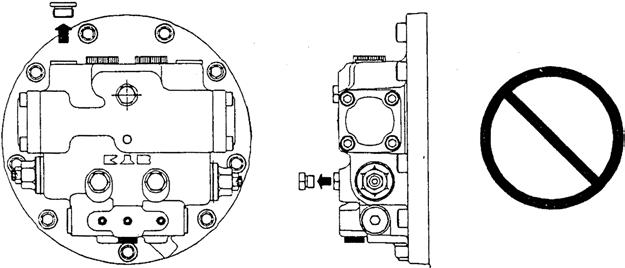

Do not remove the cover from the reduction gear with the motor attached to the machine body. Doing so may cause your fingers or hands to get pinched causing injury.

Warning

Warning

Do not disassemble the motor with the motor attached to the machine body. Doing so may cause the machine to go out of control resulting in personal injury. Always remove the motor from the machine body before disassembling.

Safety Cautions Be sure to follow the instructions below:

Warning

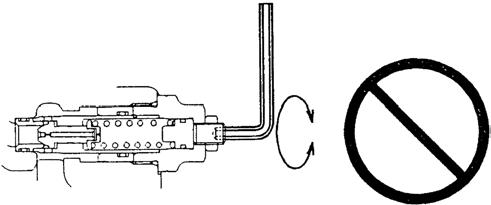

Do not remove the spool from the double counter balance valve with the motor attached to the machine body. Doing so may cause the machine to go out of control causing personal injury or damage to the machine.

Warning

Never tamper with the relief valve adjuster. Doing so will change the set pressure of the relief valve, and the machine may go out of control causing personal injury or damage to the machine.