Assembly Manual

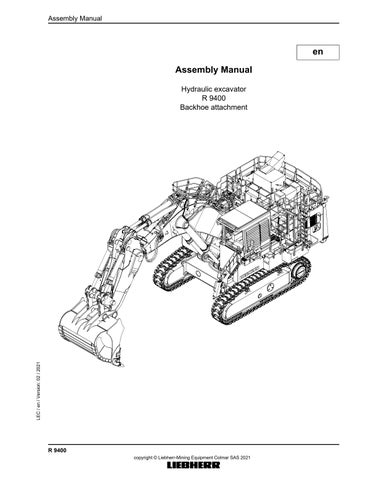

en Assembly Manual

LEC / en / Version: 02 / 2021

Hydraulic excavator R 9400 Backhoe attachment

R 9400 copyright © Liebherr-Mining Equipment Colmar SAS 2021

MJFCIFSS

Assembly Manual

en Assembly Manual

LEC / en / Version: 02 / 2021

Hydraulic excavator R 9400 Backhoe attachment

R 9400 copyright © Liebherr-Mining Equipment Colmar SAS 2021

MJFCIFSS