6 minute read

5.EPF (Engine Protection Feature

3.Purpose of Motor

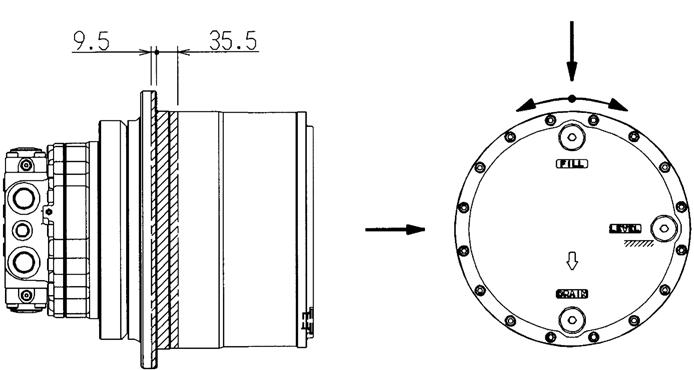

This motor is exclusive for open circuit. Do not use it for closed circuit. This motor employs a direct drive. The reduction gear housing (output part) must be directly installed to the driven part of the machine main unit. Also, this motor should be used with a sprocket drive mechanism. Therefore, the driven part must conform to this mechanism. Do not use this motor when the motor installed position is significantly displaced from the load-operating position, or when a large bending moment is applied to the motor from the driven part. This motor should only be used when the motor shaft is horizontal. Do not use this motor when the driven part is held horizontal. This motor can be used storing inside the drum. In that case, install the roller bearing on the side opposite the motor. Although the double counter balance valve and the parking brake function come equipped with this motor, it cannot be used as a winch.

4.Motor Specifications

[1]Specifications

Table 1 shows specifications of the motor.

Table 1. Motor Specifications

Table 1 shows general specifications of the motor. Refer to the external shape diagrams at the end of the book for the specifications of individual models.

Equivalent capacity cm3/rev q × i

Motor capacity q High capacity q1 cm3/rev 129.3 to 181.3 Low capacity q2 cm3/rev q1 × 0.5 or more

Reduction ratio i 43.246, (50.579)

2nd-speed pilot pressure

Low speed to high speed MPa 1.5 or more High speed to low speed MPa 0.4 or less Parking brake N•m 581 × i Operating flow L/min. 270 or less Operating pressure MPa 34.3 or less Surge pressure MPa 44.1 or less Number of times operated when the pressure is greater than 34.3 MPa or less than 44.1 MPa Times 1.20M or less

Rotation speed

Input horsepower

Drain pressure Motor shaft High capacity rpm Low capacity rpm 2500 or less

Reduction gear Output torque

High capacity rpm Low capacity rpm 60 or less kN•m 37.3 or less Normal use PS

Mass Max.

PS 210 or less (30 or less consecutive seconds) Normal use MPa 0.2 or less Moment max. MPa 0.5 or less (0.3M pulse or less) kg 250

Important

Set the operating conditions within the above specifications. Use beyond the specified range will shorten the motor life.

[2]Allowable external load

Table 2 shows allowable external load for this motor.

Table 2. Allowable External Load

External Load Reverse input torque kN•m 35.3 or less Radial load Normal use N 111266 or less Moment max. N 222532 or less Thrust load Normal use N 18152 or less Moment max. N 27228 or less Rolling moment Normal use N•m 7174 or less Moment max. N•m 10762 or less Gravity acceleration 10 G or less Vibration Hz 30 or less

Figure 1 shows the operation range of the external load.

Radial load

Reverse input torque

Radial load

Important

The external load must be limited within the allowable load shown in Table 2 within the operating range shown in Figure 1. If the external load exceeds the limit, the reduction gear main bearing will not be able to hold the external load. This may damage the reduction gear, and cause damage to the machine main unit.

[3]Temperature conditions 1.)Ambient temperature

This motor is intended for use based on -20 to +40°C temperature ranges. For this reason, if the motor is used at ambient temperatures outside this range, degradation of the seals will be accelerated. Should you use the motor at ambient temperatures outside this range, the seals must be changed. Contact us at the address shown in Section 1.

2.)Temperature of the hydraulic oil

The temperature of the hydraulic oil rises as the motor runs. Using the motor for long periods of time when the hydraulic oil is at high temperatures may accelerate the degradation of the hydraulic oil and cause the hydraulic equipment to fail. Run the motor at the temperature of the hydraulic oils within -10 to +80°C.

Also, read "Hydraulic Oil" in Section 7 carefully to learn about controlling the temperature of the hydraulic oil.

3.)Reduction gear lubricating oil temperature

The reduction gear lubricating oil temperature rises as the motor runs and the gear meshes. Using the motor for long periods of time when the lubricating oil is at high temperatures may accelerate the degradation of the lubricating oil and result in a mechanical failure of the reduction gear. Run the motor at the temperature of the lubricating oil within -10 to +80°C.

Also, read "Reduction Gear Lubricating Oil" in Section 8 carefully to learn about controlling the temperature of the reduction gear lubricating oil.

[4]Model code

MAG 170VP

3800 E E 1

(1) (2) (3) (4) (5) (6) (7)

1 In-shoe design motor with travel reduction gear 2 Piston motor series 3 2nd-speed function V: With 2nd-speed function 4 Parking brake function P: With parking brake function 5 Output torque 6 Motor type 7 Additional number for design change

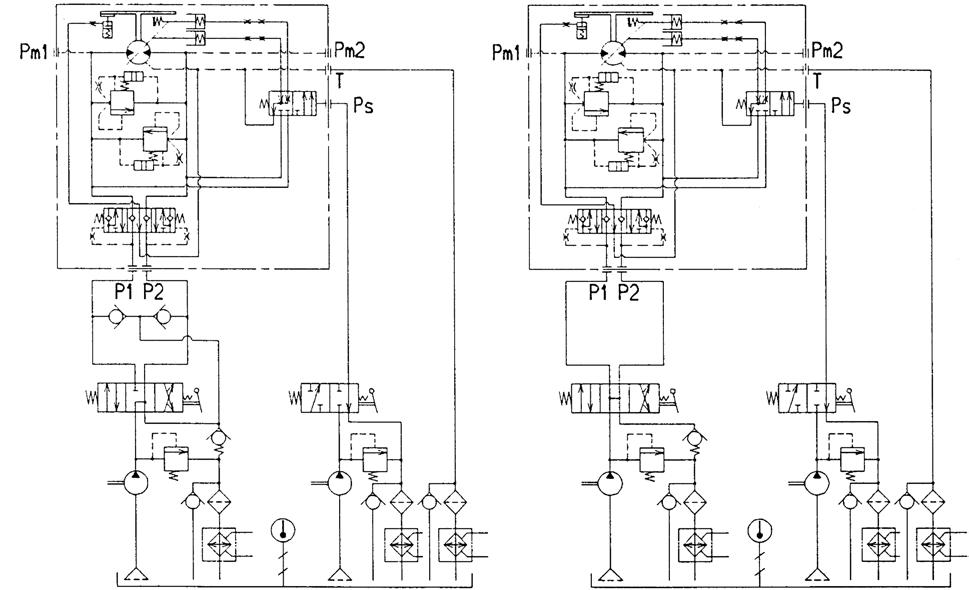

5.Hydraulic Circuits

The hydraulic pump, directional control valve, and pressure control valve are required to operate this motor. This motor is exclusive for open circuit. Figure 2 shows the basic hydraulic circuits. Other items of equipment are connected as necessary to make up the hydraulic circuits. Should you have any questions or require further information about the hydraulic circuits, contact us at the address shown in Section 1.

Important

Be sure to observe the instructions of Items 1 - 7 below. Failure to observe the instructions will degrade the performance of the motor. Also, damage or malfunction of the equipment may result.

Control valve Motor

Speed control valve

Control valve

Figure 2. Basic open circuit

Motor

Speed control valve

[1]Installation of relief valve

Be sure to provide the relief valve on the discharge circuit of the hydraulic pump in the hydraulic circuits for hydraulic circuit protection. Otherwise, it may cause the pipe to rupture or damage to the hydraulic equipment if the hydraulic equipment is operated abruptly, stopped suddenly, or overload is applied from an external source and the pressure inside the circuit rises. The relief valve on the motor is designed for determining the motor starting force and braking force and is not for hydraulic circuit protection.

[2]Installation of filter and strainer

Be sure to provide a 150-mesh strainer on the suction circuit from the tank and a 10-micron filter on the return charge circuit in the hydraulic circuits. The hydraulic equipment is extremely sensitive to hydraulic oil contamination. Contamination of the hydraulic oil may result in damage or lead to improper operation of the hydraulic equipment, and induce malfunctioning of the machine. To prevent this, it is important to control the contamination level of the hydraulic oil. Read "Hydraulic Oil" in Section 7 carefully to learn about and understand for controlling the hydraulic oil contamination level.

[3]Installation of cooler and heater

Be sure to provide the cooler and heater (designed for cold regions) on the hydraulic circuits. The hydraulic equipment is extremely sensitive to hydraulic oil viscosity. If the temperature of the hydraulic oil inside the hydraulic equipment rises causing low viscosity of the hydraulic oil, it may result in damage or improper operation of the hydraulic equipment, and induce malfunctioning of the machine. If the temperature of the hydraulic oil lowers causing abnormally high viscosity of the hydraulic oil, it may disable the hydraulic equipment operation. To prevent such failure, it is important to control the temperature of the hydraulic oil.

Read "Hydraulic Oil" in Section 7 carefully to learn about controlling the temperature of the hydraulic oil.

[4]Pressure inside the drain pipe

Choose the appropriate equipment such as pipe size, filter, strainer, cooler to keep the drain pressure within the pressure range shown in Table 3. Also, return the drain pipe alone directly to the hydraulic tank.

The allowable drain pressure is determined based on the compression strength of the oil seal in the piston motor and the strength of the piston motor components. Table 3 shows the allowable drain pressure.

Table 3. Allowable Drain Pressure

Drain Pressure Normal use MPa 0.2 or less Moment max. MPa 0.5 or less (30M pulse or less)